TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 2571 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–33

BC

DESCRIPTION

The ABS motor relay supplies power to the ABS pump motor. While the ABS is activated, the ECU turns

the motor relay on and operates the ABS pump motor.

If the voltage supplied to the motor relay (+BM) is below the DTCs detection threshold due to low voltage

from the battery/alternator, the DTCs may be stored.

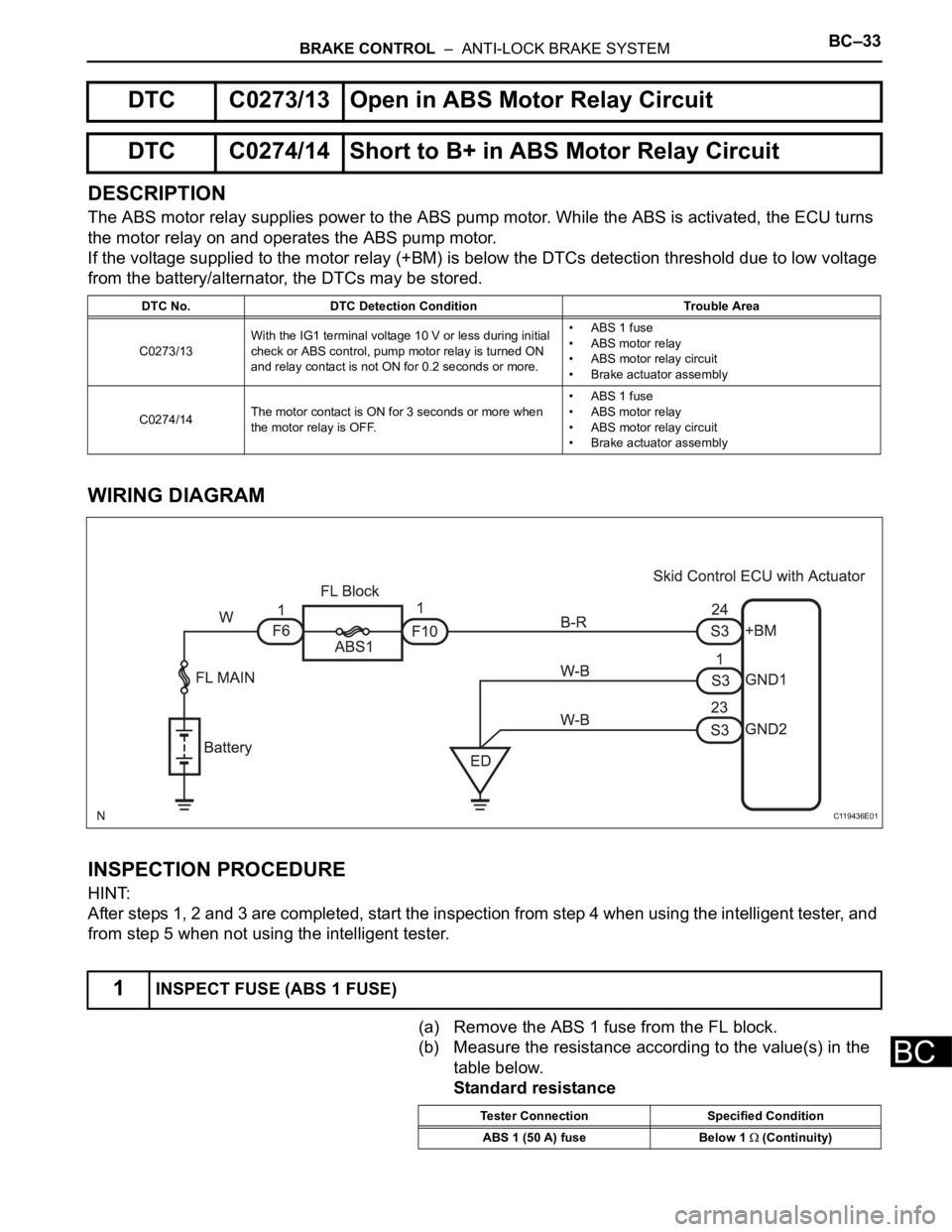

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

After steps 1, 2 and 3 are completed, start the inspection from step 4 when using the intelligent tester, and

from step 5 when not using the intelligent tester.

(a) Remove the ABS 1 fuse from the FL block.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

DTC C0273/13 Open in ABS Motor Relay Circuit

DTC C0274/14 Short to B+ in ABS Motor Relay Circuit

DTC No. DTC Detection Condition Trouble Area

C0273/13With the IG1 terminal voltage 10 V or less during initial

check or ABS control, pump motor relay is turned ON

and relay contact is not ON for 0.2 seconds or more.• ABS 1 fuse

• ABS motor relay

• ABS motor relay circuit

• Brake actuator assembly

C0274/14The motor contact is ON for 3 seconds or more when

the motor relay is OFF.• ABS 1 fuse

• ABS motor relay

• ABS motor relay circuit

• Brake actuator assembly

1INSPECT FUSE (ABS 1 FUSE)

C119436E01

Tester Connection Specified Condition

ABS 1 (50 A) fuse Below 1

(Continuity)

Page 2572 of 3000

BC–34BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

NG

OK

(a) Install the ABS 1 fuse.

