oil TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 907 of 3000

EM–1022GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

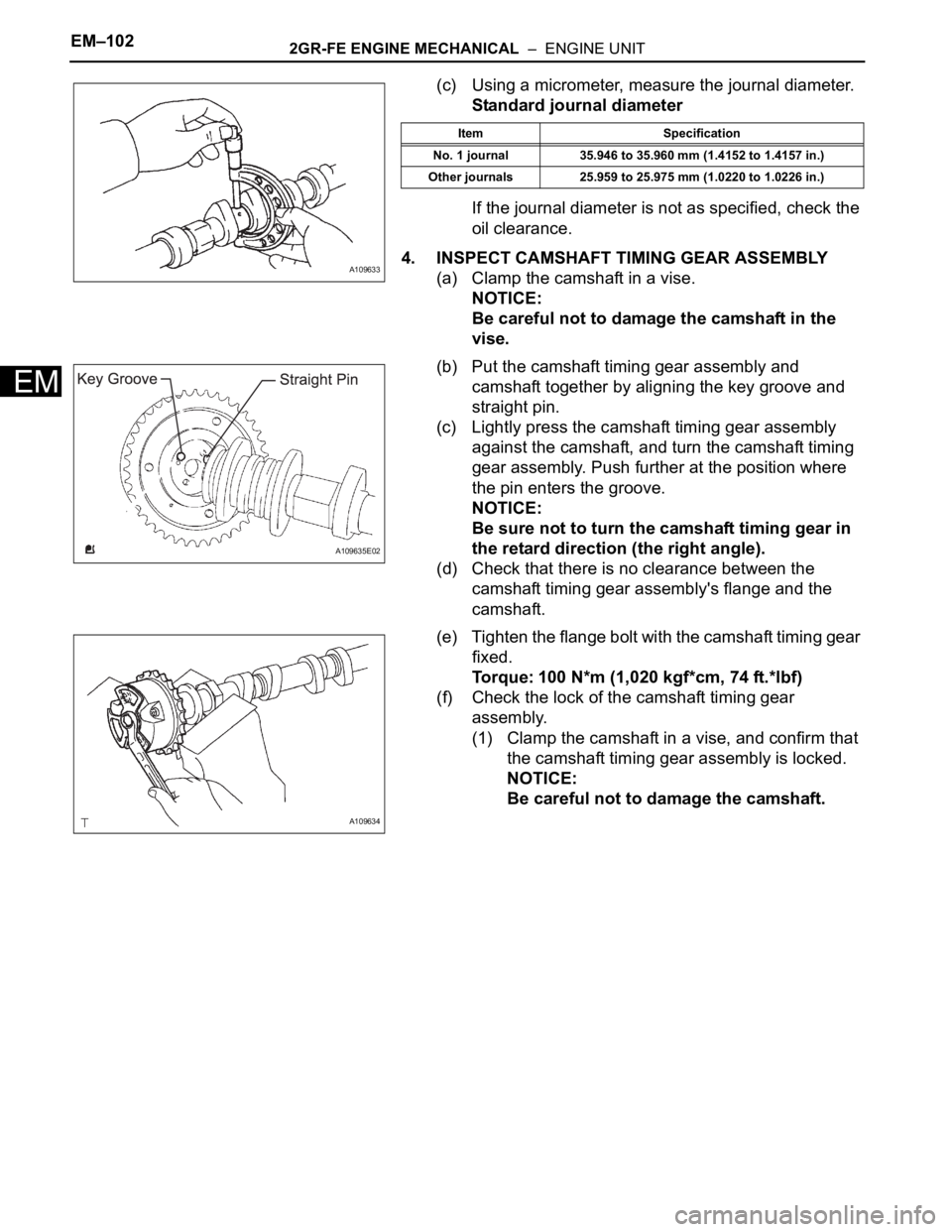

(c) Using a micrometer, measure the journal diameter.

Standard journal diameter

If the journal diameter is not as specified, check the

oil clearance.

4. INSPECT CAMSHAFT TIMING GEAR ASSEMBLY

(a) Clamp the camshaft in a vise.

NOTICE:

Be careful not to damage the camshaft in the

vise.

(b) Put the camshaft timing gear assembly and

camshaft together by aligning the key groove and

straight pin.

(c) Lightly press the camshaft timing gear assembly

against the camshaft, and turn the camshaft timing

gear assembly. Push further at the position where

the pin enters the groove.

NOTICE:

Be sure not to turn the camshaft timing gear in

the retard direction (the right angle).

(d) Check that there is no clearance between the

camshaft timing gear assembly's flange and the

camshaft.

(e) Tighten the flange bolt with the camshaft timing gear

fixed.

Torque: 100 N*m (1,020 kgf*cm, 74 ft.*lbf)

(f) Check the lock of the camshaft timing gear

assembly.

(1) Clamp the camshaft in a vise, and confirm that

the camshaft timing gear assembly is locked.

NOTICE:

Be careful not to damage the camshaft.

A109633

Item Specification

No. 1 journal 35.946 to 35.960 mm (1.4152 to 1.4157 in.)

Other journals 25.959 to 25.975 mm (1.0220 to 1.0226 in.)

