oil TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 865 of 3000

EM–482GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

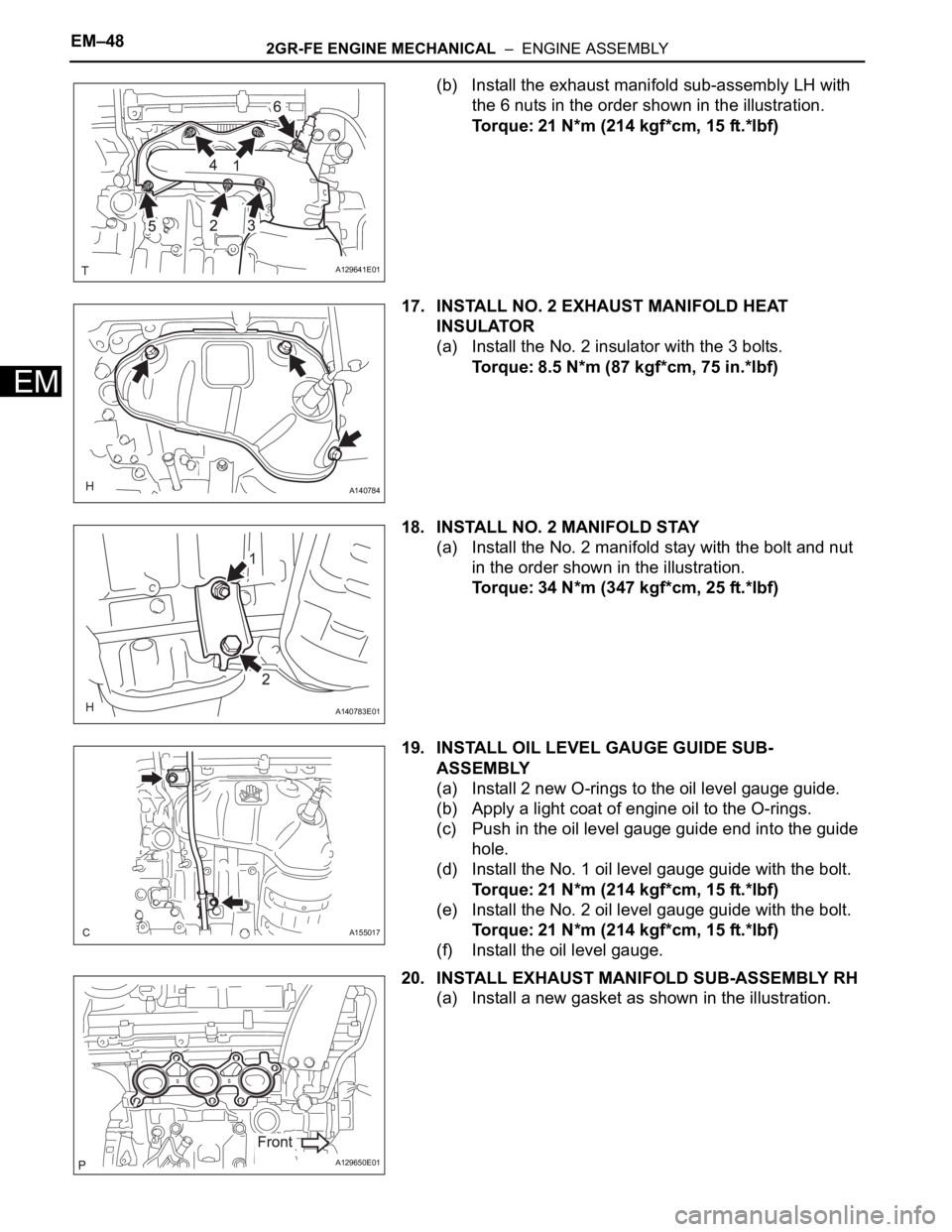

(b) Install the exhaust manifold sub-assembly LH with

the 6 nuts in the order shown in the illustration.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

17. INSTALL NO. 2 EXHAUST MANIFOLD HEAT

INSULATOR

(a) Install the No. 2 insulator with the 3 bolts.

Torque: 8.5 N*m (87 kgf*cm, 75 in.*lbf)

18. INSTALL NO. 2 MANIFOLD STAY

(a) Install the No. 2 manifold stay with the bolt and nut

in the order shown in the illustration.

Torque: 34 N*m (347 kgf*cm, 25 ft.*lbf)

19. INSTALL OIL LEVEL GAUGE GUIDE SUB-

ASSEMBLY

(a) Install 2 new O-rings to the oil level gauge guide.

(b) Apply a light coat of engine oil to the O-rings.

(c) Push in the oil level gauge guide end into the guide

hole.

(d) Install the No. 1 oil level gauge guide with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(e) Install the No. 2 oil level gauge guide with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(f) Install the oil level gauge.

