check engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 547 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–241

ES

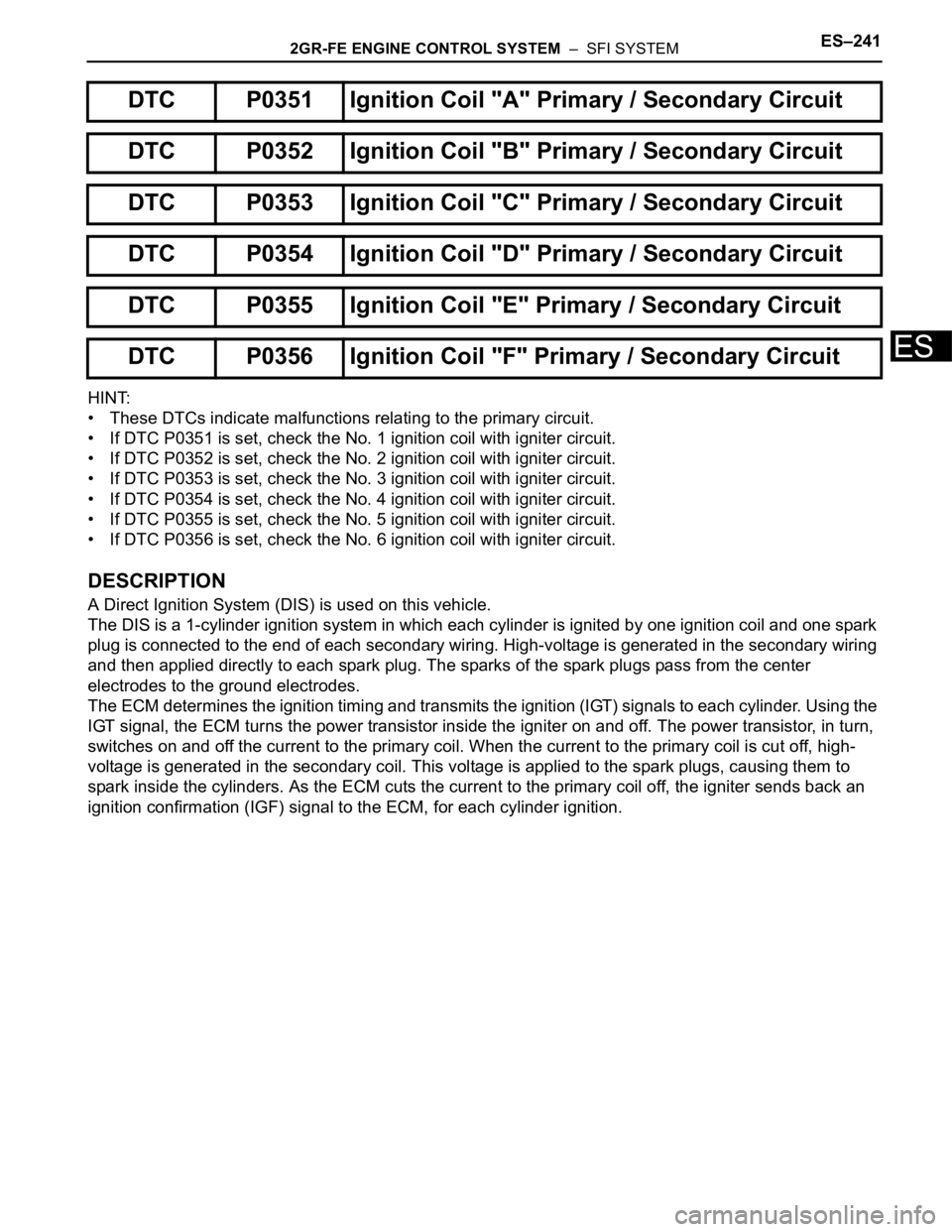

HINT:

• These DTCs indicate malfunctions relating to the primary circuit.

• If DTC P0351 is set, check the No. 1 ignition coil with igniter circuit.

• If DTC P0352 is set, check the No. 2 ignition coil with igniter circuit.

• If DTC P0353 is set, check the No. 3 ignition coil with igniter circuit.

• If DTC P0354 is set, check the No. 4 ignition coil with igniter circuit.

• If DTC P0355 is set, check the No. 5 ignition coil with igniter circuit.

• If DTC P0356 is set, check the No. 6 ignition coil with igniter circuit.

DESCRIPTION

A Direct Ignition System (DIS) is used on this vehicle.

The DIS is a 1-cylinder ignition system in which each cylinder is ignited by one ignition coil and one spark

plug is connected to the end of each secondary wiring. High-voltage is generated in the secondary wiring

and then applied directly to each spark plug. The sparks of the spark plugs pass from the center

electrodes to the ground electrodes.

The ECM determines the ignition timing and transmits the ignition (IGT) signals to each cylinder. Using the

IGT signal, the ECM turns the power transistor inside the igniter on and off. The power transistor, in turn,

switches on and off the current to the primary coil. When the current to the primary coil is cut off, high-

voltage is generated in the secondary coil. This voltage is applied to the spark plugs, causing them to

spark inside the cylinders. As the ECM cuts the current to the primary coil off, the igniter sends back an

ignition confirmation (IGF) signal to the ECM, for each cylinder ignition.

