Oil for u140 TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 954 of 2000

AX–20U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

(g) Depress the accelerator pedal as much as possible

with your right foot. Quickly read the highest line

pressure reading when the engine speed reaches

stall speed.

(h) Perform the measure line pressure test again with

the shift lever on R.

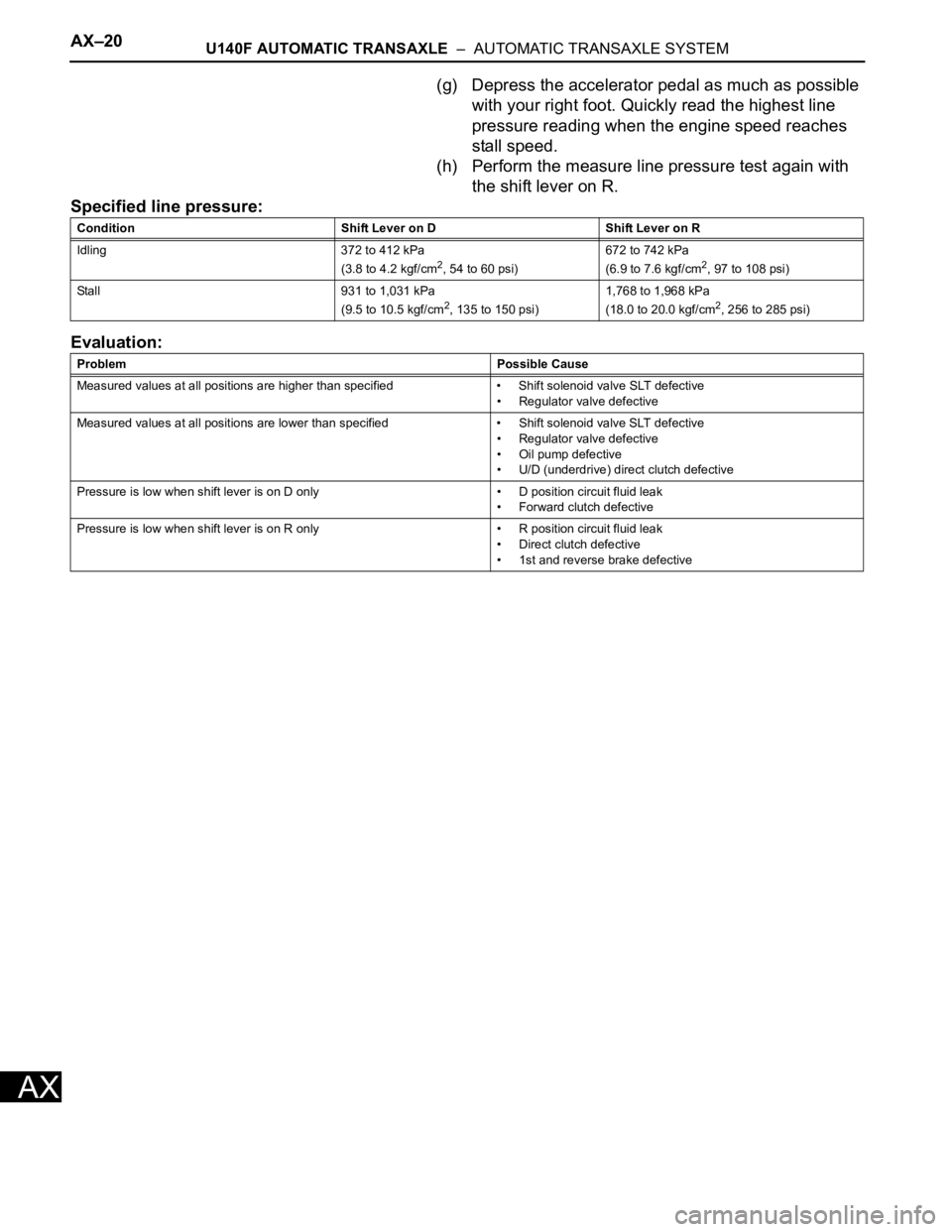

Specified line pressure:

Evaluation:

Condition Shift Lever on D Shift Lever on R

Idling 372 to 412 kPa

(3.8 to 4.2 kgf/cm

2, 54 to 60 psi)672 to 742 kPa

(6.9 to 7.6 kgf/cm2, 97 to 108 psi)

Stall 931 to 1,031 kPa

(9.5 to 10.5 kgf/cm

2, 135 to 150 psi)1,768 to 1,968 kPa

(18.0 to 20.0 kgf/cm2, 256 to 285 psi)

Problem Possible Cause

Measured values at all positions are higher than specified • Shift solenoid valve SLT defective

• Regulator valve defective

Measured values at all positions are lower than specified • Shift solenoid valve SLT defective