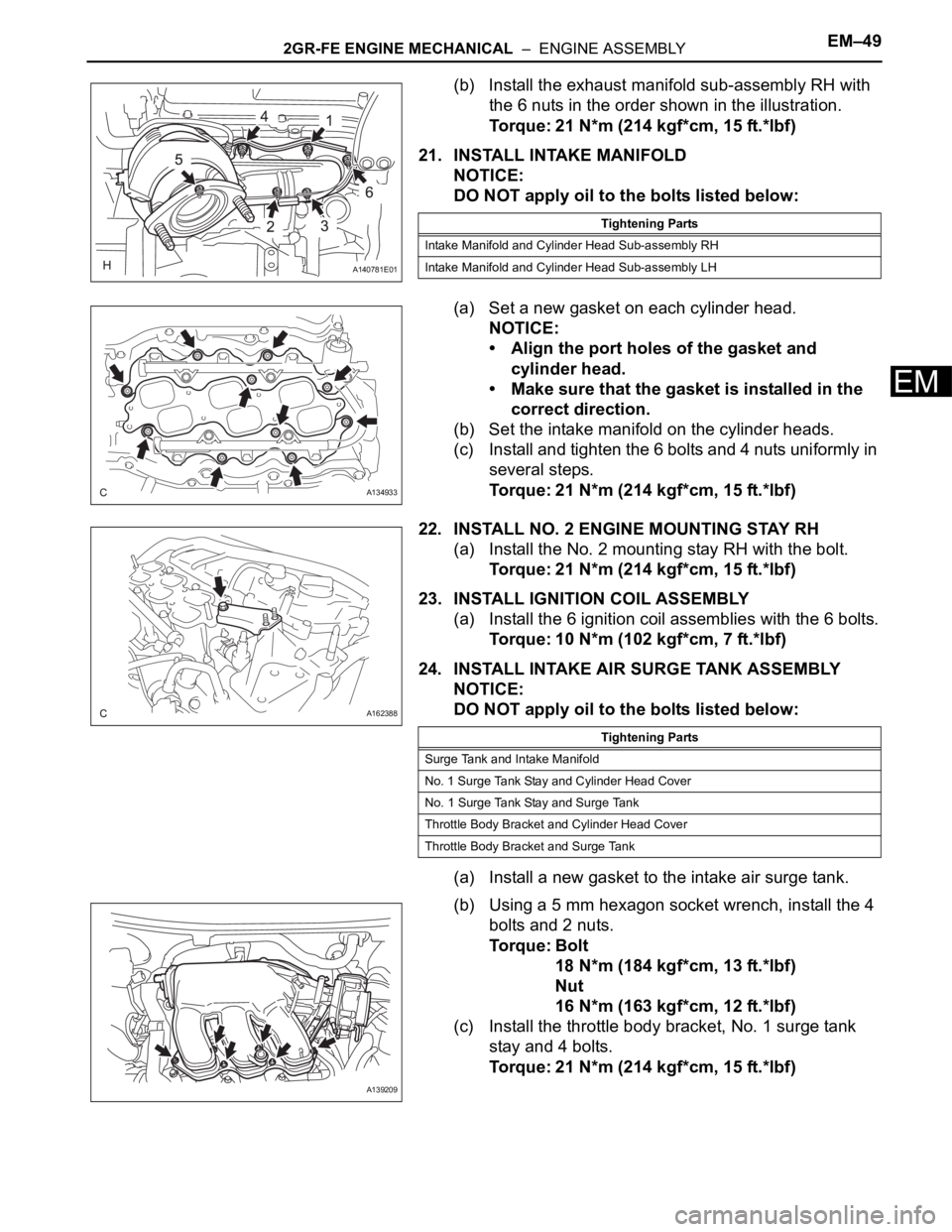

20. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY RH

(a) Install a new gasket as shown in the illustration.

A129641E01

A140784

A140783E01

A155017

A129650E01

Page 866 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–49

EM

(b) Install the exhaust manifold sub-assembly RH with

the 6 nuts in the order shown in the illustration.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

21. INSTALL INTAKE MANIFOLD

NOTICE:

DO NOT apply oil to the bolts listed below:

(a) Set a new gasket on each cylinder head.

NOTICE:

• Align the port holes of the gasket and

cylinder head.

• Make sure that the gasket is installed in the

correct direction.

(b) Set the intake manifold on the cylinder heads.

(c) Install and tighten the 6 bolts and 4 nuts uniformly in

several steps.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

22. INSTALL NO. 2 ENGINE MOUNTING STAY RH

(a) Install the No. 2 mounting stay RH with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

23. INSTALL IGNITION COIL ASSEMBLY

(a) Install the 6 ignition coil assemblies with the 6 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

24. INSTALL INTAKE AIR SURGE TANK ASSEMBLY

NOTICE:

DO NOT apply oil to the bolts listed below:

(a) Install a new gasket to the intake air surge tank.

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts and 2 nuts.

Torque: Bolt

18 N*m (184 kgf*cm, 13 ft.*lbf)

Nut

16 N*m (163 kgf*cm, 12 ft.*lbf)

(c) Install the throttle body bracket, No. 1 surge tank

stay and 4 bolts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

A140781E01

Tightening Parts

Intake Manifold and Cylinder Head Sub-assembly RH

Intake Manifold and Cylinder Head Sub-assembly LH

A134933

A162388

Tightening Parts

Surge Tank and Intake Manifold

No. 1 Surge Tank Stay and Cylinder Head Cover

No. 1 Surge Tank Stay and Surge Tank

Throttle Body Bracket and Cylinder Head Cover

Throttle Body Bracket and Surge Tank

A139209

Page 869 of 3000

EM–522GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

(c) Install the engine mounting insulator RR with the 2

bolts.

Torque: 78 N*m (795 kgf*cm, 58 ft.*lbf)

(d) Connect the connector and clamp.

40. INSTALL POWER STEERING LINK (See page PS-39)

41. INSTALL FRONT STABILIZER BAR

HINT:

(See page SP-36).

