sensor TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1173 of 3000

EC–102GR-FE EMISSION CONTROL – CANISTER

EC

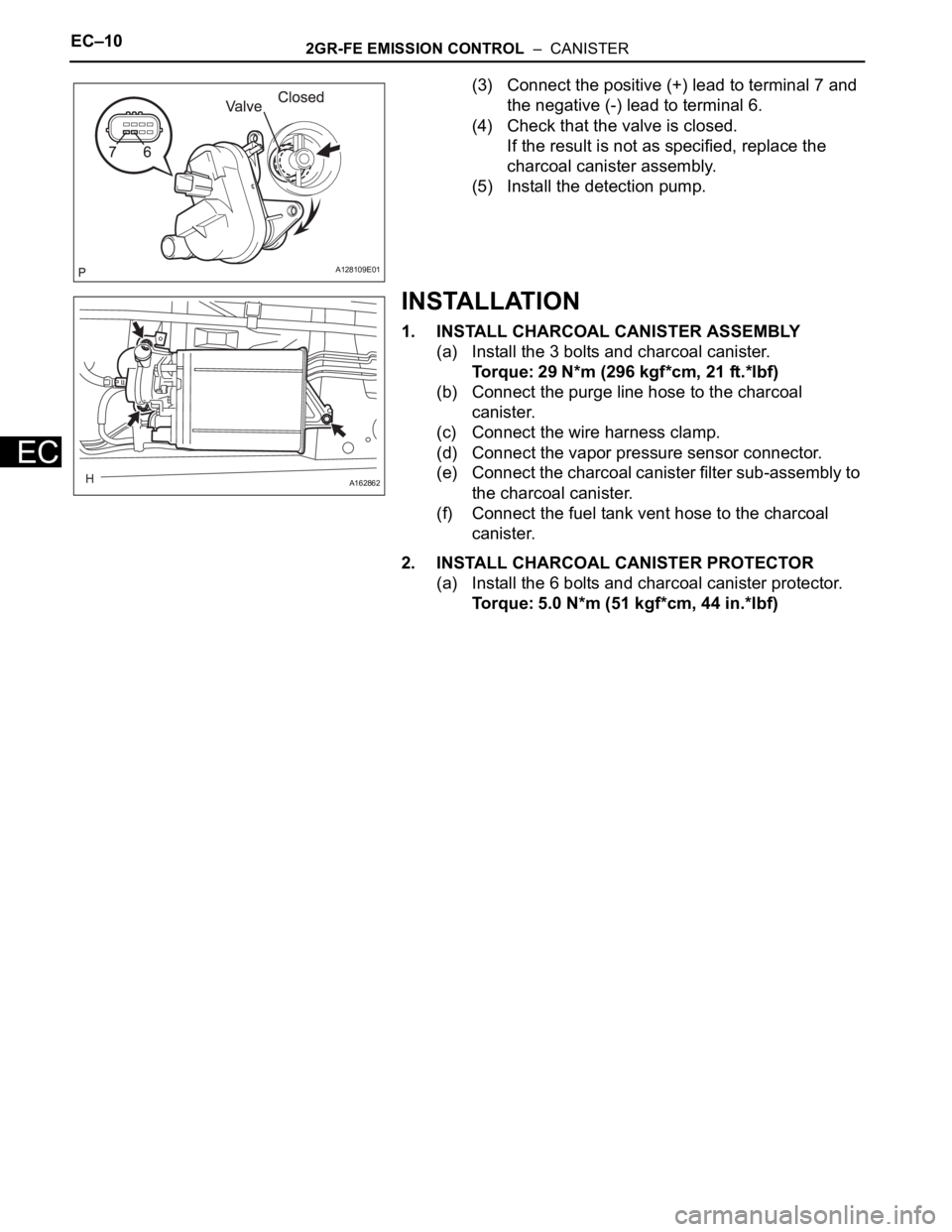

(3) Connect the positive (+) lead to terminal 7 and

the negative (-) lead to terminal 6.

(4) Check that the valve is closed.

If the result is not as specified, replace the

charcoal canister assembly.

(5) Install the detection pump.

