oil TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 884 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–79

EM

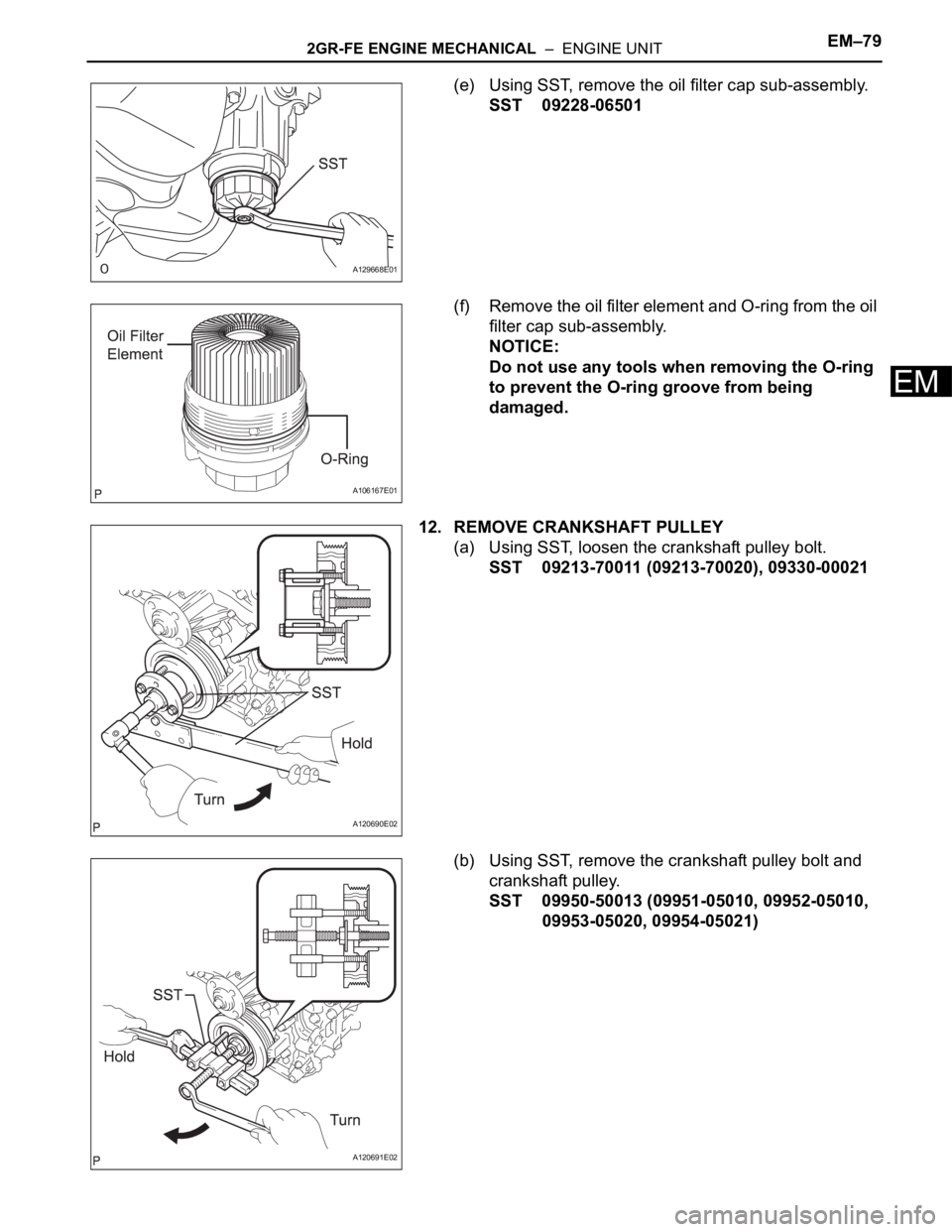

(e) Using SST, remove the oil filter cap sub-assembly.

SST 09228-06501

(f) Remove the oil filter element and O-ring from the oil

filter cap sub-assembly.

NOTICE:

Do not use any tools when removing the O-ring

to prevent the O-ring groove from being

damaged.