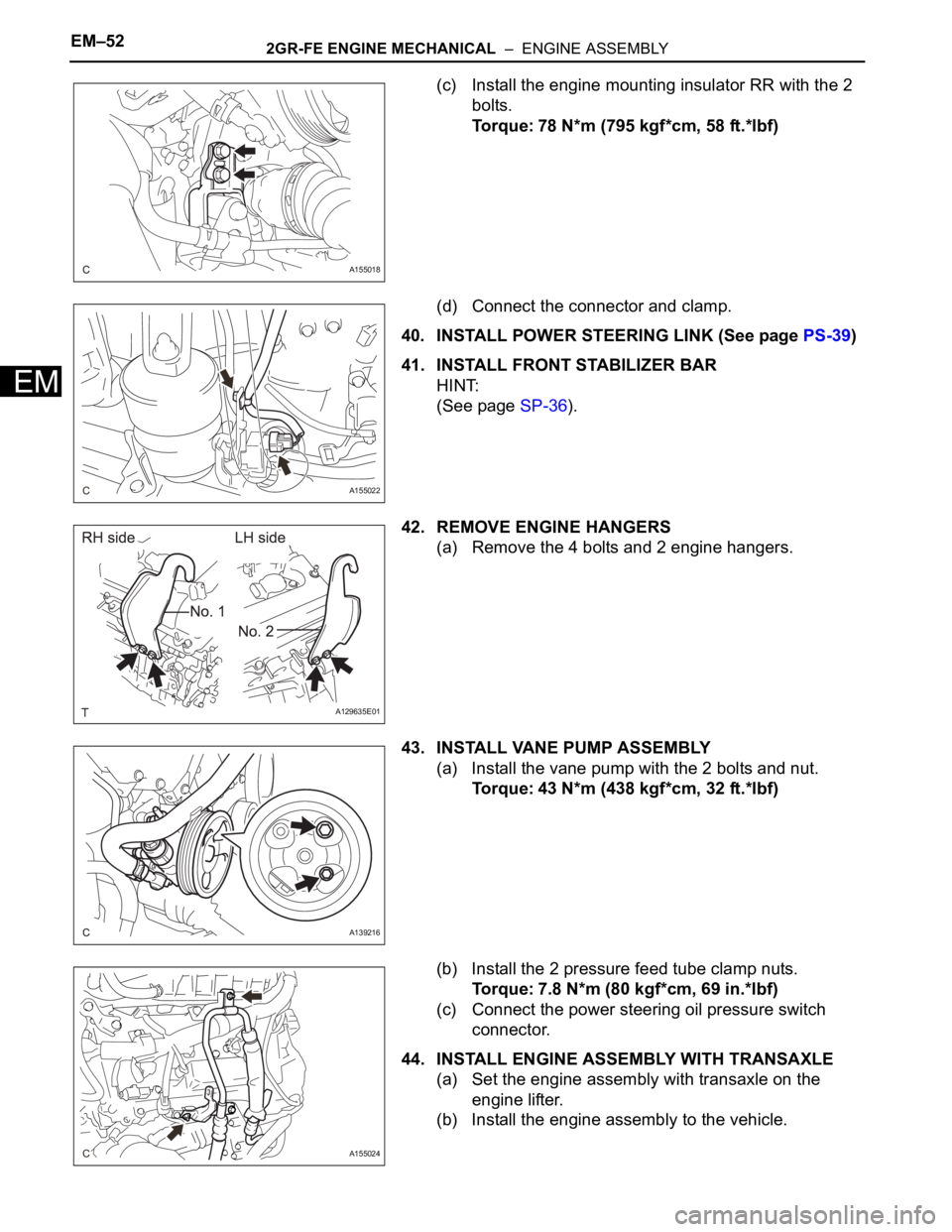

42. REMOVE ENGINE HANGERS

(a) Remove the 4 bolts and 2 engine hangers.

43. INSTALL VANE PUMP ASSEMBLY

(a) Install the vane pump with the 2 bolts and nut.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

(b) Install the 2 pressure feed tube clamp nuts.

Torque: 7.8 N*m (80 kgf*cm, 69 in.*lbf)

(c) Connect the power steering oil pressure switch

connector.

44. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

(a) Set the engine assembly with transaxle on the

engine lifter.

(b) Install the engine assembly to the vehicle.

A155018

A155022

A129635E01

A139216

A155024

Page 872 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–55

EM

(b) Install the bolt and 2 clamps to the body.

Torque: 8.4 N*m (85 kgf*cm, 74 in.*lbf)

(c) Connect the wire to the engine room junction block.

Then, install it with the nut.

Torque: 8.4 N*m (85 kgf*cm, 74 in.*lbf)

(d) Install the engine wire to the body with the 2 nuts.

Torque: 8.4 N*m (85 kgf*cm, 74 in.*lbf)

66. CONNECT NO. 1 OIL RESERVOIR TO PUMP HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to connect the No. 1 oil reservoir to pump hose

to the oil reservoir tank.

