TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1881 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLYAX–165

AX

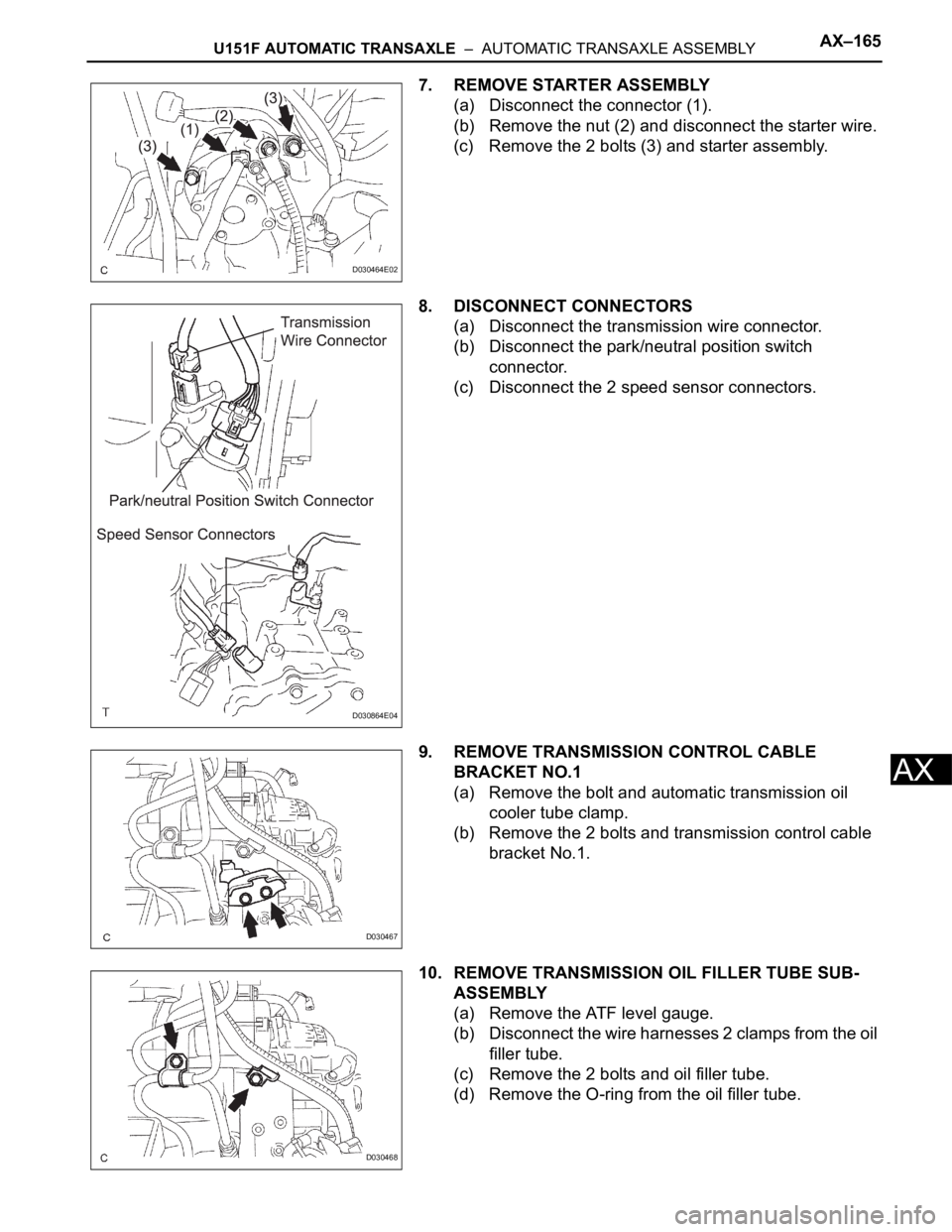

7. REMOVE STARTER ASSEMBLY

(a) Disconnect the connector (1).

(b) Remove the nut (2) and disconnect the starter wire.

(c) Remove the 2 bolts (3) and starter assembly.

