sensor TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1232 of 3000

EX–122GR-FE EXHAUST – EXHAUST PIPE (for 4WD)

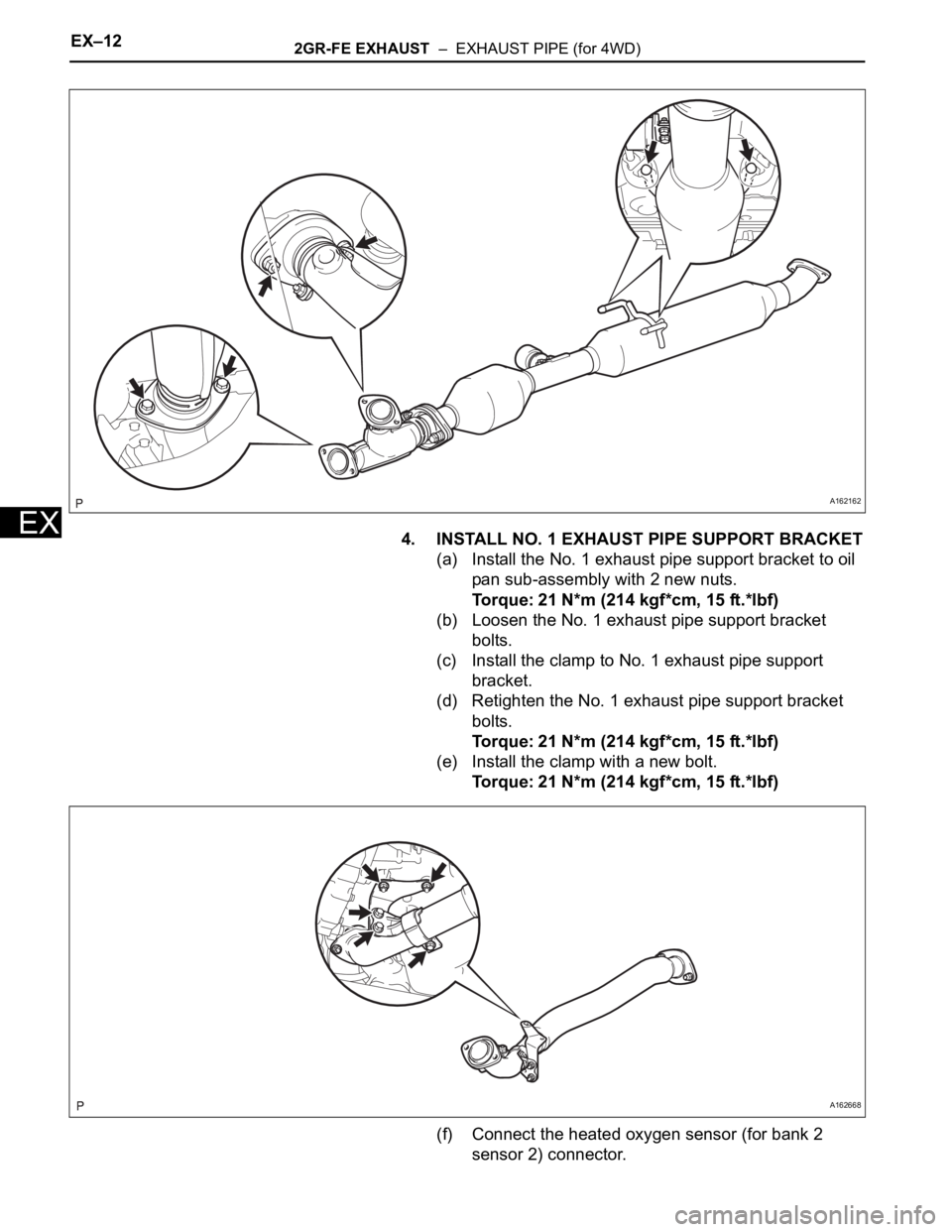

EX4. INSTALL NO. 1 EXHAUST PIPE SUPPORT BRACKET

(a) Install the No. 1 exhaust pipe support bracket to oil

pan sub-assembly with 2 new nuts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(b) Loosen the No. 1 exhaust pipe support bracket

bolts.

(c) Install the clamp to No. 1 exhaust pipe support

bracket.

(d) Retighten the No. 1 exhaust pipe support bracket

bolts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(e) Install the clamp with a new bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(f) Connect the heated oxygen sensor (for bank 2

sensor 2) connector.

