TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 2531 of 3000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–169

BC

DESCRIPTION

The skid control ECU is connected to the combination meter via CAN and multiplex communications.

The SLIP indicator blinks during VSC and/or TRAC operation.

When the system fails, the SLIP indicator comes on to warn the driver.

WIRING DIAGRAM

Refer to Slip Indicator Light Remains ON (See page BC-164).

INSPECTION PROCEDURE

NOTICE:

When replacing the brake actuator assembly, perform zero point calibration (See page BC-70).

(a) Check if the CAN communication system DTC is output

(See page CA-17).

Result

B

A

(a) Check if the multiplex communication system DTC is

output (See page MP-14).

Result

B

A

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine.

(c) Select the Active Test mode on the intelligent tester (See

page BC-85).

ABS / VSC:

Slip Indicator Light does not Come ON

1CHECK CAN COMMUNICATION SYSTEM

Result Proceed to

CAN communication system DTC is not output A

CAN communication system DTC is output B

INSPECT CAN COMMUNICATION SYSTEM

2CHECK MULTIPLEX COMMUNICATION SYSTEM

Result Proceed to

Multiplex communication system DTC is not output A

Multiplex communication system DTC is output B

INSPECT MULTIPLEX COMMUNICATION

SYSTEM

3CHECK SLIP INDICATOR LIGHT

Tester Display Test Part Control Range Diagnostic Note

SLIP INDI LIGHT SLIP indicator light Indicator light ON / OFF Observe combination meter

Page 2532 of 3000

BC–170BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

(d) Check that "ON" and "OFF" of the SLIP indicator light

are indicated on the combination meter when using the

intelligent tester.

OK:

The SLIP indicator light turns on or off in

accordance with the intelligent tester.

HINT:

If troubleshooting has been carried out according to the

Problem Symptoms Table, refer back to the table and

proceed to the next step before replacing the part (See

page BC-79).

NG

OK

(a) Turn the ignition switch off.

(b) Perform Active Test of the combination meter (meter

CPU) using the intelligent tester (See page ME-19).

OK:

The SLIP indicator light turns on or off in

accordance with the intelligent tester.

HINT:

If troubleshooting has been carried out according to the

Problem Symptoms Table, refer back to the table and

proceed to the next step (See page BC-79).

