TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1531 of 3000

AX–26U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

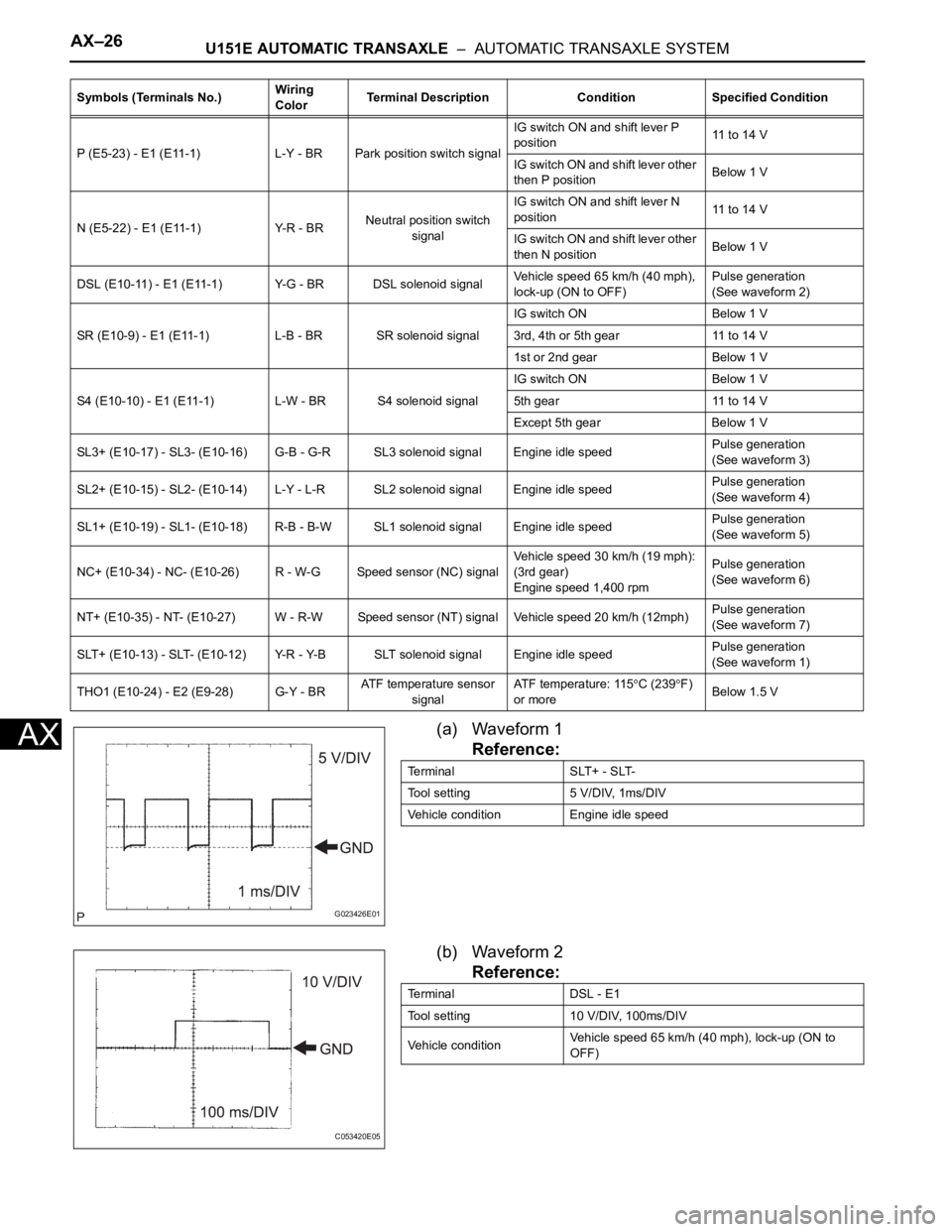

AX(a) Waveform 1

Reference:

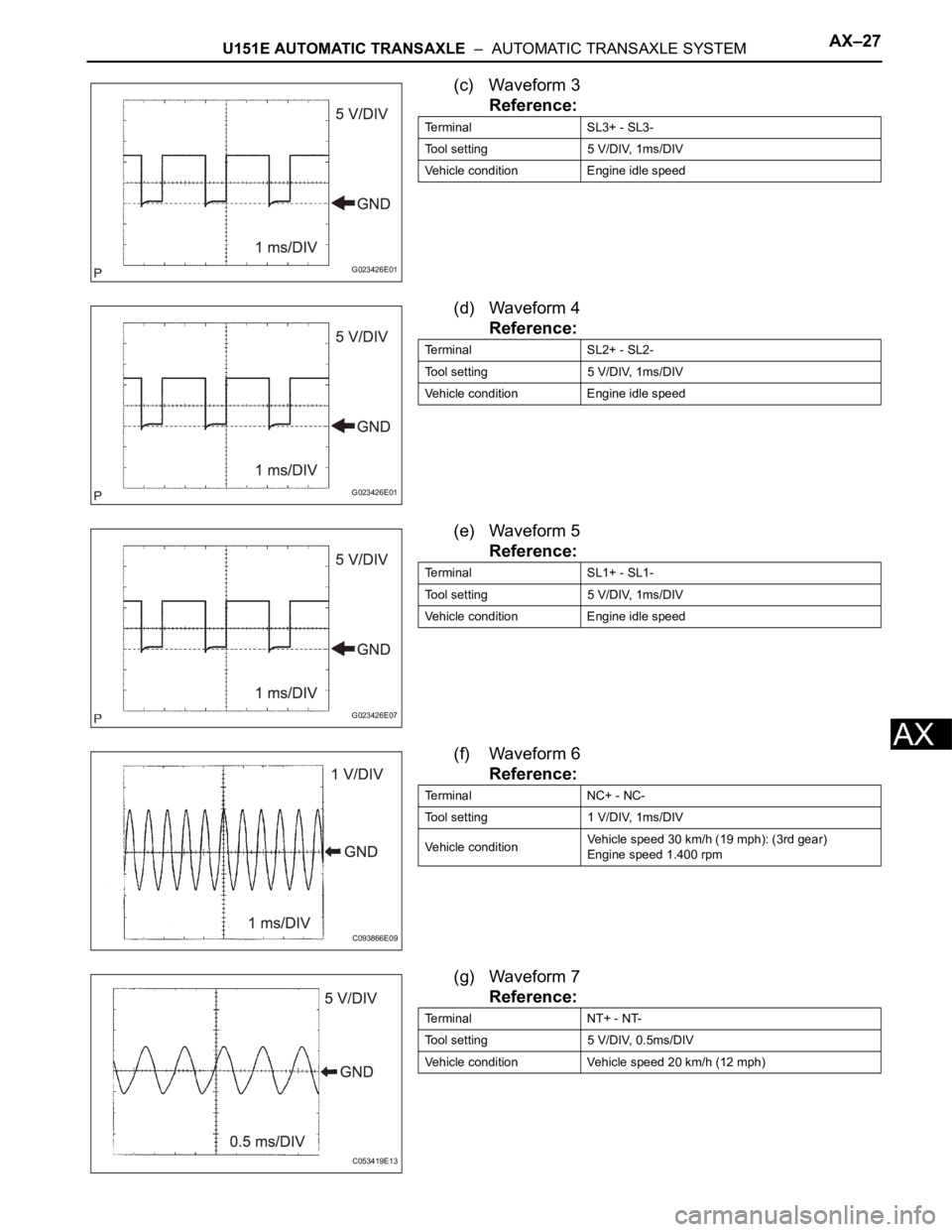

(b) Waveform 2

Reference:

P (E5-23) - E1 (E11-1) L-Y - BR Park position switch signalIG switch ON and shift lever P

position11 to 14 V

IG switch ON and shift lever other

then P positionBelow 1 V

N (E5-22) - E1 (E11-1) Y-R - BRNeutral position switch

signalIG switch ON and shift lever N

position11 to 14 V

IG switch ON and shift lever other

then N positionBelow 1 V

DSL (E10-11) - E1 (E11-1) Y-G - BR DSL solenoid signalVehicle speed 65 km/h (40 mph),

lock-up (ON to OFF)Pulse generation

(See waveform 2)

SR (E10-9) - E1 (E11-1) L-B - BR SR solenoid signalIG switch ON Below 1 V

3rd, 4th or 5th gear 11 to 14 V

1st or 2nd gear Below 1 V

S4 (E10-10) - E1 (E11-1) L-W - BR S4 solenoid signalIG switch ON Below 1 V

5th gear 11 to 14 V

Except 5th gear Below 1 V

SL3+ (E10-17) - SL3- (E10-16) G-B - G-R SL3 solenoid signal Engine idle speedPulse generation

(See waveform 3)

SL2+ (E10-15) - SL2- (E10-14) L-Y - L-R SL2 solenoid signal Engine idle speedPulse generation

(See waveform 4)

SL1+ (E10-19) - SL1- (E10-18) R-B - B-W SL1 solenoid signal Engine idle speedPulse generation

(See waveform 5)

NC+ (E10-34) - NC- (E10-26) R - W-G Speed sensor (NC) signalVehicle speed 30 km/h (19 mph):

(3rd gear)

Engine speed 1,400 rpmPulse generation

(See waveform 6)

NT+ (E10-35) - NT- (E10-27) W - R-W Speed sensor (NT) signal Vehicle speed 20 km/h (12mph)Pulse generation

(See waveform 7)

SLT+ (E10-13) - SLT- (E10-12) Y-R - Y-B SLT solenoid signal Engine idle speedPulse generation

(See waveform 1)

THO1 (E10-24) - E2 (E9-28) G-Y - BRATF temperature sensor

signalATF temperature: 115

C (239F)

or moreBelow 1.5 V Symbols (Terminals No.)Wiring

ColorTerminal Description Condition Specified Condition

G023426E01

Terminal SLT+ - SLT-

Tool setting 5 V/DIV, 1ms/DIV

Vehicle condition Engine idle speed

C053420E05

Terminal DSL - E1

Tool setting 10 V/DIV, 100ms/DIV

Vehicle conditionVehicle speed 65 km/h (40 mph), lock-up (ON to

OFF)