DTC P0351 Ignition Coil "A" Primary / Secondary Circuit

DTC P0352 Ignition Coil "B" Primary / Secondary Circuit

DTC P0353 Ignition Coil "C" Primary / Secondary Circuit

DTC P0354 Ignition Coil "D" Primary / Secondary Circuit

DTC P0355 Ignition Coil "E" Primary / Secondary Circuit

DTC P0356 Ignition Coil "F" Primary / Secondary Circuit

Page 549 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–243

ES

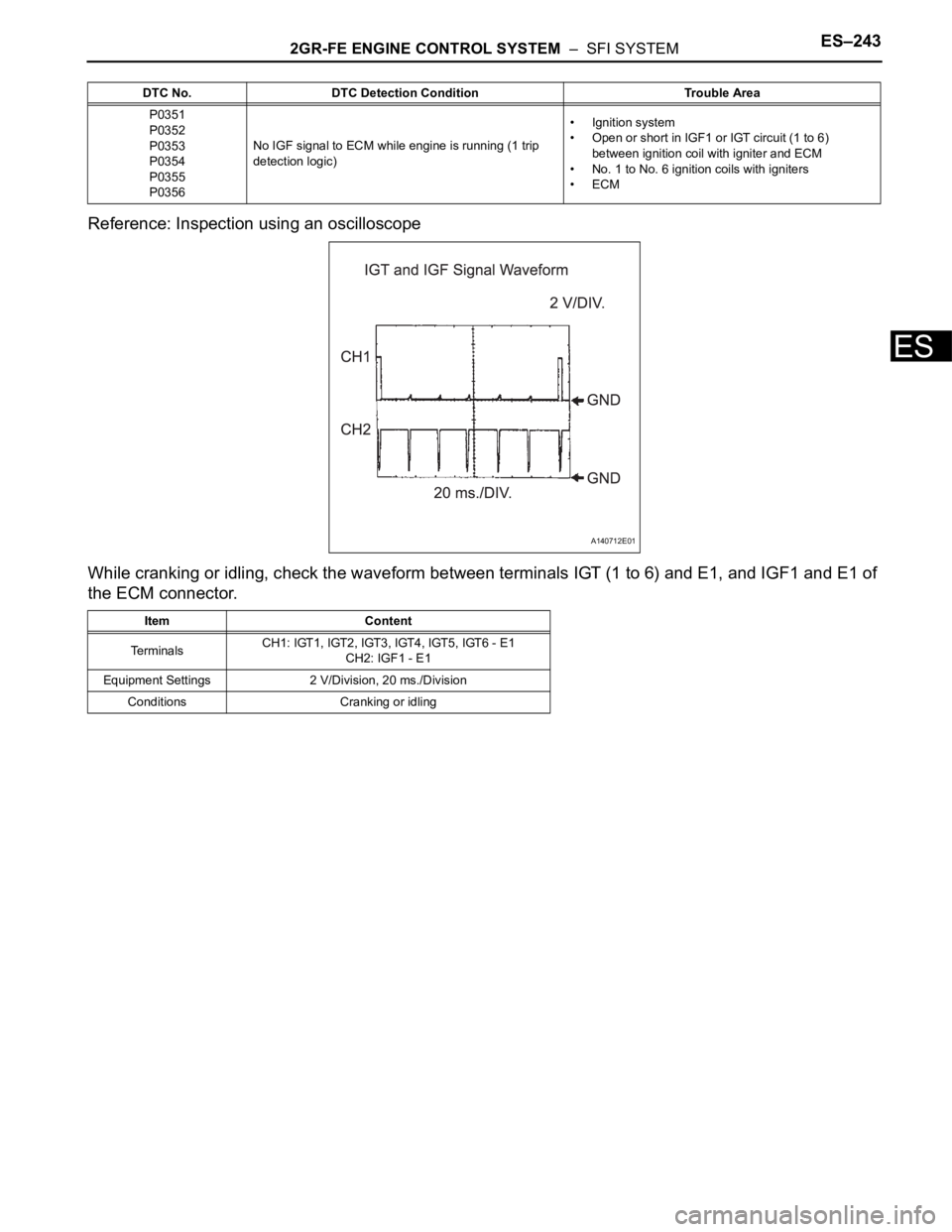

Reference: Inspection using an oscilloscope

While cranking or idling, check the waveform between terminals IGT (1 to 6) and E1, and IGF1 and E1 of

the ECM connector.

DTC No. DTC Detection Condition Trouble Area

P0351

P0352

P0353

P0354

P0355

P0356No IGF signal to ECM while engine is running (1 trip

detection logic)• Ignition system

• Open or short in IGF1 or IGT circuit (1 to 6)

between ignition coil with igniter and ECM

• No. 1 to No. 6 ignition coils with igniters

•ECM

Item Content

TerminalsCH1: IGT1, IGT2, IGT3, IGT4, IGT5, IGT6 - E1

CH2: IGF1 - E1

Equipment Settings 2 V/Division, 20 ms./Division

Conditions Cranking or idling

A140712E01

Page 553 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–247

ES

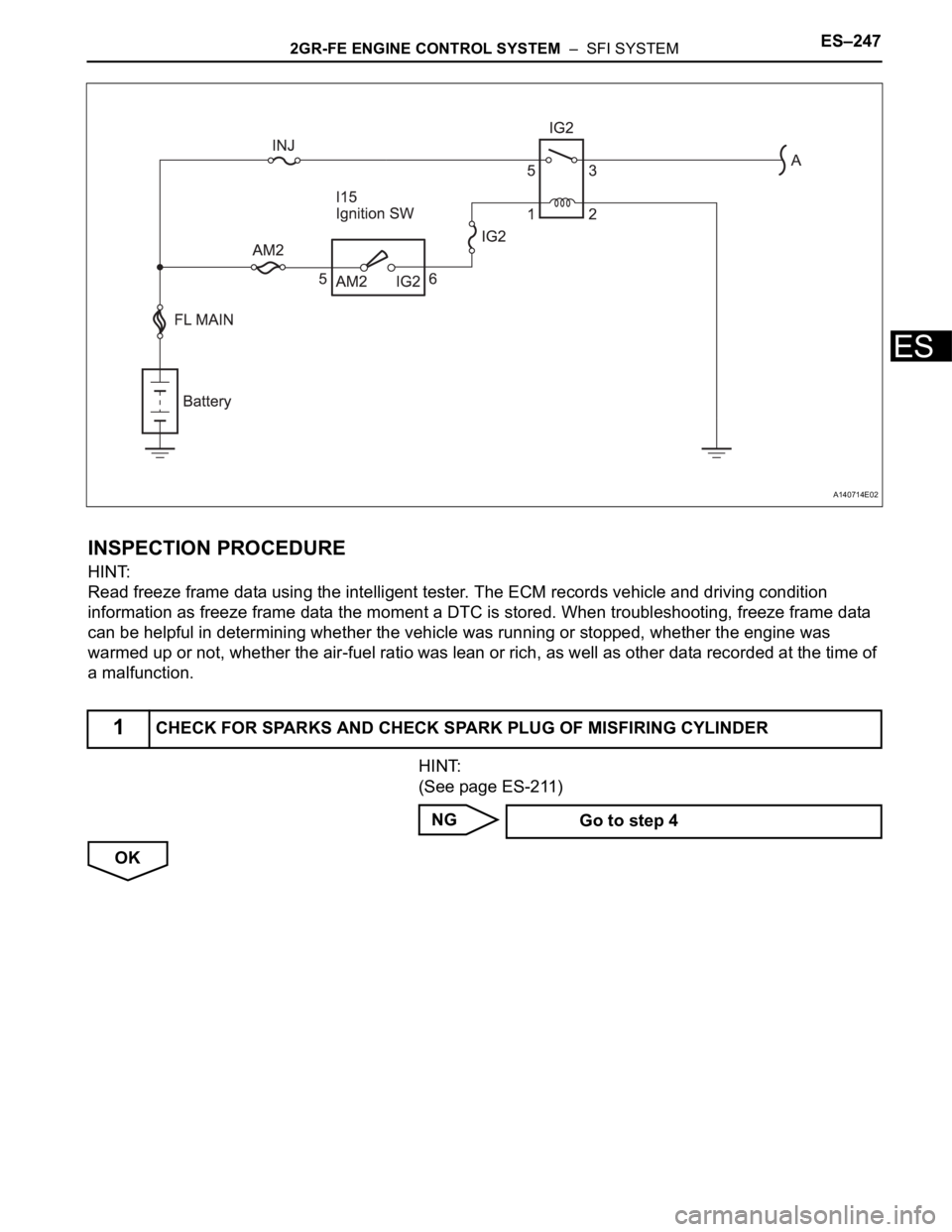

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of

a malfunction.