NG

OK Go to step 4

REPLACE BRAKE ACTUATOR ASSEMBLY

4INSPECT COMBINATION METER ASSEMBLY

REPLACE COMBINATION METER

ASSEMBLY

REPLACE BRAKE ACTUATOR ASSEMBLY

Page 2533 of 3000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–171

BC

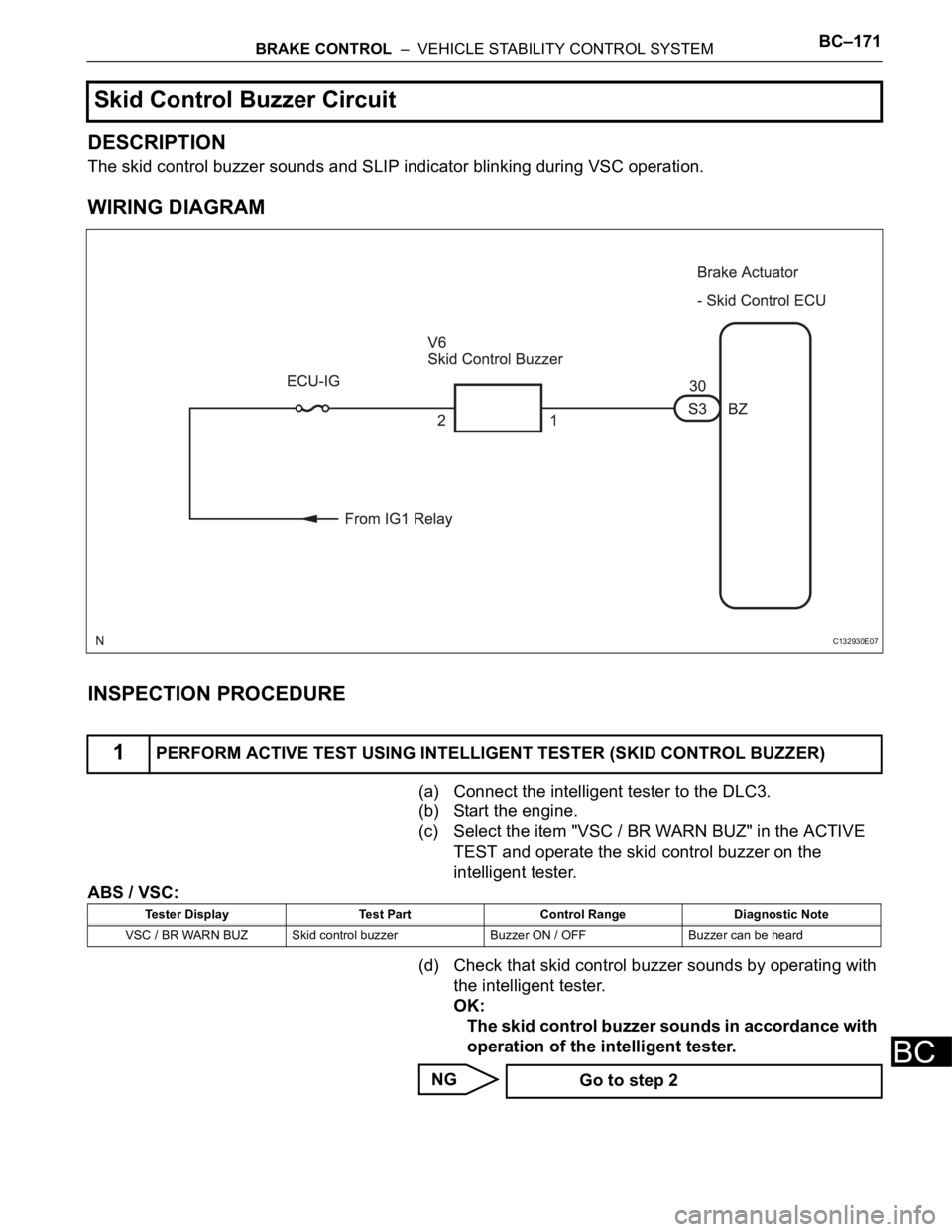

DESCRIPTION

The skid control buzzer sounds and SLIP indicator blinking during VSC operation.

WIRING DIAGRAM

INSPECTION PROCEDURE

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine.

(c) Select the item "VSC / BR WARN BUZ" in the ACTIVE

TEST and operate the skid control buzzer on the

intelligent tester.

ABS / VSC:

(d) Check that skid control buzzer sounds by operating with

the intelligent tester.

OK:

The skid control buzzer sounds in accordance with

operation of the intelligent tester.

NG

Skid Control Buzzer Circuit

1PERFORM ACTIVE TEST USING INTELLIGENT TESTER (SKID CONTROL BUZZER)