Page 1532 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–27

AX

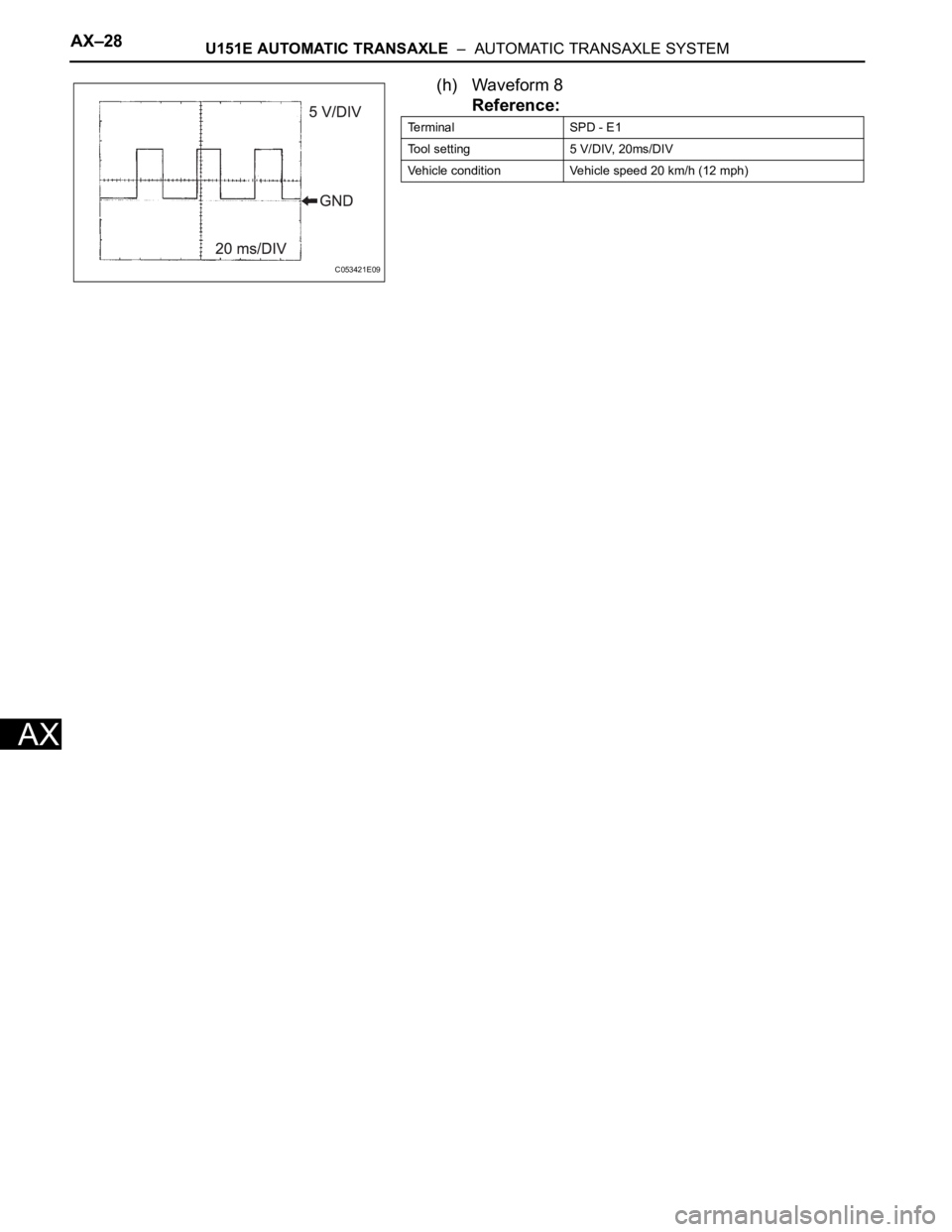

(c) Waveform 3

Reference:

(d) Waveform 4

Reference:

(e) Waveform 5

Reference:

(f) Waveform 6

Reference:

(g) Waveform 7

Reference:

G023426E01

Terminal SL3+ - SL3-

Tool setting 5 V/DIV, 1ms/DIV

Vehicle condition Engine idle speed

G023426E01

Terminal SL2+ - SL2-

Tool setting 5 V/DIV, 1ms/DIV

Vehicle condition Engine idle speed

G023426E07

Terminal SL1+ - SL1-

Tool setting 5 V/DIV, 1ms/DIV

Vehicle condition Engine idle speed

C093866E09

Terminal NC+ - NC-

Tool setting 1 V/DIV, 1ms/DIV

Vehicle conditionVehicle speed 30 km/h (19 mph): (3rd gear)

Engine speed 1.400 rpm

C053419E13

Terminal NT+ - NT-

Tool setting 5 V/DIV, 0.5ms/DIV

Vehicle condition Vehicle speed 20 km/h (12 mph)

Page 1533 of 3000

AX–28U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

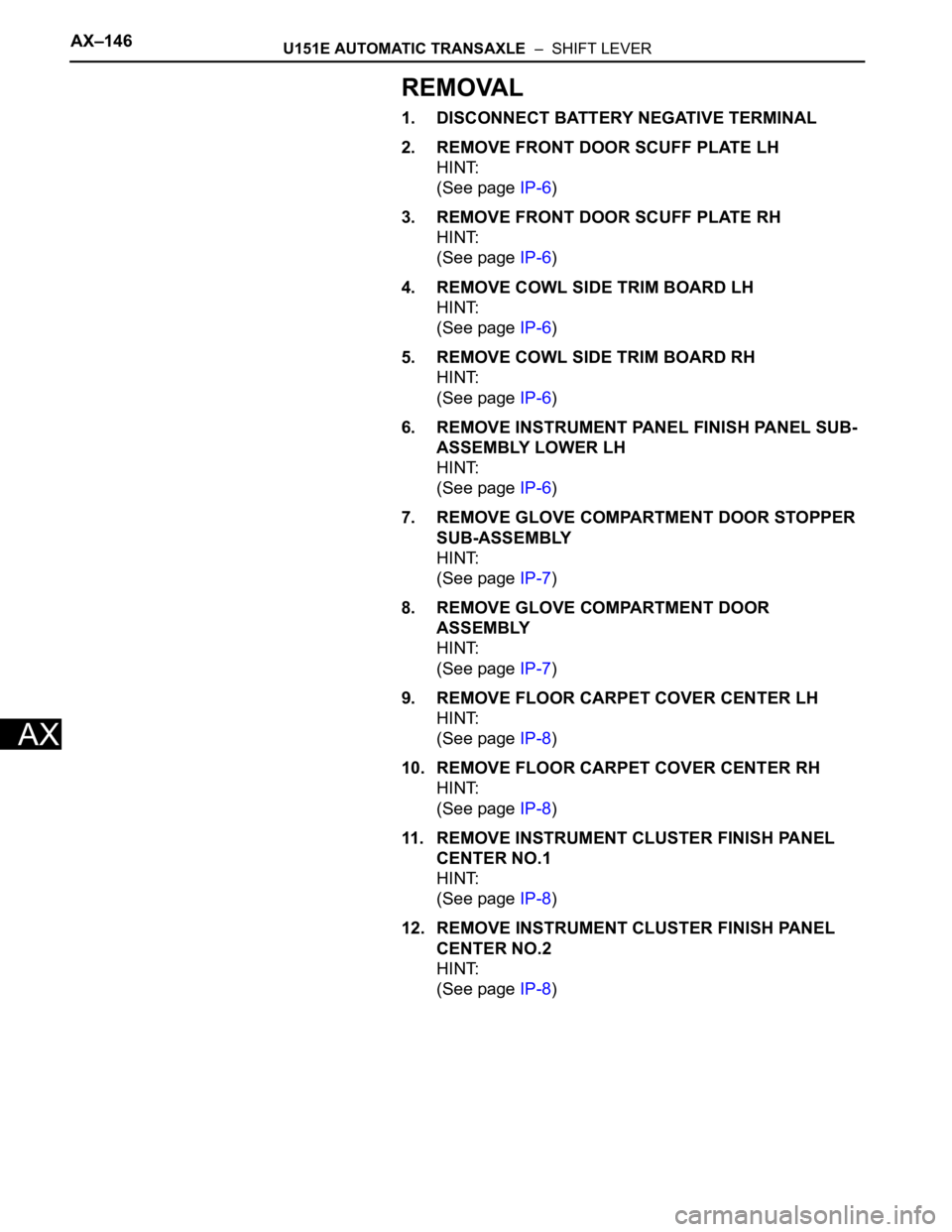

(h) Waveform 8

Reference:

C053421E09

Terminal SPD - E1

Tool setting 5 V/DIV, 20ms/DIV

Vehicle condition Vehicle speed 20 km/h (12 mph)

Page 1534 of 3000

AX–146U151E AUTOMATIC TRANSAXLE – SHIFT LEVER

AX

REMOVAL

1. DISCONNECT BATTERY NEGATIVE TERMINAL

2. REMOVE FRONT DOOR SCUFF PLATE LH

HINT:

(See page IP-6)

3. REMOVE FRONT DOOR SCUFF PLATE RH

HINT:

(See page IP-6)

4. REMOVE COWL SIDE TRIM BOARD LH

HINT:

(See page IP-6)

5. REMOVE COWL SIDE TRIM BOARD RH

HINT:

(See page IP-6)

6. REMOVE INSTRUMENT PANEL FINISH PANEL SUB-

ASSEMBLY LOWER LH

HINT:

(See page IP-6)

7. REMOVE GLOVE COMPARTMENT DOOR STOPPER

SUB-ASSEMBLY

HINT:

(See page IP-7)

8. REMOVE GLOVE COMPARTMENT DOOR

ASSEMBLY

HINT:

(See page IP-7)

9. REMOVE FLOOR CARPET COVER CENTER LH

HINT:

(See page IP-8)

10. REMOVE FLOOR CARPET COVER CENTER RH

HINT:

(See page IP-8)

11. REMOVE INSTRUMENT CLUSTER FINISH PANEL

CENTER NO.1

HINT:

(See page IP-8)

12. REMOVE INSTRUMENT CLUSTER FINISH PANEL

CENTER NO.2

HINT:

(See page IP-8)

Page 1535 of 3000

U151E AUTOMATIC TRANSAXLE – SHIFT LEVERAX–147

AX

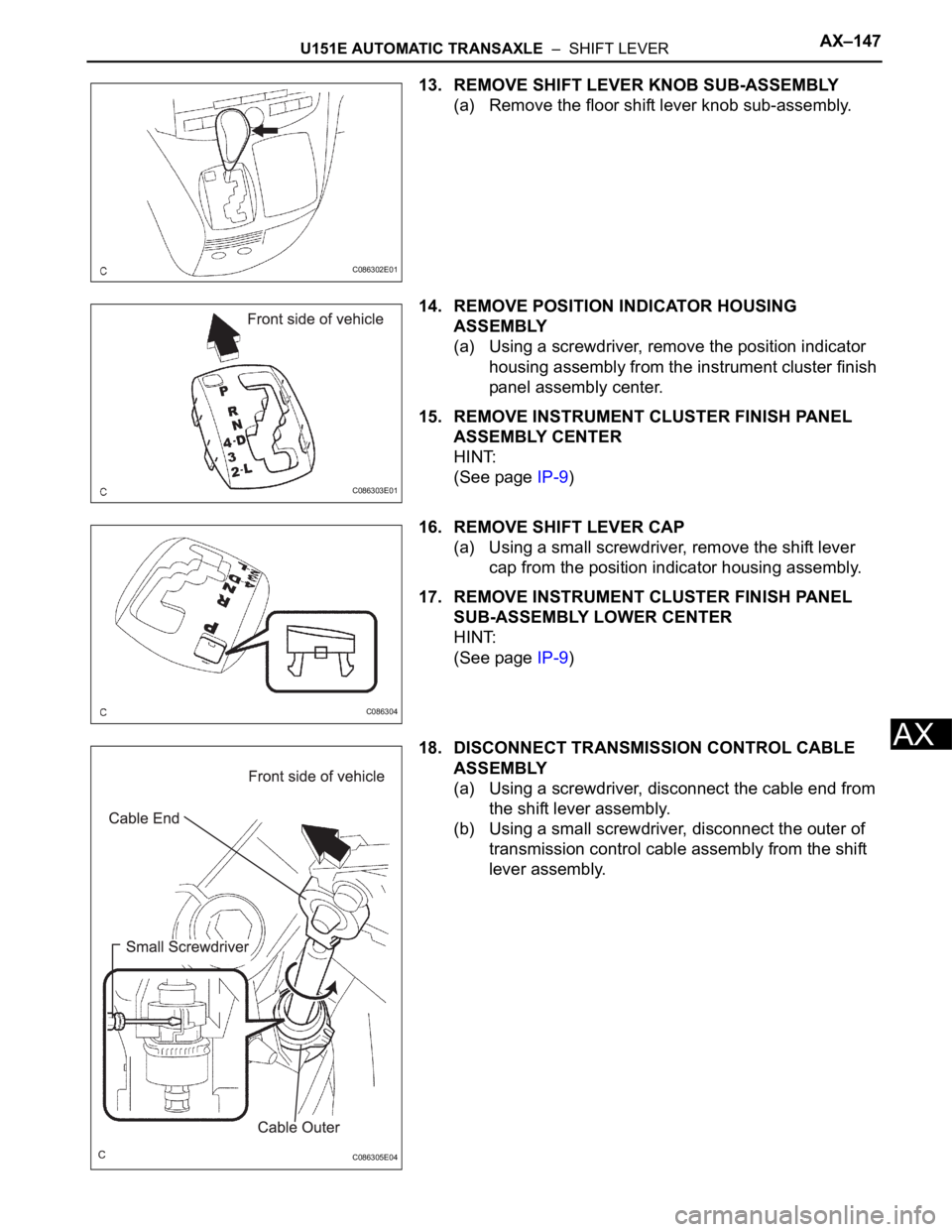

13. REMOVE SHIFT LEVER KNOB SUB-ASSEMBLY

(a) Remove the floor shift lever knob sub-assembly.