• Regulator valve defective

• Oil pump defective

• U/D (underdrive) direct clutch defective

Pressure is low when shift lever is on D only • D position circuit fluid leak

• Forward clutch defective

Pressure is low when shift lever is on R only • R position circuit fluid leak

• Direct clutch defective

• 1st and reverse brake defective

Page 961 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–27

AX

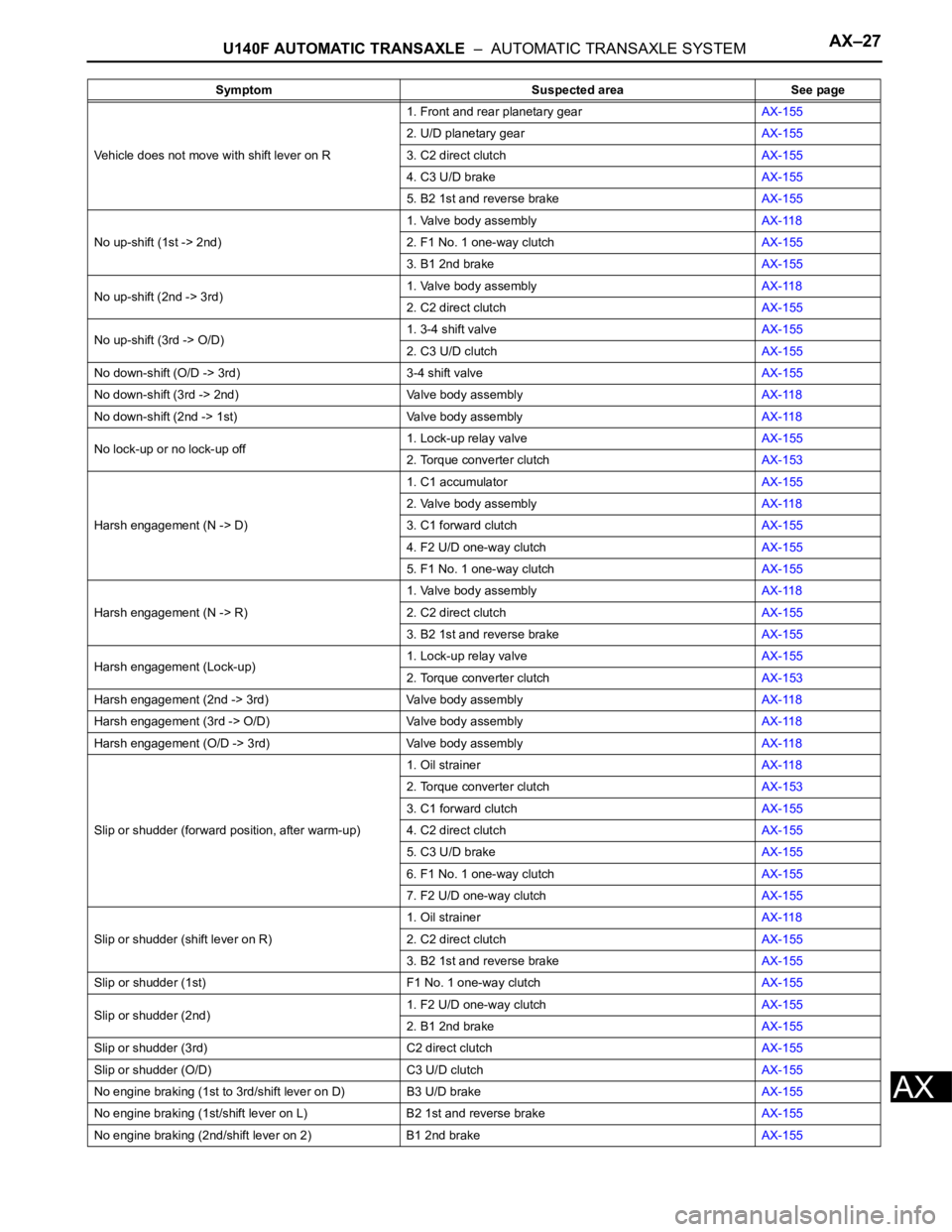

Vehicle does not move with shift lever on R1. Front and rear planetary gearAX-155

2. U/D planetary gearAX-155

3. C2 direct clutchAX-155

4. C3 U/D brakeAX-155

5. B2 1st and reverse brakeAX-155

No up-shift (1st -> 2nd)1. Valve body assemblyAX-118

2. F1 No. 1 one-way clutchAX-155

3. B1 2nd brakeAX-155

No up-shift (2nd -> 3rd)1. Valve body assemblyAX-118

2. C2 direct clutchAX-155

No up-shift (3rd -> O/D)1. 3-4 shift valveAX-155

2. C3 U/D clutchAX-155

No down-shift (O/D -> 3rd) 3-4 shift valveAX-155

No down-shift (3rd -> 2nd) Valve body assemblyAX-118

No down-shift (2nd -> 1st) Valve body assemblyAX-118

No lock-up or no lock-up off1. Lock-up relay valveAX-155

2. Torque converter clutchAX-153

Harsh engagement (N -> D)1. C1 accumulatorAX-155

2. Valve body assemblyAX-118

3. C1 forward clutchAX-155

4. F2 U/D one-way clutchAX-155

5. F1 No. 1 one-way clutchAX-155

Harsh engagement (N -> R)1. Valve body assemblyAX-118

2. C2 direct clutchAX-155

3. B2 1st and reverse brakeAX-155

Harsh engagement (Lock-up)1. Lock-up relay valveAX-155

2. Torque converter clutchAX-153

Harsh engagement (2nd -> 3rd) Valve body assemblyAX-118

Harsh engagement (3rd -> O/D) Valve body assemblyAX-118

Harsh engagement (O/D -> 3rd) Valve body assemblyAX-118

Slip or shudder (forward position, after warm-up)1. Oil strainerAX-118

2. Torque converter clutchAX-153

3. C1 forward clutchAX-155

4. C2 direct clutchAX-155

5. C3 U/D brakeAX-155

6. F1 No. 1 one-way clutchAX-155

7. F2 U/D one-way clutchAX-155

Slip or shudder (shift lever on R)1. Oil strainerAX-118

2. C2 direct clutchAX-155

3. B2 1st and reverse brakeAX-155

Slip or shudder (1st) F1 No. 1 one-way clutchAX-155

Slip or shudder (2nd)1. F2 U/D one-way clutchAX-155

2. B1 2nd brakeAX-155

Slip or shudder (3rd) C2 direct clutchAX-155

Slip or shudder (O/D) C3 U/D clutchAX-155

No engine braking (1st to 3rd/shift lever on D) B3 U/D brakeAX-155

No engine braking (1st/shift lever on L) B2 1st and reverse brakeAX-155

No engine braking (2nd/shift lever on 2) B1 2nd brakeAX-155 Symptom Suspected area See page

Page 980 of 2000

AX–152U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLY

AX

9. INSTALL ENGINE MOUNTING BRACKET RR

(a) Install the mounting bracket with the 3 bolts.