(b) Disconnect the skid control ECU connector.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

NG

OK

(a) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

(a) Reconnect the skid control ECU connector.

(b) Connect the intelligent tester to the DLC3.

(c) Turn the ignition switch to the ON position and turn the

intelligent tester main switch on.

(d) Start the engine.

(e) Select the ACTIVE TEST mode on the intelligent tester.

ABS:REPLACE FUSE (ABS 1 FUSE)

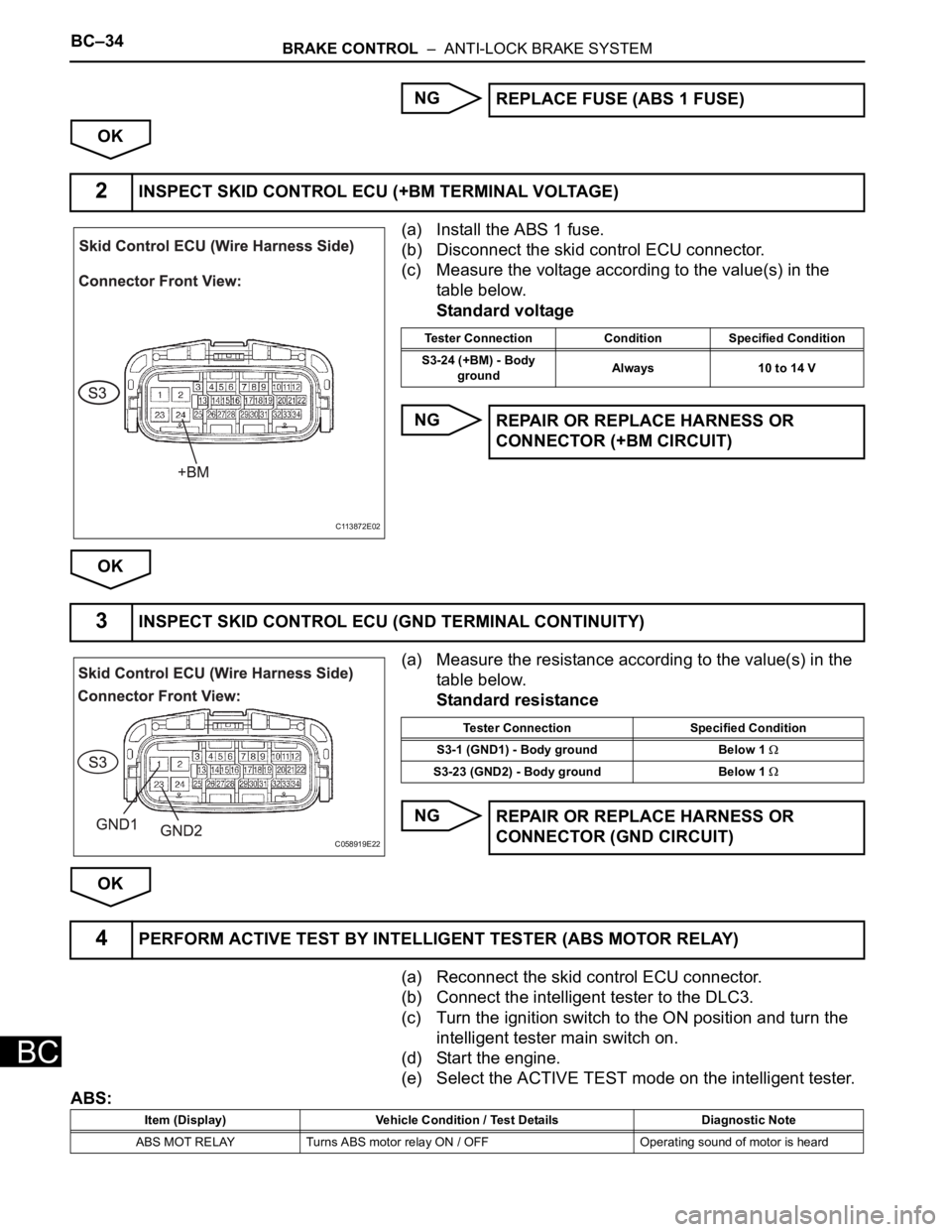

2INSPECT SKID CONTROL ECU (+BM TERMINAL VOLTAGE)

C113872E02

Tester Connection Condition Specified Condition

S3-24 (+BM) - Body

groundAlways 10 to 14 V

REPAIR OR REPLACE HARNESS OR

CONNECTOR (+BM CIRCUIT)

3INSPECT SKID CONTROL ECU (GND TERMINAL CONTINUITY)

C058919E22

Tester Connection Specified Condition

S3-1 (GND1) - Body ground Below 1

S3-23 (GND2) - Body ground Below 1

REPAIR OR REPLACE HARNESS OR

CONNECTOR (GND CIRCUIT)

4PERFORM ACTIVE TEST BY INTELLIGENT TESTER (ABS MOTOR RELAY)

Item (Display) Vehicle Condition / Test Details Diagnostic Note

ABS MOT RELAY Turns ABS motor relay ON / OFF Operating sound of motor is heard

Page 2573 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–35

BC

(f) Check operating sound of the ABS motor when

operating it with the intelligent tester.

