sensor TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 816 of 3000

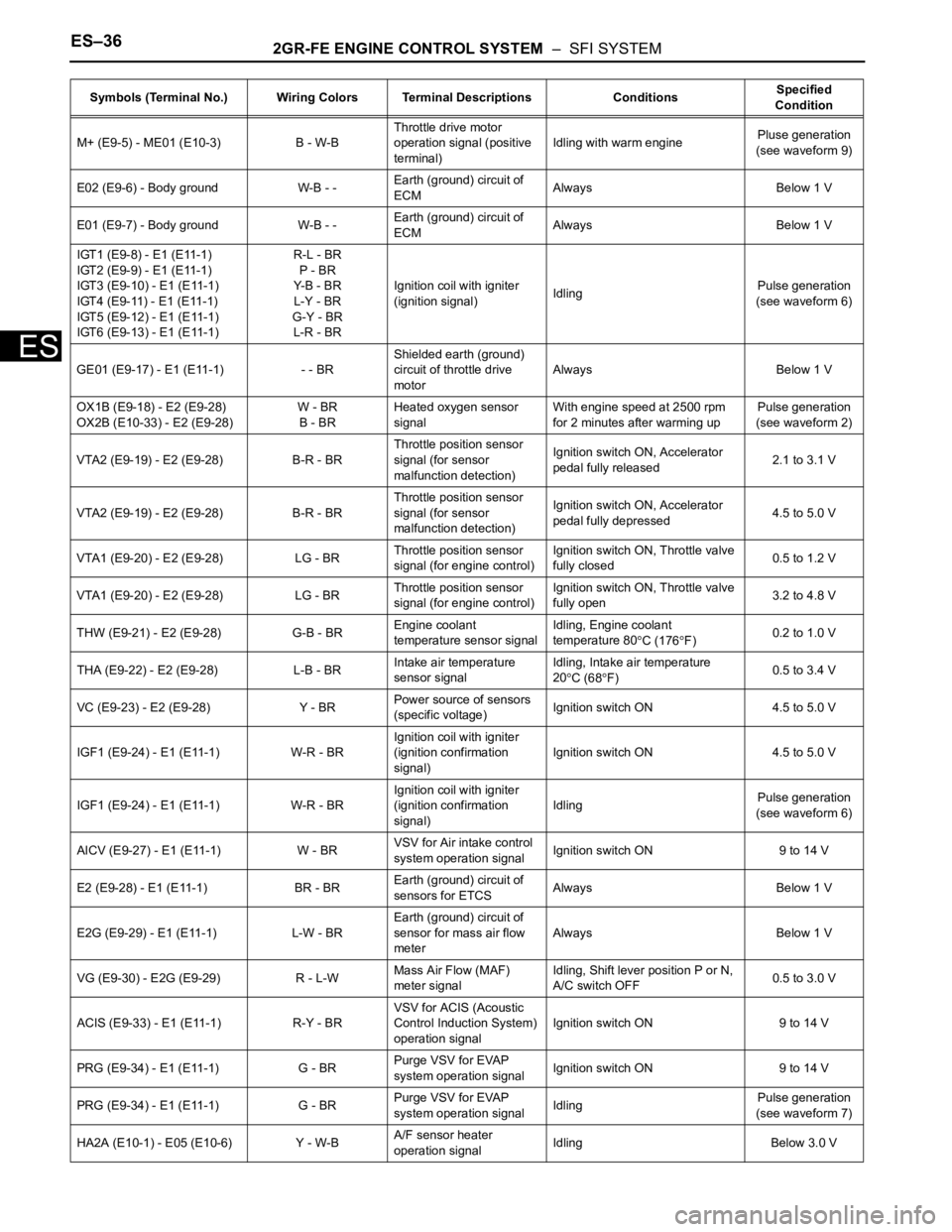

ES–362GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

M+ (E9-5) - ME01 (E10-3) B - W-BThrottle drive motor

operation signal (positive

terminal)Idling with warm enginePluse generation

(see waveform 9)