Torque: 45 N*m (459 kgf*cm, 33 ft.*lbf)

10. INSTALL TRANSMISSION OIL COOLER

(a) Install the oil cooler (see page AX-127).

11. CONNECT WIRE HARNESS

(a) Connect the wire harness clamps.

(b) Connect the 2 speed sensor connectors.

(c) Connect the transaxle wire connector.

(d) Connect the park/neutral position switch connector.

12. INSTALL STARTER ASSEMBLY

(a) Install the starter with the 2 bolts.

Torque: 37 N*m (377 kgf*cm, 27 ft.*lbf)

(b) Connect the starter wire with the nut.

Torque: 13 N*m (133 kgf*cm, 10 ft.*lbf)

(c) Connect the starter connector.

(d) Install the terminal nut and cover the nut with the

cap.

Torque: 9.8 N*m (100 kgf*cm, 7 in.*lbf)

13. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

(a) Install the engine with transaxle. (see page EM-

105).

14. ADD AUTOMATIC TRANSAXLE FLUID

Fluid type:

Toyota Genuine ATF WS

15. INSPECT AUTOMATIC TRANSAXLE FLUID

(a) Inspect the automatic transaxle fluid (see page AX-

102).

16. PERFORM RESET MEMORY

(a) Perform the RESET MEMORY procedures (A/T

initialization) (see page AX-18).

C130913

C127821

A124921

A124920

Page 983 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–189

AX

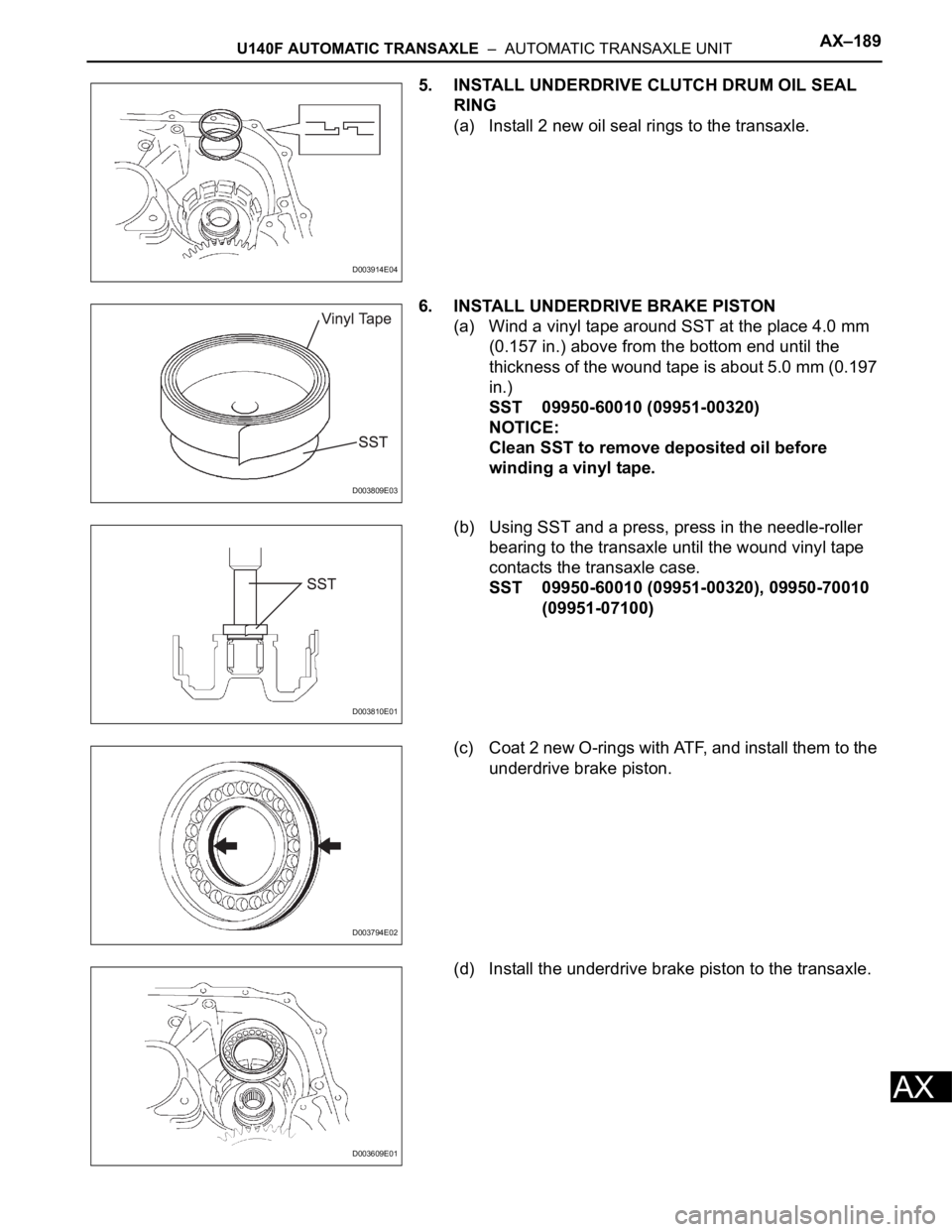

5. INSTALL UNDERDRIVE CLUTCH DRUM OIL SEAL

RING

(a) Install 2 new oil seal rings to the transaxle.