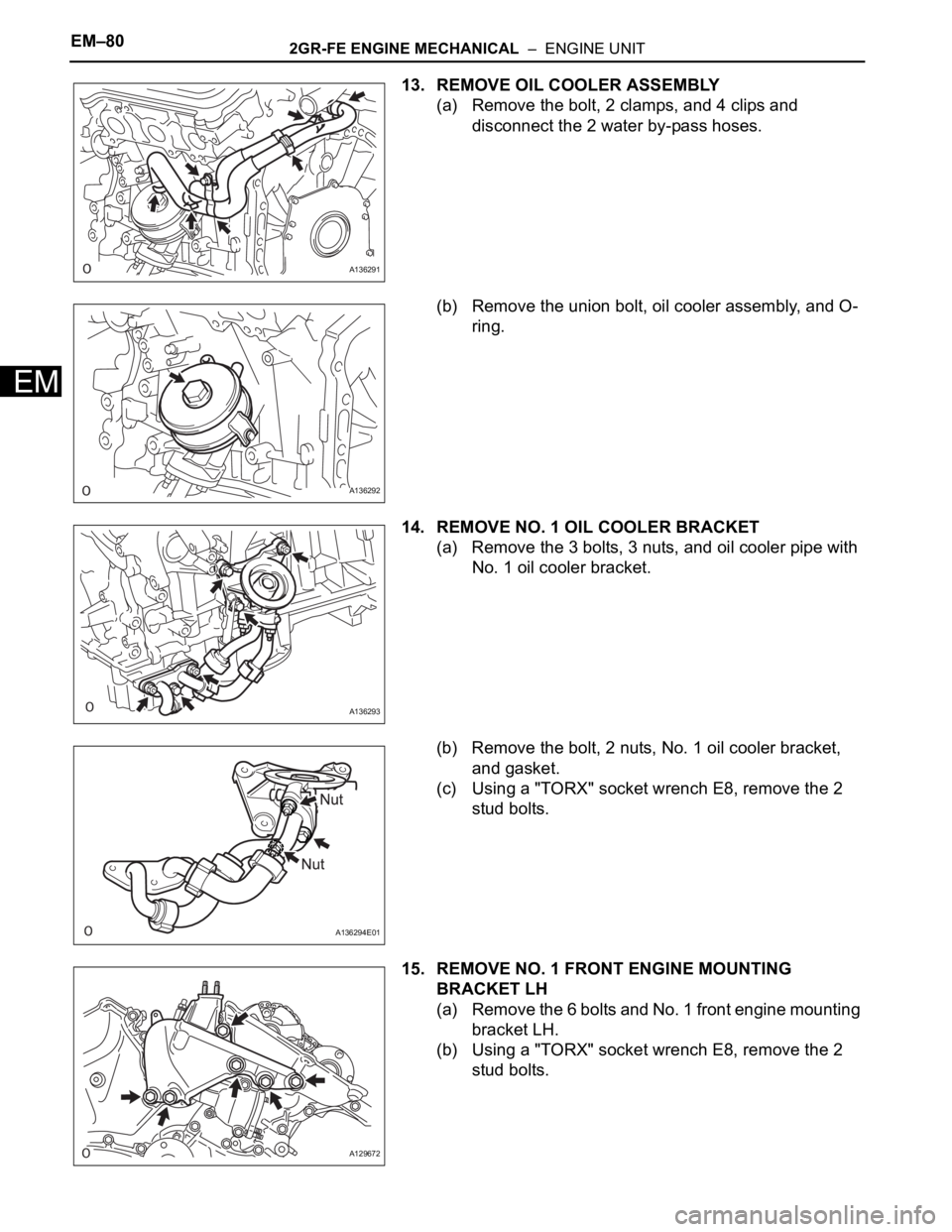

12. REMOVE CRANKSHAFT PULLEY

(a) Using SST, loosen the crankshaft pulley bolt.

SST 09213-70011 (09213-70020), 09330-00021

(b) Using SST, remove the crankshaft pulley bolt and

crankshaft pulley.

SST 09950-50013 (09951-05010, 09952-05010,

09953-05020, 09954-05021)

A129668E01

A106167E01

A120690E02

A120691E02

Page 885 of 3000

EM–802GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

13. REMOVE OIL COOLER ASSEMBLY

(a) Remove the bolt, 2 clamps, and 4 clips and

disconnect the 2 water by-pass hoses.

(b) Remove the union bolt, oil cooler assembly, and O-

ring.

14. REMOVE NO. 1 OIL COOLER BRACKET

(a) Remove the 3 bolts, 3 nuts, and oil cooler pipe with

No. 1 oil cooler bracket.

(b) Remove the bolt, 2 nuts, No. 1 oil cooler bracket,

and gasket.

(c) Using a "TORX" socket wrench E8, remove the 2

stud bolts.

15. REMOVE NO. 1 FRONT ENGINE MOUNTING

BRACKET LH

(a) Remove the 6 bolts and No. 1 front engine mounting

bracket LH.

(b) Using a "TORX" socket wrench E8, remove the 2

stud bolts.