HINT:

(See page ES-211)

NG

OK

1CHECK FOR SPARKS AND CHECK SPARK PLUG OF MISFIRING CYLINDER

A140714E02

Go to step 4

Page 554 of 3000

ES–2482GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

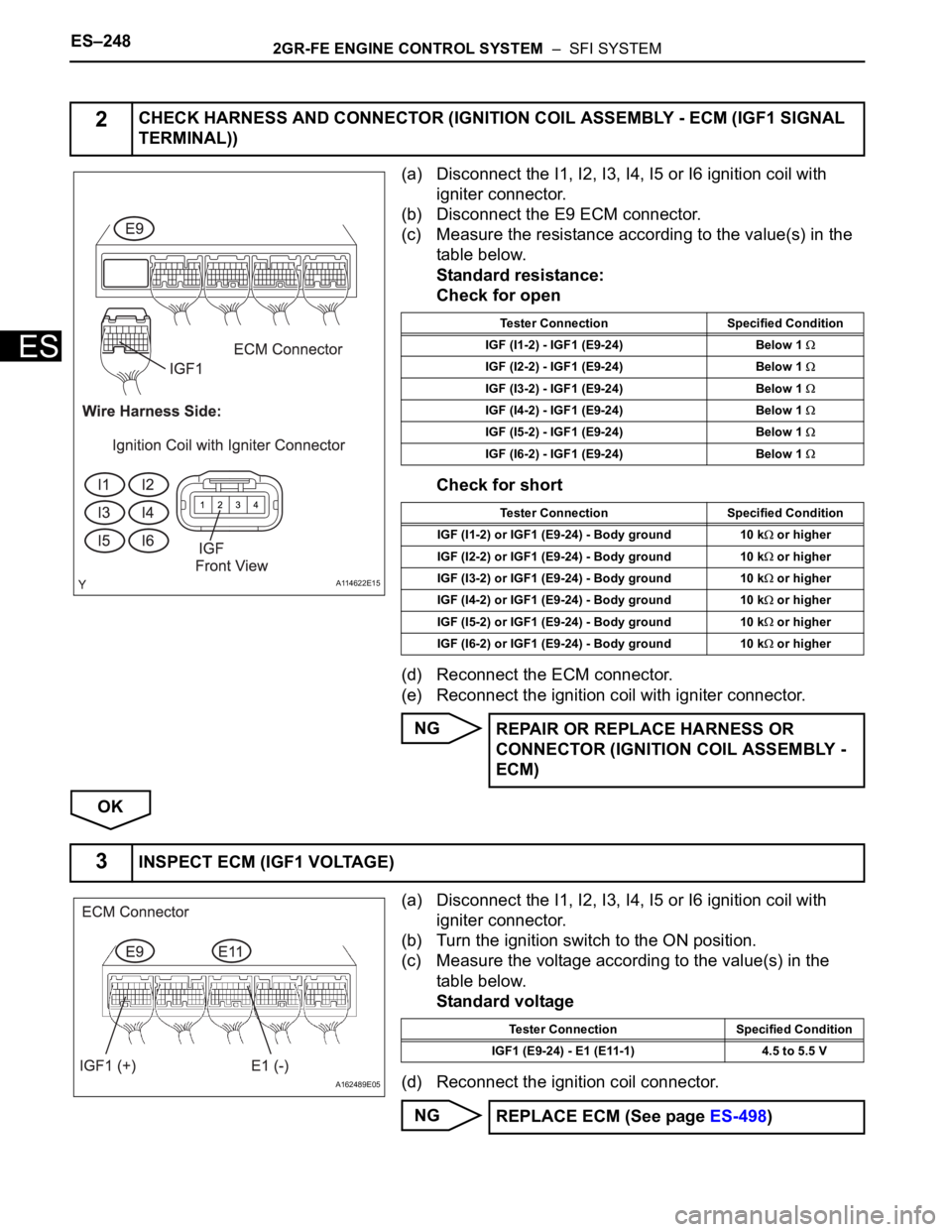

(a) Disconnect the I1, I2, I3, I4, I5 or I6 ignition coil with

igniter connector.

(b) Disconnect the E9 ECM connector.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Check for open

Check for short

(d) Reconnect the ECM connector.

(e) Reconnect the ignition coil with igniter connector.

NG

OK

(a) Disconnect the I1, I2, I3, I4, I5 or I6 ignition coil with

igniter connector.

(b) Turn the ignition switch to the ON position.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

(d) Reconnect the ignition coil connector.

NG

2CHECK HARNESS AND CONNECTOR (IGNITION COIL ASSEMBLY - ECM (IGF1 SIGNAL

TERMINAL))

A114622E15

Tester Connection Specified Condition

IGF (I1-2) - IGF1 (E9-24) Below 1

IGF (I2-2) - IGF1 (E9-24) Below 1

IGF (I3-2) - IGF1 (E9-24) Below 1

IGF (I4-2) - IGF1 (E9-24) Below 1

IGF (I5-2) - IGF1 (E9-24) Below 1

IGF (I6-2) - IGF1 (E9-24) Below 1

Tester Connection Specified Condition

IGF (I1-2) or IGF1 (E9-24) - Body ground 10 k

or higher

IGF (I2-2) or IGF1 (E9-24) - Body ground 10 k

or higher

IGF (I3-2) or IGF1 (E9-24) - Body ground 10 k

or higher

IGF (I4-2) or IGF1 (E9-24) - Body ground 10 k

or higher

IGF (I5-2) or IGF1 (E9-24) - Body ground 10 k

or higher

IGF (I6-2) or IGF1 (E9-24) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (IGNITION COIL ASSEMBLY -

ECM)

3INSPECT ECM (IGF1 VOLTAGE)

A162489E05

Tester Connection Specified Condition

IGF1 (E9-24) - E1 (E11-1) 4.5 to 5.5 V

REPLACE ECM (See page ES-498)