6. INSTALL UNDERDRIVE BRAKE PISTON

(a) Wind a vinyl tape around SST at the place 4.0 mm

(0.157 in.) above from the bottom end until the

thickness of the wound tape is about 5.0 mm (0.197

in.)

SST 09950-60010 (09951-00320)

NOTICE:

Clean SST to remove deposited oil before

winding a vinyl tape.

(b) Using SST and a press, press in the needle-roller

bearing to the transaxle until the wound vinyl tape

contacts the transaxle case.

SST 09950-60010 (09951-00320), 09950-70010

(09951-07100)

(c) Coat 2 new O-rings with ATF, and install them to the

underdrive brake piston.

(d) Install the underdrive brake piston to the transaxle.

D003914E04

D003809E03

D003810E01

D003794E02

D003609E01

Page 1000 of 2000

AX–206U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

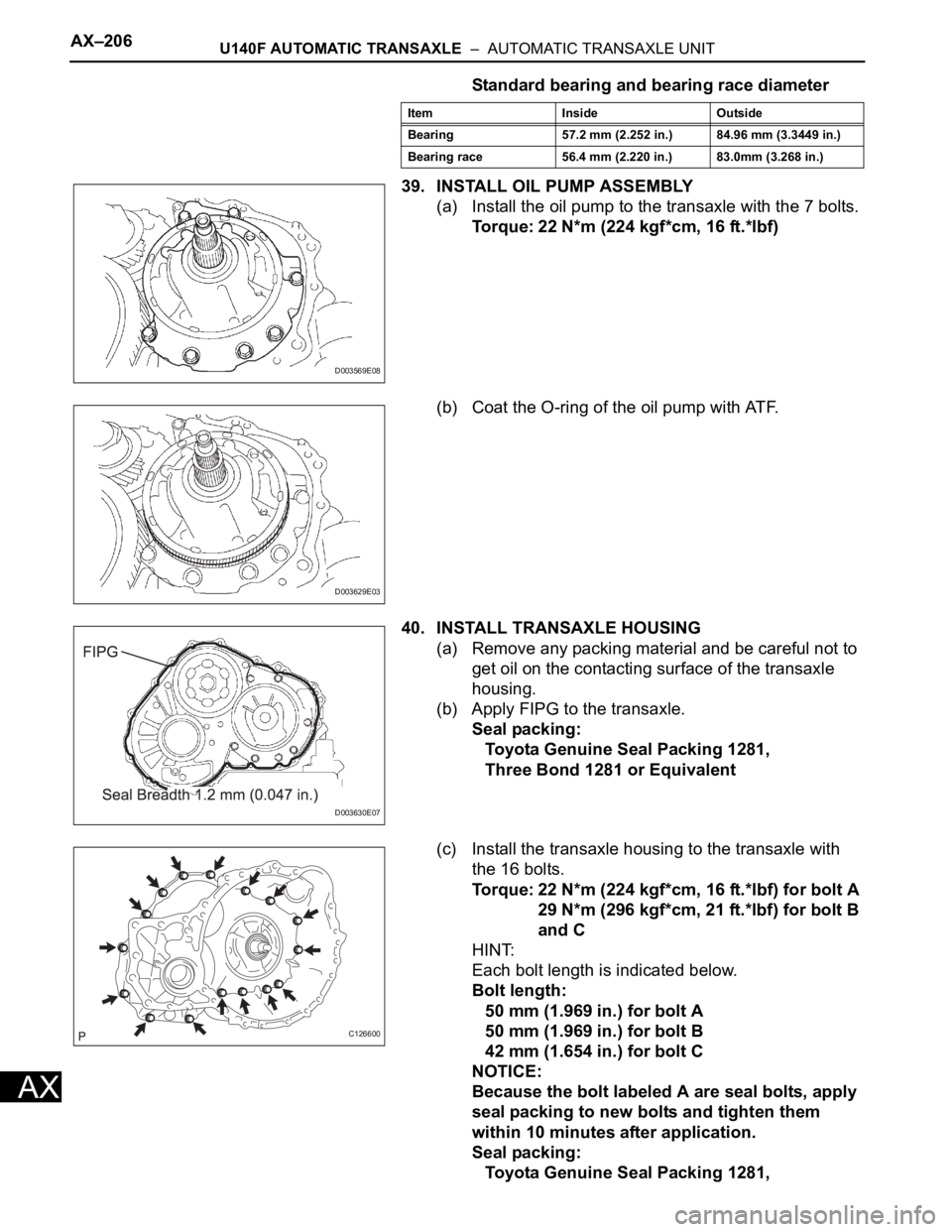

Standard bearing and bearing race diameter

39. INSTALL OIL PUMP ASSEMBLY

(a) Install the oil pump to the transaxle with the 7 bolts.

Torque: 22 N*m (224 kgf*cm, 16 ft.*lbf)

(b) Coat the O-ring of the oil pump with ATF.

40. INSTALL TRANSAXLE HOUSING

(a) Remove any packing material and be careful not to

get oil on the contacting surface of the transaxle

housing.

(b) Apply FIPG to the transaxle.