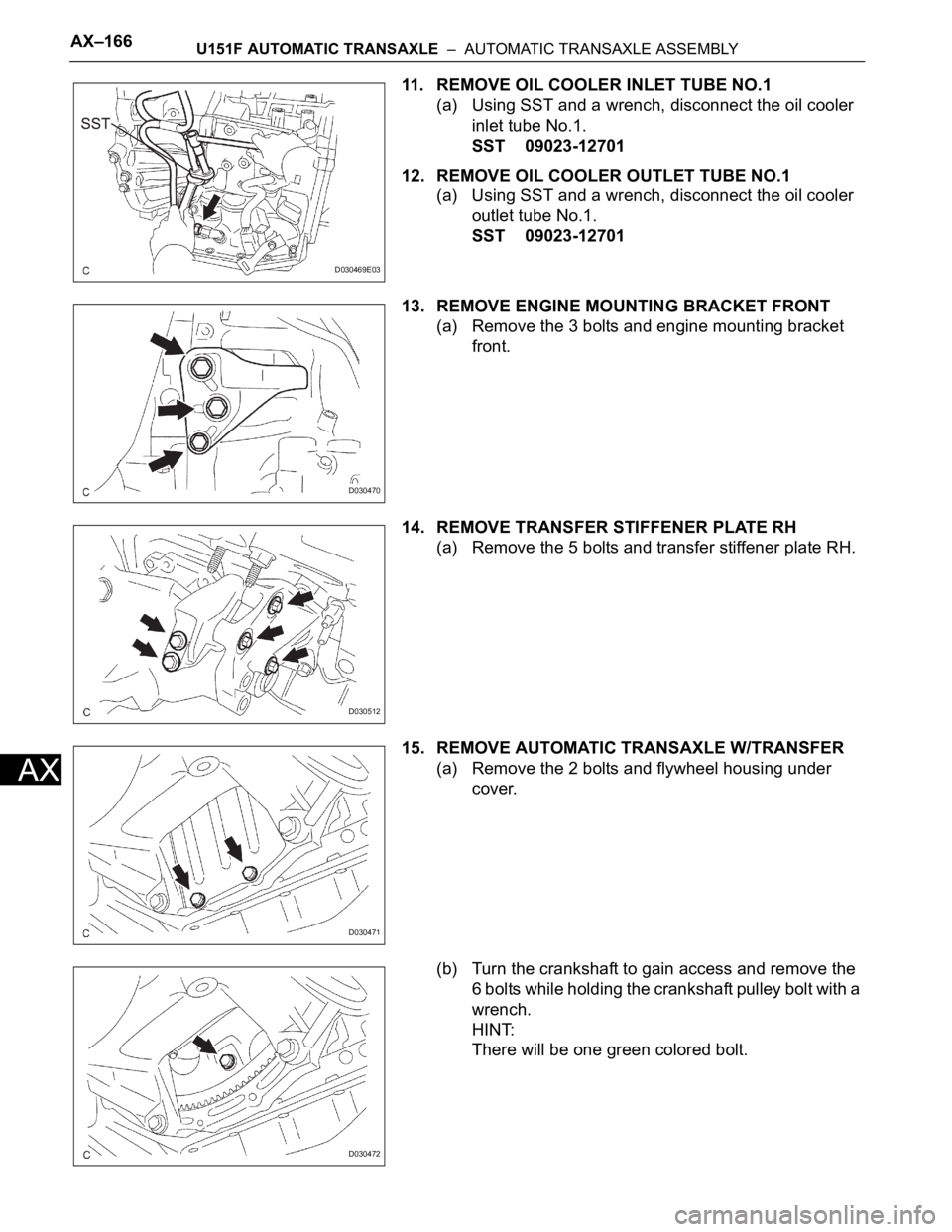

8. DISCONNECT CONNECTORS

(a) Disconnect the transmission wire connector.

(b) Disconnect the park/neutral position switch

connector.

(c) Disconnect the 2 speed sensor connectors.

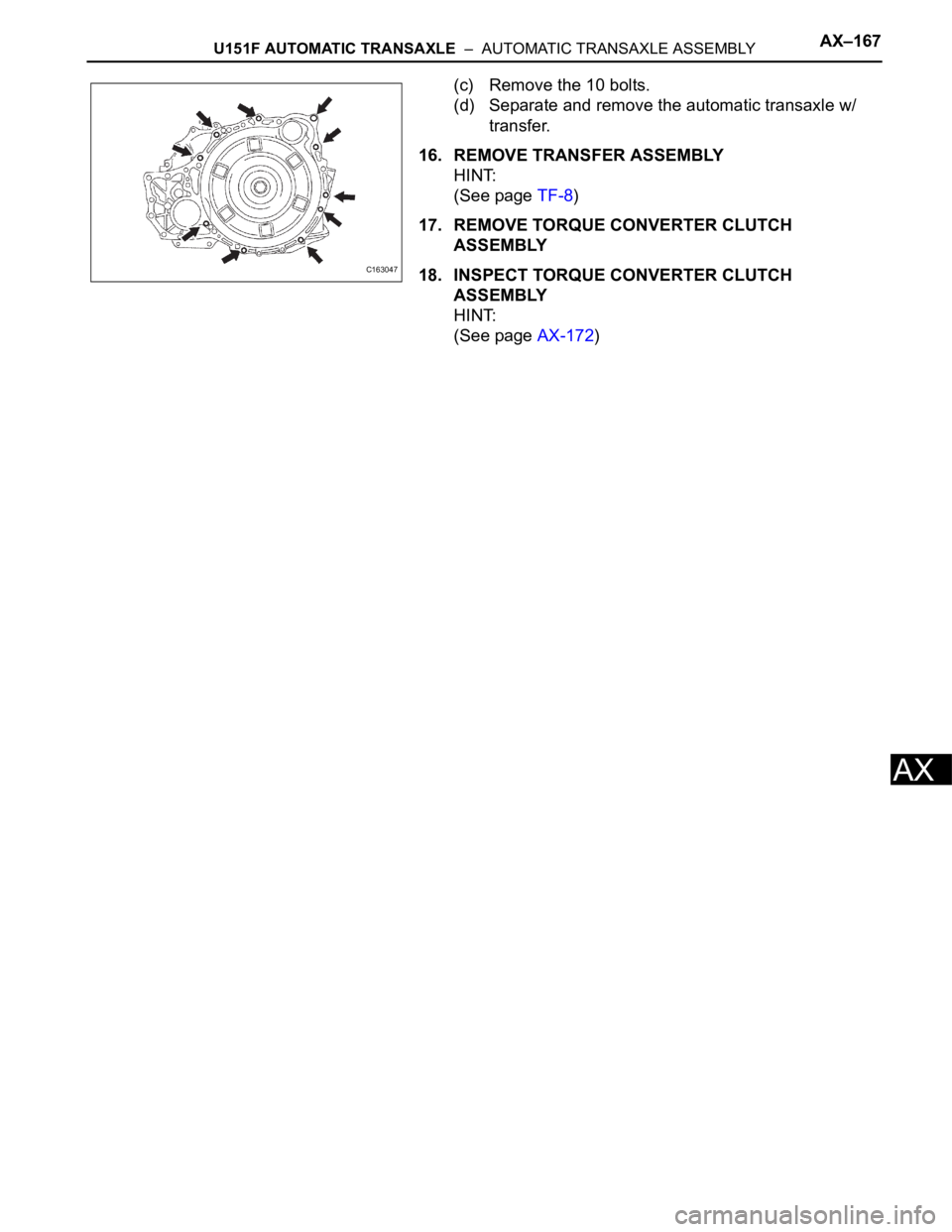

9. REMOVE TRANSMISSION CONTROL CABLE

BRACKET NO.1

(a) Remove the bolt and automatic transmission oil

cooler tube clamp.

(b) Remove the 2 bolts and transmission control cable

bracket No.1.

