check engine TOYOTA SIENNA 2007 Service Manual PDF

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 360 of 3000

ES–422GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

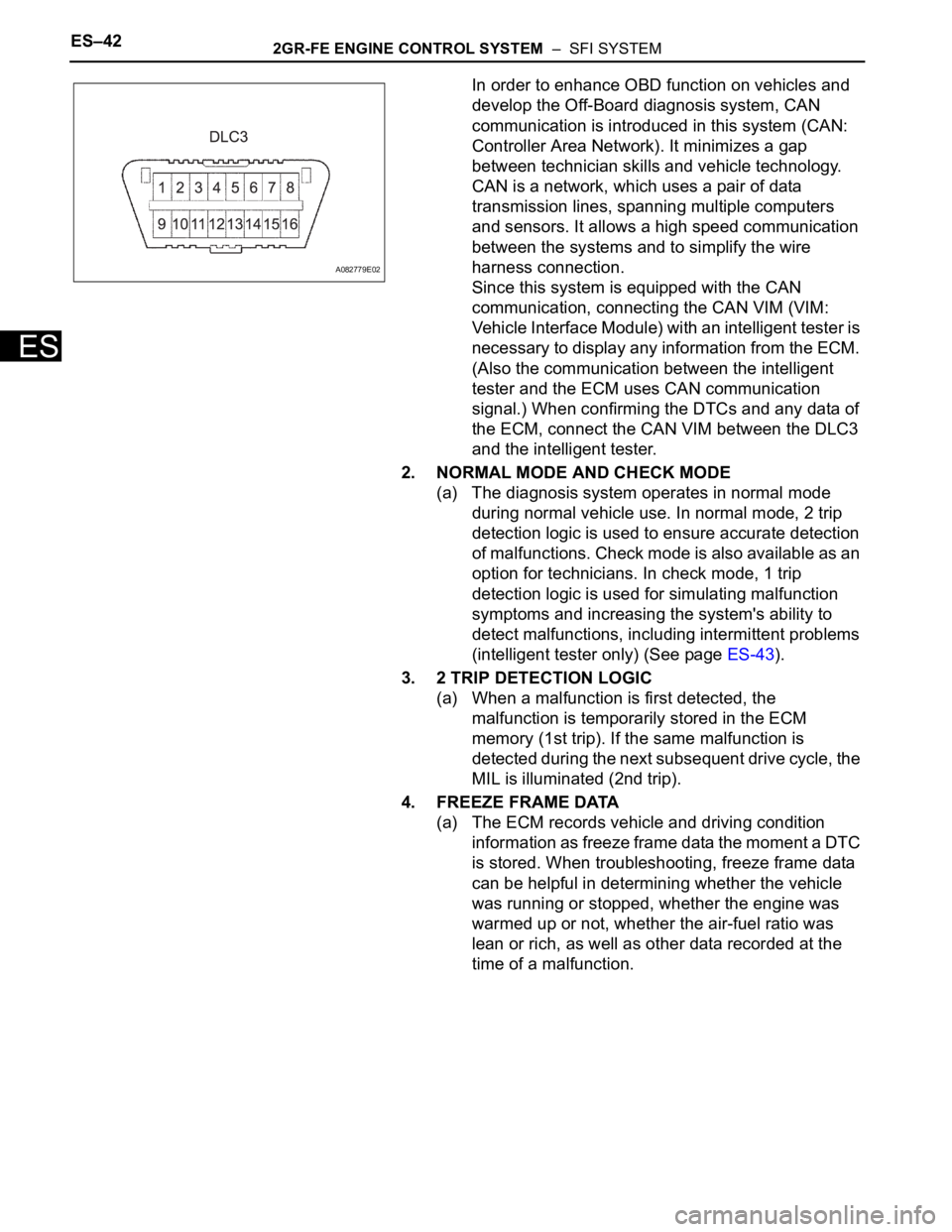

In order to enhance OBD function on vehicles and

develop the Off-Board diagnosis system, CAN

communication is introduced in this system (CAN:

Controller Area Network). It minimizes a gap

between technician skills and vehicle technology.

CAN is a network, which uses a pair of data

transmission lines, spanning multiple computers

and sensors. It allows a high speed communication

between the systems and to simplify the wire

harness connection.

Since this system is equipped with the CAN

communication, connecting the CAN VIM (VIM:

Vehicle Interface Module) with an intelligent tester is

necessary to display any information from the ECM.

(Also the communication between the intelligent

tester and the ECM uses CAN communication

signal.) When confirming the DTCs and any data of

the ECM, connect the CAN VIM between the DLC3

and the intelligent tester.

2. NORMAL MODE AND CHECK MODE

(a) The diagnosis system operates in normal mode

during normal vehicle use. In normal mode, 2 trip

detection logic is used to ensure accurate detection

of malfunctions. Check mode is also available as an

option for technicians. In check mode, 1 trip

detection logic is used for simulating malfunction

symptoms and increasing the system's ability to

detect malfunctions, including intermittent problems

(intelligent tester only) (See page ES-43).

3. 2 TRIP DETECTION LOGIC

(a) When a malfunction is first detected, the

malfunction is temporarily stored in the ECM

memory (1st trip). If the same malfunction is

detected during the next subsequent drive cycle, the

MIL is illuminated (2nd trip).

4. FREEZE FRAME DATA

(a) The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC

is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle

was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was

lean or rich, as well as other data recorded at the

time of a malfunction.

A082779E02

Page 362 of 3000

ES–442GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

(b) The MIL should turn off when the engine is started.

If the MIL remains illuminated, the diagnosis system

has detected a malfunction or abnormality in the

system.

HINT:

If the MIL is not illuminated when the ignition switch

is first turned to the ON position, check the MIL

circuit (See page ES-478).