E02 (E9-6) - Body ground W-B - -Earth (ground) circuit of

ECMAlways Below 1 V

E01 (E9-7) - Body ground W-B - -Earth (ground) circuit of

ECMAlways Below 1 V

IGT1 (E9-8) - E1 (E11-1)

IGT2 (E9-9) - E1 (E11-1)

IGT3 (E9-10) - E1 (E11-1)

IGT4 (E9-11) - E1 (E11-1)

IGT5 (E9-12) - E1 (E11-1)

IGT6 (E9-13) - E1 (E11-1)R-L - BR

P - BR

Y- B - B R

L-Y - BR

G-Y - BR

L-R - BRIgnition coil with igniter

(ignition signal)IdlingPulse generation

(see waveform 6)

GE01 (E9-17) - E1 (E11-1) - - BRShielded earth (ground)

circuit of throttle drive

motorAlways Below 1 V

OX1B (E9-18) - E2 (E9-28)

OX2B (E10-33) - E2 (E9-28)W - BR

B - BRHeated oxygen sensor

signalWith engine speed at 2500 rpm

for 2 minutes after warming upPulse generation

(see waveform 2)

VTA2 (E9-19) - E2 (E9-28) B-R - BRThrottle position sensor

signal (for sensor

malfunction detection)Ignition switch ON, Accelerator

pedal fully released2.1 to 3.1 V

VTA2 (E9-19) - E2 (E9-28) B-R - BRThrottle position sensor

signal (for sensor

malfunction detection)Ignition switch ON, Accelerator

pedal fully depressed4.5 to 5.0 V

VTA1 (E9-20) - E2 (E9-28) LG - BRThrottle position sensor

signal (for engine control)Ignition switch ON, Throttle valve

fully closed0.5 to 1.2 V

VTA1 (E9-20) - E2 (E9-28) LG - BRThrottle position sensor

signal (for engine control)Ignition switch ON, Throttle valve

fully open3.2 to 4.8 V

THW (E9-21) - E2 (E9-28) G-B - BREngine coolant

temperature sensor signalIdling, Engine coolant

temperature 80

C (176F)0.2 to 1.0 V

THA (E9-22) - E2 (E9-28) L-B - BRIntake air temperature

sensor signalIdling, Intake air temperature

20

C (68F)0.5 to 3.4 V

VC (E9-23) - E2 (E9-28) Y - BRPower source of sensors

(specific voltage)Ignition switch ON 4.5 to 5.0 V

IGF1 (E9-24) - E1 (E11-1) W-R - BRIgnition coil with igniter

(ignition confirmation

signal)Ignition switch ON 4.5 to 5.0 V

IGF1 (E9-24) - E1 (E11-1) W-R - BRIgnition coil with igniter

(ignition confirmation

signal)IdlingPulse generation

(see waveform 6)

AICV (E9-27) - E1 (E11-1) W - BRVSV for Air intake control

system operation signalIgnition switch ON 9 to 14 V

E2 (E9-28) - E1 (E11-1) BR - BREarth (ground) circuit of

sensors for ETCSAlways Below 1 V

E2G (E9-29) - E1 (E11-1) L-W - BREarth (ground) circuit of

sensor for mass air flow

meterAlways Below 1 V

VG (E9-30) - E2G (E9-29) R - L-WMass Air Flow (MAF)

meter signalIdling, Shift lever position P or N,

A/C switch OFF0.5 to 3.0 V

ACIS (E9-33) - E1 (E11-1) R-Y - BRVSV for ACIS (Acoustic

Control Induction System)

operation signalIgnition switch ON 9 to 14 V

PRG (E9-34) - E1 (E11-1) G - BRPurge VSV for EVAP

system operation signalIgnition switch ON 9 to 14 V

PRG (E9-34) - E1 (E11-1) G - BRPurge VSV for EVAP

system operation signalIdlingPulse generation

(see waveform 7)