A162162

A162668

Page 1233 of 3000

2GR-FE EXHAUST – EXHAUST PIPE (for 4WD)EX–13

EX

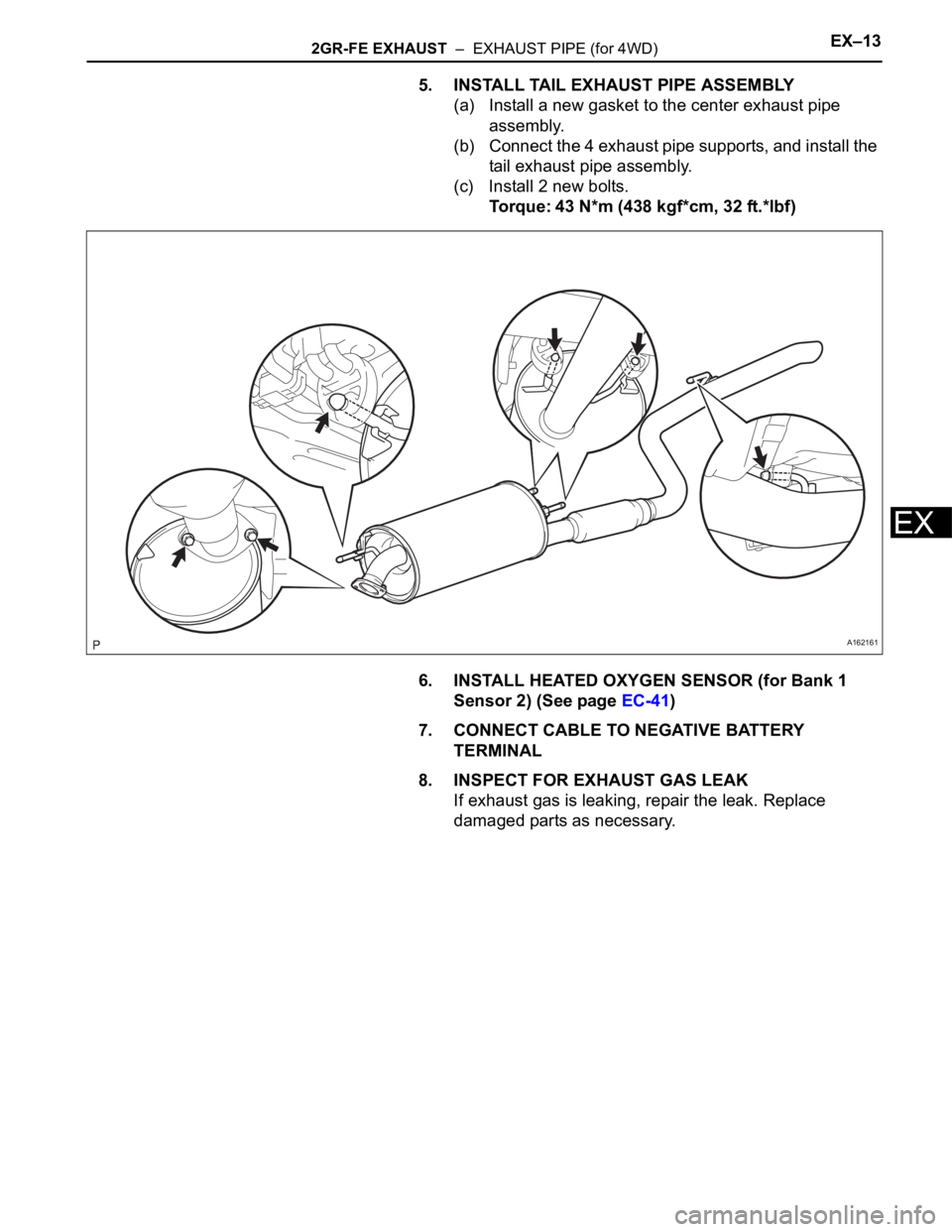

5. INSTALL TAIL EXHAUST PIPE ASSEMBLY

(a) Install a new gasket to the center exhaust pipe

assembly.

(b) Connect the 4 exhaust pipe supports, and install the

tail exhaust pipe assembly.

(c) Install 2 new bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

6. INSTALL HEATED OXYGEN SENSOR (for Bank 1

Sensor 2) (See page EC-41)

7. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

8. INSPECT FOR EXHAUST GAS LEAK

If exhaust gas is leaking, repair the leak. Replace

damaged parts as necessary.

A162161

Page 1242 of 3000

2GR-FE COOLING – COOLING FAN SYSTEMCO–5

CO

ON-VEHICLE INSPECTION

1. INSPECT COOLING FAN SYSTEM

(a) Put the vehicle in the following conditions:

(1) The engine switch is off.

(2) The coolant temperature is less than 95

C

(203

F).

(3) The battery voltage is between 9 and 14 V.

(4) The A/C switch is OFF.

(b) Clamp the 400 A probe of an ammeter over the M+

wire of each cooling fan motor.

(c) Turn the ignition switch to the ON position and wait

for approximately 10 seconds. Check that the fan

stops.

(d) Start the engine. Check that the fan stops with the

engine idling.

HINT:

• Make sure that the radiator engine coolant

temperature is less than 95

C (203F).

• Turn the A/C switch OFF.

(e) Check that the fan operates when the A/C switch is

turned ON (MAX COOL and the magnetic clutch is

operating).

Standard current

HINT:

The coolant temperature is less than 95

C (203F).

(f) Check that the fan operates when the engine

coolant temperature sensor connector is

disconnected.