OK:

The operating sound of the ABS motor is heard.

NG

OK

(a) Clear the DTCs (See page BC-10).

(b) Start the engine.

(c) Drive the vehicle at the speed of 6 km/h (4 mph) or more.

(d) Check that the same DTCs are recorded (See page BC-

10).

HINT:

• Reinstall the sensors, connectors, etc. and restore the

vehicle to its prior condition before rechecking for

DTCs.

• If a speed signal of 6 km/h (4 mph) or more is input to

the skid control ECU, with the ignition switch on and

the stop light switch off, the ECU performs self-

diagnosis of the motor and solenoid circuits.

Result

HINT:

• If any DTCs are output while jiggling a connector or

wire harness of the brake actuator (skid control ECU),

inspect and repair the connector or wire harness.

• If the normal system code is output, slightly jiggle the

connectors, wire harnesses, and fuses of the brake

actuator assembly. Make sure that no DTCs are

output.

• These DTCs may be stored due to a malfunction in

the connector terminal connection, etc.

B

AREPLACE BRAKE ACTUATOR ASSEMBLY

5RECONFIRM DTC

Condition Proceed to

DTCs (C0273/13 and C0274/14) are output A

DTCs (C0273/13 and C0274/14) are not output B

END

REPLACE BRAKE ACTUATOR ASSEMBLY

Page 2574 of 3000

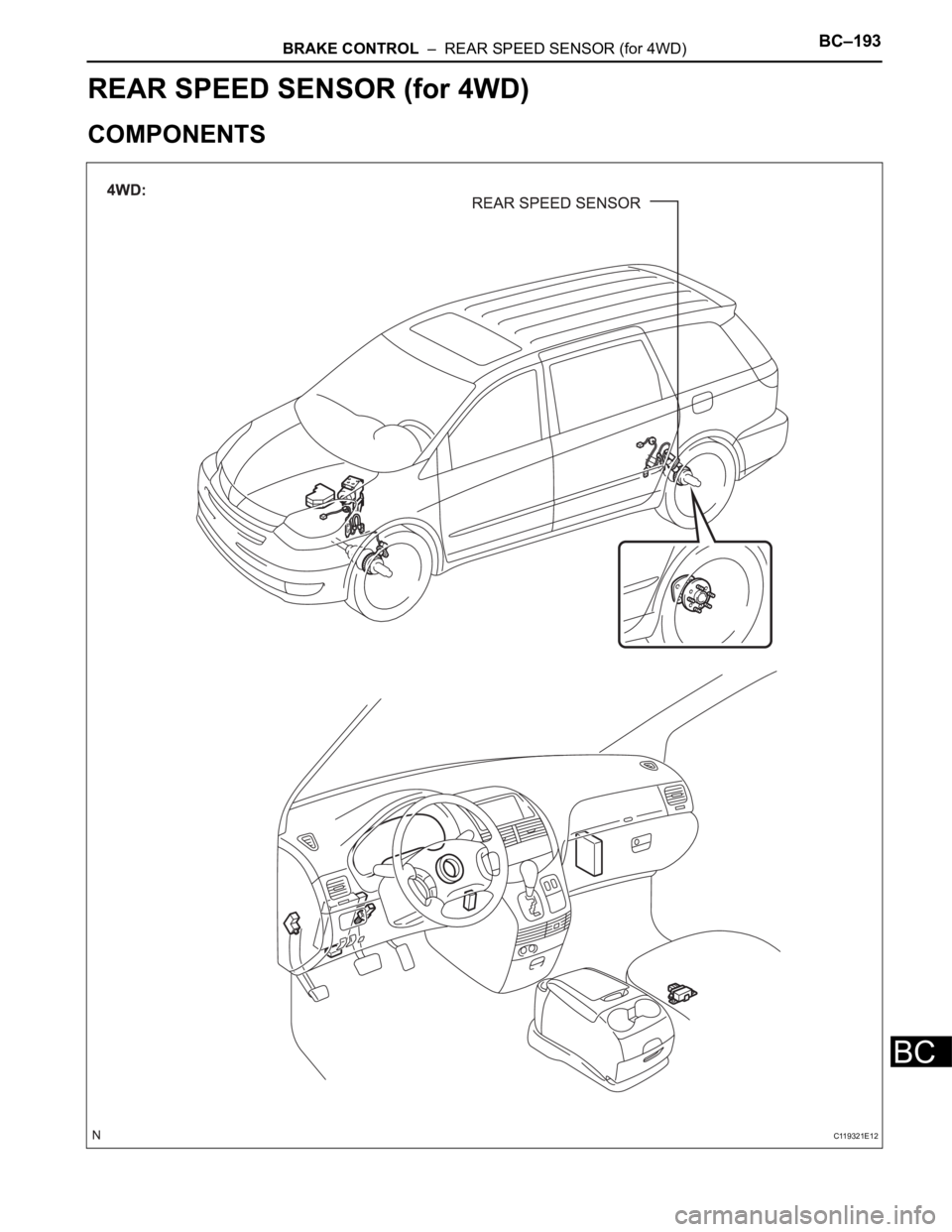

BRAKE CONTROL – REAR SPEED SENSOR (for 4WD)BC–193

BC

BRAKE

BRAKE CONTROL

REAR SPEED SENSOR (for 4WD)

COMPONENTS

C119321E12

Page 2575 of 3000

BC–194BRAKE CONTROL – REAR SPEED SENSOR (for 4WD)

BC

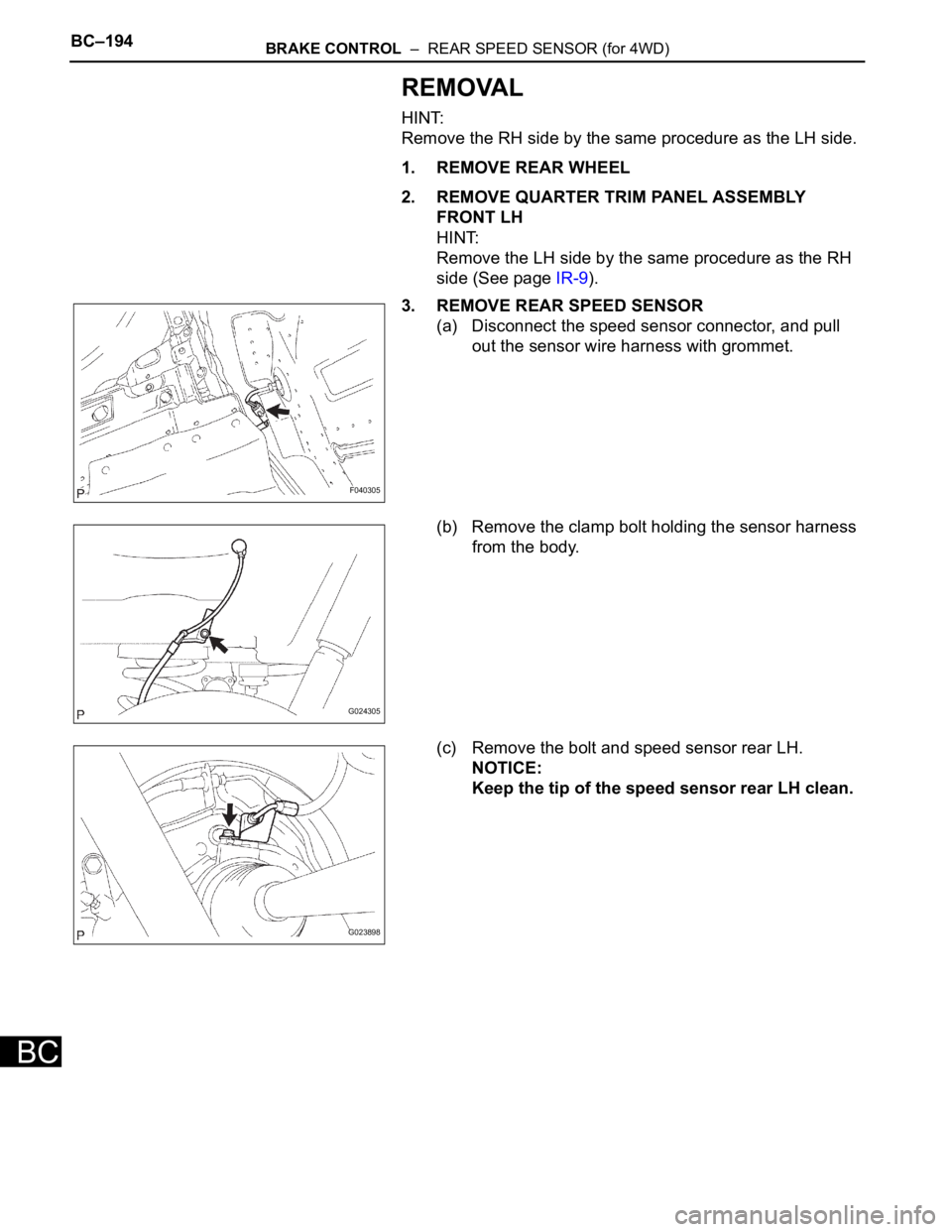

REMOVAL

HINT:

Remove the RH side by the same procedure as the LH side.

1. REMOVE REAR WHEEL

2. REMOVE QUARTER TRIM PANEL ASSEMBLY

FRONT LH

HINT:

Remove the LH side by the same procedure as the RH

side (See page IR-9).