A109635E02

A109634

Page 908 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–103

EM

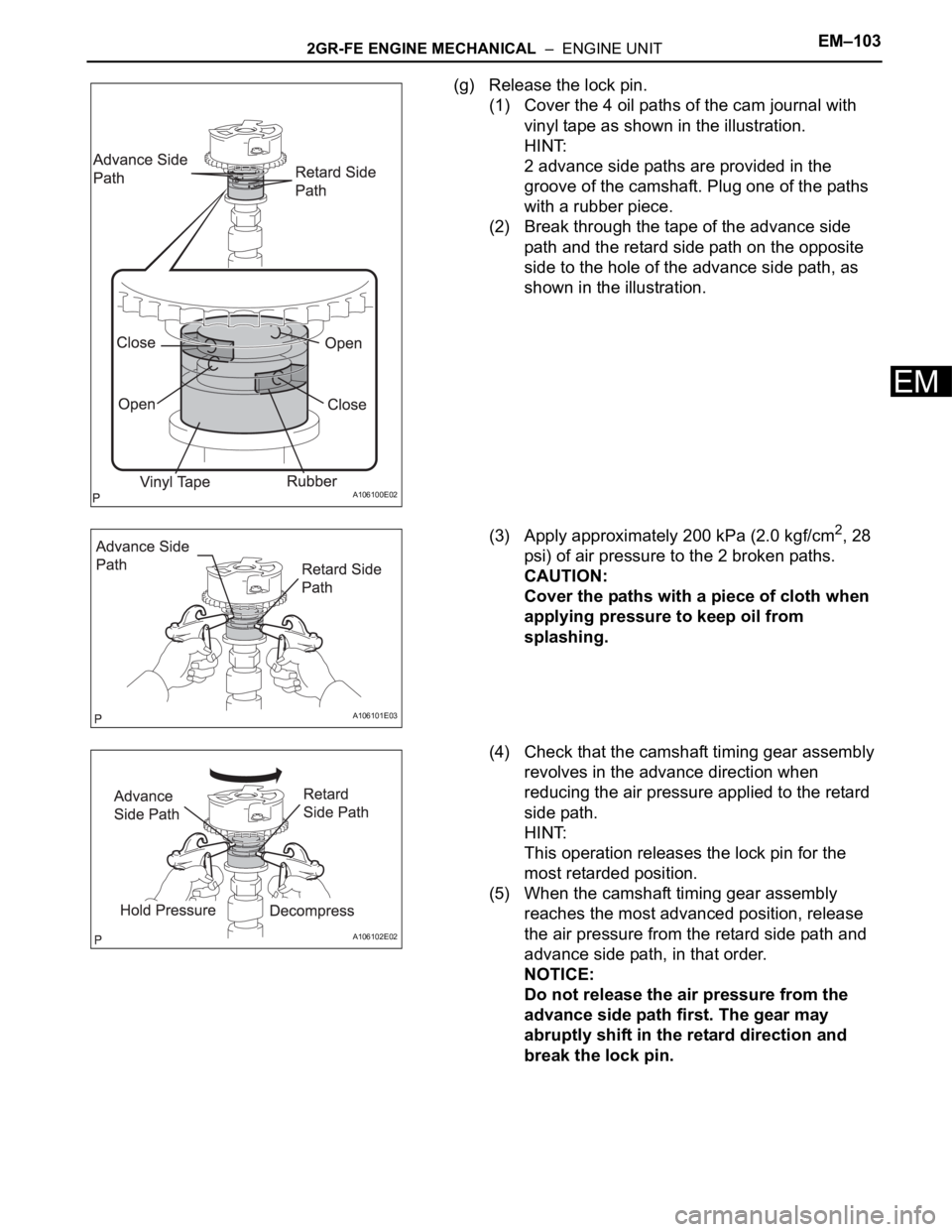

(g) Release the lock pin.

(1) Cover the 4 oil paths of the cam journal with

vinyl tape as shown in the illustration.

HINT:

2 advance side paths are provided in the

groove of the camshaft. Plug one of the paths

with a rubber piece.

(2) Break through the tape of the advance side

path and the retard side path on the opposite

side to the hole of the advance side path, as

shown in the illustration.

(3) Apply approximately 200 kPa (2.0 kgf/cm

2, 28

psi) of air pressure to the 2 broken paths.

CAUTION:

Cover the paths with a piece of cloth when

applying pressure to keep oil from

splashing.

(4) Check that the camshaft timing gear assembly

revolves in the advance direction when

reducing the air pressure applied to the retard

side path.

HINT:

This operation releases the lock pin for the

most retarded position.

(5) When the camshaft timing gear assembly

reaches the most advanced position, release

the air pressure from the retard side path and

advance side path, in that order.

NOTICE:

Do not release the air pressure from the

advance side path first. The gear may

abruptly shift in the retard direction and

break the lock pin.

A106100E02

A106101E03

A106102E02

Page 910 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–105

EM

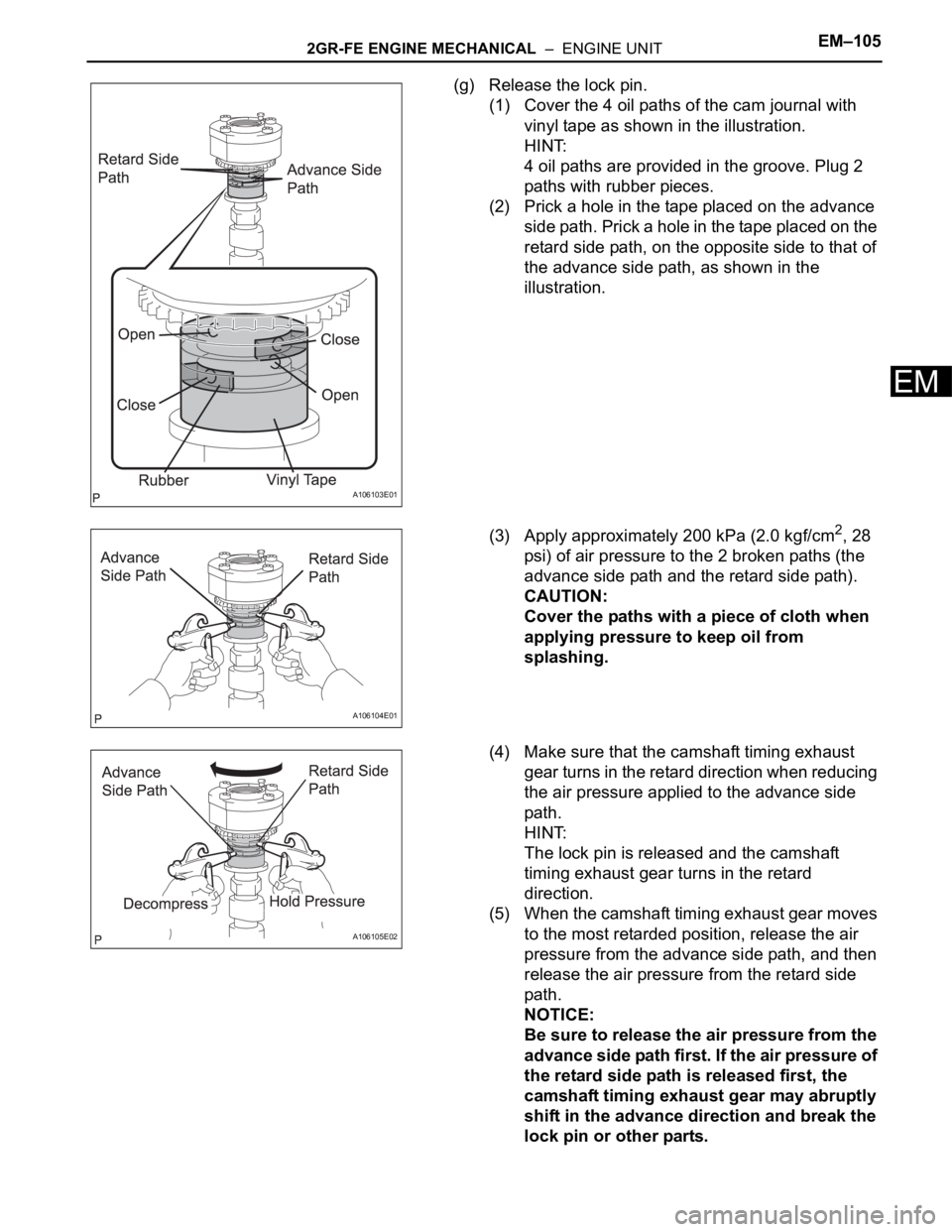

(g) Release the lock pin.

