sensor TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 870 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–53

EM

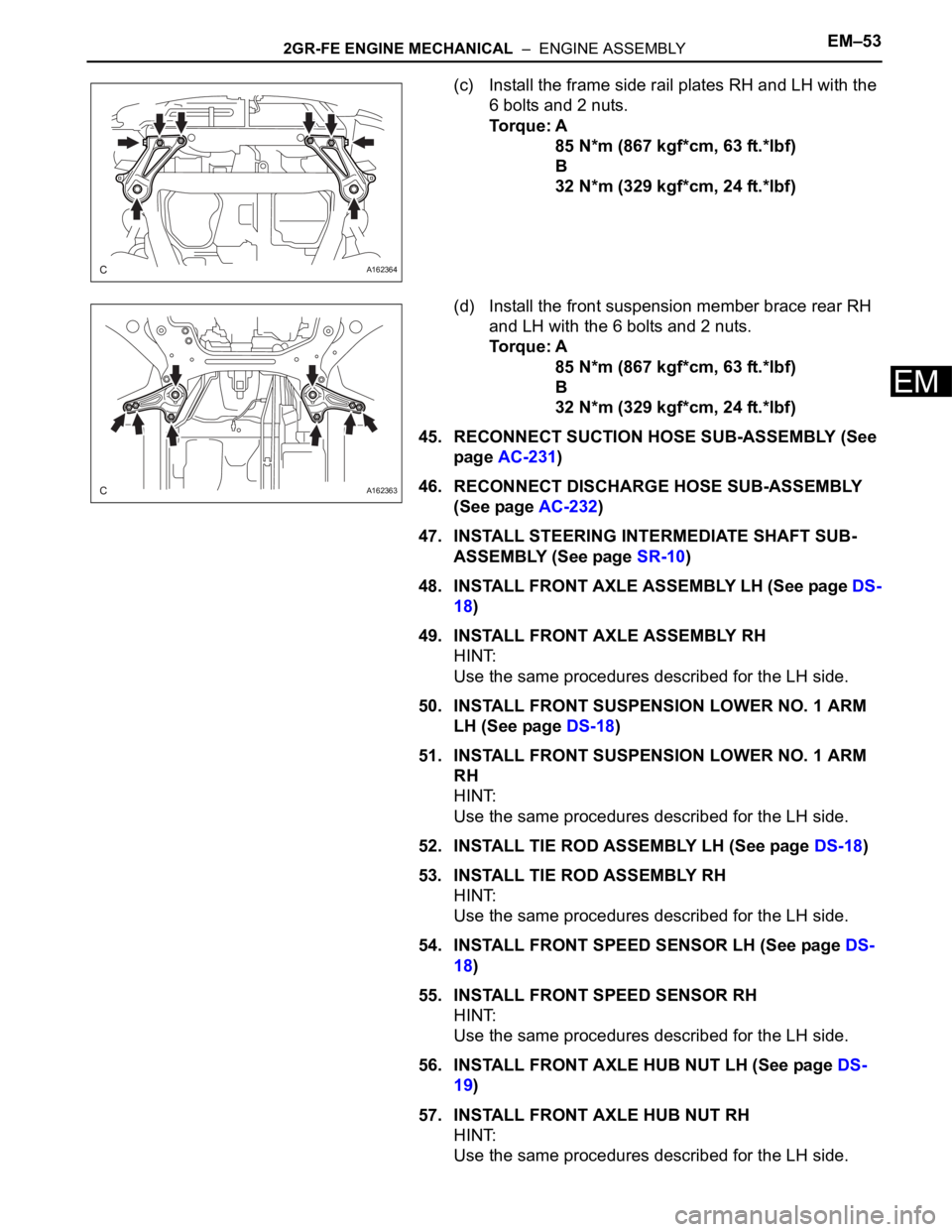

(c) Install the frame side rail plates RH and LH with the

6 bolts and 2 nuts.

Torque: A

85 N*m (867 kgf*cm, 63 ft.*lbf)

B

32 N*m (329 kgf*cm, 24 ft.*lbf)

(d) Install the front suspension member brace rear RH

and LH with the 6 bolts and 2 nuts.

Torque: A

85 N*m (867 kgf*cm, 63 ft.*lbf)

B

32 N*m (329 kgf*cm, 24 ft.*lbf)

45. RECONNECT SUCTION HOSE SUB-ASSEMBLY (See

page AC-231)

46. RECONNECT DISCHARGE HOSE SUB-ASSEMBLY

(See page AC-232)

47. INSTALL STEERING INTERMEDIATE SHAFT SUB-

ASSEMBLY (See page SR-10)

48. INSTALL FRONT AXLE ASSEMBLY LH (See page DS-

18)

49. INSTALL FRONT AXLE ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

50. INSTALL FRONT SUSPENSION LOWER NO. 1 ARM

LH (See page DS-18)

51. INSTALL FRONT SUSPENSION LOWER NO. 1 ARM

RH

HINT:

Use the same procedures described for the LH side.

52. INSTALL TIE ROD ASSEMBLY LH (See page DS-18)

53. INSTALL TIE ROD ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

54. INSTALL FRONT SPEED SENSOR LH (See page DS-

18)

55. INSTALL FRONT SPEED SENSOR RH

HINT:

Use the same procedures described for the LH side.

56. INSTALL FRONT AXLE HUB NUT LH (See page DS-

19)

57. INSTALL FRONT AXLE HUB NUT RH

HINT:

Use the same procedures described for the LH side.

