oil TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 777 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–15

ES

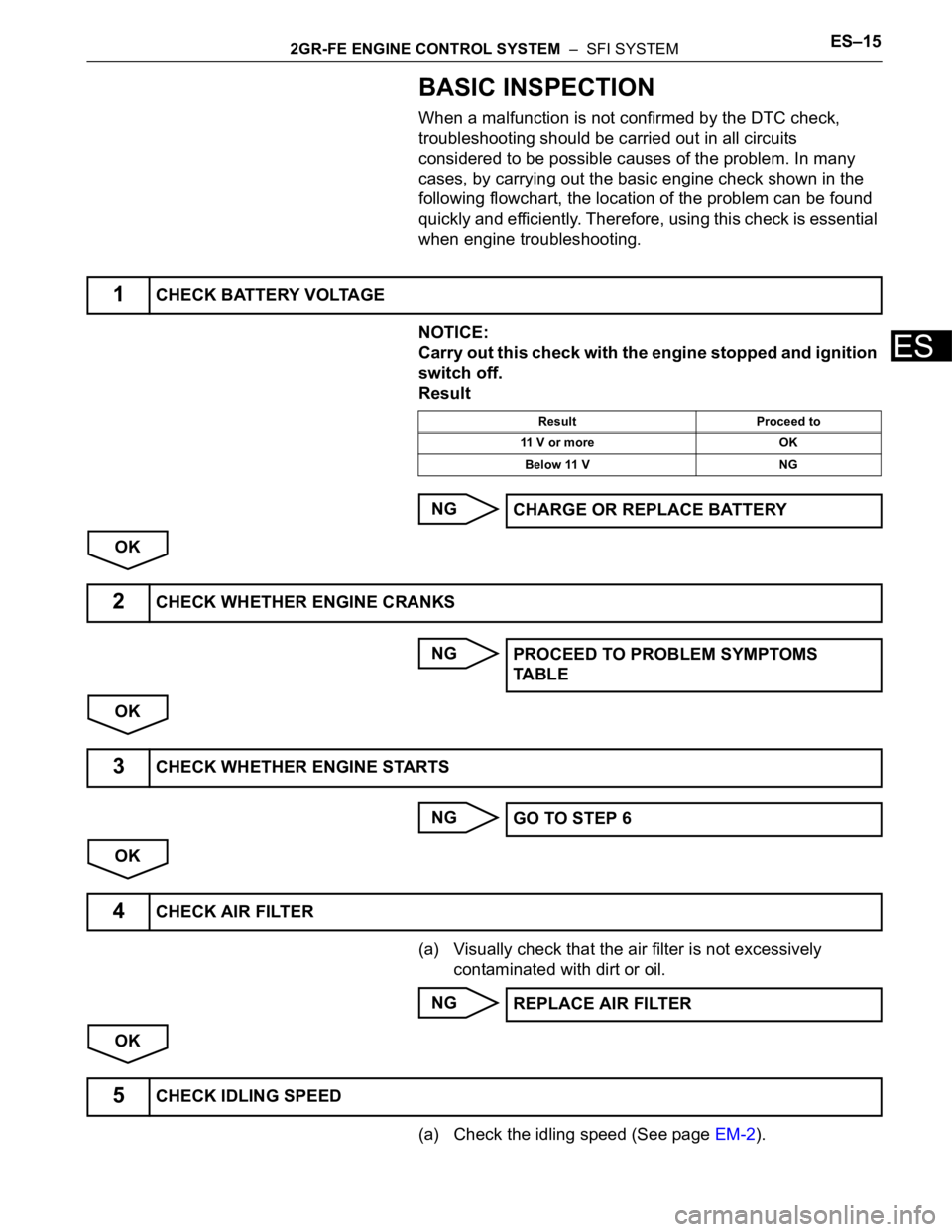

BASIC INSPECTION

When a malfunction is not confirmed by the DTC check,

troubleshooting should be carried out in all circuits

considered to be possible causes of the problem. In many

cases, by carrying out the basic engine check shown in the

following flowchart, the location of the problem can be found

quickly and efficiently. Therefore, using this check is essential

when engine troubleshooting.

NOTICE:

Carry out this check with the engine stopped and ignition

switch off.

Result

NG

OK

NG

OK

NG

OK

(a) Visually check that the air filter is not excessively

contaminated with dirt or oil.

NG

OK

(a) Check the idling speed (See page EM-2).

1CHECK BATTERY VOLTAGE

Result Proceed to

11 V or more OK

Below 11 V NG

CHARGE OR REPLACE BATTERY

2CHECK WHETHER ENGINE CRANKS

PROCEED TO PROBLEM SYMPTOMS

TA B L E

3CHECK WHETHER ENGINE STARTS

GO TO STEP 6

4CHECK AIR FILTER

REPLACE AIR FILTER

5CHECK IDLING SPEED

Page 779 of 3000

ES–4862GR-FE ENGINE CONTROL SYSTEM – CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY

ES

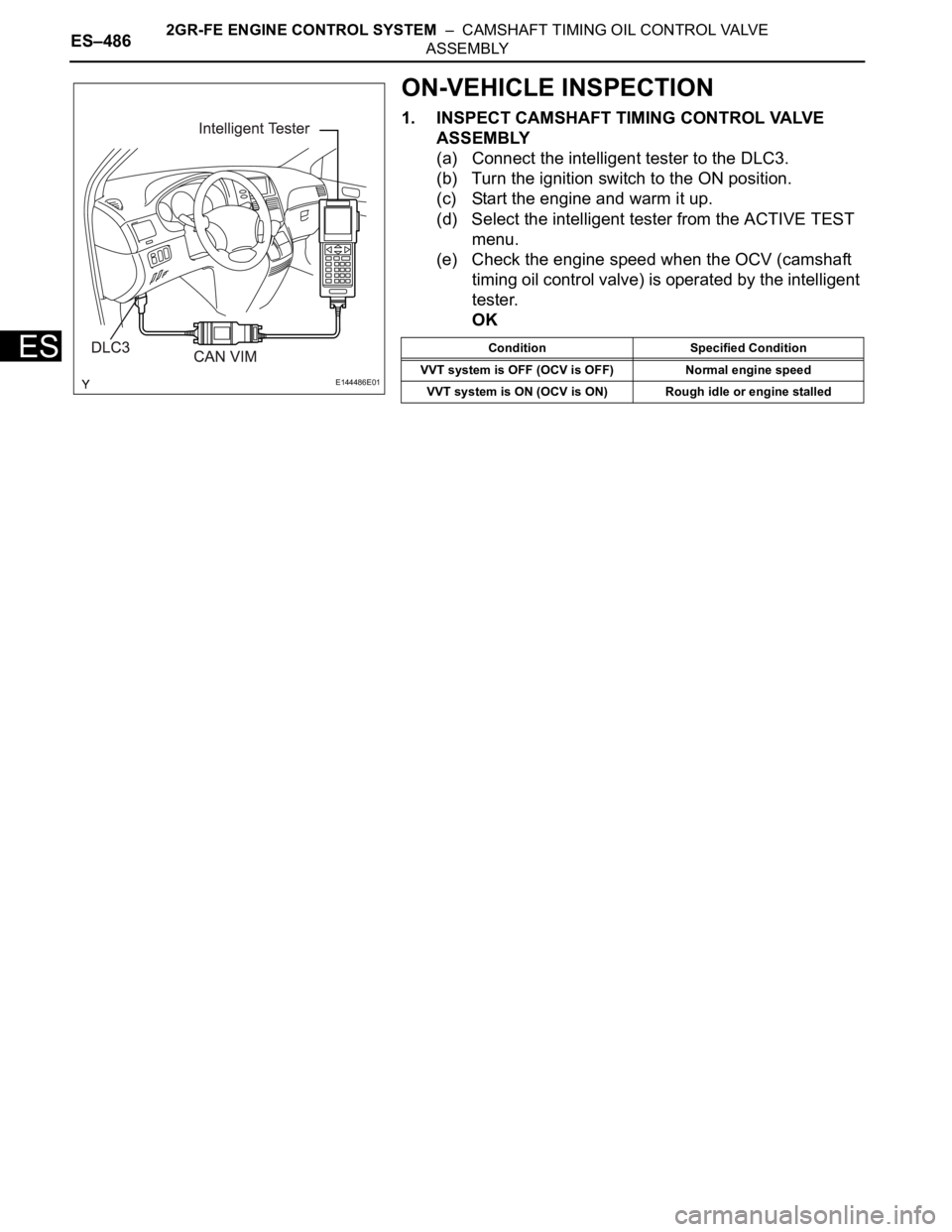

ON-VEHICLE INSPECTION

1. INSPECT CAMSHAFT TIMING CONTROL VALVE

ASSEMBLY

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Start the engine and warm it up.

(d) Select the intelligent tester from the ACTIVE TEST

menu.

(e) Check the engine speed when the OCV (camshaft

timing oil control valve) is operated by the intelligent

tester.

OK

E144486E01

Condition Specified Condition

VVT system is OFF (OCV is OFF) Normal engine speed

VVT system is ON (OCV is ON) Rough idle or engine stalled

Page 780 of 3000

2GR-FE ENGINE CONTROL SYSTEM – CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLYES–487

ES

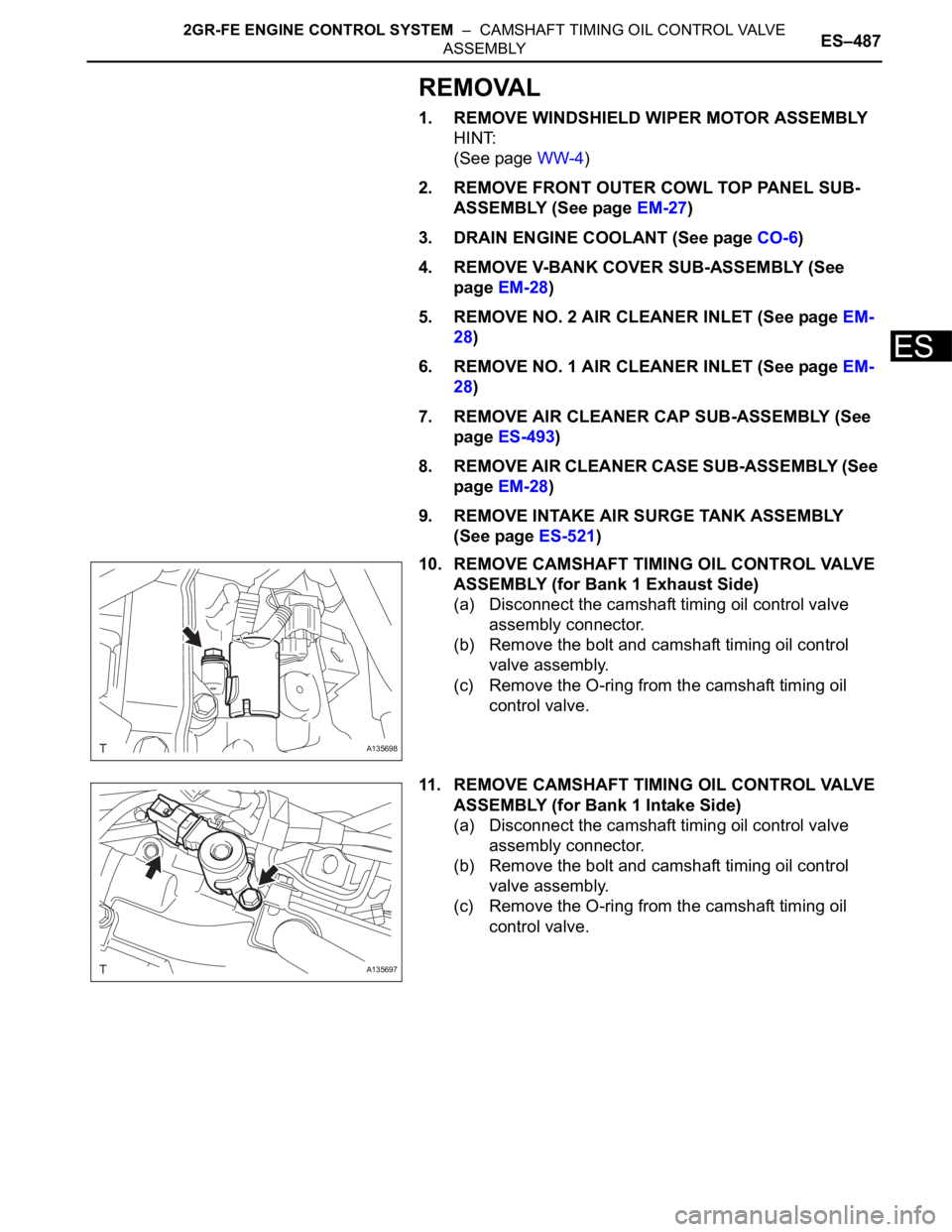

REMOVAL

1. REMOVE WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-4)

2. REMOVE FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-27)

3. DRAIN ENGINE COOLANT (See page CO-6)

4. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

5. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

6. REMOVE NO. 1 AIR CLEANER INLET (See page EM-

28)

7. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-493)

8. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-28)

9. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

(See page ES-521)

10. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY (for Bank 1 Exhaust Side)

(a) Disconnect the camshaft timing oil control valve

assembly connector.

(b) Remove the bolt and camshaft timing oil control

valve assembly.