(1) Cover the 4 oil paths of the cam journal with

vinyl tape as shown in the illustration.

HINT:

4 oil paths are provided in the groove. Plug 2

paths with rubber pieces.

(2) Prick a hole in the tape placed on the advance

side path. Prick a hole in the tape placed on the

retard side path, on the opposite side to that of

the advance side path, as shown in the

illustration.

(3) Apply approximately 200 kPa (2.0 kgf/cm

2, 28

psi) of air pressure to the 2 broken paths (the

advance side path and the retard side path).

CAUTION:

Cover the paths with a piece of cloth when

applying pressure to keep oil from

splashing.

(4) Make sure that the camshaft timing exhaust

gear turns in the retard direction when reducing

the air pressure applied to the advance side

path.

HINT:

The lock pin is released and the camshaft

timing exhaust gear turns in the retard

direction.

(5) When the camshaft timing exhaust gear moves

to the most retarded position, release the air

pressure from the advance side path, and then

release the air pressure from the retard side

path.

NOTICE:

Be sure to release the air pressure from the

advance side path first. If the air pressure of

the retard side path is released first, the

camshaft timing exhaust gear may abruptly

shift in the advance direction and break the

lock pin or other parts.

A106103E01

A106104E01

A106105E02

Page 913 of 3000

EM–1082GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

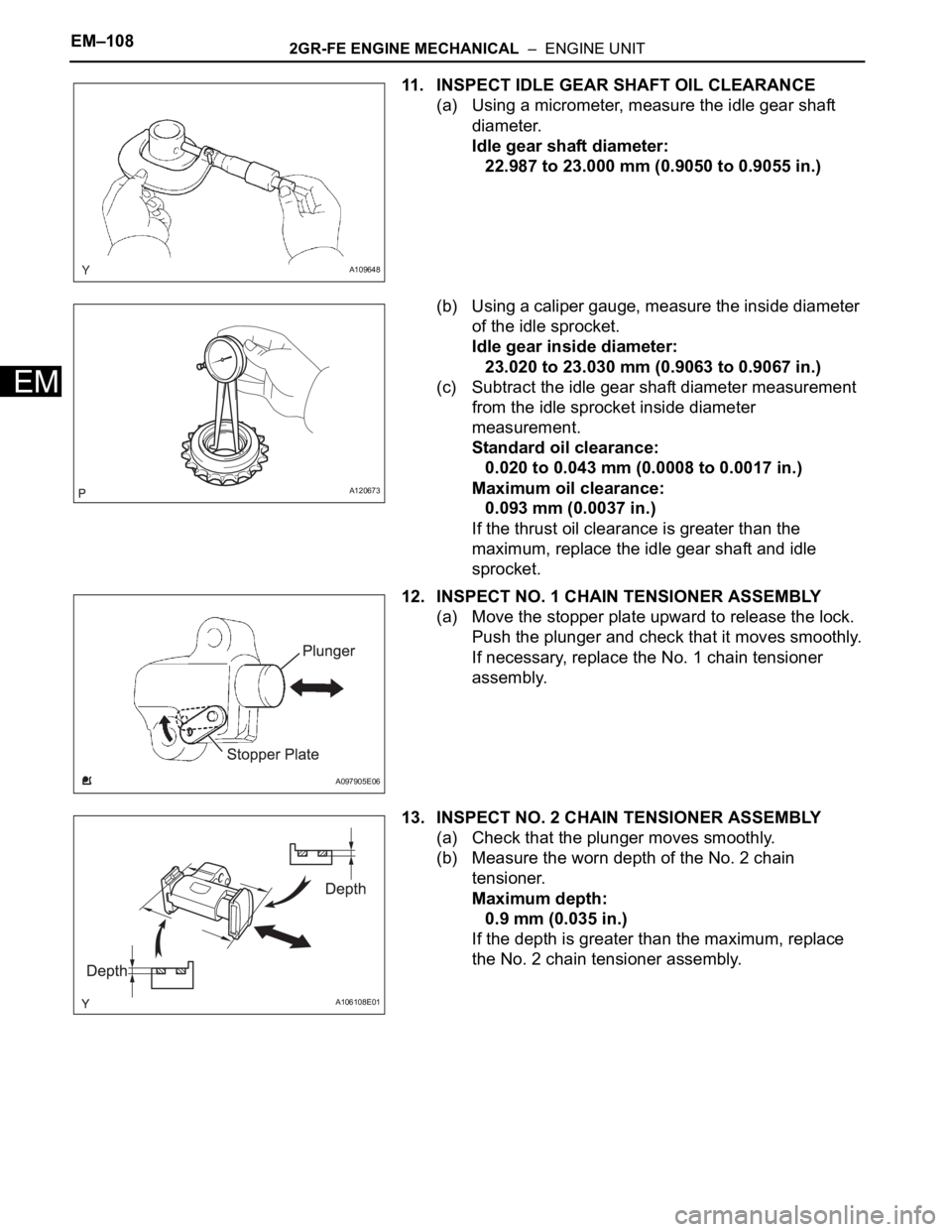

11. INSPECT IDLE GEAR SHAFT OIL CLEARANCE

(a) Using a micrometer, measure the idle gear shaft

diameter.

Idle gear shaft diameter:

22.987 to 23.000 mm (0.9050 to 0.9055 in.)

(b) Using a caliper gauge, measure the inside diameter

of the idle sprocket.

Idle gear inside diameter:

23.020 to 23.030 mm (0.9063 to 0.9067 in.)

(c) Subtract the idle gear shaft diameter measurement

from the idle sprocket inside diameter

measurement.

Standard oil clearance:

0.020 to 0.043 mm (0.0008 to 0.0017 in.)

Maximum oil clearance:

0.093 mm (0.0037 in.)

