traction control TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 40 of 2000

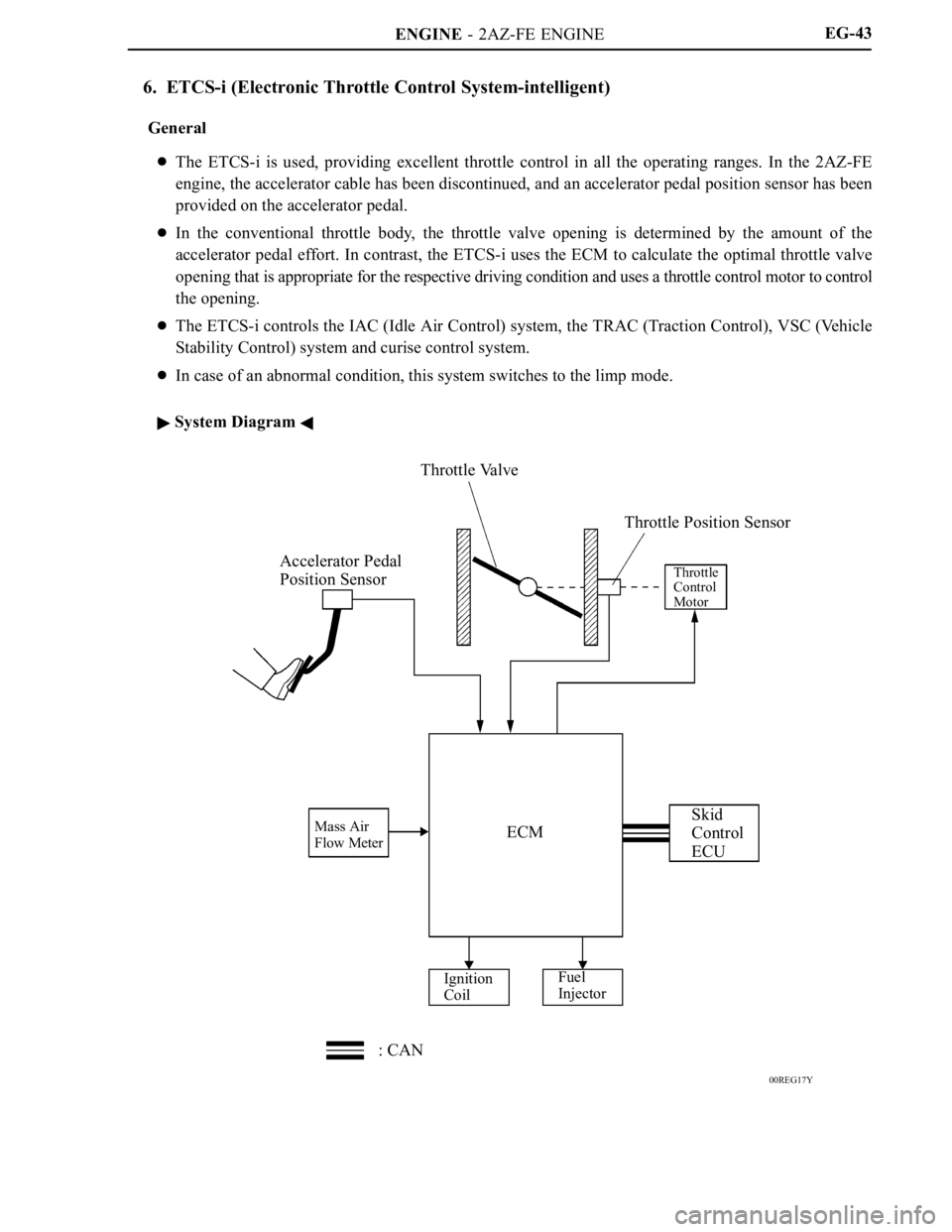

ENGINE - 2AZ-FE ENGINE

00REG17Y

Accelerator Pedal

Position SensorThrottle Valve

Throttle Position SensorThrottle

Control

Motor

Mass Air

Flow MeterECMSkid

Control

ECU

Ignition

CoilFuel

Injector

: CANEG-43

6. ETCS-i (Electronic Throttle Control System-intelligent)

General

The ETCS-i is used, providing excellent throttle control in all the operating ranges. In the 2AZ-FE

engine, the accelerator cable has been discontinued, and an accelerator pedal position sensor has been

provided on the accelerator pedal.

In the conventional throttle body, the throttle valve opening is determined by the amount of the

accelerator pedal effort. In contrast, the ETCS-i uses the ECM to calculate the optimal throttle valve

opening that is appropriate for the respective driving condition and uses a throttle control motor to control

the opening.

The ETCS-i controls the IAC (Idle Air Control) system, the TRAC (Traction Control), VSC (Vehicle

Stability Control) system and curise control system.