3. REMOVE REAR SPEED SENSOR

(a) Disconnect the speed sensor connector, and pull

out the sensor wire harness with grommet.

(b) Remove the clamp bolt holding the sensor harness

from the body.

(c) Remove the bolt and speed sensor rear LH.

NOTICE:

Keep the tip of the speed sensor rear LH clean.

F040305

G024305

G023898

Page 2576 of 3000

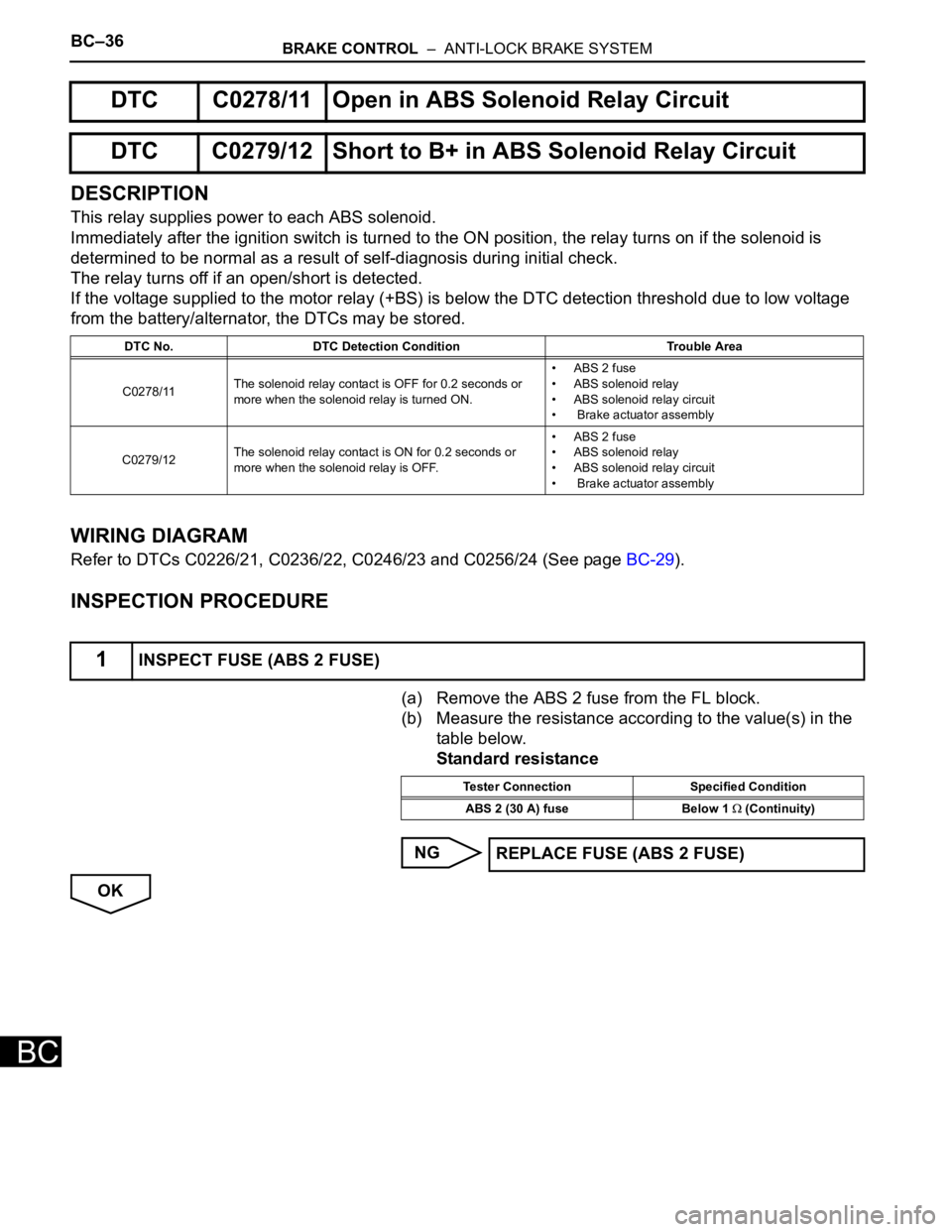

BC–36BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

DESCRIPTION

This relay supplies power to each ABS solenoid.

Immediately after the ignition switch is turned to the ON position, the relay turns on if the solenoid is

determined to be normal as a result of self-diagnosis during initial check.

The relay turns off if an open/short is detected.

If the voltage supplied to the motor relay (+BS) is below the DTC detection threshold due to low voltage

from the battery/alternator, the DTCs may be stored.

WIRING DIAGRAM

Refer to DTCs C0226/21, C0236/22, C0246/23 and C0256/24 (See page BC-29).