C132930E07

Tester Display Test Part Control Range Diagnostic Note

VSC / BR WARN BUZ Skid control buzzer Buzzer ON / OFF Buzzer can be heard

Go to step 2

Page 2534 of 3000

BC–172BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

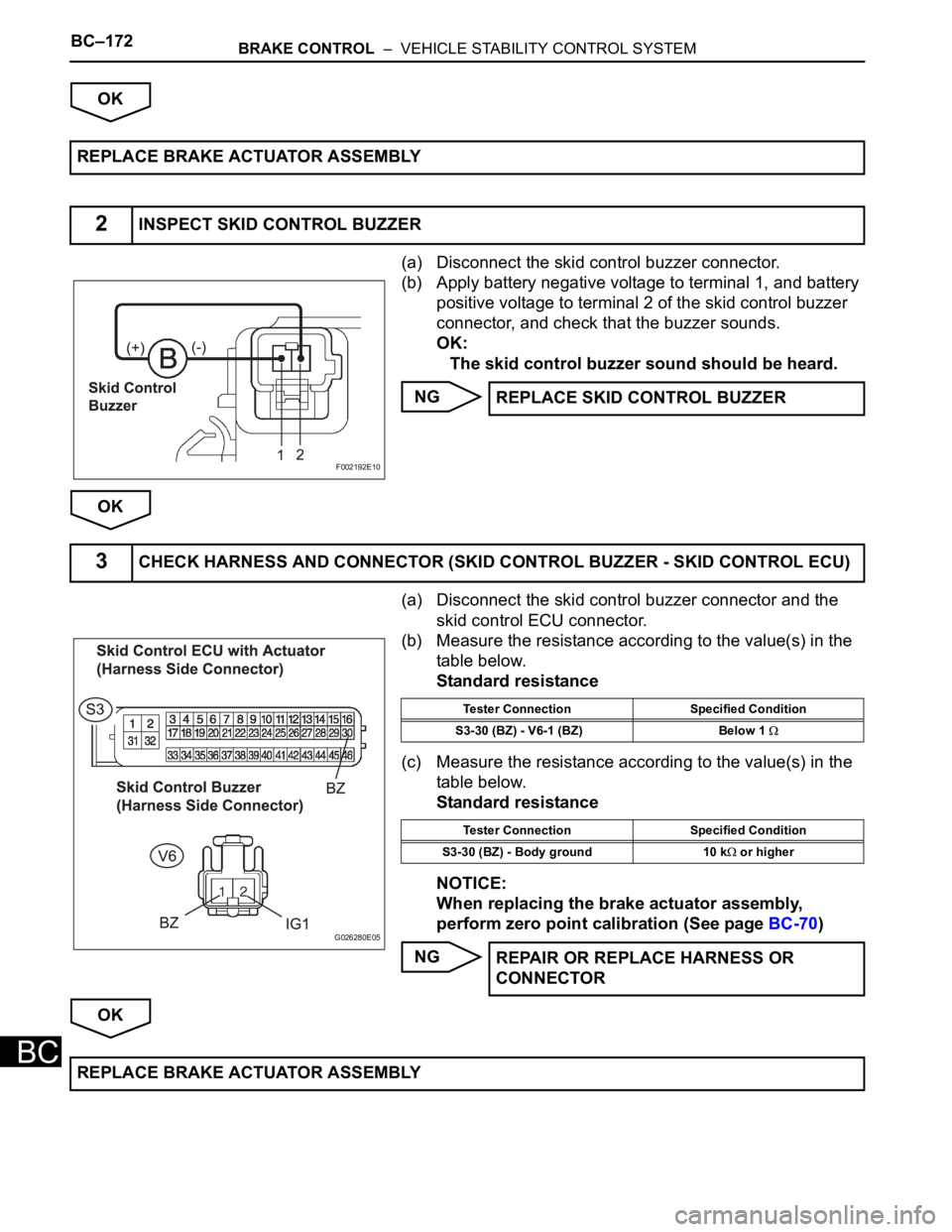

OK

(a) Disconnect the skid control buzzer connector.

(b) Apply battery negative voltage to terminal 1, and battery

positive voltage to terminal 2 of the skid control buzzer

connector, and check that the buzzer sounds.

OK:

The skid control buzzer sound should be heard.

NG

OK

(a) Disconnect the skid control buzzer connector and the

skid control ECU connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NOTICE:

When replacing the brake actuator assembly,

perform zero point calibration (See page BC-70)

NG

OK REPLACE BRAKE ACTUATOR ASSEMBLY

2INSPECT SKID CONTROL BUZZER

F002192E10

REPLACE SKID CONTROL BUZZER

3CHECK HARNESS AND CONNECTOR (SKID CONTROL BUZZER - SKID CONTROL ECU)