If the thrust oil clearance is greater than the

maximum, replace the idle gear shaft and idle

sprocket.

12. INSPECT NO. 1 CHAIN TENSIONER ASSEMBLY

(a) Move the stopper plate upward to release the lock.

Push the plunger and check that it moves smoothly.

If necessary, replace the No. 1 chain tensioner

assembly.

13. INSPECT NO. 2 CHAIN TENSIONER ASSEMBLY

(a) Check that the plunger moves smoothly.

(b) Measure the worn depth of the No. 2 chain

tensioner.

Maximum depth:

0.9 mm (0.035 in.)

If the depth is greater than the maximum, replace

the No. 2 chain tensioner assembly.

A109648

A120673

A097905E06

A106108E01

Page 915 of 3000

EM–1102GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

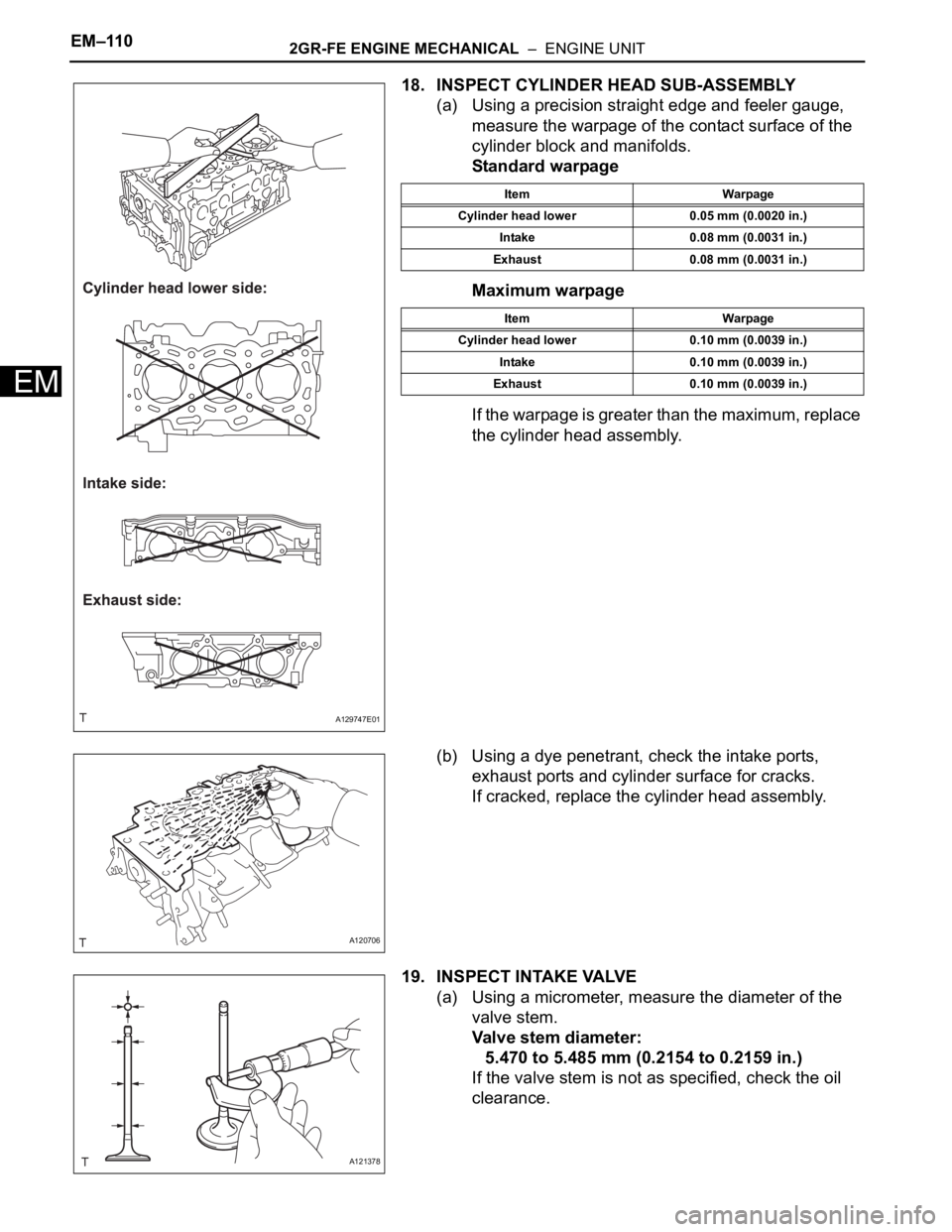

18. INSPECT CYLINDER HEAD SUB-ASSEMBLY

(a) Using a precision straight edge and feeler gauge,

measure the warpage of the contact surface of the

cylinder block and manifolds.

Standard warpage

Maximum warpage

If the warpage is greater than the maximum, replace

the cylinder head assembly.

(b) Using a dye penetrant, check the intake ports,

exhaust ports and cylinder surface for cracks.

If cracked, replace the cylinder head assembly.