INSPECTION PROCEDURE

(a) Remove the ABS 2 fuse from the FL block.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

DTC C0278/11 Open in ABS Solenoid Relay Circuit

DTC C0279/12 Short to B+ in ABS Solenoid Relay Circuit

DTC No. DTC Detection Condition Trouble Area

C0278/11The solenoid relay contact is OFF for 0.2 seconds or

more when the solenoid relay is turned ON.• ABS 2 fuse

• ABS solenoid relay

• ABS solenoid relay circuit

• Brake actuator assembly

C0279/12The solenoid relay contact is ON for 0.2 seconds or

more when the solenoid relay is OFF.• ABS 2 fuse

• ABS solenoid relay

• ABS solenoid relay circuit

• Brake actuator assembly

1INSPECT FUSE (ABS 2 FUSE)

Tester Connection Specified Condition

ABS 2 (30 A) fuse Below 1

(Continuity)

REPLACE FUSE (ABS 2 FUSE)

Page 2577 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–37

BC

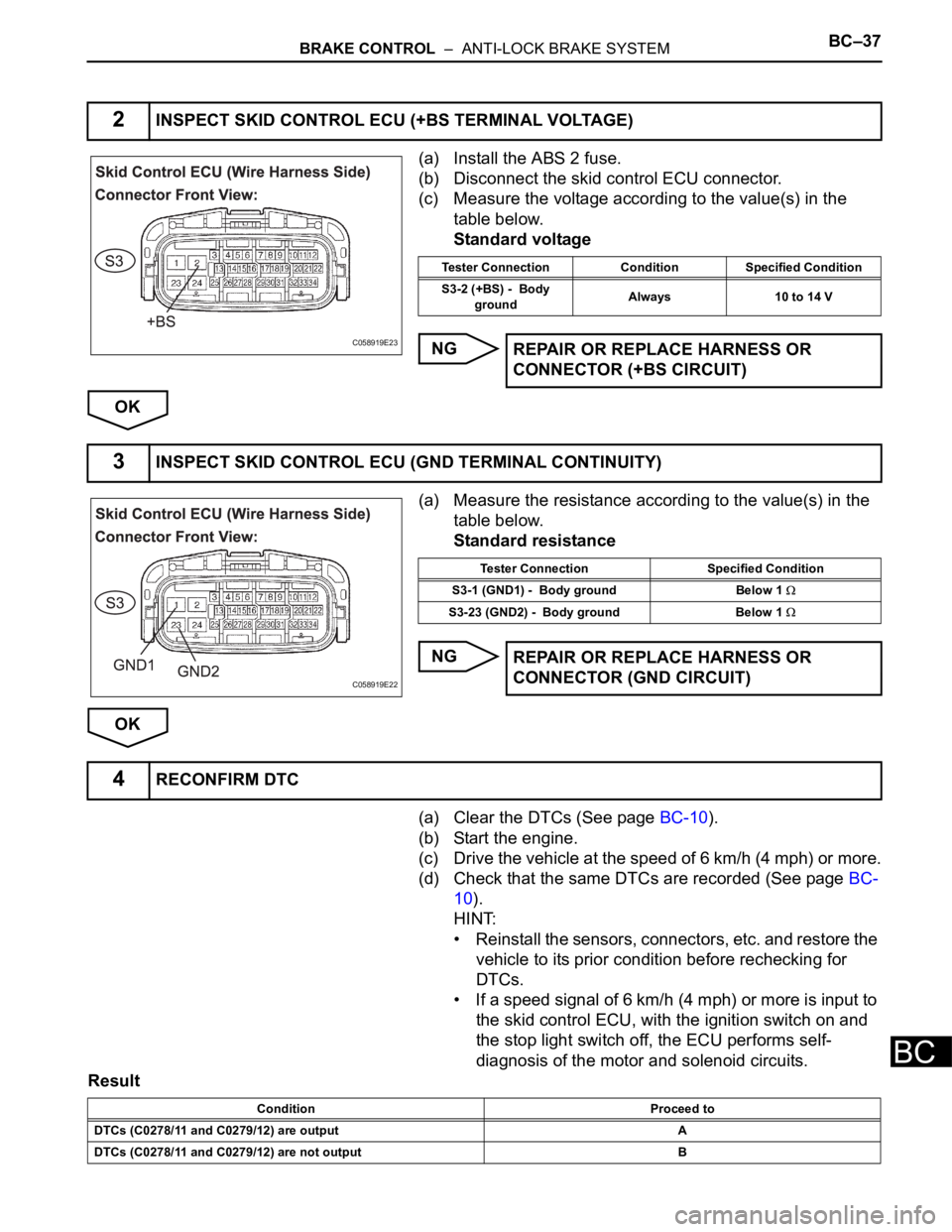

(a) Install the ABS 2 fuse.

(b) Disconnect the skid control ECU connector.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

NG

OK

(a) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

(a) Clear the DTCs (See page BC-10).

(b) Start the engine.

(c) Drive the vehicle at the speed of 6 km/h (4 mph) or more.

(d) Check that the same DTCs are recorded (See page BC-

10).

HINT:

• Reinstall the sensors, connectors, etc. and restore the

vehicle to its prior condition before rechecking for

DTCs.