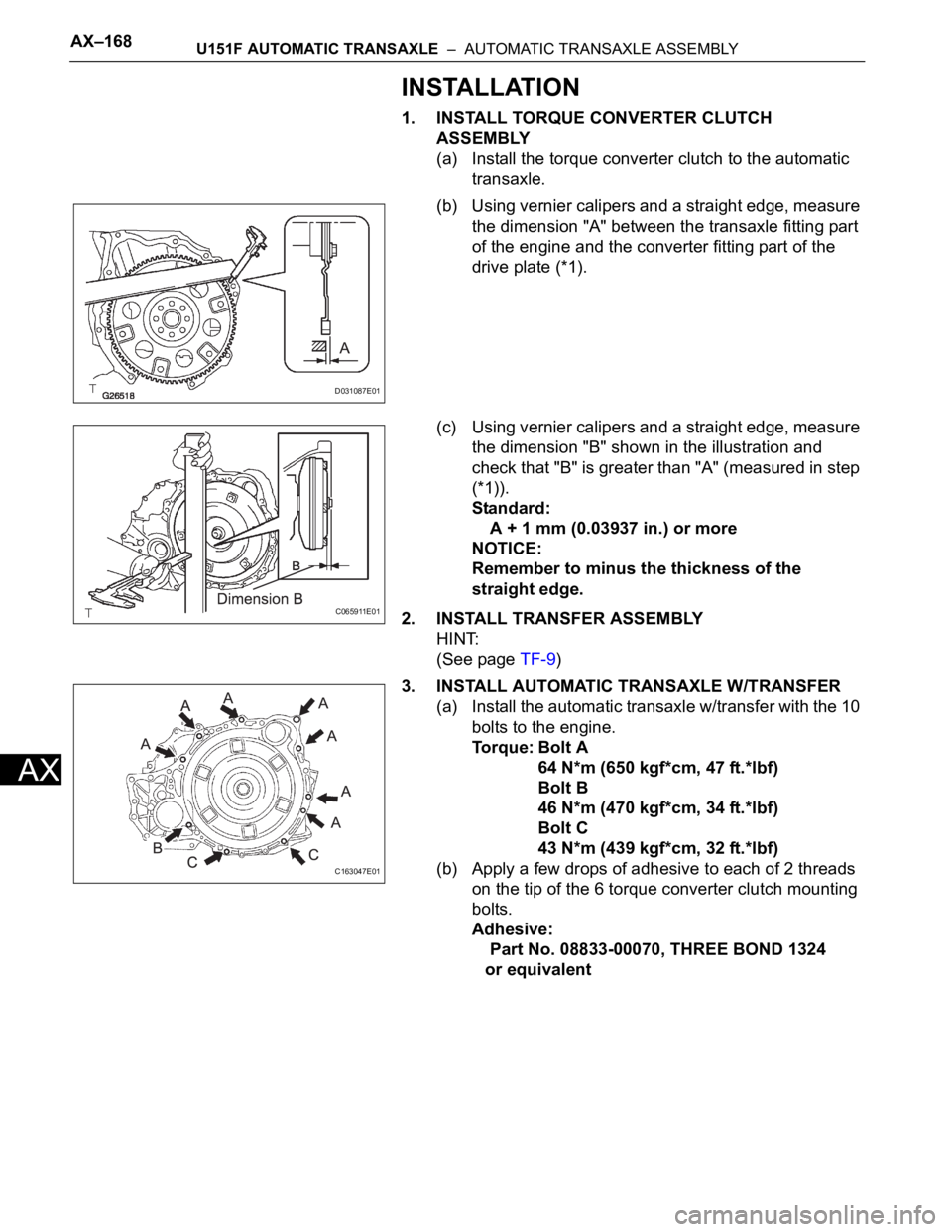

10. REMOVE TRANSMISSION OIL FILLER TUBE SUB-

ASSEMBLY

(a) Remove the ATF level gauge.

(b) Disconnect the wire harnesses 2 clamps from the oil

filler tube.

(c) Remove the 2 bolts and oil filler tube.

(d) Remove the O-ring from the oil filler tube.

D030464E02

D030864E04

D030467

D030468

Page 1882 of 3000

AX–166U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLY

AX

11. REMOVE OIL COOLER INLET TUBE NO.1

(a) Using SST and a wrench, disconnect the oil cooler

inlet tube No.1.

SST 09023-12701

12. REMOVE OIL COOLER OUTLET TUBE NO.1

(a) Using SST and a wrench, disconnect the oil cooler

outlet tube No.1.

SST 09023-12701

13. REMOVE ENGINE MOUNTING BRACKET FRONT

(a) Remove the 3 bolts and engine mounting bracket

front.

14. REMOVE TRANSFER STIFFENER PLATE RH

(a) Remove the 5 bolts and transfer stiffener plate RH.

15. REMOVE AUTOMATIC TRANSAXLE W/TRANSFER

(a) Remove the 2 bolts and flywheel housing under

cover.

(b) Turn the crankshaft to gain access and remove the

6 bolts while holding the crankshaft pulley bolt with a

wrench.

HINT:

There will be one green colored bolt.

D030469E03

D030470

D030512

D030471

D030472

Page 1883 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLYAX–167

AX

(c) Remove the 10 bolts.

(d) Separate and remove the automatic transaxle w/

transfer.

16. REMOVE TRANSFER ASSEMBLY

HINT:

(See page TF-8)

17. REMOVE TORQUE CONVERTER CLUTCH

ASSEMBLY

18. INSPECT TORQUE CONVERTER CLUTCH

ASSEMBLY

HINT:

(See page AX-172)

C163047

Page 1884 of 3000

AX–168U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLY

AX

INSTALLATION

1. INSTALL TORQUE CONVERTER CLUTCH

ASSEMBLY

(a) Install the torque converter clutch to the automatic

transaxle.

(b) Using vernier calipers and a straight edge, measure

the dimension "A" between the transaxle fitting part

of the engine and the converter fitting part of the

drive plate (*1).

(c) Using vernier calipers and a straight edge, measure

the dimension "B" shown in the illustration and

check that "B" is greater than "A" (measured in step

(*1)).

Standard:

A + 1 mm (0.03937 in.) or more

NOTICE:

Remember to minus the thickness of the

straight edge.

2. INSTALL TRANSFER ASSEMBLY

HINT:

(See page TF-9)

3. INSTALL AUTOMATIC TRANSAXLE W/TRANSFER

(a) Install the automatic transaxle w/transfer with the 10

bolts to the engine.