G026280E05

Tester Connection Specified Condition

S3-30 (BZ) - V6-1 (BZ) Below 1

Tester Connection Specified Condition

S3-30 (BZ) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR

REPLACE BRAKE ACTUATOR ASSEMBLY

Page 2535 of 3000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–173

BC

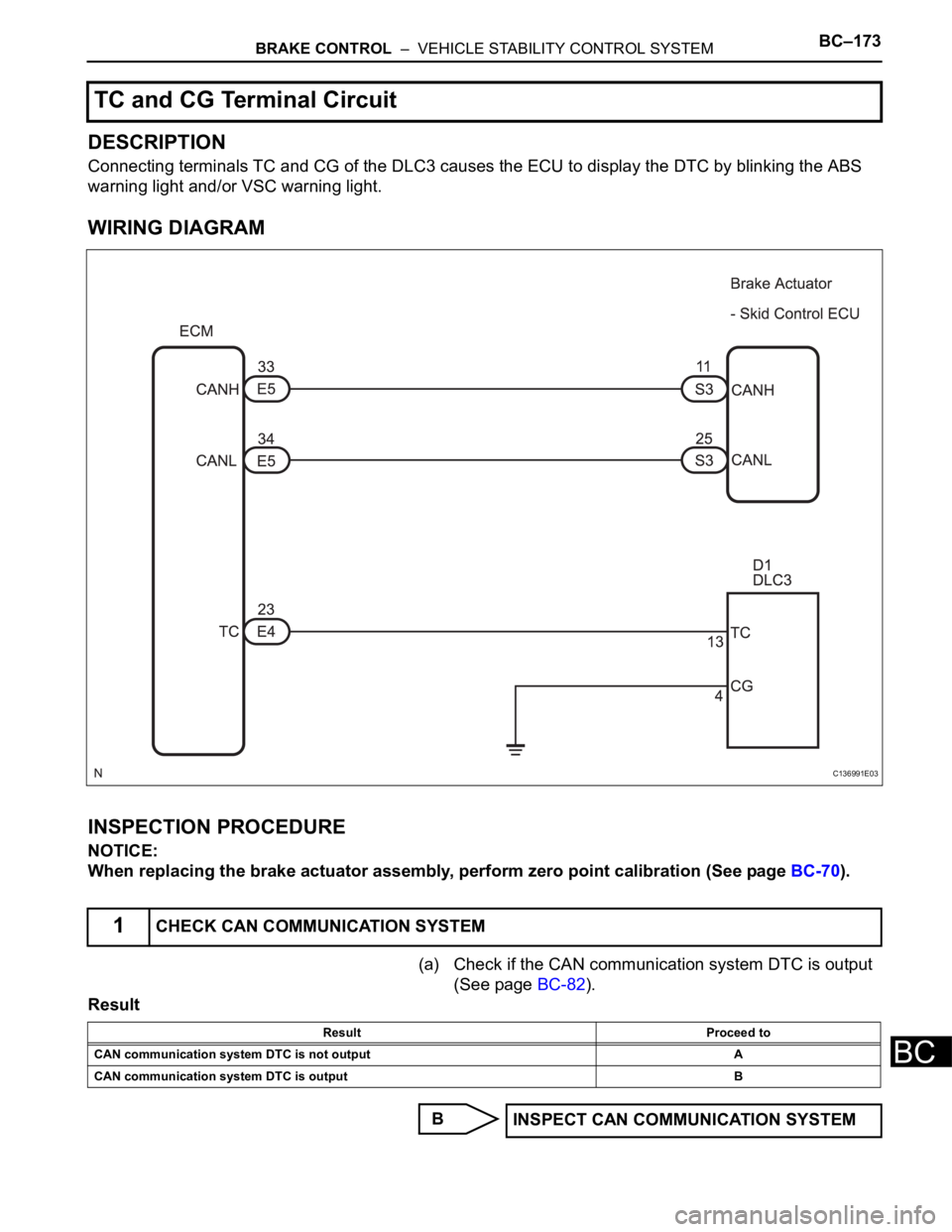

DESCRIPTION

Connecting terminals TC and CG of the DLC3 causes the ECU to display the DTC by blinking the ABS

warning light and/or VSC warning light.

WIRING DIAGRAM

INSPECTION PROCEDURE

NOTICE:

When replacing the brake actuator assembly, perform zero point calibration (See page BC-70).

(a) Check if the CAN communication system DTC is output

(See page BC-82).