Standard current

Item Specified Condition

No. 1 cooling fan motor 5 to 14 A

No. 2 cooling fan motor 4 to 12 A

Item Specified Condition

No. 1 cooling fan motor 5 to 19 A

No. 2 cooling fan motor 4 to 16 A

Page 1245 of 3000

CO–302GR-FE COOLING – RADIATOR

CO

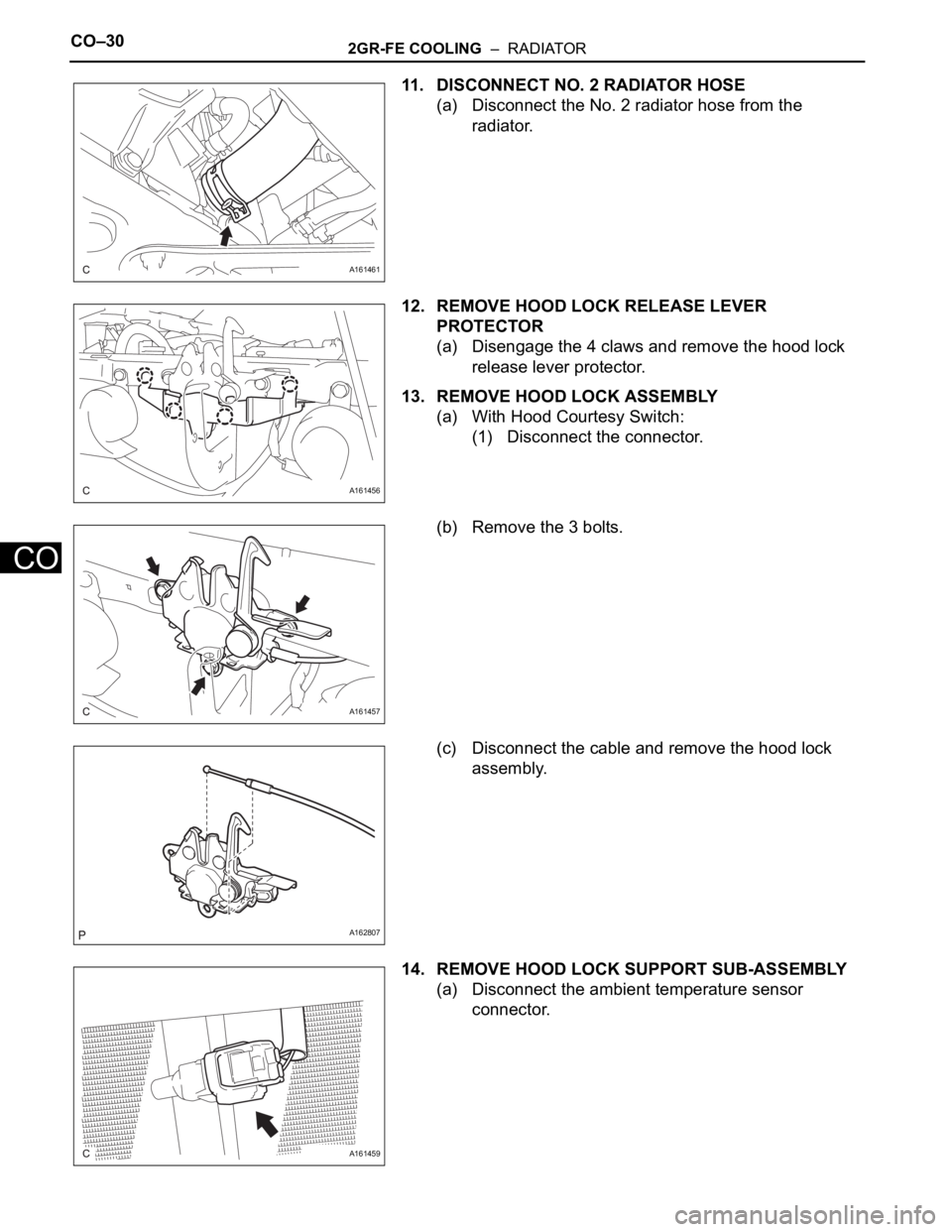

11. DISCONNECT NO. 2 RADIATOR HOSE

(a) Disconnect the No. 2 radiator hose from the

radiator.

12. REMOVE HOOD LOCK RELEASE LEVER

PROTECTOR

(a) Disengage the 4 claws and remove the hood lock

release lever protector.