INSTALLATION

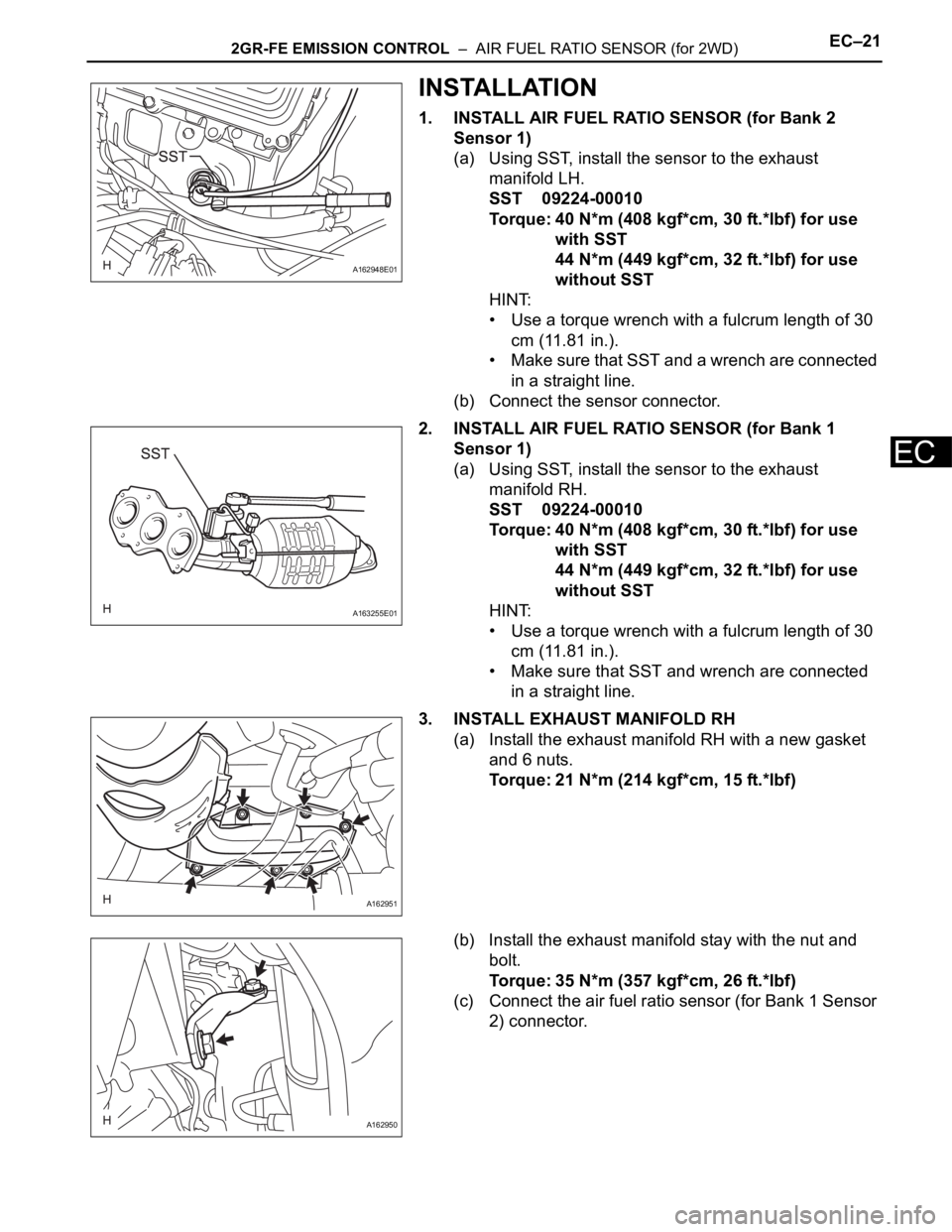

1. INSTALL CHARCOAL CANISTER ASSEMBLY

(a) Install the 3 bolts and charcoal canister.

Torque: 29 N*m (296 kgf*cm, 21 ft.*lbf)

(b) Connect the purge line hose to the charcoal

canister.

(c) Connect the wire harness clamp.

(d) Connect the vapor pressure sensor connector.

(e) Connect the charcoal canister filter sub-assembly to

the charcoal canister.

(f) Connect the fuel tank vent hose to the charcoal

canister.

2. INSTALL CHARCOAL CANISTER PROTECTOR

(a) Install the 6 bolts and charcoal canister protector.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

A128109E01

A162862

Page 1177 of 3000

2GR-FE EMISSION CONTROL – AIR FUEL RATIO SENSOR (for 2WD)EC–21

EC

INSTALLATION

1. INSTALL AIR FUEL RATIO SENSOR (for Bank 2

Sensor 1)

(a) Using SST, install the sensor to the exhaust

manifold LH.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use

with SST

44 N*m (449 kgf*cm, 32 ft.*lbf) for use

without SST

HINT:

• Use a torque wrench with a fulcrum length of 30

cm (11.81 in.).

• Make sure that SST and a wrench are connected

in a straight line.

(b) Connect the sensor connector.

2. INSTALL AIR FUEL RATIO SENSOR (for Bank 1

Sensor 1)

(a) Using SST, install the sensor to the exhaust

manifold RH.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use

with SST

44 N*m (449 kgf*cm, 32 ft.*lbf) for use

without SST

HINT:

• Use a torque wrench with a fulcrum length of 30

cm (11.81 in.).

• Make sure that SST and wrench are connected

in a straight line.

3. INSTALL EXHAUST MANIFOLD RH

(a) Install the exhaust manifold RH with a new gasket

and 6 nuts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(b) Install the exhaust manifold stay with the nut and

bolt.

Torque: 35 N*m (357 kgf*cm, 26 ft.*lbf)

(c) Connect the air fuel ratio sensor (for Bank 1 Sensor

2) connector.

A162948E01

A163255E01

A162951

A162950

Page 1178 of 3000

EC–222GR-FE EMISSION CONTROL – AIR FUEL RATIO SENSOR (for 2WD)