A162364

A162363

Page 880 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–63

EM

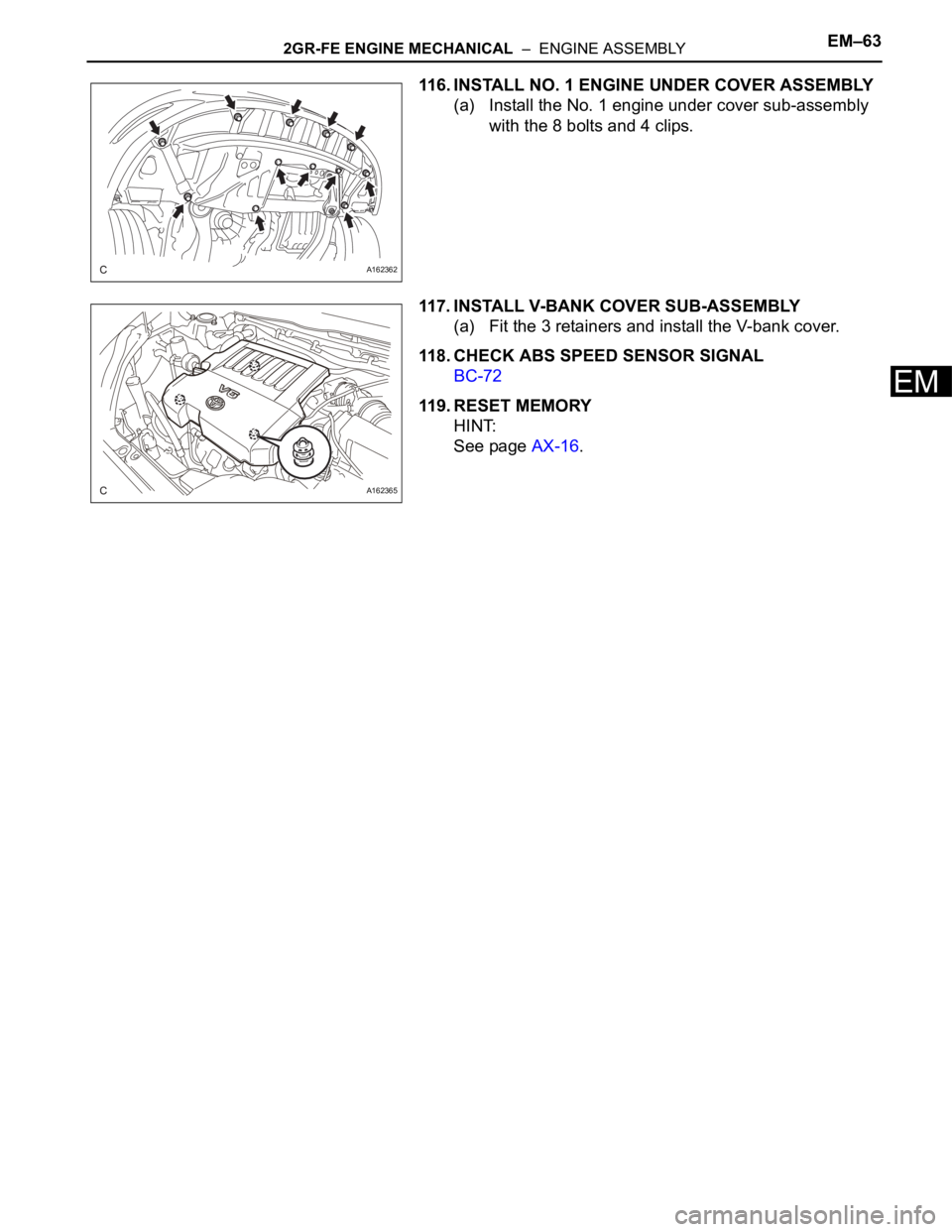

116. INSTALL NO. 1 ENGINE UNDER COVER ASSEMBLY

(a) Install the No. 1 engine under cover sub-assembly

with the 8 bolts and 4 clips.

117. INSTALL V-BANK COVER SUB-ASSEMBLY

(a) Fit the 3 retainers and install the V-bank cover.

118. CHECK ABS SPEED SENSOR SIGNAL

BC-72

119. RESET MEMORY

HINT:

See page AX-16.

