check oil TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1130 of 3000

FU–182GR-FE FUEL – FUEL INJECTOR

FU

INSTALLATION

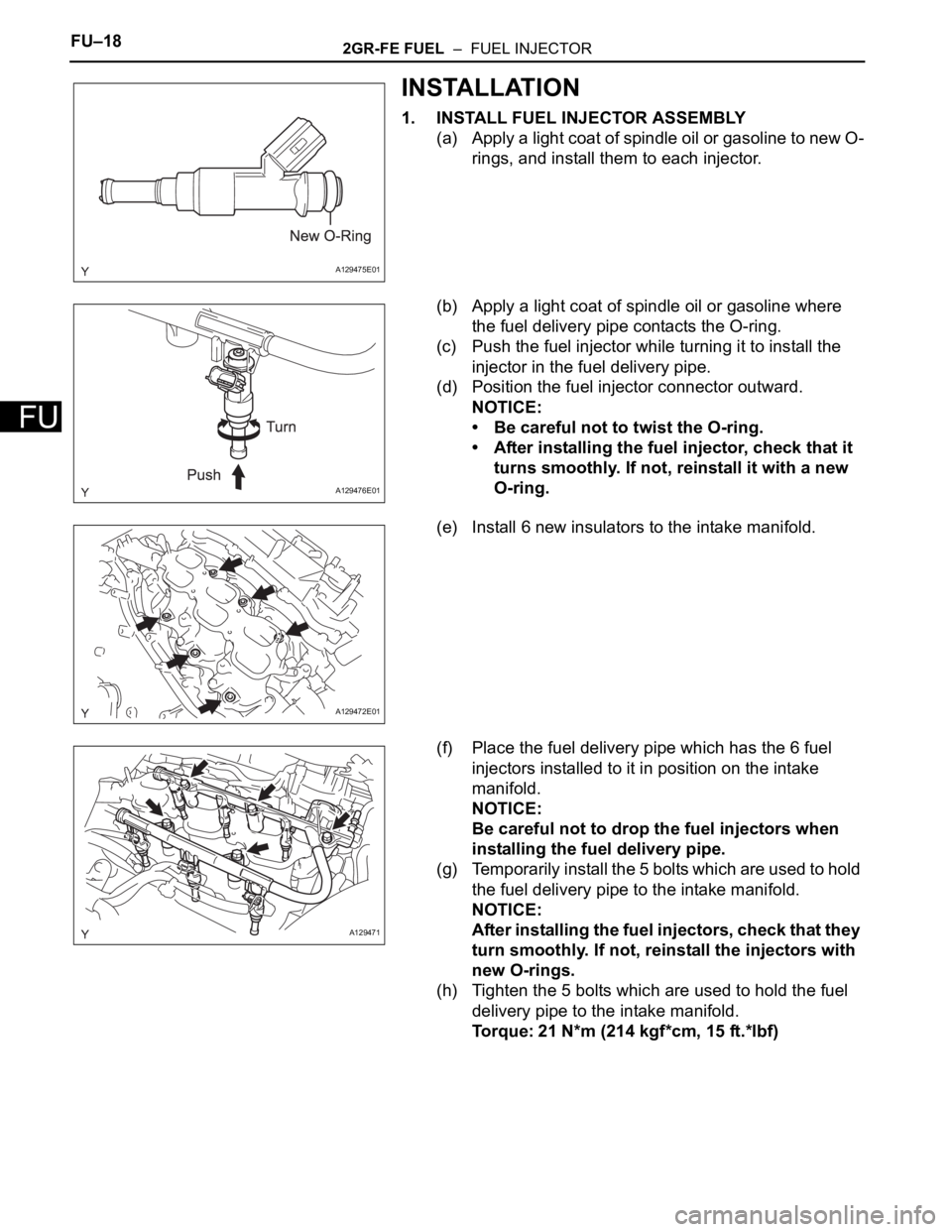

1. INSTALL FUEL INJECTOR ASSEMBLY

(a) Apply a light coat of spindle oil or gasoline to new O-

rings, and install them to each injector.

