transaxle TOYOTA RAV4 2006 Service Owner's Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 357 of 2000

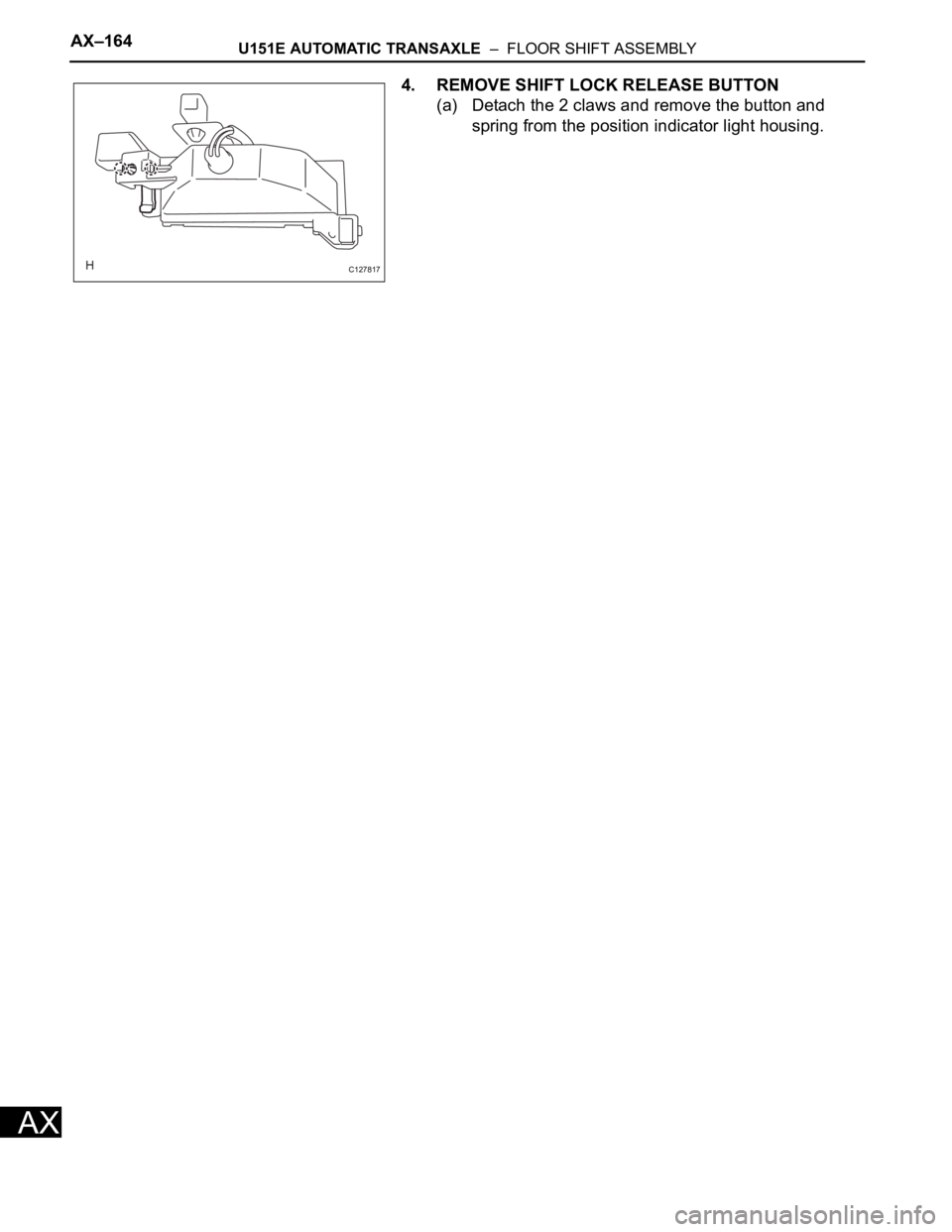

AX–164U151E AUTOMATIC TRANSAXLE – FLOOR SHIFT ASSEMBLY

AX

4. REMOVE SHIFT LOCK RELEASE BUTTON

(a) Detach the 2 claws and remove the button and

spring from the position indicator light housing.