Page 363 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–45

ES

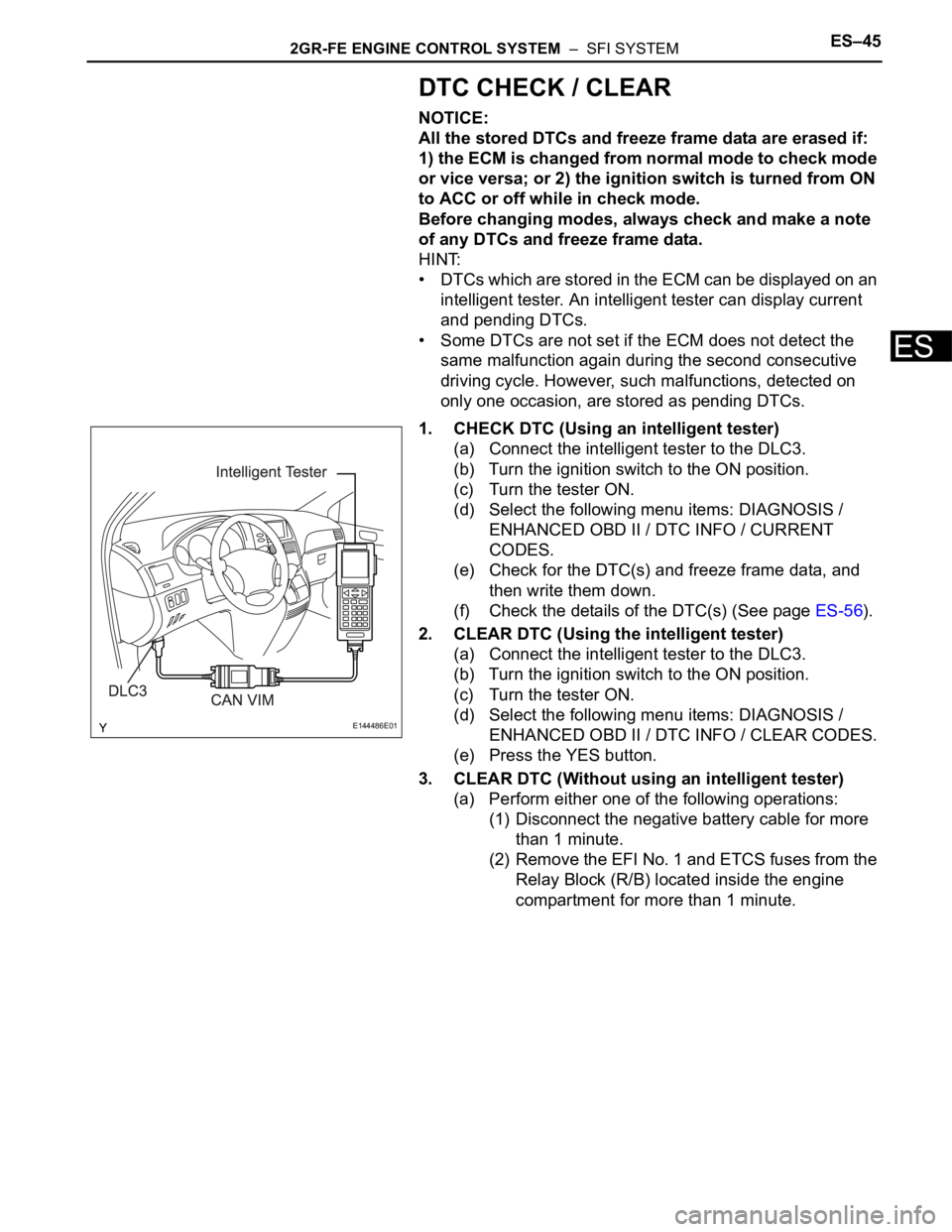

DTC CHECK / CLEAR

NOTICE:

All the stored DTCs and freeze frame data are erased if:

1) the ECM is changed from normal mode to check mode

or vice versa; or 2) the ignition switch is turned from ON

to ACC or off while in check mode.

Before changing modes, always check and make a note

of any DTCs and freeze frame data.

HINT:

• DTCs which are stored in the ECM can be displayed on an

intelligent tester. An intelligent tester can display current

and pending DTCs.

• Some DTCs are not set if the ECM does not detect the

same malfunction again during the second consecutive

driving cycle. However, such malfunctions, detected on

only one occasion, are stored as pending DTCs.

1. CHECK DTC (Using an intelligent tester)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester ON.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT

CODES.

(e) Check for the DTC(s) and freeze frame data, and

then write them down.

(f) Check the details of the DTC(s) (See page ES-56).

2. CLEAR DTC (Using the intelligent tester)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester ON.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CLEAR CODES.

(e) Press the YES button.

3. CLEAR DTC (Without using an intelligent tester)

(a) Perform either one of the following operations:

(1) Disconnect the negative battery cable for more

than 1 minute.

(2) Remove the EFI No. 1 and ETCS fuses from the

Relay Block (R/B) located inside the engine

compartment for more than 1 minute.