Page 555 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–249

ES

OK

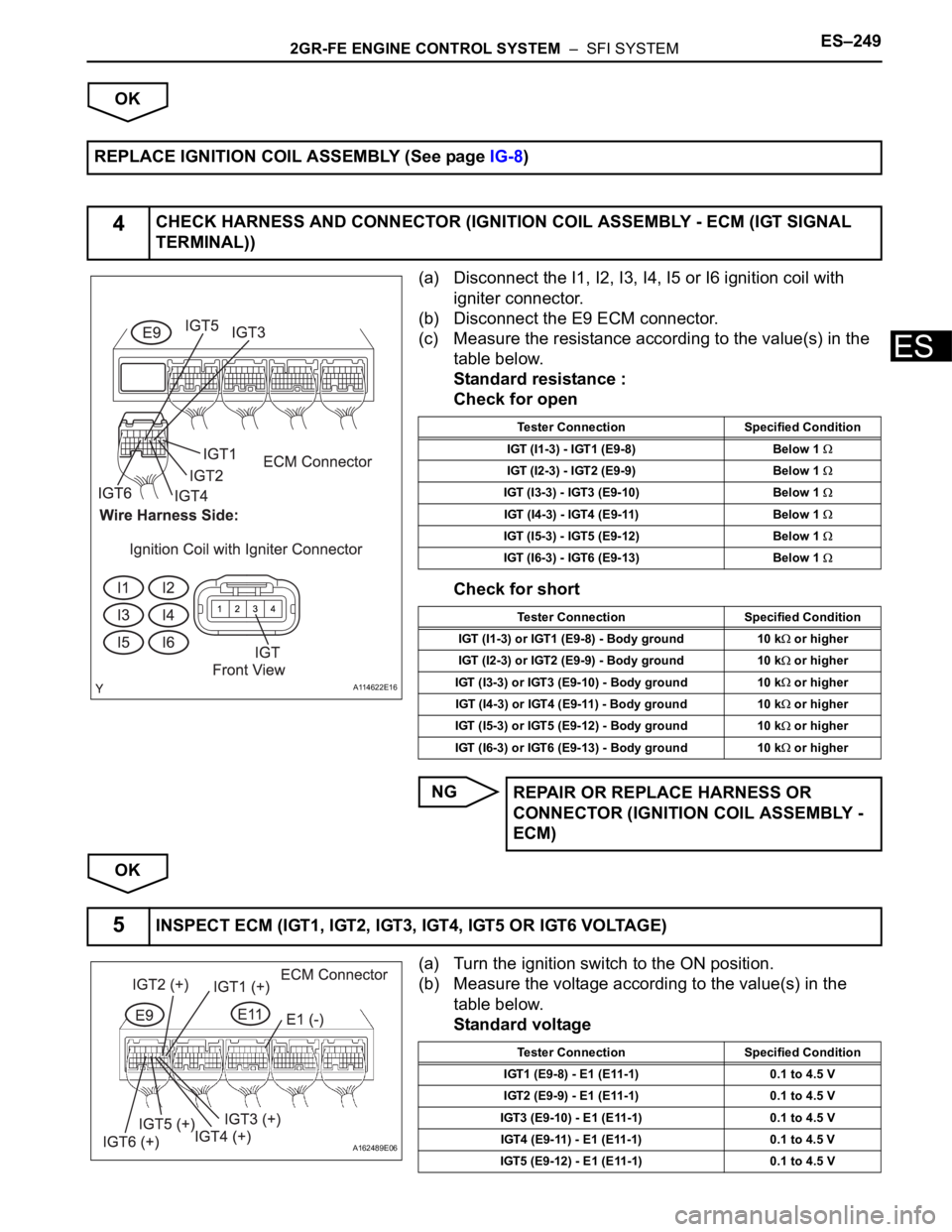

(a) Disconnect the I1, I2, I3, I4, I5 or I6 ignition coil with

igniter connector.

(b) Disconnect the E9 ECM connector.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance :

Check for open

Check for short

NG

OK

(a) Turn the ignition switch to the ON position.

(b) Measure the voltage according to the value(s) in the

table below.

Standard voltage REPLACE IGNITION COIL ASSEMBLY (See page IG-8)

4CHECK HARNESS AND CONNECTOR (IGNITION COIL ASSEMBLY - ECM (IGT SIGNAL

TERMINAL))

A114622E16

Tester Connection Specified Condition

IGT (I1-3) - IGT1 (E9-8) Below 1

IGT (I2-3) - IGT2 (E9-9) Below 1

IGT (I3-3) - IGT3 (E9-10) Below 1

IGT (I4-3) - IGT4 (E9-11) Below 1

IGT (I5-3) - IGT5 (E9-12) Below 1

IGT (I6-3) - IGT6 (E9-13) Below 1

Tester Connection Specified Condition

IGT (I1-3) or IGT1 (E9-8) - Body ground 10 k

or higher

IGT (I2-3) or IGT2 (E9-9) - Body ground 10 k

or higher

IGT (I3-3) or IGT3 (E9-10) - Body ground 10 k

or higher

IGT (I4-3) or IGT4 (E9-11) - Body ground 10 k

or higher

IGT (I5-3) or IGT5 (E9-12) - Body ground 10 k

or higher

IGT (I6-3) or IGT6 (E9-13) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (IGNITION COIL ASSEMBLY -

ECM)

5INSPECT ECM (IGT1, IGT2, IGT3, IGT4, IGT5 OR IGT6 VOLTAGE)

