drain TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 47 of 2000

ENGINE - 2AZ-FE ENGINE

169EG36

HousingLock Pin

Intake Camshaft

Vane (Fixed on Intake Camshaft)

Oil Pressure

At a Stop In Operation

Lock Pin

221EG17

To VVT-i Controller

(Advance Side)To V V T- i C o n t r o l l e r

(Retard Side)

Sleeve

Spring

Drain

Oil PressureDrain

Spool ValveCoil

Plunger EG-50

Construction

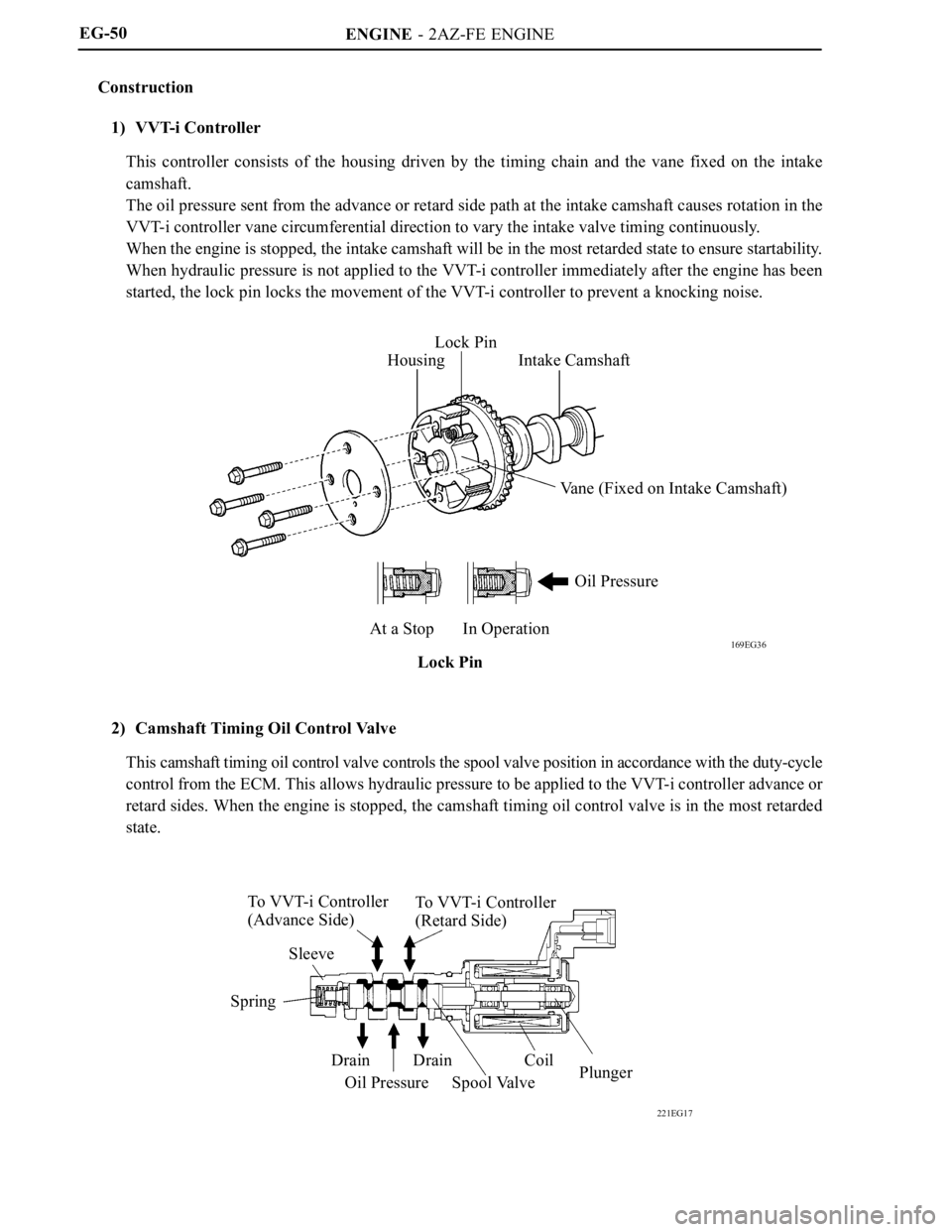

1) VVT-i Controller

This controller consists of the housing driven by the timing chain and the vane fixed on the intake

camshaft.

The oil pressure sent from the advance or retard side path at the intake camshaft causes rotation in the

VVT-i controller vane circumferential direction to vary the intake valve timing continuously.

When the engine is stopped, the intake camshaft will be in the most retarded state to ensure startability.

When hydraulic pressure is not applied to the VVT-i controller immediately after the engine has been

started, the lock pin locks the movement of the VVT-i controller to prevent a knocking noise.

2) Camshaft Timing Oil Control Valve

This camshaft timing oil control valve controls the spool valve position in accordance with the duty-cycle

control from the ECM. This allows hydraulic pressure to be applied to the VVT-i controller advance or

retard sides. When the engine is stopped, the camshaft timing oil control valve is in the most retarded

state.