E144486E01

Page 364 of 3000

ES–462GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

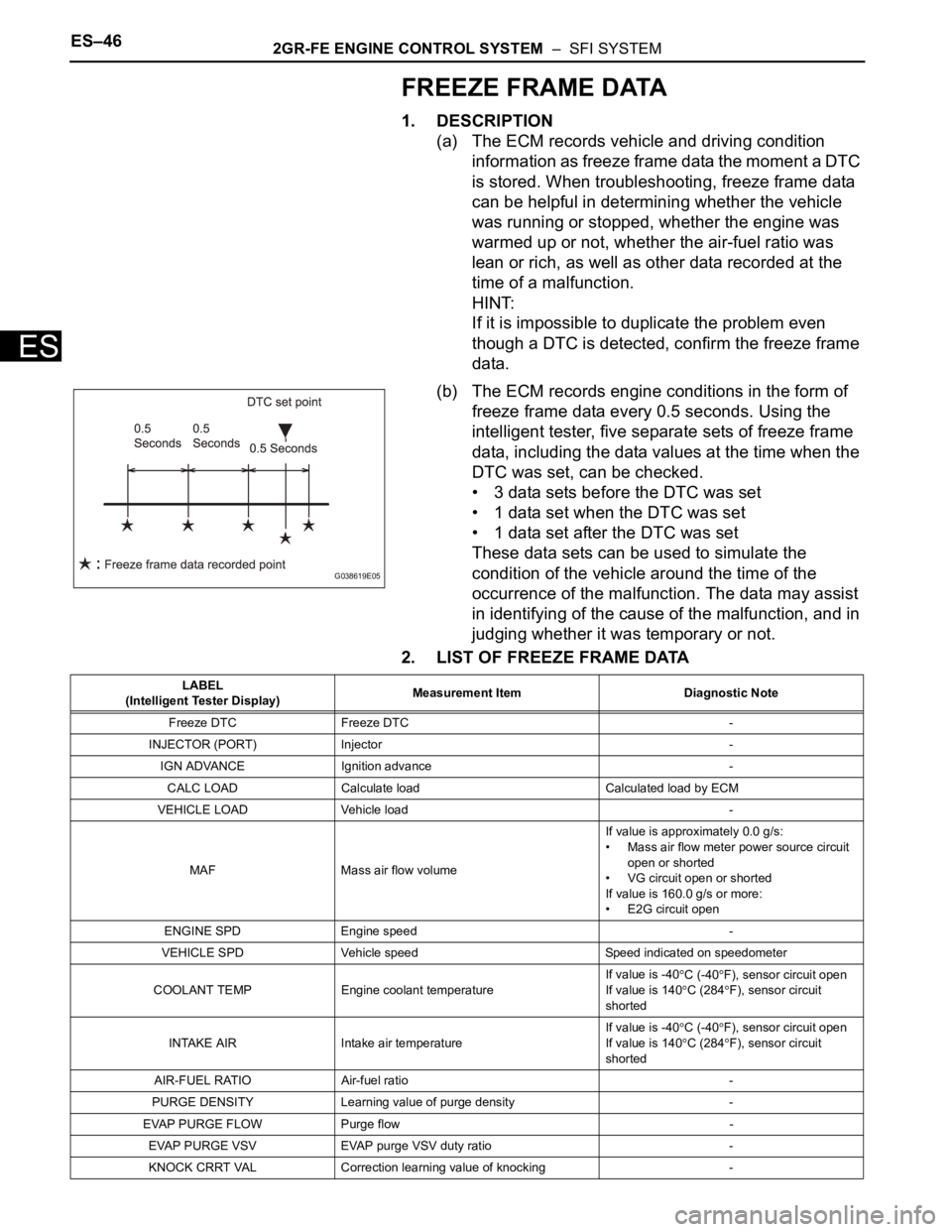

FREEZE FRAME DATA

1. DESCRIPTION

(a) The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC

is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle

was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was

lean or rich, as well as other data recorded at the

time of a malfunction.

HINT:

If it is impossible to duplicate the problem even

though a DTC is detected, confirm the freeze frame

data.

(b) The ECM records engine conditions in the form of

freeze frame data every 0.5 seconds. Using the

intelligent tester, five separate sets of freeze frame

data, including the data values at the time when the

DTC was set, can be checked.

• 3 data sets before the DTC was set

• 1 data set when the DTC was set

• 1 data set after the DTC was set

These data sets can be used to simulate the

condition of the vehicle around the time of the

occurrence of the malfunction. The data may assist

in identifying of the cause of the malfunction, and in

judging whether it was temporary or not.