C127817

Page 358 of 2000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–3

AX

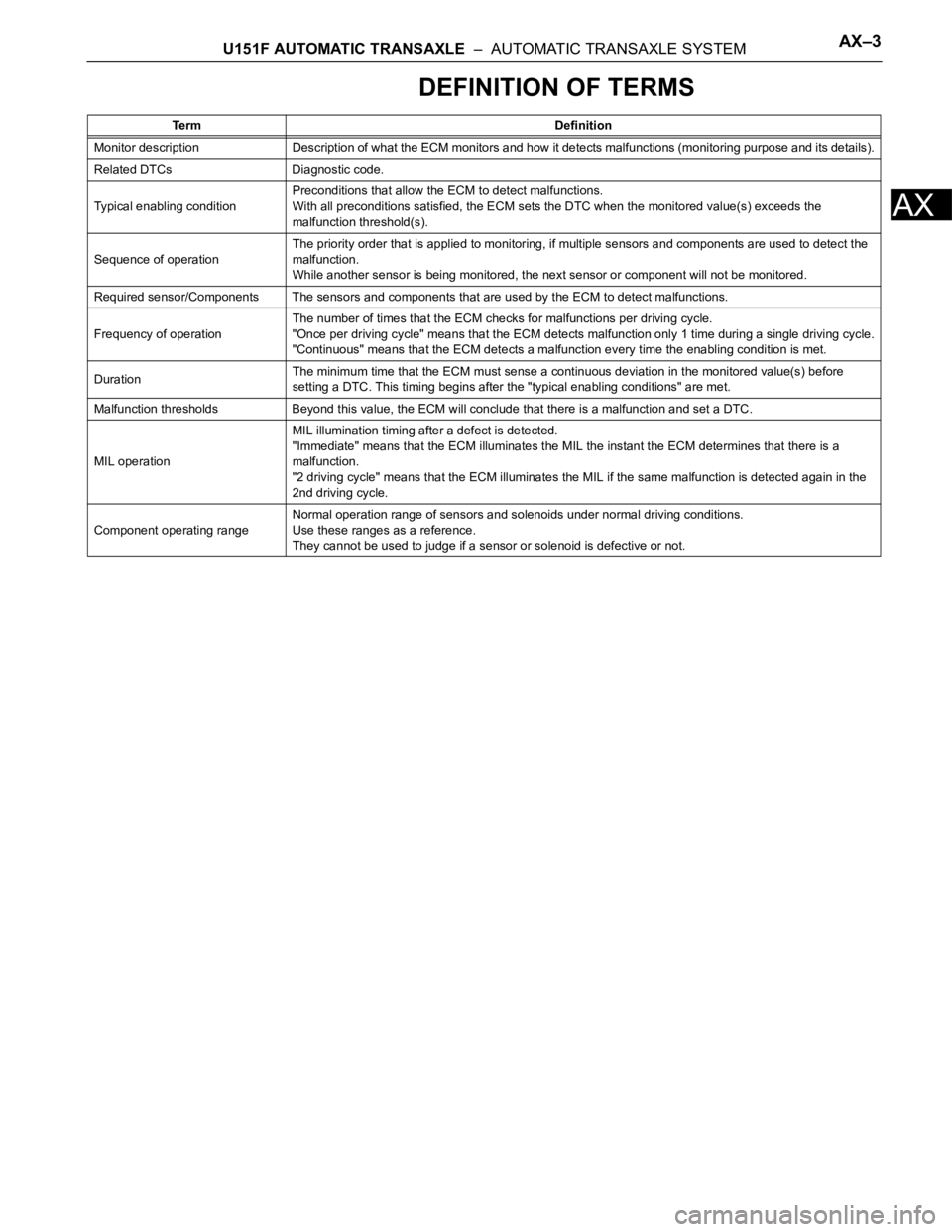

DEFINITION OF TERMS

Te r m D e f i n i t i o n

Monitor description Description of what the ECM monitors and how it detects malfunctions (monitoring purpose and its details).

Related DTCs Diagnostic code.

Typical enabling conditionPreconditions that allow the ECM to detect malfunctions.

With all preconditions satisfied, the ECM sets the DTC when the monitored value(s) exceeds the

malfunction threshold(s).

Sequence of operationThe priority order that is applied to monitoring, if multiple sensors and components are used to detect the

malfunction.

While another sensor is being monitored, the next sensor or component will not be monitored.

Required sensor/Components The sensors and components that are used by the ECM to detect malfunctions.

Frequency of operationThe number of times that the ECM checks for malfunctions per driving cycle.

"Once per driving cycle" means that the ECM detects malfunction only 1 time during a single driving cycle.

"Continuous" means that the ECM detects a malfunction every time the enabling condition is met.

DurationThe minimum time that the ECM must sense a continuous deviation in the monitored value(s) before

setting a DTC. This timing begins after the "typical enabling conditions" are met.

Malfunction thresholds Beyond this value, the ECM will conclude that there is a malfunction and set a DTC.

MIL operationMIL illumination timing after a defect is detected.

"Immediate" means that the ECM illuminates the MIL the instant the ECM determines that there is a

malfunction.

"2 driving cycle" means that the ECM illuminates the MIL if the same malfunction is detected again in the

2nd driving cycle.

Component operating rangeNormal operation range of sensors and solenoids under normal driving conditions.

Use these ranges as a reference.

They cannot be used to judge if a sensor or solenoid is defective or not.