HA2A (E10-1) - E05 (E10-6) Y - W-BA/F sensor heater

operation signalIdling Below 3.0 V Symbols (Terminal No.) Wiring Colors Terminal Descriptions ConditionsSpecified

Condition

Page 817 of 3000

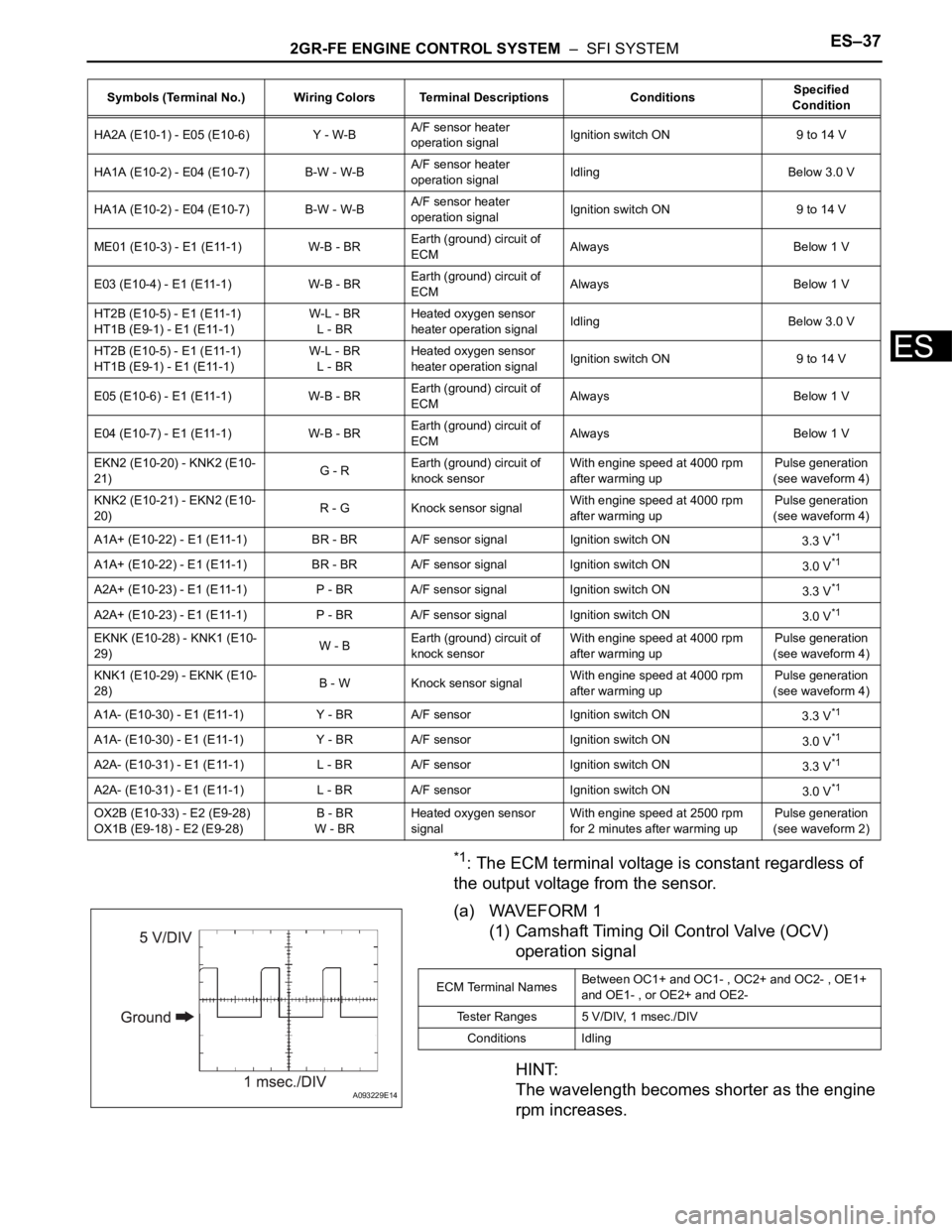

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–37

ES

*1: The ECM terminal voltage is constant regardless of

the output voltage from the sensor.