EC

4. INSTALL FRONT EXHAUST PIPE ASSEMBLY

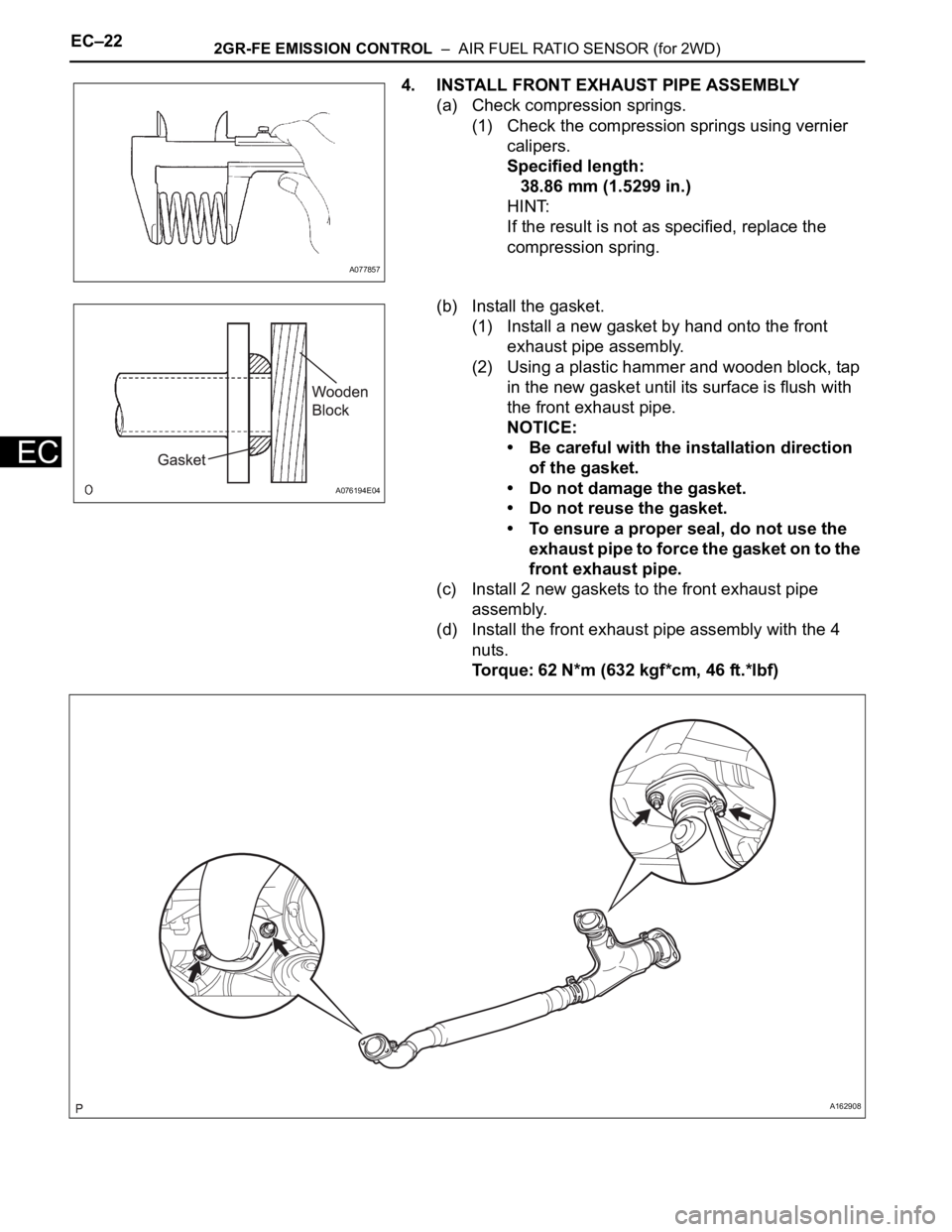

(a) Check compression springs.

(1) Check the compression springs using vernier

calipers.

Specified length:

38.86 mm (1.5299 in.)

HINT:

If the result is not as specified, replace the

compression spring.

(b) Install the gasket.

(1) Install a new gasket by hand onto the front

exhaust pipe assembly.

(2) Using a plastic hammer and wooden block, tap

in the new gasket until its surface is flush with

the front exhaust pipe.

NOTICE:

• Be careful with the installation direction

of the gasket.

• Do not damage the gasket.

• Do not reuse the gasket.

• To ensure a proper seal, do not use the

exhaust pipe to force the gasket on to the

front exhaust pipe.

(c) Install 2 new gaskets to the front exhaust pipe

assembly.

(d) Install the front exhaust pipe assembly with the 4

nuts.

Torque: 62 N*m (632 kgf*cm, 46 ft.*lbf)

A077857

A076194E04

A162908

Page 1179 of 3000

2GR-FE EMISSION CONTROL – AIR FUEL RATIO SENSOR (for 2WD)EC–23

EC

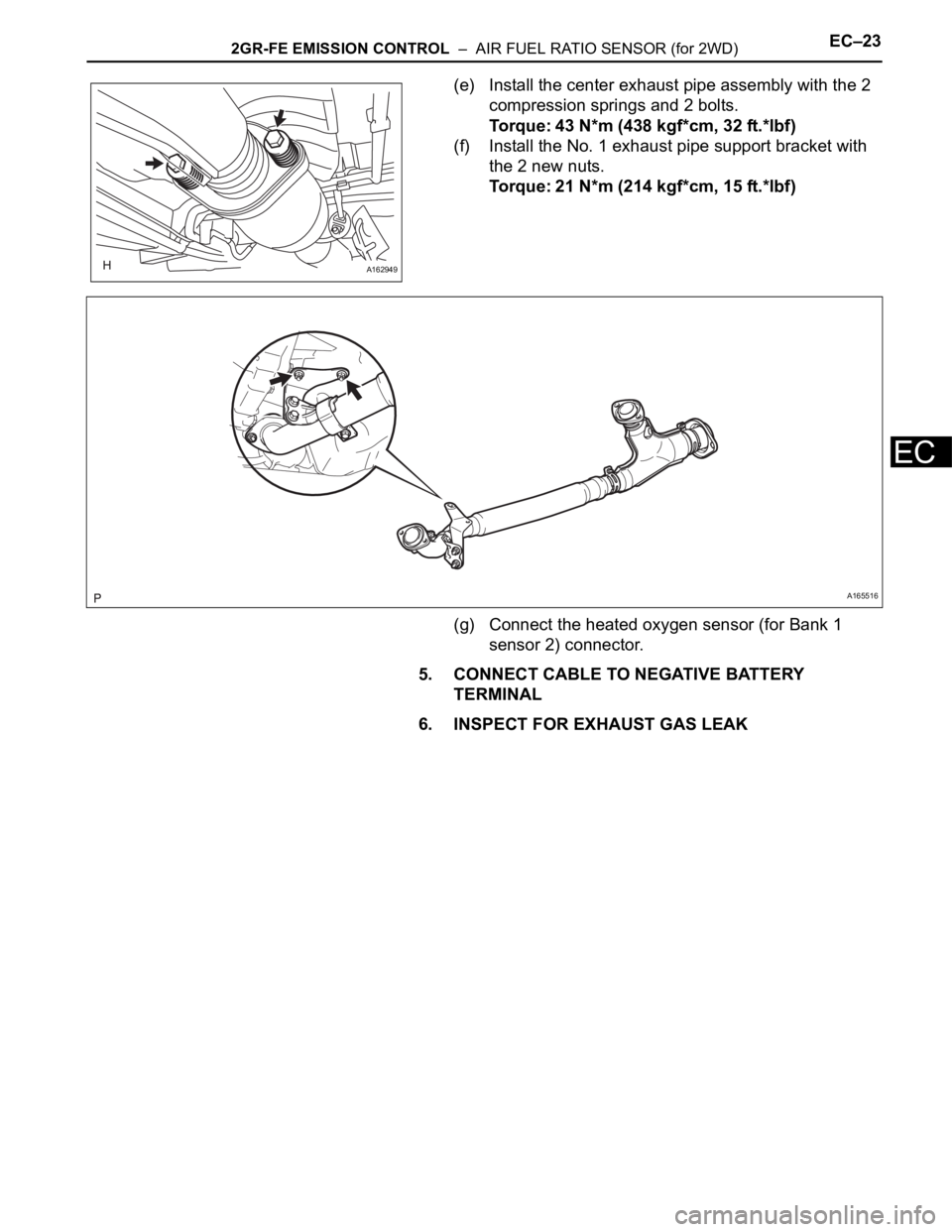

(e) Install the center exhaust pipe assembly with the 2

compression springs and 2 bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

(f) Install the No. 1 exhaust pipe support bracket with

the 2 new nuts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(g) Connect the heated oxygen sensor (for Bank 1

sensor 2) connector.

5. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

6. INSPECT FOR EXHAUST GAS LEAK

A162949

A165516

Page 1181 of 3000

EC–82GR-FE EMISSION CONTROL – CANISTER

EC

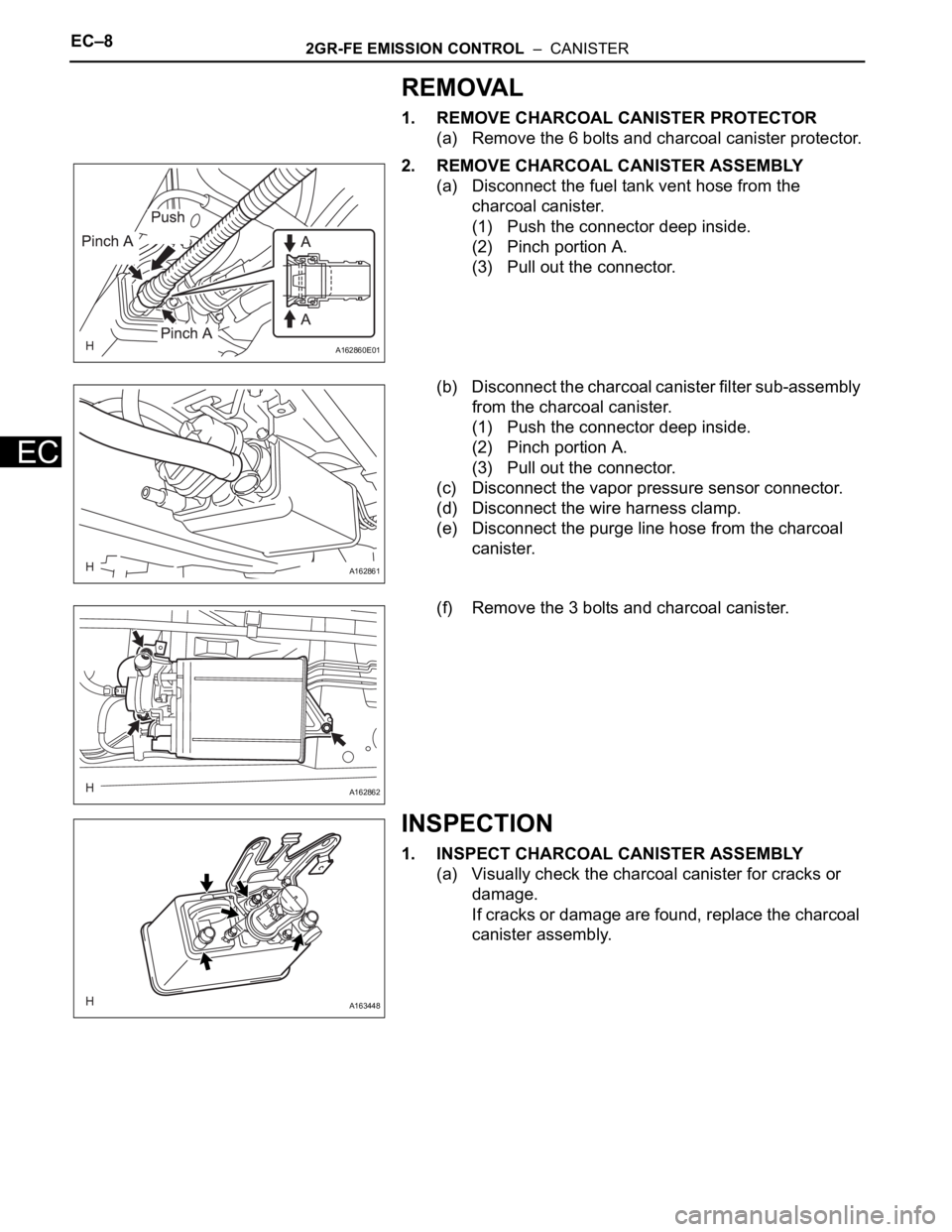

REMOVAL

1. REMOVE CHARCOAL CANISTER PROTECTOR

(a) Remove the 6 bolts and charcoal canister protector.

2. REMOVE CHARCOAL CANISTER ASSEMBLY

(a) Disconnect the fuel tank vent hose from the

charcoal canister.

(1) Push the connector deep inside.

(2) Pinch portion A.

(3) Pull out the connector.

(b) Disconnect the charcoal canister filter sub-assembly

from the charcoal canister.

(1) Push the connector deep inside.

(2) Pinch portion A.

(3) Pull out the connector.

(c) Disconnect the vapor pressure sensor connector.

(d) Disconnect the wire harness clamp.

(e) Disconnect the purge line hose from the charcoal

canister.

(f) Remove the 3 bolts and charcoal canister.

INSPECTION

1. INSPECT CHARCOAL CANISTER ASSEMBLY

(a) Visually check the charcoal canister for cracks or

damage.

If cracks or damage are found, replace the charcoal

canister assembly.