A136291

A136292

A136293

A136294E01

A129672

Page 887 of 3000

EM–822GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

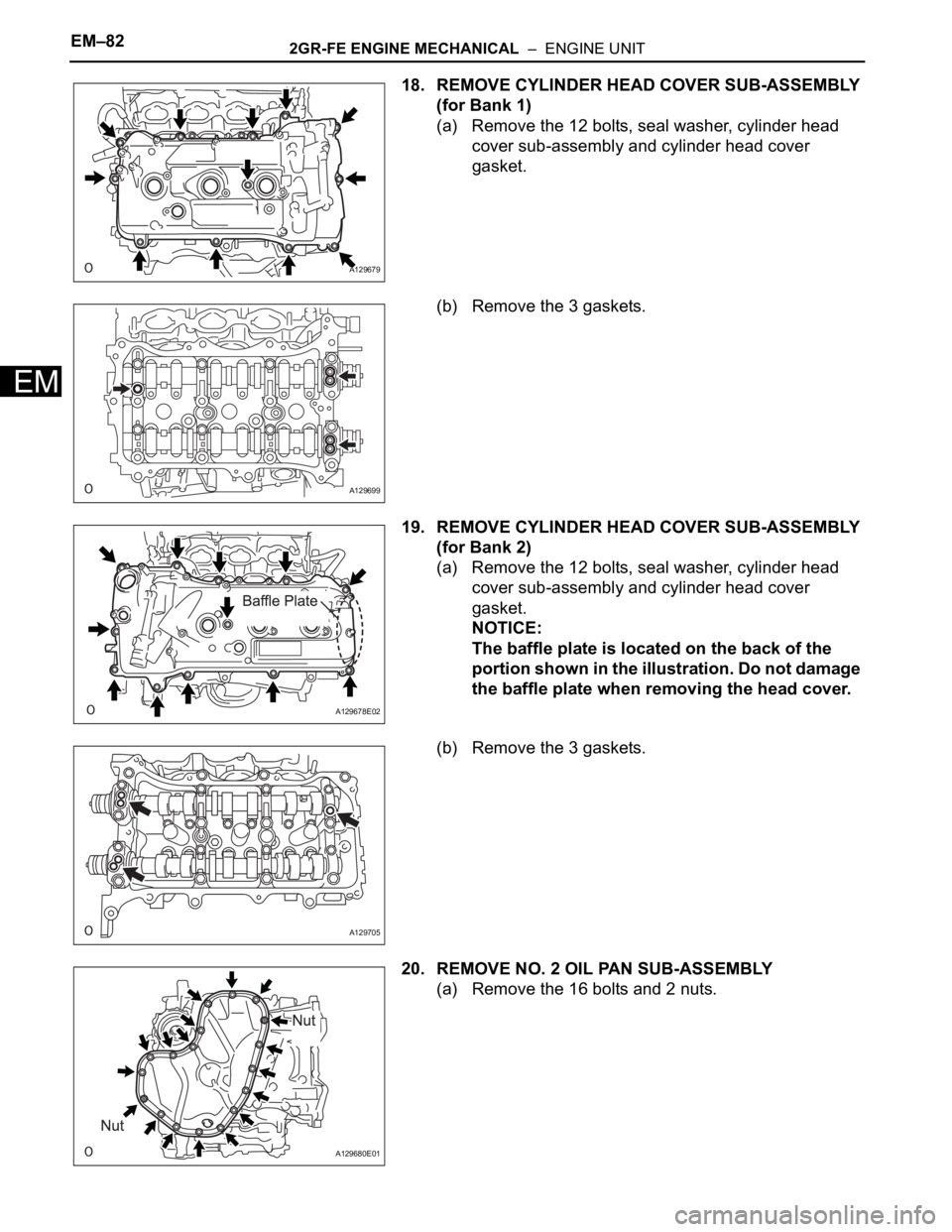

18. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

(for Bank 1)

(a) Remove the 12 bolts, seal washer, cylinder head

cover sub-assembly and cylinder head cover

gasket.

(b) Remove the 3 gaskets.

19. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

(for Bank 2)

(a) Remove the 12 bolts, seal washer, cylinder head

cover sub-assembly and cylinder head cover

gasket.

NOTICE:

The baffle plate is located on the back of the

portion shown in the illustration. Do not damage

the baffle plate when removing the head cover.

(b) Remove the 3 gaskets.

20. REMOVE NO. 2 OIL PAN SUB-ASSEMBLY

(a) Remove the 16 bolts and 2 nuts.

A129679

A129699

A129678E02

A129705

A129680E01

Page 888 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–83

EM

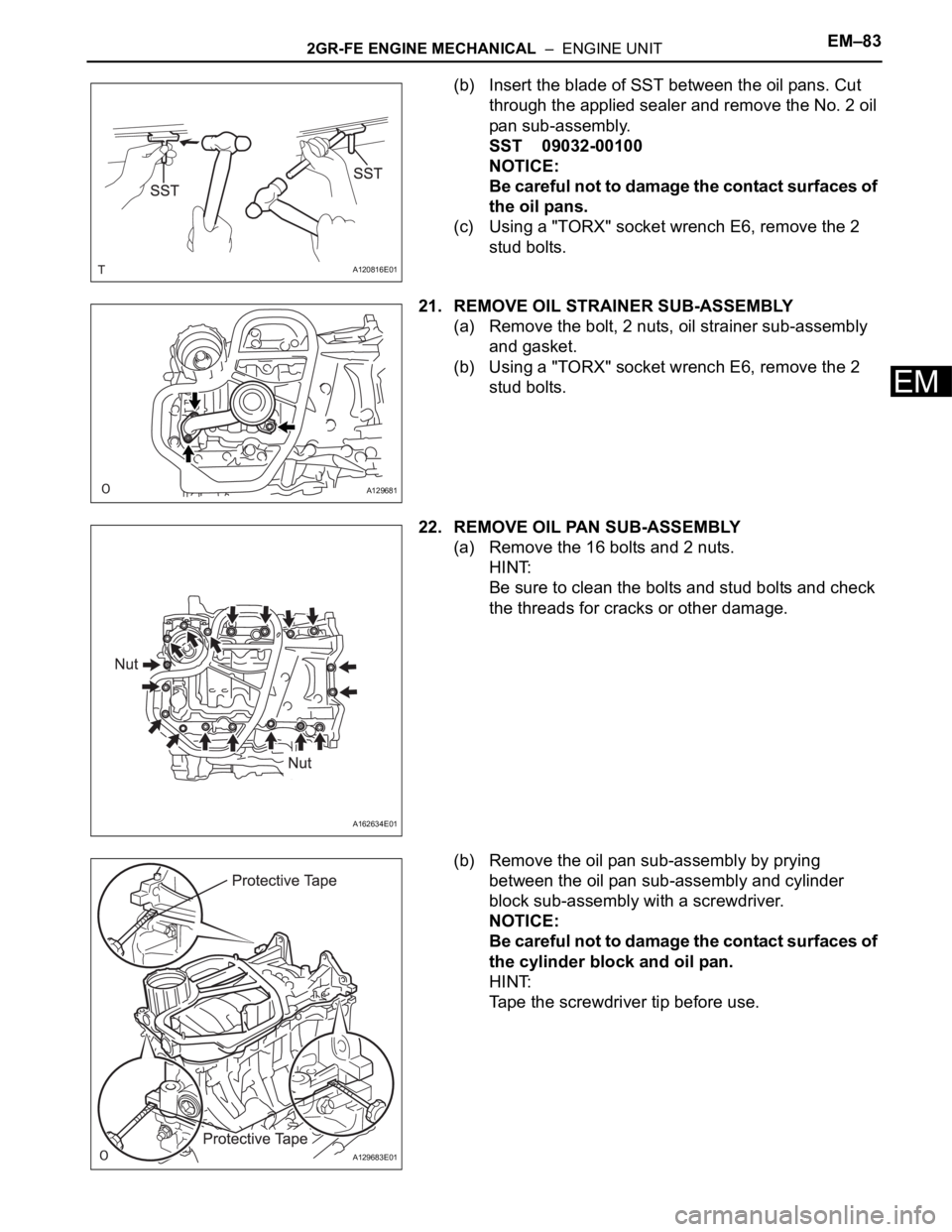

(b) Insert the blade of SST between the oil pans. Cut

through the applied sealer and remove the No. 2 oil

pan sub-assembly.

SST 09032-00100

NOTICE:

Be careful not to damage the contact surfaces of

the oil pans.

(c) Using a "TORX" socket wrench E6, remove the 2

stud bolts.

21. REMOVE OIL STRAINER SUB-ASSEMBLY

(a) Remove the bolt, 2 nuts, oil strainer sub-assembly

and gasket.