• If a speed signal of 6 km/h (4 mph) or more is input to

the skid control ECU, with the ignition switch on and

the stop light switch off, the ECU performs self-

diagnosis of the motor and solenoid circuits.

Result

2INSPECT SKID CONTROL ECU (+BS TERMINAL VOLTAGE)

C058919E23

Tester Connection Condition Specified Condition

S3-2 (+BS) - Body

groundAlways 10 to 14 V

REPAIR OR REPLACE HARNESS OR

CONNECTOR (+BS CIRCUIT)

3INSPECT SKID CONTROL ECU (GND TERMINAL CONTINUITY)

C058919E22

Tester Connection Specified Condition

S3-1 (GND1) - Body ground Below 1

S3-23 (GND2) - Body ground Below 1

REPAIR OR REPLACE HARNESS OR

CONNECTOR (GND CIRCUIT)

4RECONFIRM DTC

Condition Proceed to

DTCs (C0278/11 and C0279/12) are output A

DTCs (C0278/11 and C0279/12) are not output B

Page 2578 of 3000

BC–38BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

HINT:

• If any DTCs are output while jiggling a connector or

wire harness of the brake actuator (skid control ECU),

inspect and repair the connector or wire harness.

• If the normal system code is output, slightly jiggle the

connectors, wire harnesses, and fuses of the brake

actuator assembly. Make sure that no DTCs are

output.

• These DTCs may be memorized due to a malfunction

in the connector terminal connection, etc.