A162362

A162365

Page 881 of 3000

EM–762GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

DISASSEMBLY

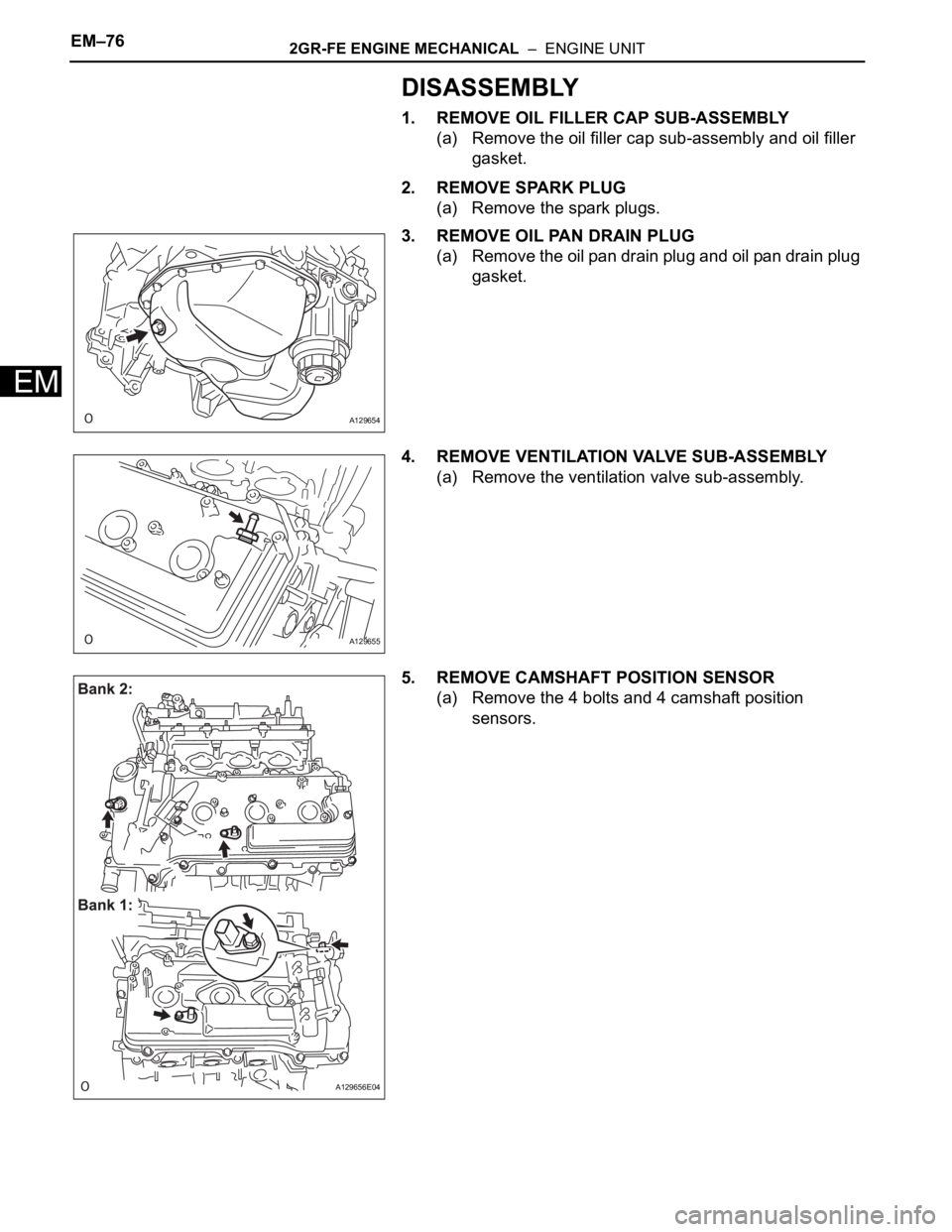

1. REMOVE OIL FILLER CAP SUB-ASSEMBLY

(a) Remove the oil filler cap sub-assembly and oil filler

gasket.

2. REMOVE SPARK PLUG

(a) Remove the spark plugs.

3. REMOVE OIL PAN DRAIN PLUG

(a) Remove the oil pan drain plug and oil pan drain plug

gasket.

4. REMOVE VENTILATION VALVE SUB-ASSEMBLY

(a) Remove the ventilation valve sub-assembly.

5. REMOVE CAMSHAFT POSITION SENSOR

(a) Remove the 4 bolts and 4 camshaft position

sensors.

A129654

A129655

A129656E04

Page 882 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–77

EM

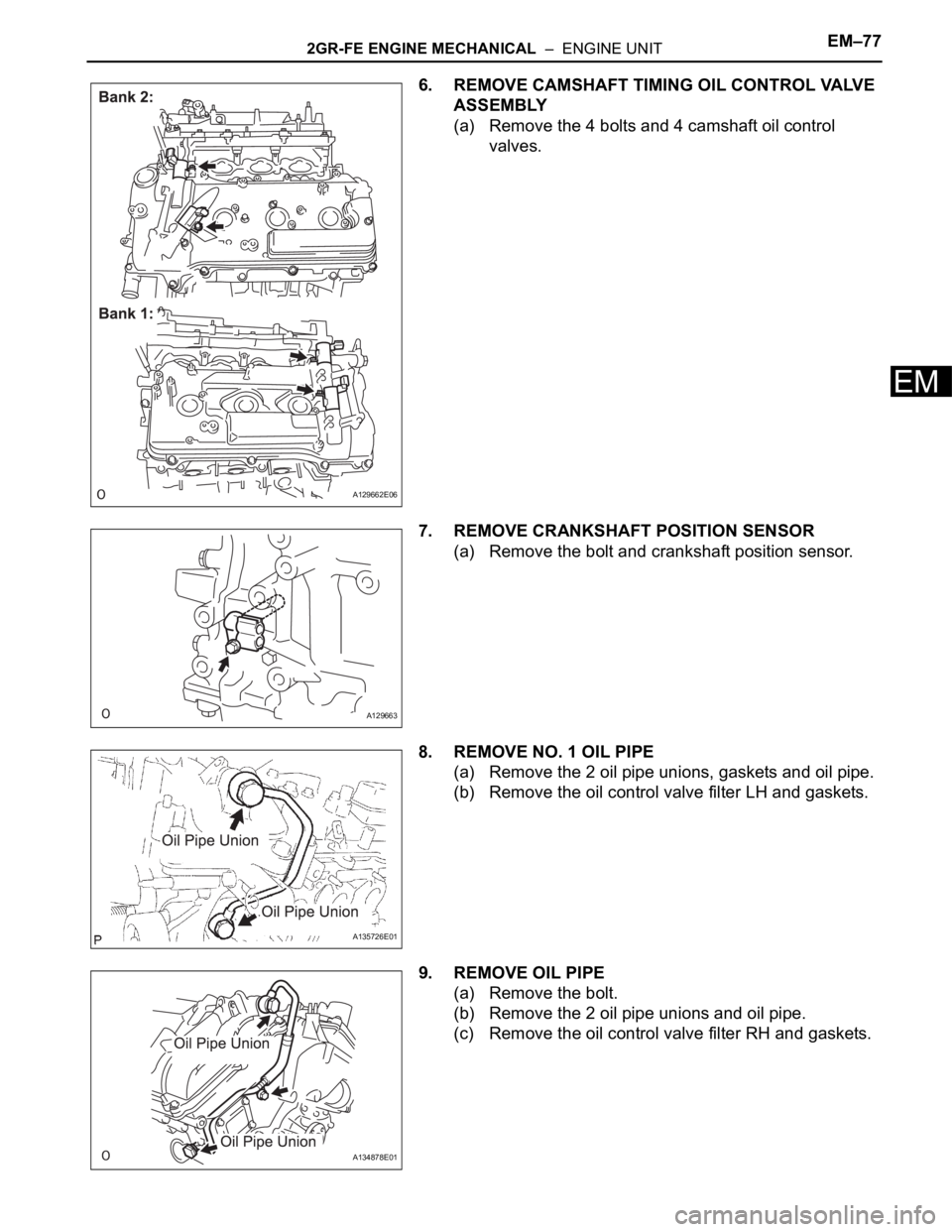

6. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY

(a) Remove the 4 bolts and 4 camshaft oil control

valves.