14. REMOVE POSITION INDICATOR HOUSING

ASSEMBLY

(a) Using a screwdriver, remove the position indicator

housing assembly from the instrument cluster finish

panel assembly center.

15. REMOVE INSTRUMENT CLUSTER FINISH PANEL

ASSEMBLY CENTER

HINT:

(See page IP-9)

16. REMOVE SHIFT LEVER CAP

(a) Using a small screwdriver, remove the shift lever

cap from the position indicator housing assembly.

17. REMOVE INSTRUMENT CLUSTER FINISH PANEL

SUB-ASSEMBLY LOWER CENTER

HINT:

(See page IP-9)

18. DISCONNECT TRANSMISSION CONTROL CABLE

ASSEMBLY

(a) Using a screwdriver, disconnect the cable end from

the shift lever assembly.

(b) Using a small screwdriver, disconnect the outer of

transmission control cable assembly from the shift

lever assembly.

C086302E01

C086303E01

C086304

C086305E04

Page 1536 of 3000

AX–148U151E AUTOMATIC TRANSAXLE – SHIFT LEVER

AX

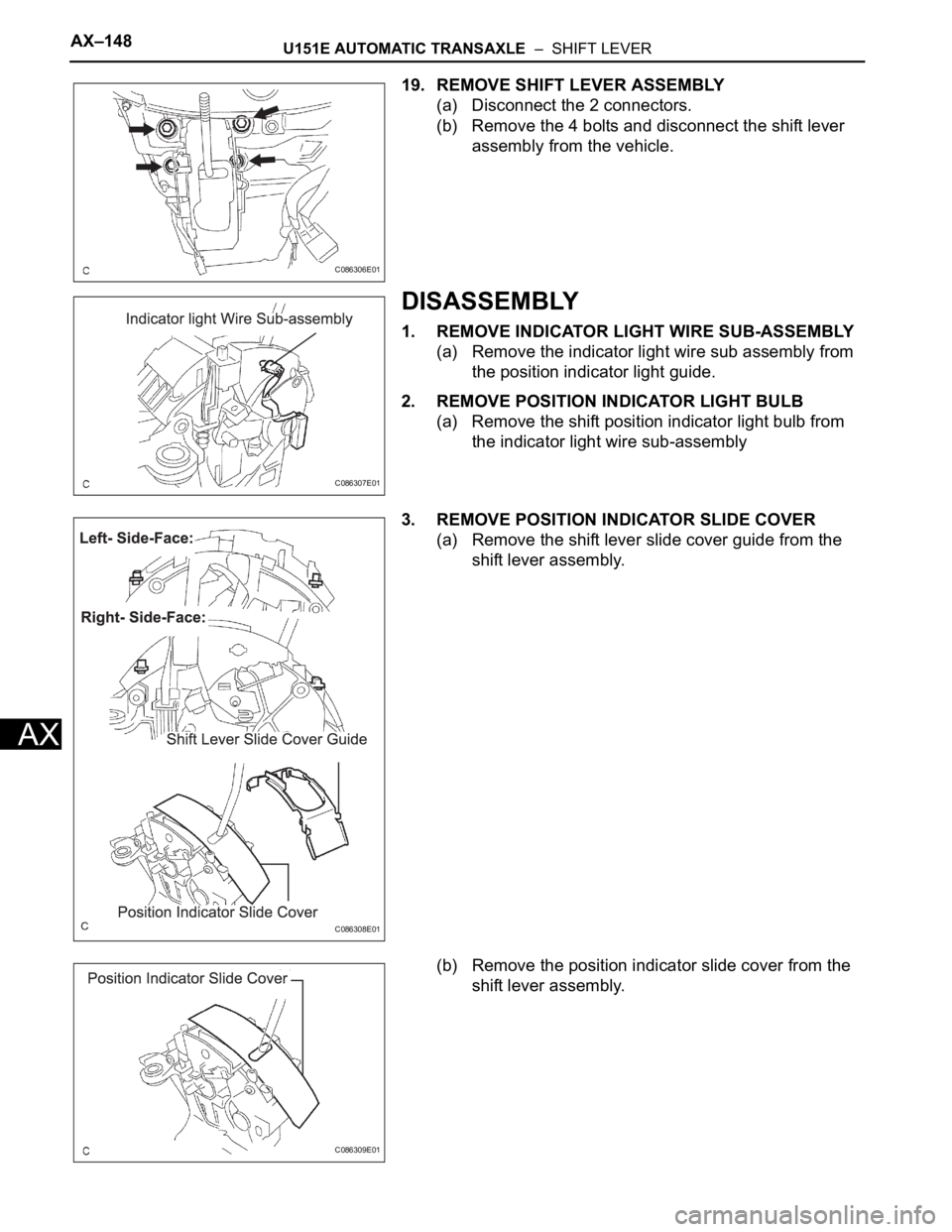

19. REMOVE SHIFT LEVER ASSEMBLY

(a) Disconnect the 2 connectors.

(b) Remove the 4 bolts and disconnect the shift lever

assembly from the vehicle.

DISASSEMBLY

1. REMOVE INDICATOR LIGHT WIRE SUB-ASSEMBLY

(a) Remove the indicator light wire sub assembly from

the position indicator light guide.

2. REMOVE POSITION INDICATOR LIGHT BULB

(a) Remove the shift position indicator light bulb from

the indicator light wire sub-assembly

3. REMOVE POSITION INDICATOR SLIDE COVER

(a) Remove the shift lever slide cover guide from the

shift lever assembly.

(b) Remove the position indicator slide cover from the

shift lever assembly.