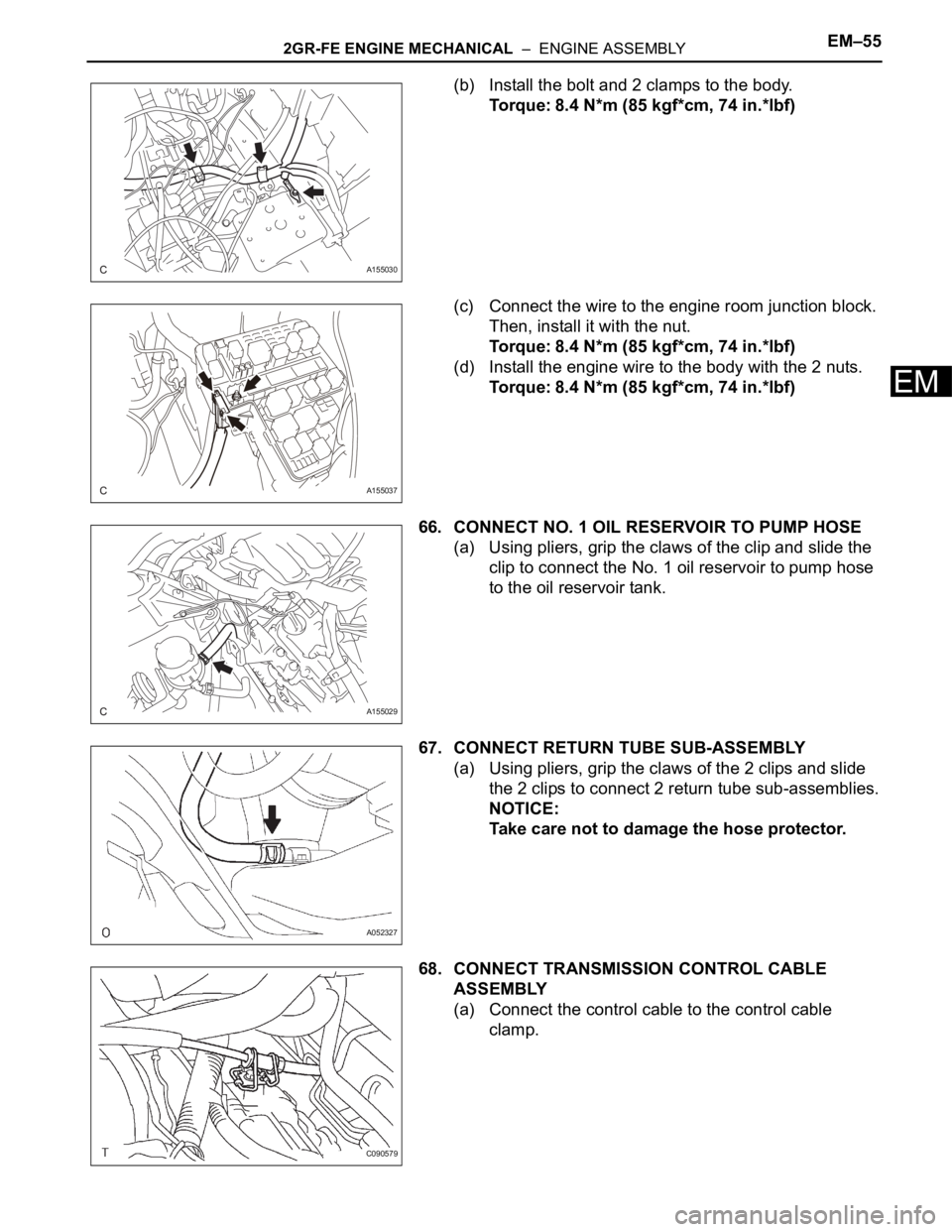

67. CONNECT RETURN TUBE SUB-ASSEMBLY

(a) Using pliers, grip the claws of the 2 clips and slide

the 2 clips to connect 2 return tube sub-assemblies.

NOTICE:

Take care not to damage the hose protector.

68. CONNECT TRANSMISSION CONTROL CABLE

ASSEMBLY

(a) Connect the control cable to the control cable

clamp.

A155030

A155037

A155029

A052327

C090579

Page 873 of 3000

EM–562GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

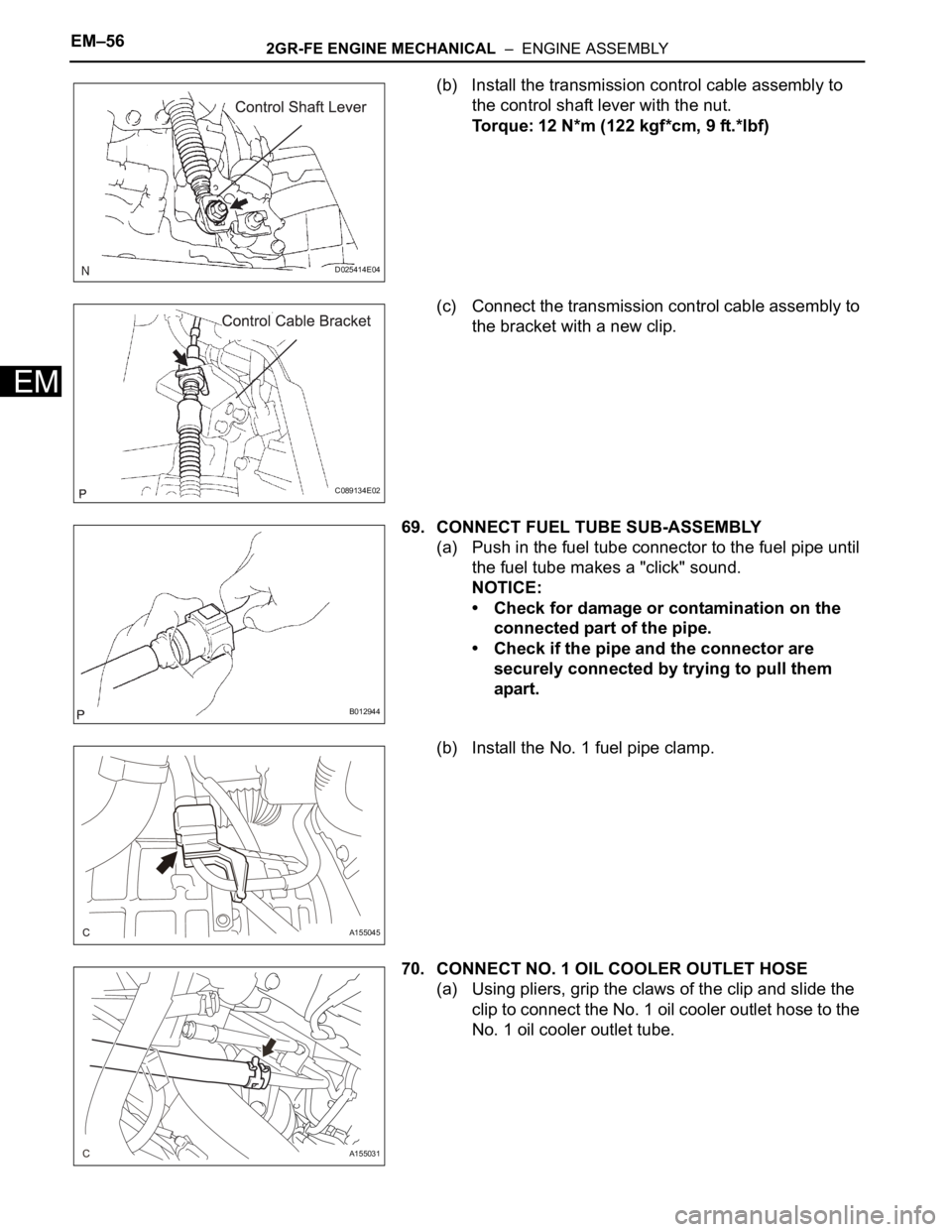

(b) Install the transmission control cable assembly to

the control shaft lever with the nut.