Seal packing:

Toyota Genuine Seal Packing 1281,

Three Bond 1281 or Equivalent

(c) Install the transaxle housing to the transaxle with

the 16 bolts.

Torque: 22 N*m (224 kgf*cm, 16 ft.*lbf) for bolt A

29 N*m (296 kgf*cm, 21 ft.*lbf) for bolt B

and C

HINT:

Each bolt length is indicated below.

Bolt length:

50 mm (1.969 in.) for bolt A

50 mm (1.969 in.) for bolt B

42 mm (1.654 in.) for bolt C

NOTICE:

Because the bolt labeled A are seal bolts, apply

seal packing to new bolts and tighten them

within 10 minutes after application.

Seal packing:

Toyota Genuine Seal Packing 1281,

Item Inside Outside

Bearing 57.2 mm (2.252 in.) 84.96 mm (3.3449 in.)

Bearing race 56.4 mm (2.220 in.) 83.0mm (3.268 in.)

D003569E08

D003629E03

D003630E07

C126600

Page 1006 of 2000

AX–212U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

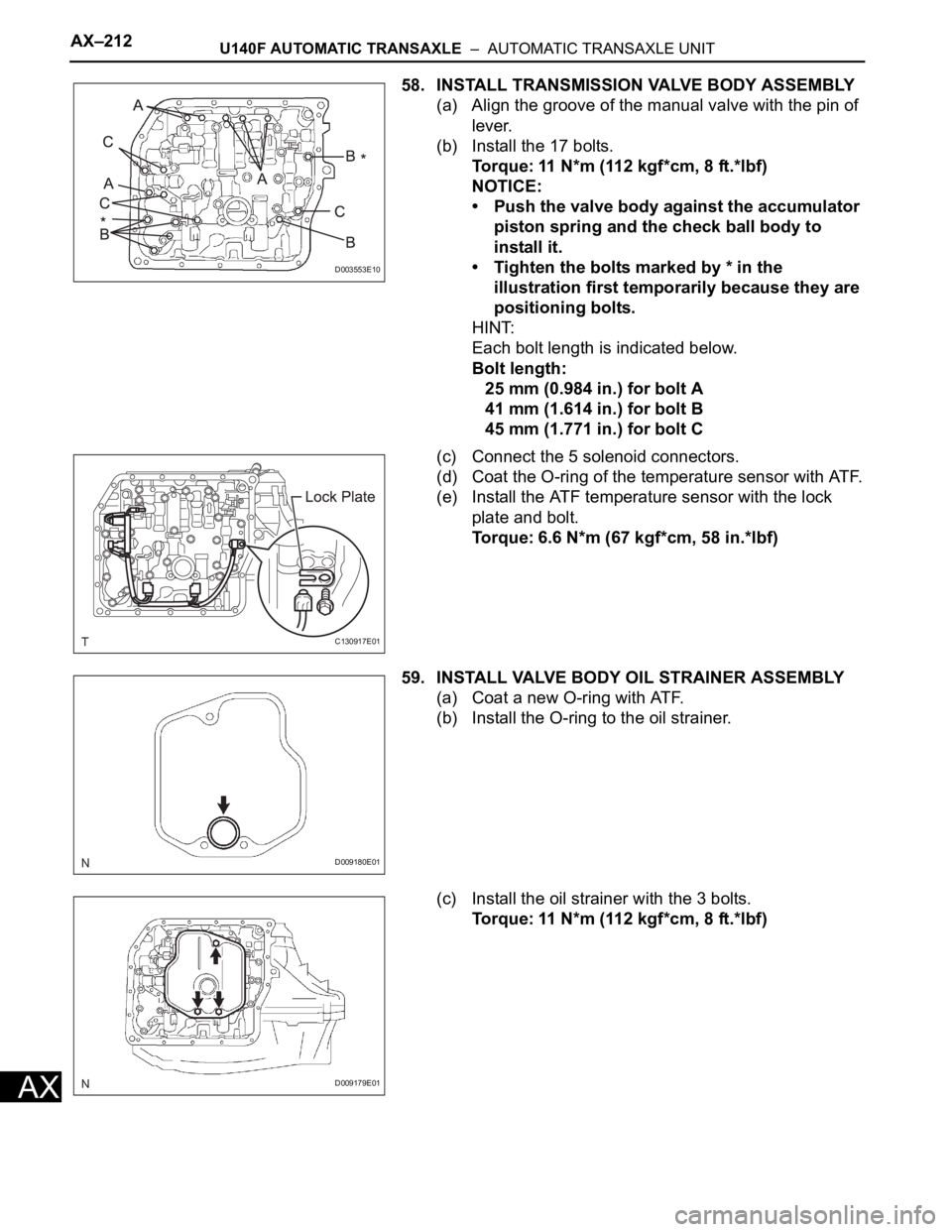

58. INSTALL TRANSMISSION VALVE BODY ASSEMBLY

(a) Align the groove of the manual valve with the pin of

lever.

(b) Install the 17 bolts.

Torque: 11 N*m (112 kgf*cm, 8 ft.*lbf)

NOTICE:

• Push the valve body against the accumulator

piston spring and the check ball body to

install it.

• Tighten the bolts marked by * in the

illustration first temporarily because they are

positioning bolts.

HINT:

Each bolt length is indicated below.