To r q u e : B o l t A

64 N*m (650 kgf*cm, 47 ft.*lbf)

Bolt B

46 N*m (470 kgf*cm, 34 ft.*lbf)

Bolt C

43 N*m (439 kgf*cm, 32 ft.*lbf)

(b) Apply a few drops of adhesive to each of 2 threads

on the tip of the 6 torque converter clutch mounting

bolts.

Adhesive:

Part No. 08833-00070, THREE BOND 1324

or equivalent

D031087E01

C065911E01

C163047E01

Page 1885 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLYAX–169

AX

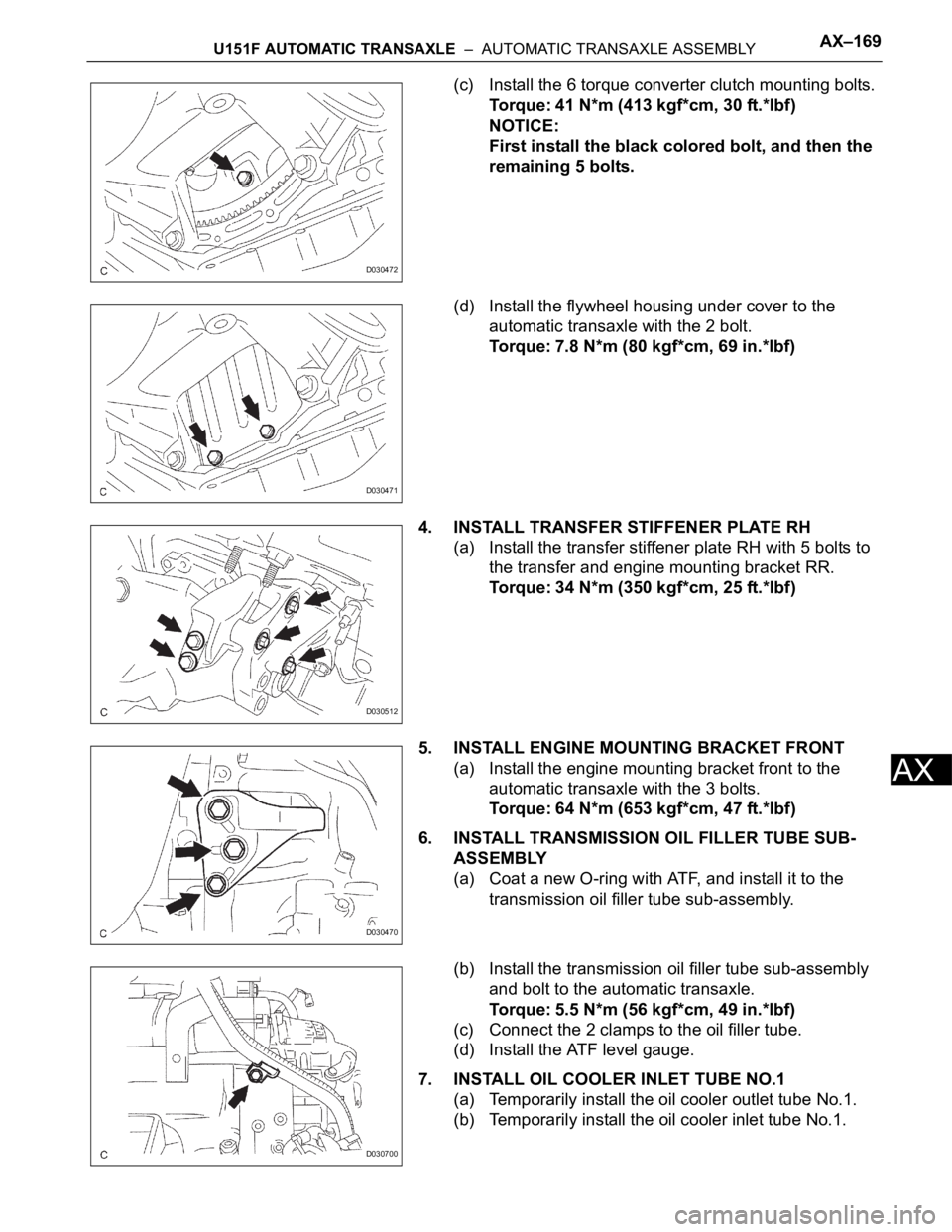

(c) Install the 6 torque converter clutch mounting bolts.

Torque: 41 N*m (413 kgf*cm, 30 ft.*lbf)

NOTICE:

First install the black colored bolt, and then the

remaining 5 bolts.

(d) Install the flywheel housing under cover to the

automatic transaxle with the 2 bolt.

Torque: 7.8 N*m (80 kgf*cm, 69 in.*lbf)

4. INSTALL TRANSFER STIFFENER PLATE RH

(a) Install the transfer stiffener plate RH with 5 bolts to

the transfer and engine mounting bracket RR.

Torque: 34 N*m (350 kgf*cm, 25 ft.*lbf)

5. INSTALL ENGINE MOUNTING BRACKET FRONT

(a) Install the engine mounting bracket front to the

automatic transaxle with the 3 bolts.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf)

6. INSTALL TRANSMISSION OIL FILLER TUBE SUB-

ASSEMBLY

(a) Coat a new O-ring with ATF, and install it to the

transmission oil filler tube sub-assembly.

(b) Install the transmission oil filler tube sub-assembly

and bolt to the automatic transaxle.

Torque: 5.5 N*m (56 kgf*cm, 49 in.*lbf)

(c) Connect the 2 clamps to the oil filler tube.

(d) Install the ATF level gauge.

7. INSTALL OIL COOLER INLET TUBE NO.1

(a) Temporarily install the oil cooler outlet tube No.1.

(b) Temporarily install the oil cooler inlet tube No.1.