Page 48 of 2000

ENGINE - 2AZ-FE ENGINE

198EG35

Va n e

Rotation DirectionOil PressureECM

IN Drain

198EG36

Va n e

Rotation DirectionOil Pressure

Drain INECMEG-51

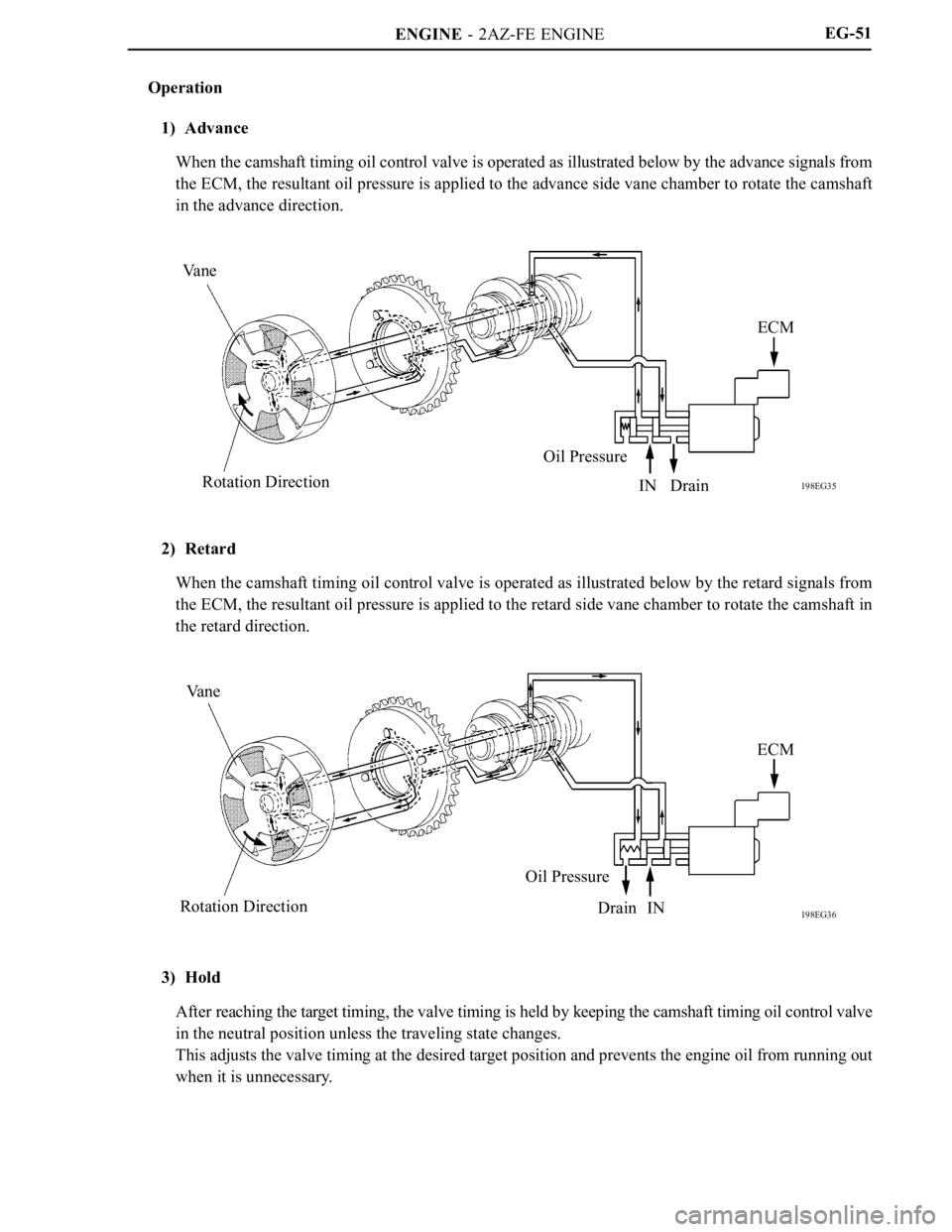

Operation

1) Advance

When the camshaft timing oil control valve is operated as illustrated below by the advance signals from

the ECM, the resultant oil pressure is applied to the advance side vane chamber to rotate the camshaft

in the advance direction.

2) Retard

When the camshaft timing oil control valve is operated as illustrated below by the retard signals from

the ECM, the resultant oil pressure is applied to the retard side vane chamber to rotate the camshaft in

the retard direction.

3) Hold

After reaching the target timing, the valve timing is held by keeping the camshaft timing oil control valve

in the neutral position unless the traveling state changes.

This adjusts the valve timing at the desired target position and prevents the engine oil from running out

when it is unnecessary.