(c) Remove the O-ring from the camshaft timing oil

control valve.

11. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY (for Bank 1 Intake Side)

(a) Disconnect the camshaft timing oil control valve

assembly connector.

(b) Remove the bolt and camshaft timing oil control

valve assembly.

(c) Remove the O-ring from the camshaft timing oil

control valve.

A135698

A135697

Page 781 of 3000

ES–4882GR-FE ENGINE CONTROL SYSTEM – CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY

ES

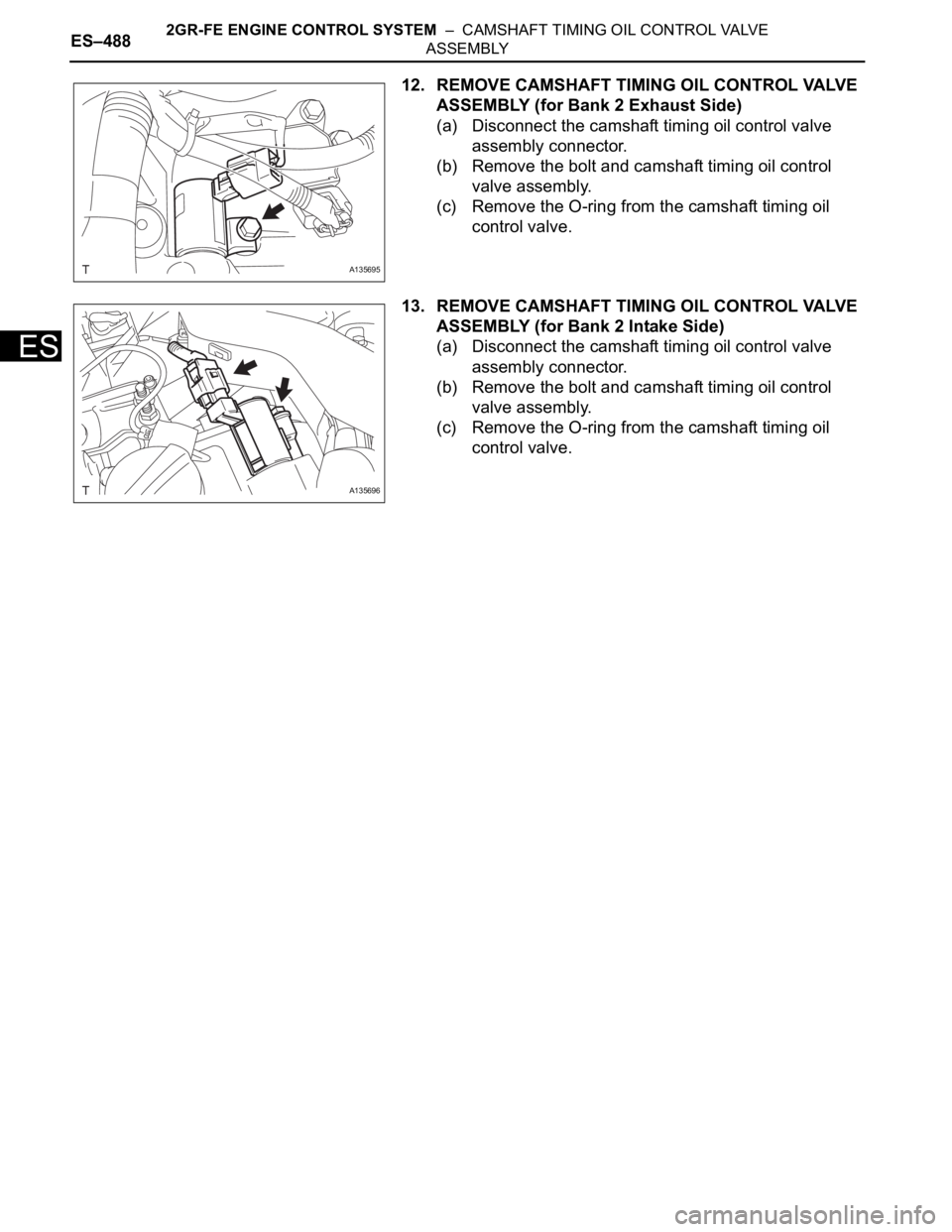

12. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY (for Bank 2 Exhaust Side)

(a) Disconnect the camshaft timing oil control valve

assembly connector.

(b) Remove the bolt and camshaft timing oil control

valve assembly.

(c) Remove the O-ring from the camshaft timing oil

control valve.

13. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY (for Bank 2 Intake Side)

(a) Disconnect the camshaft timing oil control valve

assembly connector.

(b) Remove the bolt and camshaft timing oil control

valve assembly.

(c) Remove the O-ring from the camshaft timing oil

control valve.