D030472

D030471

D030512

D030470

D030700

Page 1886 of 3000

AX–170U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLY

AX

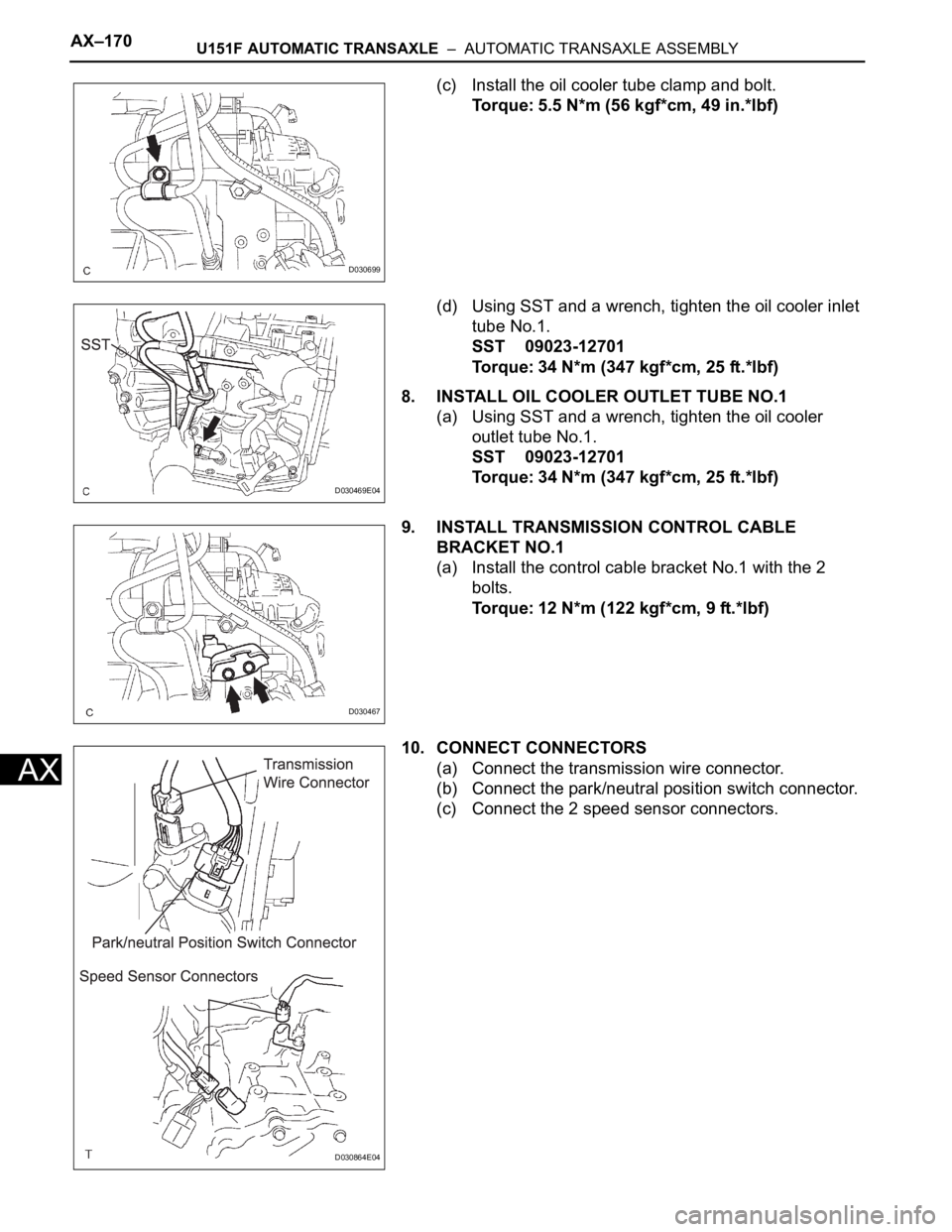

(c) Install the oil cooler tube clamp and bolt.

Torque: 5.5 N*m (56 kgf*cm, 49 in.*lbf)

(d) Using SST and a wrench, tighten the oil cooler inlet

tube No.1.

SST 09023-12701

Torque: 34 N*m (347 kgf*cm, 25 ft.*lbf)

8. INSTALL OIL COOLER OUTLET TUBE NO.1

(a) Using SST and a wrench, tighten the oil cooler

outlet tube No.1.

SST 09023-12701

Torque: 34 N*m (347 kgf*cm, 25 ft.*lbf)

9. INSTALL TRANSMISSION CONTROL CABLE

BRACKET NO.1

(a) Install the control cable bracket No.1 with the 2

bolts.

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf)

10. CONNECT CONNECTORS

(a) Connect the transmission wire connector.

(b) Connect the park/neutral position switch connector.

(c) Connect the 2 speed sensor connectors.