Page 52 of 2000

ENGINE - 2AZ-FE ENGINE

00REG22Y

To Intake Manifold

Purge VSV

Purge Air

Line

ECMFuel Tank

Canister Filter

Fresh Air LineRefueling Valve

Canister Pump Module

Ve n t

Va l v e

Leak Detection Pump

& Pump Motor

Canister

Pressure SensorCanisterP M

EG-55

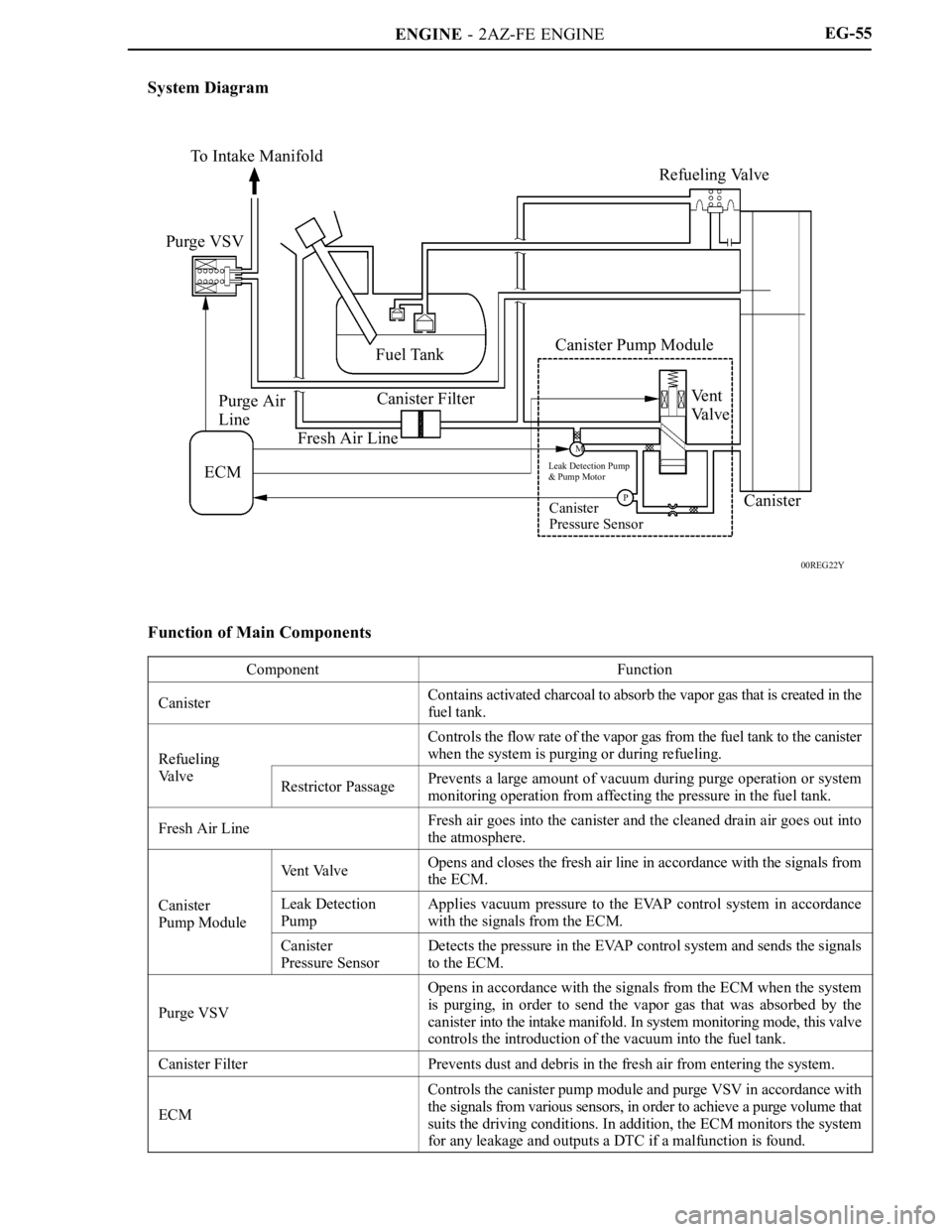

System Diagram

Function of Main Components

ComponentFunction

CanisterContains activated charcoal to absorb the vapor gas that is created in the

fuel tank.

Refueling

Controls the flow rate of the vapor gas from the fuel tank to the canister

when the system is purging or during refueling.

Refueling

Va l v eRestrictor PassagePrevents a large amount of vacuum during purge operation or system

monitoring operation from affecting the pressure in the fuel tank.

Fresh Air LineFresh air goes into the canister and the cleaned drain air goes out into

the atmosphere.

Vent ValveOpens and closes the fresh air line in accordance with the signals from

the ECM.

Canister

Pump ModuleLeak Detection

PumpApplies vacuum pressure to the EVAP control system in accordance

with the signals from the ECM.

p

Canister

Pressure SensorDetects the pressure in the EVAP control system and sends the signals

to the ECM.

Purge VSV

Opens in accordance with the signals from the ECM when the system

is purging, in order to send the vapor gas that was absorbed by the

canister into the intake manifold. In system monitoring mode, this valve

controls the introduction of the vacuum into the fuel tank.

Canister FilterPrevents dust and debris in the fresh air from entering the system.

ECM

Controls the canister pump module and purge VSV in accordance with

the signals from various sensors, in order to achieve a purge volume that

suits the driving conditions. In addition, the ECM monitors the system

for any leakage and outputs a DTC if a malfunction is found.

Page 53 of 2000

ENGINE - 2AZ-FE ENGINE

D13N07 285EG76

Chamber A

Fresh Air Line

Refueling

Valve (Open)

Chamber B

From Fuel

Ta n k

Internal PressureCanister

To F u e l

Ta n k

Positive Pressure

(Fuel Tank Pressure)

Restrictor PassageNegative Pressure

(Intake Manifold Pressure)