Page 359 of 2000

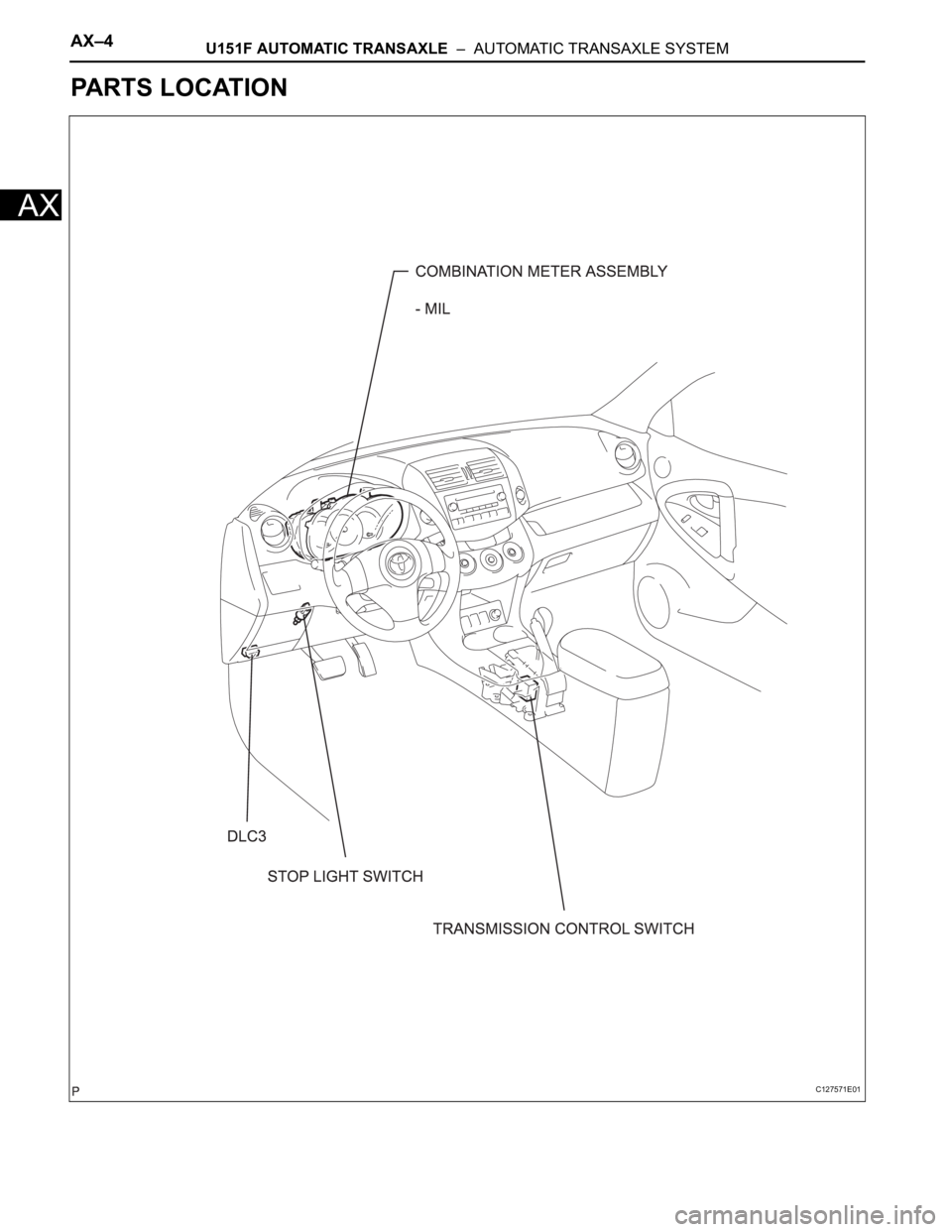

AX–4U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

PARTS LOCATION

C127571E01

Page 360 of 2000

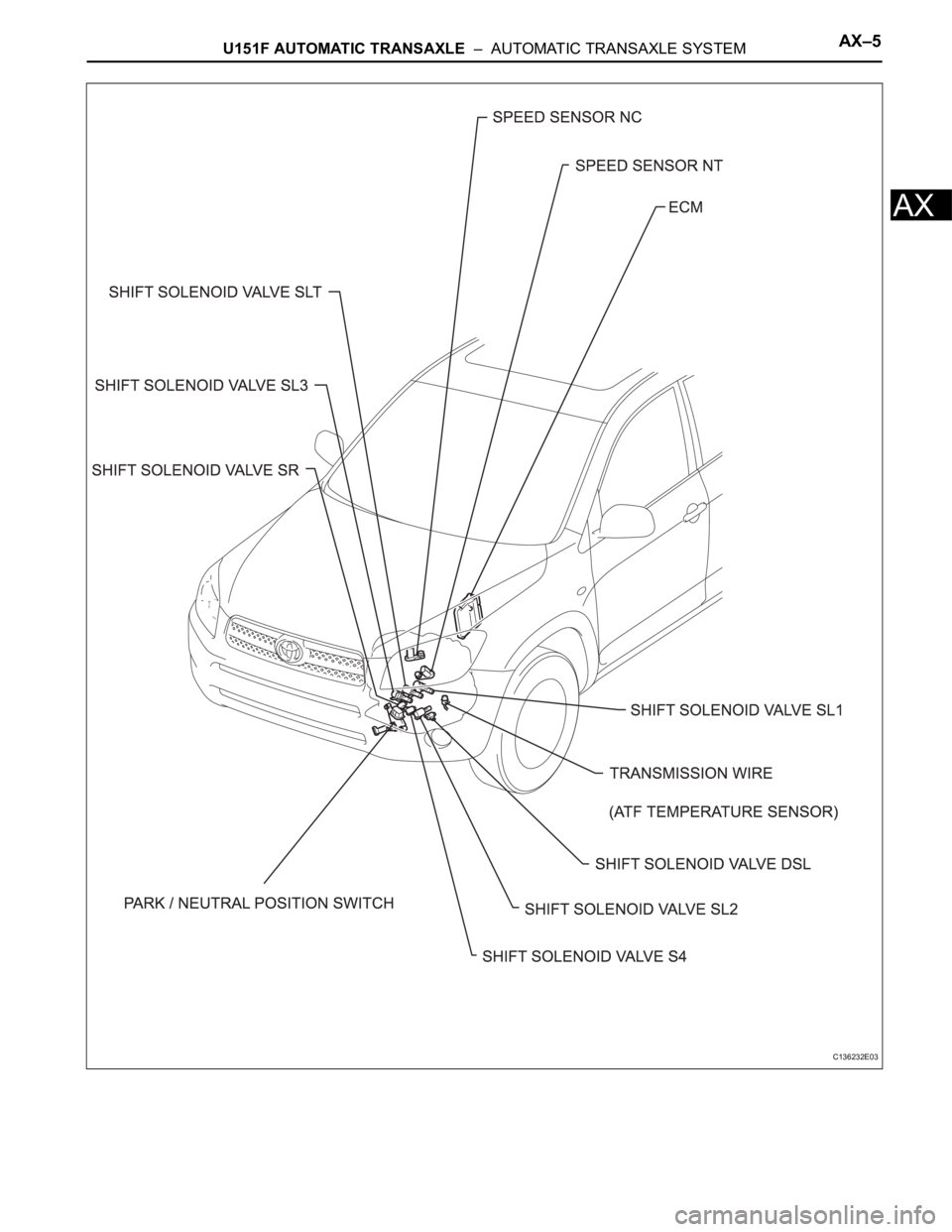

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–5

AX

C136232E03

Page 361 of 2000

AX–162U151F AUTOMATIC TRANSAXLE – FLOOR SHIFT ASSEMBLY

AX

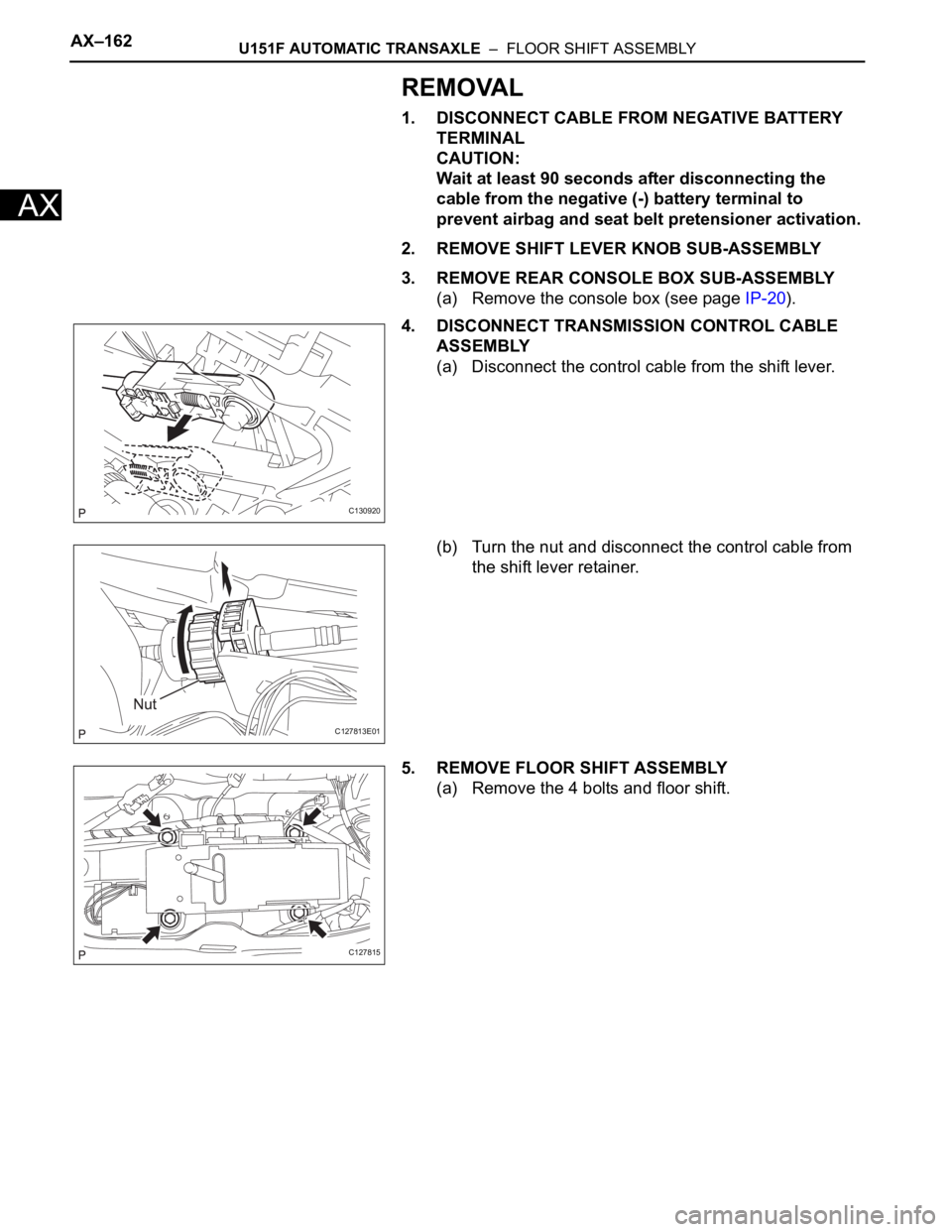

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

2. REMOVE SHIFT LEVER KNOB SUB-ASSEMBLY

3. REMOVE REAR CONSOLE BOX SUB-ASSEMBLY

(a) Remove the console box (see page IP-20).

4. DISCONNECT TRANSMISSION CONTROL CABLE

ASSEMBLY

(a) Disconnect the control cable from the shift lever.

(b) Turn the nut and disconnect the control cable from

the shift lever retainer.

5. REMOVE FLOOR SHIFT ASSEMBLY

(a) Remove the 4 bolts and floor shift.