(a) WAVEFORM 1

(1) Camshaft Timing Oil Control Valve (OCV)

operation signal

HINT:

The wavelength becomes shorter as the engine

rpm increases.

HA2A (E10-1) - E05 (E10-6) Y - W-BA/F sensor heater

operation signalIgnition switch ON 9 to 14 V

HA1A (E10-2) - E04 (E10-7) B-W - W-BA/F sensor heater

operation signalIdling Below 3.0 V

HA1A (E10-2) - E04 (E10-7) B-W - W-BA/F sensor heater

operation signalIgnition switch ON 9 to 14 V

ME01 (E10-3) - E1 (E11-1) W-B - BREarth (ground) circuit of

ECMAlways Below 1 V

E03 (E10-4) - E1 (E11-1) W-B - BREarth (ground) circuit of

ECMAlways Below 1 V

HT2B (E10-5) - E1 (E11-1)

HT1B (E9-1) - E1 (E11-1)W-L - BR

L - BRHeated oxygen sensor

heater operation signalIdling Below 3.0 V

HT2B (E10-5) - E1 (E11-1)

HT1B (E9-1) - E1 (E11-1)W-L - BR

L - BRHeated oxygen sensor

heater operation signalIgnition switch ON 9 to 14 V

E05 (E10-6) - E1 (E11-1) W-B - BREarth (ground) circuit of

ECMAlways Below 1 V

E04 (E10-7) - E1 (E11-1) W-B - BREarth (ground) circuit of

ECMAlways Below 1 V

EKN2 (E10-20) - KNK2 (E10-

21)G - REarth (ground) circuit of

knock sensorWith engine speed at 4000 rpm

after warming upPulse generation

(see waveform 4)

KNK2 (E10-21) - EKN2 (E10-

20)R - G Knock sensor signalWith engine speed at 4000 rpm

after warming upPulse generation

(see waveform 4)

A1A+ (E10-22) - E1 (E11-1) BR - BR A/F sensor signal Ignition switch ON

3.3 V

*1

A1A+ (E10-22) - E1 (E11-1) BR - BR A/F sensor signal Ignition switch ON

3.0 V*1

A2A+ (E10-23) - E1 (E11-1) P - BR A/F sensor signal Ignition switch ON

3.3 V*1

A2A+ (E10-23) - E1 (E11-1) P - BR A/F sensor signal Ignition switch ON

3.0 V*1

EKNK (E10-28) - KNK1 (E10-

29)W - BEarth (ground) circuit of

knock sensorWith engine speed at 4000 rpm

after warming upPulse generation

(see waveform 4)

KNK1 (E10-29) - EKNK (E10-

28)B - W Knock sensor signalWith engine speed at 4000 rpm

after warming upPulse generation

(see waveform 4)

A1A- (E10-30) - E1 (E11-1) Y - BR A/F sensor Ignition switch ON

3.3 V

*1

A1A- (E10-30) - E1 (E11-1) Y - BR A/F sensor Ignition switch ON

3.0 V*1

A2A- (E10-31) - E1 (E11-1) L - BR A/F sensor Ignition switch ON

3.3 V*1

A2A- (E10-31) - E1 (E11-1) L - BR A/F sensor Ignition switch ON

3.0 V*1

OX2B (E10-33) - E2 (E9-28)

OX1B (E9-18) - E2 (E9-28)B - BR

W - BRHeated oxygen sensor

signalWith engine speed at 2500 rpm

for 2 minutes after warming upPulse generation

(see waveform 2) Symbols (Terminal No.) Wiring Colors Terminal Descriptions ConditionsSpecified