A162489E06

Tester Connection Specified Condition

IGT1 (E9-8) - E1 (E11-1) 0.1 to 4.5 V

IGT2 (E9-9) - E1 (E11-1) 0.1 to 4.5 V

IGT3 (E9-10) - E1 (E11-1) 0.1 to 4.5 V

IGT4 (E9-11) - E1 (E11-1) 0.1 to 4.5 V

IGT5 (E9-12) - E1 (E11-1) 0.1 to 4.5 V

Page 556 of 3000

ES–2502GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

NG

OK

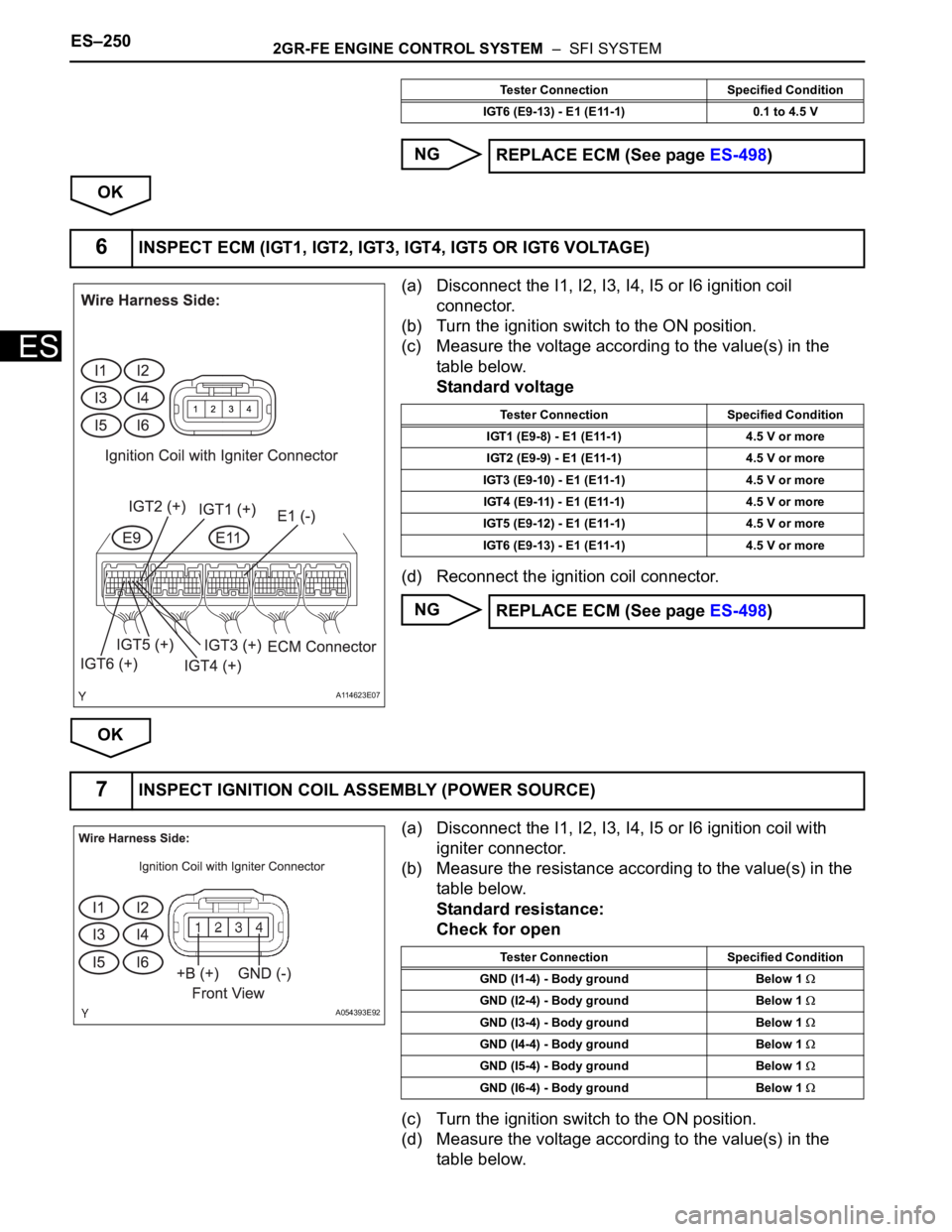

(a) Disconnect the I1, I2, I3, I4, I5 or I6 ignition coil

connector.

(b) Turn the ignition switch to the ON position.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

(d) Reconnect the ignition coil connector.

NG

OK

(a) Disconnect the I1, I2, I3, I4, I5 or I6 ignition coil with

igniter connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Check for open

(c) Turn the ignition switch to the ON position.

(d) Measure the voltage according to the value(s) in the

table below.

IGT6 (E9-13) - E1 (E11-1) 0.1 to 4.5 V

REPLACE ECM (See page ES-498)

Tester Connection Specified Condition

6INSPECT ECM (IGT1, IGT2, IGT3, IGT4, IGT5 OR IGT6 VOLTAGE)

A114623E07

Tester Connection Specified Condition

IGT1 (E9-8) - E1 (E11-1) 4.5 V or more

IGT2 (E9-9) - E1 (E11-1) 4.5 V or more

IGT3 (E9-10) - E1 (E11-1) 4.5 V or more

IGT4 (E9-11) - E1 (E11-1) 4.5 V or more

IGT5 (E9-12) - E1 (E11-1) 4.5 V or more

IGT6 (E9-13) - E1 (E11-1) 4.5 V or more

REPLACE ECM (See page ES-498)

7INSPECT IGNITION COIL ASSEMBLY (POWER SOURCE)