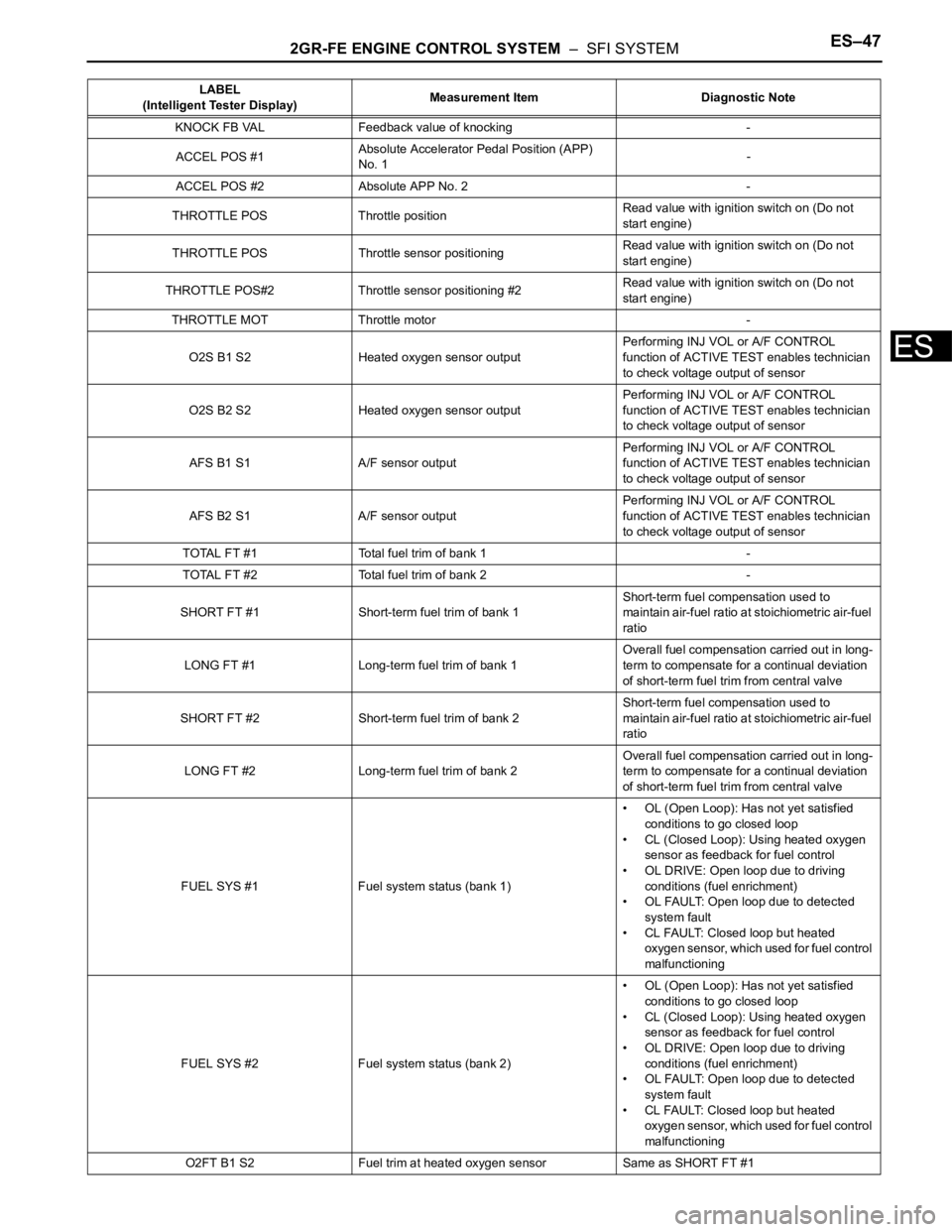

2. LIST OF FREEZE FRAME DATA

G038619E05

LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

Freeze DTC Freeze DTC -

INJECTOR (PORT) Injector -

IGN ADVANCE Ignition advance -

CALC LOAD Calculate load Calculated load by ECM

VEHICLE LOAD Vehicle load -

MAF Mass air flow volumeIf value is approximately 0.0 g/s:

• Mass air flow meter power source circuit

open or shorted

• VG circuit open or shorted

If value is 160.0 g/s or more:

• E2G circuit open

ENGINE SPD Engine speed -

VEHICLE SPD Vehicle speed Speed indicated on speedometer

COOLANT TEMP Engine coolant temperatureIf value is -40

C (-40F), sensor circuit open

If value is 140

C (284F), sensor circuit

shorted

INTAKE AIR Intake air temperatureIf value is -40

C (-40F), sensor circuit open

If value is 140C (284F), sensor circuit

shorted

AIR-FUEL RATIO Air-fuel ratio -

PURGE DENSITY Learning value of purge density -

EVAP PURGE FLOW Purge flow -

EVAP PURGE VSV EVAP purge VSV duty ratio -

KNOCK CRRT VAL Correction learning value of knocking -

Page 365 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–47

ES

KNOCK FB VAL Feedback value of knocking -

ACCEL POS #1Absolute Accelerator Pedal Position (APP)

No. 1-

ACCEL POS #2 Absolute APP No. 2 -

THROTTLE POS Throttle positionRead value with ignition switch on (Do not

start engine)

THROTTLE POS Throttle sensor positioningRead value with ignition switch on (Do not

start engine)

THROTTLE POS#2 Throttle sensor positioning #2Read value with ignition switch on (Do not

start engine)

THROTTLE MOT Throttle motor -

O2S B1 S2 Heated oxygen sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check voltage output of sensor

O2S B2 S2 Heated oxygen sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check voltage output of sensor

AFS B1 S1 A/F sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check voltage output of sensor

AFS B2 S1 A/F sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check voltage output of sensor

TOTAL FT #1 Total fuel trim of bank 1 -

TOTAL FT #2 Total fuel trim of bank 2 -

SHORT FT #1 Short-term fuel trim of bank 1Short-term fuel compensation used to

maintain air-fuel ratio at stoichiometric air-fuel

ratio

LONG FT #1 Long-term fuel trim of bank 1Overall fuel compensation carried out in long-

term to compensate for a continual deviation

of short-term fuel trim from central valve

SHORT FT #2 Short-term fuel trim of bank 2Short-term fuel compensation used to

maintain air-fuel ratio at stoichiometric air-fuel

ratio

LONG FT #2 Long-term fuel trim of bank 2Overall fuel compensation carried out in long-

term to compensate for a continual deviation

of short-term fuel trim from central valve

FUEL SYS #1 Fuel system status (bank 1)• OL (Open Loop): Has not yet satisfied

conditions to go closed loop

• CL (Closed Loop): Using heated oxygen

sensor as feedback for fuel control

• OL DRIVE: Open loop due to driving

conditions (fuel enrichment)

• OL FAULT: Open loop due to detected

system fault

• CL FAULT: Closed loop but heated

oxygen sensor, which used for fuel control

malfunctioning

FUEL SYS #2 Fuel system status (bank 2)• OL (Open Loop): Has not yet satisfied

conditions to go closed loop

• CL (Closed Loop): Using heated oxygen

sensor as feedback for fuel control

• OL DRIVE: Open loop due to driving

conditions (fuel enrichment)

• OL FAULT: Open loop due to detected

system fault

• CL FAULT: Closed loop but heated

oxygen sensor, which used for fuel control

malfunctioning

O2FT B1 S2 Fuel trim at heated oxygen sensor Same as SHORT FT #1LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