During Refueling During Purge Operation or

System Monitoring Operation

228TU119

Fuel Tank Cap

Fresh Air

Fuel Inlet PipeTo Canister

Cleaned Drain Air EG-56

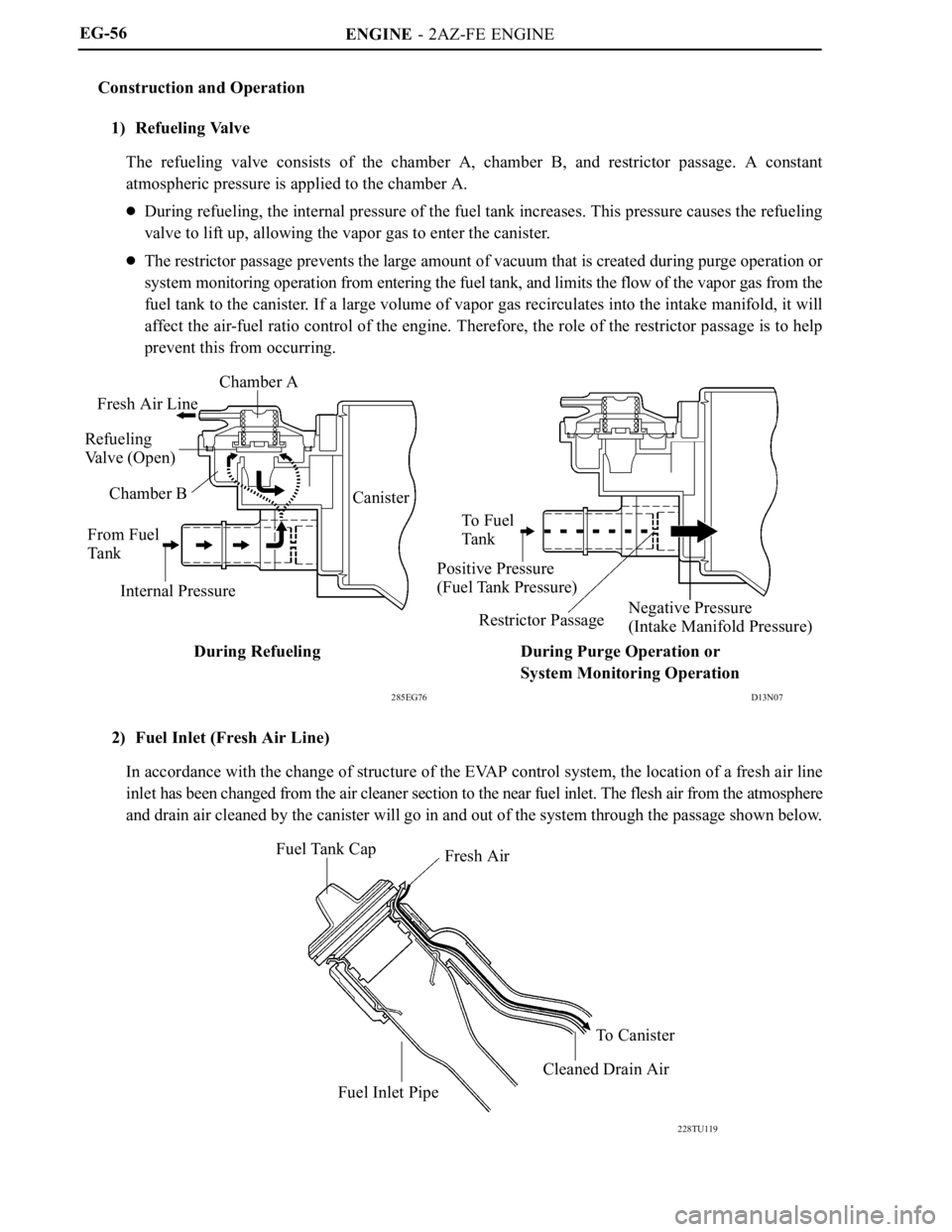

Construction and Operation

1) Refueling Valve

The refueling valve consists of the chamber A, chamber B, and restrictor passage. A constant

atmospheric pressure is applied to the chamber A.

During refueling, the internal pressure of the fuel tank increases. This pressure causes the refueling

valve to lift up, allowing the vapor gas to enter the canister.

The restrictor passage prevents the large amount of vacuum that is created during purge operation or

system monitoring operation from entering the fuel tank, and limits the flow of the vapor gas from the

fuel tank to the canister. If a large volume of vapor gas recirculates into the intake manifold, it will

affect the air-fuel ratio control of the engine. Therefore, the role of the restrictor passage is to help

prevent this from occurring.

2) Fuel Inlet (Fresh Air Line)

In accordance with the change of structure of the EVAP control system, the location of a fresh air line

inlet has been changed from the air cleaner section to the near fuel inlet. The flesh air from the atmosphere

and drain air cleaned by the canister will go in and out of the system through the passage shown below.

Page 83 of 2000

ENGINE - 2GR-FE ENGINE

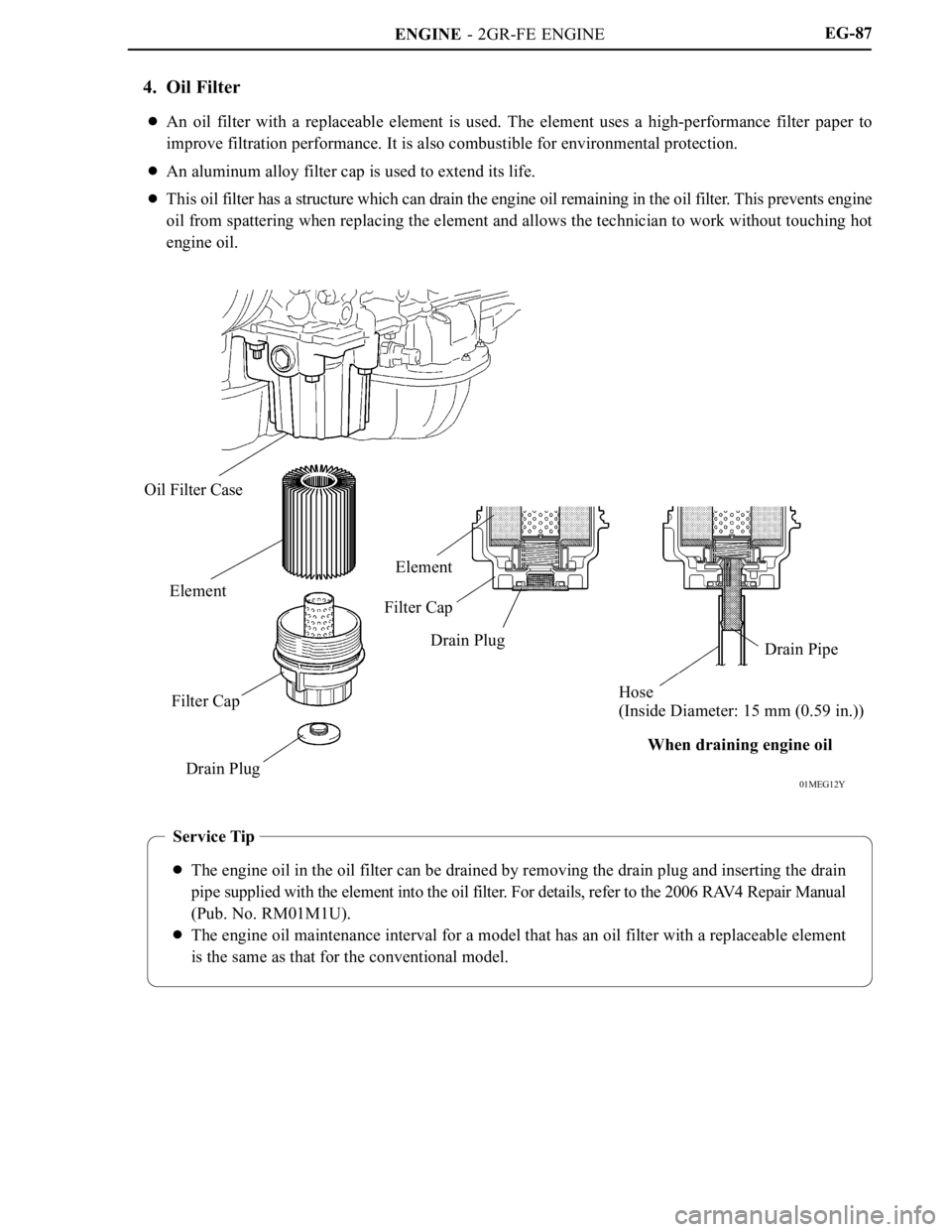

01MEG12Y

Oil Filter Case

Element

Filter Cap

Drain PlugElement

Filter Cap

Drain Plug

Drain Pipe

Hose

(Inside Diameter: 15 mm (0.59 in.))

When draining engine oil

Service Tip

The engine oil in the oil filter can be drained by removing the drain plug and inserting the drain

pipe supplied with the element into the oil filter. For details, refer to the 2006 RAV4 Repair Manual

(Pub. No. RM01M1U).

The engine oil maintenance interval for a model that has an oil filter with a replaceable element

is the same as that for the conventional model.

