TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1911 of 3000

AX–228U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

(b) Using a pin punch and hammer, drive in a new pin.

(c) Turn the spacer and the lever shaft to align the small

hole for locating the staking position in the spacer

with the staking position mark on the lever shaft.

(d) Using a pin punch, stake the spacer through the

small hole.

(e) Check that the spacer does not turn.

56. INSTALL MANUAL VALVE LEVER SHAFT RETAINER

SPRING

(a) Using needle-nose pliers, install the retainer spring.

NOTICE:

Hang the spring on the shaft firmly.

57. INSTALL PARKING LOCK PAWL BRACKET

(a) Install the parking lock pawl bracket with the 2 bolts.

Torque: 20 N*m (205 kgf*cm, 15 ft.*lbf)

Bolt length:

25 mm (0.984 in.)

NOTICE:

Make sure that the parking rod is placed

between the parking pawl and the guide of the

parking bracket when the parking bracket is

installed.

58. INSTALL MANUAL DETENT SPRING SUB-

ASSEMBLY

(a) Install the manual detent spring and cover with the 2

bolts.

NOTICE:

Make sure to install the manual detent spring

and cover in this order.

HINT:

Tighten bolt A first, and then bolt B.

To r q u e : B o l t A

20 N*m (205 kgf*cm, 15 ft.*lbf)

D003564

D026765

D003559

D003561E01

D003560E01

Page 1912 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–229

AX

Bolt B

12 N*m (120 kgf*cm, 9 ft.*lbf)

Bolt length:

Bolt A:

27 mm (1.063 in.)

Bolt B:

16 mm (0.630 in.)

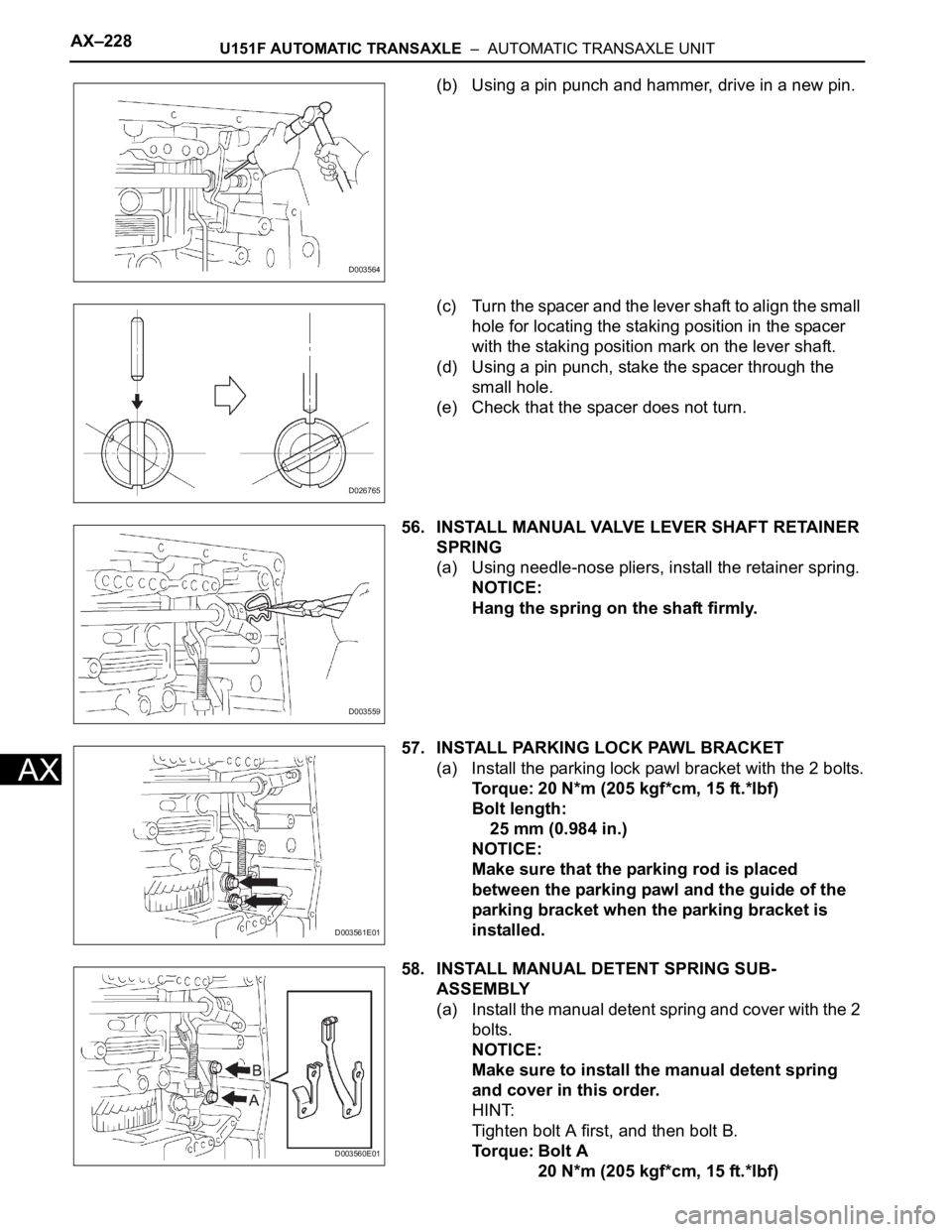

59. INSTALL B-3 ACCUMULATOR PISTON

(a) Coat a new O-ring with ATF, install it to the B-3

accumulator piston.

NOTICE:

Make sure that the O-ring is not twisted and that

it does not protrude abnormally from the

accumulator piston. Apply sufficient ATF before

installing the O-ring. The O-ring must be

installed in the correct position.

(b) Coat the piston with ATF, install it to the transaxle

case.

NOTICE:

Install the springs to each accumulator piston,

checking the identification color or each spring.