Page 368 of 3000

ES–502GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

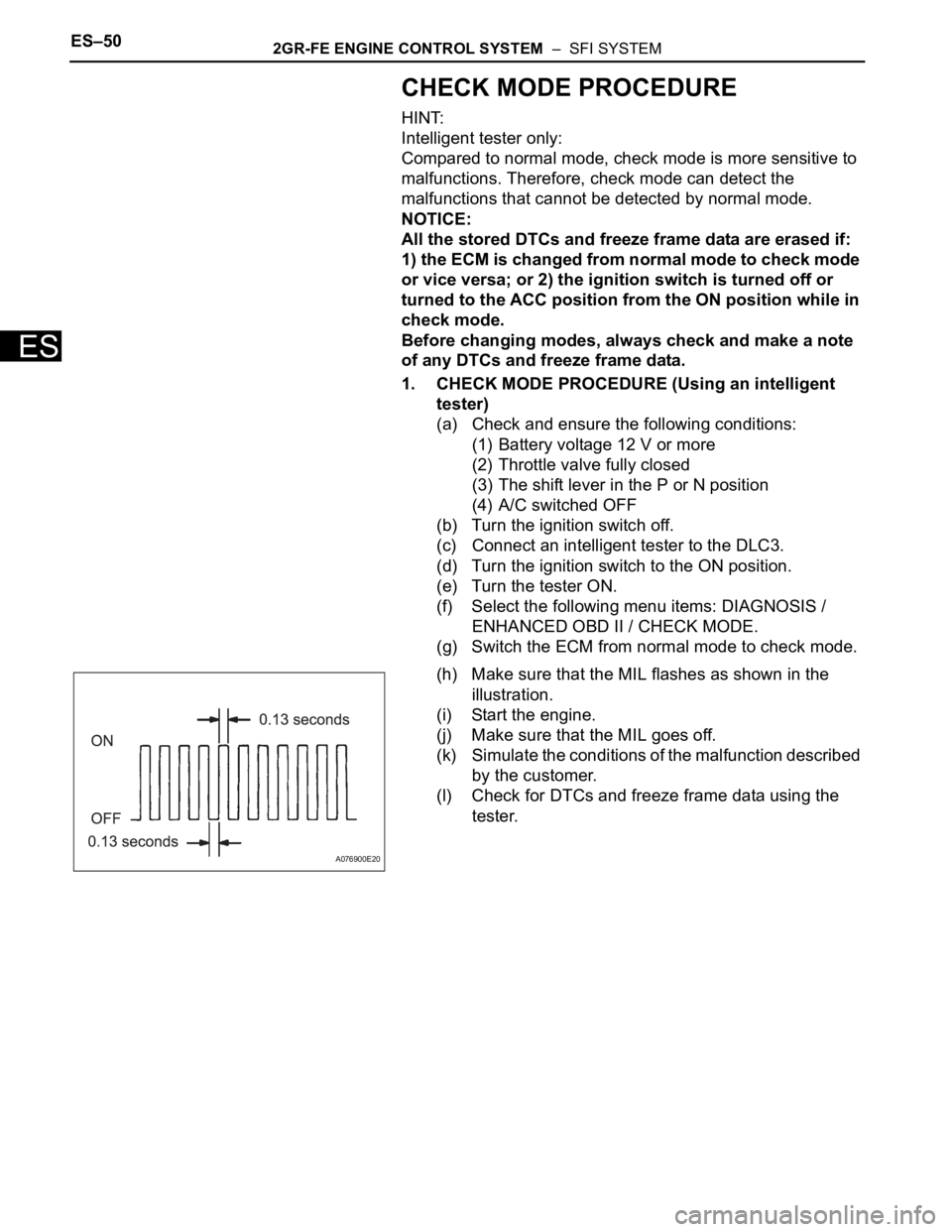

CHECK MODE PROCEDURE

HINT:

Intelligent tester only:

Compared to normal mode, check mode is more sensitive to

malfunctions. Therefore, check mode can detect the

malfunctions that cannot be detected by normal mode.

NOTICE:

All the stored DTCs and freeze frame data are erased if:

1) the ECM is changed from normal mode to check mode

or vice versa; or 2) the ignition switch is turned off or

turned to the ACC position from the ON position while in

check mode.

Before changing modes, always check and make a note

of any DTCs and freeze frame data.

1. CHECK MODE PROCEDURE (Using an intelligent

tester)

(a) Check and ensure the following conditions:

(1) Battery voltage 12 V or more

(2) Throttle valve fully closed

(3) The shift lever in the P or N position

(4) A/C switched OFF

(b) Turn the ignition switch off.

(c) Connect an intelligent tester to the DLC3.

(d) Turn the ignition switch to the ON position.

(e) Turn the tester ON.

(f) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / CHECK MODE.

(g) Switch the ECM from normal mode to check mode.

(h) Make sure that the MIL flashes as shown in the

illustration.

(i) Start the engine.

(j) Make sure that the MIL goes off.

(k) Simulate the conditions of the malfunction described

by the customer.

(l) Check for DTCs and freeze frame data using the

tester.