EG-87

4. Oil Filter

An oil filter with a replaceable element is used. The element uses a high-performance filter paper to

improve filtration performance. It is also combustible for environmental protection.

An aluminum alloy filter cap is used to extend its life.

This oil filter has a structure which can drain the engine oil remaining in the oil filter. This prevents engine

oil from spattering when replacing the element and allows the technician to work without touching hot

engine oil.

Page 119 of 2000

ENGINE - 2GR-FE ENGINE

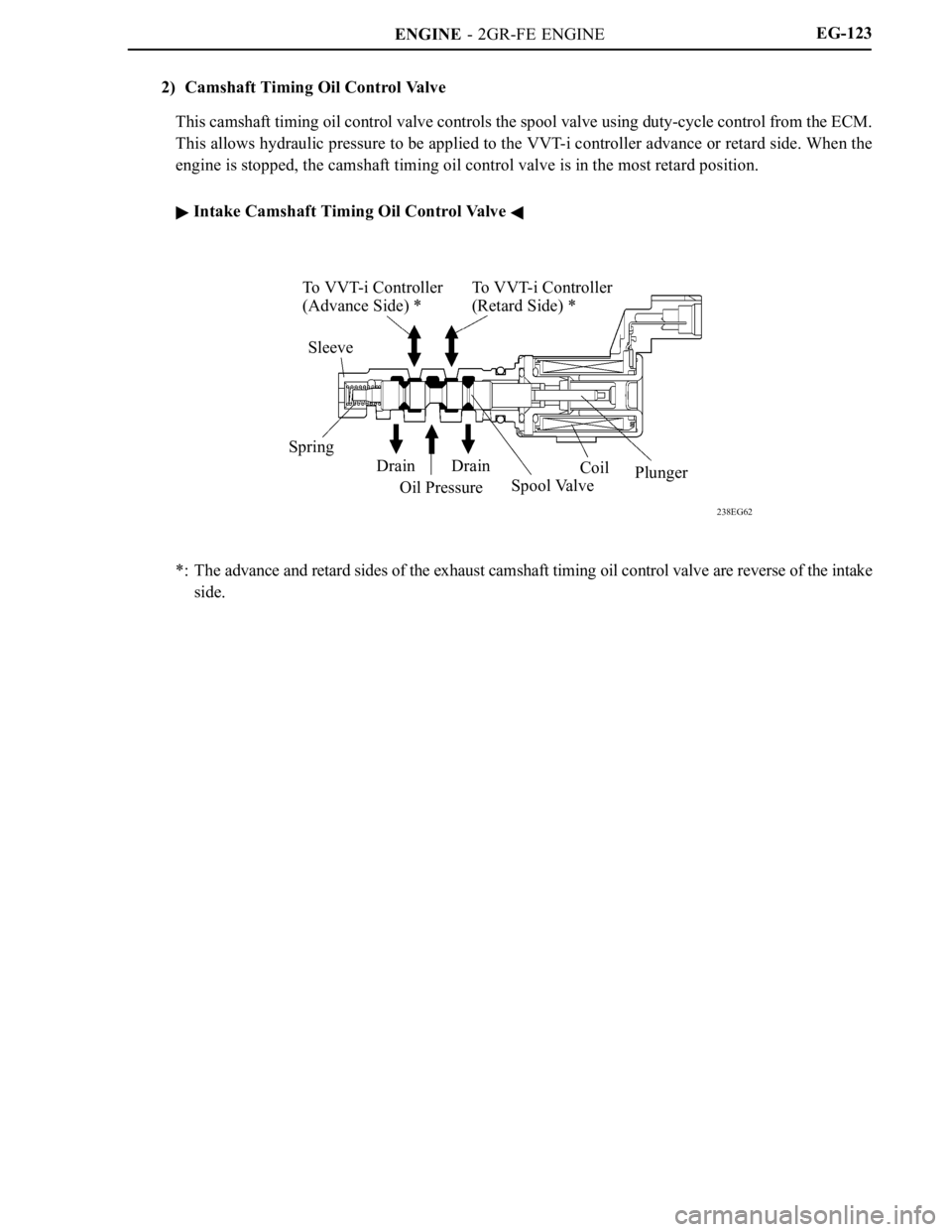

238EG62

To VVT-i Controller

(Advance Side) *To VVT-i Controller

(Retard Side) *

Sleeve

Spring

Drain

Oil PressureDrain

Spool ValveCoil

PlungerEG-123

2) Camshaft Timing Oil Control Valve

This camshaft timing oil control valve controls the spool valve using duty-cycle control from the ECM.

This allows hydraulic pressure to be applied to the VVT-i controller advance or retard side. When the

engine is stopped, the camshaft timing oil control valve is in the most retard position.

Intake Camshaft Timing Oil Control Valve

*: The advance and retard sides of the exhaust camshaft timing oil control valve are reverse of the intake

side.