Accumulator spring:

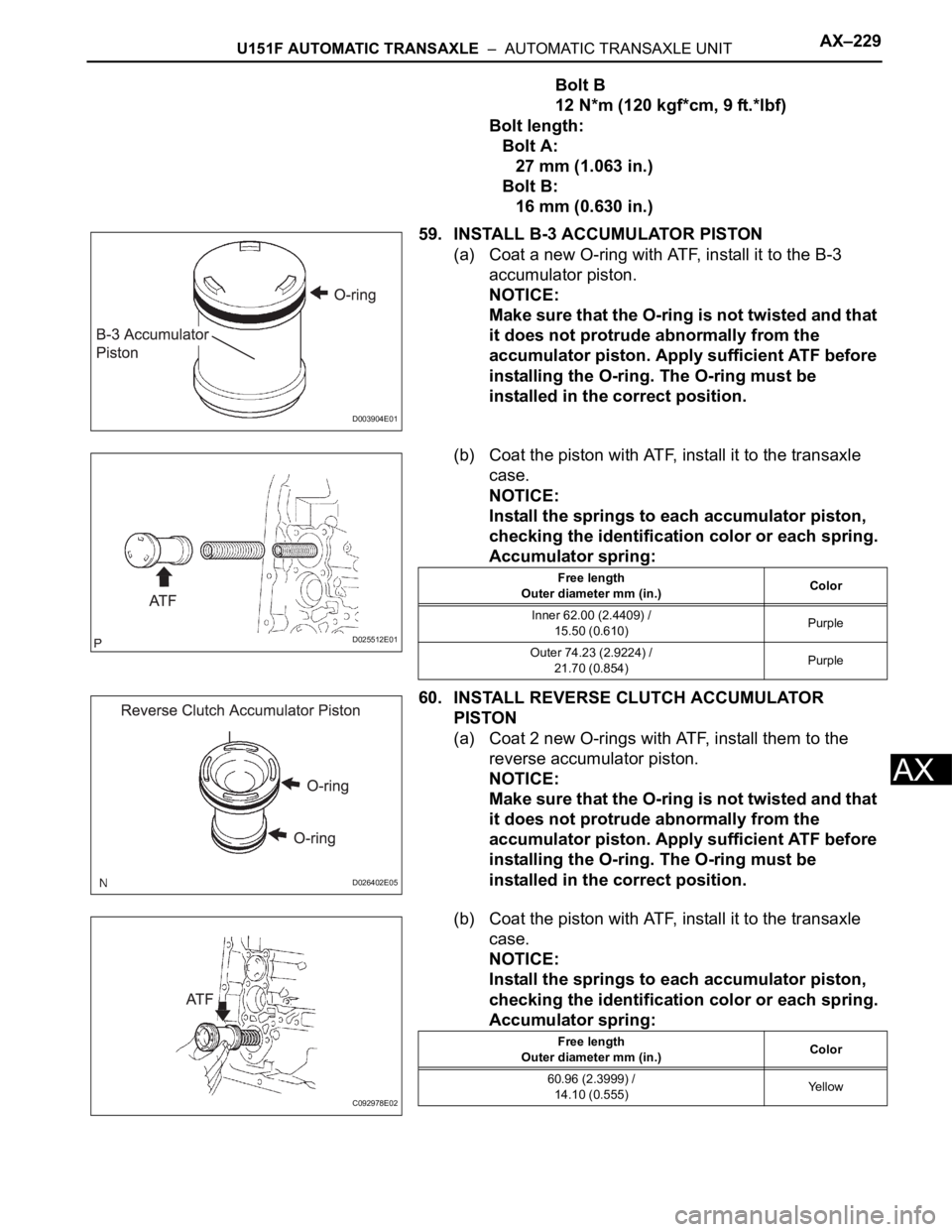

60. INSTALL REVERSE CLUTCH ACCUMULATOR

PISTON

(a) Coat 2 new O-rings with ATF, install them to the

reverse accumulator piston.

NOTICE:

Make sure that the O-ring is not twisted and that

it does not protrude abnormally from the

accumulator piston. Apply sufficient ATF before

installing the O-ring. The O-ring must be

installed in the correct position.

(b) Coat the piston with ATF, install it to the transaxle

case.

NOTICE:

Install the springs to each accumulator piston,

checking the identification color or each spring.

Accumulator spring:

D003904E01

D025512E01

Free length

Outer diameter mm (in.)Color

Inner 62.00 (2.4409) /

15.50 (0.610)Purple

Outer 74.23 (2.9224) /

21.70 (0.854)Purple

D026402E05

C092978E02

Free length

Outer diameter mm (in.)Color

60.96 (2.3999) /

14.10 (0.555)Ye l l o w

Page 1913 of 3000

AX–230U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

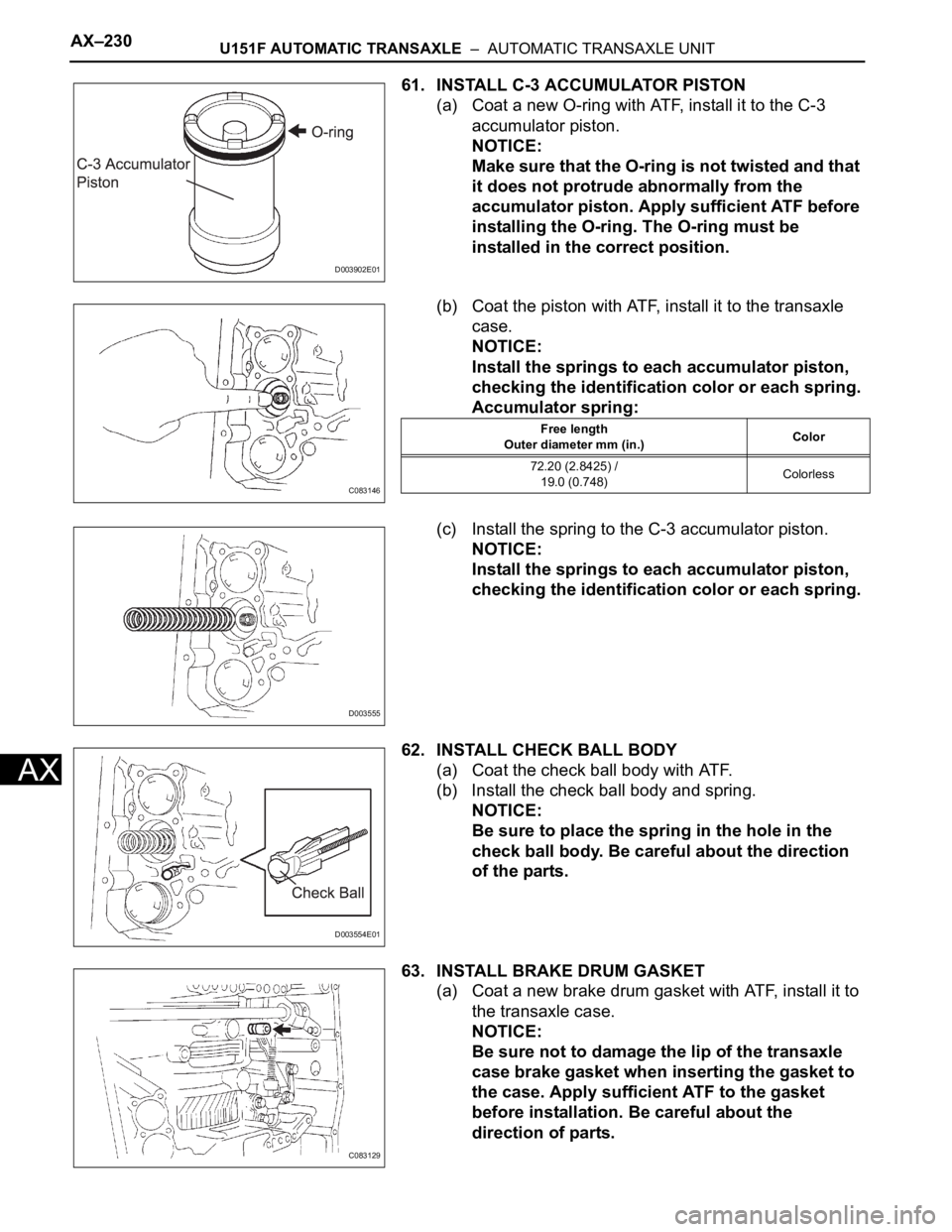

61. INSTALL C-3 ACCUMULATOR PISTON

(a) Coat a new O-ring with ATF, install it to the C-3

accumulator piston.

NOTICE:

Make sure that the O-ring is not twisted and that

it does not protrude abnormally from the

accumulator piston. Apply sufficient ATF before

installing the O-ring. The O-ring must be

installed in the correct position.

(b) Coat the piston with ATF, install it to the transaxle

case.

NOTICE:

Install the springs to each accumulator piston,

checking the identification color or each spring.

Accumulator spring:

(c) Install the spring to the C-3 accumulator piston.

NOTICE:

Install the springs to each accumulator piston,

checking the identification color or each spring.

62. INSTALL CHECK BALL BODY

(a) Coat the check ball body with ATF.

(b) Install the check ball body and spring.

NOTICE:

Be sure to place the spring in the hole in the

check ball body. Be careful about the direction

of the parts.

63. INSTALL BRAKE DRUM GASKET

(a) Coat a new brake drum gasket with ATF, install it to

the transaxle case.

NOTICE:

Be sure not to damage the lip of the transaxle

case brake gasket when inserting the gasket to

the case. Apply sufficient ATF to the gasket

before installation. Be careful about the

direction of parts.

D003902E01

C083146

Free length

Outer diameter mm (in.)Color

72.20 (2.8425) /

19.0 (0.748)Colorless

D003555

D003554E01

C083129

Page 1914 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–231

AX

64. INSTALL TRANSAXLE CASE 2ND BRAKE GASKET

(a) Coat a new transaxle case 2nd brake gasket with

ATF, and install it to the transaxle case.

NOTICE:

Be sure not to damage the lip of the transaxle

case brake gasket when inserting the gasket to

the case. Apply sufficient ATF to the gasket

before installation. Be careful about the

direction of parts.

65. INSTALL GOVERNOR APPLY GASKET NO.1

(a) Coat a new governor apply gasket No.1 with ATF,

and install it to the transaxle case.

NOTICE:

Be sure not to damage the lip of the transaxle

case brake gasket when inserting the gasket to

the case. Apply sufficient ATF to the gasket

before installation. Be careful about the

direction of parts.

66. INSTALL TRANSMISSION WIRE

(a) Coat a new O-ring with ATF, and install it to the

transmission wire.

NOTICE:

Make sure that the O-ring is not twisted,

protruded, or pinched when installing the wire

transmission to the transaxle case. Apply

sufficient ATF to the O-ring before installation.

(b) Install the transmission wire retaining bolt.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