Result

B

TC and CG Terminal Circuit

1CHECK CAN COMMUNICATION SYSTEM

C136991E03

Result Proceed to

CAN communication system DTC is not output A

CAN communication system DTC is output B

INSPECT CAN COMMUNICATION SYSTEM

Page 2536 of 3000

BC–174BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

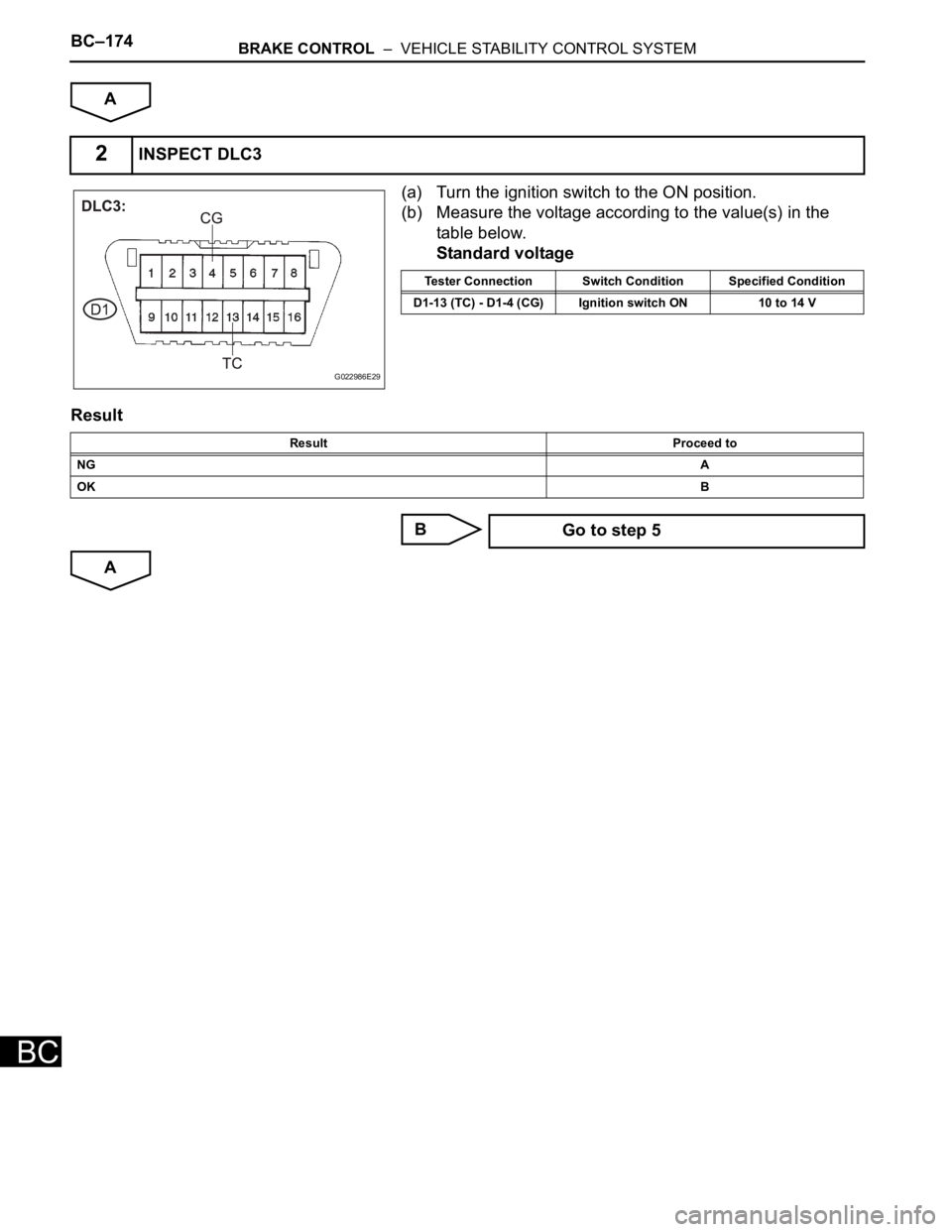

A

(a) Turn the ignition switch to the ON position.

(b) Measure the voltage according to the value(s) in the

table below.

Standard voltage

Result

B

A

2INSPECT DLC3

G022986E29

Tester Connection Switch Condition Specified Condition

D1-13 (TC) - D1-4 (CG) Ignition switch ON 10 to 14 V

Result Proceed to

NGA

OKB

Go to step 5

Page 2537 of 3000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–175

BC

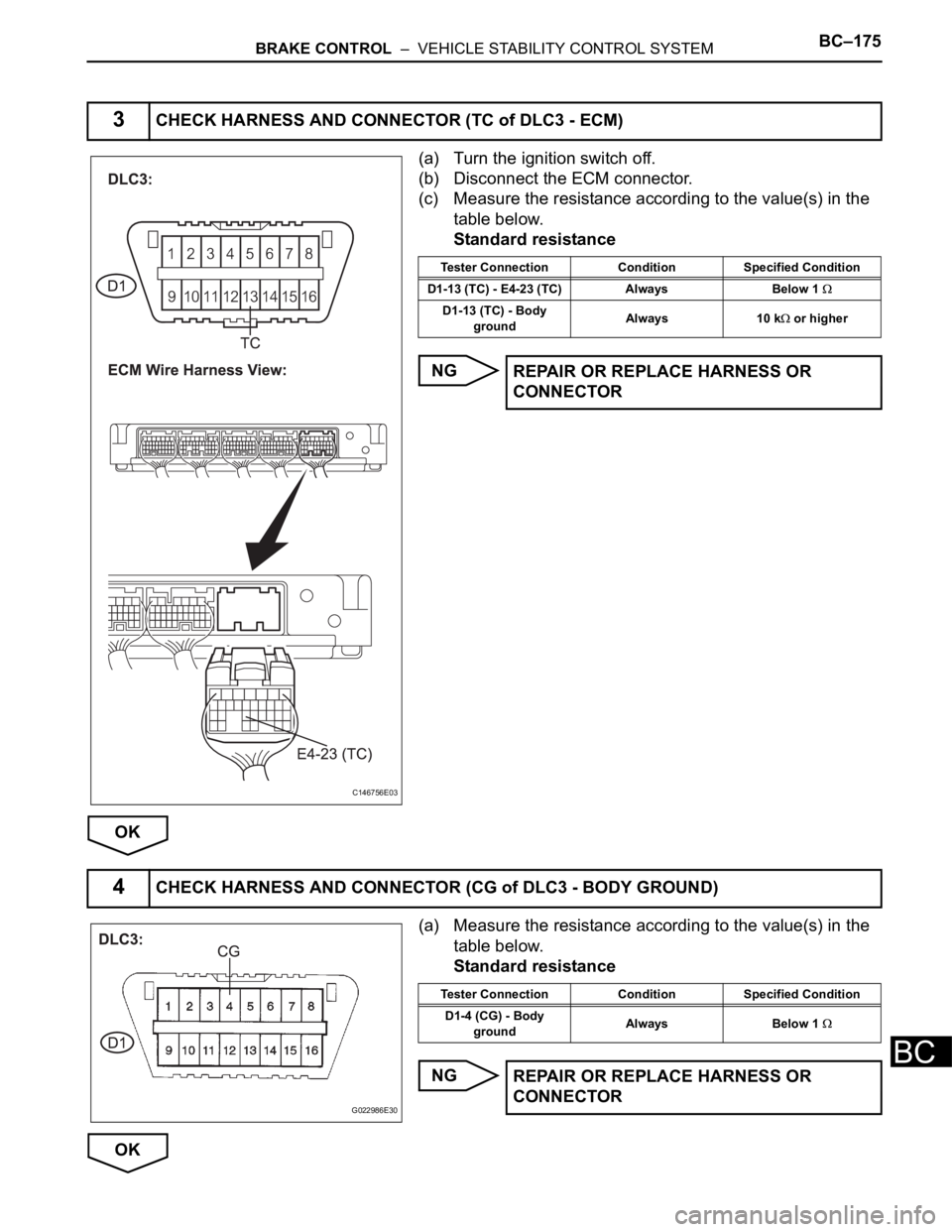

(a) Turn the ignition switch off.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