In case of an abnormal condition, this system switches to the limp mode.

System Diagram

Page 114 of 2000

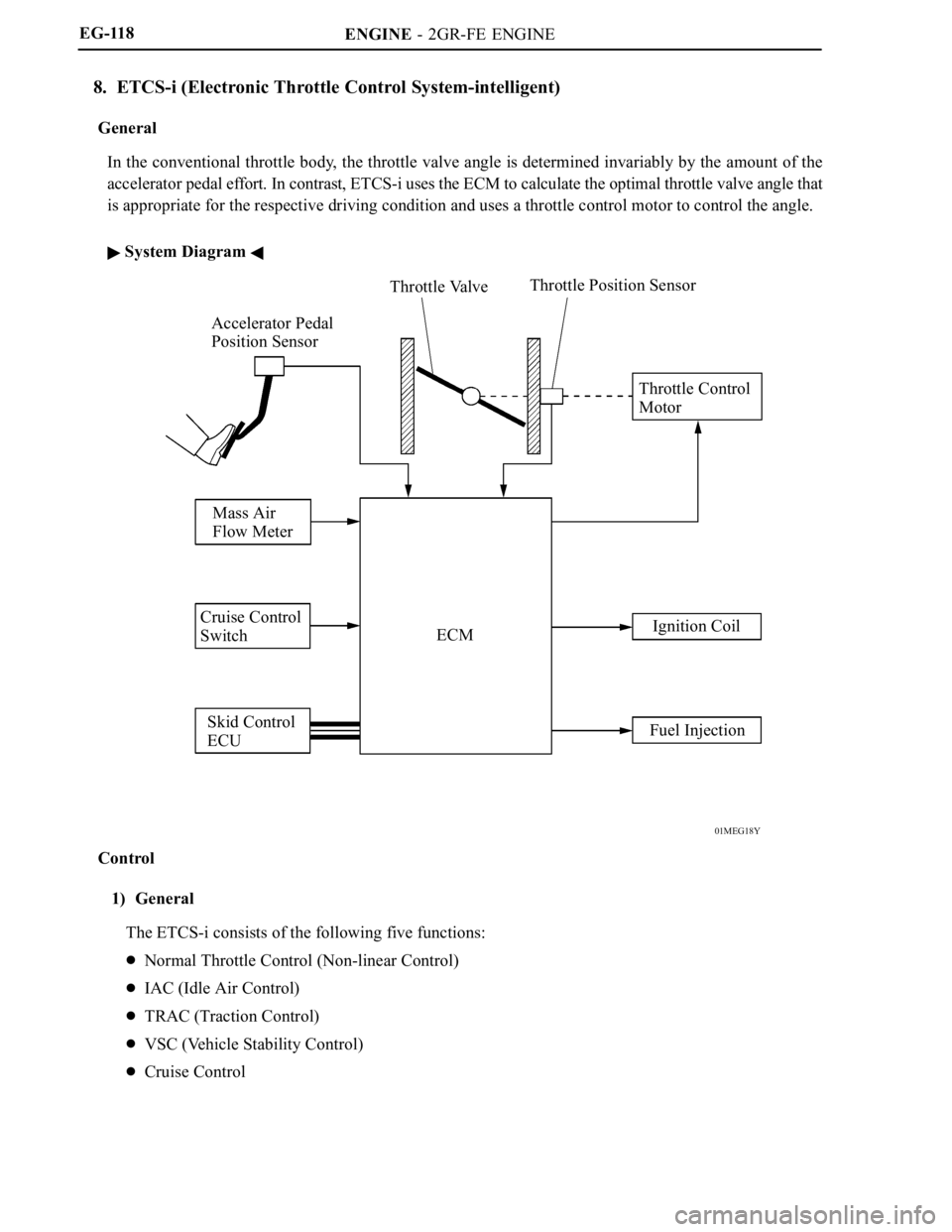

ENGINE - 2GR-FE ENGINE

01MEG18Y

Accelerator Pedal

Position SensorThrottle ValveThrottle Position Sensor

Throttle Control

Motor

Mass Air

Flow Meter

Cruise Control

Switch

Skid Control

ECUECMIgnition Coil

Fuel Injection EG-118

8. ETCS-i (Electronic Throttle Control System-intelligent)

General

In the conventional throttle body, the throttle valve angle is determined invariably by the amount of the

accelerator pedal effort. In contrast, ETCS-i uses the ECM to calculate the optimal throttle valve angle that

is appropriate for the respective driving condition and uses a throttle control motor to control the angle.