D030699

D030469E04

D030467

D030864E04

Page 1887 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLYAX–171

AX

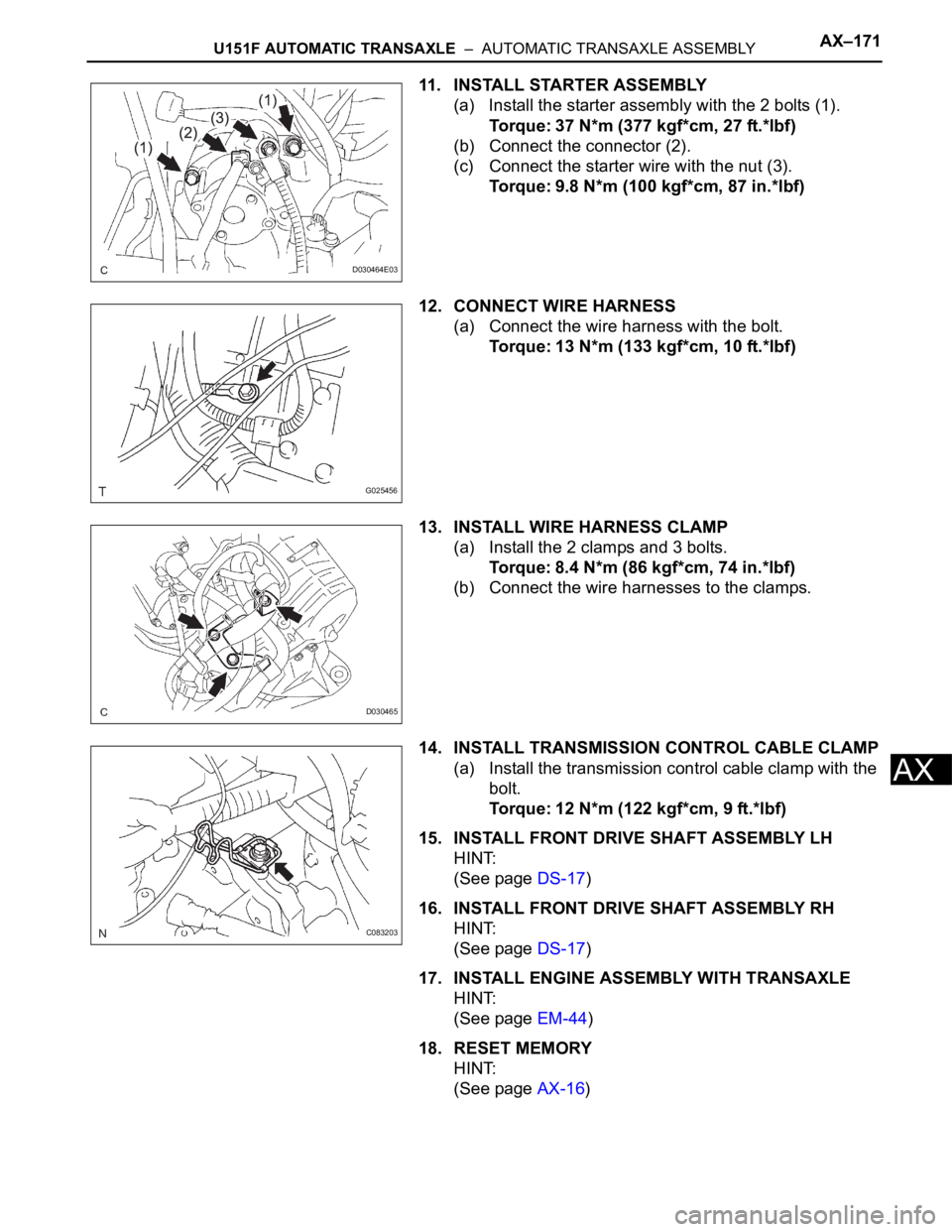

11. INSTALL STARTER ASSEMBLY

(a) Install the starter assembly with the 2 bolts (1).

Torque: 37 N*m (377 kgf*cm, 27 ft.*lbf)

(b) Connect the connector (2).

(c) Connect the starter wire with the nut (3).

Torque: 9.8 N*m (100 kgf*cm, 87 in.*lbf)

12. CONNECT WIRE HARNESS

(a) Connect the wire harness with the bolt.

Torque: 13 N*m (133 kgf*cm, 10 ft.*lbf)

13. INSTALL WIRE HARNESS CLAMP

(a) Install the 2 clamps and 3 bolts.

Torque: 8.4 N*m (86 kgf*cm, 74 in.*lbf)

(b) Connect the wire harnesses to the clamps.

14. INSTALL TRANSMISSION CONTROL CABLE CLAMP

(a) Install the transmission control cable clamp with the

bolt.

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf)

15. INSTALL FRONT DRIVE SHAFT ASSEMBLY LH

HINT:

(See page DS-17)

16. INSTALL FRONT DRIVE SHAFT ASSEMBLY RH

HINT:

(See page DS-17)

17. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

HINT:

(See page EM-44)

18. RESET MEMORY

HINT:

(See page AX-16)