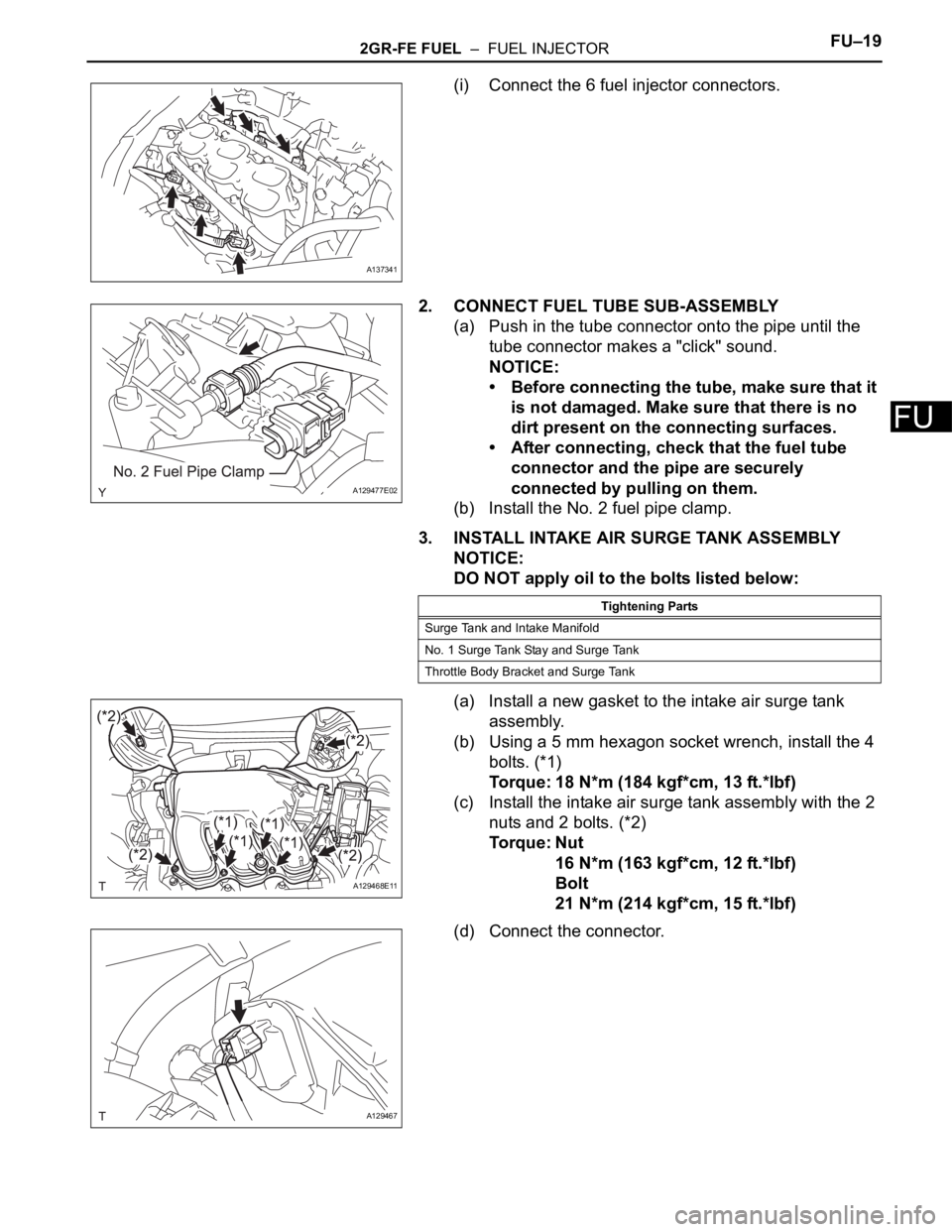

(b) Apply a light coat of spindle oil or gasoline where

the fuel delivery pipe contacts the O-ring.

(c) Push the fuel injector while turning it to install the

injector in the fuel delivery pipe.

(d) Position the fuel injector connector outward.

NOTICE:

• Be careful not to twist the O-ring.

• After installing the fuel injector, check that it

turns smoothly. If not, reinstall it with a new

O-ring.

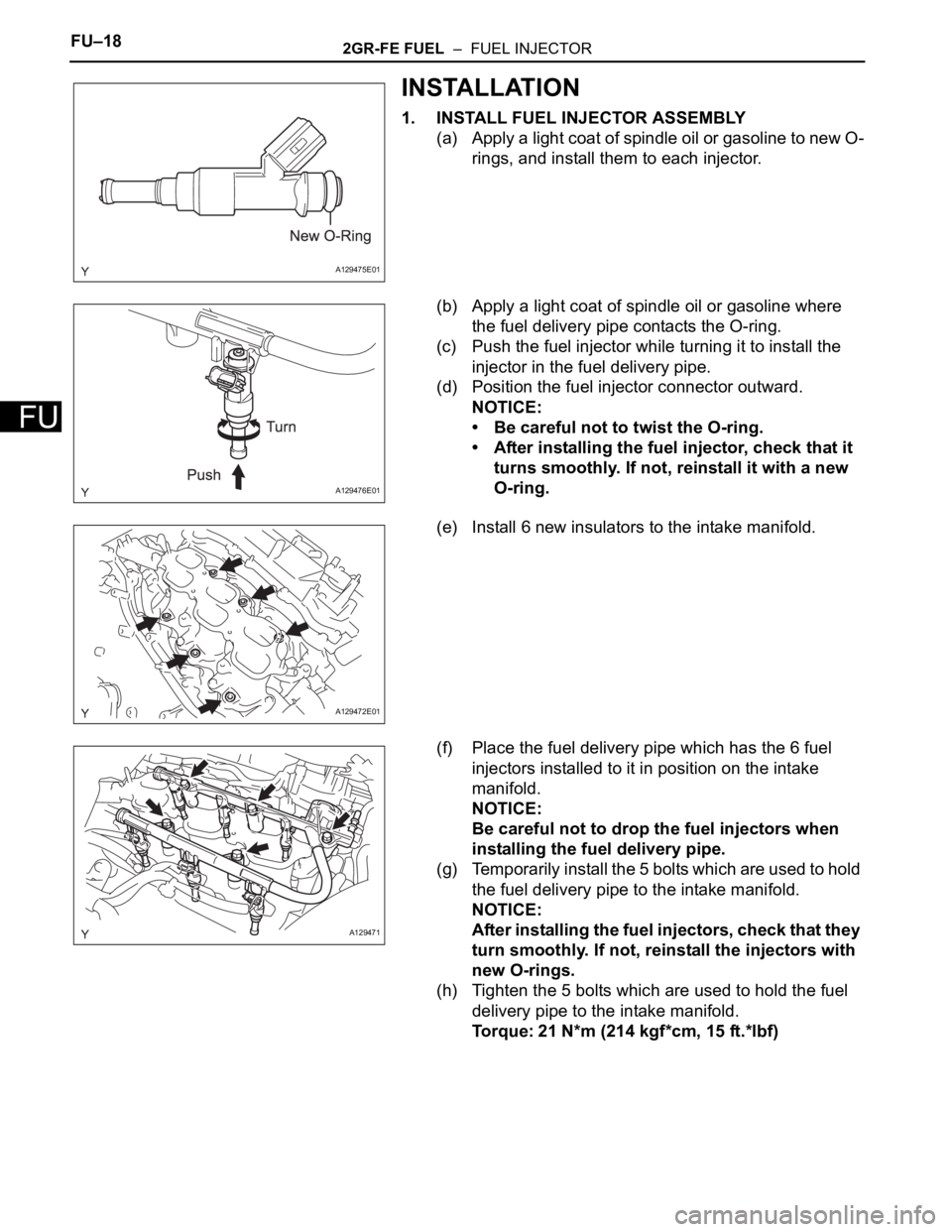

(e) Install 6 new insulators to the intake manifold.