Bolt length:

25 mm (0.984 in.) for bolt A

41 mm (1.614 in.) for bolt B

45 mm (1.771 in.) for bolt C

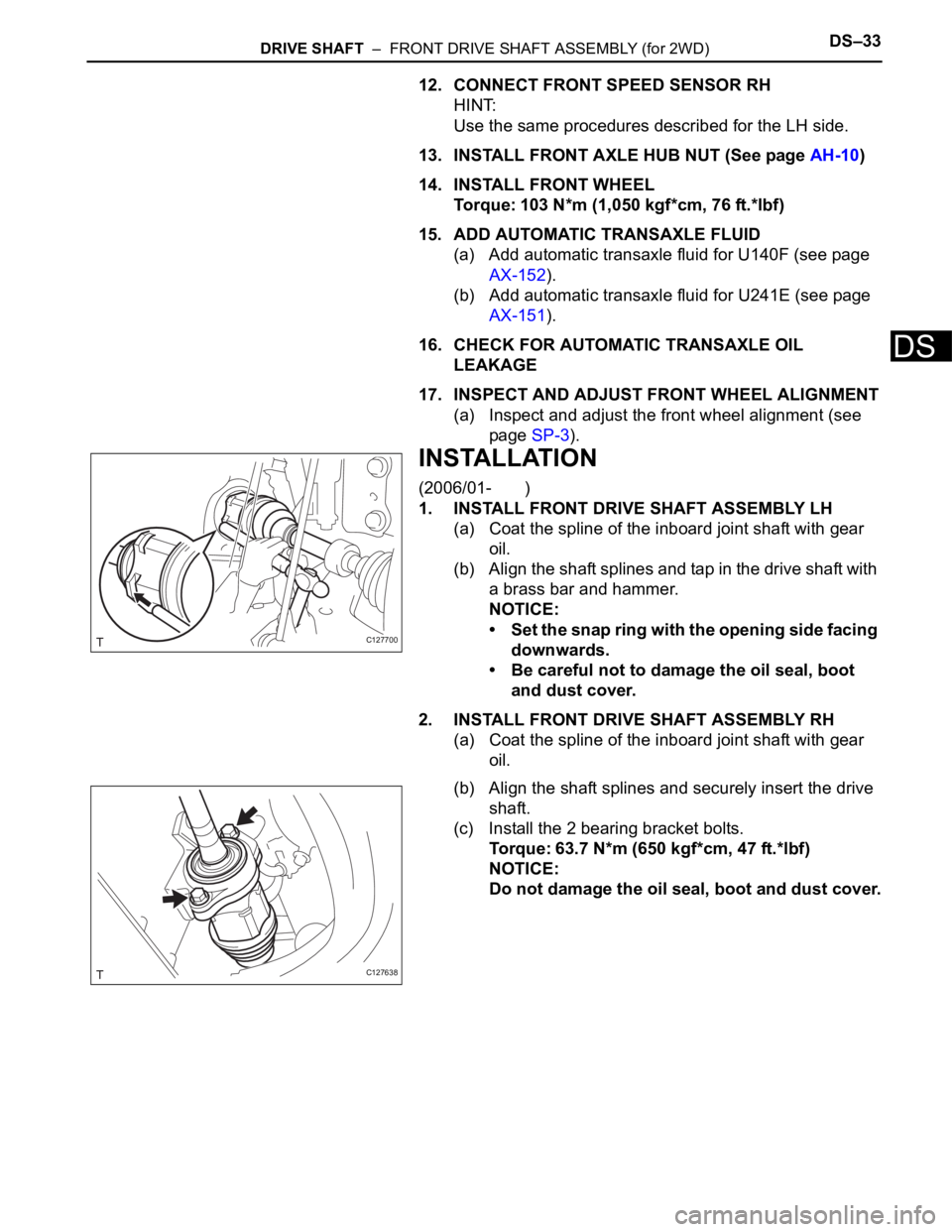

(c) Connect the 5 solenoid connectors.

(d) Coat the O-ring of the temperature sensor with ATF.

(e) Install the ATF temperature sensor with the lock

plate and bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf)