System Diagram

Control

1) General

The ETCS-i consists of the following five functions:

Normal Throttle Control (Non-linear Control)

IAC (Idle Air Control)

TRAC (Traction Control)

VSC (Vehicle Stability Control)

Cruise Control

Page 133 of 2000

CHASSIS - 4WD SYSTEM CH-66

4WD SYSTEM

DESCRIPTION

The 4WD system of the ’06 RAV4 uses an active torque control 4WD system.

It is a compact, lightweight, and high performance 4WD system that optimally controls the torque

distribution to the front and rear wheels through the electric control coupling in the rear differential.

ACTIVE TORQUE CONTROL 4WD SYSTEM

1. General

Based on information provided by various sensors, the 4WD ECU controls the amperage that is applied

to the electric control coupling, in order to transmit drive torque to the rear wheels when needed, and in

the amount needed. The following describes the features of the active torque control 4WD system.

Traction performance

Realizes stable start-off and acceleration performance

Driving stability performanceRealizes stable cornering performance

Fuel economyRealizes better fuel economy by transmitting drive torque to the rear

wheels when needed, in the amount needed.

A four-wheel drive lock switch has been provided. This enables the driver to select between the AUTO

and LOCK modes by operating the switch. The system optimally controls the torque distribution to the

front and rear wheels in the respective modes.

Mode

Four-wheel Drive

Lock Switch and

Indicator Light

Outline

AUTOOFF

Optimally distributes drive torque to the front and rear wheels.

Ensures optimal start-off performance during a start-off, based on

information provided by various sensors.

Suppresses the tight corner braking phenomenon* during low-speed

cornering.

Reduces the amount of torque distribution to the rear wheels and

improves fuel economy when the system judges that the vehicle is

traveling steadily.

Disengages the 4WD during braking deceleration.

LOCKON

Distributes the maximum torque limit to the rear wheels.

Distributes the maximum torque limit to the rear wheels during

start-off.

Distributes optimal torque during low-speed cornering.

Disengages the 4WD during braking deceleration.

Disengages the LOCK mode and transfers to the AUTO mode when

the vehicle speed exceeds 40 km / h (25 mph).

*: Tight corner braking phenomenon: a condition in which the brakes are applied due to a rotational difference

between the front and rear wheels, such as during low-speed cornering in the 4WD mode.

The 4WD ECU effects cooperative control with the skid control ECU, in order to control the drive torque

distribution to the front and rear wheels in accordance with information received from the skid control

ECU. These controls ensure a smooth acceleration and driving stability.