A076900E20

Page 370 of 3000

ES–642GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

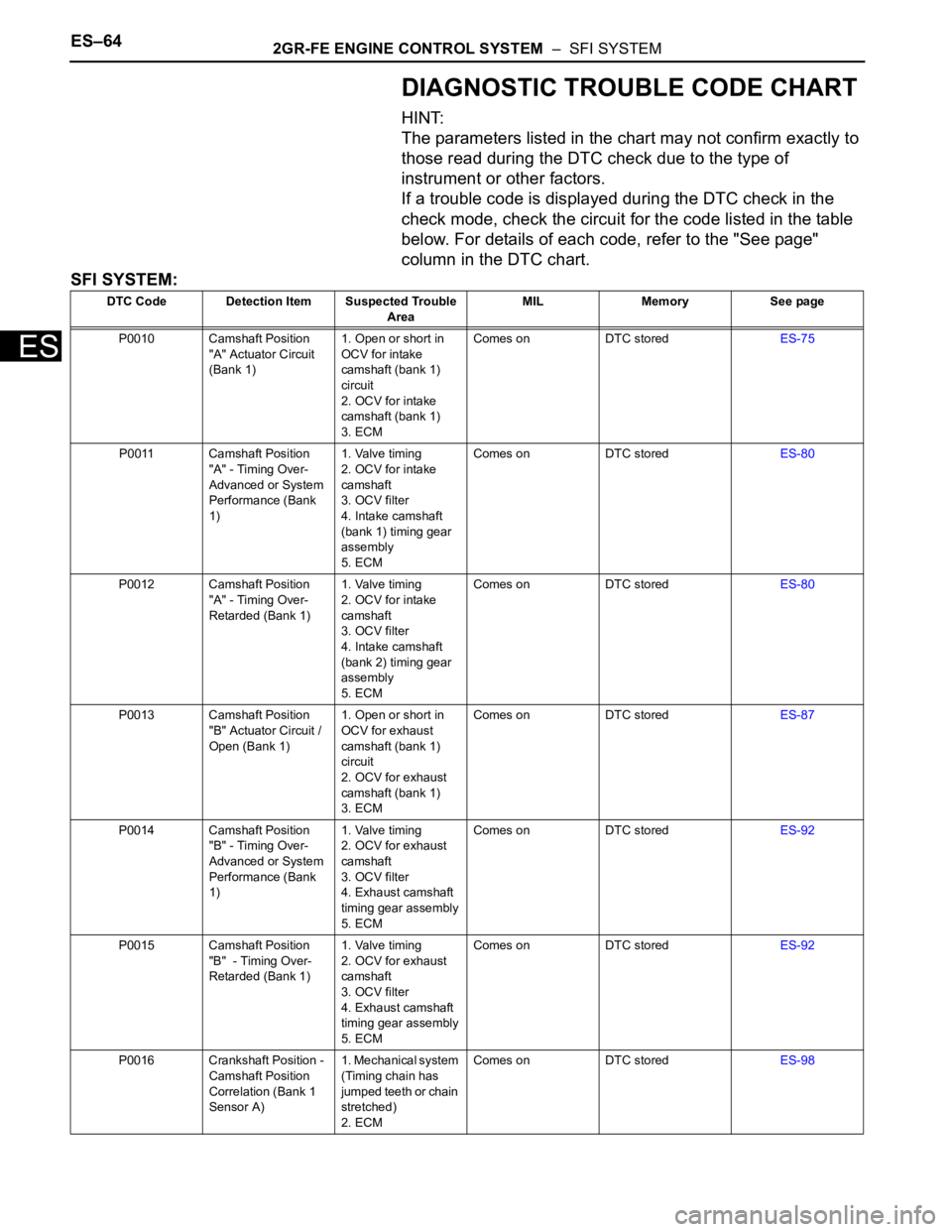

DIAGNOSTIC TROUBLE CODE CHART

HINT:

The parameters listed in the chart may not confirm exactly to

those read during the DTC check due to the type of

instrument or other factors.

If a trouble code is displayed during the DTC check in the

check mode, check the circuit for the code listed in the table

below. For details of each code, refer to the "See page"

column in the DTC chart.

SFI SYSTEM:

DTC Code Detection Item Suspected Trouble

AreaMIL Memory See page

P0010 Camshaft Position

"A" Actuator Circuit

(Bank 1)1. Open or short in

OCV for intake

camshaft (bank 1)

circuit

2. OCV for intake

camshaft (bank 1)

3. ECMComes on DTC storedES-75

P0011 Camshaft Position

"A" - Timing Over-

Advanced or System

Performance (Bank

1)1. Valve timing

2. OCV for intake

camshaft

3. OCV filter

4. Intake camshaft

(bank 1) timing gear

assembly

5. ECMComes on DTC storedES-80

P0012 Camshaft Position

"A" - Timing Over-

Retarded (Bank 1)1. Valve timing

2. OCV for intake

camshaft

3. OCV filter

4. Intake camshaft

(bank 2) timing gear

assembly

5. ECMComes on DTC storedES-80

P0013 Camshaft Position

"B" Actuator Circuit /

Open (Bank 1)1. Open or short in

OCV for exhaust

camshaft (bank 1)

circuit

2. OCV for exhaust

camshaft (bank 1)

3. ECMComes on DTC storedES-87

P0014 Camshaft Position

"B" - Timing Over-

Advanced or System

Performance (Bank

1)1. Valve timing

2. OCV for exhaust

camshaft

3. OCV filter

4. Exhaust camshaft

timing gear assembly

5. ECMComes on DTC storedES-92

P0015 Camshaft Position

"B" - Timing Over-

Retarded (Bank 1)1. Valve timing

2. OCV for exhaust

camshaft

3. OCV filter

4. Exhaust camshaft

timing gear assembly

5. ECMComes on DTC storedES-92

P0016 Crankshaft Position -

Camshaft Position

Correlation (Bank 1

Sensor A)1. Mechanical system

(Timing chain has

jumped teeth or chain

stretched)