Page 120 of 2000

ENGINE - 2GR-FE ENGINE

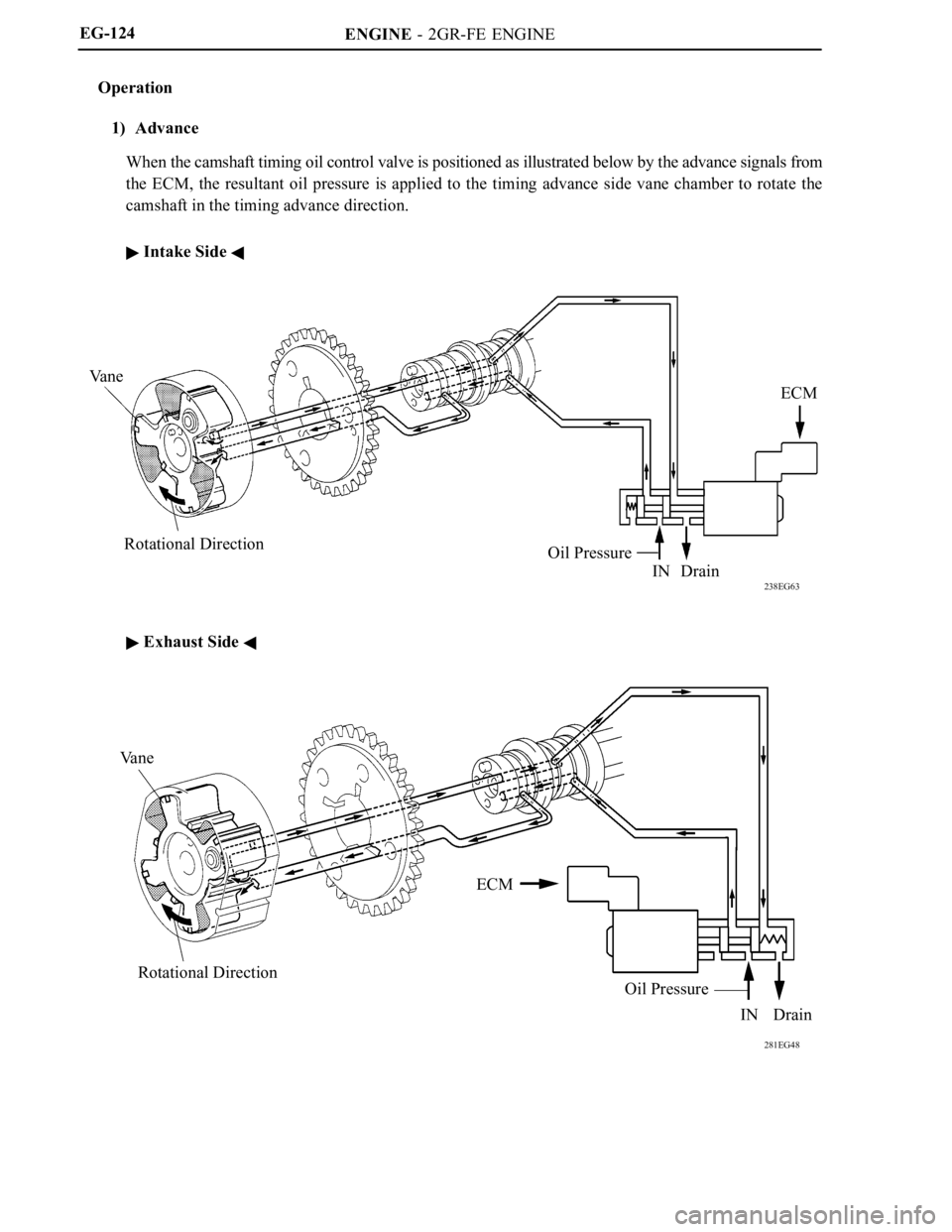

238EG63

Va n e

Rotational Direction

Oil Pressure

IN DrainECM

281EG48

Va n e

Rotational DirectionECM

Oil Pressure

IN Drain EG-124

Operation

1) Advance

When the camshaft timing oil control valve is positioned as illustrated below by the advance signals from

the ECM, the resultant oil pressure is applied to the timing advance side vane chamber to rotate the

camshaft in the timing advance direction.

Intake Side

Exhaust Side

Page 121 of 2000

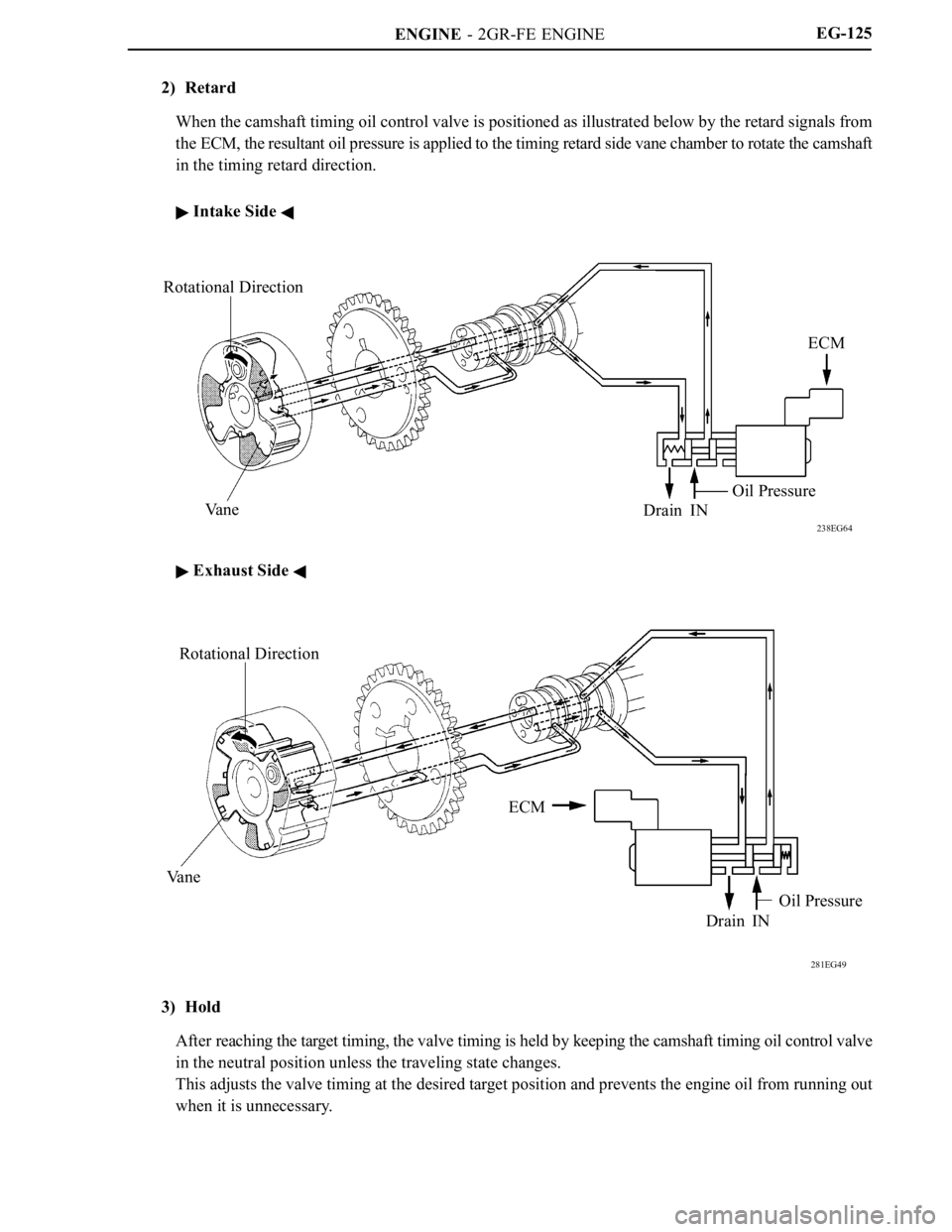

ENGINE - 2GR-FE ENGINE

238EG64

Rotational Direction

Va n e

Drain INOil PressureECM

281EG49

Rotational Direction

Va n eECM

Drain INOil Pressure

EG-125

2) Retard

When the camshaft timing oil control valve is positioned as illustrated below by the retard signals from

the ECM, the resultant oil pressure is applied to the timing retard side vane chamber to rotate the camshaft

in the timing retard direction.