A135695

A135696

Page 815 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–35

ES

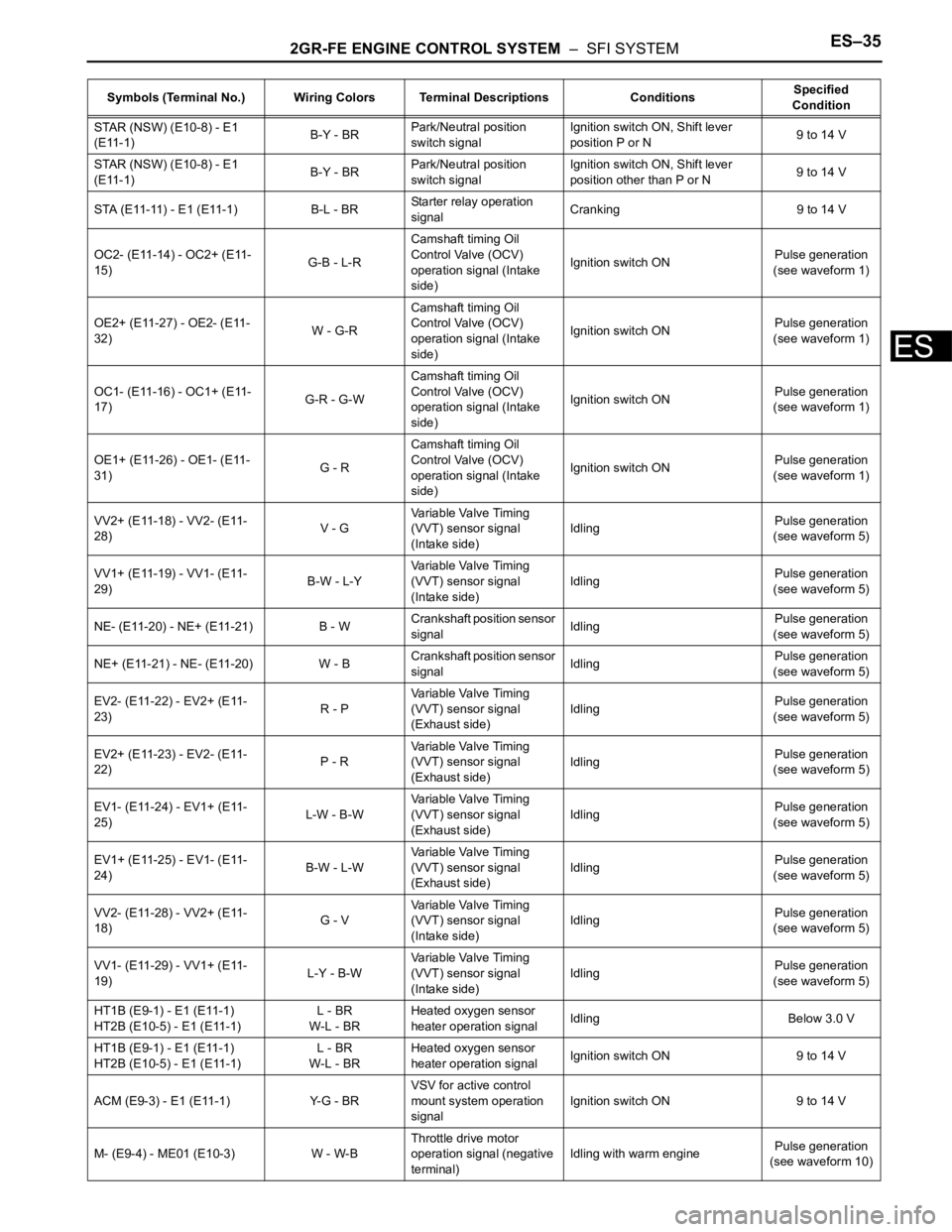

STAR (NSW) (E10-8) - E1

(E11-1)B-Y - BRPark/Neutral position

switch signalIgnition switch ON, Shift lever

position P or N9 to 14 V

STAR (NSW) (E10-8) - E1

(E11-1)B-Y - BRPark/Neutral position

switch signalIgnition switch ON, Shift lever

position other than P or N9 to 14 V

STA (E11-11) - E1 (E11-1) B-L - BRStarter relay operation

signalCranking 9 to 14 V

OC2- (E11-14) - OC2+ (E11-

15)G-B - L-RCamshaft timing Oil

Control Valve (OCV)

operation signal (Intake

side)Ignition switch ONPulse generation

(see waveform 1)

OE2+ (E11-27) - OE2- (E11-

32)W - G-RCamshaft timing Oil

Control Valve (OCV)

operation signal (Intake

side)Ignition switch ONPulse generation

(see waveform 1)

OC1- (E11-16) - OC1+ (E11-

17)G-R - G-WCamshaft timing Oil

Control Valve (OCV)

operation signal (Intake

side)Ignition switch ONPulse generation

(see waveform 1)

OE1+ (E11-26) - OE1- (E11-

31)G - RCamshaft timing Oil

Control Valve (OCV)

operation signal (Intake

side)Ignition switch ONPulse generation

(see waveform 1)

VV2+ (E11-18) - VV2- (E11-

28)V - GVariable Valve Timing

(VVT) sensor signal

(Intake side)IdlingPulse generation

(see waveform 5)

VV1+ (E11-19) - VV1- (E11-

29)B-W - L-YVariable Valve Timing

(VVT) sensor signal

(Intake side)IdlingPulse generation

(see waveform 5)

NE- (E11-20) - NE+ (E11-21) B - WCrankshaft position sensor

signalIdlingPulse generation

(see waveform 5)

NE+ (E11-21) - NE- (E11-20) W - BCrankshaft position sensor

signalIdlingPulse generation

(see waveform 5)

EV2- (E11-22) - EV2+ (E11-

23)R - PVariable Valve Timing

(VVT) sensor signal

(Exhaust side)IdlingPulse generation

(see waveform 5)

EV2+ (E11-23) - EV2- (E11-

22)P - RVariable Valve Timing

(VVT) sensor signal

(Exhaust side)IdlingPulse generation

(see waveform 5)

EV1- (E11-24) - EV1+ (E11-

25)L-W - B-WVariable Valve Timing

(VVT) sensor signal

(Exhaust side)IdlingPulse generation

(see waveform 5)

EV1+ (E11-25) - EV1- (E11-

24)B-W - L-WVariable Valve Timing

(VVT) sensor signal

(Exhaust side)IdlingPulse generation

(see waveform 5)

VV2- (E11-28) - VV2+ (E11-

18)G - VVariable Valve Timing

(VVT) sensor signal

(Intake side)IdlingPulse generation

(see waveform 5)

VV1- (E11-29) - VV1+ (E11-

19)L-Y - B-WVariable Valve Timing

(VVT) sensor signal

(Intake side)IdlingPulse generation

(see waveform 5)

HT1B (E9-1) - E1 (E11-1)

HT2B (E10-5) - E1 (E11-1)L - BR

W-L - BRHeated oxygen sensor

heater operation signalIdling Below 3.0 V

HT1B (E9-1) - E1 (E11-1)

HT2B (E10-5) - E1 (E11-1)L - BR

W-L - BRHeated oxygen sensor

heater operation signalIgnition switch ON 9 to 14 V

ACM (E9-3) - E1 (E11-1) Y-G - BRVSV for active control

mount system operation

signalIgnition switch ON 9 to 14 V

M- (E9-4) - ME01 (E10-3) W - W-BThrottle drive motor

operation signal (negative

terminal)Idling with warm enginePulse generation

(see waveform 10) Symbols (Terminal No.) Wiring Colors Terminal Descriptions ConditionsSpecified