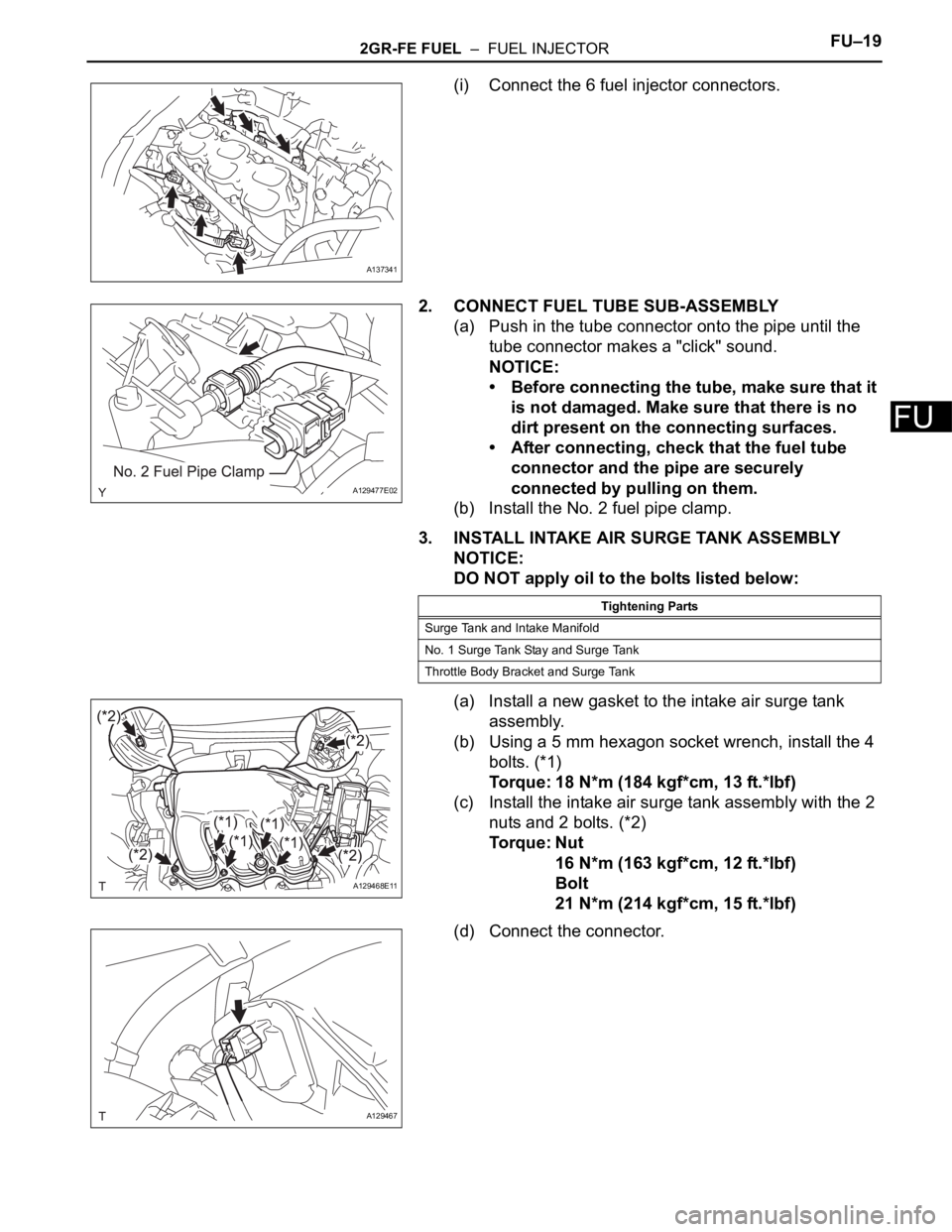

(f) Place the fuel delivery pipe which has the 6 fuel

injectors installed to it in position on the intake

manifold.

NOTICE:

Be careful not to drop the fuel injectors when

installing the fuel delivery pipe.

(g) Temporarily install the 5 bolts which are used to hold

the fuel delivery pipe to the intake manifold.

NOTICE:

After installing the fuel injectors, check that they

turn smoothly. If not, reinstall the injectors with

new O-rings.

(h) Tighten the 5 bolts which are used to hold the fuel

delivery pipe to the intake manifold.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

A129475E01

A129476E01

A129472E01

A129471

Page 1131 of 3000

2GR-FE FUEL – FUEL INJECTORFU–19

FU

(i) Connect the 6 fuel injector connectors.

2. CONNECT FUEL TUBE SUB-ASSEMBLY

(a) Push in the tube connector onto the pipe until the

tube connector makes a "click" sound.

NOTICE:

• Before connecting the tube, make sure that it

is not damaged. Make sure that there is no

dirt present on the connecting surfaces.

• After connecting, check that the fuel tube

connector and the pipe are securely

connected by pulling on them.

(b) Install the No. 2 fuel pipe clamp.

3. INSTALL INTAKE AIR SURGE TANK ASSEMBLY

NOTICE:

DO NOT apply oil to the bolts listed below:

(a) Install a new gasket to the intake air surge tank

assembly.

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts. (*1)

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

(c) Install the intake air surge tank assembly with the 2

nuts and 2 bolts. (*2)

Torque: Nut

16 N*m (163 kgf*cm, 12 ft.*lbf)

Bolt

21 N*m (214 kgf*cm, 15 ft.*lbf)

(d) Connect the connector.

A137341

A129477E02

Tightening Parts

Surge Tank and Intake Manifold

No. 1 Surge Tank Stay and Surge Tank

Throttle Body Bracket and Surge Tank

A129468E11

A129467

Page 1139 of 3000

FU–182GR-FE FUEL – FUEL INJECTOR

FU

INSTALLATION

1. INSTALL FUEL INJECTOR ASSEMBLY

(a) Apply a light coat of spindle oil or gasoline to new O-

rings, and install them to each injector.

(b) Apply a light coat of spindle oil or gasoline where

the fuel delivery pipe contacts the O-ring.

(c) Push the fuel injector while turning it to install the

injector in the fuel delivery pipe.

(d) Position the fuel injector connector outward.

NOTICE:

• Be careful not to twist the O-ring.

• After installing the fuel injector, check that it

turns smoothly. If not, reinstall it with a new

O-ring.

(e) Install 6 new insulators to the intake manifold.

(f) Place the fuel delivery pipe which has the 6 fuel

injectors installed to it in position on the intake

manifold.

NOTICE:

Be careful not to drop the fuel injectors when

installing the fuel delivery pipe.

(g) Temporarily install the 5 bolts which are used to hold

the fuel delivery pipe to the intake manifold.

NOTICE:

After installing the fuel injectors, check that they

turn smoothly. If not, reinstall the injectors with

new O-rings.

(h) Tighten the 5 bolts which are used to hold the fuel

delivery pipe to the intake manifold.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

A129475E01

A129476E01

A129472E01

A129471

Page 1140 of 3000

2GR-FE FUEL – FUEL INJECTORFU–19

FU

(i) Connect the 6 fuel injector connectors.

2. CONNECT FUEL TUBE SUB-ASSEMBLY

(a) Push in the tube connector onto the pipe until the

tube connector makes a "click" sound.

NOTICE:

• Before connecting the tube, make sure that it

is not damaged. Make sure that there is no

dirt present on the connecting surfaces.

• After connecting, check that the fuel tube

connector and the pipe are securely

connected by pulling on them.