(a) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

3CHECK HARNESS AND CONNECTOR (TC of DLC3 - ECM)

C146756E03

Tester Connection Condition Specified Condition

D1-13 (TC) - E4-23 (TC) Always Below 1

D1-13 (TC) - Body

groundAlways 10 k or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR

4CHECK HARNESS AND CONNECTOR (CG of DLC3 - BODY GROUND)

G022986E30

Tester Connection Condition Specified Condition

D1-4 (CG) - Body

groundAlways Below 1

REPAIR OR REPLACE HARNESS OR

CONNECTOR

Page 2538 of 3000

BC–176BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

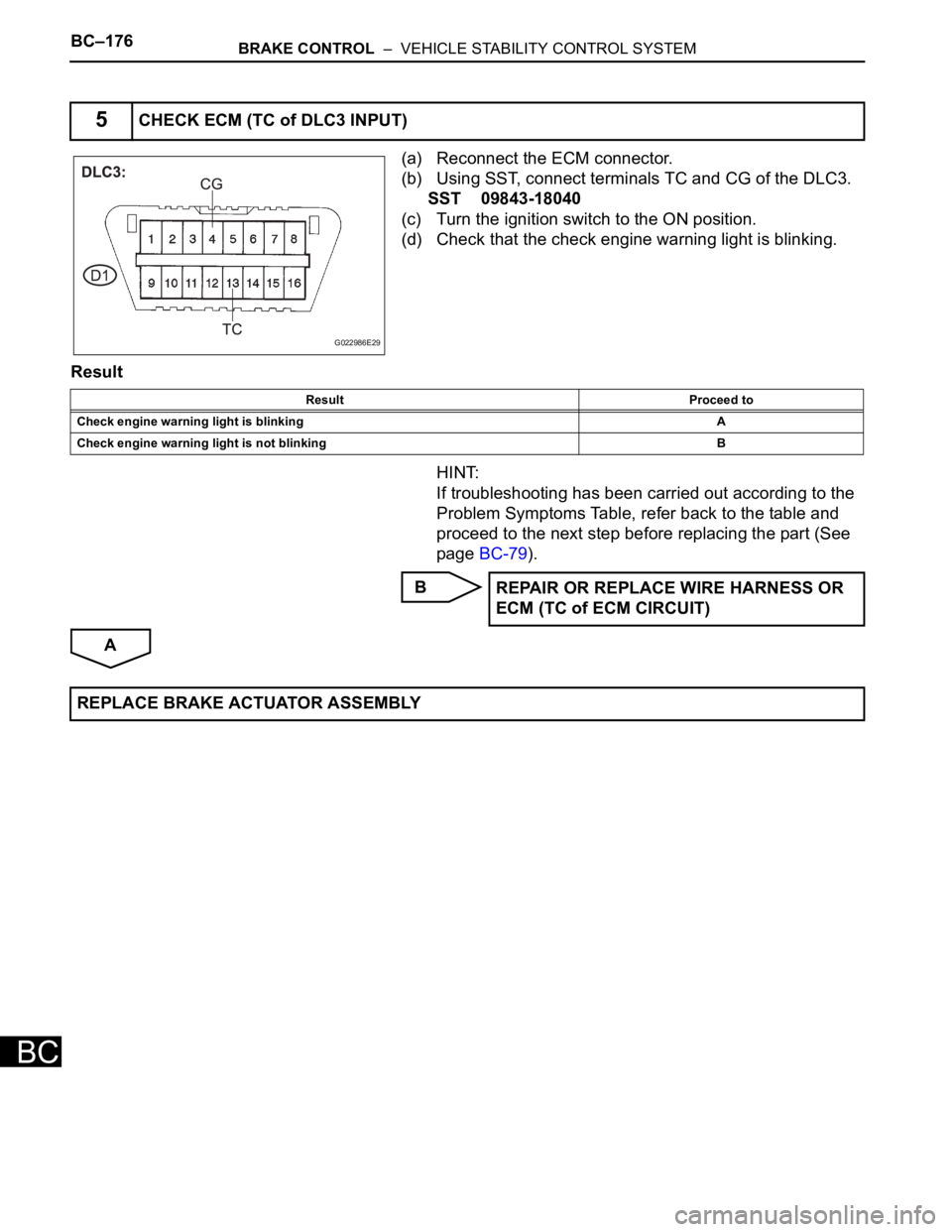

(a) Reconnect the ECM connector.