D030464E03

G025456

D030465

C083203

Page 1888 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–205

AX

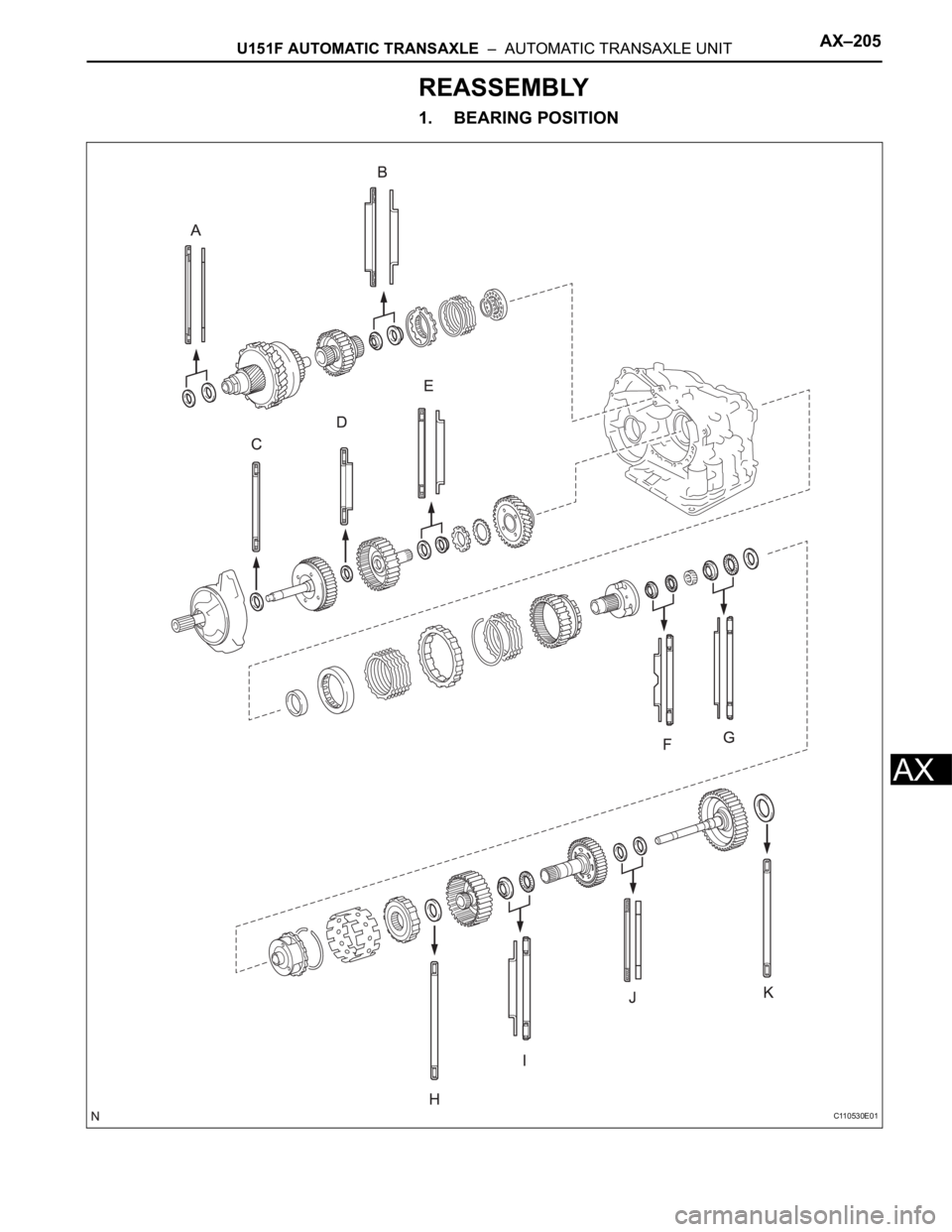

REASSEMBLY

1. BEARING POSITION

C110530E01

Page 1889 of 3000

AX–206U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

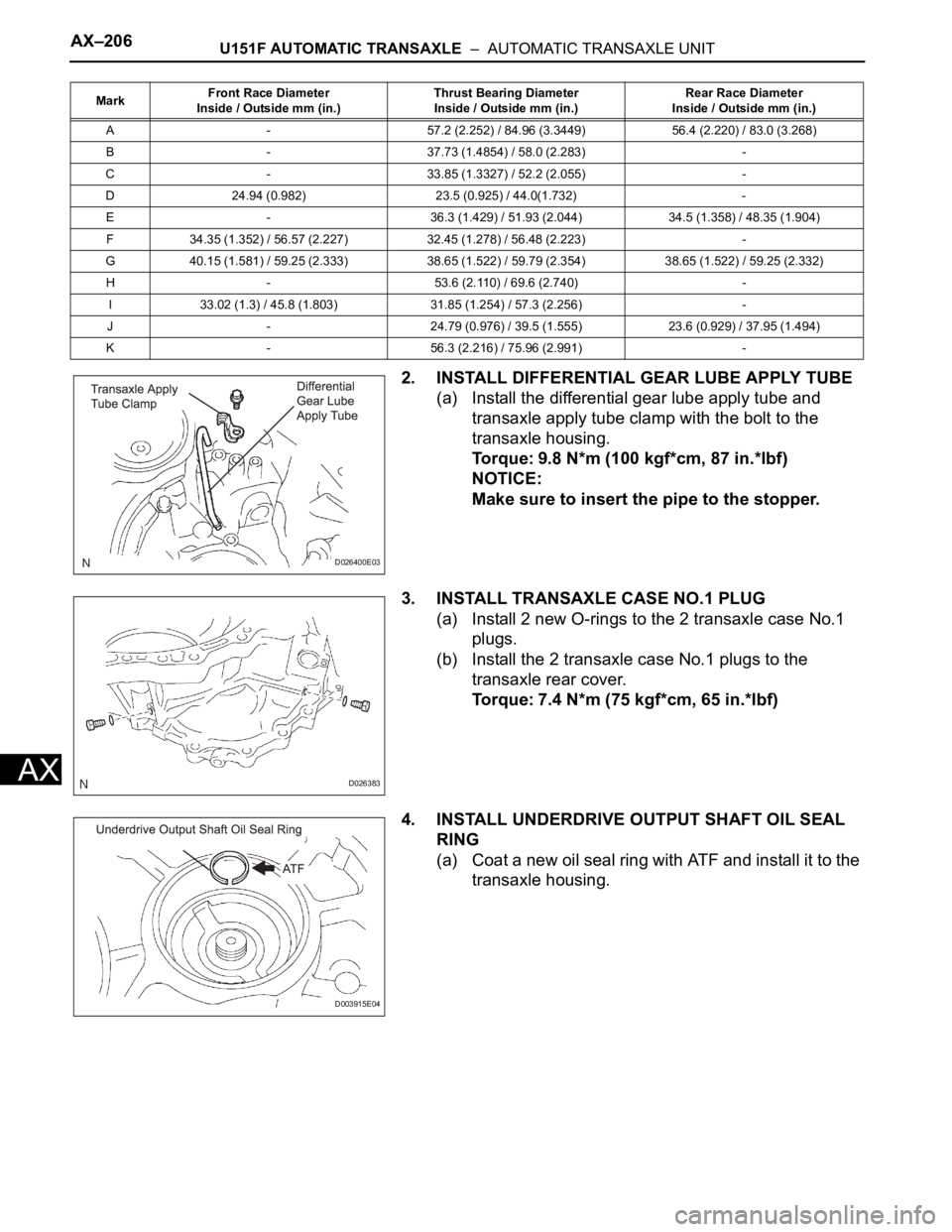

2. INSTALL DIFFERENTIAL GEAR LUBE APPLY TUBE

(a) Install the differential gear lube apply tube and

transaxle apply tube clamp with the bolt to the

transaxle housing.

Torque: 9.8 N*m (100 kgf*cm, 87 in.*lbf)

NOTICE:

Make sure to insert the pipe to the stopper.

3. INSTALL TRANSAXLE CASE NO.1 PLUG

(a) Install 2 new O-rings to the 2 transaxle case No.1

plugs.

(b) Install the 2 transaxle case No.1 plugs to the

transaxle rear cover.

Torque: 7.4 N*m (75 kgf*cm, 65 in.*lbf)

4. INSTALL UNDERDRIVE OUTPUT SHAFT OIL SEAL

RING

(a) Coat a new oil seal ring with ATF and install it to the

transaxle housing.

MarkFront Race Diameter

Inside / Outside mm (in.)Thrust Bearing Diameter

Inside / Outside mm (in.)Rear Race Diameter

Inside / Outside mm (in.)