Condition

A093229E14

ECM Terminal NamesBetween OC1+ and OC1- , OC2+ and OC2- , OE1+

and OE1- , or OE2+ and OE2-

Tester Ranges 5 V/DIV, 1 msec./DIV

Conditions Idling

Page 818 of 3000

ES–382GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

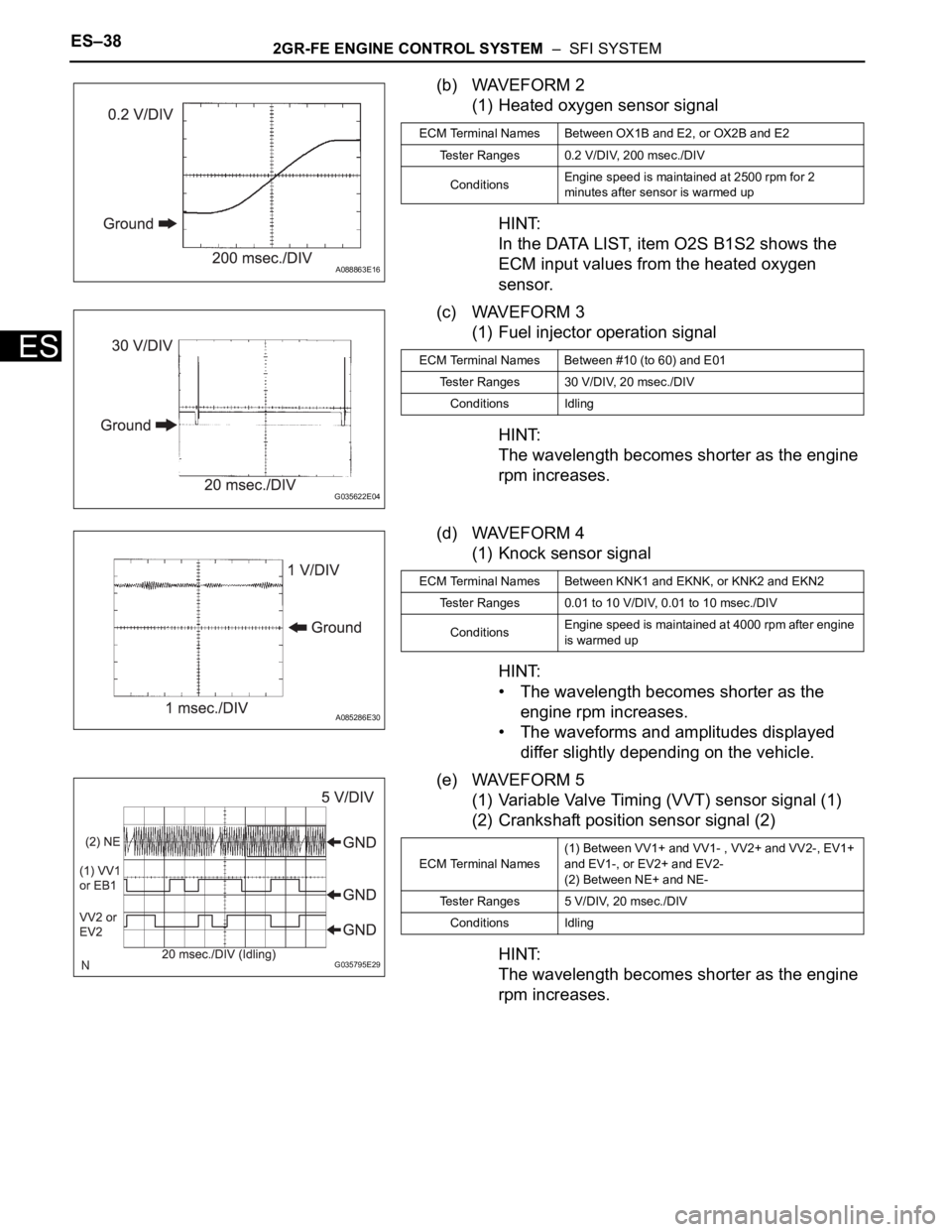

(b) WAVEFORM 2

(1) Heated oxygen sensor signal

HINT:

In the DATA LIST, item O2S B1S2 shows the

ECM input values from the heated oxygen

sensor.