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf)

(c) Connect the transmission control cable assembly to

the bracket with a new clip.

69. CONNECT FUEL TUBE SUB-ASSEMBLY

(a) Push in the fuel tube connector to the fuel pipe until

the fuel tube makes a "click" sound.

NOTICE:

• Check for damage or contamination on the

connected part of the pipe.

• Check if the pipe and the connector are

securely connected by trying to pull them

apart.

(b) Install the No. 1 fuel pipe clamp.

70. CONNECT NO. 1 OIL COOLER OUTLET HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to connect the No. 1 oil cooler outlet hose to the

No. 1 oil cooler outlet tube.

D025414E04

C089134E02

B012944

A155045

A155031

Page 874 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–57

EM

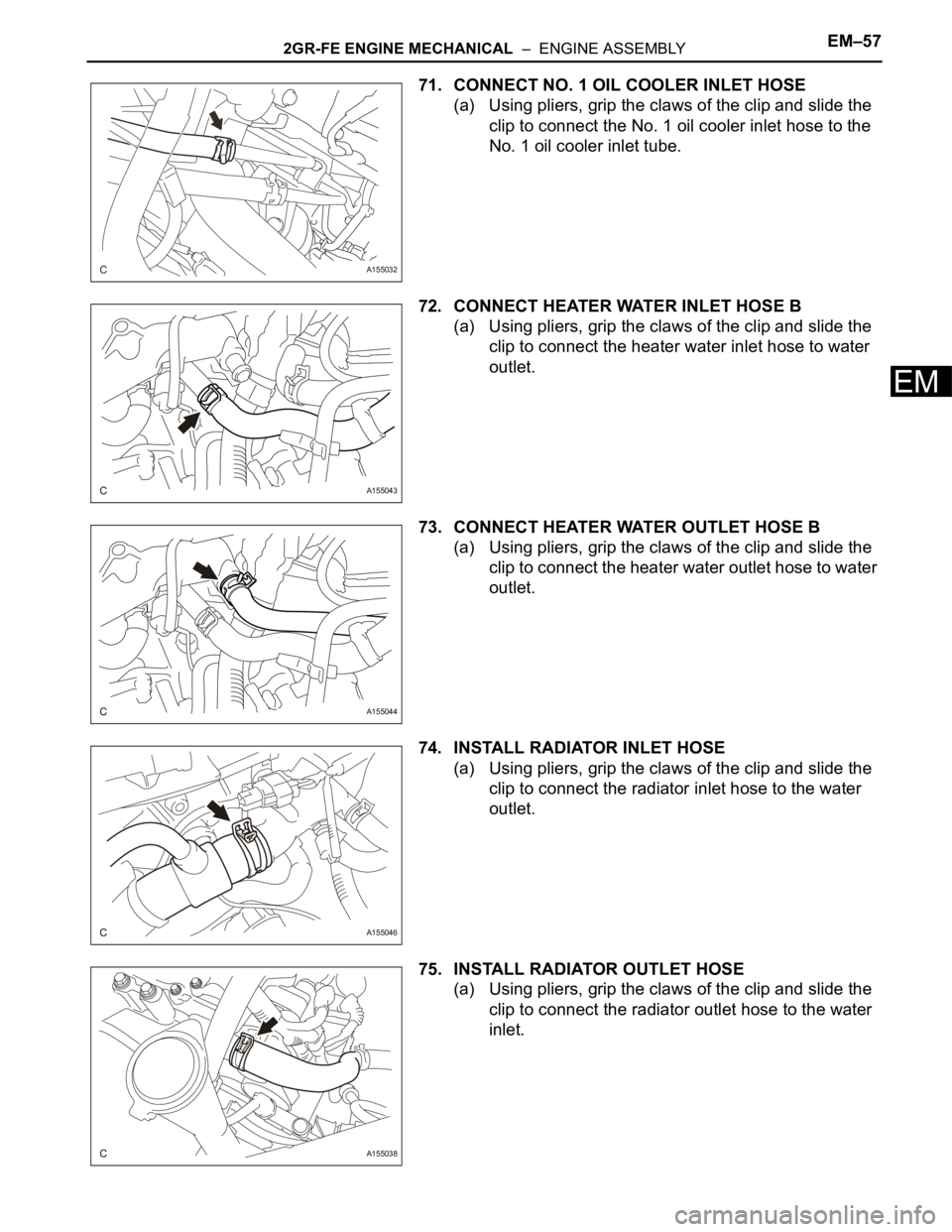

71. CONNECT NO. 1 OIL COOLER INLET HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to connect the No. 1 oil cooler inlet hose to the

No. 1 oil cooler inlet tube.

72. CONNECT HEATER WATER INLET HOSE B

(a) Using pliers, grip the claws of the clip and slide the

clip to connect the heater water inlet hose to water

outlet.

73. CONNECT HEATER WATER OUTLET HOSE B

(a) Using pliers, grip the claws of the clip and slide the

clip to connect the heater water outlet hose to water

outlet.

74. INSTALL RADIATOR INLET HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to connect the radiator inlet hose to the water

outlet.

75. INSTALL RADIATOR OUTLET HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to connect the radiator outlet hose to the water

inlet.