Page 1509 of 2000

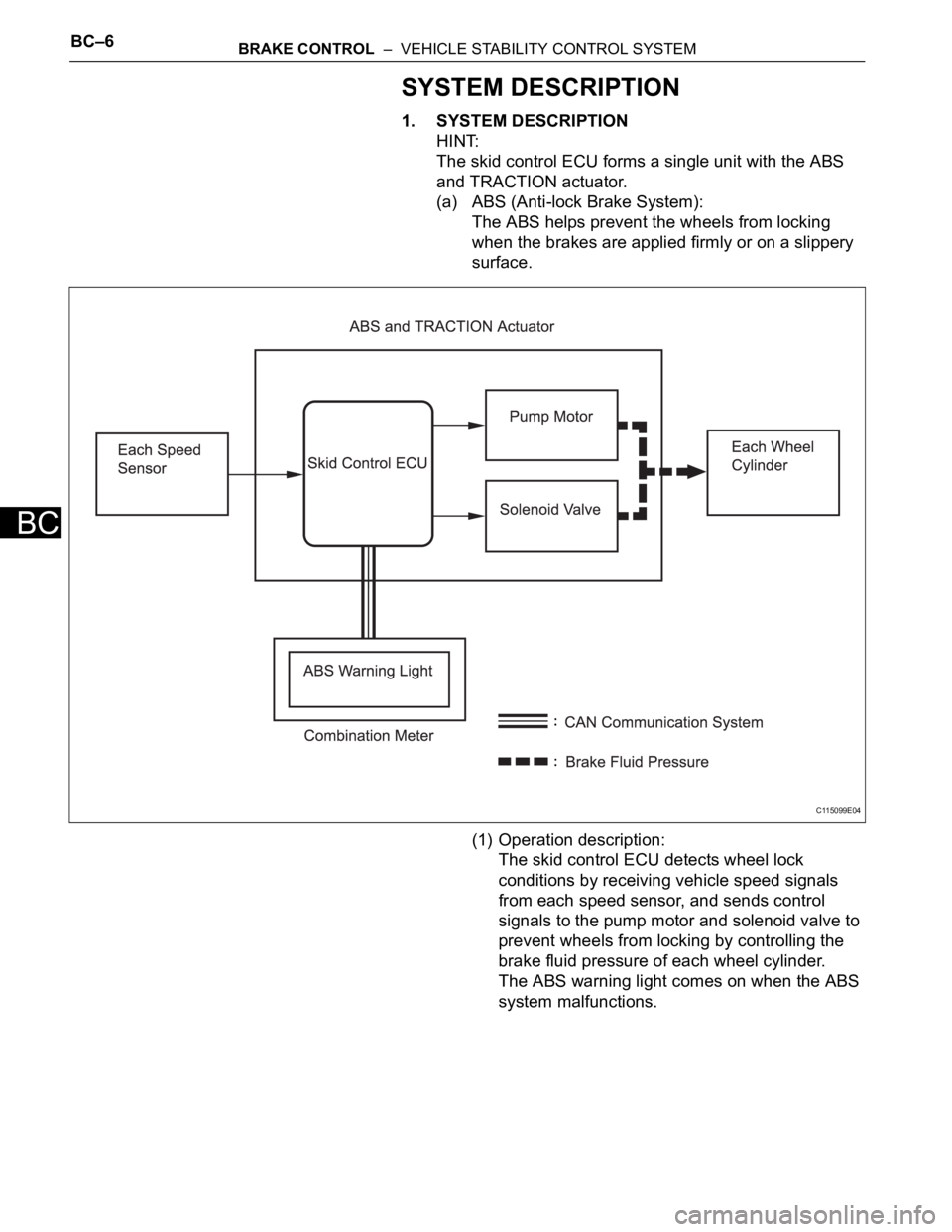

BC–6BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

SYSTEM DESCRIPTION

1. SYSTEM DESCRIPTION

HINT:

The skid control ECU forms a single unit with the ABS

and TRACTION actuator.

(a) ABS (Anti-lock Brake System):

The ABS helps prevent the wheels from locking

when the brakes are applied firmly or on a slippery

surface.

(1) Operation description:

The skid control ECU detects wheel lock

conditions by receiving vehicle speed signals

from each speed sensor, and sends control

signals to the pump motor and solenoid valve to

prevent wheels from locking by controlling the

brake fluid pressure of each wheel cylinder.

The ABS warning light comes on when the ABS

system malfunctions.