Intake Side

Exhaust Side

3) Hold

After reaching the target timing, the valve timing is held by keeping the camshaft timing oil control valve

in the neutral position unless the traveling state changes.

This adjusts the valve timing at the desired target position and prevents the engine oil from running out

when it is unnecessary.

Page 179 of 2000

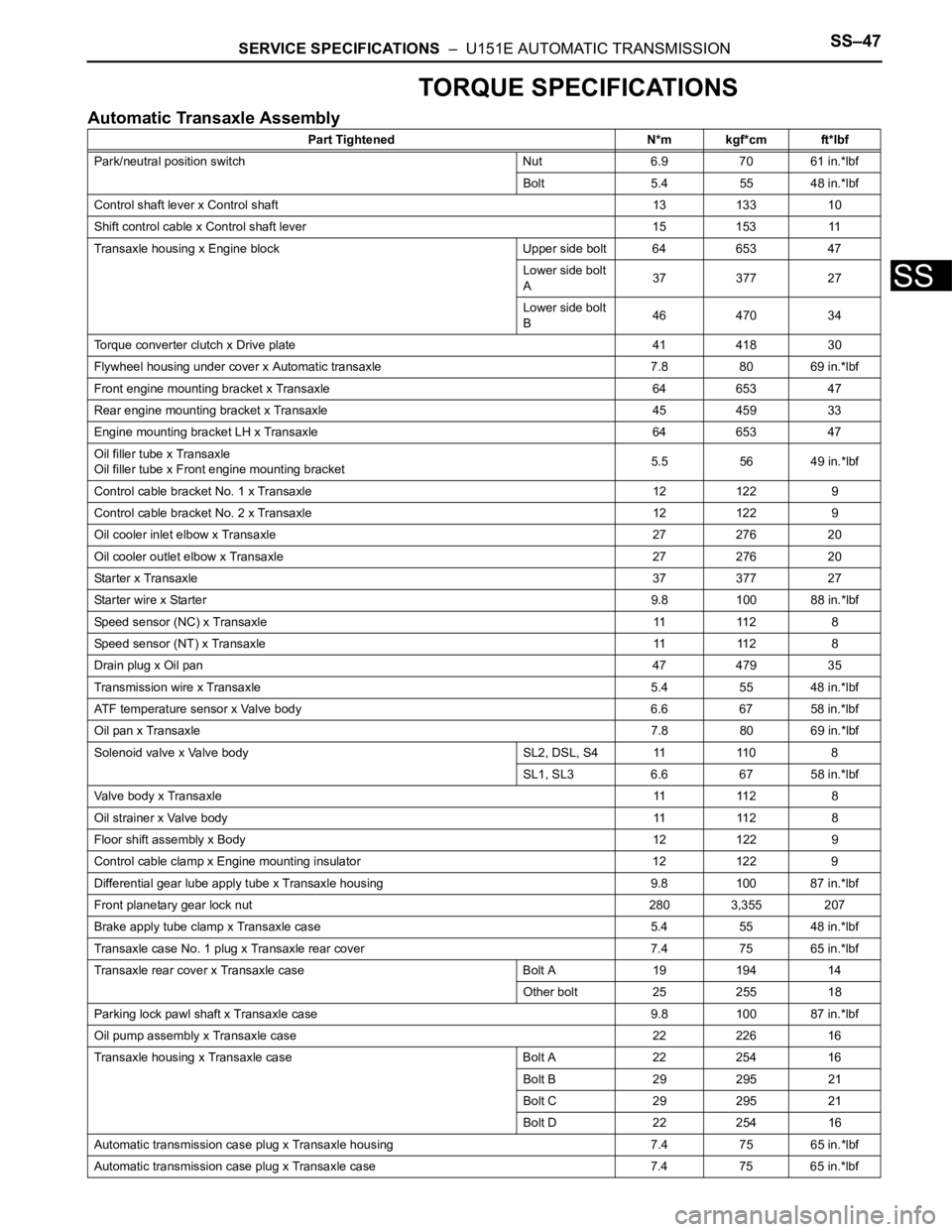

SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSMISSIONSS–47

SS

TORQUE SPECIFICATIONS

Automatic Transaxle Assembly

Part Tightened N*m kgf*cm ft*lbf

Park/neutral position switch Nut 6.9 70 61 in.*lbf

Bolt 5.4 55 48 in.*lbf

Control shaft lever x Control shaft 13 133 10

Shift control cable x Control shaft lever 15 153 11

Transaxle housing x Engine block Upper side bolt 64 653 47

Lower side bolt

A37 377 27

Lower side bolt

B46 470 34

Torque converter clutch x Drive plate 41 418 30

Flywheel housing under cover x Automatic transaxle 7.8 80 69 in.*lbf

Front engine mounting bracket x Transaxle 64 653 47

Rear engine mounting bracket x Transaxle 45 459 33

Engine mounting bracket LH x Transaxle 64 653 47

Oil filler tube x Transaxle

Oil filler tube x Front engine mounting bracket5.5 56 49 in.*lbf

Control cable bracket No. 1 x Transaxle 12 122 9

Control cable bracket No. 2 x Transaxle 12 122 9

Oil cooler inlet elbow x Transaxle 27 276 20

Oil cooler outlet elbow x Transaxle 27 276 20

Starter x Transaxle37 377 27

Starter wire x Starter9.8 100 88 in.*lbf

Speed sensor (NC) x Transaxle 11 112 8

Speed sensor (NT) x Transaxle 11 112 8

Drain plug x Oil pan47 479 35

Transmission wire x Transaxle 5.4 55 48 in.*lbf

ATF temperature sensor x Valve body 6.6 67 58 in.*lbf

Oil pan x Transaxle7.8 80 69 in.*lbf

Solenoid valve x Valve body SL2, DSL, S4 11 110 8

SL1, SL3 6.6 67 58 in.*lbf

Valve body x Transaxle11 11 2 8