A162860E01

A162861

A162862

A163448

Page 1183 of 3000

EC–282GR-FE EMISSION CONTROL – AIR FUEL RATIO SENSOR (for 4WD)

EC

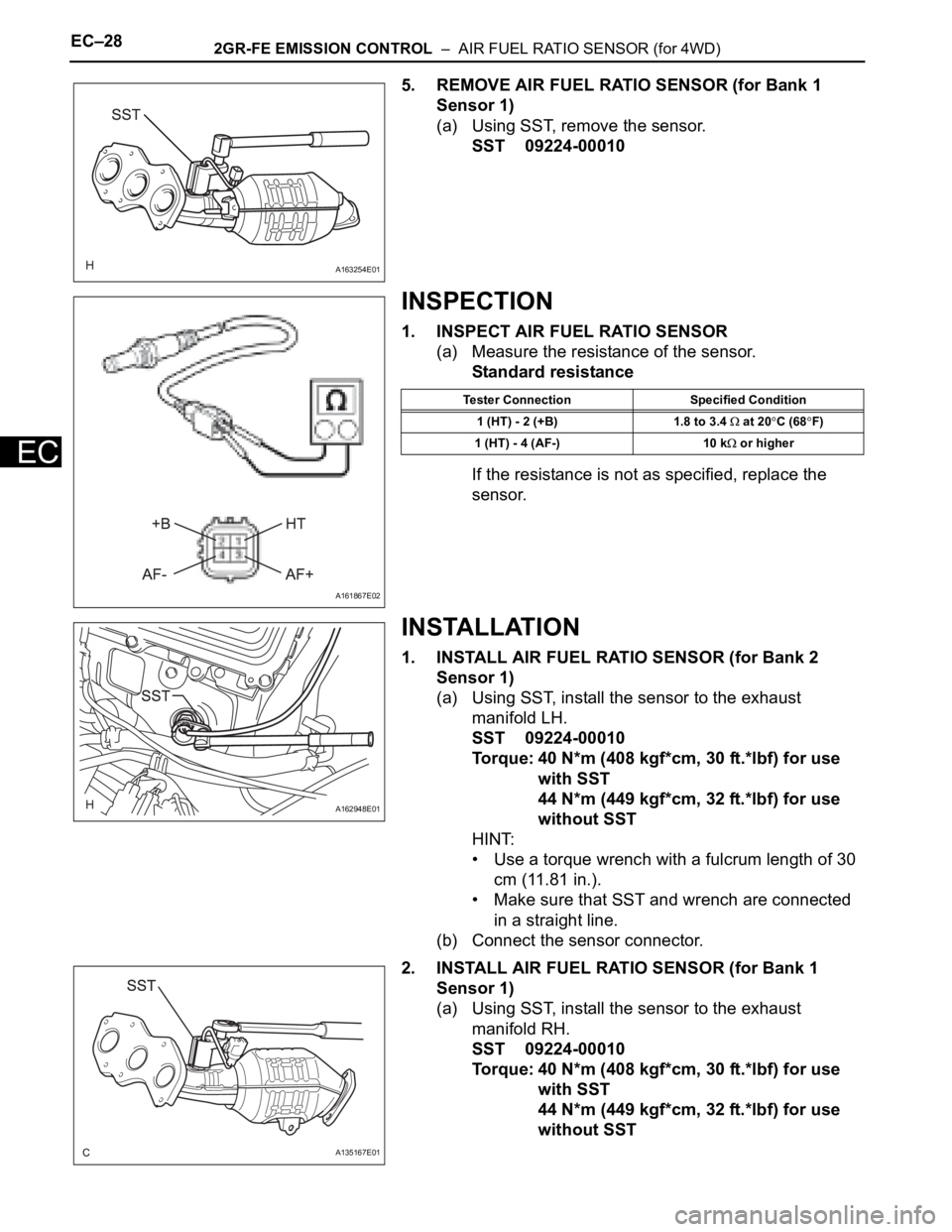

5. REMOVE AIR FUEL RATIO SENSOR (for Bank 1

Sensor 1)

(a) Using SST, remove the sensor.

SST 09224-00010

INSPECTION

1. INSPECT AIR FUEL RATIO SENSOR

(a) Measure the resistance of the sensor.

Standard resistance

If the resistance is not as specified, replace the

sensor.

INSTALLATION

1. INSTALL AIR FUEL RATIO SENSOR (for Bank 2

Sensor 1)

(a) Using SST, install the sensor to the exhaust

manifold LH.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use

with SST

44 N*m (449 kgf*cm, 32 ft.*lbf) for use

without SST

HINT:

• Use a torque wrench with a fulcrum length of 30

cm (11.81 in.).

• Make sure that SST and wrench are connected

in a straight line.

(b) Connect the sensor connector.

2. INSTALL AIR FUEL RATIO SENSOR (for Bank 1

Sensor 1)

(a) Using SST, install the sensor to the exhaust

manifold RH.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use

with SST

44 N*m (449 kgf*cm, 32 ft.*lbf) for use

without SST

A163254E01

A161867E02

Tester Connection Specified Condition

1 (HT) - 2 (+B) 1.8 to 3.4

at 20C (68F)

1 (HT) - 4 (AF-) 10 k

or higher

A162948E01

A135167E01

Page 1184 of 3000

2GR-FE EMISSION CONTROL – AIR FUEL RATIO SENSOR (for 4WD)EC–29

EC

HINT:

• Use a torque wrench with a fulcrum length of 30

cm (11.81 in.).

• Make sure that SST and wrench are connected

in a straight line.