(b) Using SST, connect terminals TC and CG of the DLC3.

SST 09843-18040

(c) Turn the ignition switch to the ON position.

(d) Check that the check engine warning light is blinking.

Result

HINT:

If troubleshooting has been carried out according to the

Problem Symptoms Table, refer back to the table and

proceed to the next step before replacing the part (See

page BC-79).

B

A

5CHECK ECM (TC of DLC3 INPUT)

G022986E29

Result Proceed to

Check engine warning light is blinkingA

Check engine warning light is not blinking B

REPAIR OR REPLACE WIRE HARNESS OR

ECM (TC of ECM CIRCUIT)

REPLACE BRAKE ACTUATOR ASSEMBLY

Page 2539 of 3000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–177

BC

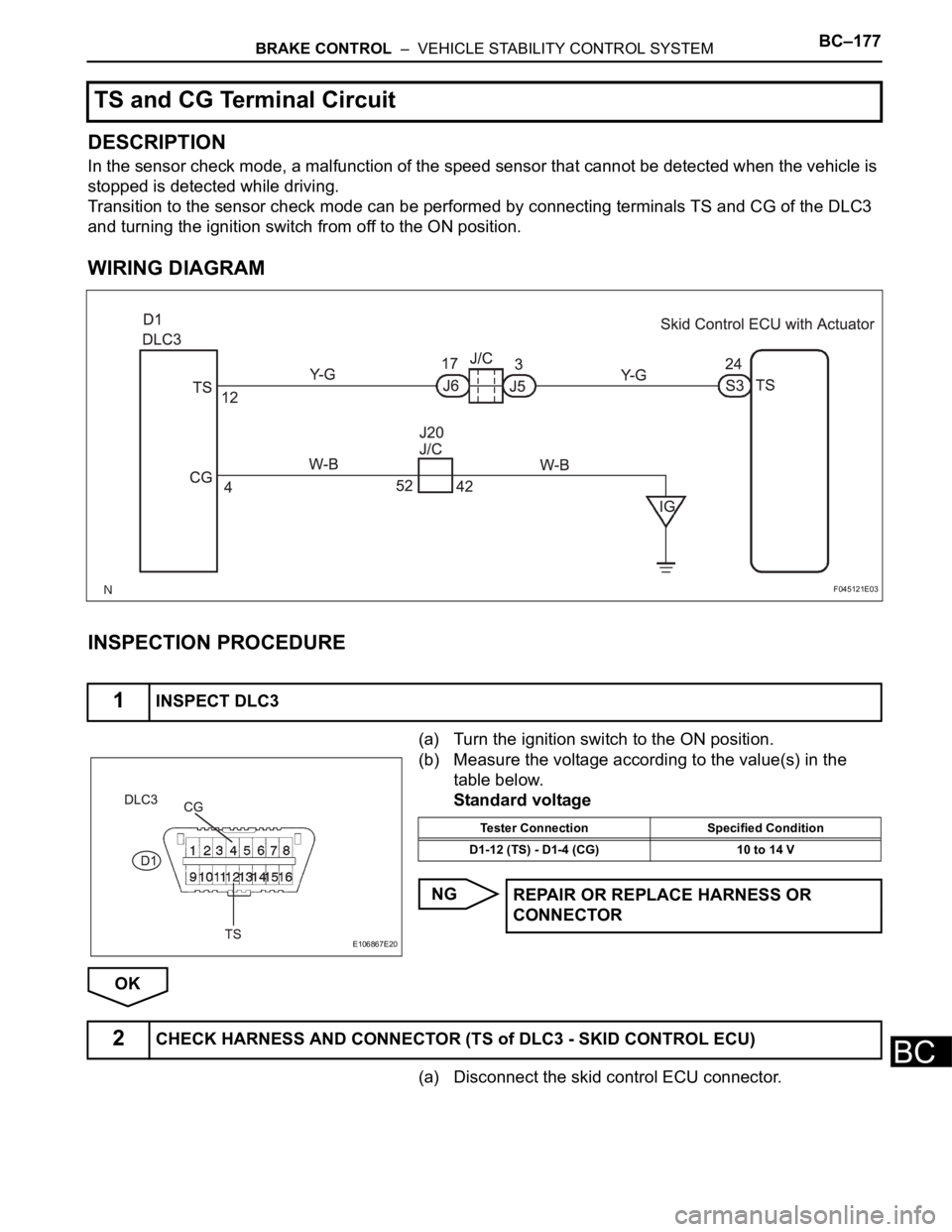

DESCRIPTION

In the sensor check mode, a malfunction of the speed sensor that cannot be detected when the vehicle is

stopped is detected while driving.

Transition to the sensor check mode can be performed by connecting terminals TS and CG of the DLC3

and turning the ignition switch from off to the ON position.