7. REMOVE CRANKSHAFT POSITION SENSOR

(a) Remove the bolt and crankshaft position sensor.

8. REMOVE NO. 1 OIL PIPE

(a) Remove the 2 oil pipe unions, gaskets and oil pipe.

(b) Remove the oil control valve filter LH and gaskets.

9. REMOVE OIL PIPE

(a) Remove the bolt.

(b) Remove the 2 oil pipe unions and oil pipe.

(c) Remove the oil control valve filter RH and gaskets.

A129662E06

A129663

A135726E01

A134878E01

Page 891 of 3000

EM–862GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

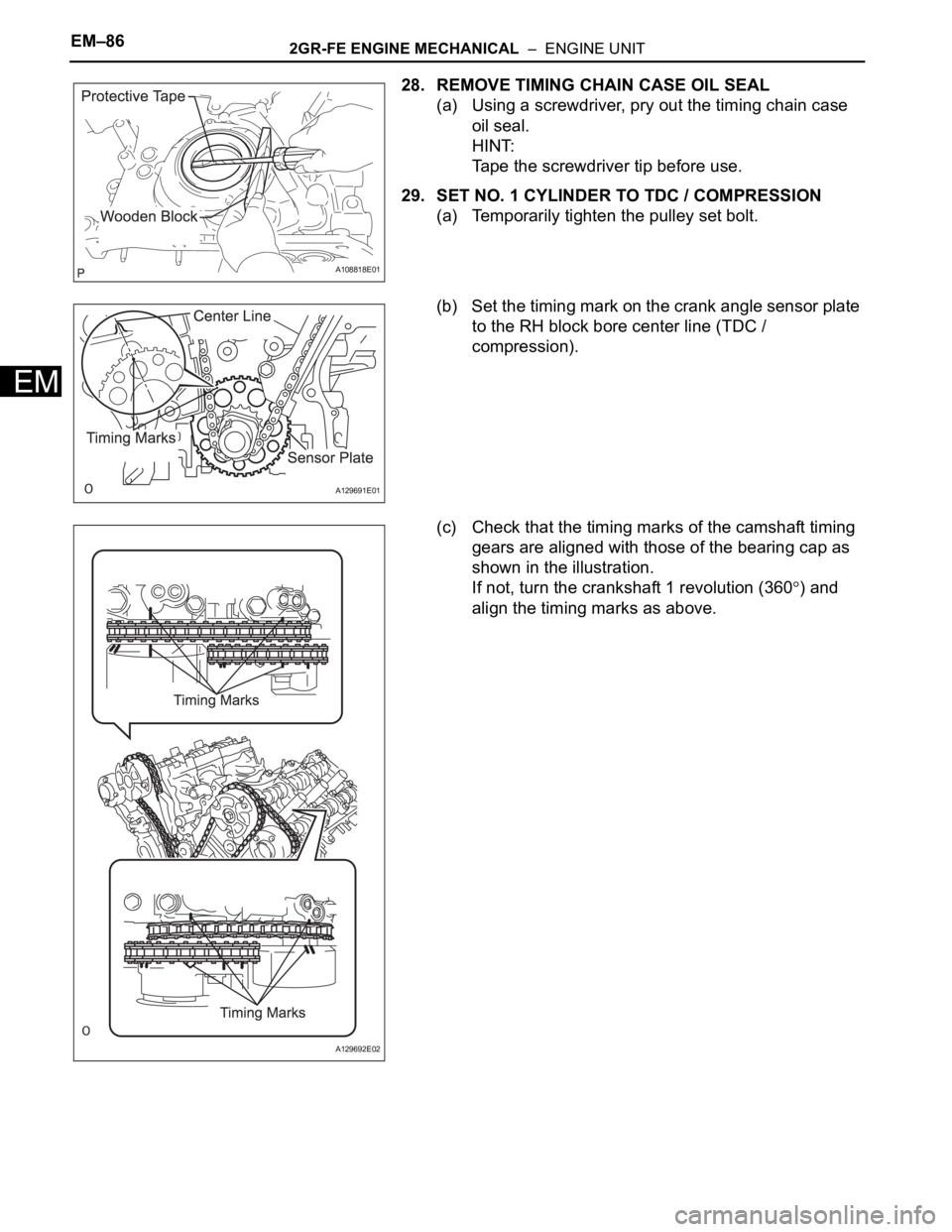

28. REMOVE TIMING CHAIN CASE OIL SEAL

(a) Using a screwdriver, pry out the timing chain case

oil seal.

HINT:

Tape the screwdriver tip before use.

29. SET NO. 1 CYLINDER TO TDC / COMPRESSION

(a) Temporarily tighten the pulley set bolt.

(b) Set the timing mark on the crank angle sensor plate

to the RH block bore center line (TDC /

compression).

(c) Check that the timing marks of the camshaft timing

gears are aligned with those of the bearing cap as

shown in the illustration.

If not, turn the crankshaft 1 revolution (360

) and

align the timing marks as above.

A108818E01

A129691E01

A129692E02

Page 934 of 3000

EM–42GR-FE ENGINE MECHANICAL – ENGINE

EM

(h) Install the 6 ignition coils.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(i) Install the intake air surge tank (See page ES-522).

10. INSPECT CO/HC

(a) Start the engine.

(b) Run the engine at 2500 rpm for approximately 180

seconds.

(c) Insert the CO/HC meter testing probe at least 40 cm

(1.3 ft.) into the tailpipe during idling.

(d) Check CO/HC concentration at idle and/or 2500

rpm.

HINT:

Check regulations and restrictions in your area

when performing 2 mode CO/HC concentration

testing (engine check at both idle speed and at 2500

rpm).

If the CO/HC concentration does not comply with

regulations, perform troubleshooting in the order

given below.

(1) Check air fuel ratio sensor and heated oxygen

sensor operation.

(2) See the table below for possible causes, and

then inspect and repair.