C130920

C127813E01

C127815

Page 362 of 2000

U151F AUTOMATIC TRANSAXLE – FLOOR SHIFT ASSEMBLYAX–163

AX

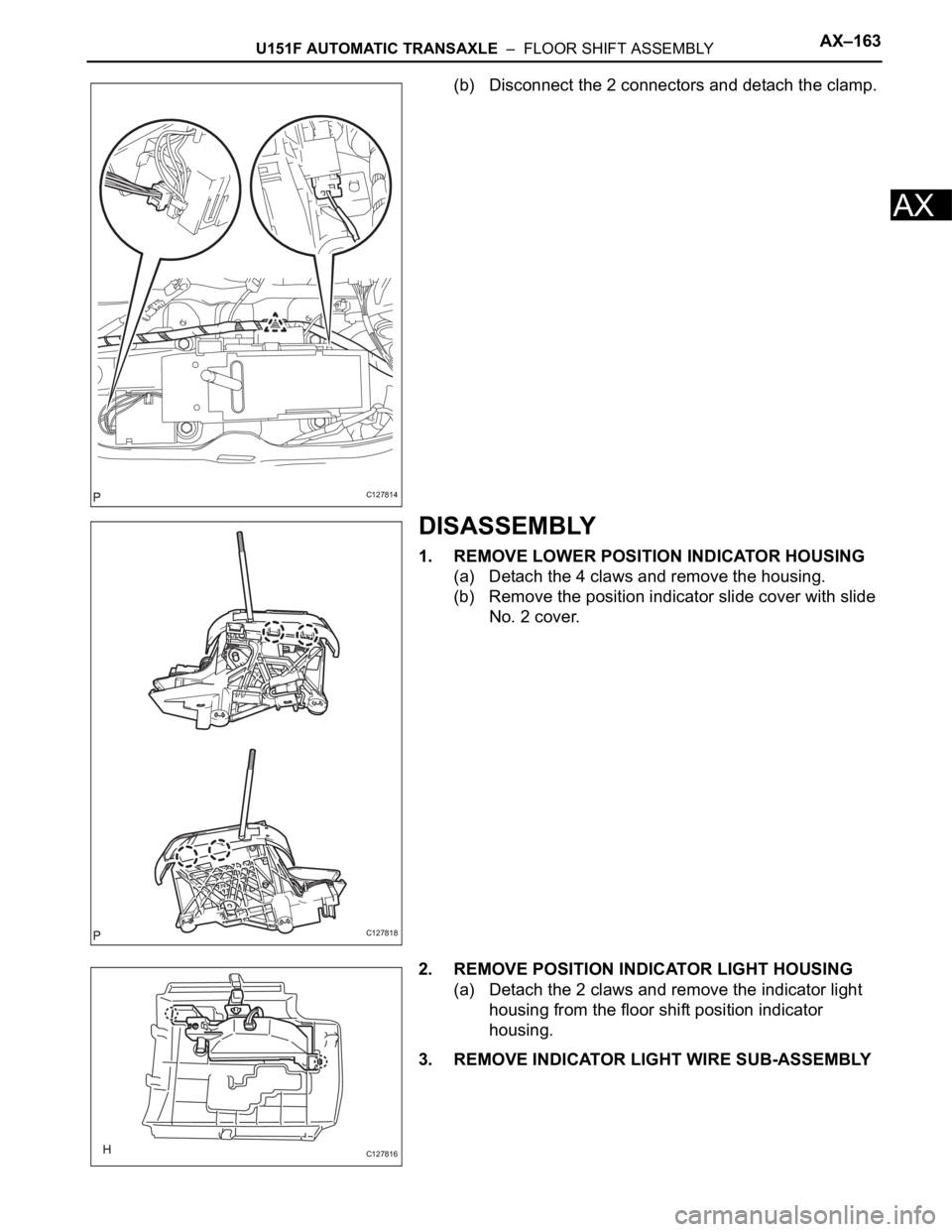

(b) Disconnect the 2 connectors and detach the clamp.

DISASSEMBLY

1. REMOVE LOWER POSITION INDICATOR HOUSING

(a) Detach the 4 claws and remove the housing.

(b) Remove the position indicator slide cover with slide

No. 2 cover.

2. REMOVE POSITION INDICATOR LIGHT HOUSING

(a) Detach the 2 claws and remove the indicator light

housing from the floor shift position indicator

housing.