A - 57.2 (2.252) / 84.96 (3.3449) 56.4 (2.220) / 83.0 (3.268)

B - 37.73 (1.4854) / 58.0 (2.283) -

C - 33.85 (1.3327) / 52.2 (2.055) -

D 24.94 (0.982) 23.5 (0.925) / 44.0(1.732) -

E - 36.3 (1.429) / 51.93 (2.044) 34.5 (1.358) / 48.35 (1.904)

F 34.35 (1.352) / 56.57 (2.227) 32.45 (1.278) / 56.48 (2.223) -

G 40.15 (1.581) / 59.25 (2.333) 38.65 (1.522) / 59.79 (2.354) 38.65 (1.522) / 59.25 (2.332)

H - 53.6 (2.110) / 69.6 (2.740) -

I 33.02 (1.3) / 45.8 (1.803) 31.85 (1.254) / 57.3 (2.256) -

J - 24.79 (0.976) / 39.5 (1.555) 23.6 (0.929) / 37.95 (1.494)

K - 56.3 (2.216) / 75.96 (2.991) -

D026400E03

D026383

D003915E04

Page 1890 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–207

AX

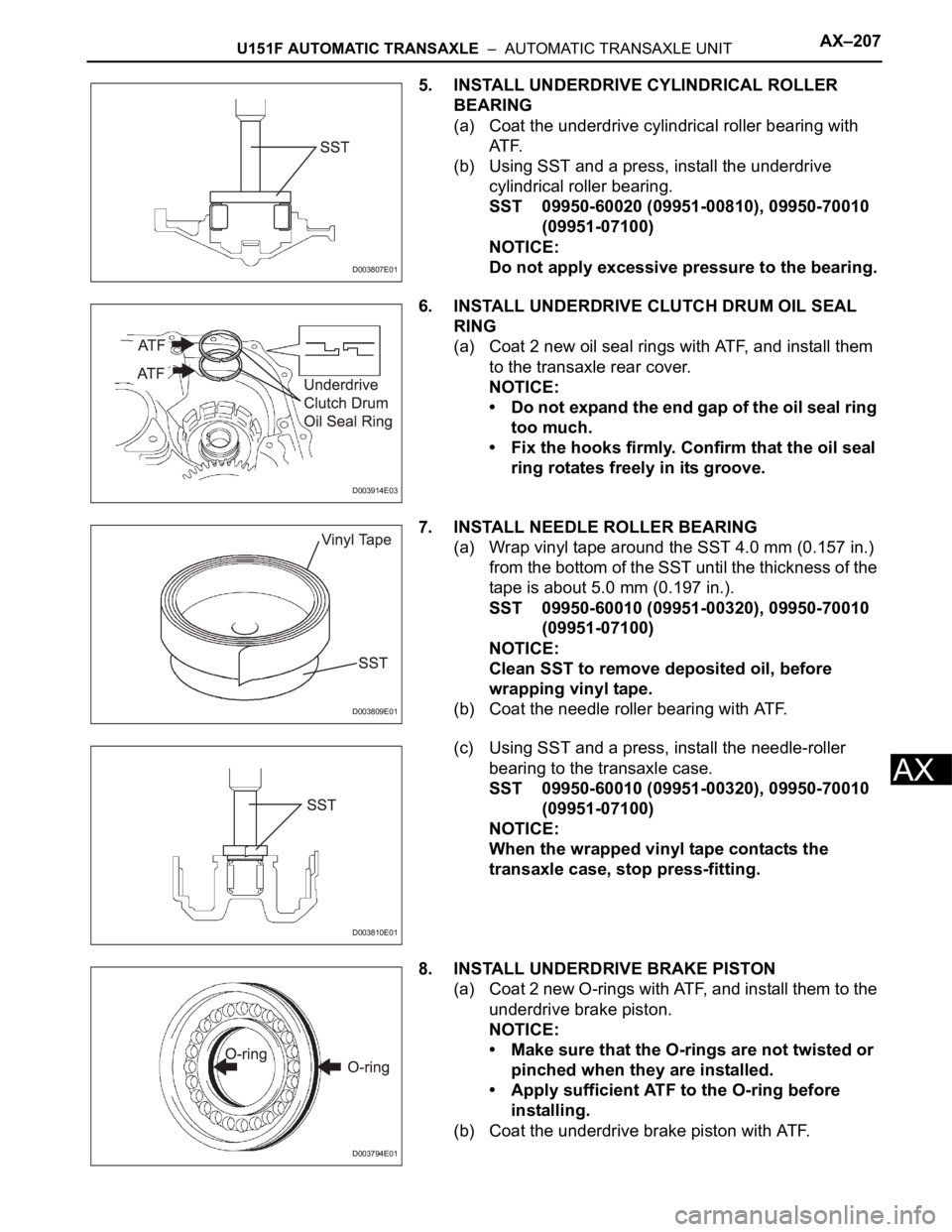

5. INSTALL UNDERDRIVE CYLINDRICAL ROLLER

BEARING

(a) Coat the underdrive cylindrical roller bearing with

AT F.

(b) Using SST and a press, install the underdrive

cylindrical roller bearing.

SST 09950-60020 (09951-00810), 09950-70010

(09951-07100)

NOTICE:

Do not apply excessive pressure to the bearing.

6. INSTALL UNDERDRIVE CLUTCH DRUM OIL SEAL

RING

(a) Coat 2 new oil seal rings with ATF, and install them

to the transaxle rear cover.

NOTICE:

• Do not expand the end gap of the oil seal ring

too much.

• Fix the hooks firmly. Confirm that the oil seal

ring rotates freely in its groove.

7. INSTALL NEEDLE ROLLER BEARING

(a) Wrap vinyl tape around the SST 4.0 mm (0.157 in.)

from the bottom of the SST until the thickness of the

tape is about 5.0 mm (0.197 in.).

SST 09950-60010 (09951-00320), 09950-70010

(09951-07100)

NOTICE:

Clean SST to remove deposited oil, before

wrapping vinyl tape.

(b) Coat the needle roller bearing with ATF.

(c) Using SST and a press, install the needle-roller

bearing to the transaxle case.

SST 09950-60010 (09951-00320), 09950-70010

(09951-07100)

NOTICE:

When the wrapped vinyl tape contacts the

transaxle case, stop press-fitting.

8. INSTALL UNDERDRIVE BRAKE PISTON

(a) Coat 2 new O-rings with ATF, and install them to the

underdrive brake piston.

NOTICE:

• Make sure that the O-rings are not twisted or

pinched when they are installed.

• Apply sufficient ATF to the O-ring before

installing.

(b) Coat the underdrive brake piston with ATF.

D003807E01

D003914E03

D003809E01

D003810E01

D003794E01