2. ECMComes on DTC storedES-98

Page 391 of 3000

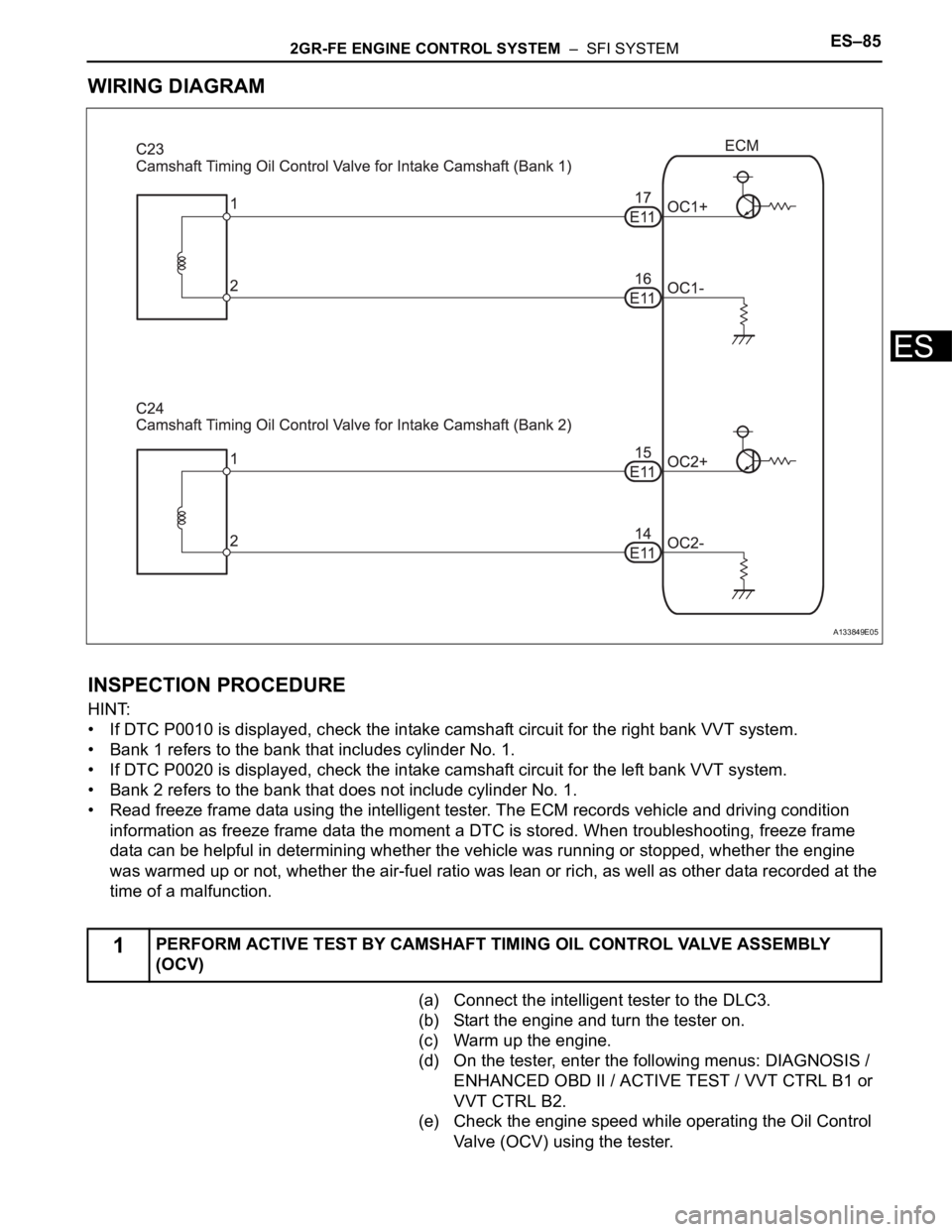

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–85

ES

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

• If DTC P0010 is displayed, check the intake camshaft circuit for the right bank VVT system.

• Bank 1 refers to the bank that includes cylinder No. 1.

• If DTC P0020 is displayed, check the intake camshaft circuit for the left bank VVT system.

• Bank 2 refers to the bank that does not include cylinder No. 1.

• Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame

data can be helpful in determining whether the vehicle was running or stopped, whether the engine

was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the

time of a malfunction.

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and turn the tester on.

(c) Warm up the engine.

(d) On the tester, enter the following menus: DIAGNOSIS /

ENHANCED OBD II / ACTIVE TEST / VVT CTRL B1 or

VVT CTRL B2.

(e) Check the engine speed while operating the Oil Control

Valve (OCV) using the tester.

1PERFORM ACTIVE TEST BY CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

(OCV)

A133849E05

Page 392 of 3000

ES–862GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

OK

OK

NG

(a) Disconnect the C23 or C24 camshaft timing oil control

valve (OCV) connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

(c) Reconnect the OCV connector.

NG

OK

Tester Operation Specified Condition

OCV OFF Normal engine speed

OCV ON Engine idles roughly or stalls (soon after OCV switched from OFF to ON)

CHECK FOR INTERMITTENT PROBLEMS

(See page ES-13)