(b) Using a "TORX" socket wrench E6, remove the 2

stud bolts.

22. REMOVE OIL PAN SUB-ASSEMBLY

(a) Remove the 16 bolts and 2 nuts.

HINT:

Be sure to clean the bolts and stud bolts and check

the threads for cracks or other damage.

(b) Remove the oil pan sub-assembly by prying

between the oil pan sub-assembly and cylinder

block sub-assembly with a screwdriver.

NOTICE:

Be careful not to damage the contact surfaces of

the cylinder block and oil pan.

HINT:

Tape the screwdriver tip before use.

A120816E01

A129681

A162634E01

A129683E01

Page 889 of 3000

EM–842GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

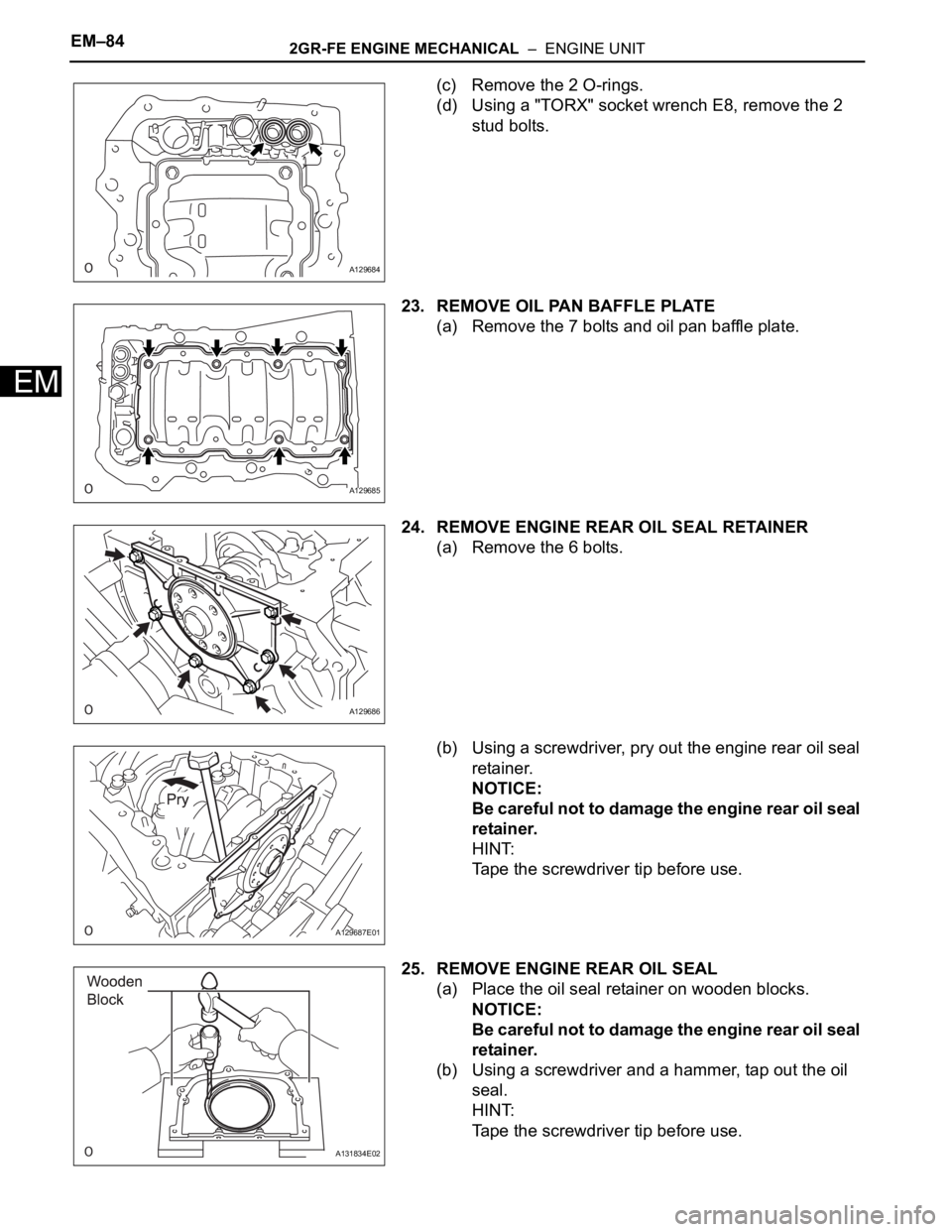

(c) Remove the 2 O-rings.

(d) Using a "TORX" socket wrench E8, remove the 2

stud bolts.

23. REMOVE OIL PAN BAFFLE PLATE

(a) Remove the 7 bolts and oil pan baffle plate.

24. REMOVE ENGINE REAR OIL SEAL RETAINER

(a) Remove the 6 bolts.

(b) Using a screwdriver, pry out the engine rear oil seal

retainer.

NOTICE:

Be careful not to damage the engine rear oil seal

retainer.

HINT:

Tape the screwdriver tip before use.

25. REMOVE ENGINE REAR OIL SEAL

(a) Place the oil seal retainer on wooden blocks.

NOTICE:

Be careful not to damage the engine rear oil seal

retainer.

(b) Using a screwdriver and a hammer, tap out the oil

seal.

HINT:

Tape the screwdriver tip before use.