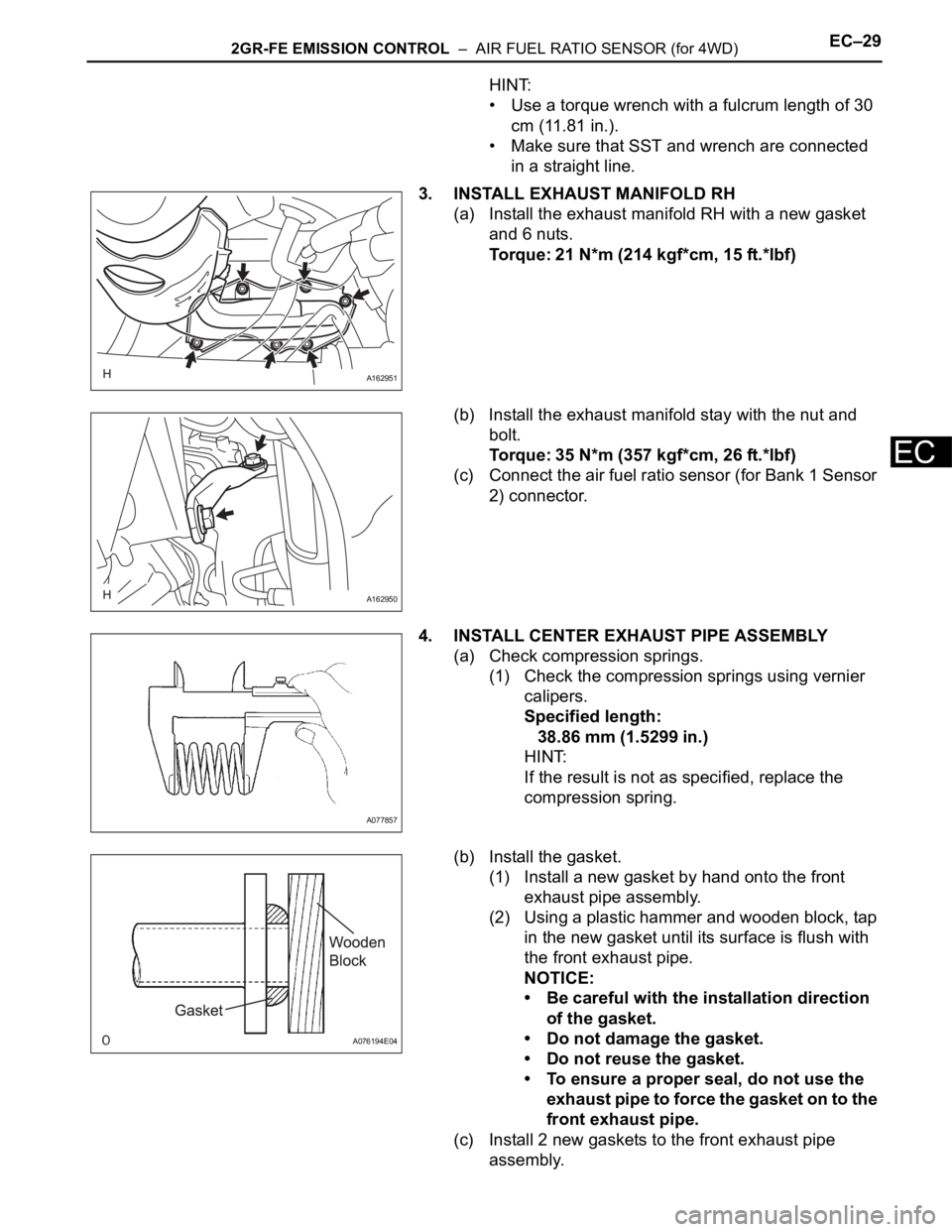

3. INSTALL EXHAUST MANIFOLD RH

(a) Install the exhaust manifold RH with a new gasket

and 6 nuts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(b) Install the exhaust manifold stay with the nut and

bolt.

Torque: 35 N*m (357 kgf*cm, 26 ft.*lbf)

(c) Connect the air fuel ratio sensor (for Bank 1 Sensor

2) connector.

4. INSTALL CENTER EXHAUST PIPE ASSEMBLY

(a) Check compression springs.

(1) Check the compression springs using vernier

calipers.

Specified length:

38.86 mm (1.5299 in.)

HINT:

If the result is not as specified, replace the

compression spring.

(b) Install the gasket.

(1) Install a new gasket by hand onto the front

exhaust pipe assembly.

(2) Using a plastic hammer and wooden block, tap

in the new gasket until its surface is flush with

the front exhaust pipe.

NOTICE:

• Be careful with the installation direction

of the gasket.

• Do not damage the gasket.

• Do not reuse the gasket.

• To ensure a proper seal, do not use the

exhaust pipe to force the gasket on to the

front exhaust pipe.

(c) Install 2 new gaskets to the front exhaust pipe

assembly.

A162951

A162950

A077857

A076194E04

Page 1185 of 3000

EC–302GR-FE EMISSION CONTROL – AIR FUEL RATIO SENSOR (for 4WD)