3. REMOVE INDICATOR LIGHT WIRE SUB-ASSEMBLY

C127814

C127818

C127816

Page 363 of 2000

AX–164U151F AUTOMATIC TRANSAXLE – FLOOR SHIFT ASSEMBLY

AX

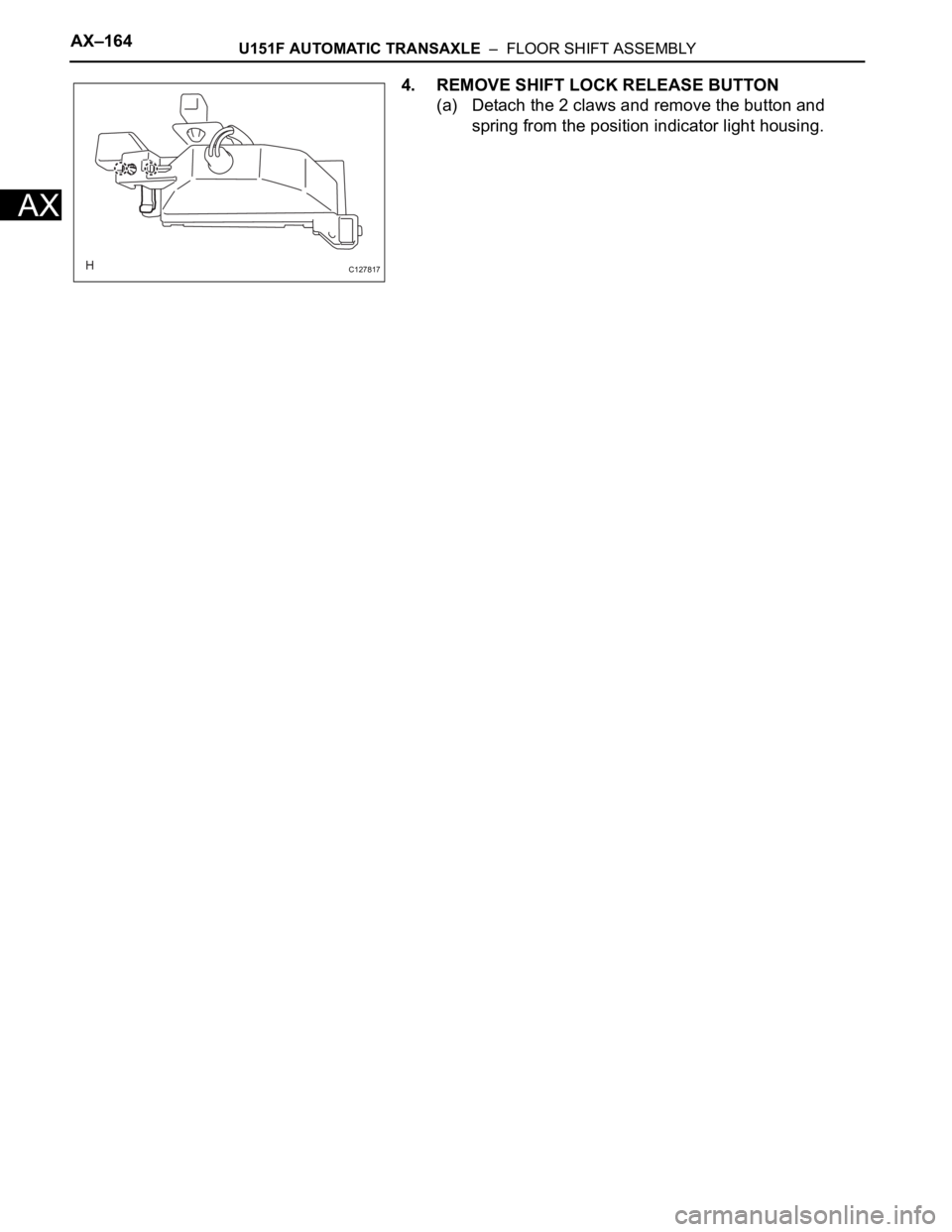

4. REMOVE SHIFT LOCK RELEASE BUTTON

(a) Detach the 2 claws and remove the button and

spring from the position indicator light housing.

C127817

Page 364 of 2000

AX–288U151F AUTOMATIC TRANSAXLE – DIFFERENTIAL CASE

AX

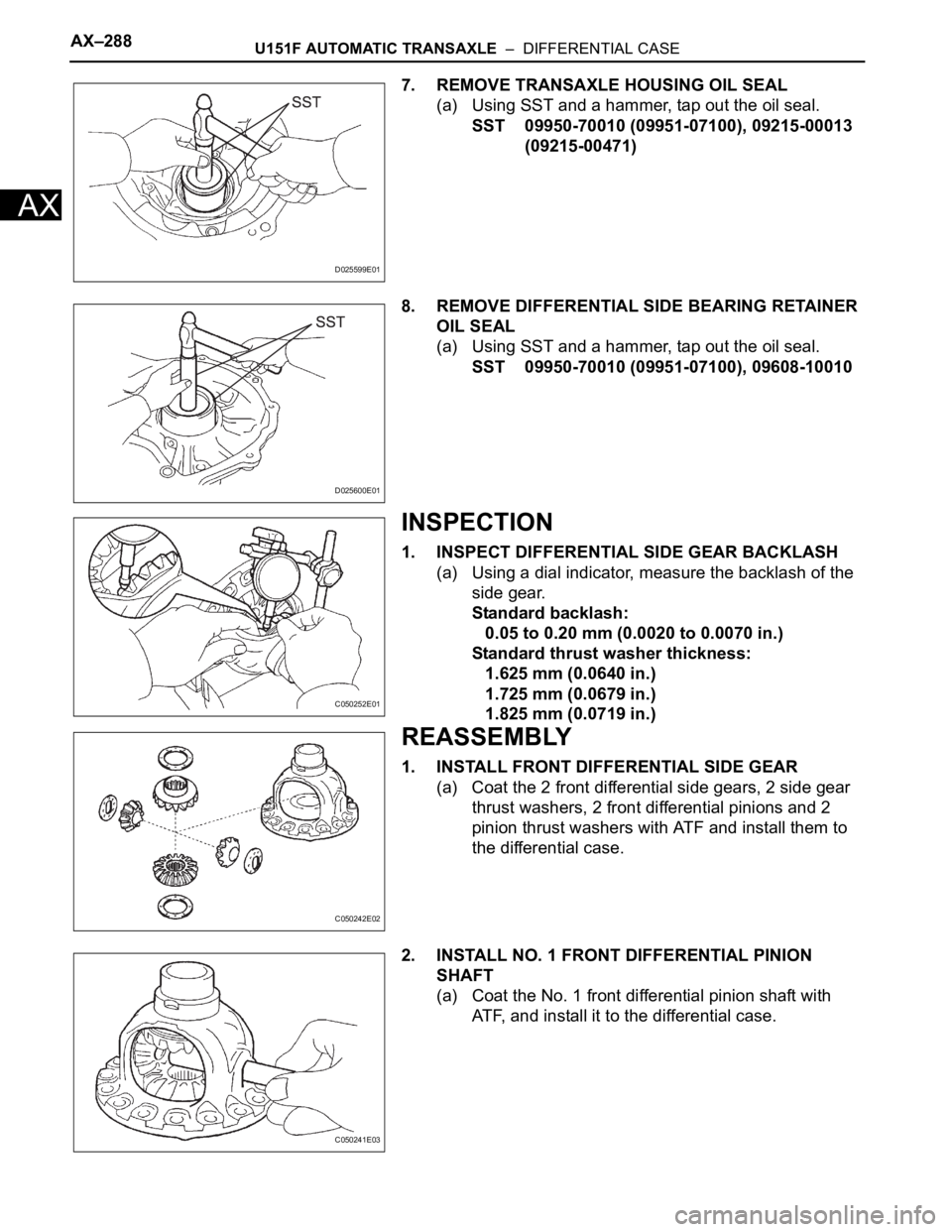

7. REMOVE TRANSAXLE HOUSING OIL SEAL

(a) Using SST and a hammer, tap out the oil seal.

SST 09950-70010 (09951-07100), 09215-00013

(09215-00471)

8. REMOVE DIFFERENTIAL SIDE BEARING RETAINER

OIL SEAL

(a) Using SST and a hammer, tap out the oil seal.

SST 09950-70010 (09951-07100), 09608-10010

INSPECTION

1. INSPECT DIFFERENTIAL SIDE GEAR BACKLASH

(a) Using a dial indicator, measure the backlash of the

side gear.