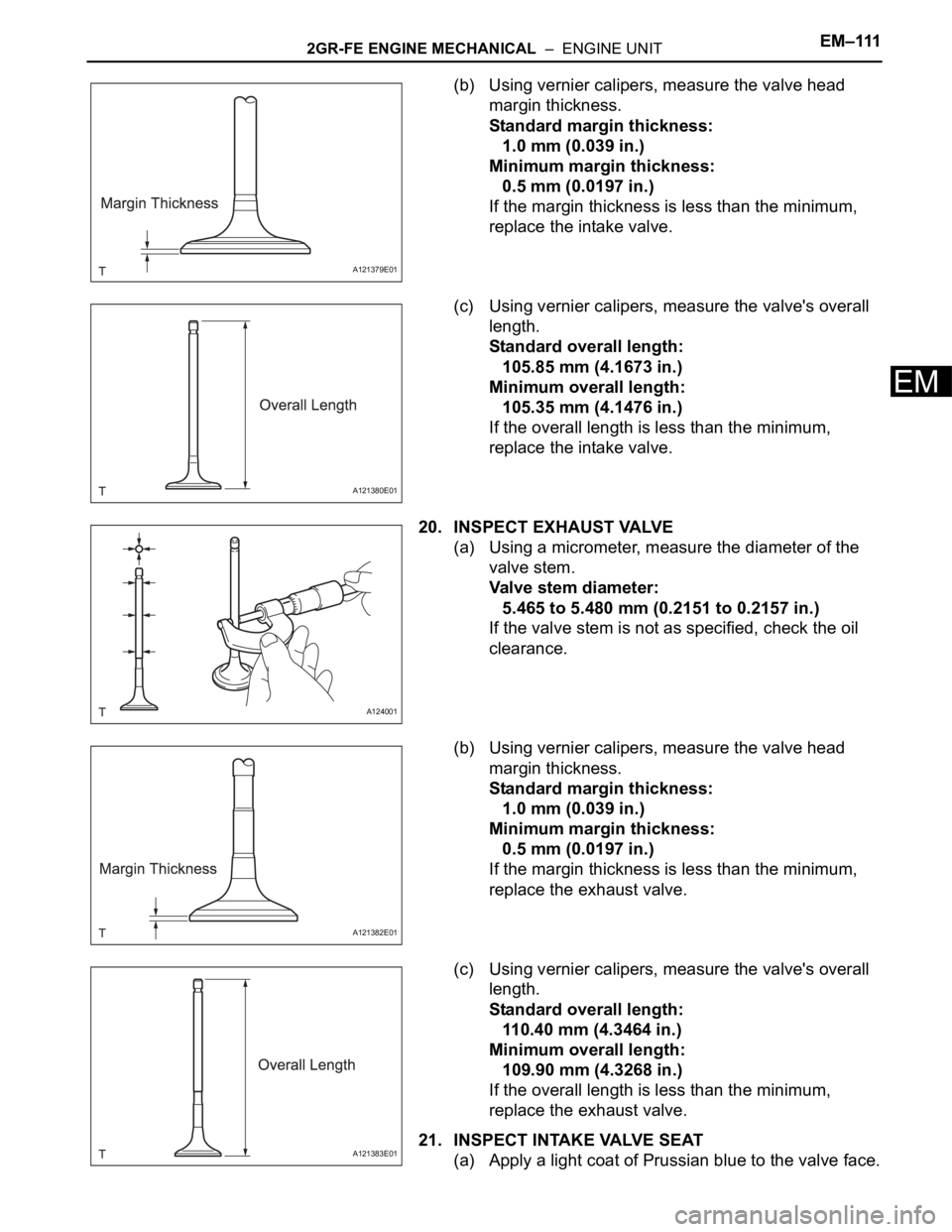

19. INSPECT INTAKE VALVE

(a) Using a micrometer, measure the diameter of the

valve stem.

Valve stem diameter:

5.470 to 5.485 mm (0.2154 to 0.2159 in.)

If the valve stem is not as specified, check the oil

clearance.

A129747E01

Item Warpage

Cylinder head lower 0.05 mm (0.0020 in.)

Intake 0.08 mm (0.0031 in.)

Exhaust 0.08 mm (0.0031 in.)

Item Warpage

Cylinder head lower 0.10 mm (0.0039 in.)

Intake 0.10 mm (0.0039 in.)

Exhaust 0.10 mm (0.0039 in.)

A120706

A121378

Page 916 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–111

EM

(b) Using vernier calipers, measure the valve head

margin thickness.

Standard margin thickness:

1.0 mm (0.039 in.)

Minimum margin thickness:

0.5 mm (0.0197 in.)

If the margin thickness is less than the minimum,

replace the intake valve.

(c) Using vernier calipers, measure the valve's overall

length.

Standard overall length:

105.85 mm (4.1673 in.)

Minimum overall length:

105.35 mm (4.1476 in.)

If the overall length is less than the minimum,

replace the intake valve.

20. INSPECT EXHAUST VALVE

(a) Using a micrometer, measure the diameter of the

valve stem.

Valve stem diameter:

5.465 to 5.480 mm (0.2151 to 0.2157 in.)

If the valve stem is not as specified, check the oil

clearance.

(b) Using vernier calipers, measure the valve head

margin thickness.

Standard margin thickness:

1.0 mm (0.039 in.)

Minimum margin thickness:

0.5 mm (0.0197 in.)

If the margin thickness is less than the minimum,

replace the exhaust valve.

(c) Using vernier calipers, measure the valve's overall

length.

Standard overall length:

110.40 mm (4.3464 in.)

Minimum overall length:

109.90 mm (4.3268 in.)

If the overall length is less than the minimum,

replace the exhaust valve.

21. INSPECT INTAKE VALVE SEAT

(a) Apply a light coat of Prussian blue to the valve face.