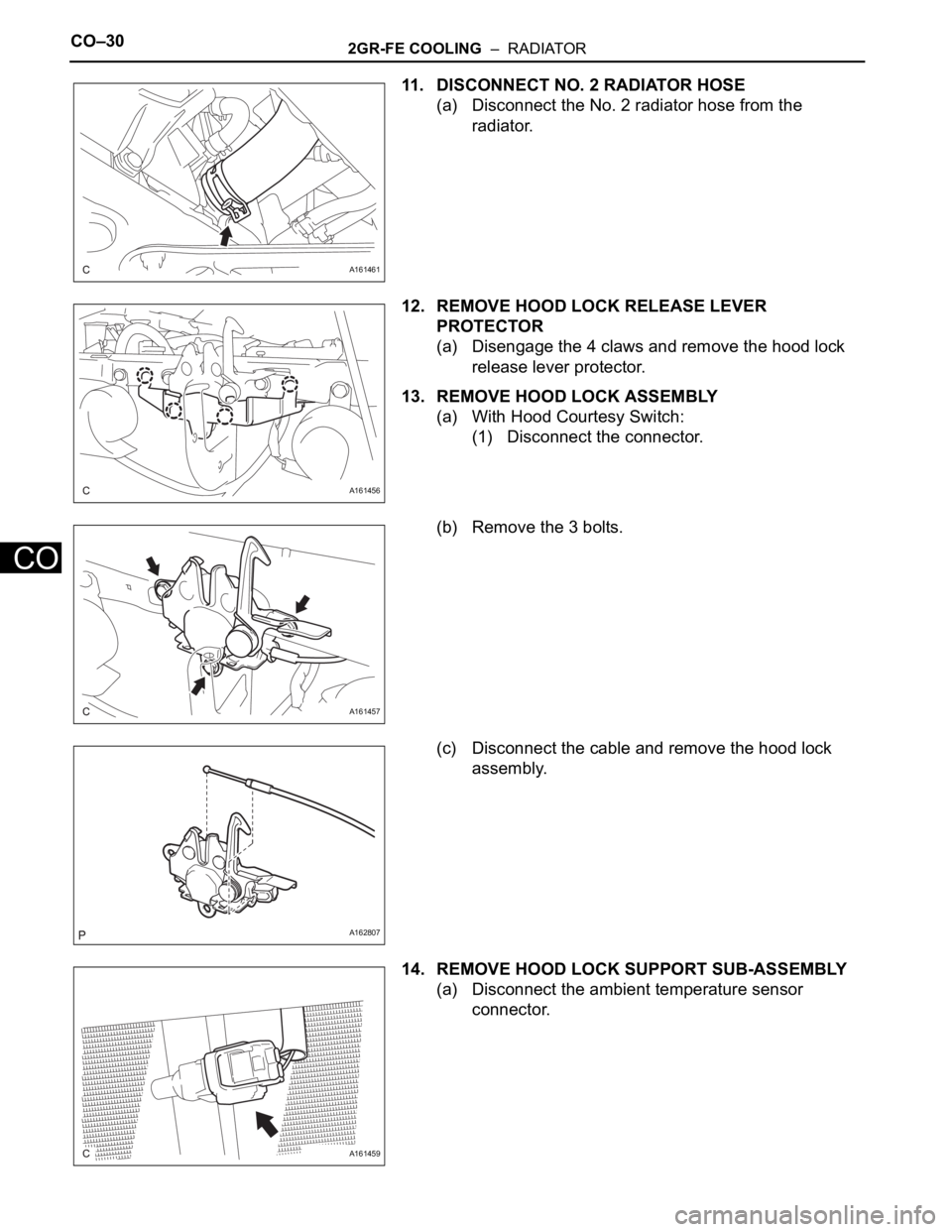

13. REMOVE HOOD LOCK ASSEMBLY

(a) With Hood Courtesy Switch:

(1) Disconnect the connector.

(b) Remove the 3 bolts.

(c) Disconnect the cable and remove the hood lock

assembly.

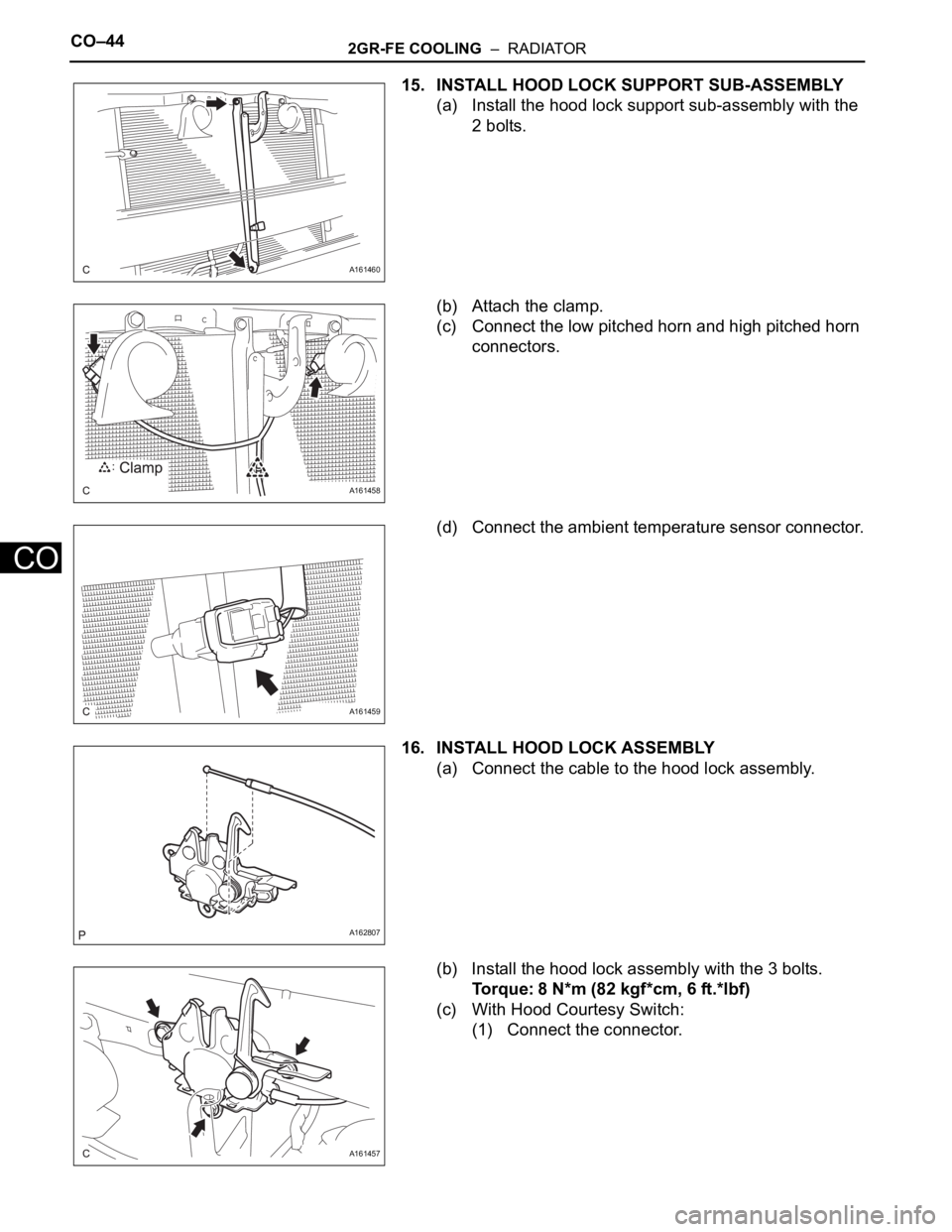

14. REMOVE HOOD LOCK SUPPORT SUB-ASSEMBLY

(a) Disconnect the ambient temperature sensor

connector.