C115099E04

Page 1512 of 2000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–9

BC

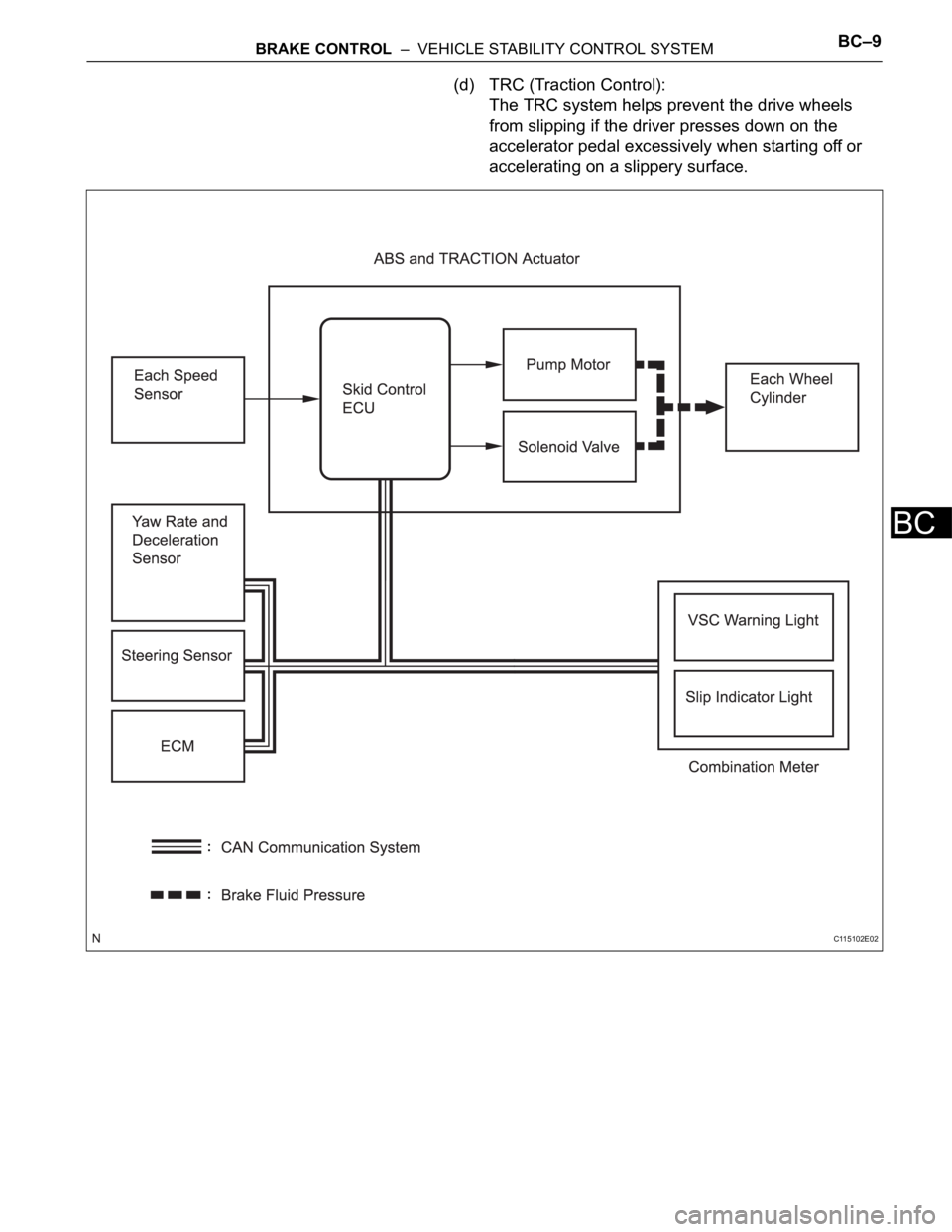

(d) TRC (Traction Control):

The TRC system helps prevent the drive wheels

from slipping if the driver presses down on the

accelerator pedal excessively when starting off or

accelerating on a slippery surface.

C115102E02

Page 1518 of 2000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–15

BC

(1) Operation description:

When the system is in operation, the following

occurs: 1) the slip indicator light blinks; 2) the

VSC light comes on; and 3) when hill-start assist

control operation starts, the skid control buzzer

sounds once; when hill-start assist control

operation ends, the skid control buzzer sounds

twice.

The VSC warning light comes on when the hill-

start assist control is malfunctioning.

(h) AUTO LSD (Auto Limited Slip Differential) for 2WD:

The AUTO LSD achieves the equivalent functions of

an LSD (Limited Slip Differential) through the use of

a traction control system. When the driver presses

the AUTO LSD switch, this system achieves the

LSD effect by regulating the hydraulic pressure that

acts on the drive wheels and controlling the engine

output in accordance with the amount of pedal effort

applied on the accelerator. The AUTO LSD

operates with the AUTO LSD switch on and the

accelerator pedal depressed.

Auto LSD restrains brake pressure and reduces

differential movement, thus transmitting the drive

torque to the other drive wheel to ensure stability

under the following conditions:

• Wheels run off the road.

• Drive wheels spin in place when starting on a

slope with one wheel on snow/ice.

HINT:

Releasing the accelerator pedal cancels control of

the AUTO LSD system.

Page 1521 of 2000

BC–18BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

(3) Front Wheel Skid Tendency

When the skid control ECU determines that

there is a front wheel skid tendency, it controls

the VSC to dampen the front wheel skid. At the

same time, it effects cooperative control with the

EPS to provide steering torque assist, which

facilitates the driver's steering maneuvers to

stabilize the vehicle posture. To prevent

excessive steering maneuvers, it provides a

steering torque assist. This assist increases the

resistance to counter the driver's steering effort,

if the driver turns the steering wheel excessively.

(4) Rear Wheel Skid Tendency

When the skid control ECU determines that

there is a rear wheel skid tendency, it controls

the VSC to dampen the rear wheel skid. At the

same time, it effects cooperative control with the

EPS to provide steering torque assist, which

facilitates the driver's steering maneuvers in the

direction to correct the rear wheel skid.

(5) Acceleration During Cornering

A sudden acceleration of the vehicle during

cornering may cause a drive wheel to freewheel,

which could cause the front wheels or rear

wheels to skid. If the skid control ECU

determines that there is freewheeling of a drive

wheel, a front wheel skid tendency, or a rear

wheel skid tendency, it effects cooperative

control with the 4WD system to optimally control

the drive torque distribution to the front and rear

wheels. Furthermore, it controls the TRC and

the VSC as needed to ensure driving stability

and acceleration performance.

(b) Operation

The operation of the solenoid valves under the

cooperative control is the same as the TRC or VSC

operation.

3. ABS WITH EBD, BA, TRC AND VSC OPERATION

(a) The skid control ECU calculates vehicle stability

tendency based on the signals from the 4 wheel

speed sensors, the yaw rate and deceleration

sensor and the steering sensor. In addition, it

evaluates the results of the calculations to

determine whether any control actions (control of

the engine output torque by electronic throttle

control and of the brake fluid pressure by the ABS

and TRACTION actuator) should be implemented.

(b) The slip indicator blinks and the skid control buzzer

sounds to inform the driver that the VSC system is

operating. The slip indicator also blinks when

traction control is operating, and the operation being

performed is displayed.