Standard backlash:

0.05 to 0.20 mm (0.0020 to 0.0070 in.)

Standard thrust washer thickness:

1.625 mm (0.0640 in.)

1.725 mm (0.0679 in.)

1.825 mm (0.0719 in.)

REASSEMBLY

1. INSTALL FRONT DIFFERENTIAL SIDE GEAR

(a) Coat the 2 front differential side gears, 2 side gear

thrust washers, 2 front differential pinions and 2

pinion thrust washers with ATF and install them to

the differential case.

2. INSTALL NO. 1 FRONT DIFFERENTIAL PINION

SHAFT

(a) Coat the No. 1 front differential pinion shaft with

ATF, and install it to the differential case.

D025599E01

D025600E01

C050252E01

C050242E02

C050241E03

Page 365 of 2000

U151F AUTOMATIC TRANSAXLE – DIFFERENTIAL CASEAX–289

AX

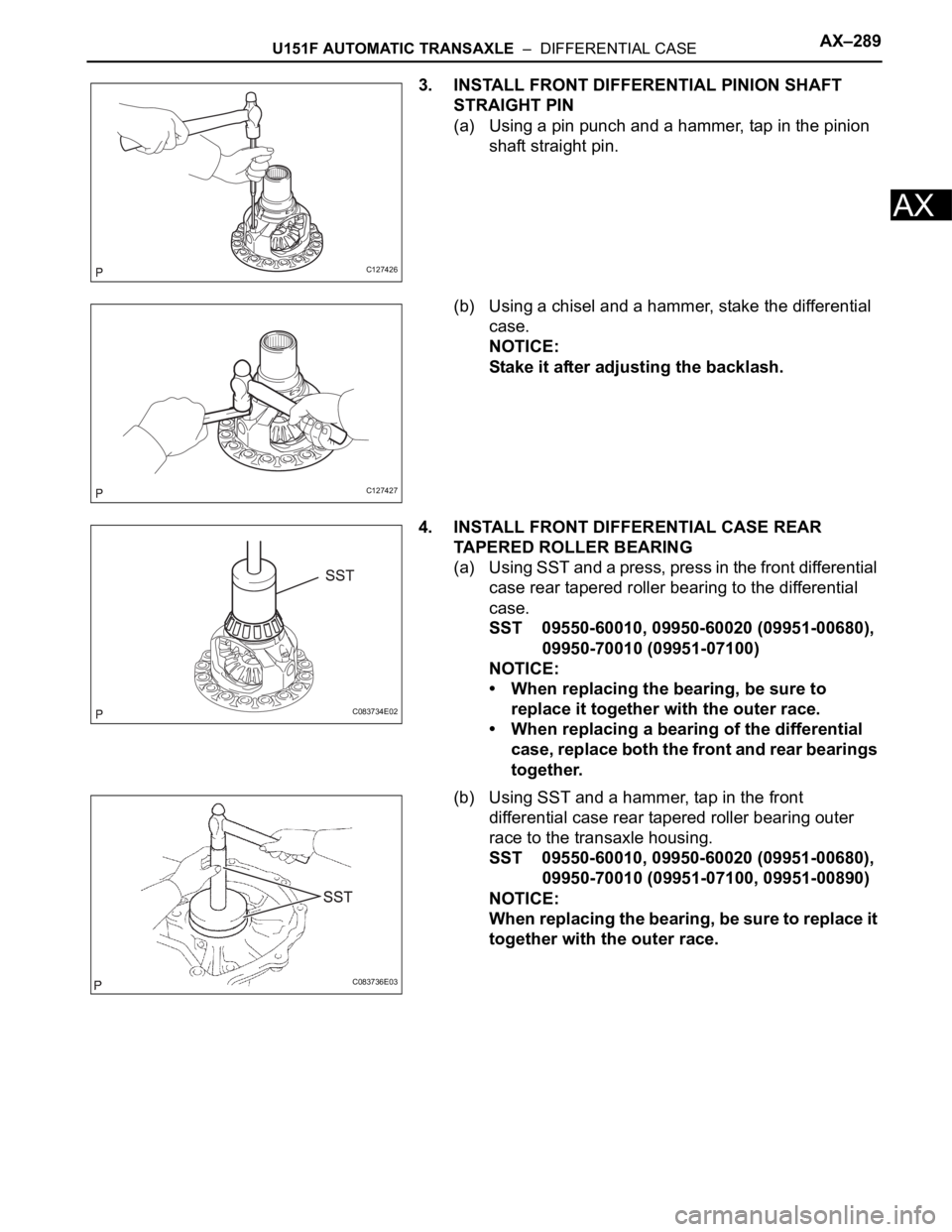

3. INSTALL FRONT DIFFERENTIAL PINION SHAFT

STRAIGHT PIN

(a) Using a pin punch and a hammer, tap in the pinion

shaft straight pin.

(b) Using a chisel and a hammer, stake the differential

case.

NOTICE:

Stake it after adjusting the backlash.

4. INSTALL FRONT DIFFERENTIAL CASE REAR

TAPERED ROLLER BEARING

(a) Using SST and a press, press in the front differential

case rear tapered roller bearing to the differential

case.

SST 09550-60010, 09950-60020 (09951-00680),

09950-70010 (09951-07100)

NOTICE:

• When replacing the bearing, be sure to

replace it together with the outer race.

• When replacing a bearing of the differential

case, replace both the front and rear bearings

together.

(b) Using SST and a hammer, tap in the front

differential case rear tapered roller bearing outer

race to the transaxle housing.

SST 09550-60010, 09950-60020 (09951-00680),

09950-70010 (09951-07100, 09951-00890)

NOTICE:

When replacing the bearing, be sure to replace it

together with the outer race.