Condition

Page 816 of 3000

ES–362GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

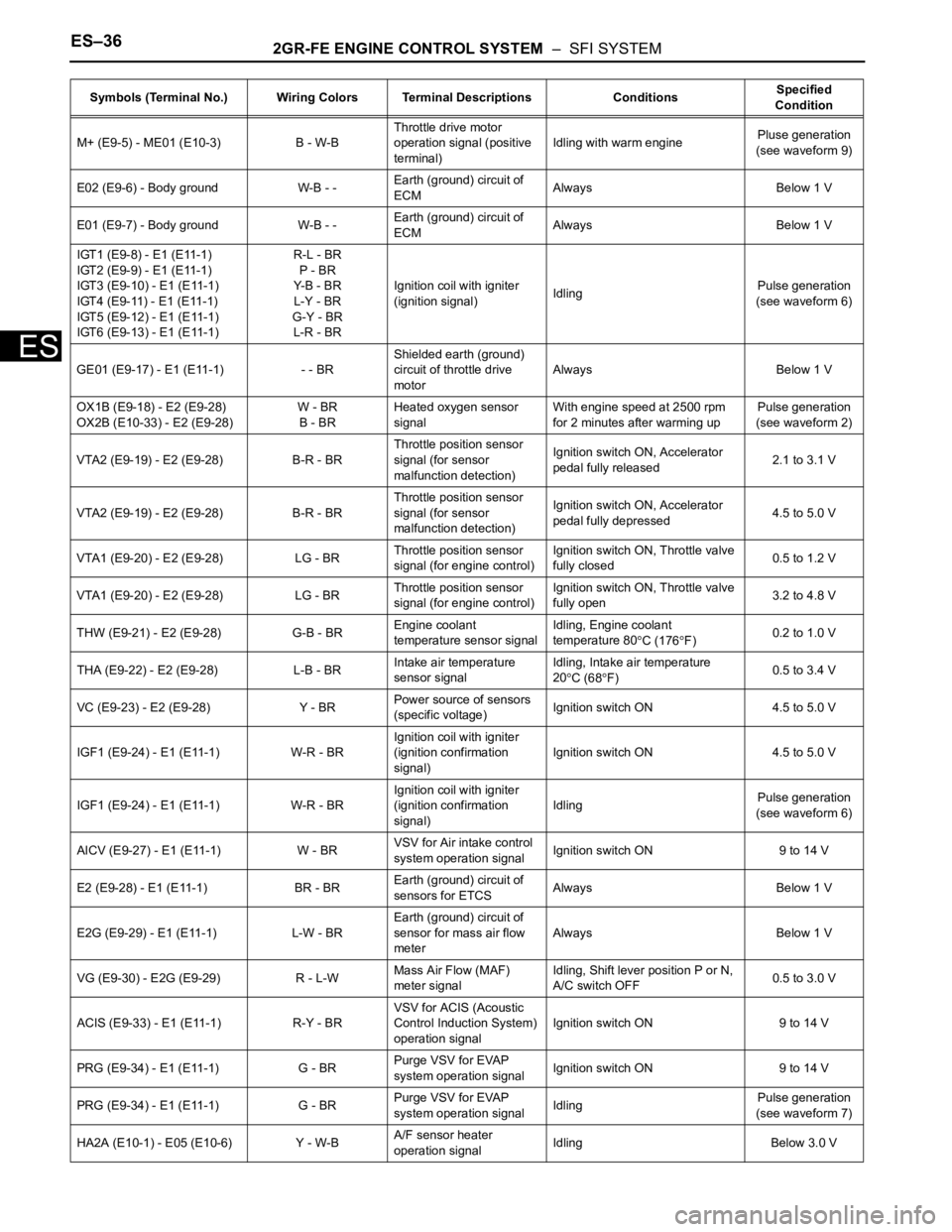

M+ (E9-5) - ME01 (E10-3) B - W-BThrottle drive motor

operation signal (positive

terminal)Idling with warm enginePluse generation

(see waveform 9)

E02 (E9-6) - Body ground W-B - -Earth (ground) circuit of

ECMAlways Below 1 V

E01 (E9-7) - Body ground W-B - -Earth (ground) circuit of

ECMAlways Below 1 V

IGT1 (E9-8) - E1 (E11-1)

IGT2 (E9-9) - E1 (E11-1)

IGT3 (E9-10) - E1 (E11-1)

IGT4 (E9-11) - E1 (E11-1)

IGT5 (E9-12) - E1 (E11-1)

IGT6 (E9-13) - E1 (E11-1)R-L - BR

P - BR

Y- B - B R

L-Y - BR

G-Y - BR

L-R - BRIgnition coil with igniter

(ignition signal)IdlingPulse generation

(see waveform 6)

GE01 (E9-17) - E1 (E11-1) - - BRShielded earth (ground)

circuit of throttle drive

motorAlways Below 1 V

OX1B (E9-18) - E2 (E9-28)

OX2B (E10-33) - E2 (E9-28)W - BR

B - BRHeated oxygen sensor

signalWith engine speed at 2500 rpm

for 2 minutes after warming upPulse generation

(see waveform 2)

VTA2 (E9-19) - E2 (E9-28) B-R - BRThrottle position sensor

signal (for sensor

malfunction detection)Ignition switch ON, Accelerator

pedal fully released2.1 to 3.1 V

VTA2 (E9-19) - E2 (E9-28) B-R - BRThrottle position sensor

signal (for sensor

malfunction detection)Ignition switch ON, Accelerator

pedal fully depressed4.5 to 5.0 V

VTA1 (E9-20) - E2 (E9-28) LG - BRThrottle position sensor

signal (for engine control)Ignition switch ON, Throttle valve

fully closed0.5 to 1.2 V

VTA1 (E9-20) - E2 (E9-28) LG - BRThrottle position sensor

signal (for engine control)Ignition switch ON, Throttle valve

fully open3.2 to 4.8 V

THW (E9-21) - E2 (E9-28) G-B - BREngine coolant

temperature sensor signalIdling, Engine coolant

temperature 80

C (176F)0.2 to 1.0 V

THA (E9-22) - E2 (E9-28) L-B - BRIntake air temperature

sensor signalIdling, Intake air temperature

20

C (68F)0.5 to 3.4 V

VC (E9-23) - E2 (E9-28) Y - BRPower source of sensors

(specific voltage)Ignition switch ON 4.5 to 5.0 V

IGF1 (E9-24) - E1 (E11-1) W-R - BRIgnition coil with igniter

(ignition confirmation

signal)Ignition switch ON 4.5 to 5.0 V

IGF1 (E9-24) - E1 (E11-1) W-R - BRIgnition coil with igniter

(ignition confirmation

signal)IdlingPulse generation

(see waveform 6)

AICV (E9-27) - E1 (E11-1) W - BRVSV for Air intake control

system operation signalIgnition switch ON 9 to 14 V

E2 (E9-28) - E1 (E11-1) BR - BREarth (ground) circuit of

sensors for ETCSAlways Below 1 V

E2G (E9-29) - E1 (E11-1) L-W - BREarth (ground) circuit of

sensor for mass air flow

meterAlways Below 1 V

VG (E9-30) - E2G (E9-29) R - L-WMass Air Flow (MAF)

meter signalIdling, Shift lever position P or N,

A/C switch OFF0.5 to 3.0 V

ACIS (E9-33) - E1 (E11-1) R-Y - BRVSV for ACIS (Acoustic

Control Induction System)

operation signalIgnition switch ON 9 to 14 V

PRG (E9-34) - E1 (E11-1) G - BRPurge VSV for EVAP

system operation signalIgnition switch ON 9 to 14 V

PRG (E9-34) - E1 (E11-1) G - BRPurge VSV for EVAP

system operation signalIdlingPulse generation

(see waveform 7)