(b) Install the No. 2 fuel pipe clamp.

3. INSTALL INTAKE AIR SURGE TANK ASSEMBLY

NOTICE:

DO NOT apply oil to the bolts listed below:

(a) Install a new gasket to the intake air surge tank

assembly.

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts. (*1)

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

(c) Install the intake air surge tank assembly with the 2

nuts and 2 bolts. (*2)

Torque: Nut

16 N*m (163 kgf*cm, 12 ft.*lbf)

Bolt

21 N*m (214 kgf*cm, 15 ft.*lbf)

(d) Connect the connector.

A137341

A129477E02

Tightening Parts

Surge Tank and Intake Manifold

No. 1 Surge Tank Stay and Surge Tank

Throttle Body Bracket and Surge Tank

A129468E11

A129467

Page 1151 of 3000

2GR-FE FUEL – FUEL PUMPFU–33

FU

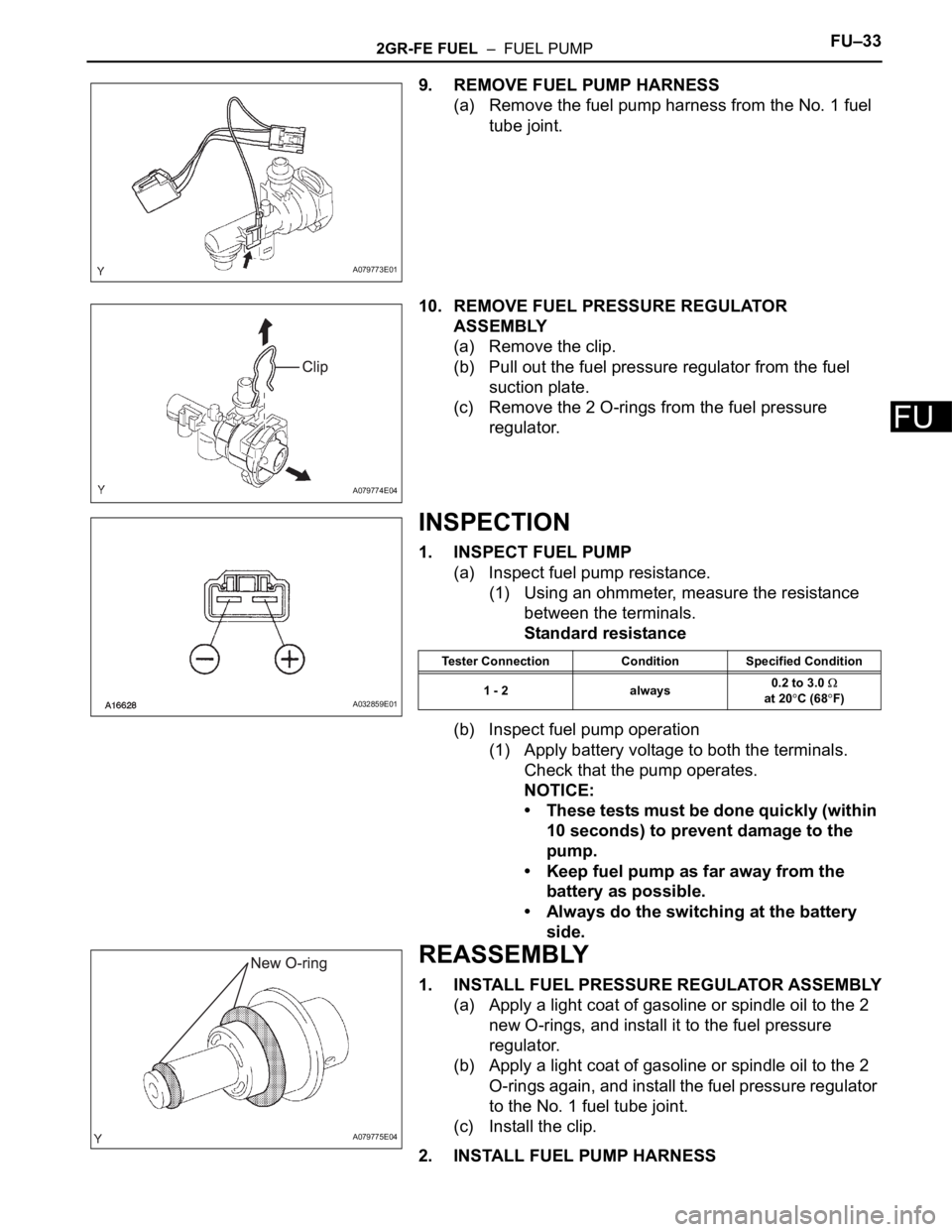

9. REMOVE FUEL PUMP HARNESS

(a) Remove the fuel pump harness from the No. 1 fuel

tube joint.

10. REMOVE FUEL PRESSURE REGULATOR

ASSEMBLY

(a) Remove the clip.

(b) Pull out the fuel pressure regulator from the fuel

suction plate.

(c) Remove the 2 O-rings from the fuel pressure

regulator.