C086306E01

C086307E01

C086308E01

C086309E01

Page 1537 of 3000

U151E AUTOMATIC TRANSAXLE – SHIFT LEVERAX–149

AX

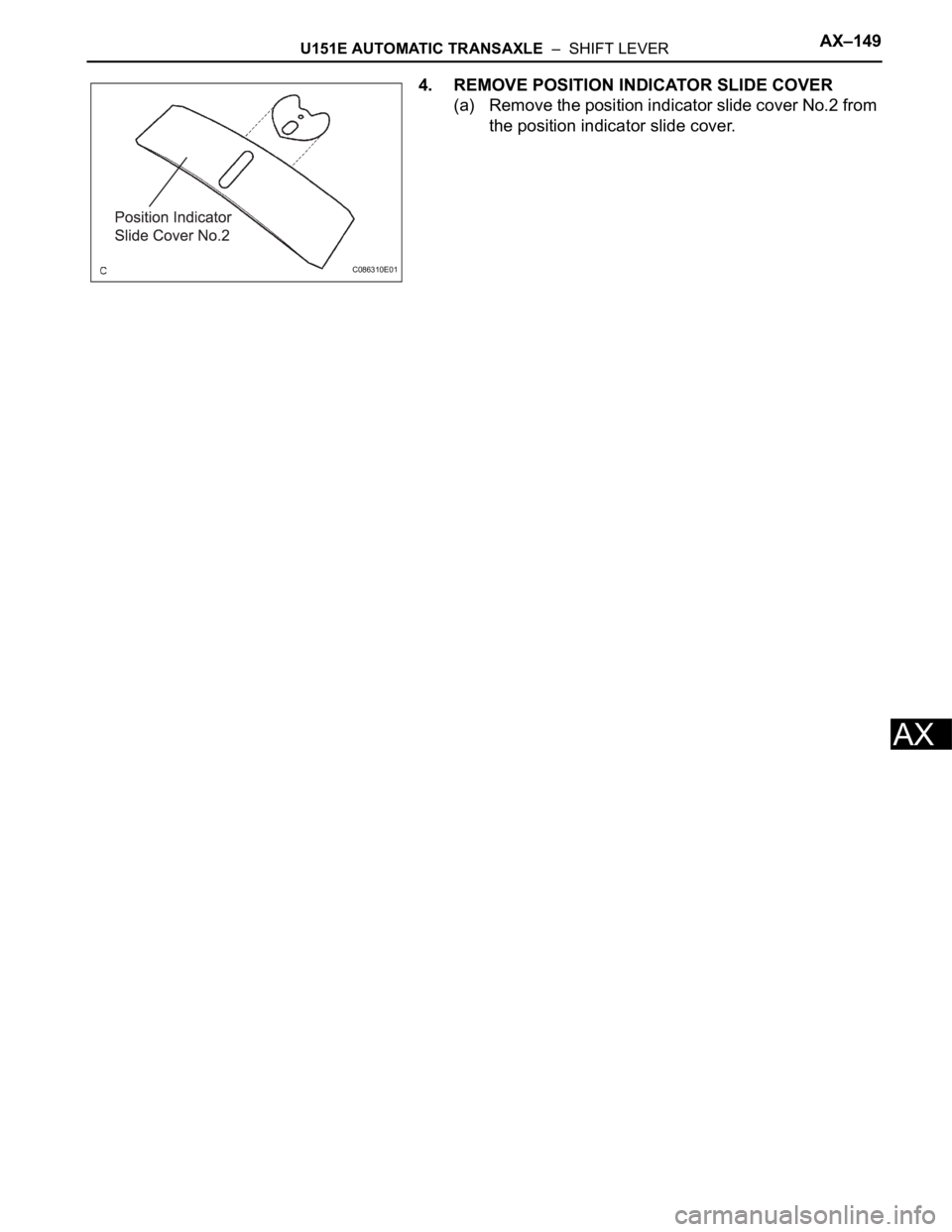

4. REMOVE POSITION INDICATOR SLIDE COVER

(a) Remove the position indicator slide cover No.2 from

the position indicator slide cover.