B

AEND

REPLACE BRAKE ACTUATOR ASSEMBLY

Page 2579 of 3000

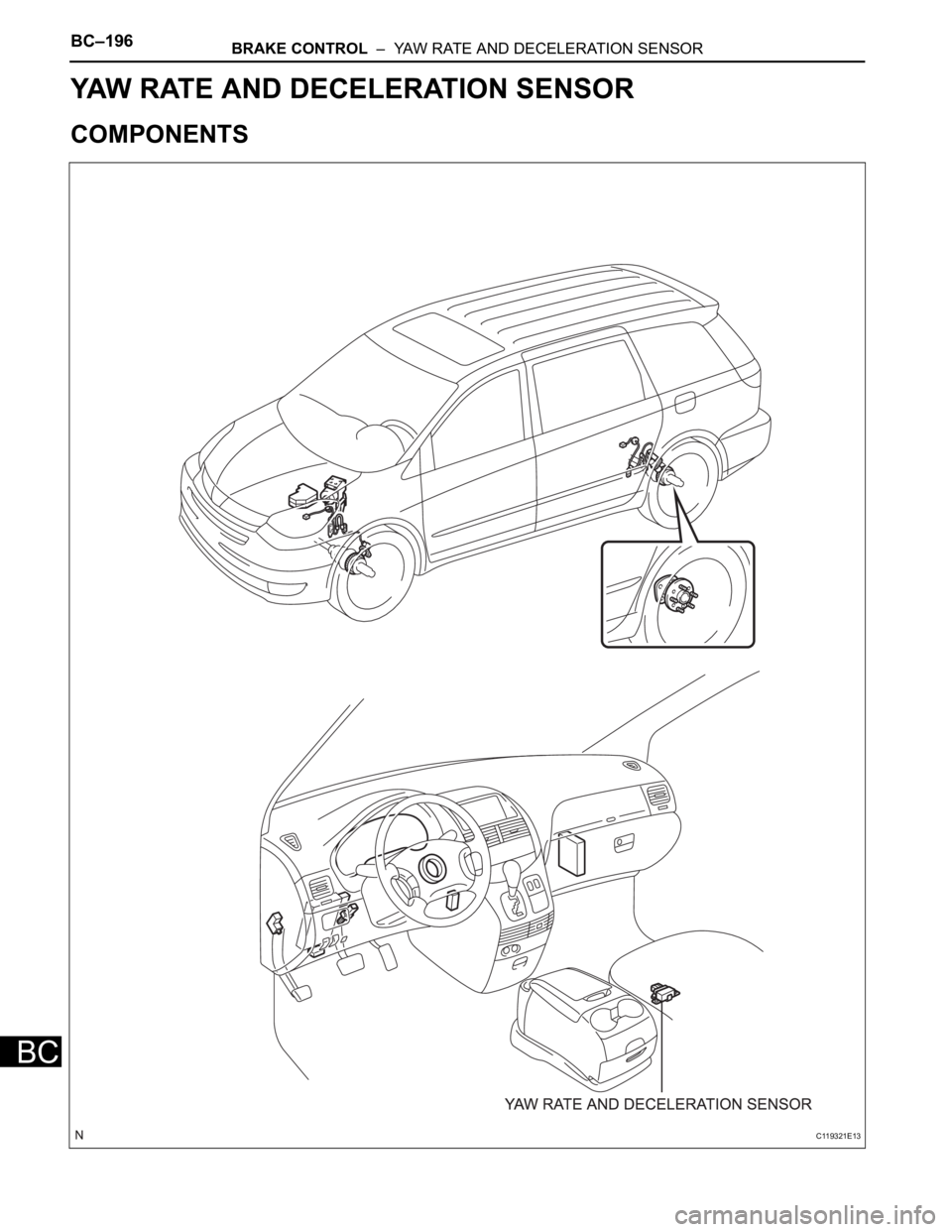

BC–196BRAKE CONTROL – YAW RATE AND DECELERATION SENSOR

BC

BRAKE

BRAKE CONTROL

YAW RATE AND DECELERATION SENSOR

COMPONENTS

C119321E13

Page 2580 of 3000

BRAKE CONTROL – YAW RATE AND DECELERATION SENSORBC–197

BC

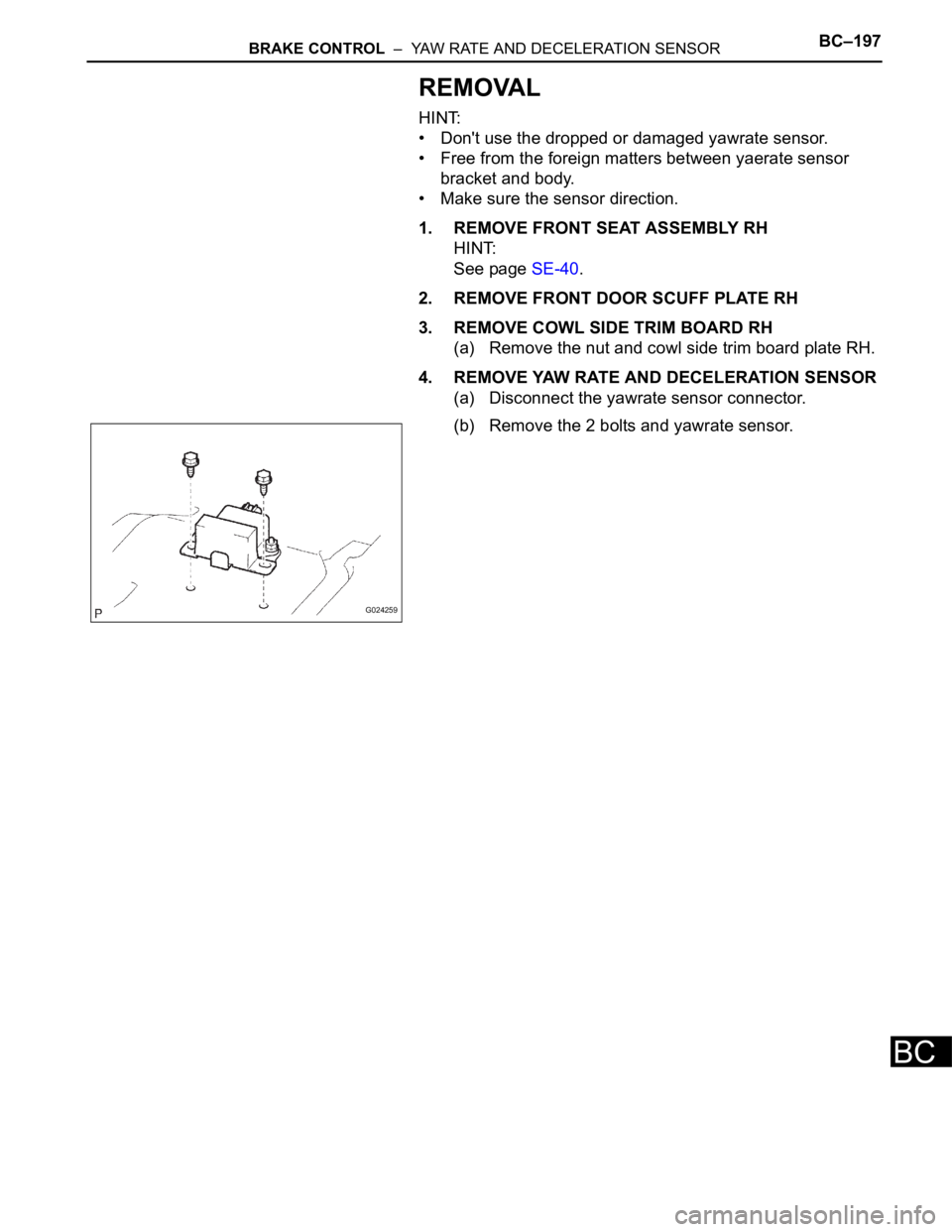

REMOVAL

HINT:

• Don't use the dropped or damaged yawrate sensor.

• Free from the foreign matters between yaerate sensor

bracket and body.

• Make sure the sensor direction.

1. REMOVE FRONT SEAT ASSEMBLY RH

HINT:

See page SE-40.

2. REMOVE FRONT DOOR SCUFF PLATE RH

3. REMOVE COWL SIDE TRIM BOARD RH

(a) Remove the nut and cowl side trim board plate RH.

4. REMOVE YAW RATE AND DECELERATION SENSOR

(a) Disconnect the yawrate sensor connector.

(b) Remove the 2 bolts and yawrate sensor.

G024259