HA2A (E10-1) - E05 (E10-6) Y - W-BA/F sensor heater

operation signalIdling Below 3.0 V Symbols (Terminal No.) Wiring Colors Terminal Descriptions ConditionsSpecified

Condition

Page 817 of 3000

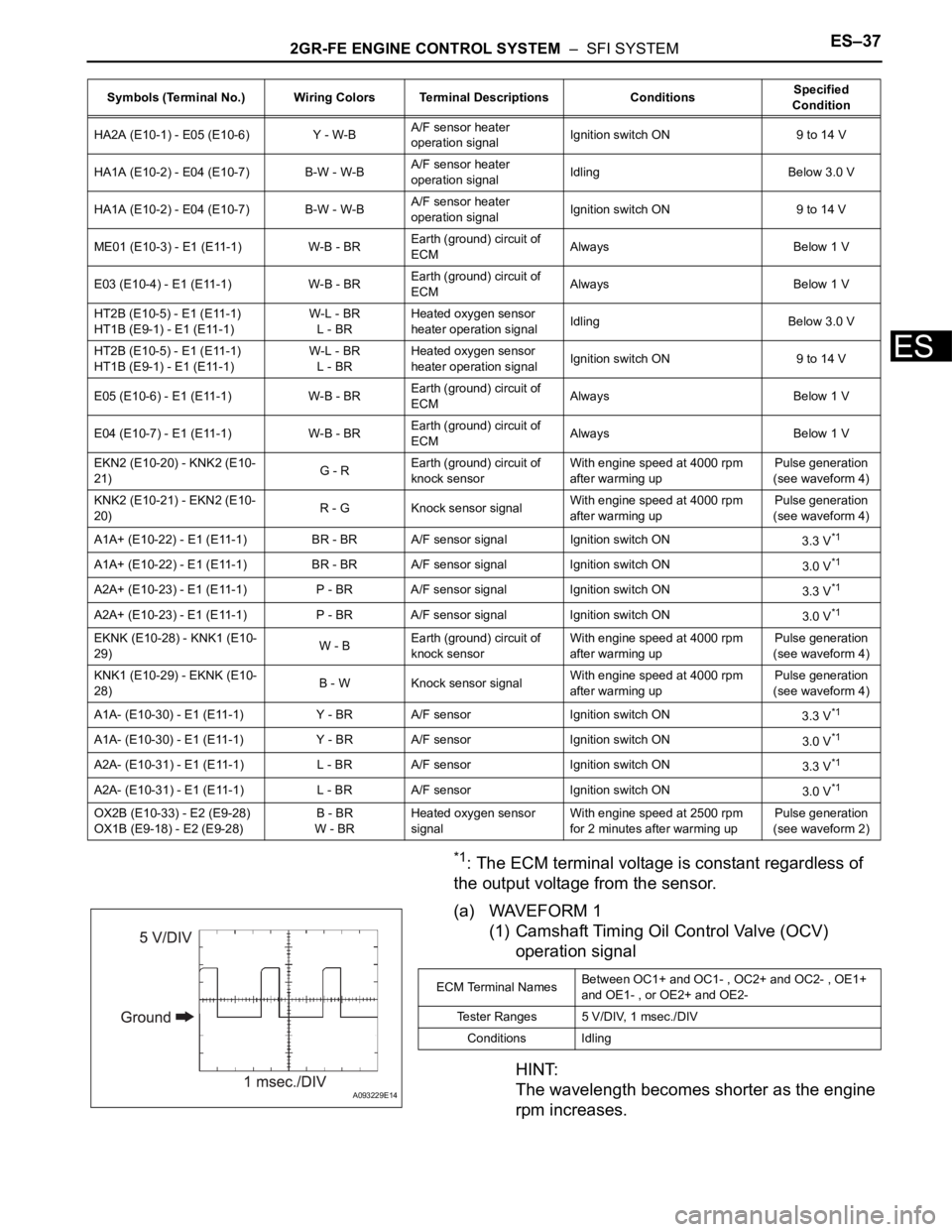

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–37

ES

*1: The ECM terminal voltage is constant regardless of

the output voltage from the sensor.

(a) WAVEFORM 1

(1) Camshaft Timing Oil Control Valve (OCV)

operation signal

HINT:

The wavelength becomes shorter as the engine

rpm increases.

HA2A (E10-1) - E05 (E10-6) Y - W-BA/F sensor heater

operation signalIgnition switch ON 9 to 14 V

HA1A (E10-2) - E04 (E10-7) B-W - W-BA/F sensor heater

operation signalIdling Below 3.0 V

HA1A (E10-2) - E04 (E10-7) B-W - W-BA/F sensor heater

operation signalIgnition switch ON 9 to 14 V

ME01 (E10-3) - E1 (E11-1) W-B - BREarth (ground) circuit of

ECMAlways Below 1 V

E03 (E10-4) - E1 (E11-1) W-B - BREarth (ground) circuit of

ECMAlways Below 1 V

HT2B (E10-5) - E1 (E11-1)

HT1B (E9-1) - E1 (E11-1)W-L - BR

L - BRHeated oxygen sensor

heater operation signalIdling Below 3.0 V

HT2B (E10-5) - E1 (E11-1)

HT1B (E9-1) - E1 (E11-1)W-L - BR

L - BRHeated oxygen sensor

heater operation signalIgnition switch ON 9 to 14 V

E05 (E10-6) - E1 (E11-1) W-B - BREarth (ground) circuit of

ECMAlways Below 1 V

E04 (E10-7) - E1 (E11-1) W-B - BREarth (ground) circuit of

ECMAlways Below 1 V

EKN2 (E10-20) - KNK2 (E10-

21)G - REarth (ground) circuit of

knock sensorWith engine speed at 4000 rpm

after warming upPulse generation

(see waveform 4)

KNK2 (E10-21) - EKN2 (E10-

20)R - G Knock sensor signalWith engine speed at 4000 rpm

after warming upPulse generation

(see waveform 4)

A1A+ (E10-22) - E1 (E11-1) BR - BR A/F sensor signal Ignition switch ON

3.3 V

*1

A1A+ (E10-22) - E1 (E11-1) BR - BR A/F sensor signal Ignition switch ON

3.0 V*1

A2A+ (E10-23) - E1 (E11-1) P - BR A/F sensor signal Ignition switch ON

3.3 V*1

A2A+ (E10-23) - E1 (E11-1) P - BR A/F sensor signal Ignition switch ON

3.0 V*1

EKNK (E10-28) - KNK1 (E10-

29)W - BEarth (ground) circuit of

knock sensorWith engine speed at 4000 rpm

after warming upPulse generation

(see waveform 4)

KNK1 (E10-29) - EKNK (E10-

28)B - W Knock sensor signalWith engine speed at 4000 rpm

after warming upPulse generation

(see waveform 4)