Page 1522 of 2000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–19

BC

4. FAIL SAFE FUNCTION

(a) When a failure occurs in the ABS with BA, TRC and

VSC systems, the ABS and VSC warning lights

illuminate, the slip indicator light comes on*1 or

remains off*2, and the operations of those systems

are prohibited. In addition to this, when a failure

which disables the EBD operation occurs, the brake

warning light comes on and its operation is

prohibited.

HINT:

*1: for 2WD

*2: for 4WD

(b) If control is prohibited due to a malfunction during

operation, control is disabled gradually to avoid

sudden vehicle instability.

5. INITIAL CHECK

(a) When the vehicle speed first reaches approximately

6 km/h (4 mph) or more after the ignition switch is

turned ON, each solenoid valve and the motor of the

ABS and TRACTION actuator are sequentially

activated to perform electrical checks. During the

initial check, the operating sound of the solenoid

valve and motor can be heard from the engine

compartment, but this does not indicate a

malfunction.

6. SERVICE MODE

(a) VSC operation can be disabled by operating the

intelligent tester.

HINT:

Refer to the intelligent tester operator's manual for

further details.

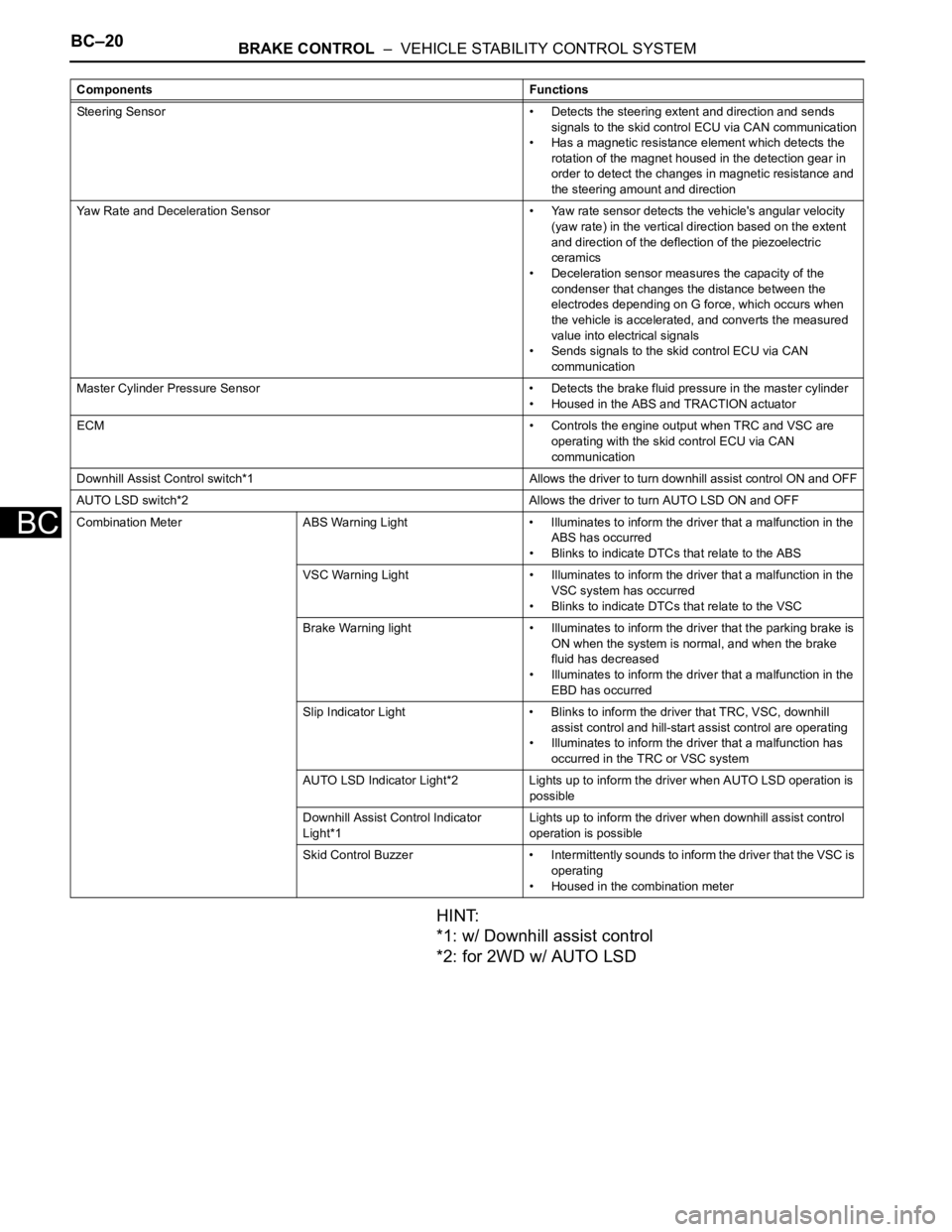

7. FUNCTION OF COMPONENTS

Components Functions

Speed Sensor

(Semiconductor Type)Detects the wheel speed and sends the signal to skid

control ECU

Skid Control ECU

(Housed in ABS and TRACTION Actuator)• Processes the signals from each sensor to control the

ABS, BA, TRC, and VSC

• Sends and receives control signals to and from the

ECM, yaw rate and deceleration sensor, steering

sensor, etc. via CAN communication.