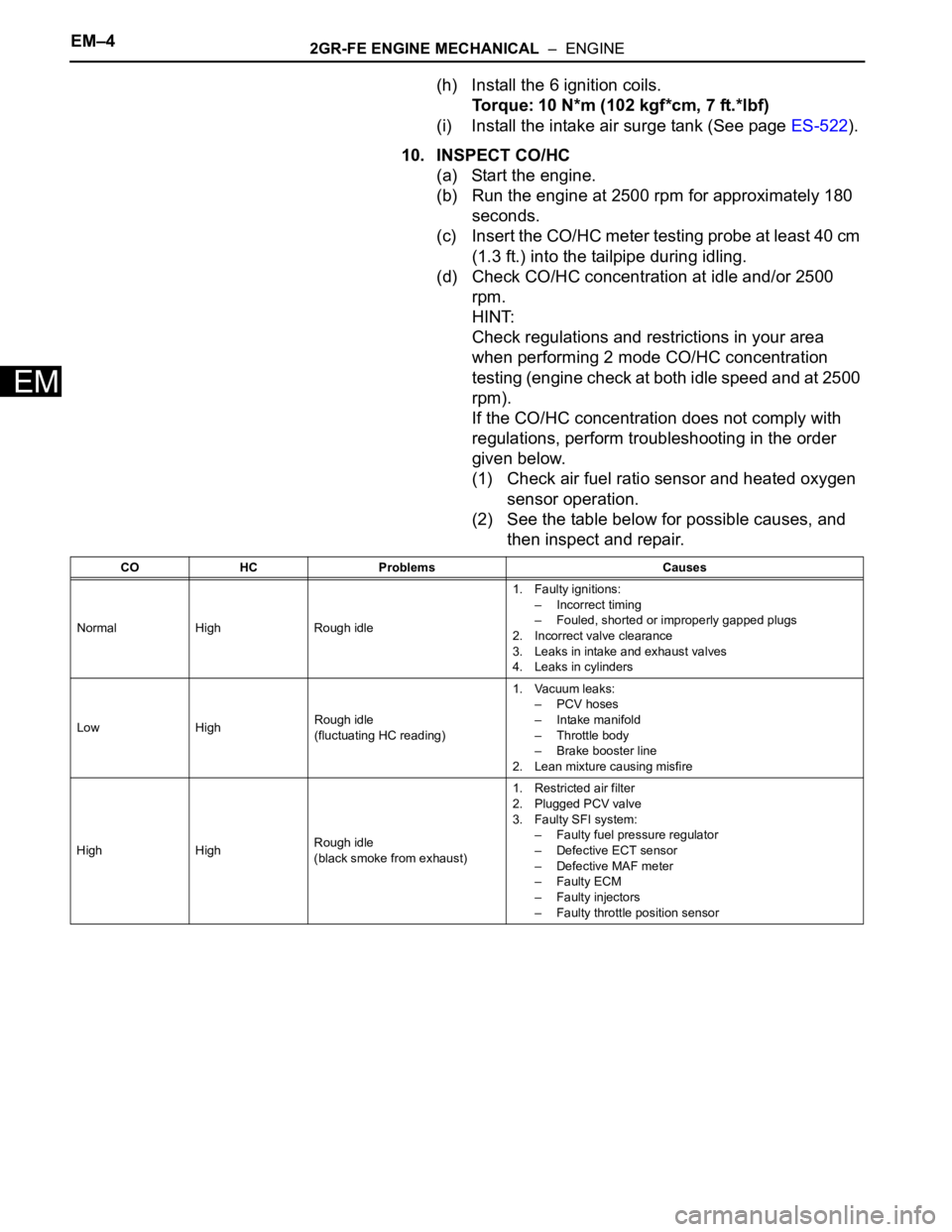

CO HC Problems Causes

Normal High Rough idle1. Faulty ignitions:

– Incorrect timing

– Fouled, shorted or improperly gapped plugs

2. Incorrect valve clearance

3. Leaks in intake and exhaust valves

4. Leaks in cylinders

Low HighRough idle

(fluctuating HC reading)1. Vacuum leaks:

– PCV hoses

– Intake manifold

– Throttle body

– Brake booster line

2. Lean mixture causing misfire

High HighRough idle

(black smoke from exhaust)1. Restricted air filter

2. Plugged PCV valve

3. Faulty SFI system:

– Faulty fuel pressure regulator

– Defective ECT sensor

– Defective MAF meter

–Faulty ECM

– Faulty injectors

– Faulty throttle position sensor

Page 977 of 3000

EM–1682GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

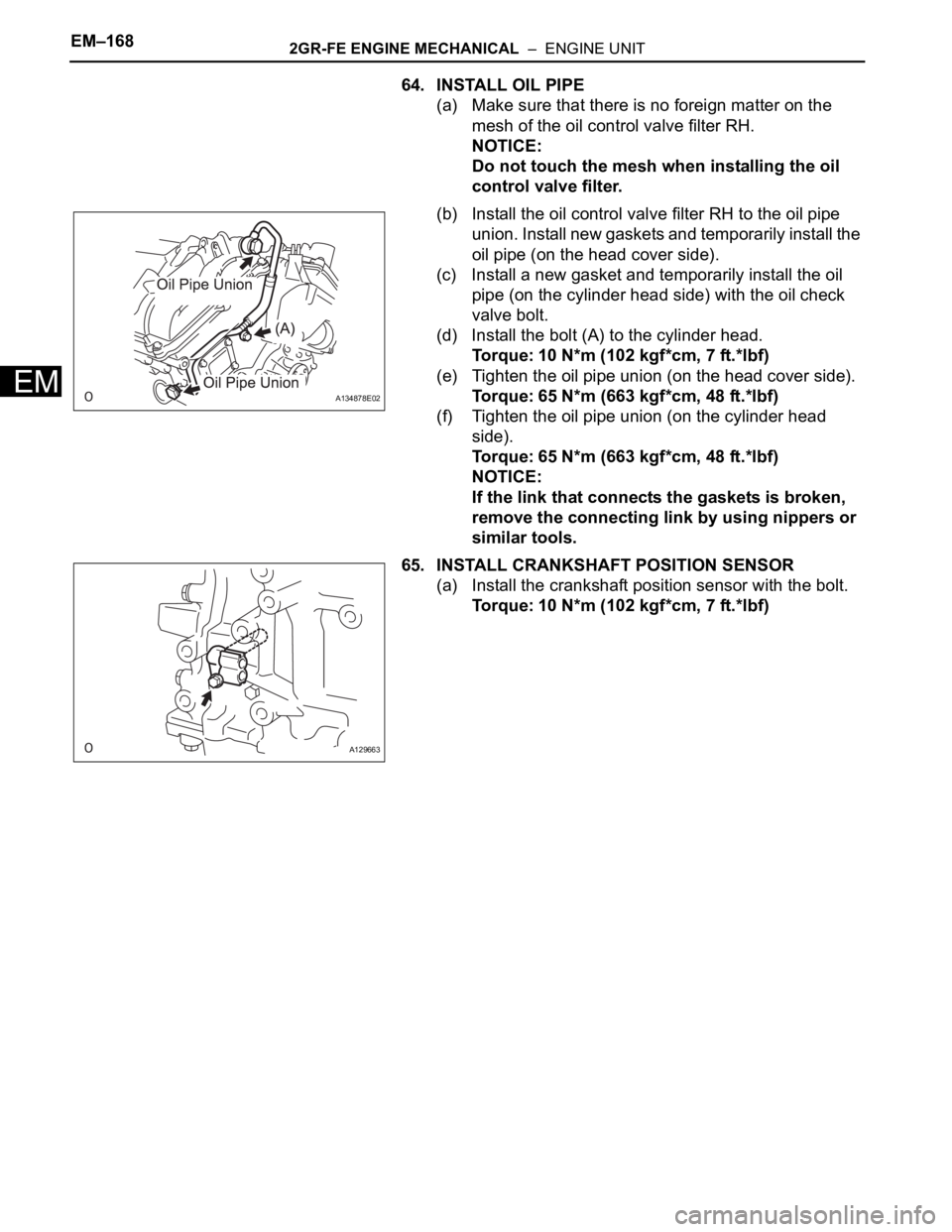

64. INSTALL OIL PIPE

(a) Make sure that there is no foreign matter on the

mesh of the oil control valve filter RH.

NOTICE:

Do not touch the mesh when installing the oil

control valve filter.

(b) Install the oil control valve filter RH to the oil pipe

union. Install new gaskets and temporarily install the

oil pipe (on the head cover side).

(c) Install a new gasket and temporarily install the oil

pipe (on the cylinder head side) with the oil check

valve bolt.

(d) Install the bolt (A) to the cylinder head.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(e) Tighten the oil pipe union (on the head cover side).

Torque: 65 N*m (663 kgf*cm, 48 ft.*lbf)

(f) Tighten the oil pipe union (on the cylinder head

side).

Torque: 65 N*m (663 kgf*cm, 48 ft.*lbf)

NOTICE:

If the link that connects the gaskets is broken,

remove the connecting link by using nippers or

similar tools.

65. INSTALL CRANKSHAFT POSITION SENSOR

(a) Install the crankshaft position sensor with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