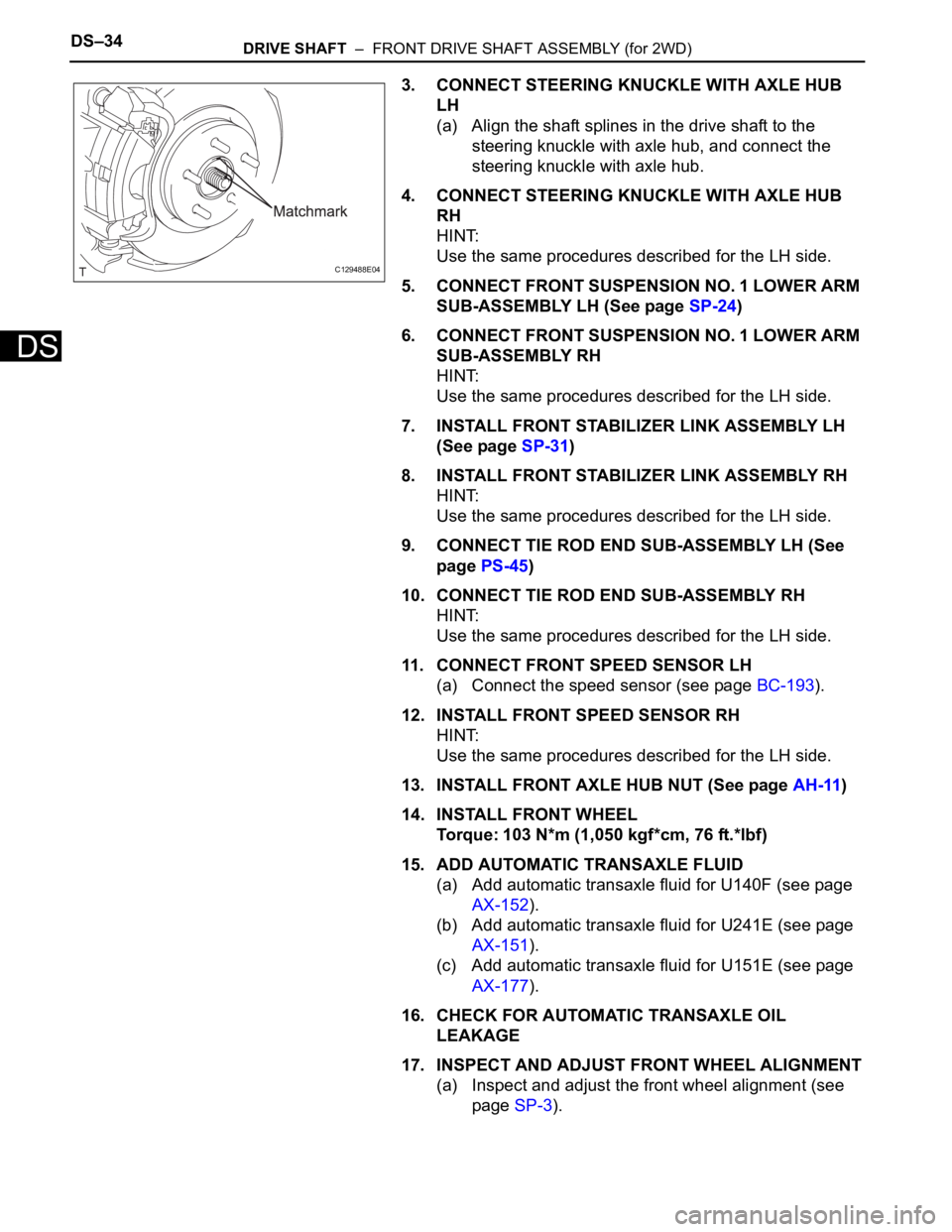

59. INSTALL VALVE BODY OIL STRAINER ASSEMBLY

(a) Coat a new O-ring with ATF.

(b) Install the O-ring to the oil strainer.

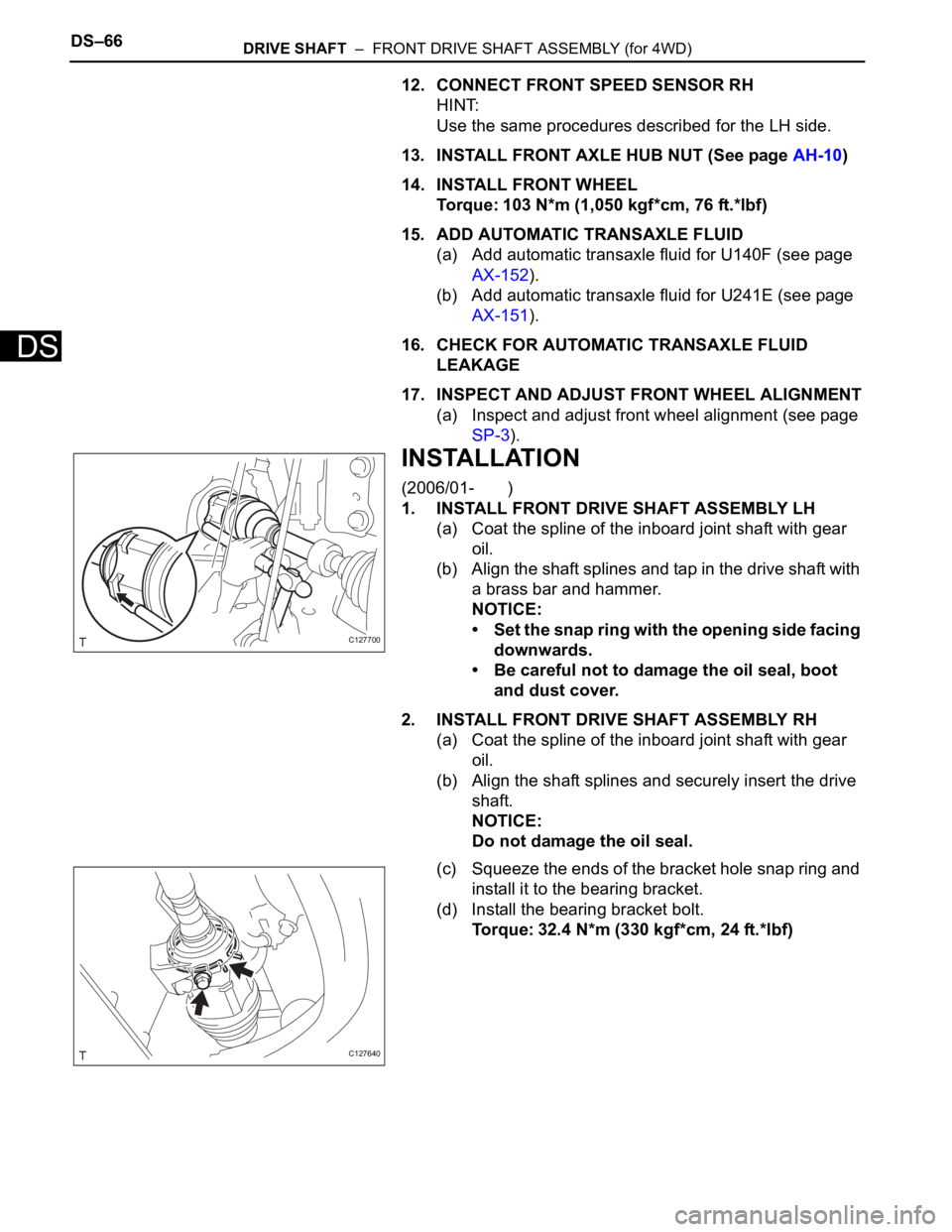

(c) Install the oil strainer with the 3 bolts.