A129684

A129685

A129686

A129687E01

A131834E02

Page 891 of 3000

EM–862GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

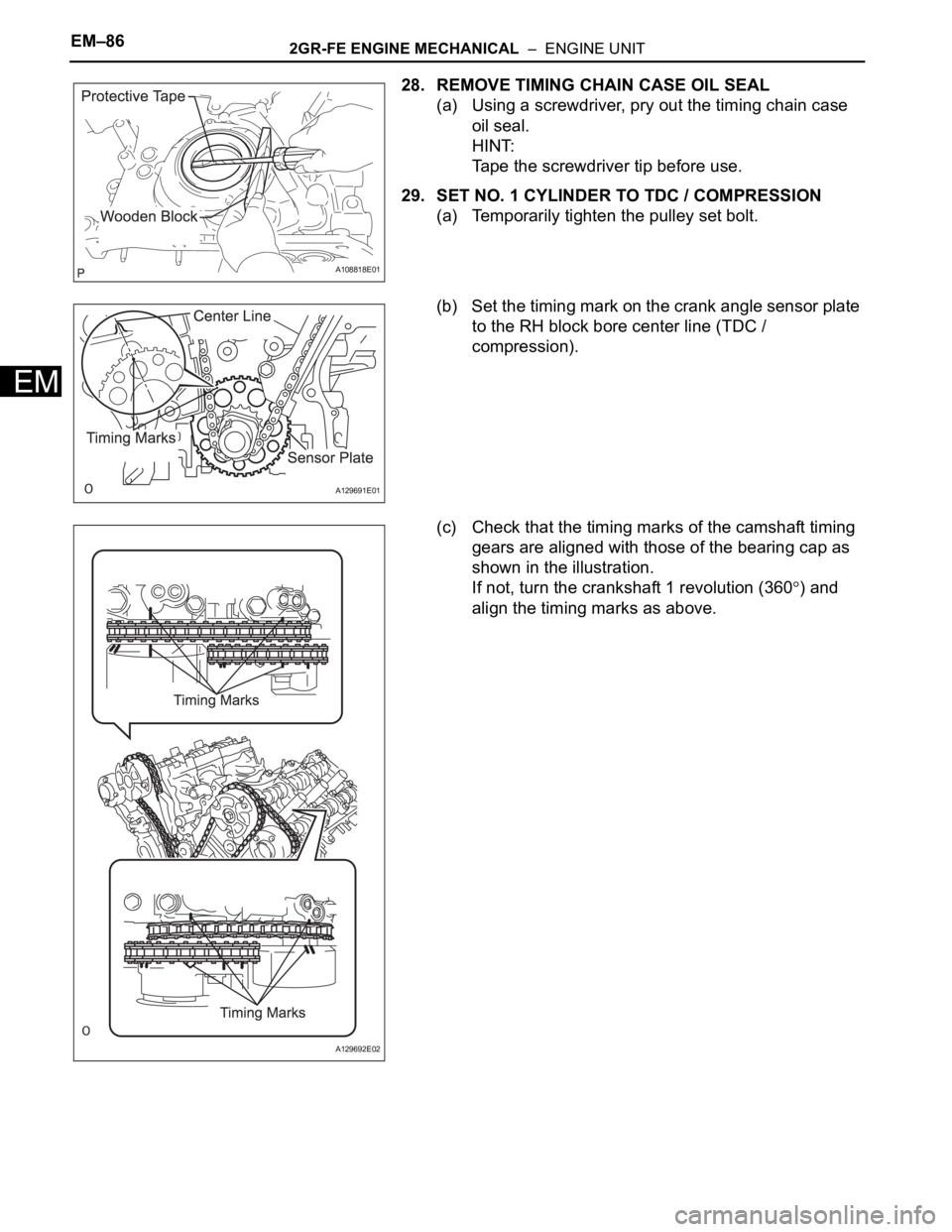

28. REMOVE TIMING CHAIN CASE OIL SEAL

(a) Using a screwdriver, pry out the timing chain case

oil seal.

HINT:

Tape the screwdriver tip before use.

29. SET NO. 1 CYLINDER TO TDC / COMPRESSION

(a) Temporarily tighten the pulley set bolt.

(b) Set the timing mark on the crank angle sensor plate

to the RH block bore center line (TDC /

compression).

(c) Check that the timing marks of the camshaft timing

gears are aligned with those of the bearing cap as

shown in the illustration.

If not, turn the crankshaft 1 revolution (360

) and

align the timing marks as above.