A121379E01

A121380E01

A124001

A121382E01

A121383E01

Page 919 of 3000

EM–1142GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

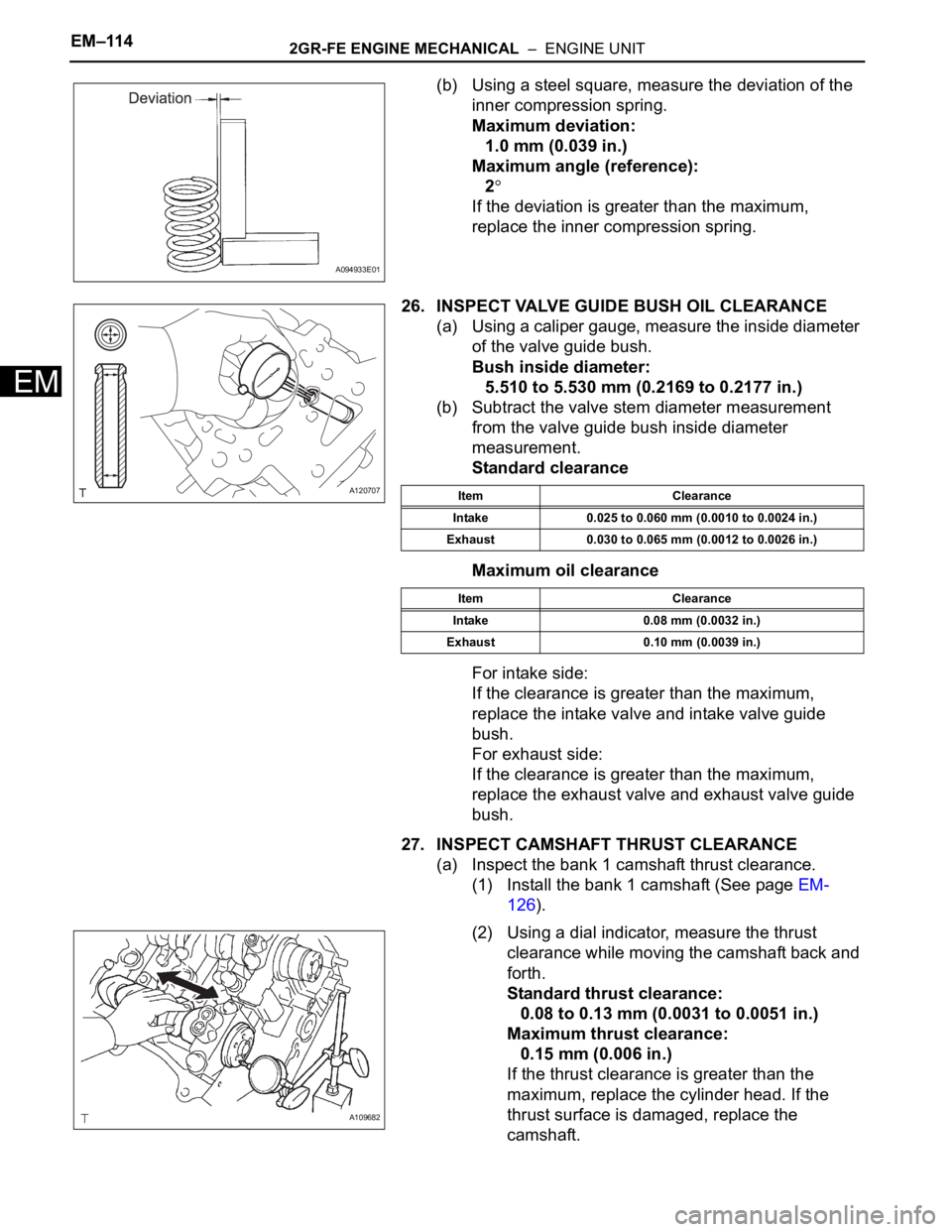

(b) Using a steel square, measure the deviation of the

inner compression spring.

Maximum deviation:

1.0 mm (0.039 in.)

Maximum angle (reference):

2

If the deviation is greater than the maximum,

replace the inner compression spring.

26. INSPECT VALVE GUIDE BUSH OIL CLEARANCE

(a) Using a caliper gauge, measure the inside diameter

of the valve guide bush.

Bush inside diameter:

5.510 to 5.530 mm (0.2169 to 0.2177 in.)

(b) Subtract the valve stem diameter measurement

from the valve guide bush inside diameter

measurement.

Standard clearance

Maximum oil clearance

For intake side:

If the clearance is greater than the maximum,

replace the intake valve and intake valve guide

bush.

For exhaust side:

If the clearance is greater than the maximum,

replace the exhaust valve and exhaust valve guide

bush.

27. INSPECT CAMSHAFT THRUST CLEARANCE

(a) Inspect the bank 1 camshaft thrust clearance.

(1) Install the bank 1 camshaft (See page EM-

126).

(2) Using a dial indicator, measure the thrust

clearance while moving the camshaft back and

forth.

Standard thrust clearance:

0.08 to 0.13 mm (0.0031 to 0.0051 in.)

Maximum thrust clearance:

0.15 mm (0.006 in.)

If the thrust clearance is greater than the

maximum, replace the cylinder head. If the

thrust surface is damaged, replace the

camshaft.

A094933E01

A120707Item Clearance

Intake 0.025 to 0.060 mm (0.0010 to 0.0024 in.)

Exhaust 0.030 to 0.065 mm (0.0012 to 0.0026 in.)

Item Clearance

Intake 0.08 mm (0.0032 in.)

Exhaust 0.10 mm (0.0039 in.)

A109682

Page 920 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–115

EM

(b) Inspect the bank 2 camshaft thrust clearance.

(1) Install the bank 2 camshaft (See page EM-

126).

(2) Using a dial indicator, measure the thrust

clearance while moving the camshaft back and

forth.

Standard thrust clearance:

0.08 to 0.13 mm (0.0031 to 0.0051 in.)

Maximum thrust clearance:

0.15 mm (0.006 in.)

If the thrust clearance is greater than the

maximum, replace the cylinder head. If the

thrust surface is damaged, replace the

camshaft.