A054393E92

Tester Connection Specified Condition

GND (I1-4) - Body ground Below 1

GND (I2-4) - Body ground Below 1

GND (I3-4) - Body ground Below 1

GND (I4-4) - Body ground Below 1

GND (I5-4) - Body ground Below 1

GND (I6-4) - Body ground Below 1

Page 558 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–265

ES

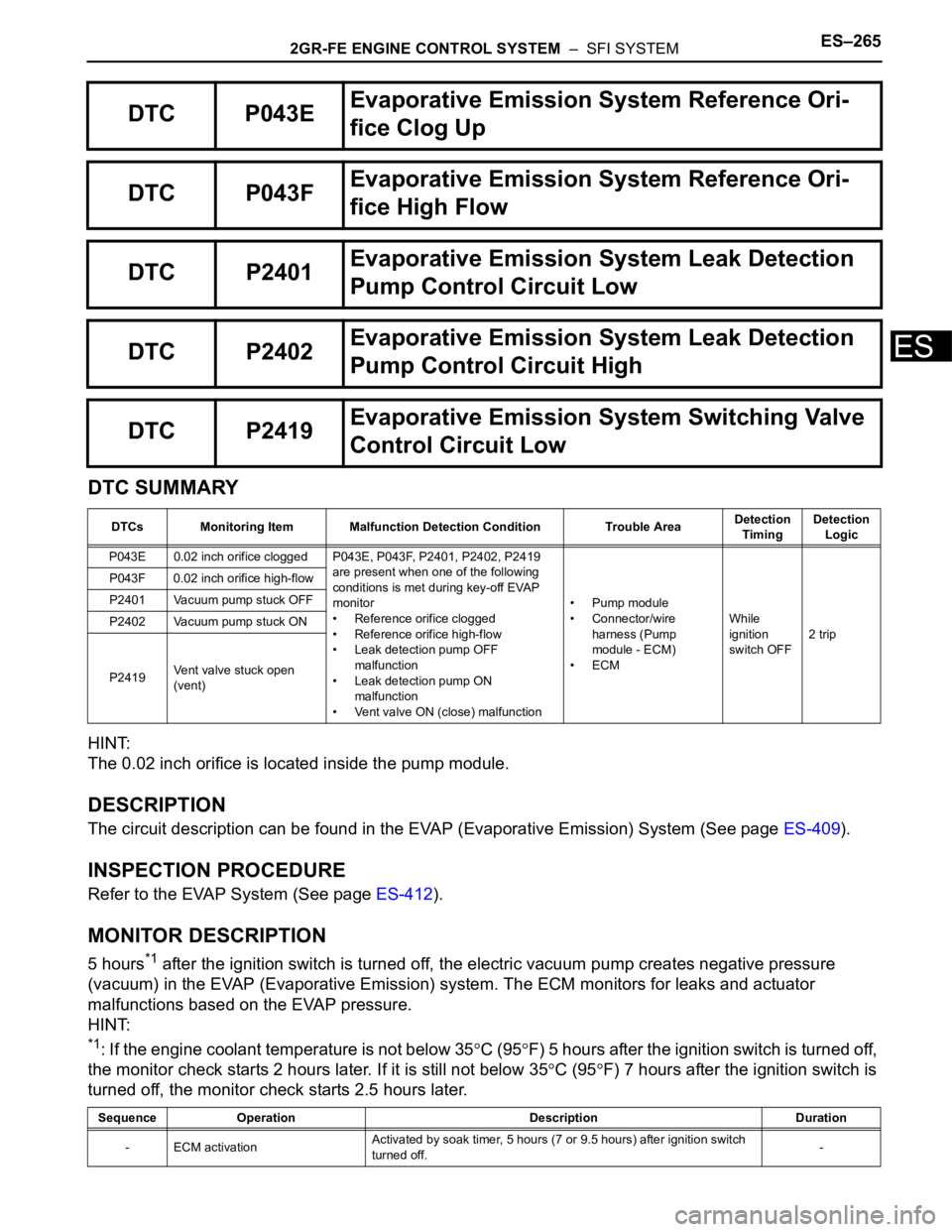

DTC SUMMARY

HINT:

The 0.02 inch orifice is located inside the pump module.

DESCRIPTION

The circuit description can be found in the EVAP (Evaporative Emission) System (See page ES-409).

INSPECTION PROCEDURE

Refer to the EVAP System (See page ES-412).

MONITOR DESCRIPTION

5 hours*1 after the ignition switch is turned off, the electric vacuum pump creates negative pressure

(vacuum) in the EVAP (Evaporative Emission) system. The ECM monitors for leaks and actuator

malfunctions based on the EVAP pressure.

HINT:

*1: If the engine coolant temperature is not below 35C (95F) 5 hours after the ignition switch is turned off,

the monitor check starts 2 hours later. If it is still not below 35

C (95F) 7 hours after the ignition switch is

turned off, the monitor check starts 2.5 hours later.

DTC P043EEvaporative Emission System Reference Ori-

fice Clog Up

DTC P043FEvaporative Emission System Reference Ori-

fice High Flow

DTC P2401Evaporative Emission System Leak Detection

Pump Control Circuit Low

DTC P2402Evaporative Emission System Leak Detection

Pump Control Circuit High

DTC P2419Evaporative Emission System Switching Valve

Control Circuit Low

DTCs Monitoring Item Malfunction Detection Condition Trouble AreaDetection

TimingDetection

Logic

P043E 0.02 inch orifice clogged P043E, P043F, P2401, P2402, P2419

are present when one of the following

conditions is met during key-off EVAP

monitor

• Reference orifice clogged

• Reference orifice high-flow

• Leak detection pump OFF

malfunction

• Leak detection pump ON

malfunction

• Vent valve ON (close) malfunction• Pump module

• Connector/wire

harness (Pump

module - ECM)

•ECMWhile

ignition

switch OFF2 trip P043F 0.02 inch orifice high-flow

P2401 Vacuum pump stuck OFF

P2402 Vacuum pump stuck ON

P2419Vent valve stuck open

(vent)

Sequence Operation Description Duration

- ECM activationActivated by soak timer, 5 hours (7 or 9.5 hours) after ignition switch