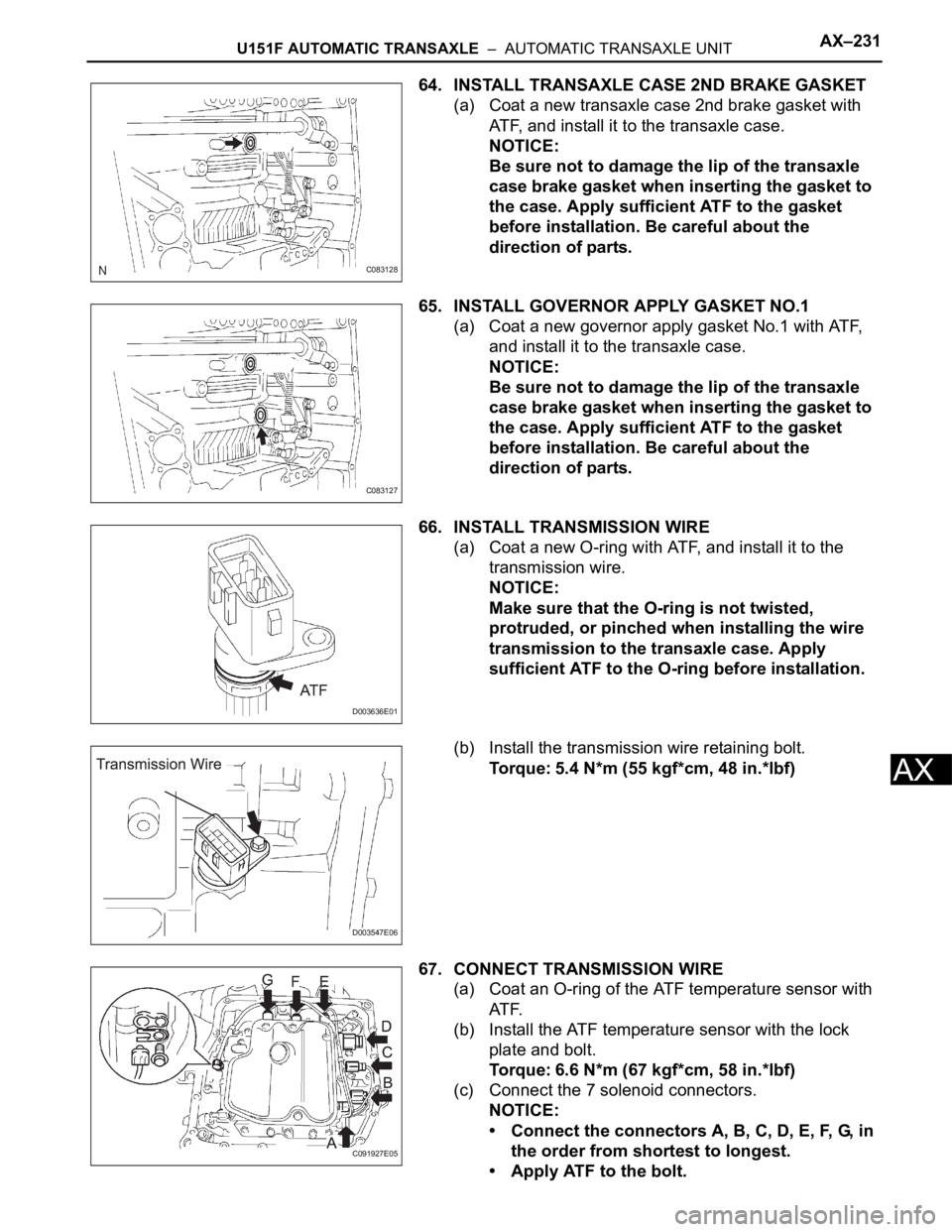

67. CONNECT TRANSMISSION WIRE

(a) Coat an O-ring of the ATF temperature sensor with

AT F.

(b) Install the ATF temperature sensor with the lock

plate and bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf)

(c) Connect the 7 solenoid connectors.

NOTICE:

• Connect the connectors A, B, C, D, E, F, G, in

the order from shortest to longest.

• Apply ATF to the bolt.

C083128

C083127

D003636E01

D003547E06

C091927E05

Page 1915 of 3000

AX–232U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

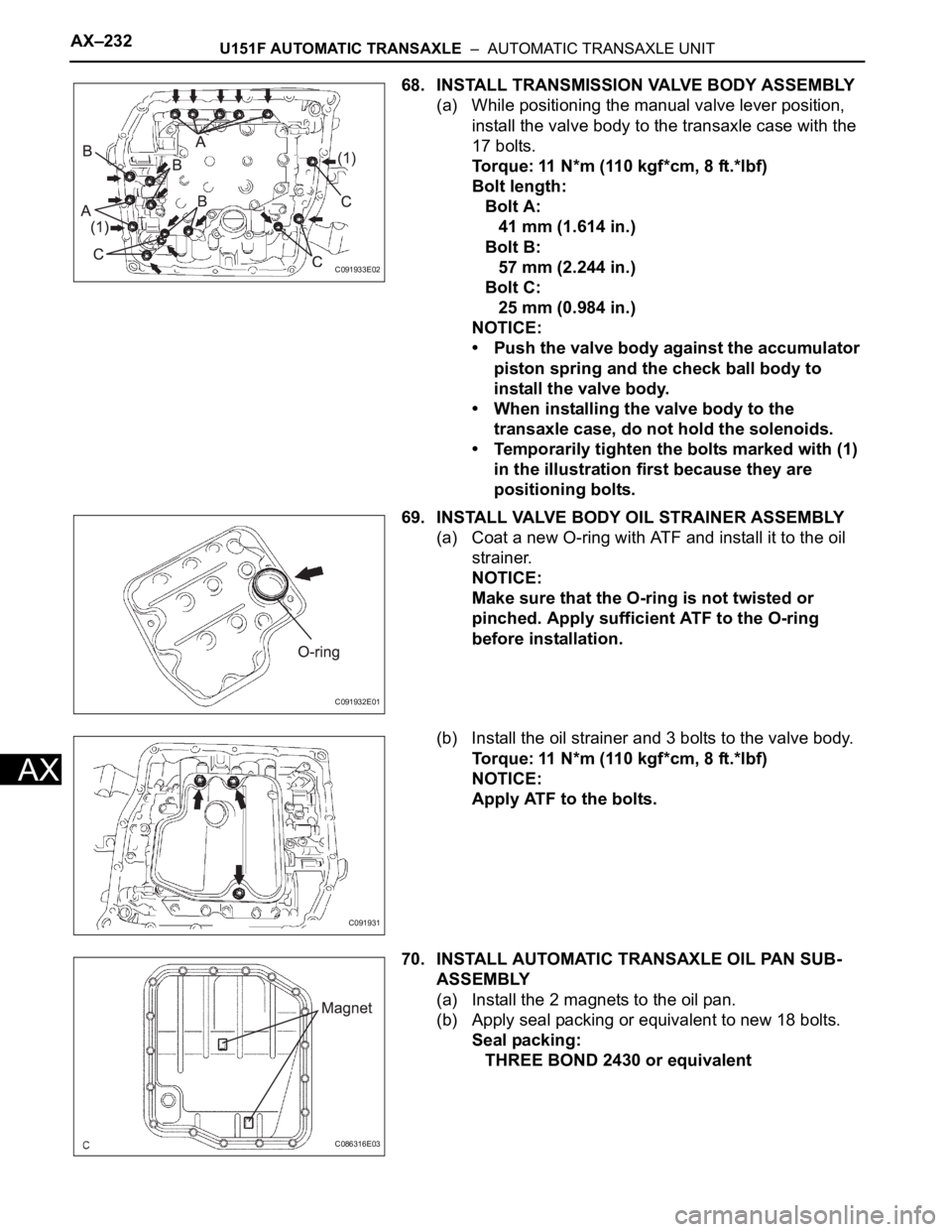

68. INSTALL TRANSMISSION VALVE BODY ASSEMBLY

(a) While positioning the manual valve lever position,

install the valve body to the transaxle case with the

17 bolts.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

Bolt length:

Bolt A:

41 mm (1.614 in.)

Bolt B:

57 mm (2.244 in.)

Bolt C:

25 mm (0.984 in.)

NOTICE:

• Push the valve body against the accumulator

piston spring and the check ball body to

install the valve body.

• When installing the valve body to the

transaxle case, do not hold the solenoids.

• Temporarily tighten the bolts marked with (1)

in the illustration first because they are

positioning bolts.