A108818E01

A129691E01

A129692E02

Page 899 of 3000

EM–942GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

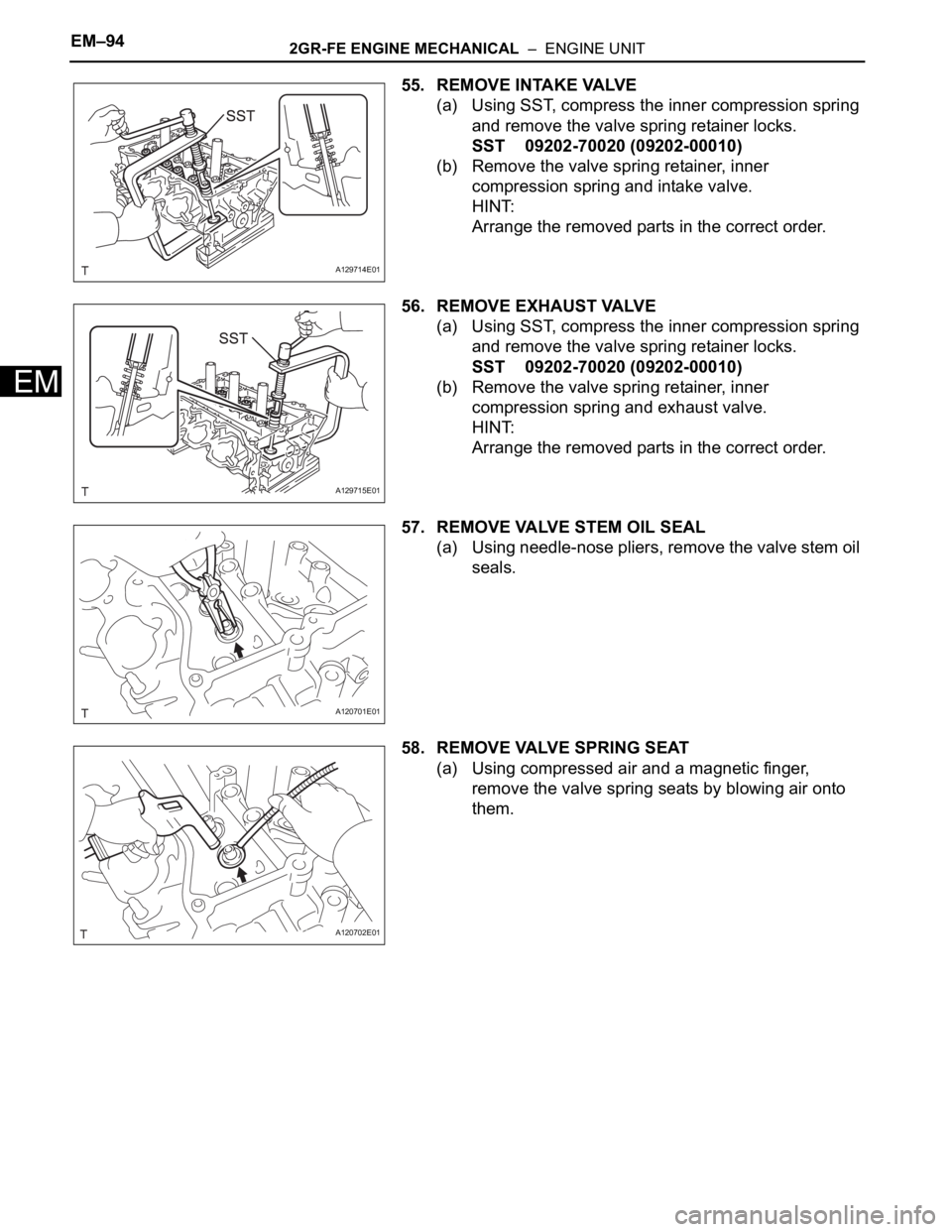

55. REMOVE INTAKE VALVE

(a) Using SST, compress the inner compression spring

and remove the valve spring retainer locks.

SST 09202-70020 (09202-00010)

(b) Remove the valve spring retainer, inner

compression spring and intake valve.

HINT:

Arrange the removed parts in the correct order.

56. REMOVE EXHAUST VALVE

(a) Using SST, compress the inner compression spring

and remove the valve spring retainer locks.

SST 09202-70020 (09202-00010)

(b) Remove the valve spring retainer, inner

compression spring and exhaust valve.

HINT:

Arrange the removed parts in the correct order.

57. REMOVE VALVE STEM OIL SEAL

(a) Using needle-nose pliers, remove the valve stem oil

seals.

58. REMOVE VALVE SPRING SEAT

(a) Using compressed air and a magnetic finger,

remove the valve spring seats by blowing air onto

them.

A129714E01

A129715E01

A120701E01

A120702E01

Page 903 of 3000

EM–982GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

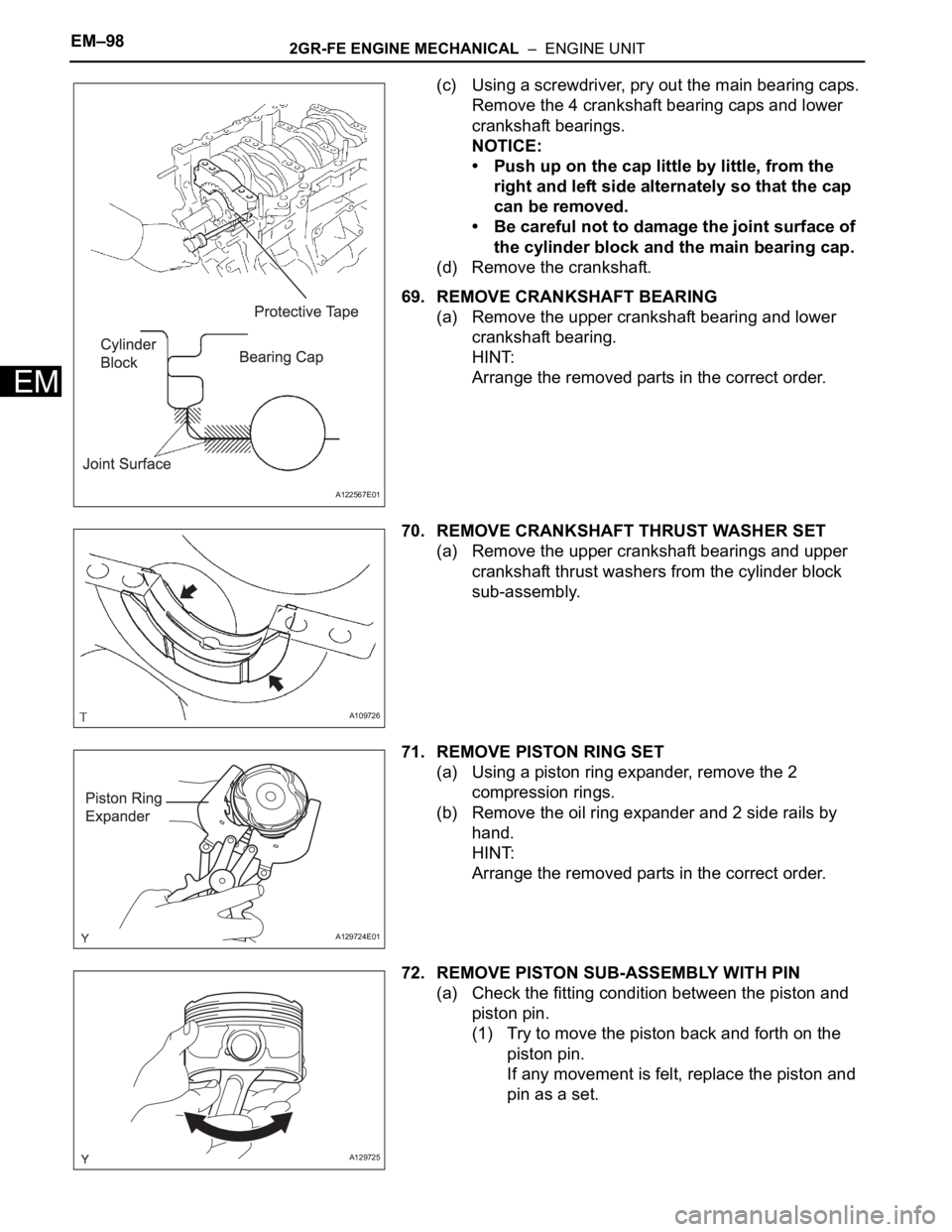

(c) Using a screwdriver, pry out the main bearing caps.