A161461

A161456

A161457

A162807

A161459

Page 1262 of 3000

CO–442GR-FE COOLING – RADIATOR

CO

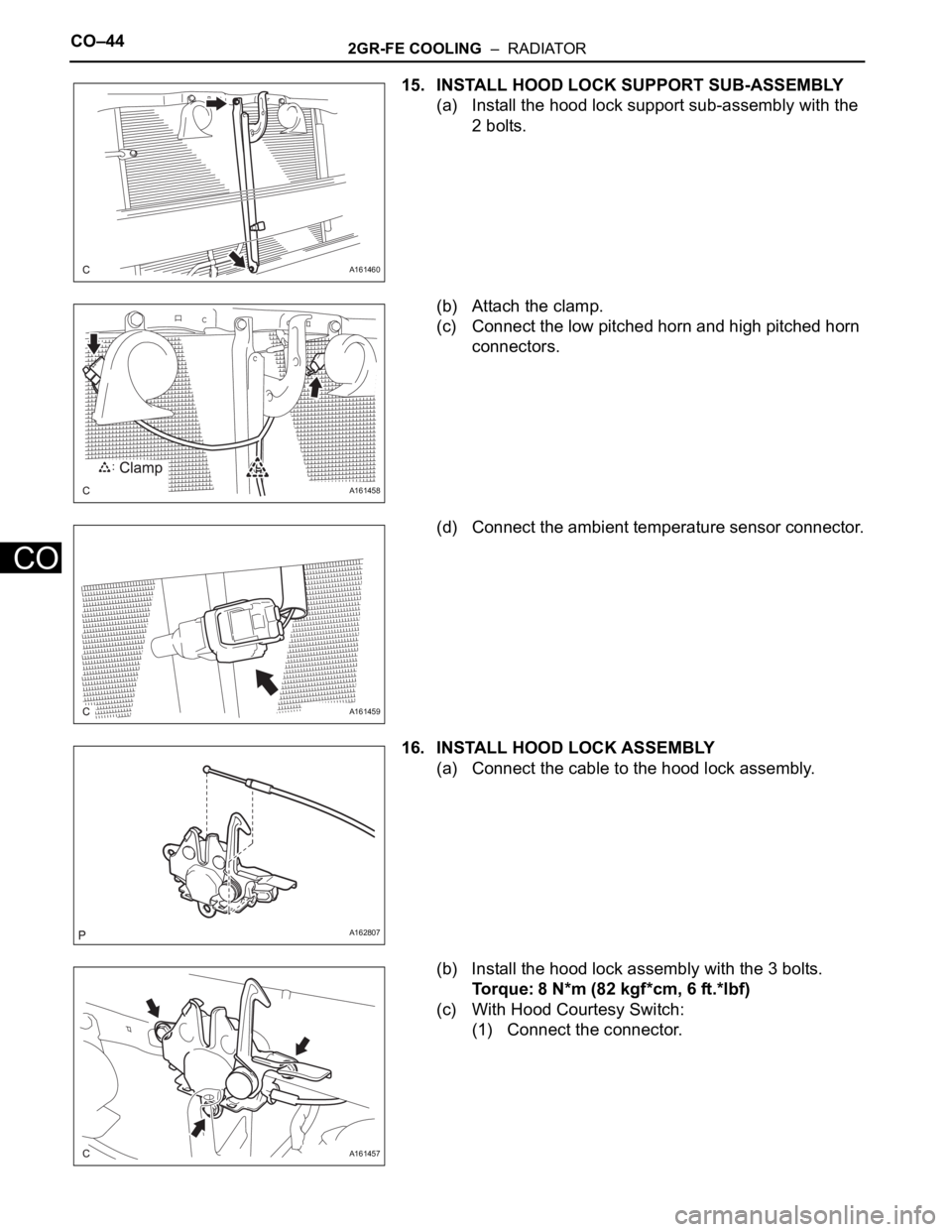

15. INSTALL HOOD LOCK SUPPORT SUB-ASSEMBLY

(a) Install the hood lock support sub-assembly with the

2 bolts.

(b) Attach the clamp.

(c) Connect the low pitched horn and high pitched horn

connectors.

(d) Connect the ambient temperature sensor connector.

16. INSTALL HOOD LOCK ASSEMBLY

(a) Connect the cable to the hood lock assembly.

(b) Install the hood lock assembly with the 3 bolts.

Torque: 8 N*m (82 kgf*cm, 6 ft.*lbf)

(c) With Hood Courtesy Switch:

(1) Connect the connector.

A161460

A161458

A161459

A162807

A161457

Page 1275 of 3000

CO–302GR-FE COOLING – RADIATOR

CO

11. DISCONNECT NO. 2 RADIATOR HOSE

(a) Disconnect the No. 2 radiator hose from the

radiator.

12. REMOVE HOOD LOCK RELEASE LEVER

PROTECTOR

(a) Disengage the 4 claws and remove the hood lock

release lever protector.

13. REMOVE HOOD LOCK ASSEMBLY

(a) With Hood Courtesy Switch:

(1) Disconnect the connector.

(b) Remove the 3 bolts.

(c) Disconnect the cable and remove the hood lock

assembly.

14. REMOVE HOOD LOCK SUPPORT SUB-ASSEMBLY

(a) Disconnect the ambient temperature sensor

connector.