A155032

A155043

A155044

A155046

A155038

Page 879 of 3000

EM–622GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

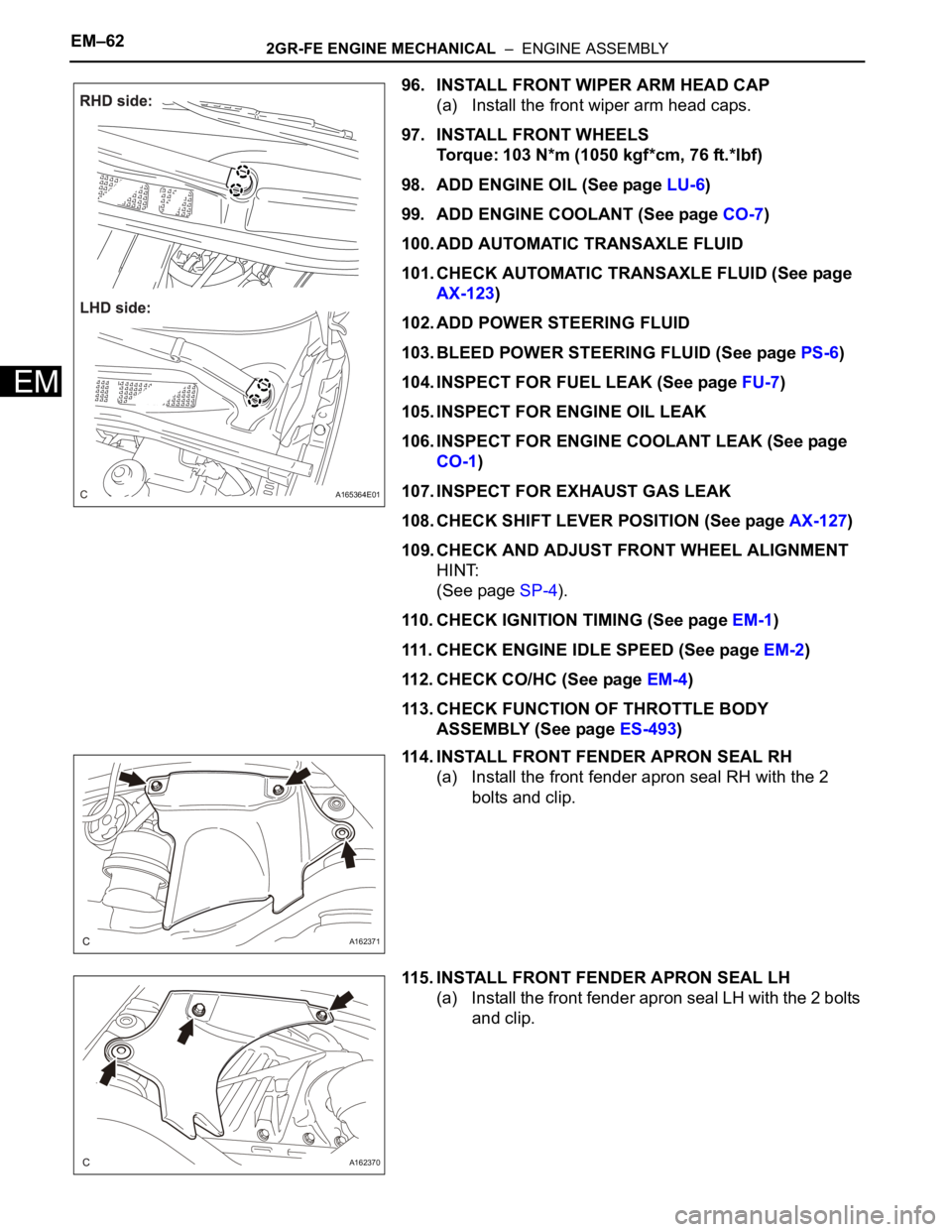

96. INSTALL FRONT WIPER ARM HEAD CAP

(a) Install the front wiper arm head caps.

97. INSTALL FRONT WHEELS

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

98. ADD ENGINE OIL (See page LU-6)

99. ADD ENGINE COOLANT (See page CO-7)

100. ADD AUTOMATIC TRANSAXLE FLUID

101. CHECK AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

102. ADD POWER STEERING FLUID

103. BLEED POWER STEERING FLUID (See page PS-6)

104. INSPECT FOR FUEL LEAK (See page FU-7)

105. INSPECT FOR ENGINE OIL LEAK

106. INSPECT FOR ENGINE COOLANT LEAK (See page

CO-1)

107. INSPECT FOR EXHAUST GAS LEAK

108. CHECK SHIFT LEVER POSITION (See page AX-127)

109. CHECK AND ADJUST FRONT WHEEL ALIGNMENT

HINT:

(See page SP-4).

110. CHECK IGNITION TIMING (See page EM-1)

111. CHECK ENGINE IDLE SPEED (See page EM-2)

112. CHECK CO/HC (See page EM-4)

113. CHECK FUNCTION OF THROTTLE BODY

ASSEMBLY (See page ES-493)

114. INSTALL FRONT FENDER APRON SEAL RH

(a) Install the front fender apron seal RH with the 2

bolts and clip.

115. INSTALL FRONT FENDER APRON SEAL LH

(a) Install the front fender apron seal LH with the 2 bolts

and clip.