Torque: 11 N*m (112 kgf*cm, 8 ft.*lbf)

D003553E10

C130917E01

D009180E01

D009179E01

Page 1389 of 2000

DRIVE SHAFT – FRONT DRIVE SHAFT ASSEMBLY (for 2WD)DS–33

DS

12. CONNECT FRONT SPEED SENSOR RH

HINT:

Use the same procedures described for the LH side.

13. INSTALL FRONT AXLE HUB NUT (See page AH-10)

14. INSTALL FRONT WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

15. ADD AUTOMATIC TRANSAXLE FLUID

(a) Add automatic transaxle fluid for U140F (see page

AX-152).

(b) Add automatic transaxle fluid for U241E (see page

AX-151).

16. CHECK FOR AUTOMATIC TRANSAXLE OIL

LEAKAGE

17. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

(a) Inspect and adjust the front wheel alignment (see

page SP-3).

INSTALLATION

(2006/01- )

1. INSTALL FRONT DRIVE SHAFT ASSEMBLY LH

(a) Coat the spline of the inboard joint shaft with gear

oil.

(b) Align the shaft splines and tap in the drive shaft with

a brass bar and hammer.

NOTICE:

• Set the snap ring with the opening side facing

downwards.

• Be careful not to damage the oil seal, boot

and dust cover.

2. INSTALL FRONT DRIVE SHAFT ASSEMBLY RH

(a) Coat the spline of the inboard joint shaft with gear

oil.

(b) Align the shaft splines and securely insert the drive

shaft.

(c) Install the 2 bearing bracket bolts.

Torque: 63.7 N*m (650 kgf*cm, 47 ft.*lbf)

NOTICE:

Do not damage the oil seal, boot and dust cover.

C127700

C127638

Page 1390 of 2000

DS–34DRIVE SHAFT – FRONT DRIVE SHAFT ASSEMBLY (for 2WD)

DS

3. CONNECT STEERING KNUCKLE WITH AXLE HUB

LH

(a) Align the shaft splines in the drive shaft to the

steering knuckle with axle hub, and connect the

steering knuckle with axle hub.

4. CONNECT STEERING KNUCKLE WITH AXLE HUB

RH

HINT:

Use the same procedures described for the LH side.

5. CONNECT FRONT SUSPENSION NO. 1 LOWER ARM

SUB-ASSEMBLY LH (See page SP-24)

6. CONNECT FRONT SUSPENSION NO. 1 LOWER ARM

SUB-ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

7. INSTALL FRONT STABILIZER LINK ASSEMBLY LH

(See page SP-31)

8. INSTALL FRONT STABILIZER LINK ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

9. CONNECT TIE ROD END SUB-ASSEMBLY LH (See

page PS-45)

10. CONNECT TIE ROD END SUB-ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

11. CONNECT FRONT SPEED SENSOR LH

(a) Connect the speed sensor (see page BC-193).

12. INSTALL FRONT SPEED SENSOR RH

HINT:

Use the same procedures described for the LH side.

13. INSTALL FRONT AXLE HUB NUT (See page AH-11)

14. INSTALL FRONT WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

15. ADD AUTOMATIC TRANSAXLE FLUID

(a) Add automatic transaxle fluid for U140F (see page

AX-152).

(b) Add automatic transaxle fluid for U241E (see page

AX-151).

(c) Add automatic transaxle fluid for U151E (see page

AX-177).

16. CHECK FOR AUTOMATIC TRANSAXLE OIL

LEAKAGE

17. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

(a) Inspect and adjust the front wheel alignment (see

page SP-3).

C129488E04

Page 1420 of 2000

DS–66DRIVE SHAFT – FRONT DRIVE SHAFT ASSEMBLY (for 4WD)

DS

12. CONNECT FRONT SPEED SENSOR RH

HINT:

Use the same procedures described for the LH side.

13. INSTALL FRONT AXLE HUB NUT (See page AH-10)

14. INSTALL FRONT WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

15. ADD AUTOMATIC TRANSAXLE FLUID

(a) Add automatic transaxle fluid for U140F (see page

AX-152).

(b) Add automatic transaxle fluid for U241E (see page

AX-151).

16. CHECK FOR AUTOMATIC TRANSAXLE FLUID

LEAKAGE

17. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

(a) Inspect and adjust front wheel alignment (see page

SP-3).

INSTALLATION

(2006/01- )

1. INSTALL FRONT DRIVE SHAFT ASSEMBLY LH

(a) Coat the spline of the inboard joint shaft with gear

oil.

(b) Align the shaft splines and tap in the drive shaft with

a brass bar and hammer.

NOTICE:

• Set the snap ring with the opening side facing

downwards.

• Be careful not to damage the oil seal, boot

and dust cover.

2. INSTALL FRONT DRIVE SHAFT ASSEMBLY RH

(a) Coat the spline of the inboard joint shaft with gear

oil.

(b) Align the shaft splines and securely insert the drive

shaft.

NOTICE:

Do not damage the oil seal.

(c) Squeeze the ends of the bracket hole snap ring and

install it to the bearing bracket.

(d) Install the bearing bracket bolt.

Torque: 32.4 N*m (330 kgf*cm, 24 ft.*lbf)

C127700

C127640