Remove the 4 crankshaft bearing caps and lower

crankshaft bearings.

NOTICE:

• Push up on the cap little by little, from the

right and left side alternately so that the cap

can be removed.

• Be careful not to damage the joint surface of

the cylinder block and the main bearing cap.

(d) Remove the crankshaft.

69. REMOVE CRANKSHAFT BEARING

(a) Remove the upper crankshaft bearing and lower

crankshaft bearing.

HINT:

Arrange the removed parts in the correct order.

70. REMOVE CRANKSHAFT THRUST WASHER SET

(a) Remove the upper crankshaft bearings and upper

crankshaft thrust washers from the cylinder block

sub-assembly.

71. REMOVE PISTON RING SET

(a) Using a piston ring expander, remove the 2

compression rings.

(b) Remove the oil ring expander and 2 side rails by

hand.

HINT:

Arrange the removed parts in the correct order.

72. REMOVE PISTON SUB-ASSEMBLY WITH PIN

(a) Check the fitting condition between the piston and

piston pin.

(1) Try to move the piston back and forth on the

piston pin.

If any movement is felt, replace the piston and

pin as a set.

A122567E01

A109726

A129724E01

A129725

Page 905 of 3000

EM–1002GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

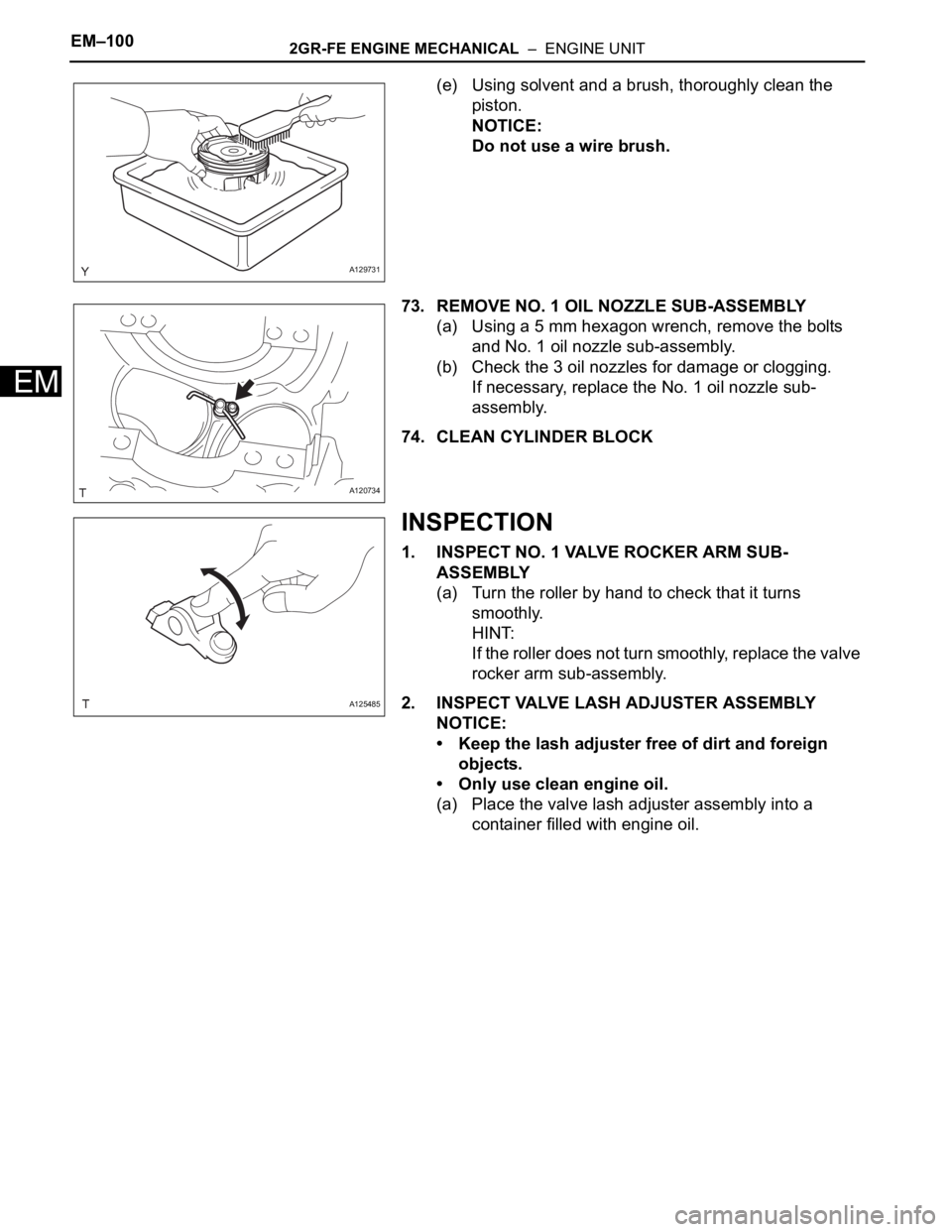

(e) Using solvent and a brush, thoroughly clean the

piston.

NOTICE:

Do not use a wire brush.

73. REMOVE NO. 1 OIL NOZZLE SUB-ASSEMBLY

(a) Using a 5 mm hexagon wrench, remove the bolts

and No. 1 oil nozzle sub-assembly.

(b) Check the 3 oil nozzles for damage or clogging.

If necessary, replace the No. 1 oil nozzle sub-

assembly.