C086310E01

Page 1538 of 3000

AX–150U151E AUTOMATIC TRANSAXLE – SHIFT LEVER

AX

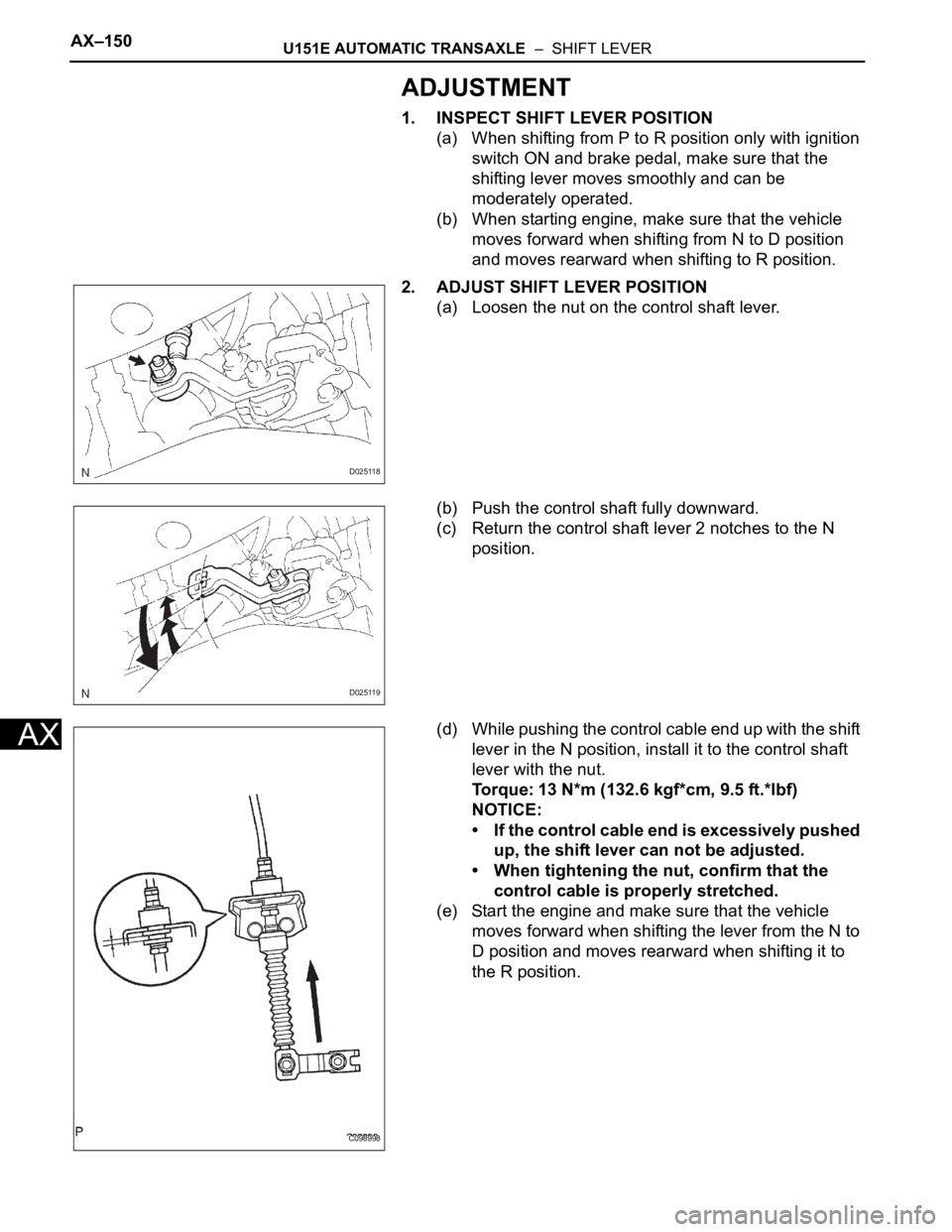

ADJUSTMENT

1. INSPECT SHIFT LEVER POSITION

(a) When shifting from P to R position only with ignition

switch ON and brake pedal, make sure that the

shifting lever moves smoothly and can be

moderately operated.

(b) When starting engine, make sure that the vehicle

moves forward when shifting from N to D position

and moves rearward when shifting to R position.

2. ADJUST SHIFT LEVER POSITION

(a) Loosen the nut on the control shaft lever.

(b) Push the control shaft fully downward.

(c) Return the control shaft lever 2 notches to the N

position.

(d) While pushing the control cable end up with the shift

lever in the N position, install it to the control shaft

lever with the nut.

Torque: 13 N*m (132.6 kgf*cm, 9.5 ft.*lbf)

NOTICE:

• If the control cable end is excessively pushed

up, the shift lever can not be adjusted.

• When tightening the nut, confirm that the

control cable is properly stretched.

(e) Start the engine and make sure that the vehicle

moves forward when shifting the lever from the N to

D position and moves rearward when shifting it to

the R position.

D025118

D025119

C098998

Page 1539 of 3000

U151E AUTOMATIC TRANSAXLE – SHIFT LEVERAX–151

AX

REASSEMBLY

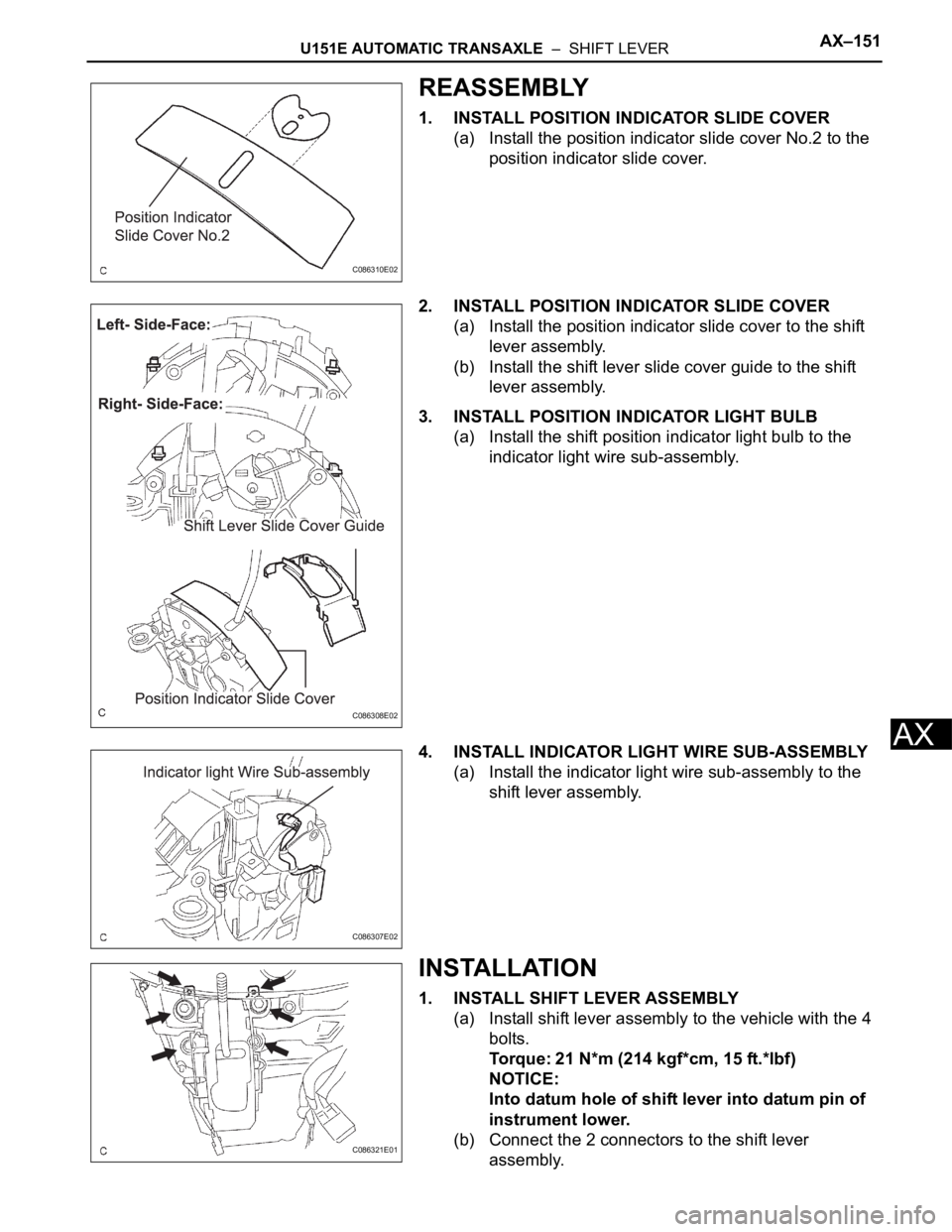

1. INSTALL POSITION INDICATOR SLIDE COVER

(a) Install the position indicator slide cover No.2 to the

position indicator slide cover.