A161461

A161456

A161457

A162807

A161459

Page 1289 of 3000

CO–442GR-FE COOLING – RADIATOR

CO

15. INSTALL HOOD LOCK SUPPORT SUB-ASSEMBLY

(a) Install the hood lock support sub-assembly with the

2 bolts.

(b) Attach the clamp.

(c) Connect the low pitched horn and high pitched horn

connectors.

(d) Connect the ambient temperature sensor connector.

16. INSTALL HOOD LOCK ASSEMBLY

(a) Connect the cable to the hood lock assembly.

(b) Install the hood lock assembly with the 3 bolts.

Torque: 8 N*m (82 kgf*cm, 6 ft.*lbf)

(c) With Hood Courtesy Switch:

(1) Connect the connector.

A161460

A161458

A161459

A162807

A161457

Page 1316 of 3000

2GR-FE IGNITION – IGNITION COIL AND SPARK PLUGIG–7

IG

(3) Check the spark plug (See page EM-1).

Result

(4) Check the power supply to the ignition coil.

1. Turn the ignition switch to the ON position.

2. Check that there is battery voltage at the

ignition coil positive (+) terminal.

Result

(5) Measure the resistance of the crankshaft

position sensor (See page ES-514).

Result

(6) Check the IGT signal from the ECM (See page

ES-233)

Result

(e) Using a 16 mm (0.63 in.) plug wrench, install the

spark plugs.

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

(f) Connect the 6 fuel injector connectors.

(g) Install the ignition coil assembly (See page IG-10).

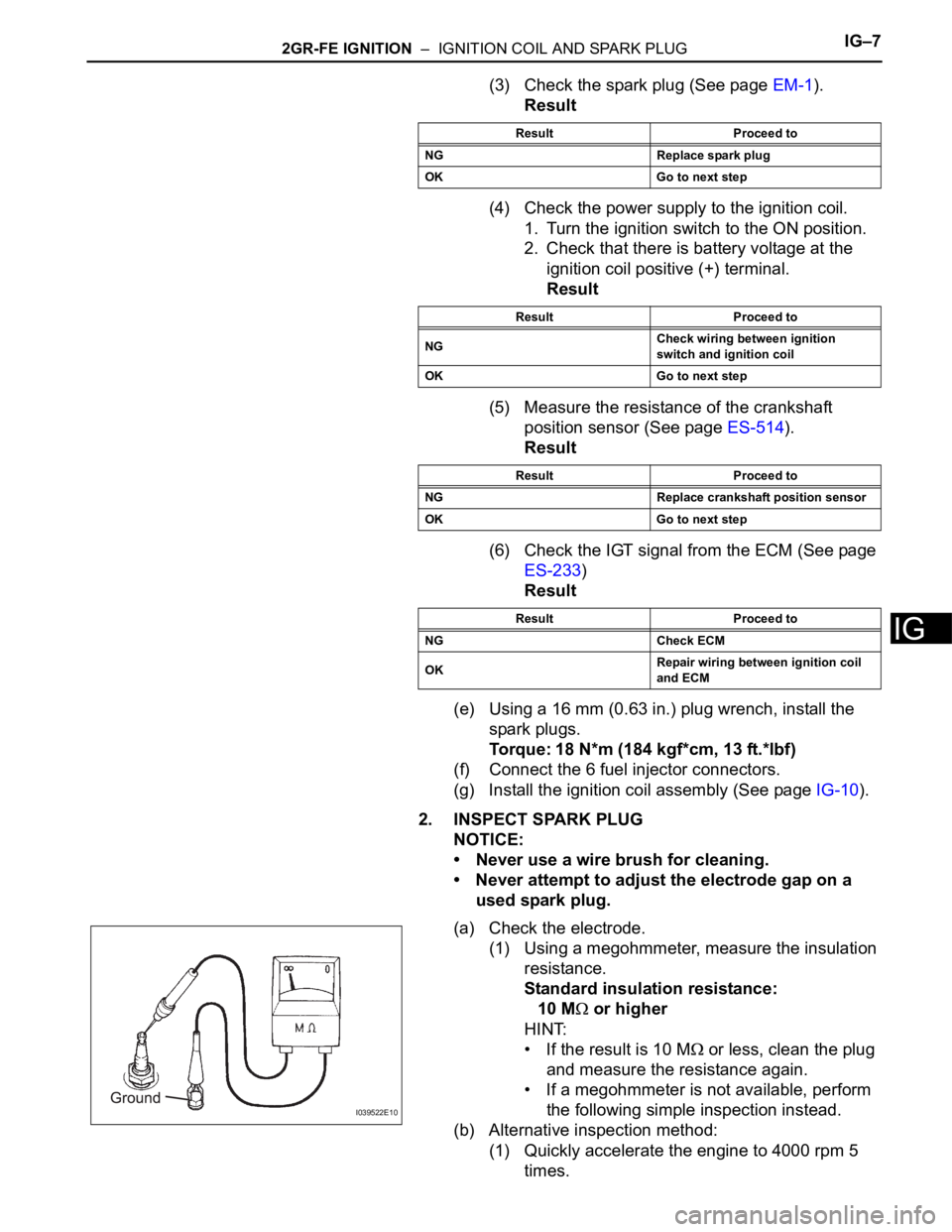

2. INSPECT SPARK PLUG

NOTICE:

• Never use a wire brush for cleaning.

• Never attempt to adjust the electrode gap on a

used spark plug.

(a) Check the electrode.

(1) Using a megohmmeter, measure the insulation

resistance.