INSPECTION

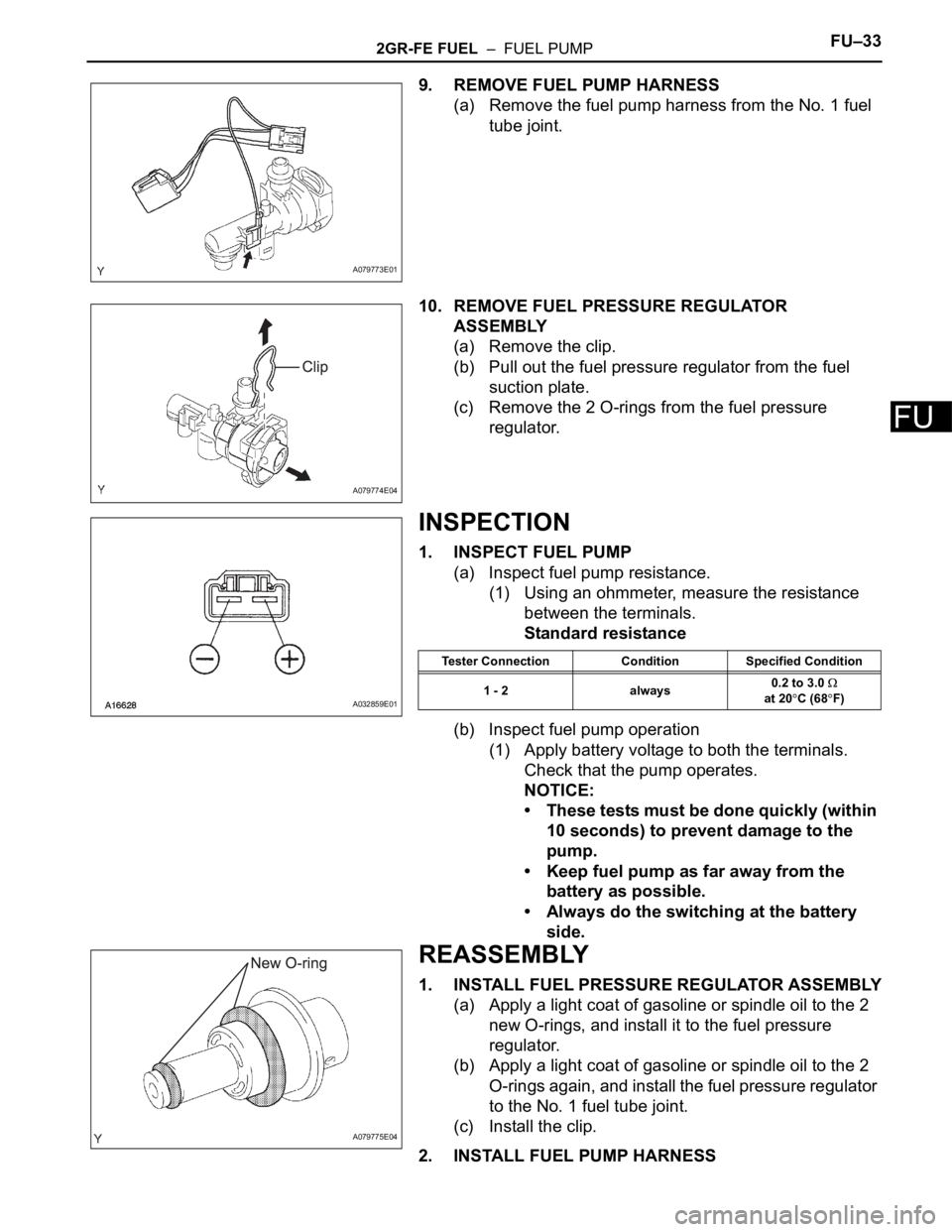

1. INSPECT FUEL PUMP

(a) Inspect fuel pump resistance.

(1) Using an ohmmeter, measure the resistance

between the terminals.

Standard resistance

(b) Inspect fuel pump operation

(1) Apply battery voltage to both the terminals.

Check that the pump operates.

NOTICE:

• These tests must be done quickly (within

10 seconds) to prevent damage to the

pump.

• Keep fuel pump as far away from the

battery as possible.

• Always do the switching at the battery

side.

REASSEMBLY

1. INSTALL FUEL PRESSURE REGULATOR ASSEMBLY

(a) Apply a light coat of gasoline or spindle oil to the 2

new O-rings, and install it to the fuel pressure

regulator.

(b) Apply a light coat of gasoline or spindle oil to the 2

O-rings again, and install the fuel pressure regulator

to the No. 1 fuel tube joint.

(c) Install the clip.

2. INSTALL FUEL PUMP HARNESS

A079773E01

A079774E04

A032859E01

Tester Connection Condition Specified Condition

1 - 2 always0.2 to 3.0

at 20

C (68F)

A079775E04

Page 1156 of 3000

2GR-FE FUEL – FUEL PUMPFU–33

FU

9. REMOVE FUEL PUMP HARNESS

(a) Remove the fuel pump harness from the No. 1 fuel

tube joint.

10. REMOVE FUEL PRESSURE REGULATOR

ASSEMBLY

(a) Remove the clip.

(b) Pull out the fuel pressure regulator from the fuel

suction plate.

(c) Remove the 2 O-rings from the fuel pressure

regulator.

INSPECTION

1. INSPECT FUEL PUMP

(a) Inspect fuel pump resistance.

(1) Using an ohmmeter, measure the resistance

between the terminals.

Standard resistance

(b) Inspect fuel pump operation

(1) Apply battery voltage to both the terminals.

Check that the pump operates.

NOTICE:

• These tests must be done quickly (within

10 seconds) to prevent damage to the

pump.

• Keep fuel pump as far away from the

battery as possible.

• Always do the switching at the battery

side.

REASSEMBLY

1. INSTALL FUEL PRESSURE REGULATOR ASSEMBLY

(a) Apply a light coat of gasoline or spindle oil to the 2

new O-rings, and install it to the fuel pressure

regulator.

(b) Apply a light coat of gasoline or spindle oil to the 2

O-rings again, and install the fuel pressure regulator

to the No. 1 fuel tube joint.

(c) Install the clip.

2. INSTALL FUEL PUMP HARNESS

A079773E01

A079774E04

A032859E01

Tester Connection Condition Specified Condition

1 - 2 always0.2 to 3.0

at 20

C (68F)