ABS and TRACTION Actuator • Consists of the master cylinder cut solenoid valve,

holding solenoid valve, pressure reduction solenoid

valve, pump motor, and reservoir, and adjusts the brake

fluid pressure applied to each wheel cylinder

• Houses the skid control ECU

Solenoid Relay • Supplies power to each solenoid

• Housed in the skid control ECU

Motor Relay (VSC MTR Relay) • Supplies power to the pump motor

• Installed in engine room No. 1 relay block

Fail-safe Relay (VSC FAIL Relay) • Cuts off power to the motor when the pump motor circuit

malfunctions

• Installed in engine room No. 1 relay block

Page 1523 of 2000

BC–20BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

HINT:

*1: w/ Downhill assist control

*2: for 2WD w/ AUTO LSD

Steering Sensor • Detects the steering extent and direction and sends

signals to the skid control ECU via CAN communication

• Has a magnetic resistance element which detects the

rotation of the magnet housed in the detection gear in

order to detect the changes in magnetic resistance and

the steering amount and direction

Yaw Rate and Deceleration Sensor • Yaw rate sensor detects the vehicle's angular velocity

(yaw rate) in the vertical direction based on the extent

and direction of the deflection of the piezoelectric

ceramics

• Deceleration sensor measures the capacity of the

condenser that changes the distance between the

electrodes depending on G force, which occurs when

the vehicle is accelerated, and converts the measured

value into electrical signals

• Sends signals to the skid control ECU via CAN

communication

Master Cylinder Pressure Sensor • Detects the brake fluid pressure in the master cylinder

• Housed in the ABS and TRACTION actuator

ECM• Controls the engine output when TRC and VSC are

operating with the skid control ECU via CAN

communication

Downhill Assist Control switch*1 Allows the driver to turn downhill assist control ON and OFF

AUTO LSD switch*2 Allows the driver to turn AUTO LSD ON and OFF

Combination Meter ABS Warning Light • Illuminates to inform the driver that a malfunction in the

ABS has occurred

• Blinks to indicate DTCs that relate to the ABS

VSC Warning Light • Illuminates to inform the driver that a malfunction in the

VSC system has occurred

• Blinks to indicate DTCs that relate to the VSC

Brake Warning light • Illuminates to inform the driver that the parking brake is

ON when the system is normal, and when the brake

fluid has decreased

• Illuminates to inform the driver that a malfunction in the

EBD has occurred

Slip Indicator Light • Blinks to inform the driver that TRC, VSC, downhill

assist control and hill-start assist control are operating

• Illuminates to inform the driver that a malfunction has

occurred in the TRC or VSC system

AUTO LSD Indicator Light*2 Lights up to inform the driver when AUTO LSD operation is