(c) WAVEFORM 3

(1) Fuel injector operation signal

HINT:

The wavelength becomes shorter as the engine

rpm increases.

(d) WAVEFORM 4

(1) Knock sensor signal

HINT:

• The wavelength becomes shorter as the

engine rpm increases.

• The waveforms and amplitudes displayed

differ slightly depending on the vehicle.

(e) WAVEFORM 5

(1) Variable Valve Timing (VVT) sensor signal (1)

(2) Crankshaft position sensor signal (2)

HINT:

The wavelength becomes shorter as the engine

rpm increases.

A088863E16

ECM Terminal Names Between OX1B and E2, or OX2B and E2

Tester Ranges 0.2 V/DIV, 200 msec./DIV

ConditionsEngine speed is maintained at 2500 rpm for 2

minutes after sensor is warmed up

G035622E04

ECM Terminal Names Between #10 (to 60) and E01

Tester Ranges 30 V/DIV, 20 msec./DIV

Conditions Idling

A085286E30

ECM Terminal Names Between KNK1 and EKNK, or KNK2 and EKN2

Tester Ranges 0.01 to 10 V/DIV, 0.01 to 10 msec./DIV

ConditionsEngine speed is maintained at 4000 rpm after engine

is warmed up

G035795E29

ECM Terminal Names(1) Between VV1+ and VV1- , VV2+ and VV2-, EV1+

and EV1-, or EV2+ and EV2-

(2) Between NE+ and NE-

Tester Ranges 5 V/DIV, 20 msec./DIV

Conditions Idling

Page 821 of 3000

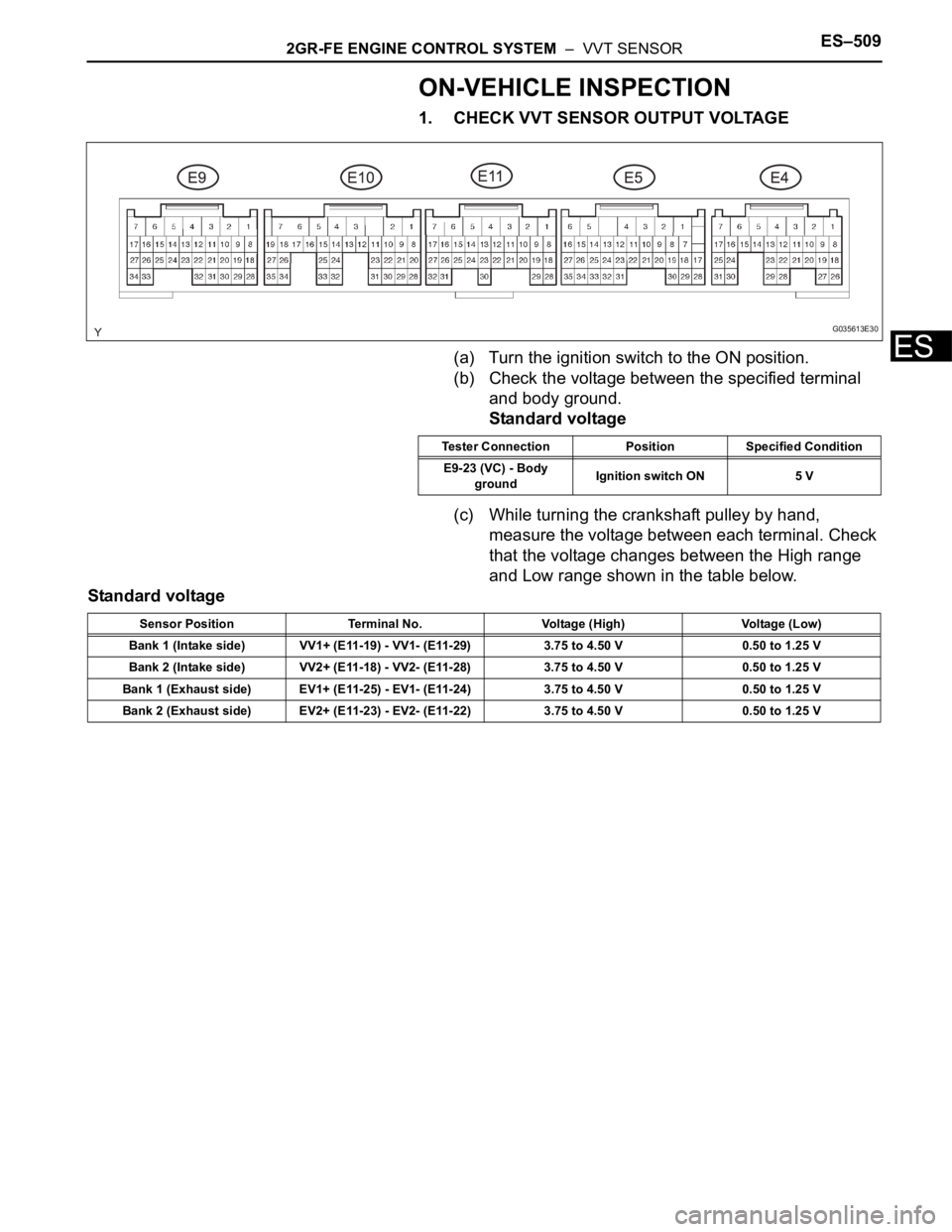

2GR-FE ENGINE CONTROL SYSTEM – VVT SENSORES–509

ES

ON-VEHICLE INSPECTION

1. CHECK VVT SENSOR OUTPUT VOLTAGE

(a) Turn the ignition switch to the ON position.