EC

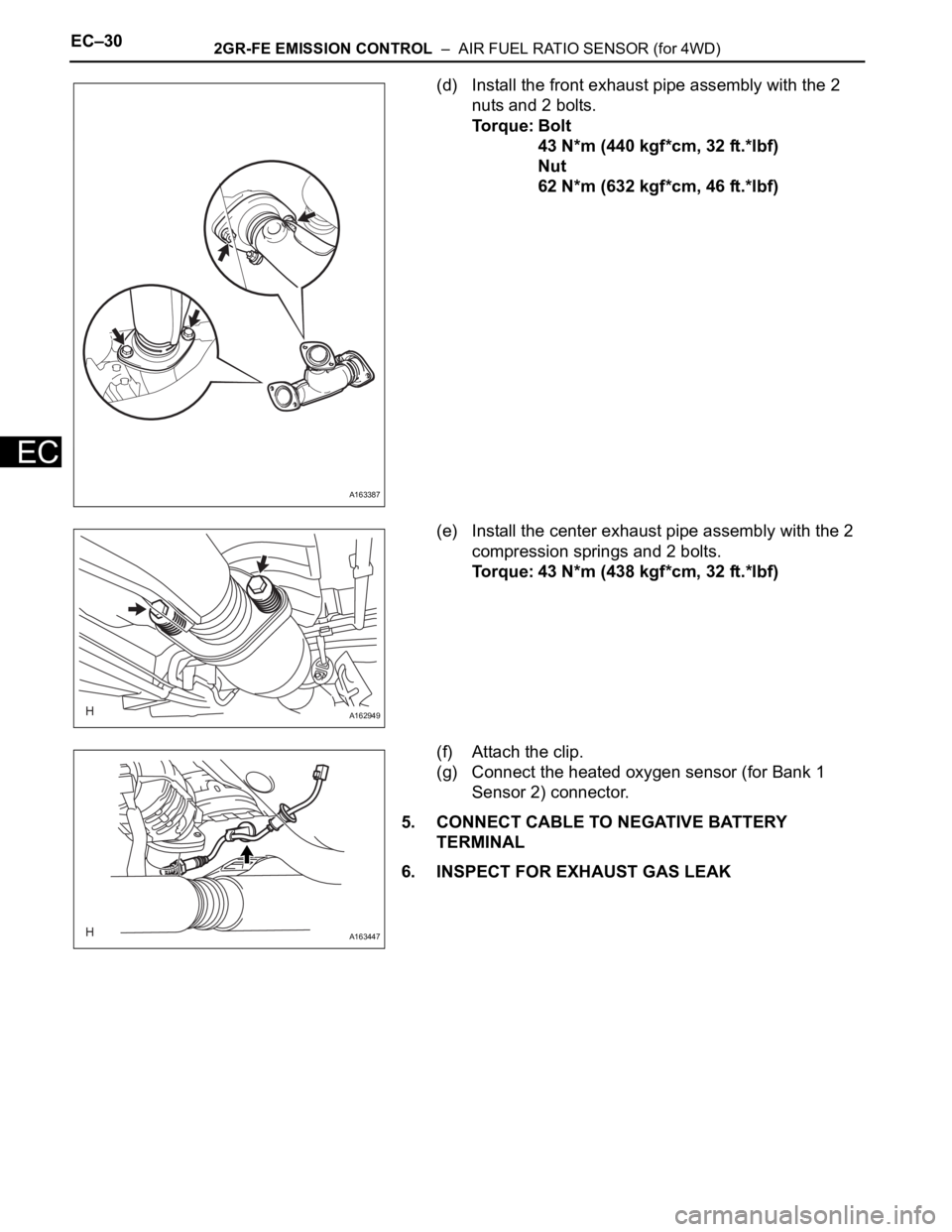

(d) Install the front exhaust pipe assembly with the 2

nuts and 2 bolts.

Torque: Bolt

43 N*m (440 kgf*cm, 32 ft.*lbf)

Nut

62 N*m (632 kgf*cm, 46 ft.*lbf)

(e) Install the center exhaust pipe assembly with the 2

compression springs and 2 bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

(f) Attach the clip.

(g) Connect the heated oxygen sensor (for Bank 1

Sensor 2) connector.

5. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

6. INSPECT FOR EXHAUST GAS LEAK

A163387

A162949

A163447

Page 1186 of 3000

2GR-FE EMISSION CONTROL – HEATED OXYGEN SENSOR (for 4WD)EC–39

EC

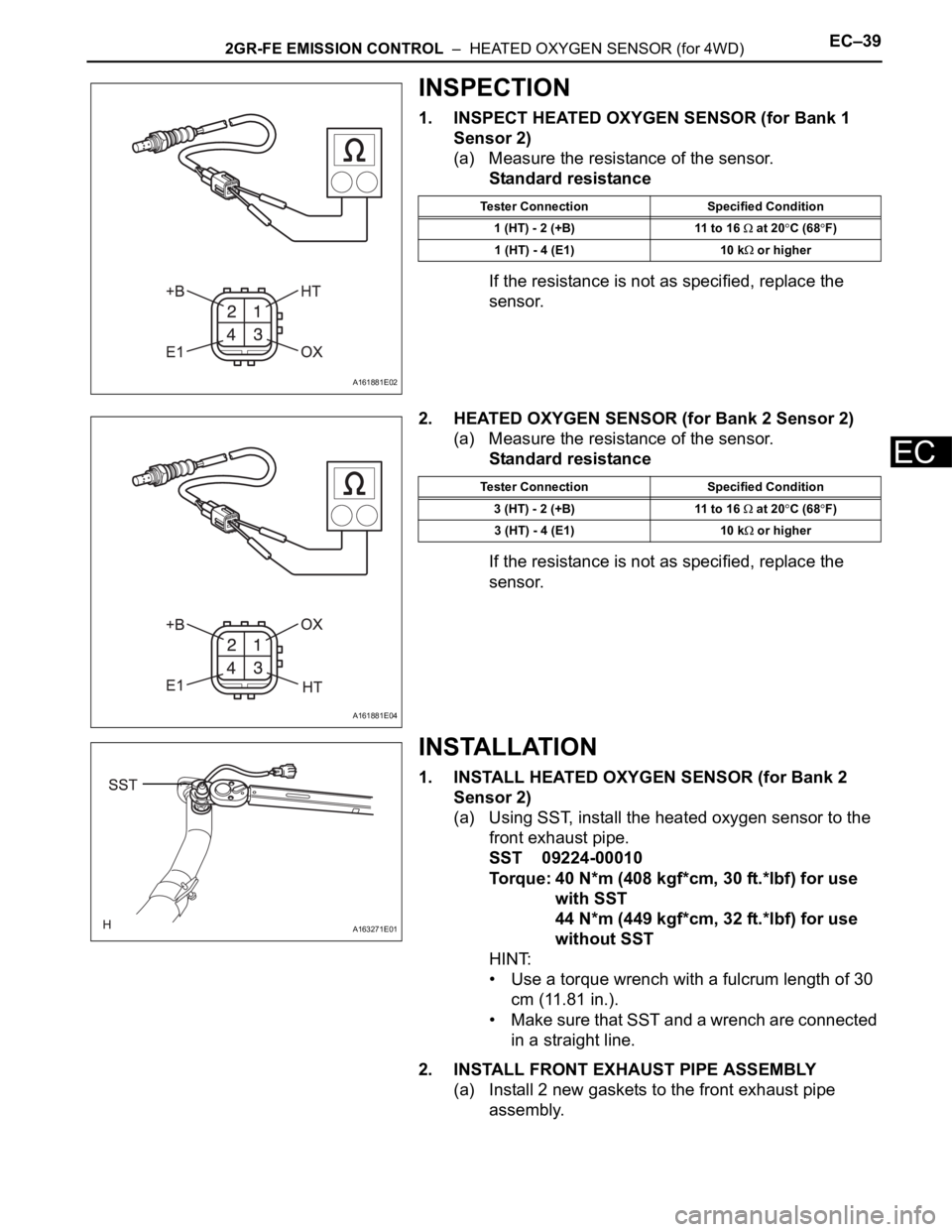

INSPECTION

1. INSPECT HEATED OXYGEN SENSOR (for Bank 1

Sensor 2)

(a) Measure the resistance of the sensor.