A134878E02

A129663

Page 978 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–169

EM

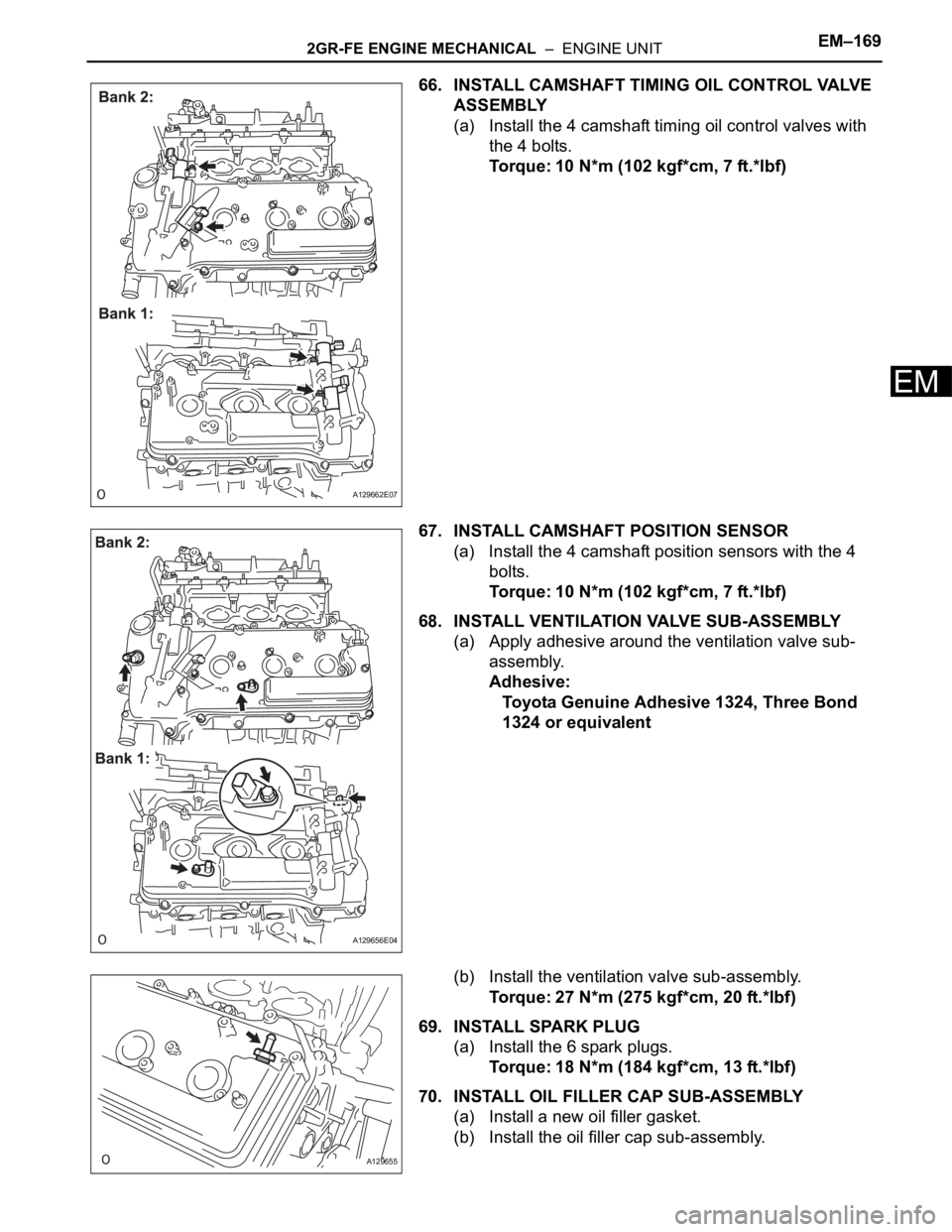

66. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY

(a) Install the 4 camshaft timing oil control valves with

the 4 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

67. INSTALL CAMSHAFT POSITION SENSOR

(a) Install the 4 camshaft position sensors with the 4

bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

68. INSTALL VENTILATION VALVE SUB-ASSEMBLY

(a) Apply adhesive around the ventilation valve sub-

assembly.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond

1324 or equivalent

(b) Install the ventilation valve sub-assembly.

Torque: 27 N*m (275 kgf*cm, 20 ft.*lbf)

69. INSTALL SPARK PLUG

(a) Install the 6 spark plugs.

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

70. INSTALL OIL FILLER CAP SUB-ASSEMBLY

(a) Install a new oil filler gasket.

(b) Install the oil filler cap sub-assembly.

A129662E07

A129656E04

A129655

Page 993 of 3000

EM–342GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

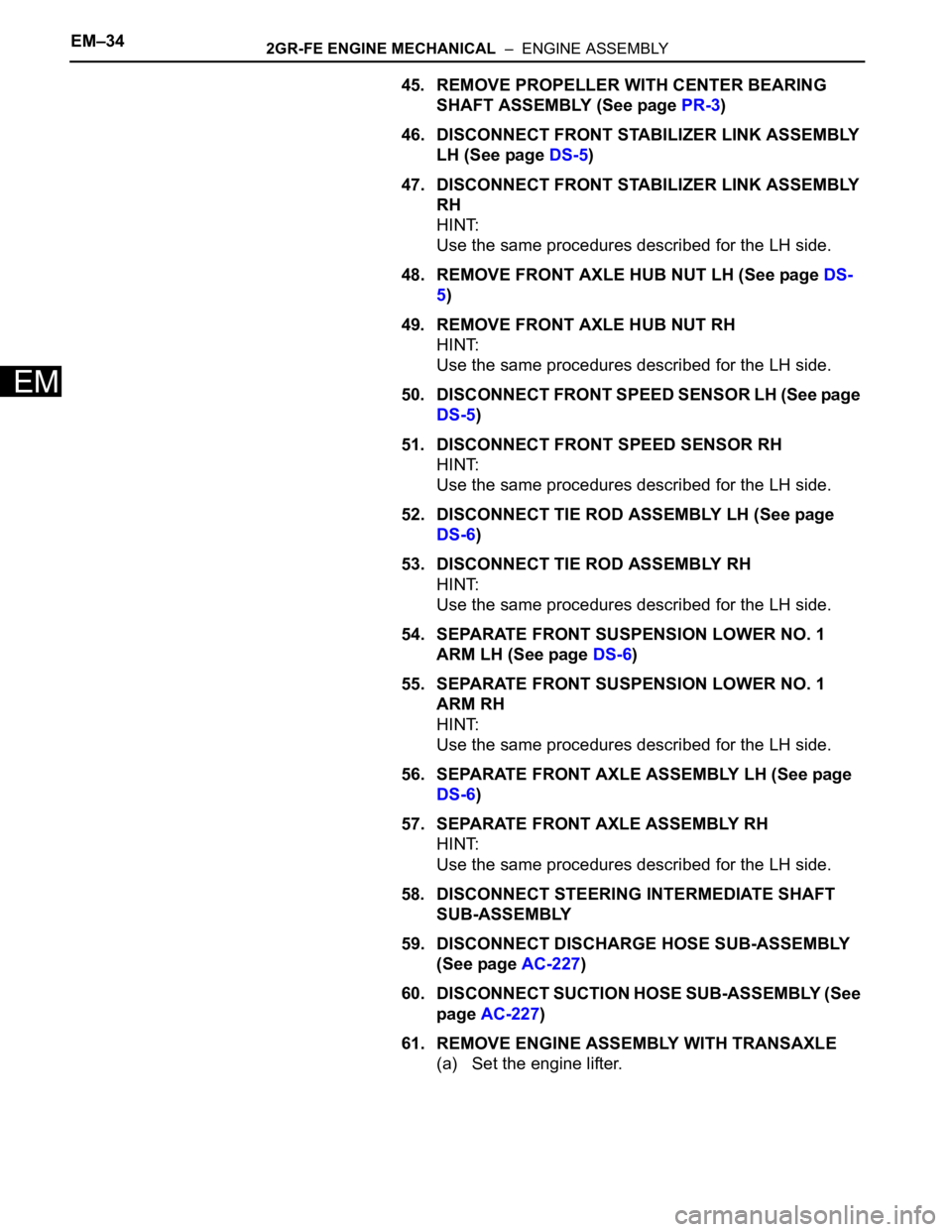

45. REMOVE PROPELLER WITH CENTER BEARING

SHAFT ASSEMBLY (See page PR-3)

46. DISCONNECT FRONT STABILIZER LINK ASSEMBLY

LH (See page DS-5)

47. DISCONNECT FRONT STABILIZER LINK ASSEMBLY

RH

HINT:

Use the same procedures described for the LH side.