(b) Check the voltage between the specified terminal

and body ground.

Standard voltage

(c) While turning the crankshaft pulley by hand,

measure the voltage between each terminal. Check

that the voltage changes between the High range

and Low range shown in the table below.

Standard voltage

G035613E30

Tester Connection Position Specified Condition

E9-23 (VC) - Body

groundIgnition switch ON 5 V

Sensor Position Terminal No. Voltage (High) Voltage (Low)

Bank 1 (Intake side) VV1+ (E11-19) - VV1- (E11-29) 3.75 to 4.50 V0.50 to 1.25 V

Bank 2 (Intake side) VV2+ (E11-18) - VV2- (E11-28) 3.75 to 4.50 V0.50 to 1.25 V

Bank 1 (Exhaust side) EV1+ (E11-25) - EV1- (E11-24) 3.75 to 4.50 V 0.50 to 1.25 V

Bank 2 (Exhaust side) EV2+ (E11-23) - EV2- (E11-22) 3.75 to 4.50 V 0.50 to 1.25 V

Page 822 of 3000

ES–5102GR-FE ENGINE CONTROL SYSTEM – VVT SENSOR

ES

REMOVAL

1. REMOVE WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-4)

2. REMOVE FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-27)

3. DRAIN ENGINE COOLANT (See page CO-6)

4. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

5. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

6. REMOVE NO. 1 AIR CLEANER INLET (See page EM-

28)

7. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-493)

8. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-28)

9. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

(See page ES-521)