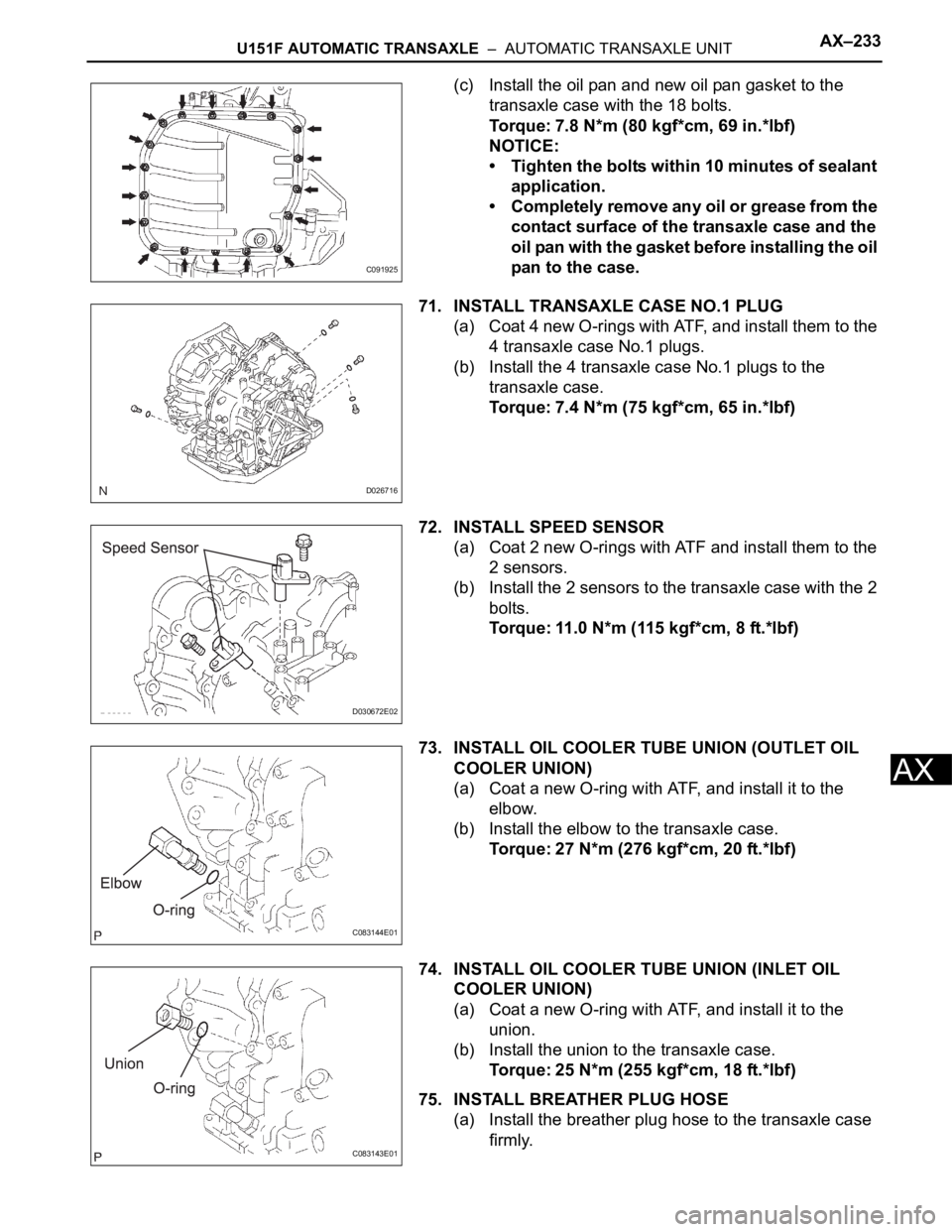

69. INSTALL VALVE BODY OIL STRAINER ASSEMBLY

(a) Coat a new O-ring with ATF and install it to the oil

strainer.

NOTICE:

Make sure that the O-ring is not twisted or

pinched. Apply sufficient ATF to the O-ring

before installation.

(b) Install the oil strainer and 3 bolts to the valve body.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

NOTICE:

Apply ATF to the bolts.