turned off.-

Page 559 of 3000

ES–2662GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

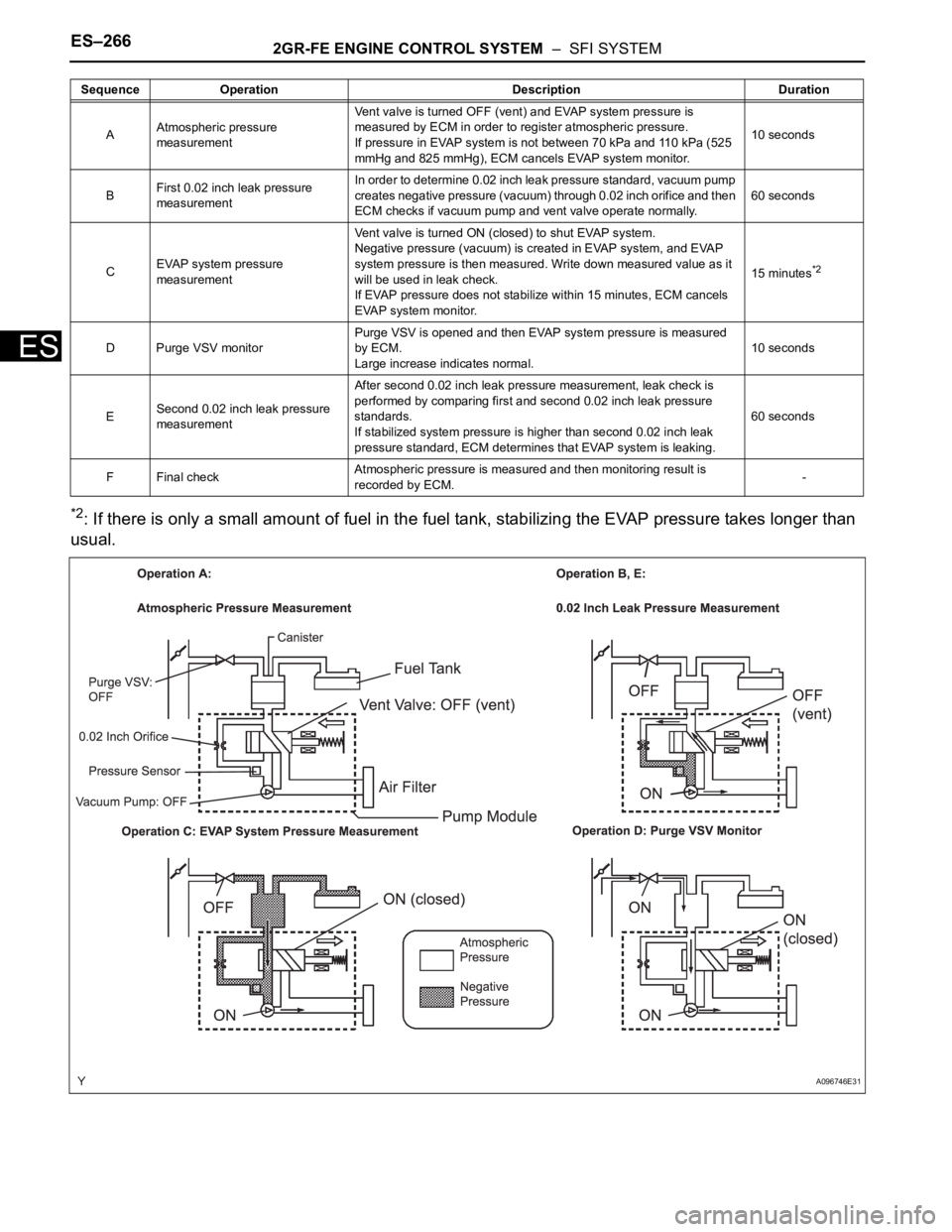

*2: If there is only a small amount of fuel in the fuel tank, stabilizing the EVAP pressure takes longer than

usual.

AAtmospheric pressure

measurementVent valve is turned OFF (vent) and EVAP system pressure is

measured by ECM in order to register atmospheric pressure.

If pressure in EVAP system is not between 70 kPa and 110 kPa (525

mmHg and 825 mmHg), ECM cancels EVAP system monitor.10 seconds

BFirst 0.02 inch leak pressure

measurementIn order to determine 0.02 inch leak pressure standard, vacuum pump

creates negative pressure (vacuum) through 0.02 inch orifice and then

ECM checks if vacuum pump and vent valve operate normally.60 seconds

CEVAP system pressure

measurementVent valve is turned ON (closed) to shut EVAP system.

Negative pressure (vacuum) is created in EVAP system, and EVAP

system pressure is then measured. Write down measured value as it

will be used in leak check.

If EVAP pressure does not stabilize within 15 minutes, ECM cancels

EVAP system monitor.15 minutes

*2

D Purge VSV monitorPurge VSV is opened and then EVAP system pressure is measured

by ECM.

Large increase indicates normal.10 seconds

ESecond 0.02 inch leak pressure

measurementAfter second 0.02 inch leak pressure measurement, leak check is

performed by comparing first and second 0.02 inch leak pressure

standards.

If stabilized system pressure is higher than second 0.02 inch leak

pressure standard, ECM determines that EVAP system is leaking.60 seconds

F Final checkAtmospheric pressure is measured and then monitoring result is

recorded by ECM.- Sequence Operation Description Duration

A096746E31

Page 561 of 3000

ES–2682GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

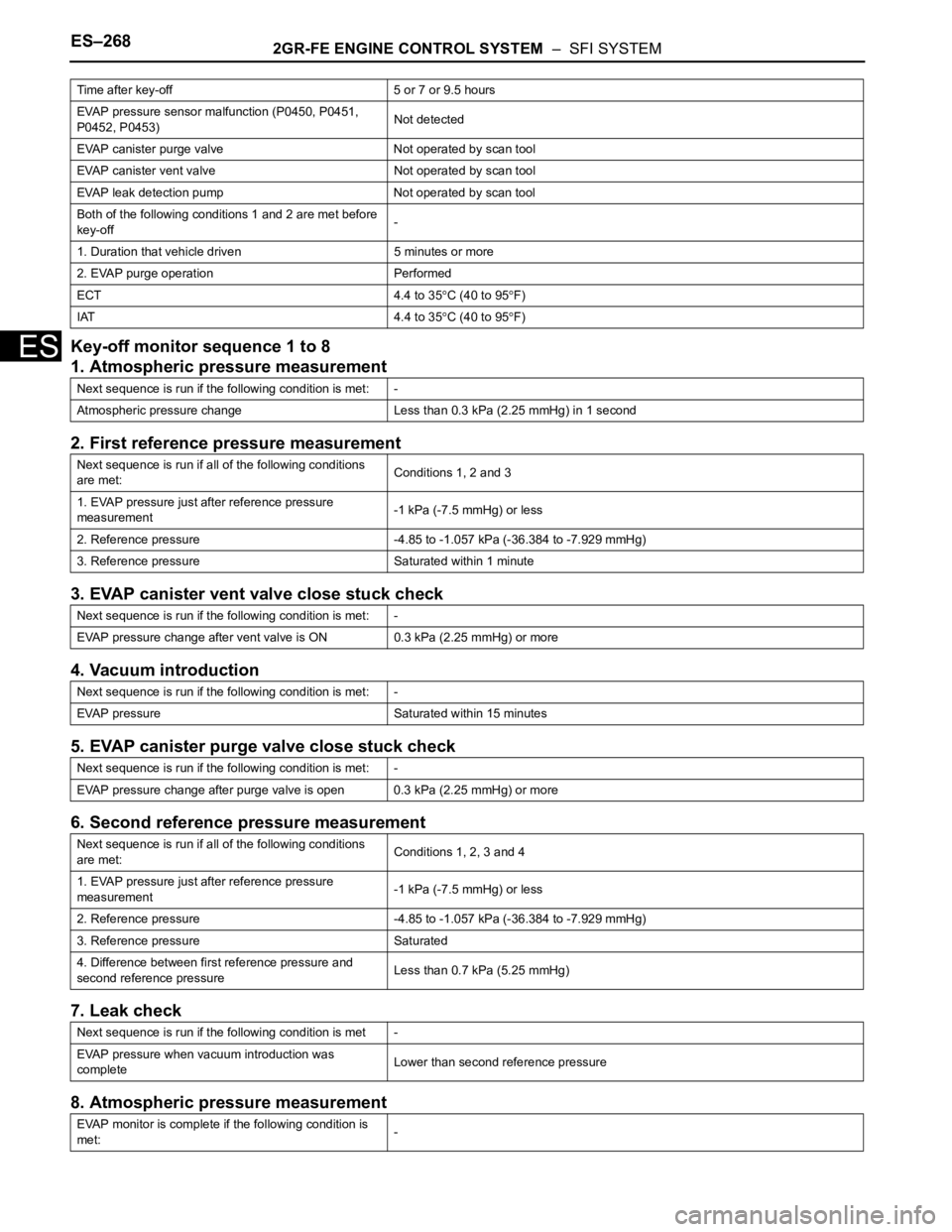

ESKey-off monitor sequence 1 to 8

1. Atmospheric pressure measurement

2. First reference pressure measurement

3. EVAP canister vent valve close stuck check

4. Vacuum introduction

5. EVAP canister purge valve close stuck check

6. Second reference pressure measurement

7. Leak check

8. Atmospheric pressure measurement

Time after key-off 5 or 7 or 9.5 hours

EVAP pressure sensor malfunction (P0450, P0451,

P0452, P0453)Not detected

EVAP canister purge valve Not operated by scan tool

EVAP canister vent valve Not operated by scan tool

EVAP leak detection pump Not operated by scan tool

Both of the following conditions 1 and 2 are met before

key-off-

1. Duration that vehicle driven 5 minutes or more

2. EVAP purge operation Performed

ECT 4.4 to 35

C (40 to 95F)