A079775E04

Page 1176 of 3000

EC–62GR-FE EMISSION CONTROL – EMISSION CONTROL SYSTEM

EC

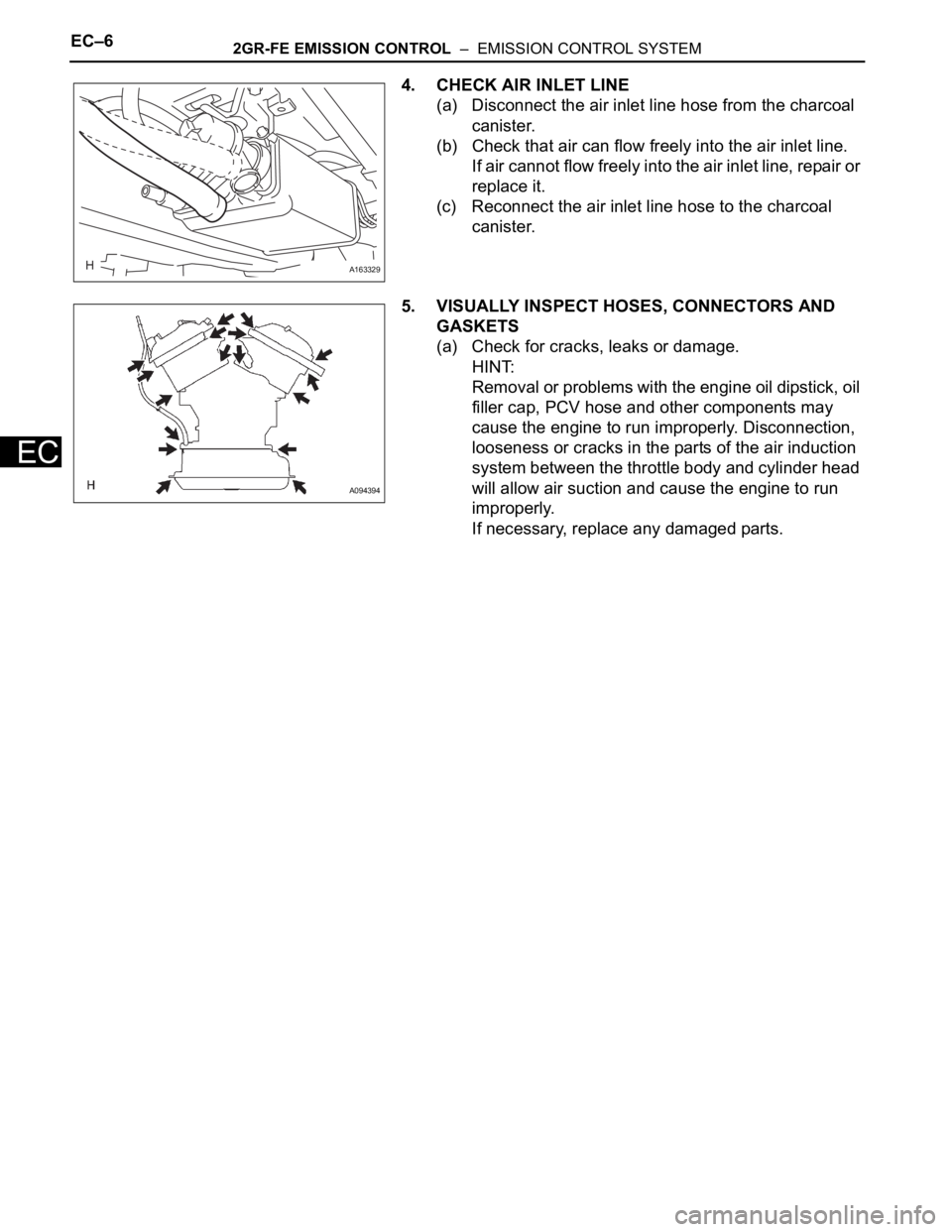

4. CHECK AIR INLET LINE

(a) Disconnect the air inlet line hose from the charcoal

canister.

(b) Check that air can flow freely into the air inlet line.

If air cannot flow freely into the air inlet line, repair or

replace it.

(c) Reconnect the air inlet line hose to the charcoal

canister.

5. VISUALLY INSPECT HOSES, CONNECTORS AND

GASKETS

(a) Check for cracks, leaks or damage.

HINT:

Removal or problems with the engine oil dipstick, oil

filler cap, PCV hose and other components may

cause the engine to run improperly. Disconnection,

looseness or cracks in the parts of the air induction

system between the throttle body and cylinder head

will allow air suction and cause the engine to run

improperly.

If necessary, replace any damaged parts.

A163329

A094394

Page 1238 of 3000

2GR-FE COOLING – COOLING SYSTEMCO–1

CO

COOLING SYSTEM

ON-VEHICLE INSPECTION

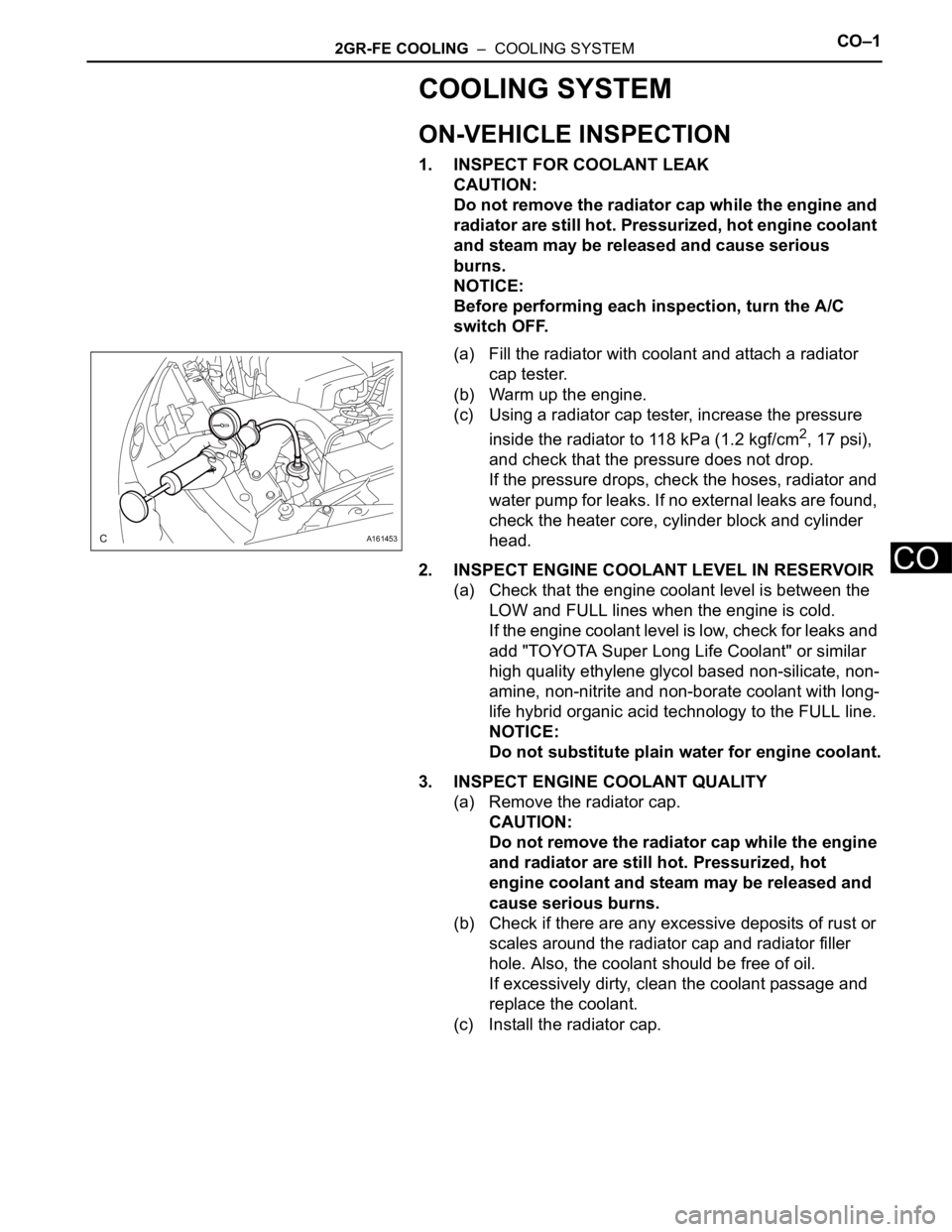

1. INSPECT FOR COOLANT LEAK

CAUTION:

Do not remove the radiator cap while the engine and

radiator are still hot. Pressurized, hot engine coolant

and steam may be released and cause serious

burns.