Standard insulation resistance:

10 M

or higher

HINT:

• If the result is 10 M

or less, clean the plug

and measure the resistance again.

• If a megohmmeter is not available, perform

the following simple inspection instead.

(b) Alternative inspection method:

(1) Quickly accelerate the engine to 4000 rpm 5

times.

Result Proceed to

NG Replace spark plug

OK Go to next step

Result Proceed to

NGCheck wiring between ignition

switch and ignition coil

OK Go to next step

Result Proceed to

NG Replace crankshaft position sensor

OK Go to next step

Result Proceed to

NG Check ECM

OKRepair wiring between ignition coil

and ECM

I039522E10

Page 1398 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–21

AX

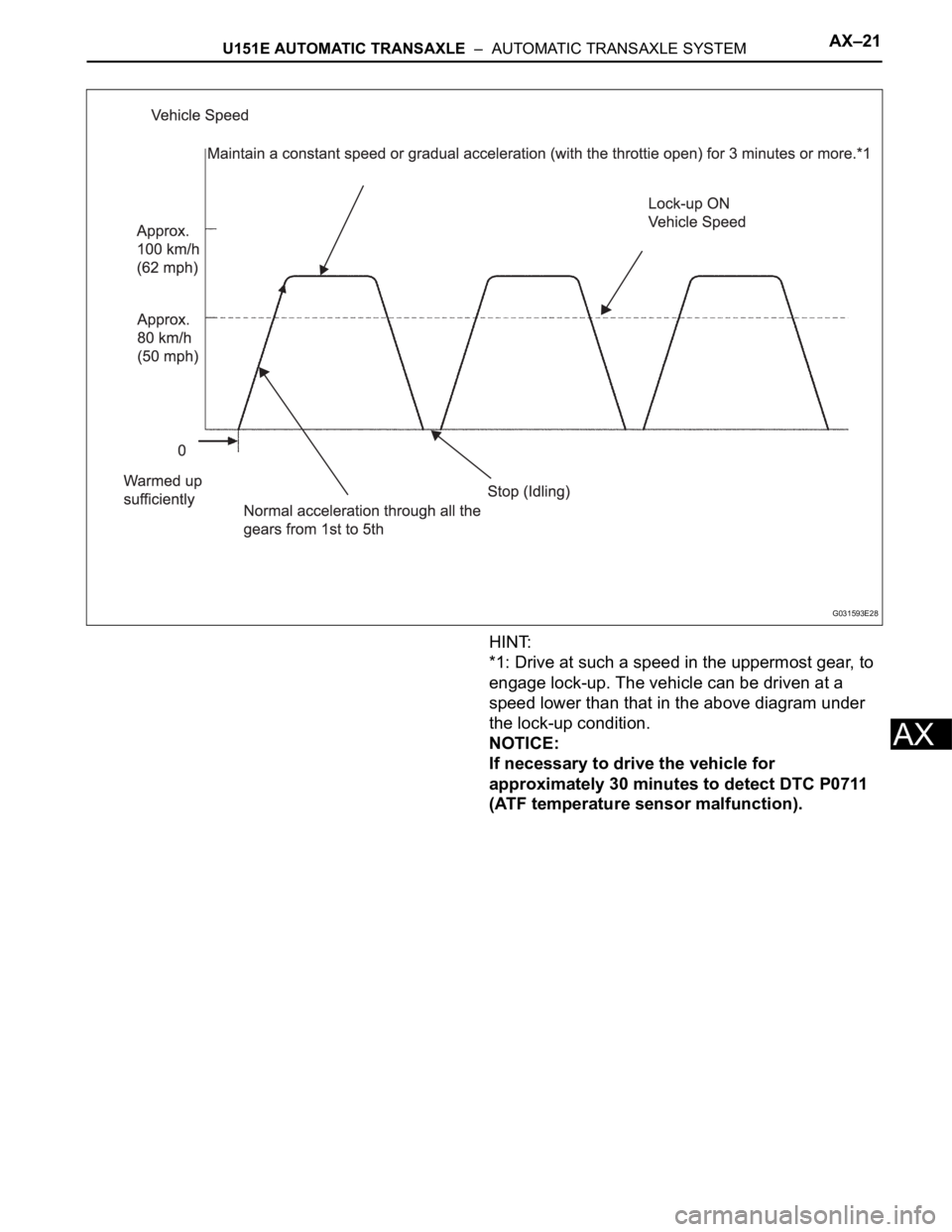

HINT:

*1: Drive at such a speed in the uppermost gear, to

engage lock-up. The vehicle can be driven at a

speed lower than that in the above diagram under

the lock-up condition.

NOTICE:

If necessary to drive the vehicle for

approximately 30 minutes to detect DTC P0711

(ATF temperature sensor malfunction).