A1A- (E10-30) - E1 (E11-1) Y - BR A/F sensor Ignition switch ON

3.3 V

*1

A1A- (E10-30) - E1 (E11-1) Y - BR A/F sensor Ignition switch ON

3.0 V*1

A2A- (E10-31) - E1 (E11-1) L - BR A/F sensor Ignition switch ON

3.3 V*1

A2A- (E10-31) - E1 (E11-1) L - BR A/F sensor Ignition switch ON

3.0 V*1

OX2B (E10-33) - E2 (E9-28)

OX1B (E9-18) - E2 (E9-28)B - BR

W - BRHeated oxygen sensor

signalWith engine speed at 2500 rpm

for 2 minutes after warming upPulse generation

(see waveform 2) Symbols (Terminal No.) Wiring Colors Terminal Descriptions ConditionsSpecified

Condition

A093229E14

ECM Terminal NamesBetween OC1+ and OC1- , OC2+ and OC2- , OE1+

and OE1- , or OE2+ and OE2-

Tester Ranges 5 V/DIV, 1 msec./DIV

Conditions Idling

Page 829 of 3000

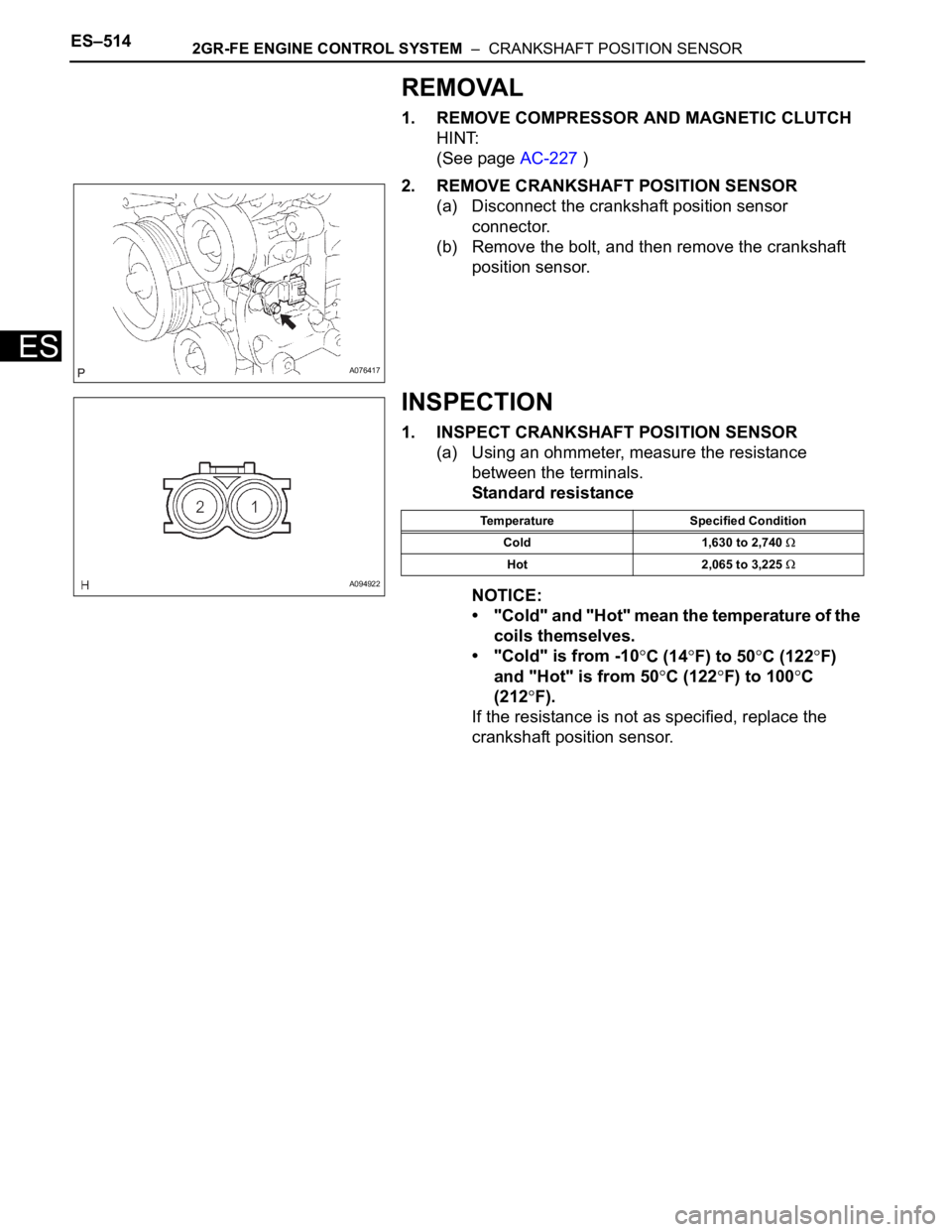

ES–5142GR-FE ENGINE CONTROL SYSTEM – CRANKSHAFT POSITION SENSOR

ES

REMOVAL

1. REMOVE COMPRESSOR AND MAGNETIC CLUTCH

HINT:

(See page AC-227 )

2. REMOVE CRANKSHAFT POSITION SENSOR

(a) Disconnect the crankshaft position sensor

connector.

(b) Remove the bolt, and then remove the crankshaft

position sensor.

INSPECTION

1. INSPECT CRANKSHAFT POSITION SENSOR

(a) Using an ohmmeter, measure the resistance

between the terminals.

Standard resistance

NOTICE:

• "Cold" and "Hot" mean the temperature of the

coils themselves.

• "Cold" is from -10

C (14F) to 50C (122F)

and "Hot" is from 50

C (122F) to 100C

(212

F).

If the resistance is not as specified, replace the

crankshaft position sensor.

A076417

A094922

Temperature Specified Condition

Cold 1,630 to 2,740

Hot 2,065 to 3,225

Page 837 of 3000

![TOYOTA SIENNA 2007 Service Repair Manual ES–5222GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSOR

ES

(g) Using a 5 mm socket hexagon wrench, remove the

4 bolts [G].

(h) Remove the 2 nuts, 2 bolts and intake air surge tank

[H].

(i) Remove th TOYOTA SIENNA 2007 Service Repair Manual ES–5222GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSOR

ES

(g) Using a 5 mm socket hexagon wrench, remove the

4 bolts [G].

(h) Remove the 2 nuts, 2 bolts and intake air surge tank

[H].

(i) Remove th](/img/14/57466/w960_57466-836.png)

ES–5222GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSOR

ES

(g) Using a 5 mm socket hexagon wrench, remove the

4 bolts [G].

(h) Remove the 2 nuts, 2 bolts and intake air surge tank

[H].