NOTICE:

Before performing each inspection, turn the A/C

switch OFF.

(a) Fill the radiator with coolant and attach a radiator

cap tester.

(b) Warm up the engine.

(c) Using a radiator cap tester, increase the pressure

inside the radiator to 118 kPa (1.2 kgf/cm

2, 17 psi),

and check that the pressure does not drop.

If the pressure drops, check the hoses, radiator and

water pump for leaks. If no external leaks are found,

check the heater core, cylinder block and cylinder

head.

2. INSPECT ENGINE COOLANT LEVEL IN RESERVOIR

(a) Check that the engine coolant level is between the

LOW and FULL lines when the engine is cold.

If the engine coolant level is low, check for leaks and

add "TOYOTA Super Long Life Coolant" or similar

high quality ethylene glycol based non-silicate, non-

amine, non-nitrite and non-borate coolant with long-

life hybrid organic acid technology to the FULL line.

NOTICE:

Do not substitute plain water for engine coolant.

3. INSPECT ENGINE COOLANT QUALITY

(a) Remove the radiator cap.

CAUTION:

Do not remove the radiator cap while the engine

and radiator are still hot. Pressurized, hot

engine coolant and steam may be released and

cause serious burns.

(b) Check if there are any excessive deposits of rust or

scales around the radiator cap and radiator filler

hole. Also, the coolant should be free of oil.

If excessively dirty, clean the coolant passage and

replace the coolant.

(c) Install the radiator cap.

A161453

Page 1292 of 3000

2GR-FE LUBRICATION – OIL PUMPLU–13

LU

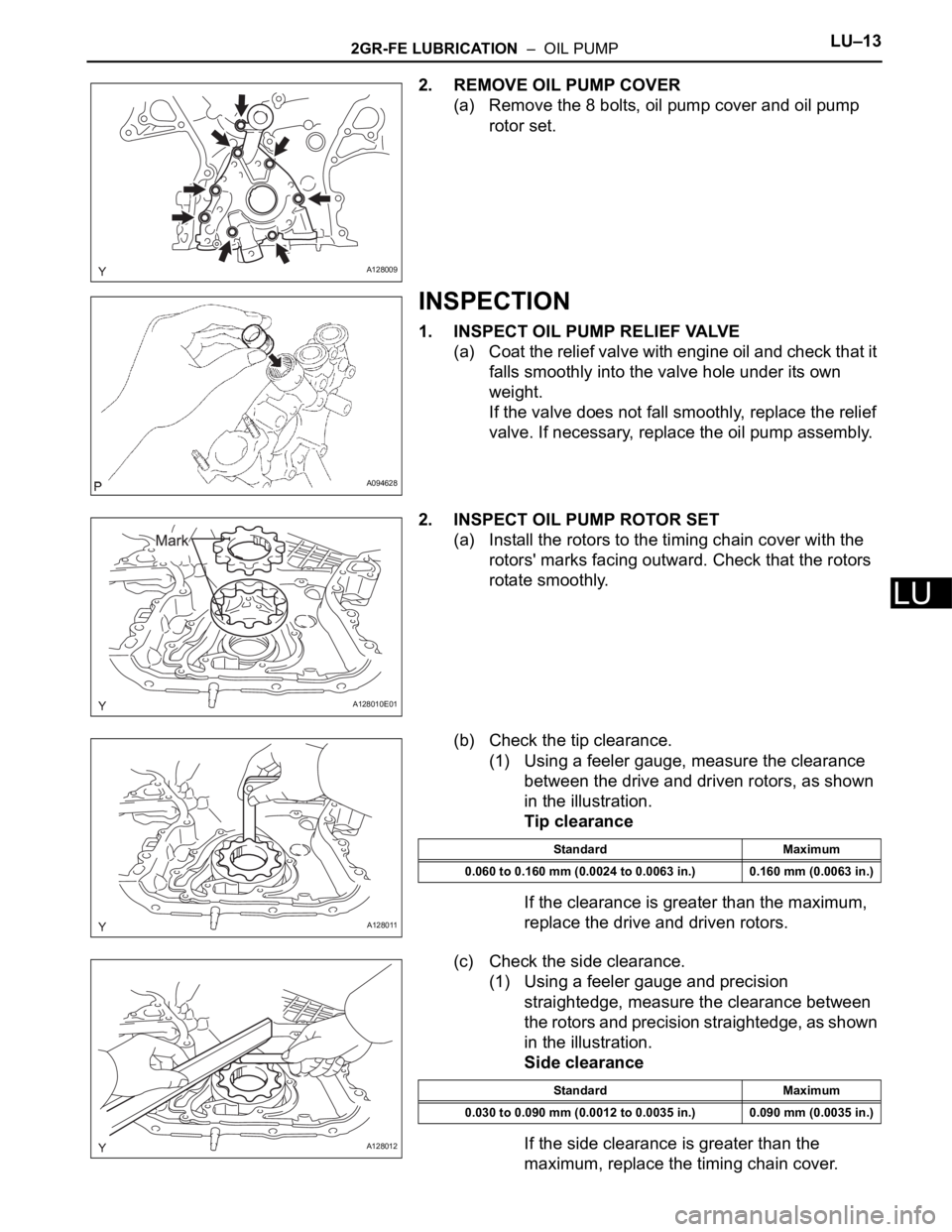

2. REMOVE OIL PUMP COVER

(a) Remove the 8 bolts, oil pump cover and oil pump

rotor set.

INSPECTION

1. INSPECT OIL PUMP RELIEF VALVE

(a) Coat the relief valve with engine oil and check that it

falls smoothly into the valve hole under its own

weight.

If the valve does not fall smoothly, replace the relief

valve. If necessary, replace the oil pump assembly.