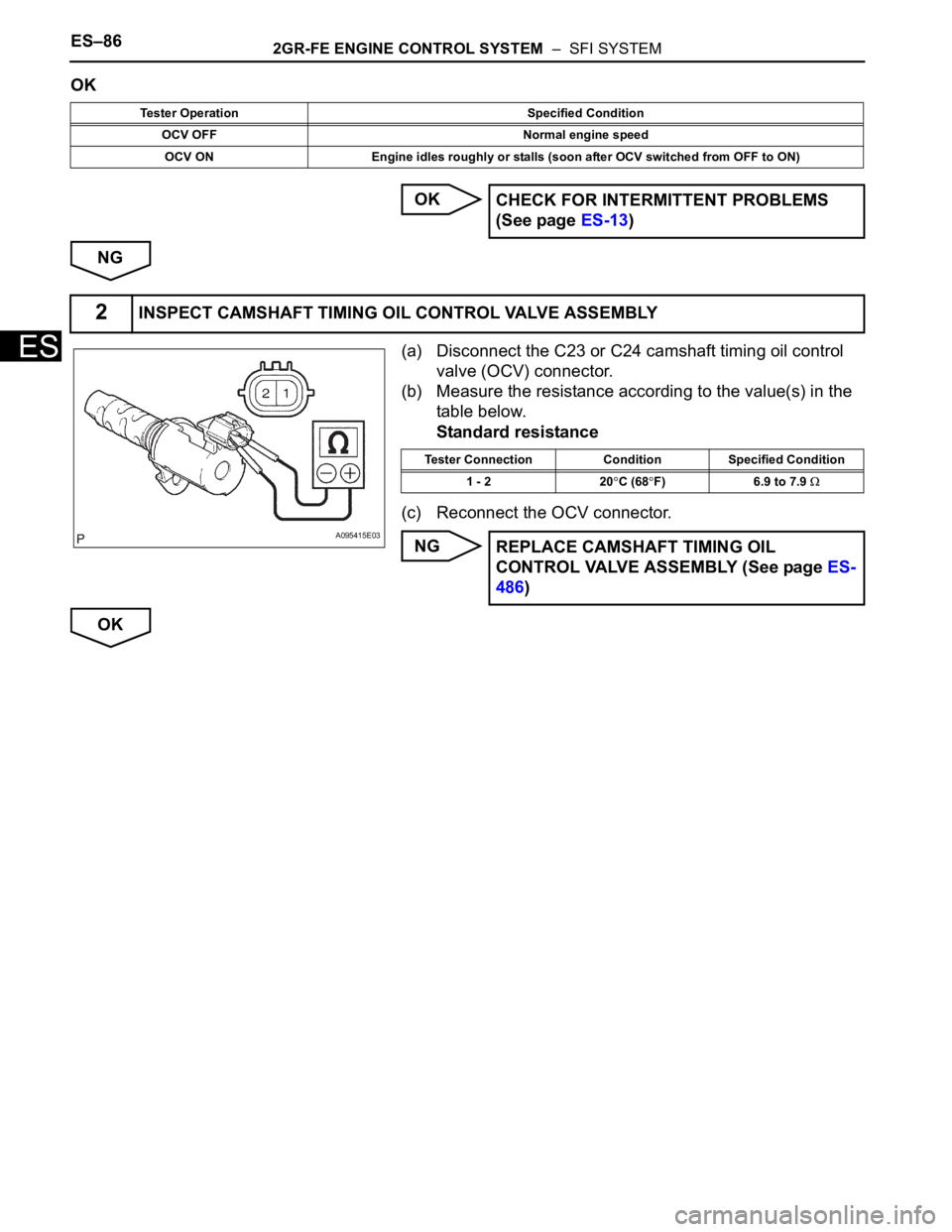

2INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

A095415E03

Tester Connection Condition Specified Condition

1 - 2 20

C (68F) 6.9 to 7.9

REPLACE CAMSHAFT TIMING OIL

CONTROL VALVE ASSEMBLY (See page ES-

486)

Page 393 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–87

ES

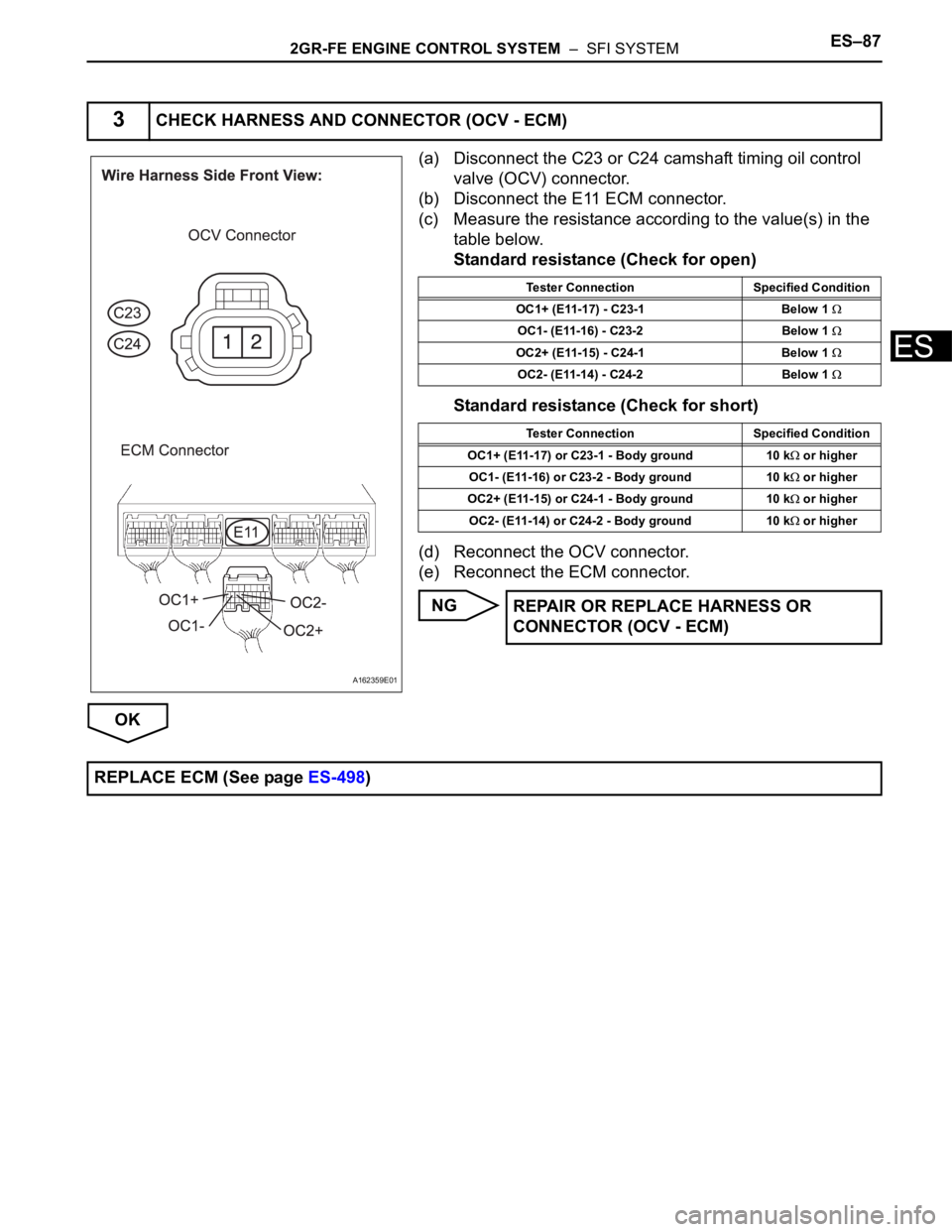

(a) Disconnect the C23 or C24 camshaft timing oil control

valve (OCV) connector.

(b) Disconnect the E11 ECM connector.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance (Check for open)

Standard resistance (Check for short)

(d) Reconnect the OCV connector.

(e) Reconnect the ECM connector.

NG

OK

3CHECK HARNESS AND CONNECTOR (OCV - ECM)

A162359E01

Tester Connection Specified Condition

OC1+ (E11-17) - C23-1 Below 1

OC1- (E11-16) - C23-2 Below 1

OC2+ (E11-15) - C24-1 Below 1

OC2- (E11-14) - C24-2 Below 1

Tester Connection Specified Condition

OC1+ (E11-17) or C23-1 - Body ground 10 k

or higher

OC1- (E11-16) or C23-2 - Body ground 10 k

or higher

OC2+ (E11-15) or C24-1 - Body ground 10 k

or higher

OC2- (E11-14) or C24-2 - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (OCV - ECM)

REPLACE ECM (See page ES-498)