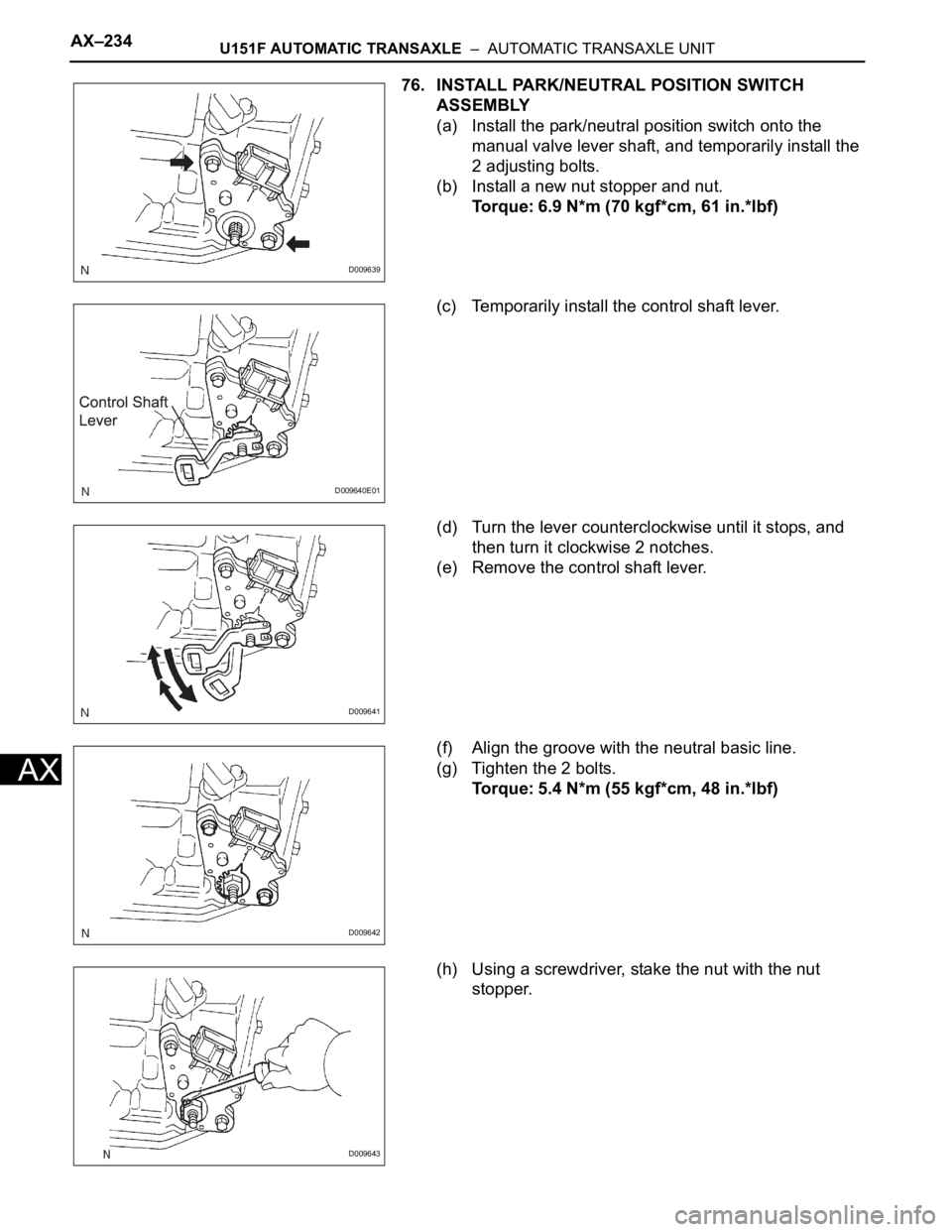

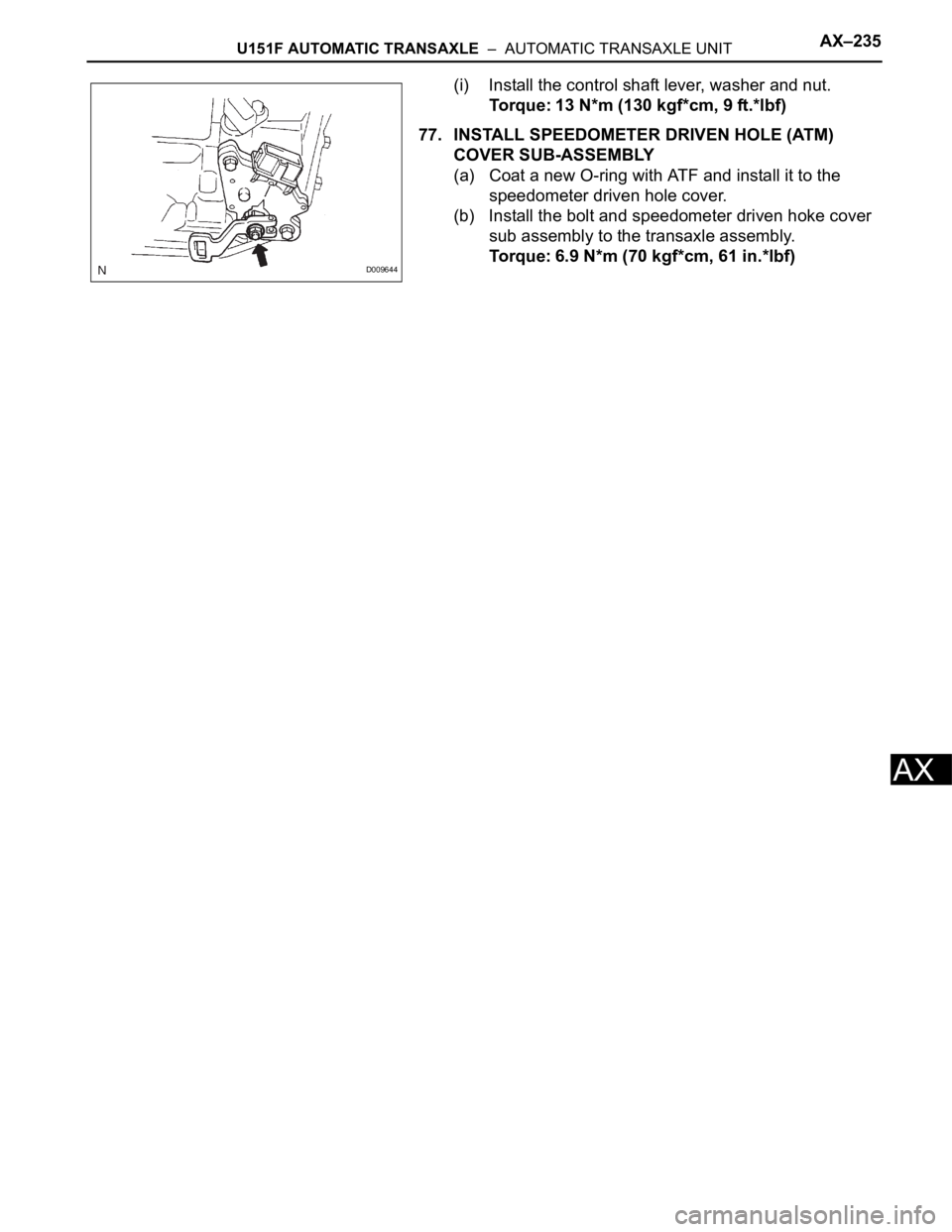

70. INSTALL AUTOMATIC TRANSAXLE OIL PAN SUB-

ASSEMBLY

(a) Install the 2 magnets to the oil pan.

(b) Apply seal packing or equivalent to new 18 bolts.

Seal packing:

THREE BOND 2430 or equivalent

C091933E02

C091932E01

C091931

C086316E03

Page 1916 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–233

AX

(c) Install the oil pan and new oil pan gasket to the

transaxle case with the 18 bolts.

Torque: 7.8 N*m (80 kgf*cm, 69 in.*lbf)

NOTICE:

• Tighten the bolts within 10 minutes of sealant

application.

• Completely remove any oil or grease from the

contact surface of the transaxle case and the

oil pan with the gasket before installing the oil

pan to the case.

71. INSTALL TRANSAXLE CASE NO.1 PLUG

(a) Coat 4 new O-rings with ATF, and install them to the

4 transaxle case No.1 plugs.

(b) Install the 4 transaxle case No.1 plugs to the

transaxle case.

Torque: 7.4 N*m (75 kgf*cm, 65 in.*lbf)

72. INSTALL SPEED SENSOR

(a) Coat 2 new O-rings with ATF and install them to the

2 sensors.