Oil strainer x Valve body11 11 2 8

Floor shift assembly x Body12 122 9

Control cable clamp x Engine mounting insulator 12 122 9

Differential gear lube apply tube x Transaxle housing 9.8 100 87 in.*lbf

Front planetary gear lock nut 280 3,355 207

Brake apply tube clamp x Transaxle case 5.4 55 48 in.*lbf

Transaxle case No. 1 plug x Transaxle rear cover 7.4 75 65 in.*lbf

Transaxle rear cover x Transaxle case Bolt A 19 194 14

Other bolt 25 255 18

Parking lock pawl shaft x Transaxle case 9.8 100 87 in.*lbf

Oil pump assembly x Transaxle case 22 226 16

Transaxle housing x Transaxle case Bolt A 22 254 16

Bolt B 29 295 21

Bolt C 29 295 21

Bolt D 22 254 16

Automatic transmission case plug x Transaxle housing 7.4 75 65 in.*lbf

Automatic transmission case plug x Transaxle case 7.4 75 65 in.*lbf

Page 181 of 2000

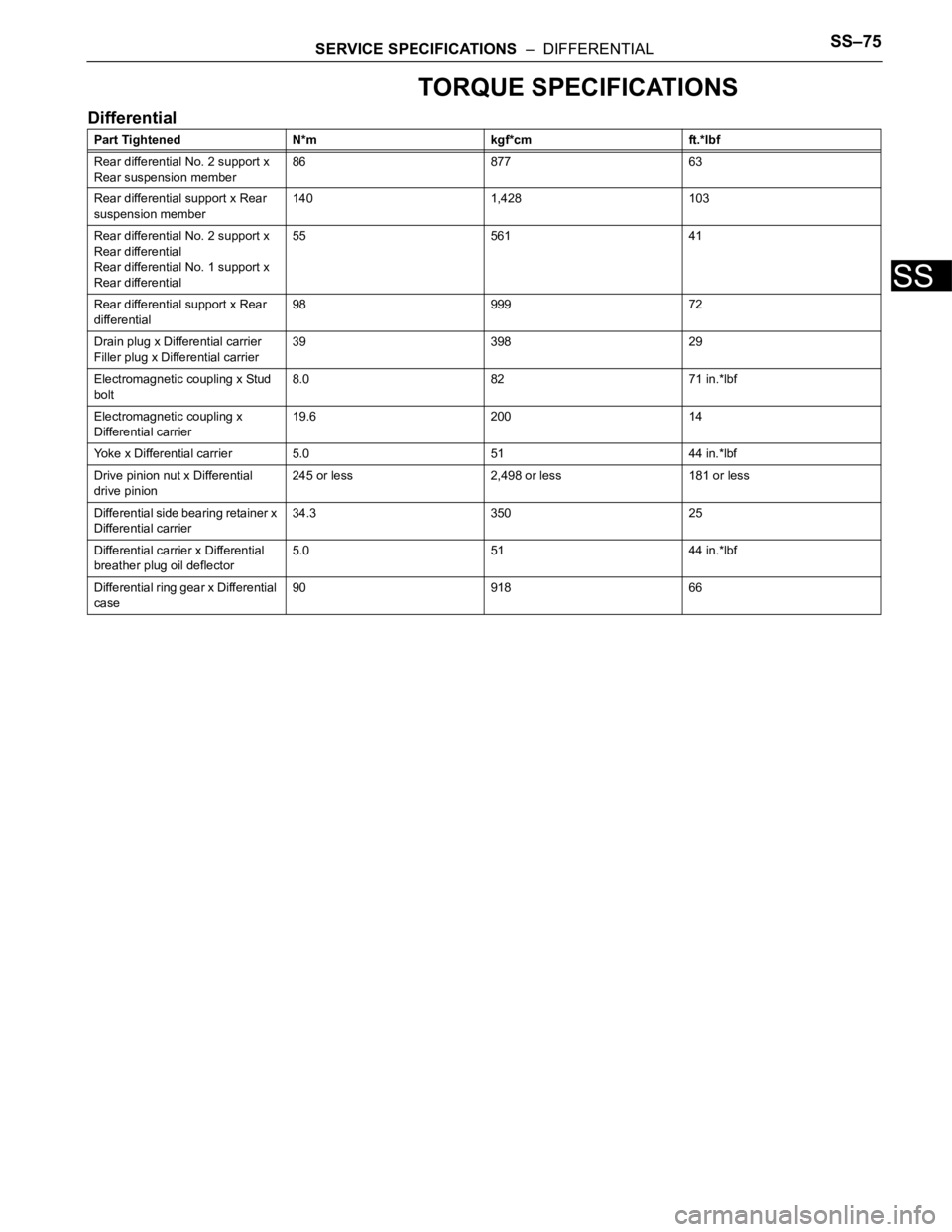

SERVICE SPECIFICATIONS – DIFFERENTIALSS–75

SS

TORQUE SPECIFICATIONS

Differential

Part Tightened N*m kgf*cm ft.*lbf

Rear differential No. 2 support x

Rear suspension member86 877 63

Rear differential support x Rear

suspension member140 1,428 103

Rear differential No. 2 support x

Rear differential

Rear differential No. 1 support x

Rear differential55 561 41

Rear differential support x Rear

differential98 999 72

Drain plug x Differential carrier

Filler plug x Differential carrier39 398 29

Electromagnetic coupling x Stud

bolt8.0 82 71 in.*lbf

Electromagnetic coupling x

Differential carrier19.6 200 14

Yoke x Differential carrier 5.0 51 44 in.*lbf

Drive pinion nut x Differential

drive pinion245 or less 2,498 or less 181 or less

Differential side bearing retainer x

Differential carrier34.3 350 25

Differential carrier x Differential

breather plug oil deflector5.0 51 44 in.*lbf

Differential ring gear x Differential

case90 918 66