2. INSTALL POSITION INDICATOR SLIDE COVER

(a) Install the position indicator slide cover to the shift

lever assembly.

(b) Install the shift lever slide cover guide to the shift

lever assembly.

3. INSTALL POSITION INDICATOR LIGHT BULB

(a) Install the shift position indicator light bulb to the

indicator light wire sub-assembly.

4. INSTALL INDICATOR LIGHT WIRE SUB-ASSEMBLY

(a) Install the indicator light wire sub-assembly to the

shift lever assembly.

INSTALLATION

1. INSTALL SHIFT LEVER ASSEMBLY

(a) Install shift lever assembly to the vehicle with the 4

bolts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

NOTICE:

Into datum hole of shift lever into datum pin of

instrument lower.

(b) Connect the 2 connectors to the shift lever

assembly.

C086310E02

C086308E02

C086307E02

C086321E01

Page 1540 of 3000

AX–152U151E AUTOMATIC TRANSAXLE – SHIFT LEVER

AX

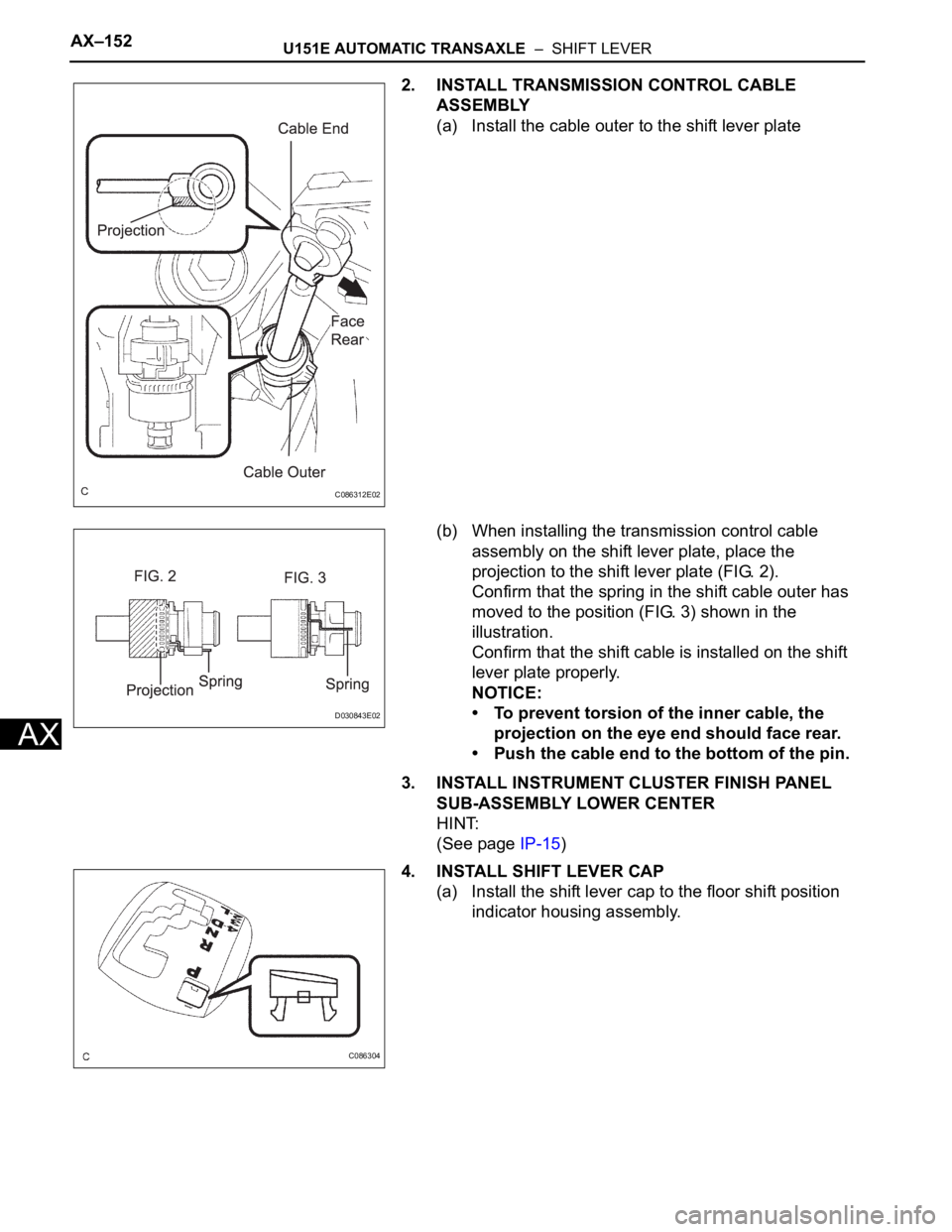

2. INSTALL TRANSMISSION CONTROL CABLE

ASSEMBLY

(a) Install the cable outer to the shift lever plate

(b) When installing the transmission control cable

assembly on the shift lever plate, place the

projection to the shift lever plate (FIG. 2).

Confirm that the spring in the shift cable outer has

moved to the position (FIG. 3) shown in the

illustration.

Confirm that the shift cable is installed on the shift

lever plate properly.

NOTICE:

• To prevent torsion of the inner cable, the

projection on the eye end should face rear.

• Push the cable end to the bottom of the pin.

3. INSTALL INSTRUMENT CLUSTER FINISH PANEL

SUB-ASSEMBLY LOWER CENTER

HINT:

(See page IP-15)

4. INSTALL SHIFT LEVER CAP

(a) Install the shift lever cap to the floor shift position

indicator housing assembly.

C086312E02

D030843E02

C086304