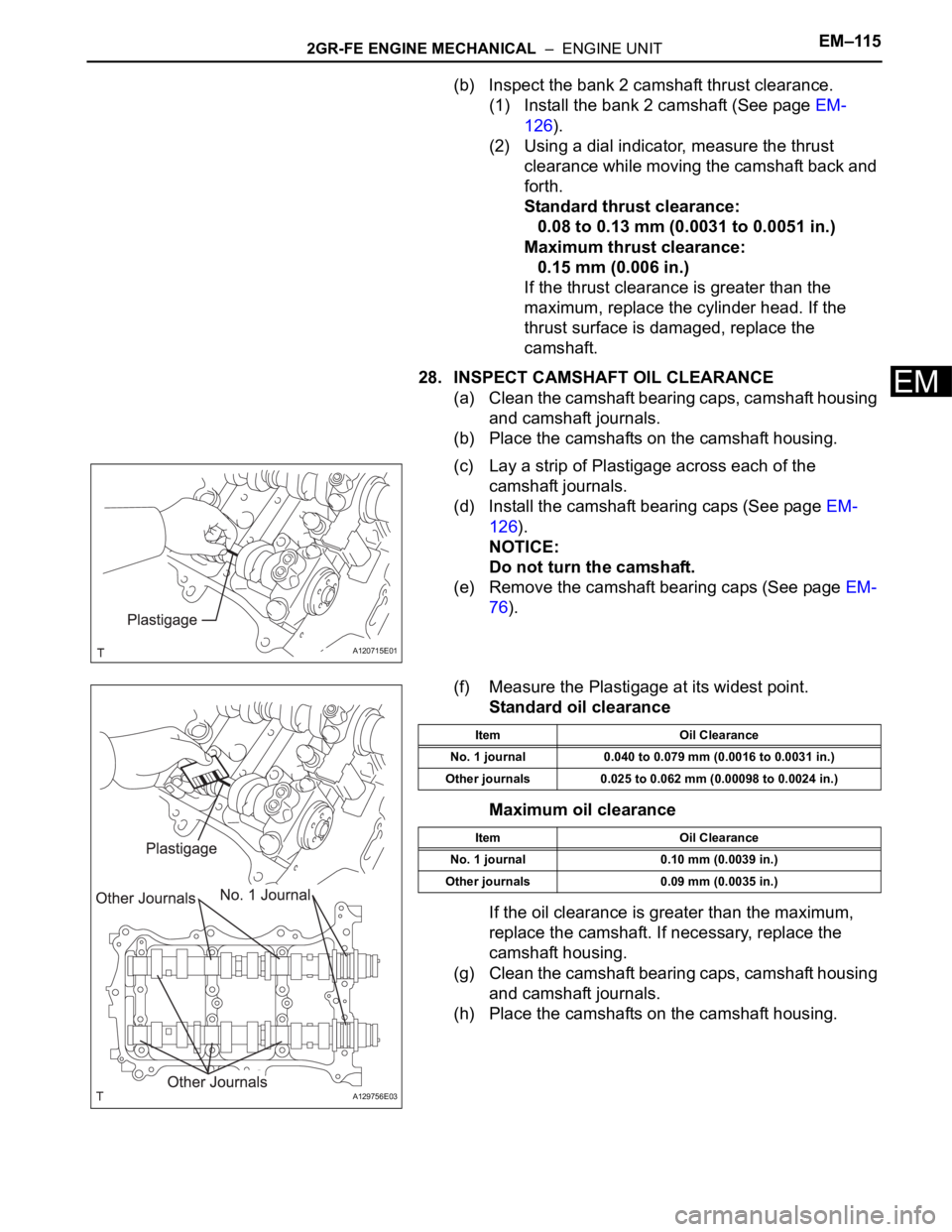

28. INSPECT CAMSHAFT OIL CLEARANCE

(a) Clean the camshaft bearing caps, camshaft housing

and camshaft journals.

(b) Place the camshafts on the camshaft housing.

(c) Lay a strip of Plastigage across each of the

camshaft journals.

(d) Install the camshaft bearing caps (See page EM-

126).

NOTICE:

Do not turn the camshaft.

(e) Remove the camshaft bearing caps (See page EM-

76).

(f) Measure the Plastigage at its widest point.

Standard oil clearance

Maximum oil clearance

If the oil clearance is greater than the maximum,

replace the camshaft. If necessary, replace the

camshaft housing.

(g) Clean the camshaft bearing caps, camshaft housing

and camshaft journals.

(h) Place the camshafts on the camshaft housing.

A120715E01

A129756E03

Item Oil Clearance

No. 1 journal 0.040 to 0.079 mm (0.0016 to 0.0031 in.)

Other journals 0.025 to 0.062 mm (0.00098 to 0.0024 in.)

Item Oil Clearance

No. 1 journal 0.10 mm (0.0039 in.)

Other journals 0.09 mm (0.0035 in.)

Page 921 of 3000

EM–1162GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

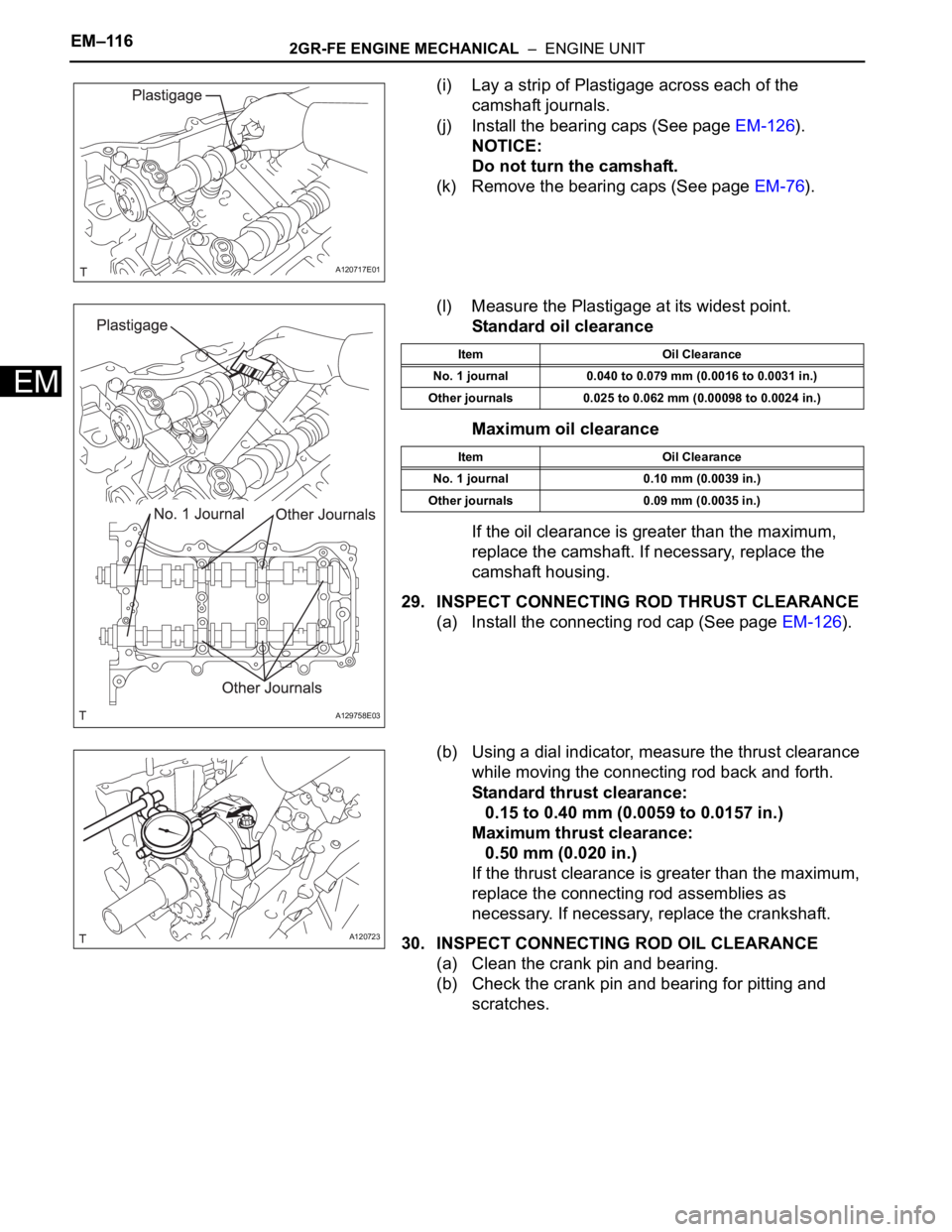

(i) Lay a strip of Plastigage across each of the

camshaft journals.

(j) Install the bearing caps (See page EM-126).

NOTICE:

Do not turn the camshaft.

(k) Remove the bearing caps (See page EM-76).

(l) Measure the Plastigage at its widest point.

Standard oil clearance

Maximum oil clearance

If the oil clearance is greater than the maximum,

replace the camshaft. If necessary, replace the

camshaft housing.

29. INSPECT CONNECTING ROD THRUST CLEARANCE

(a) Install the connecting rod cap (See page EM-126).