IAT 4.4 to 35

C (40 to 95F)

Next sequence is run if the following condition is met: -

Atmospheric pressure change Less than 0.3 kPa (2.25 mmHg) in 1 second

Next sequence is run if all of the following conditions

are met:Conditions 1, 2 and 3

1. EVAP pressure just after reference pressure

measurement-1 kPa (-7.5 mmHg) or less

2. Reference pressure -4.85 to -1.057 kPa (-36.384 to -7.929 mmHg)

3. Reference pressure Saturated within 1 minute

Next sequence is run if the following condition is met: -

EVAP pressure change after vent valve is ON 0.3 kPa (2.25 mmHg) or more

Next sequence is run if the following condition is met: -

EVAP pressure Saturated within 15 minutes

Next sequence is run if the following condition is met: -

EVAP pressure change after purge valve is open 0.3 kPa (2.25 mmHg) or more

Next sequence is run if all of the following conditions

are met:Conditions 1, 2, 3 and 4

1. EVAP pressure just after reference pressure

measurement-1 kPa (-7.5 mmHg) or less

2. Reference pressure -4.85 to -1.057 kPa (-36.384 to -7.929 mmHg)

3. Reference pressure Saturated

4. Difference between first reference pressure and

second reference pressureLess than 0.7 kPa (5.25 mmHg)

Next sequence is run if the following condition is met -

EVAP pressure when vacuum introduction was

completeLower than second reference pressure

EVAP monitor is complete if the following condition is

met:-

Page 562 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–269

ES

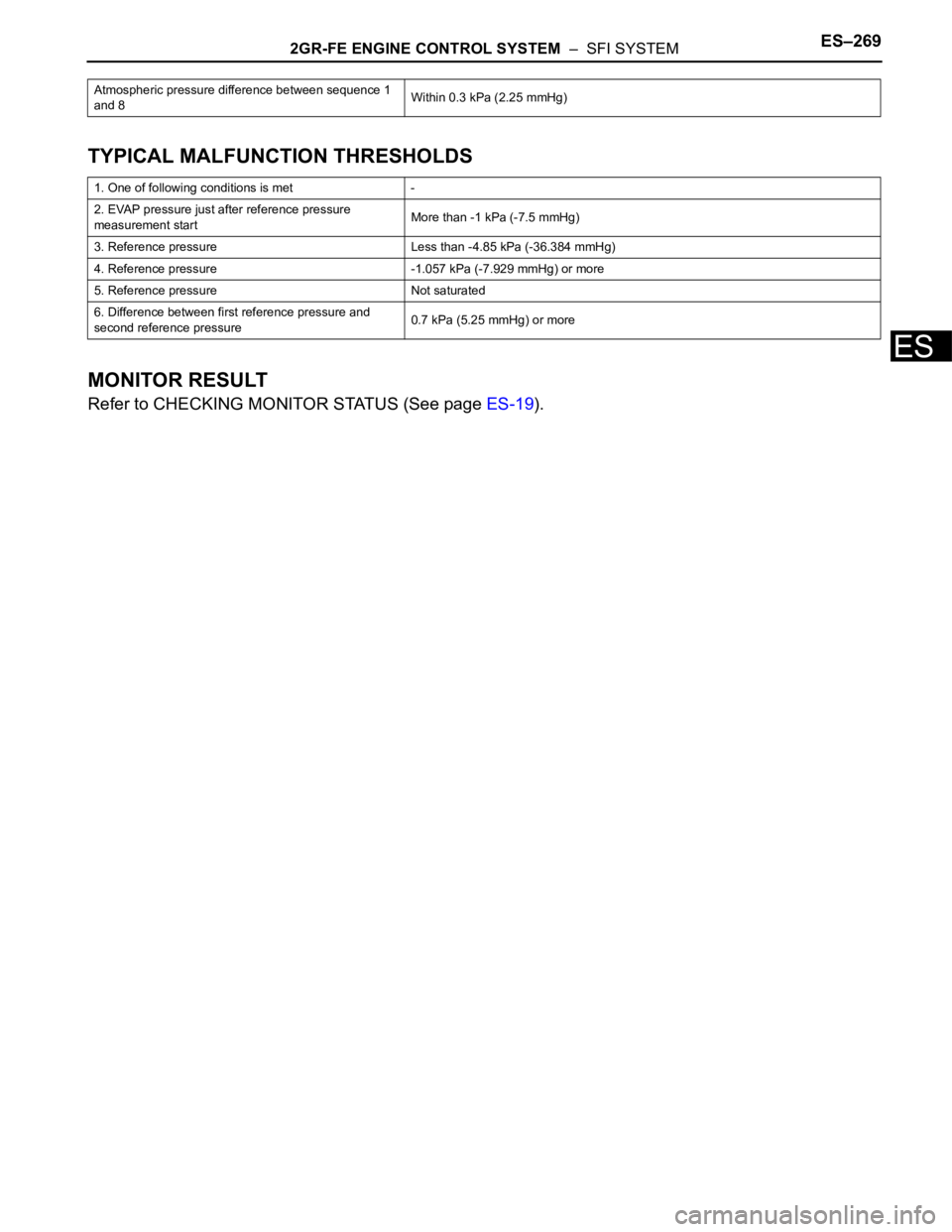

TYPICAL MALFUNCTION THRESHOLDS

MONITOR RESULT

Refer to CHECKING MONITOR STATUS (See page ES-19).

Atmospheric pressure difference between sequence 1

and 8Within 0.3 kPa (2.25 mmHg)

1. One of following conditions is met -

2. EVAP pressure just after reference pressure

measurement startMore than -1 kPa (-7.5 mmHg)

3. Reference pressure Less than -4.85 kPa (-36.384 mmHg)

4. Reference pressure -1.057 kPa (-7.929 mmHg) or more

5. Reference pressure Not saturated

6. Difference between first reference pressure and

second reference pressure0.7 kPa (5.25 mmHg) or more