C127426

C127427

C083734E02

C083736E03

Page 366 of 2000

AX–290U151F AUTOMATIC TRANSAXLE – DIFFERENTIAL CASE

AX

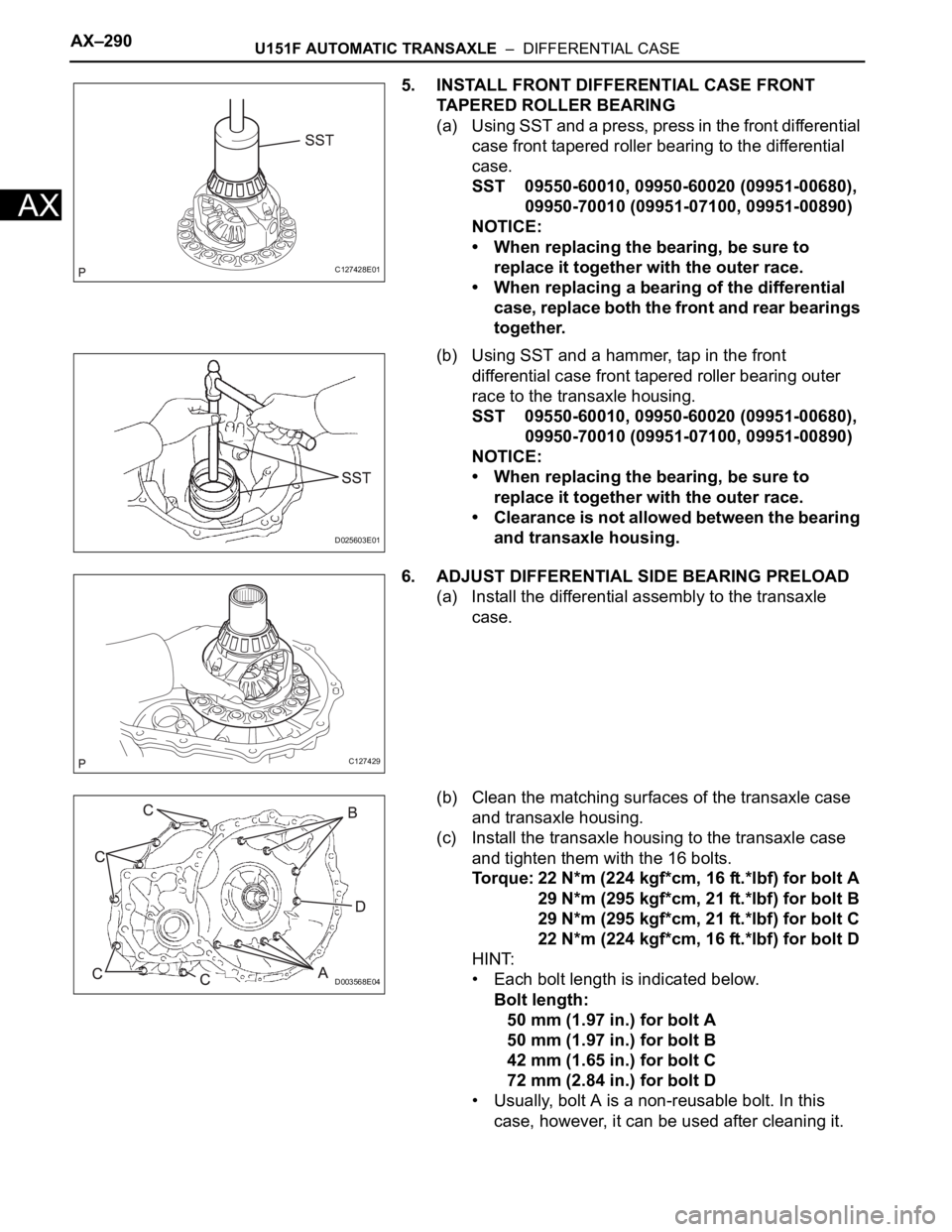

5. INSTALL FRONT DIFFERENTIAL CASE FRONT

TAPERED ROLLER BEARING

(a) U si ng SST and a pres s, pr es s in the f ron t di fferent ial

case front tapered roller bearing to the differential

case.

SST 09550-60010, 09950-60020 (09951-00680),

09950-70010 (09951-07100, 09951-00890)

NOTICE:

• When replacing the bearing, be sure to

replace it together with the outer race.

• When replacing a bearing of the differential

case, replace both the front and rear bearings

together.

(b) Using SST and a hammer, tap in the front

differential case front tapered roller bearing outer

race to the transaxle housing.

SST 09550-60010, 09950-60020 (09951-00680),

09950-70010 (09951-07100, 09951-00890)

NOTICE:

• When replacing the bearing, be sure to

replace it together with the outer race.

• Clearance is not allowed between the bearing

and transaxle housing.

6. ADJUST DIFFERENTIAL SIDE BEARING PRELOAD

(a) Install the differential assembly to the transaxle

case.

(b) Clean the matching surfaces of the transaxle case

and transaxle housing.

(c) Install the transaxle housing to the transaxle case

and tighten them with the 16 bolts.

Torque: 22 N*m (224 kgf*cm, 16 ft.*lbf) for bolt A

29 N*m (295 kgf*cm, 21 ft.*lbf) for bolt B

29 N*m (295 kgf*cm, 21 ft.*lbf) for bolt C

22 N*m (224 kgf*cm, 16 ft.*lbf) for bolt D

HINT:

• Each bolt length is indicated below.

Bolt length:

50 mm (1.97 in.) for bolt A

50 mm (1.97 in.) for bolt B

42 mm (1.65 in.) for bolt C

72 mm (2.84 in.) for bolt D

• Usually, bolt A is a non-reusable bolt. In this

case, however, it can be used after cleaning it.

C127428E01

D025603E01

C127429

D003568E04