(i) Remove the gasket from the intake air surge tank [I].

9. REMOVE FUEL MAIN TUBE SUB-ASSEMBLY (See

page EM-30)

10. REMOVE INTAKE MANIFOLD (See page EM-39)

11. REMOVE KNOCK CONTROL SENSOR

(a) Disconnect the 2 knock sensor connectors.

(b) Remove the 2 bolts and then remove the 2 knock

control sensors.

INSPECTION

1. KNOCK CONTROL SENSOR

(a) Using an ohmmeter, measure the resistance

between the terminals.

Resistance:

120 to 280 k

at 20C (68F)

If the resistance is not specified, replace the knock

control sensor.

INSTALLATION

1. INSTALL KNOCK CONTROL SENSOR

(a) Install the 2 knock control sensors with the 2 bolts

as shown in the illustration.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf)

(b) Connect the 2 knock control sensor connectors.

2. INSTALL INTAKE MANIFOLD (See page EM-49)

3. INSTALL FUEL MAIN TUBE SUB-ASSEMBLY (See

page EM-56)

4. INSTALL INTAKE AIR SURGE TANK

NOTICE:

DO NOT apply oil to the bolts listed below.

A129468E08

A129615

A065174

A132951E01

Tightening PartsTo r q u e

N*m (kgf*cm, ft.*lbf)QTY

Surge Tank and Intake Manifold 18 (184, 13) 4

No. 1 Surge Tank Stay and Surge Tank 21 (214, 15) 1

Throttle Body Bracket and Surge Tank 21 (214, 15) 1

Page 861 of 3000

EM–442GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

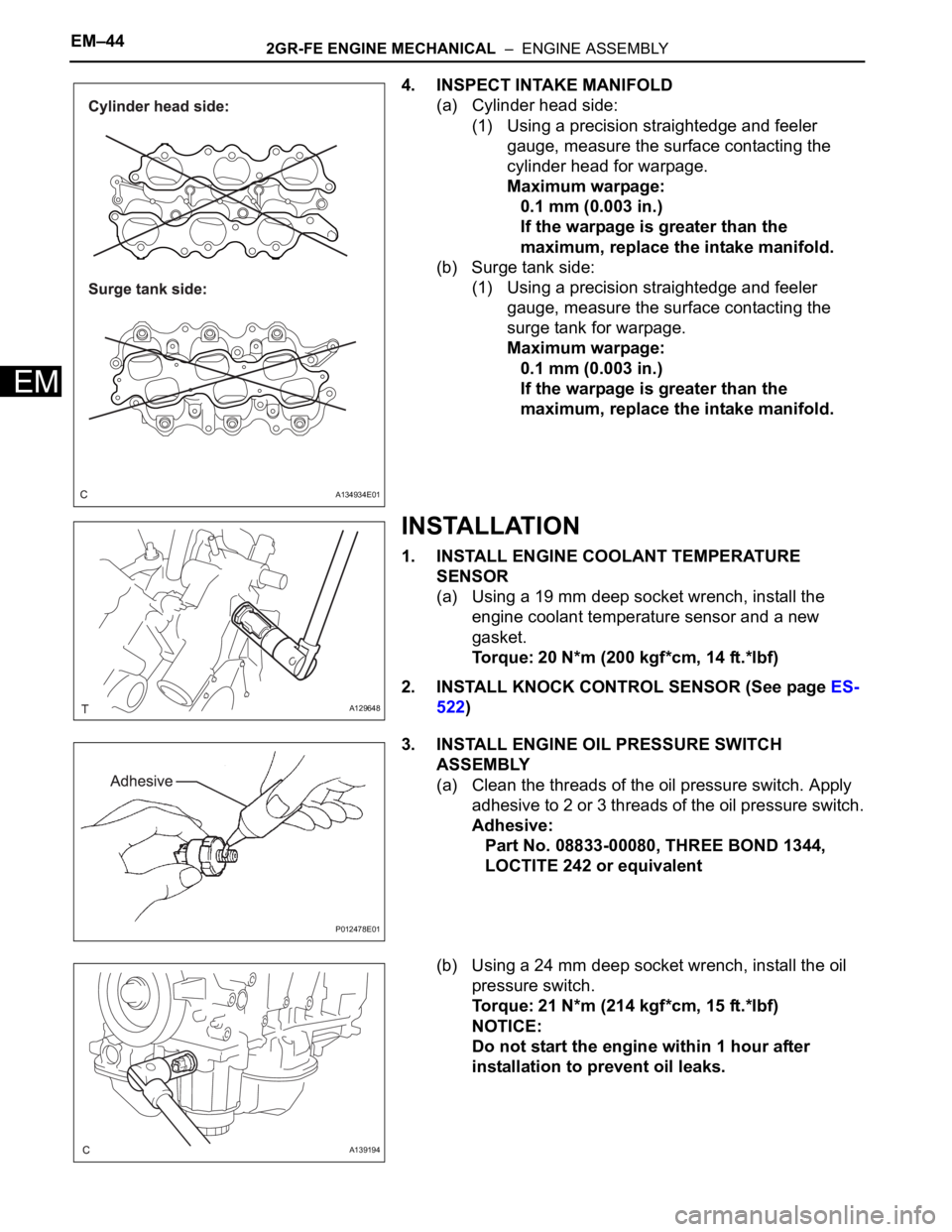

4. INSPECT INTAKE MANIFOLD

(a) Cylinder head side:

(1) Using a precision straightedge and feeler

gauge, measure the surface contacting the

cylinder head for warpage.

Maximum warpage:

0.1 mm (0.003 in.)

If the warpage is greater than the

maximum, replace the intake manifold.

(b) Surge tank side:

(1) Using a precision straightedge and feeler

gauge, measure the surface contacting the

surge tank for warpage.

Maximum warpage:

0.1 mm (0.003 in.)

If the warpage is greater than the

maximum, replace the intake manifold.

INSTALLATION

1. INSTALL ENGINE COOLANT TEMPERATURE

SENSOR

(a) Using a 19 mm deep socket wrench, install the

engine coolant temperature sensor and a new

gasket.

Torque: 20 N*m (200 kgf*cm, 14 ft.*lbf)

2. INSTALL KNOCK CONTROL SENSOR (See page ES-

522)

3. INSTALL ENGINE OIL PRESSURE SWITCH

ASSEMBLY

(a) Clean the threads of the oil pressure switch. Apply

adhesive to 2 or 3 threads of the oil pressure switch.

Adhesive:

Part No. 08833-00080, THREE BOND 1344,

LOCTITE 242 or equivalent

(b) Using a 24 mm deep socket wrench, install the oil

pressure switch.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

NOTICE:

Do not start the engine within 1 hour after

installation to prevent oil leaks.

A134934E01

A129648

P012478E01

A139194