A165364E01

A162371

A162370

Page 881 of 3000

EM–762GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

DISASSEMBLY

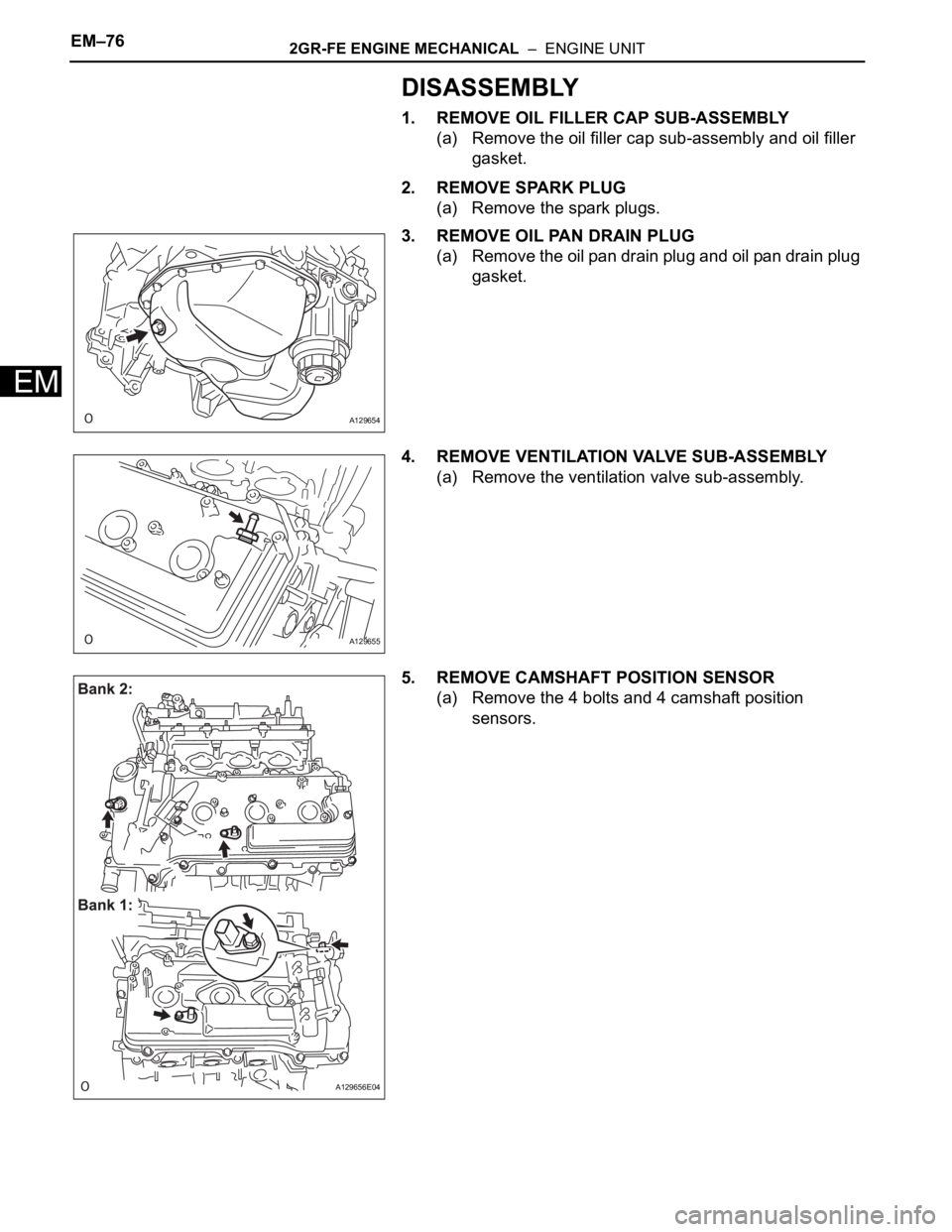

1. REMOVE OIL FILLER CAP SUB-ASSEMBLY

(a) Remove the oil filler cap sub-assembly and oil filler

gasket.

2. REMOVE SPARK PLUG

(a) Remove the spark plugs.

3. REMOVE OIL PAN DRAIN PLUG

(a) Remove the oil pan drain plug and oil pan drain plug

gasket.

4. REMOVE VENTILATION VALVE SUB-ASSEMBLY

(a) Remove the ventilation valve sub-assembly.

5. REMOVE CAMSHAFT POSITION SENSOR

(a) Remove the 4 bolts and 4 camshaft position

sensors.