74. CLEAN CYLINDER BLOCK

INSPECTION

1. INSPECT NO. 1 VALVE ROCKER ARM SUB-

ASSEMBLY

(a) Turn the roller by hand to check that it turns

smoothly.

HINT:

If the roller does not turn smoothly, replace the valve

rocker arm sub-assembly.

2. INSPECT VALVE LASH ADJUSTER ASSEMBLY

NOTICE:

• Keep the lash adjuster free of dirt and foreign

objects.

• Only use clean engine oil.

(a) Place the valve lash adjuster assembly into a

container filled with engine oil.

A129731

A120734

A125485

Page 906 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–101

EM

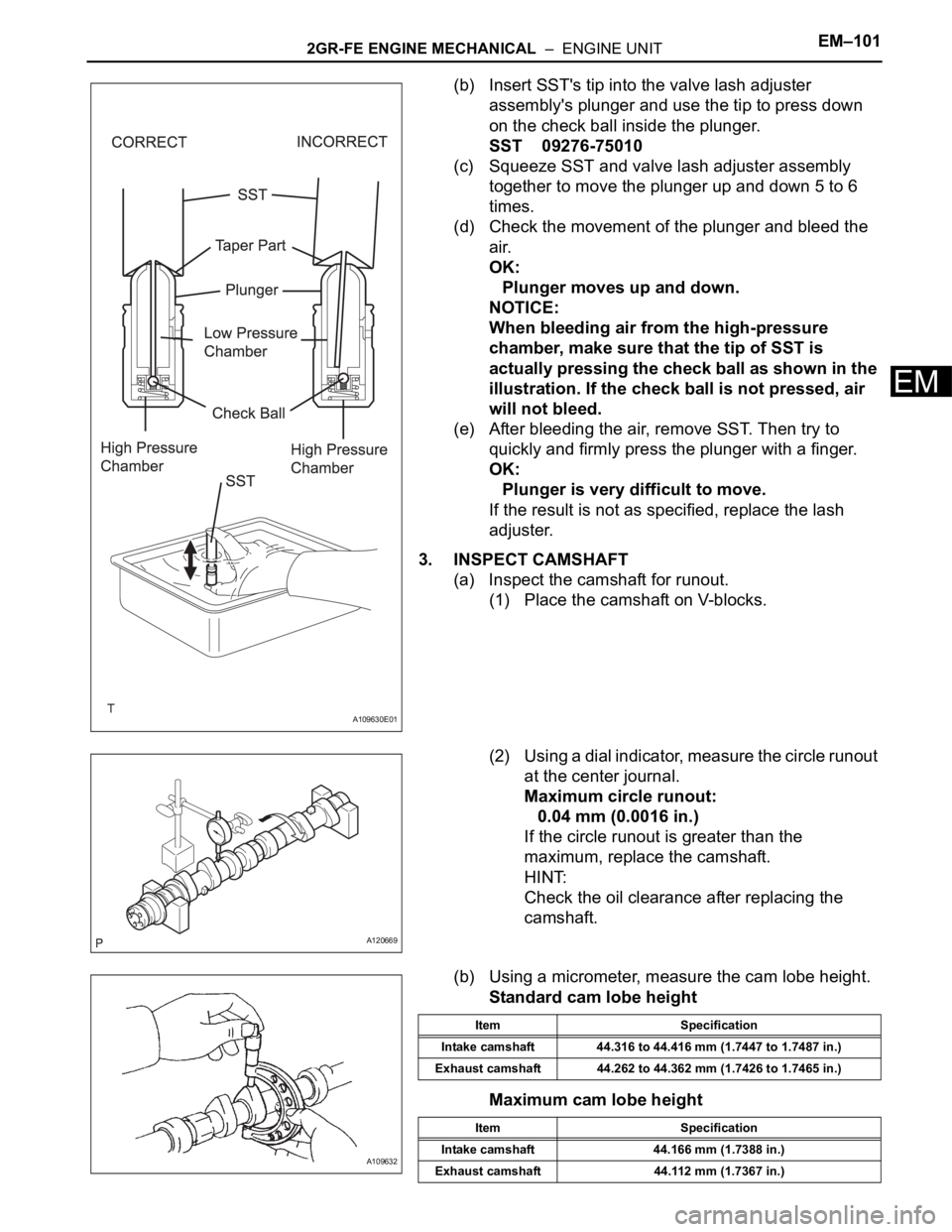

(b) Insert SST's tip into the valve lash adjuster

assembly's plunger and use the tip to press down

on the check ball inside the plunger.

SST 09276-75010

(c) Squeeze SST and valve lash adjuster assembly

together to move the plunger up and down 5 to 6

times.

(d) Check the movement of the plunger and bleed the

air.

OK:

Plunger moves up and down.

NOTICE:

When bleeding air from the high-pressure

chamber, make sure that the tip of SST is

actually pressing the check ball as shown in the

illustration. If the check ball is not pressed, air

will not bleed.

(e) After bleeding the air, remove SST. Then try to

quickly and firmly press the plunger with a finger.

OK:

Plunger is very difficult to move.

If the result is not as specified, replace the lash

adjuster.

3. INSPECT CAMSHAFT

(a) Inspect the camshaft for runout.

(1) Place the camshaft on V-blocks.

(2) Using a dial indicator, measure the circle runout

at the center journal.

Maximum circle runout:

0.04 mm (0.0016 in.)

If the circle runout is greater than the

maximum, replace the camshaft.

HINT:

Check the oil clearance after replacing the

camshaft.

(b) Using a micrometer, measure the cam lobe height.

Standard cam lobe height

Maximum cam lobe height

A109630E01

A120669

A109632

Item Specification

Intake camshaft 44.316 to 44.416 mm (1.7447 to 1.7487 in.)

Exhaust camshaft 44.262 to 44.362 mm (1.7426 to 1.7465 in.)

Item Specification

Intake camshaft 44.166 mm (1.7388 in.)

Exhaust camshaft 44.112 mm (1.7367 in.)