(b) Install the 2 sensors to the transaxle case with the 2

bolts.

Torque: 11.0 N*m (115 kgf*cm, 8 ft.*lbf)

73. INSTALL OIL COOLER TUBE UNION (OUTLET OIL

COOLER UNION)

(a) Coat a new O-ring with ATF, and install it to the

elbow.

(b) Install the elbow to the transaxle case.

Torque: 27 N*m (276 kgf*cm, 20 ft.*lbf)

74. INSTALL OIL COOLER TUBE UNION (INLET OIL

COOLER UNION)

(a) Coat a new O-ring with ATF, and install it to the

union.

(b) Install the union to the transaxle case.

Torque: 25 N*m (255 kgf*cm, 18 ft.*lbf)

75. INSTALL BREATHER PLUG HOSE

(a) Install the breather plug hose to the transaxle case

firmly.

C091925

D026716

D030672E02

C083144E01

C083143E01

Page 1917 of 3000

AX–234U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

76. INSTALL PARK/NEUTRAL POSITION SWITCH

ASSEMBLY

(a) Install the park/neutral position switch onto the

manual valve lever shaft, and temporarily install the

2 adjusting bolts.

(b) Install a new nut stopper and nut.

Torque: 6.9 N*m (70 kgf*cm, 61 in.*lbf)

(c) Temporarily install the control shaft lever.

(d) Turn the lever counterclockwise until it stops, and

then turn it clockwise 2 notches.

(e) Remove the control shaft lever.

(f) Align the groove with the neutral basic line.

(g) Tighten the 2 bolts.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

(h) Using a screwdriver, stake the nut with the nut

stopper.

D009639

D009640E01

D009641

D009642

D009643

Page 1918 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–235

AX

(i) Install the control shaft lever, washer and nut.

Torque: 13 N*m (130 kgf*cm, 9 ft.*lbf)

77. INSTALL SPEEDOMETER DRIVEN HOLE (ATM)

COVER SUB-ASSEMBLY

(a) Coat a new O-ring with ATF and install it to the

speedometer driven hole cover.

(b) Install the bolt and speedometer driven hoke cover

sub assembly to the transaxle assembly.

Torque: 6.9 N*m (70 kgf*cm, 61 in.*lbf)

D009644

Page 1919 of 3000

AX–172U151F AUTOMATIC TRANSAXLE – TORQUE CONVERTER CLUTCH AND DRIVE PLATE

AX

TORQUE CONVERTER CLUTCH

AND DRIVE PLATE

INSPECTION

1. INSPECT TORQUE CONVERTER CLUTCH

ASSEMBLY

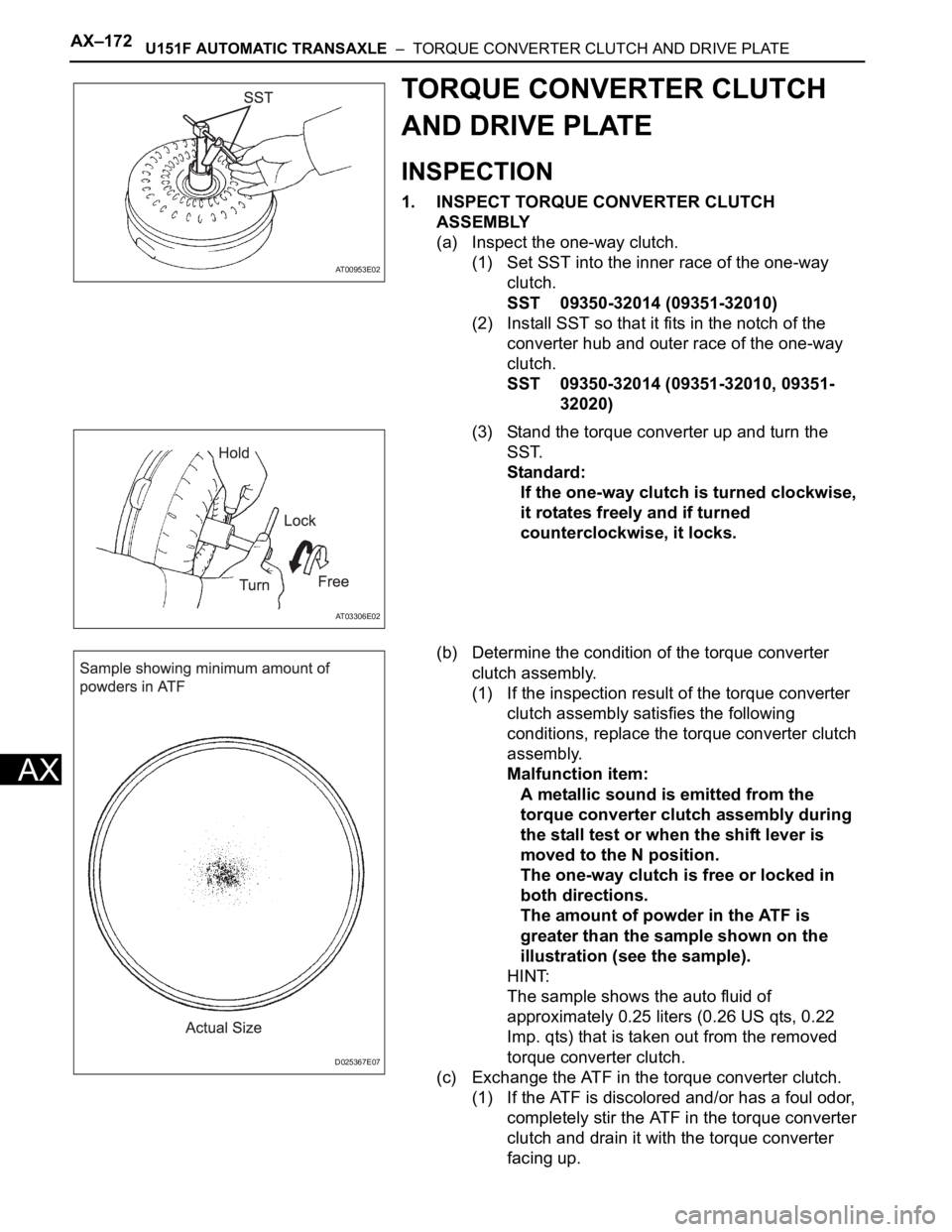

(a) Inspect the one-way clutch.