WIRING DIAGRAM

INSPECTION PROCEDURE

(a) Turn the ignition switch to the ON position.

(b) Measure the voltage according to the value(s) in the

table below.

Standard voltage

NG

OK

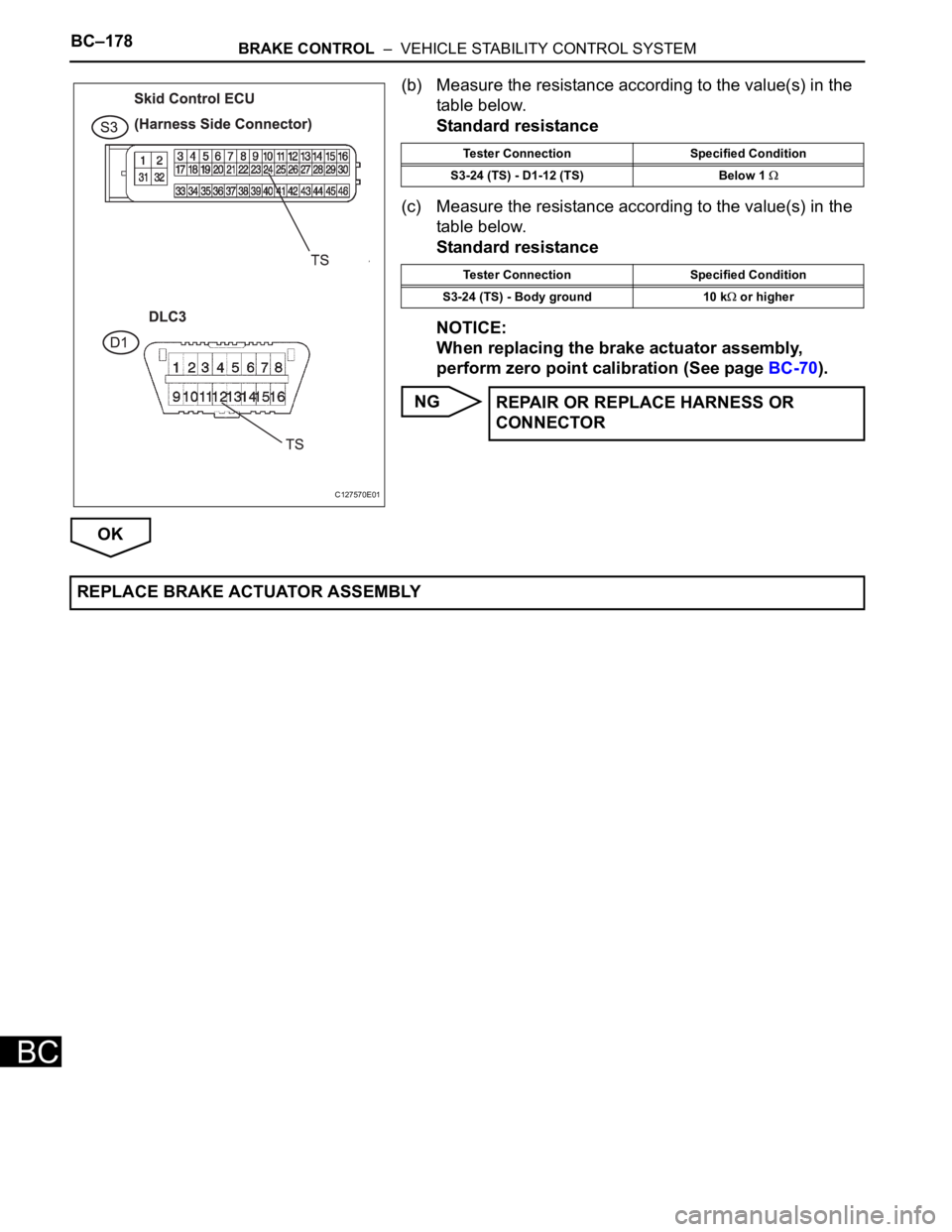

(a) Disconnect the skid control ECU connector.

TS and CG Terminal Circuit

1INSPECT DLC3

F045121E03

E106867E20

Tester Connection Specified Condition

D1-12 (TS) - D1-4 (CG) 10 to 14 V

REPAIR OR REPLACE HARNESS OR

CONNECTOR

2CHECK HARNESS AND CONNECTOR (TS of DLC3 - SKID CONTROL ECU)

Page 2540 of 3000

BC–178BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NOTICE:

When replacing the brake actuator assembly,

perform zero point calibration (See page BC-70).

NG

OK

C127570E01

Tester Connection Specified Condition

S3-24 (TS) - D1-12 (TS) Below 1

Tester Connection Specified Condition

S3-24 (TS) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR

REPLACE BRAKE ACTUATOR ASSEMBLY