2. INSPECT OIL PUMP ROTOR SET

(a) Install the rotors to the timing chain cover with the

rotors' marks facing outward. Check that the rotors

rotate smoothly.

(b) Check the tip clearance.

(1) Using a feeler gauge, measure the clearance

between the drive and driven rotors, as shown

in the illustration.

Tip clearance

If the clearance is greater than the maximum,

replace the drive and driven rotors.

(c) Check the side clearance.

(1) Using a feeler gauge and precision

straightedge, measure the clearance between

the rotors and precision straightedge, as shown

in the illustration.

Side clearance

If the side clearance is greater than the

maximum, replace the timing chain cover.

A128009

A094628

A128010E01

A128011

Standard Maximum

0.060 to 0.160 mm (0.0024 to 0.0063 in.) 0.160 mm (0.0063 in.)

A128012

Standard Maximum

0.030 to 0.090 mm (0.0012 to 0.0035 in.) 0.090 mm (0.0035 in.)

Page 1293 of 3000

LU–142GR-FE LUBRICATION – OIL PUMP

LU

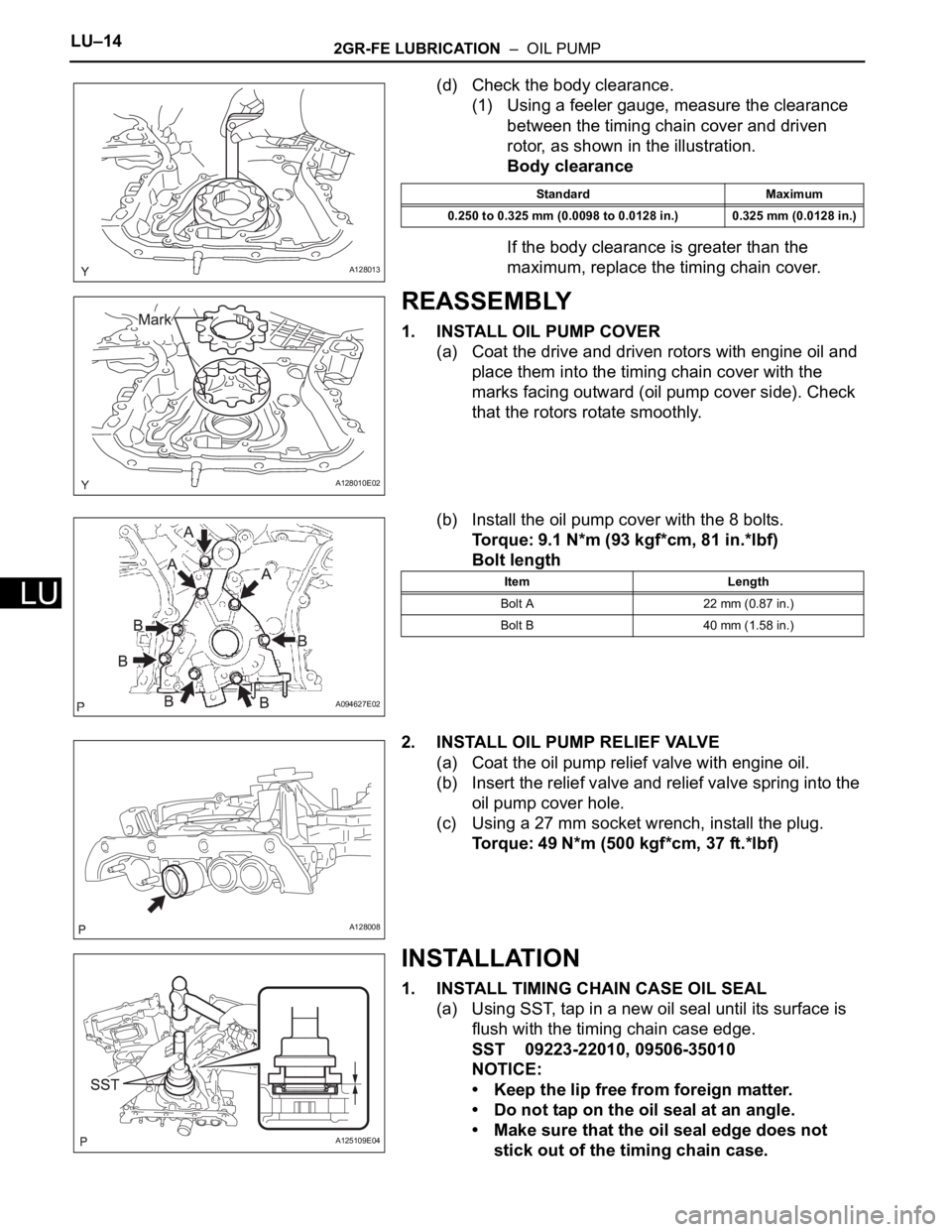

(d) Check the body clearance.

(1) Using a feeler gauge, measure the clearance

between the timing chain cover and driven

rotor, as shown in the illustration.

Body clearance

If the body clearance is greater than the

maximum, replace the timing chain cover.

REASSEMBLY

1. INSTALL OIL PUMP COVER

(a) Coat the drive and driven rotors with engine oil and

place them into the timing chain cover with the

marks facing outward (oil pump cover side). Check

that the rotors rotate smoothly.

(b) Install the oil pump cover with the 8 bolts.

Torque: 9.1 N*m (93 kgf*cm, 81 in.*lbf)

Bolt length

2. INSTALL OIL PUMP RELIEF VALVE

(a) Coat the oil pump relief valve with engine oil.

(b) Insert the relief valve and relief valve spring into the

oil pump cover hole.

(c) Using a 27 mm socket wrench, install the plug.

Torque: 49 N*m (500 kgf*cm, 37 ft.*lbf)

INSTALLATION

1. INSTALL TIMING CHAIN CASE OIL SEAL

(a) Using SST, tap in a new oil seal until its surface is

flush with the timing chain case edge.

SST 09223-22010, 09506-35010

NOTICE:

• Keep the lip free from foreign matter.

• Do not tap on the oil seal at an angle.

• Make sure that the oil seal edge does not

stick out of the timing chain case.

A128013

Standard Maximum

0.250 to 0.325 mm (0.0098 to 0.0128 in.) 0.325 mm (0.0128 in.)

A128010E02

A094627E02

Item Length

Bolt A 22 mm (0.87 in.)

Bolt B 40 mm (1.58 in.)

A128008

A125109E04