(1) Set SST into the inner race of the one-way

clutch.

SST 09350-32014 (09351-32010)

(2) Install SST so that it fits in the notch of the

converter hub and outer race of the one-way

clutch.

SST 09350-32014 (09351-32010, 09351-

32020)

(3) Stand the torque converter up and turn the

SST.

Standard:

If the one-way clutch is turned clockwise,

it rotates freely and if turned

counterclockwise, it locks.

(b) Determine the condition of the torque converter

clutch assembly.

(1) If the inspection result of the torque converter

clutch assembly satisfies the following

conditions, replace the torque converter clutch

assembly.

Malfunction item:

A metallic sound is emitted from the

torque converter clutch assembly during

the stall test or when the shift lever is

moved to the N position.

The one-way clutch is free or locked in

both directions.

The amount of powder in the ATF is

greater than the sample shown on the

illustration (see the sample).

HINT:

The sample shows the auto fluid of

approximately 0.25 liters (0.26 US qts, 0.22

Imp. qts) that is taken out from the removed

torque converter clutch.

(c) Exchange the ATF in the torque converter clutch.

(1) If the ATF is discolored and/or has a foul odor,

completely stir the ATF in the torque converter

clutch and drain it with the torque converter

facing up.

AT00953E02

AT03306E02

D025367E07

Page 1920 of 3000

U151F AUTOMATIC TRANSAXLE – TORQUE CONVERTER CLUTCH AND DRIVE PLATEAX–173

AX

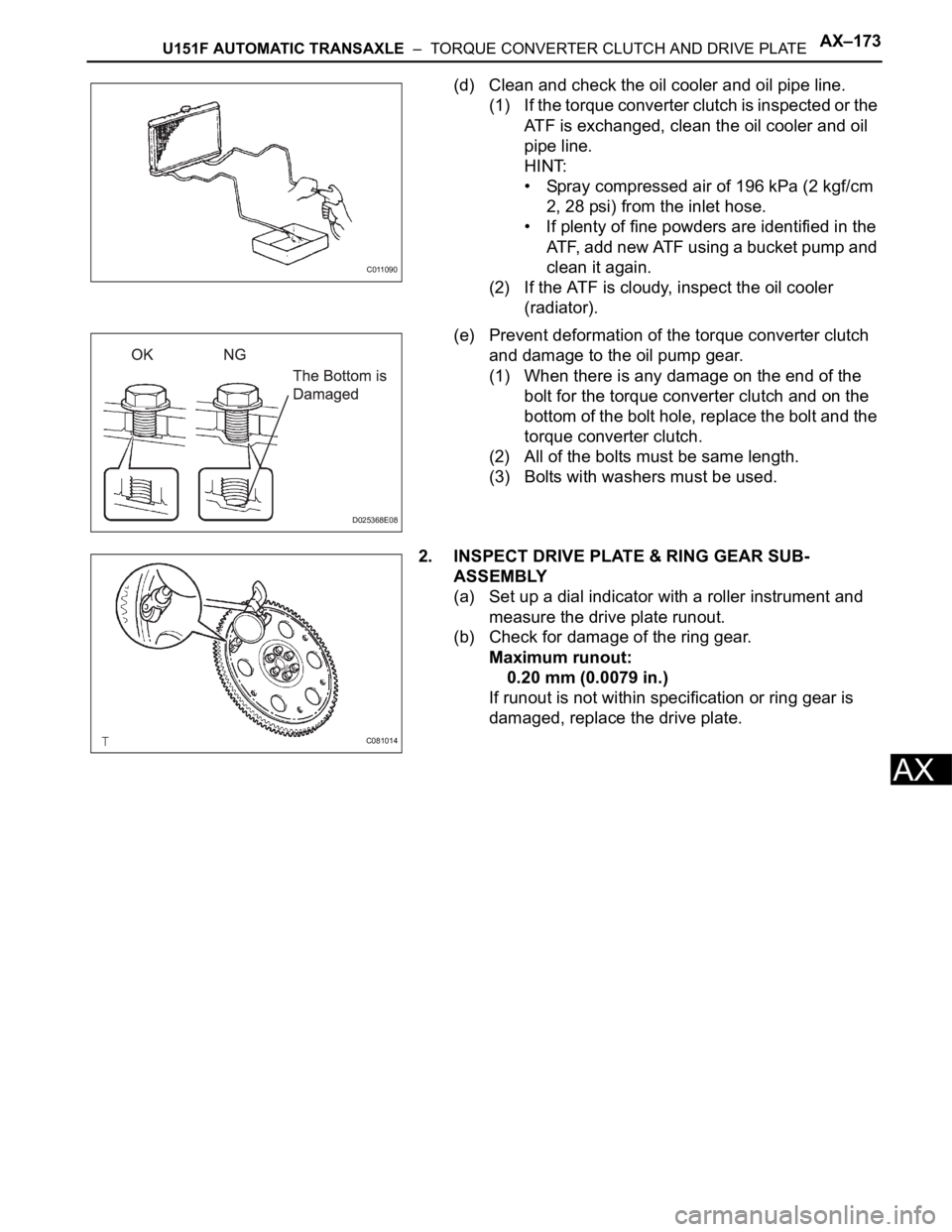

(d) Clean and check the oil cooler and oil pipe line.

(1) If the torque converter clutch is inspected or the

ATF is exchanged, clean the oil cooler and oil

pipe line.

HINT:

• Spray compressed air of 196 kPa (2 kgf/cm

2, 28 psi) from the inlet hose.

• If plenty of fine powders are identified in the

ATF, add new ATF using a bucket pump and

clean it again.

(2) If the ATF is cloudy, inspect the oil cooler

(radiator).

(e) Prevent deformation of the torque converter clutch

and damage to the oil pump gear.

(1) When there is any damage on the end of the

bolt for the torque converter clutch and on the

bottom of the bolt hole, replace the bolt and the

torque converter clutch.

(2) All of the bolts must be same length.

(3) Bolts with washers must be used.

2. INSPECT DRIVE PLATE & RING GEAR SUB-

ASSEMBLY

(a) Set up a dial indicator with a roller instrument and

measure the drive plate runout.

(b) Check for damage of the ring gear.

Maximum runout:

0.20 mm (0.0079 in.)

If runout is not within specification or ring gear is

damaged, replace the drive plate.

C011090

D025368E08

C081014