possible

Downhill Assist Control Indicator

Light*1Lights up to inform the driver when downhill assist control

operation is possible

Skid Control Buzzer • Intermittently sounds to inform the driver that the VSC is

operating

• Housed in the combination meter Components Functions

Page 1545 of 2000

BC–42BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

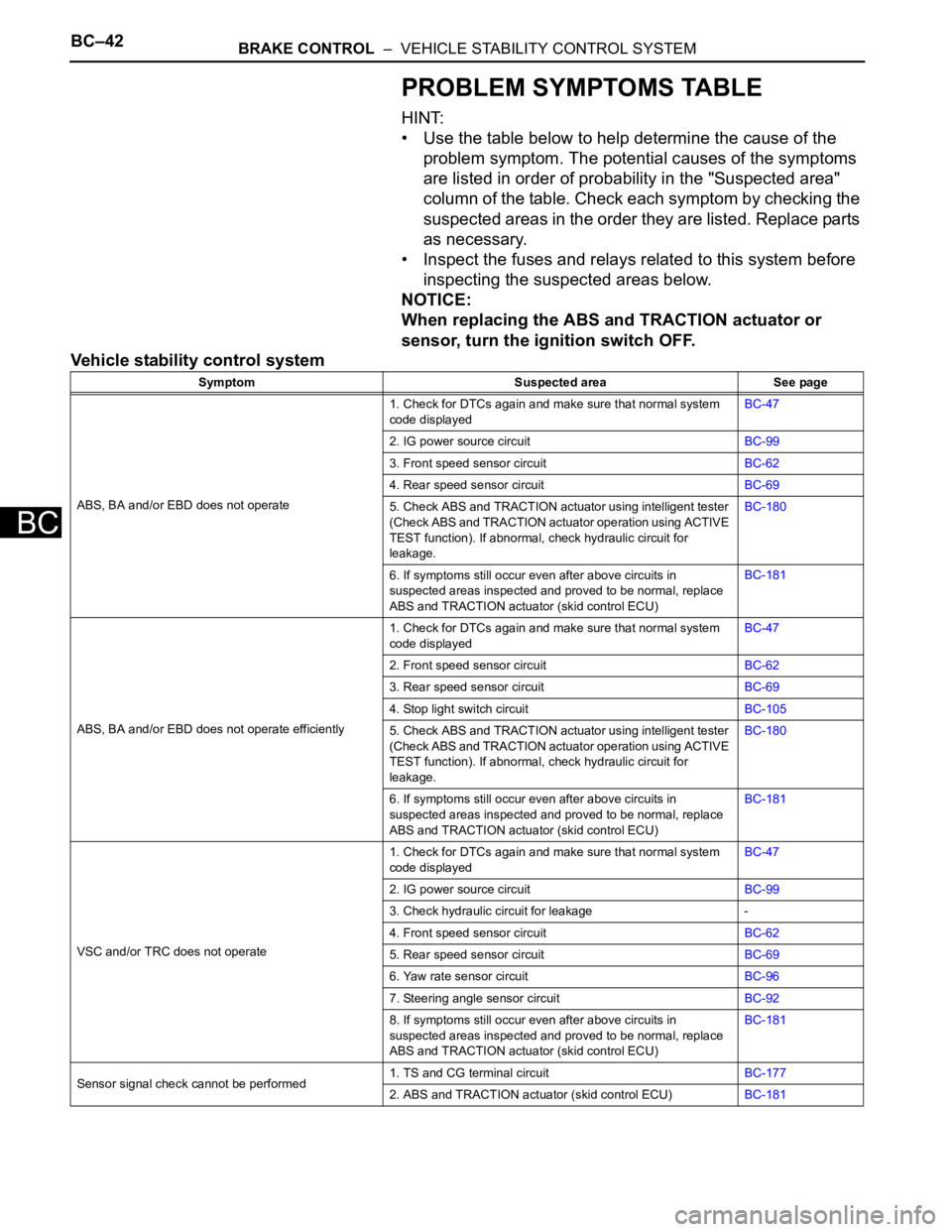

PROBLEM SYMPTOMS TABLE

HINT:

• Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "Suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Replace parts

as necessary.

• Inspect the fuses and relays related to this system before

inspecting the suspected areas below.

NOTICE:

When replacing the ABS and TRACTION actuator or

sensor, turn the ignition switch OFF.

Vehicle stability control system

Symptom Suspected area See page

ABS, BA and/or EBD does not operate1. Check for DTCs again and make sure that normal system

code displayedBC-47

2. IG power source circuitBC-99

3. Front speed sensor circuitBC-62

4. Rear speed sensor circuitBC-69

5. Check ABS and TRACTION actuator using intelligent tester

(Check ABS and TRACTION actuator operation using ACTIVE

TEST function). If abnormal, check hydraulic circuit for

leakage.BC-180

6. If symptoms still occur even after above circuits in

suspected areas inspected and proved to be normal, replace

ABS and TRACTION actuator (skid control ECU)BC-181

ABS, BA and/or EBD does not operate efficiently1. Check for DTCs again and make sure that normal system

code displayedBC-47

2. Front speed sensor circuitBC-62

3. Rear speed sensor circuitBC-69

4. Stop light switch circuitBC-105

5. Check ABS and TRACTION actuator using intelligent tester

(Check ABS and TRACTION actuator operation using ACTIVE

TEST function). If abnormal, check hydraulic circuit for

leakage.BC-180

6. If symptoms still occur even after above circuits in

suspected areas inspected and proved to be normal, replace

ABS and TRACTION actuator (skid control ECU)BC-181

VSC and/or TRC does not operate1. Check for DTCs again and make sure that normal system

code displayedBC-47

2. IG power source circuitBC-99

3. Check hydraulic circuit for leakage -

4. Front speed sensor circuitBC-62

5. Rear speed sensor circuitBC-69

6. Yaw rate sensor circuitBC-96

7. Steering angle sensor circuitBC-92

8. If symptoms still occur even after above circuits in

suspected areas inspected and proved to be normal, replace

ABS and TRACTION actuator (skid control ECU)BC-181

Sensor signal check cannot be performed1. TS and CG terminal circuitBC-177

2. ABS and TRACTION actuator (skid control ECU)BC-181