Standard resistance

If the resistance is not as specified, replace the

sensor.

2. HEATED OXYGEN SENSOR (for Bank 2 Sensor 2)

(a) Measure the resistance of the sensor.

Standard resistance

If the resistance is not as specified, replace the

sensor.

INSTALLATION

1. INSTALL HEATED OXYGEN SENSOR (for Bank 2

Sensor 2)

(a) Using SST, install the heated oxygen sensor to the

front exhaust pipe.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use

with SST

44 N*m (449 kgf*cm, 32 ft.*lbf) for use

without SST

HINT:

• Use a torque wrench with a fulcrum length of 30

cm (11.81 in.).

• Make sure that SST and a wrench are connected

in a straight line.

2. INSTALL FRONT EXHAUST PIPE ASSEMBLY

(a) Install 2 new gaskets to the front exhaust pipe

assembly.

A161881E02

Tester Connection Specified Condition

1 (HT) - 2 (+B) 11 to 16

at 20C (68F)

1 (HT) - 4 (E1) 10 k

or higher

A161881E04

Tester Connection Specified Condition

3 (HT) - 2 (+B) 11 to 16

at 20C (68F)

3 (HT) - 4 (E1) 10 k

or higher

A163271E01

Page 1187 of 3000

EC–402GR-FE EMISSION CONTROL – HEATED OXYGEN SENSOR (for 4WD)

EC

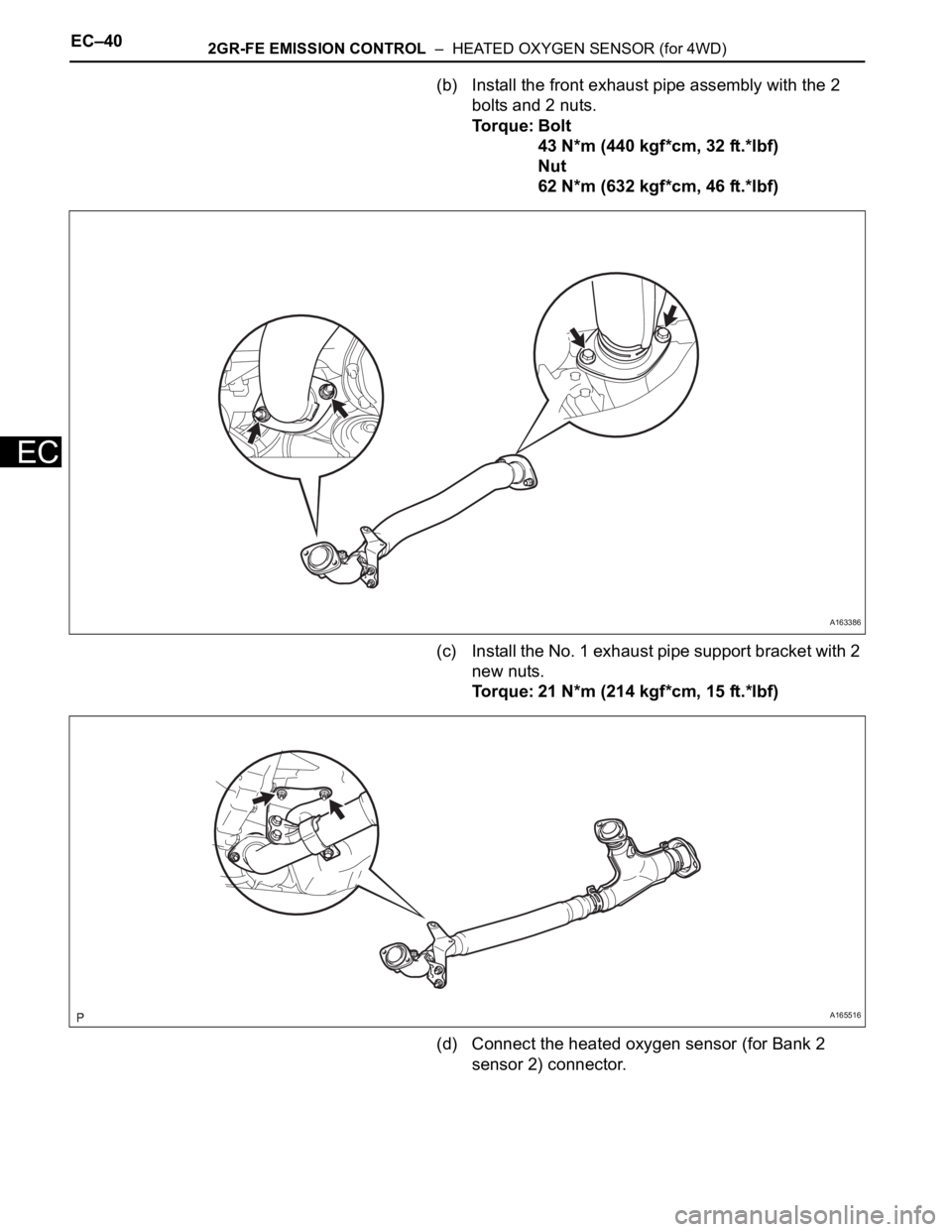

(b) Install the front exhaust pipe assembly with the 2

bolts and 2 nuts.

Torque: Bolt

43 N*m (440 kgf*cm, 32 ft.*lbf)

Nut

62 N*m (632 kgf*cm, 46 ft.*lbf)

(c) Install the No. 1 exhaust pipe support bracket with 2

new nuts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(d) Connect the heated oxygen sensor (for Bank 2

sensor 2) connector.

A163386

A165516