(b) Using a dial indicator, measure the thrust clearance

while moving the connecting rod back and forth.

Standard thrust clearance:

0.15 to 0.40 mm (0.0059 to 0.0157 in.)

Maximum thrust clearance:

0.50 mm (0.020 in.)

If the thrust clearance is greater than the maximum,

replace the connecting rod assemblies as

necessary. If necessary, replace the crankshaft.

30. INSPECT CONNECTING ROD OIL CLEARANCE

(a) Clean the crank pin and bearing.

(b) Check the crank pin and bearing for pitting and

scratches.

A120717E01

A129758E03

Item Oil Clearance

No. 1 journal 0.040 to 0.079 mm (0.0016 to 0.0031 in.)

Other journals 0.025 to 0.062 mm (0.00098 to 0.0024 in.)

Item Oil Clearance

No. 1 journal 0.10 mm (0.0039 in.)

Other journals 0.09 mm (0.0035 in.)

A120723

Page 922 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–117

EM

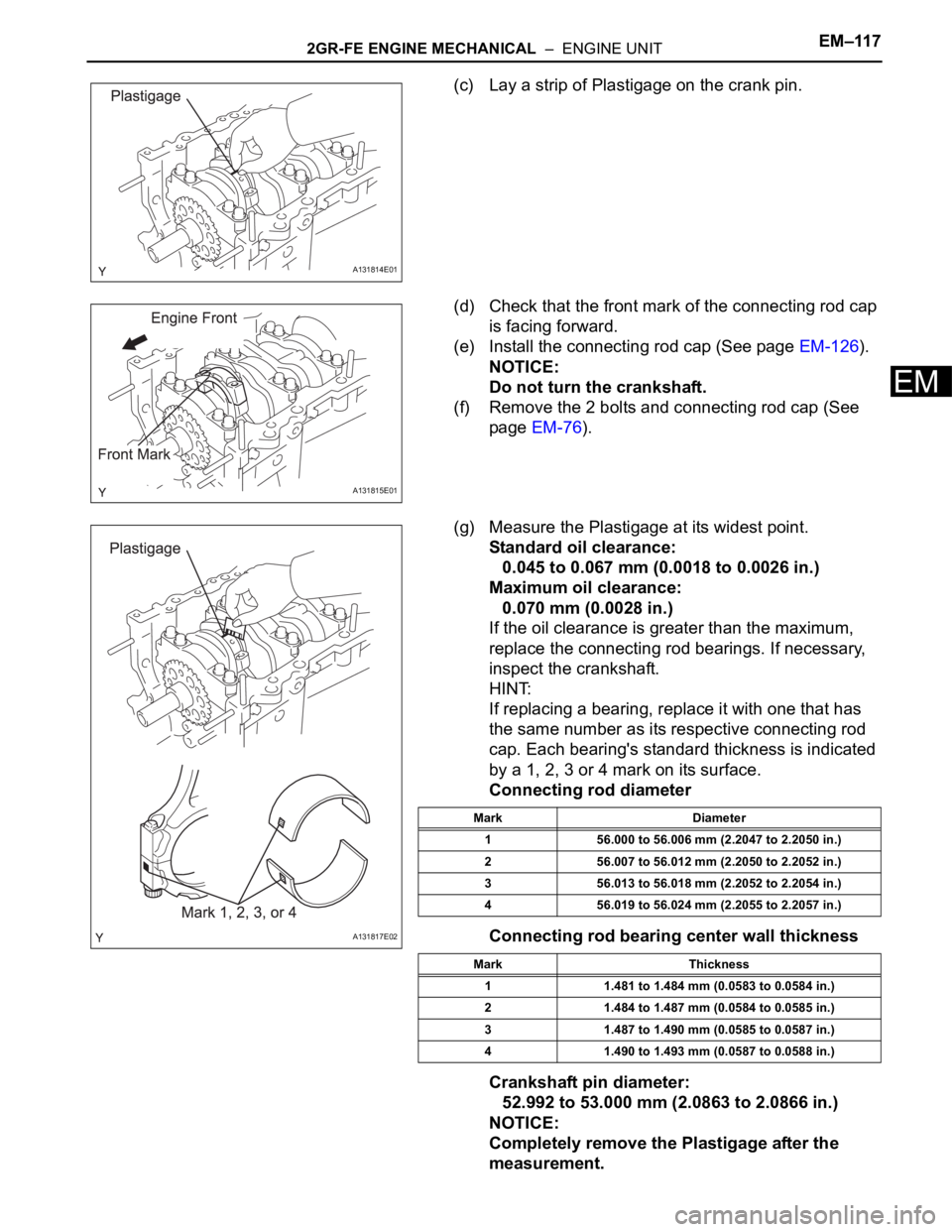

(c) Lay a strip of Plastigage on the crank pin.

(d) Check that the front mark of the connecting rod cap

is facing forward.

(e) Install the connecting rod cap (See page EM-126).

NOTICE:

Do not turn the crankshaft.

(f) Remove the 2 bolts and connecting rod cap (See

page EM-76).

(g) Measure the Plastigage at its widest point.

Standard oil clearance:

0.045 to 0.067 mm (0.0018 to 0.0026 in.)

Maximum oil clearance:

0.070 mm (0.0028 in.)

If the oil clearance is greater than the maximum,

replace the connecting rod bearings. If necessary,

inspect the crankshaft.

HINT:

If replacing a bearing, replace it with one that has

the same number as its respective connecting rod

cap. Each bearing's standard thickness is indicated

by a 1, 2, 3 or 4 mark on its surface.

Connecting rod diameter

Connecting rod bearing center wall thickness

Crankshaft pin diameter:

52.992 to 53.000 mm (2.0863 to 2.0866 in.)

NOTICE:

Completely remove the Plastigage after the

measurement.

A131814E01

A131815E01

A131817E02

Mark Diameter

1 56.000 to 56.006 mm (2.2047 to 2.2050 in.)

2 56.007 to 56.012 mm (2.2050 to 2.2052 in.)

3 56.013 to 56.018 mm (2.2052 to 2.2054 in.)

4 56.019 to 56.024 mm (2.2055 to 2.2057 in.)

Mark Thickness

1 1.481 to 1.484 mm (0.0583 to 0.0584 in.)

2 1.484 to 1.487 mm (0.0584 to 0.0585 in.)

3 1.487 to 1.490 mm (0.0585 to 0.0587 in.)

4 1.490 to 1.493 mm (0.0587 to 0.0588 in.)