48. REMOVE FRONT AXLE HUB NUT LH (See page DS-

5)

49. REMOVE FRONT AXLE HUB NUT RH

HINT:

Use the same procedures described for the LH side.

50. DISCONNECT FRONT SPEED SENSOR LH (See page

DS-5)

51. DISCONNECT FRONT SPEED SENSOR RH

HINT:

Use the same procedures described for the LH side.

52. DISCONNECT TIE ROD ASSEMBLY LH (See page

DS-6)

53. DISCONNECT TIE ROD ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

54. SEPARATE FRONT SUSPENSION LOWER NO. 1

ARM LH (See page DS-6)

55. SEPARATE FRONT SUSPENSION LOWER NO. 1

ARM RH

HINT:

Use the same procedures described for the LH side.

56. SEPARATE FRONT AXLE ASSEMBLY LH (See page

DS-6)

57. SEPARATE FRONT AXLE ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

58. DISCONNECT STEERING INTERMEDIATE SHAFT

SUB-ASSEMBLY

59. DISCONNECT DISCHARGE HOSE SUB-ASSEMBLY

(See page AC-227)

60. DISCONNECT SUCTION HOSE SUB-ASSEMBLY (See

page AC-227)

61. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

(a) Set the engine lifter.

Page 998 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–39

EM

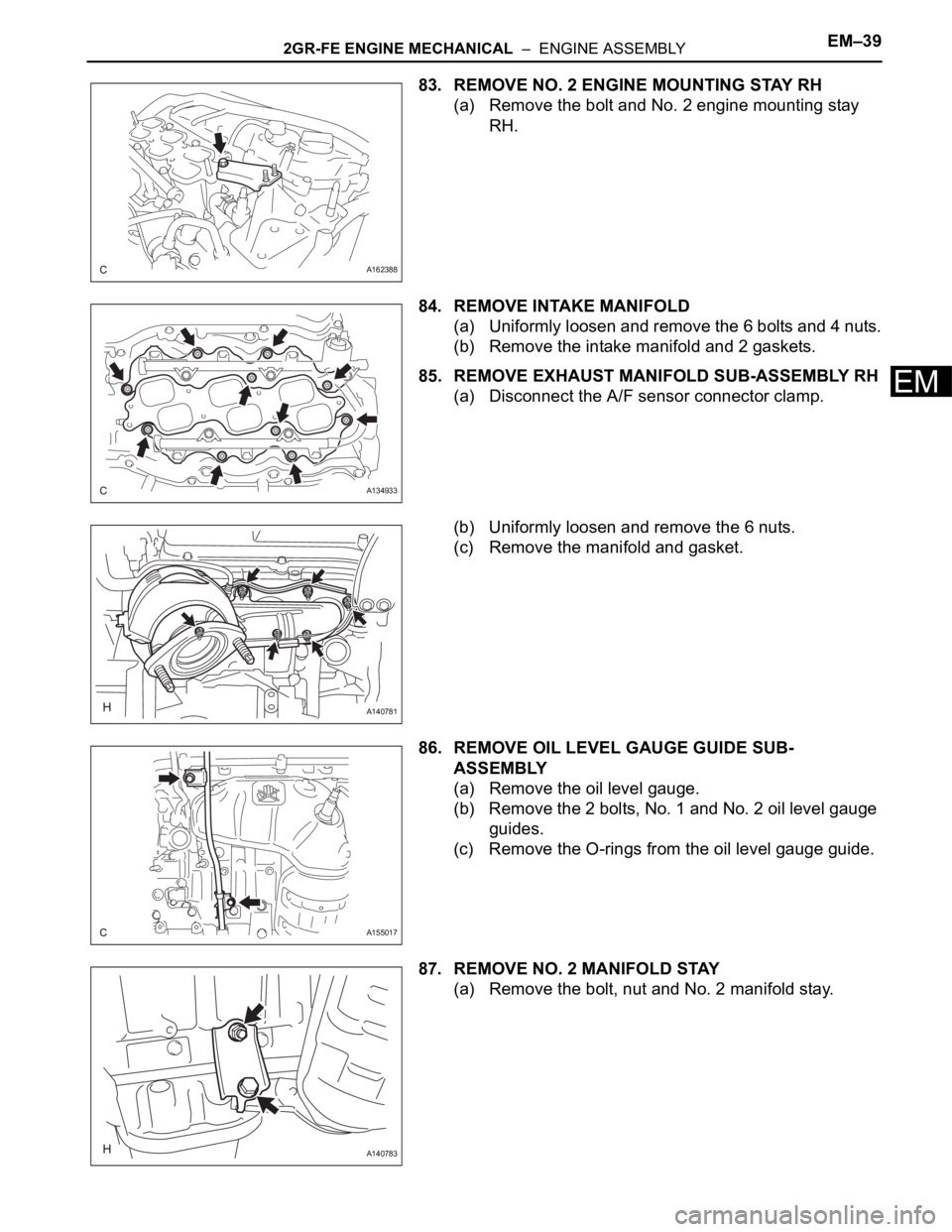

83. REMOVE NO. 2 ENGINE MOUNTING STAY RH

(a) Remove the bolt and No. 2 engine mounting stay

RH.

84. REMOVE INTAKE MANIFOLD

(a) Uniformly loosen and remove the 6 bolts and 4 nuts.

(b) Remove the intake manifold and 2 gaskets.

85. REMOVE EXHAUST MANIFOLD SUB-ASSEMBLY RH

(a) Disconnect the A/F sensor connector clamp.

(b) Uniformly loosen and remove the 6 nuts.

(c) Remove the manifold and gasket.

86. REMOVE OIL LEVEL GAUGE GUIDE SUB-

ASSEMBLY

(a) Remove the oil level gauge.

(b) Remove the 2 bolts, No. 1 and No. 2 oil level gauge

guides.

(c) Remove the O-rings from the oil level gauge guide.

87. REMOVE NO. 2 MANIFOLD STAY

(a) Remove the bolt, nut and No. 2 manifold stay.

A162388

A134933

A140781

A155017

A140783