A129654

A129655

A129656E04

Page 882 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–77

EM

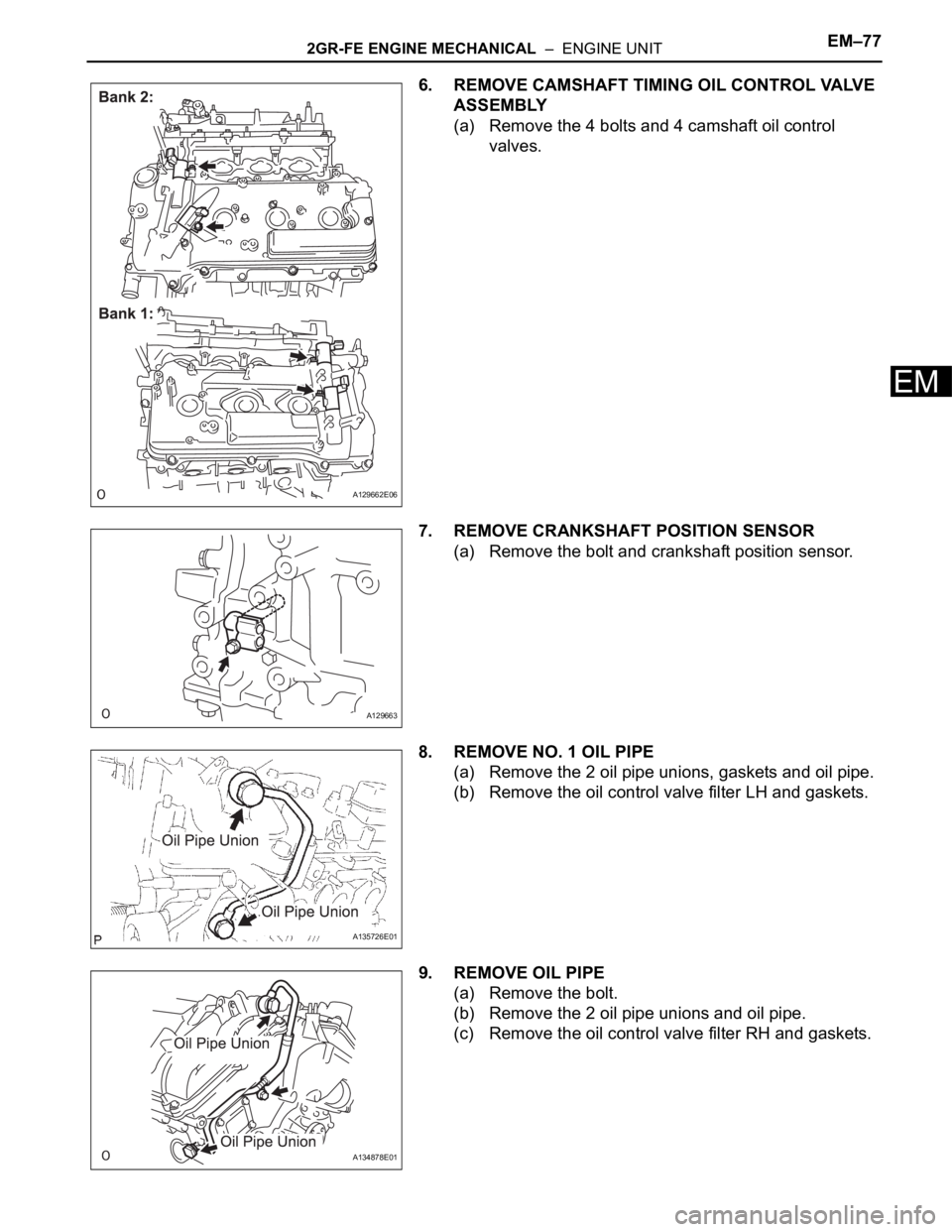

6. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY

(a) Remove the 4 bolts and 4 camshaft oil control

valves.

7. REMOVE CRANKSHAFT POSITION SENSOR

(a) Remove the bolt and crankshaft position sensor.

8. REMOVE NO. 1 OIL PIPE

(a) Remove the 2 oil pipe unions, gaskets and oil pipe.

(b) Remove the oil control valve filter LH and gaskets.

9. REMOVE OIL PIPE

(a) Remove the bolt.

(b) Remove the 2 oil pipe unions and oil pipe.

(c) Remove the oil control valve filter RH and gaskets.

A129662E06

A129663

A135726E01

A134878E01

Page 883 of 3000

EM–782GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

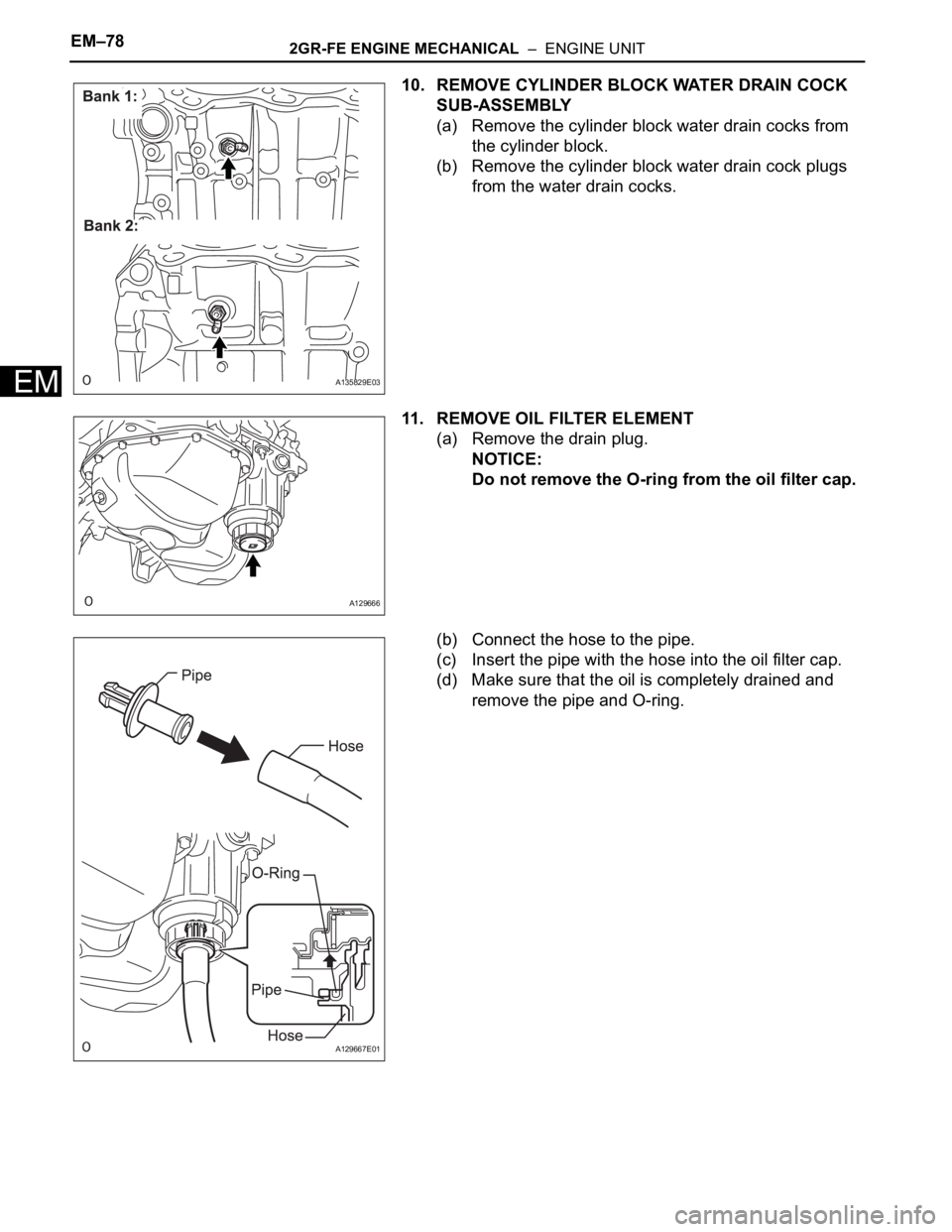

10. REMOVE CYLINDER BLOCK WATER DRAIN COCK

SUB-ASSEMBLY

(a) Remove the cylinder block water drain cocks from

the cylinder block.

(b) Remove the cylinder block water drain cock plugs

from the water drain cocks.

11. REMOVE OIL FILTER ELEMENT

(a) Remove the drain plug.

NOTICE:

Do not remove the O-ring from the oil filter cap.

(b) Connect the hose to the pipe.

(c) Insert the pipe with the hose into the oil filter cap.

(d) Make sure that the oil is completely drained and

remove the pipe and O-ring.

A135829E03

A129666

A129667E01