G031593E28

Page 1399 of 3000

AX–22U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

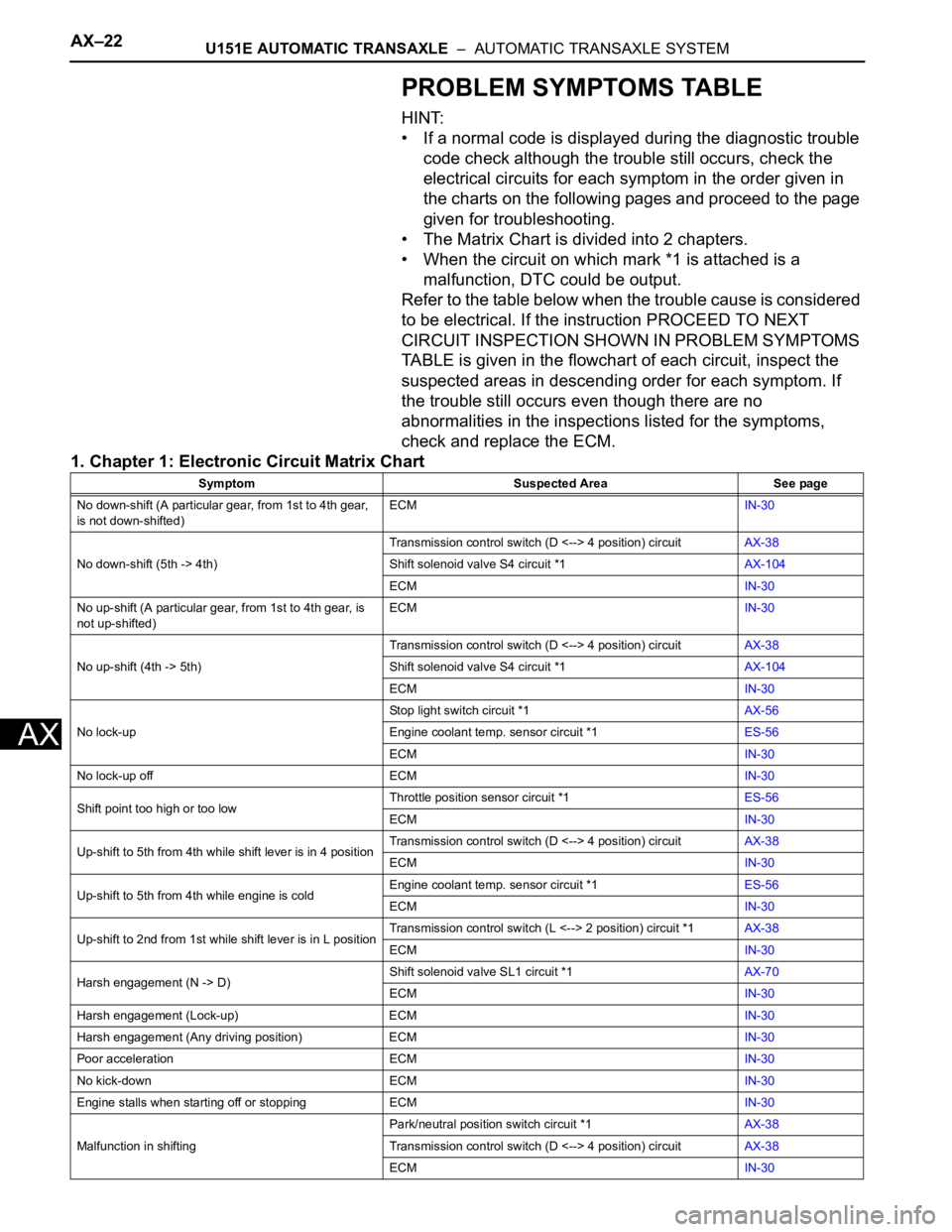

PROBLEM SYMPTOMS TABLE

HINT:

• If a normal code is displayed during the diagnostic trouble

code check although the trouble still occurs, check the

electrical circuits for each symptom in the order given in

the charts on the following pages and proceed to the page

given for troubleshooting.

• The Matrix Chart is divided into 2 chapters.

• When the circuit on which mark *1 is attached is a

malfunction, DTC could be output.

Refer to the table below when the trouble cause is considered

to be electrical. If the instruction PROCEED TO NEXT

CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS

TABLE is given in the flowchart of each circuit, inspect the

suspected areas in descending order for each symptom. If

the trouble still occurs even though there are no

abnormalities in the inspections listed for the symptoms,

check and replace the ECM.

1. Chapter 1: Electronic Circuit Matrix Chart

Symptom Suspected Area See page

No down-shift (A particular gear, from 1st to 4th gear,

is not down-shifted)ECMIN-30

No down-shift (5th -> 4th)Transmission control switch (D <--> 4 position) circuitAX-38

Shift solenoid valve S4 circuit *1AX-104

ECMIN-30

No up-shift (A particular gear, from 1st to 4th gear, is

not up-shifted)ECMIN-30

No up-shift (4th -> 5th)Transmission control switch (D <--> 4 position) circuitAX-38

Shift solenoid valve S4 circuit *1AX-104

ECMIN-30

No lock-upStop light switch circuit *1AX-56

Engine coolant temp. sensor circuit *1ES-56

ECMIN-30

No lock-up off ECMIN-30

Shift point too high or too lowThrottle position sensor circuit *1ES-56

ECMIN-30

Up-shift to 5th from 4th while shift lever is in 4 positionTransmission control switch (D <--> 4 position) circuitAX-38

ECMIN-30

Up-shift to 5th from 4th while engine is coldEngine coolant temp. sensor circuit *1ES-56

ECMIN-30

Up-shift to 2nd from 1st while shift lever is in L positionTransmission control switch (L <--> 2 position) circuit *1AX-38

ECMIN-30

Harsh engagement (N -> D)Shift solenoid valve SL1 circuit *1AX-70

ECMIN-30

Harsh engagement (Lock-up) ECMIN-30

Harsh engagement (Any driving position) ECMIN-30

Poor acceleration ECMIN-30

No kick-down ECMIN-30

Engine stalls when starting off or stopping ECMIN-30

Malfunction in shiftingPark/neutral position switch circuit *1AX-38

Transmission control switch (D <--> 4 position) circuitAX-38

ECMIN-30