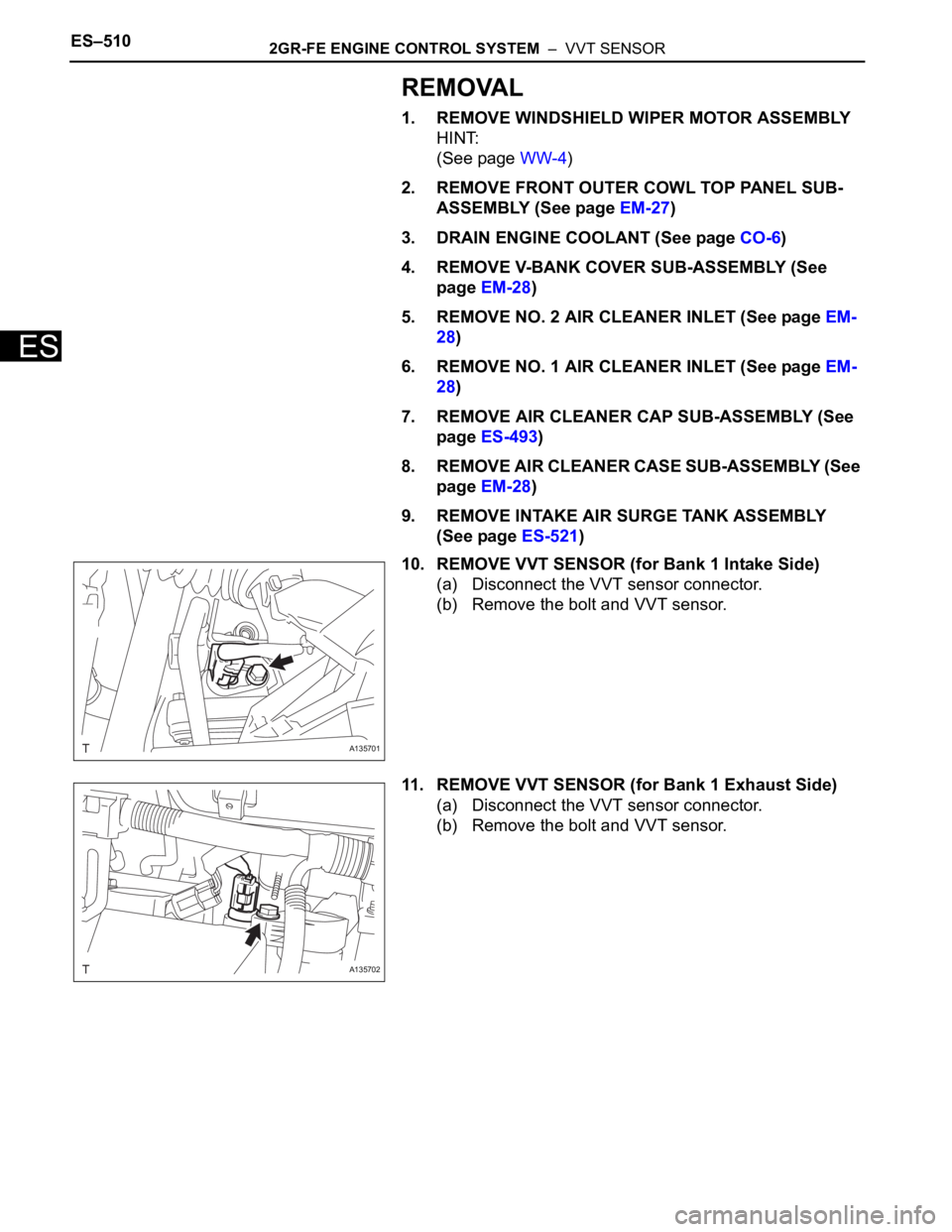

10. REMOVE VVT SENSOR (for Bank 1 Intake Side)

(a) Disconnect the VVT sensor connector.

(b) Remove the bolt and VVT sensor.

11. REMOVE VVT SENSOR (for Bank 1 Exhaust Side)

(a) Disconnect the VVT sensor connector.

(b) Remove the bolt and VVT sensor.

A135701

A135702

Page 824 of 3000

ES–422GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

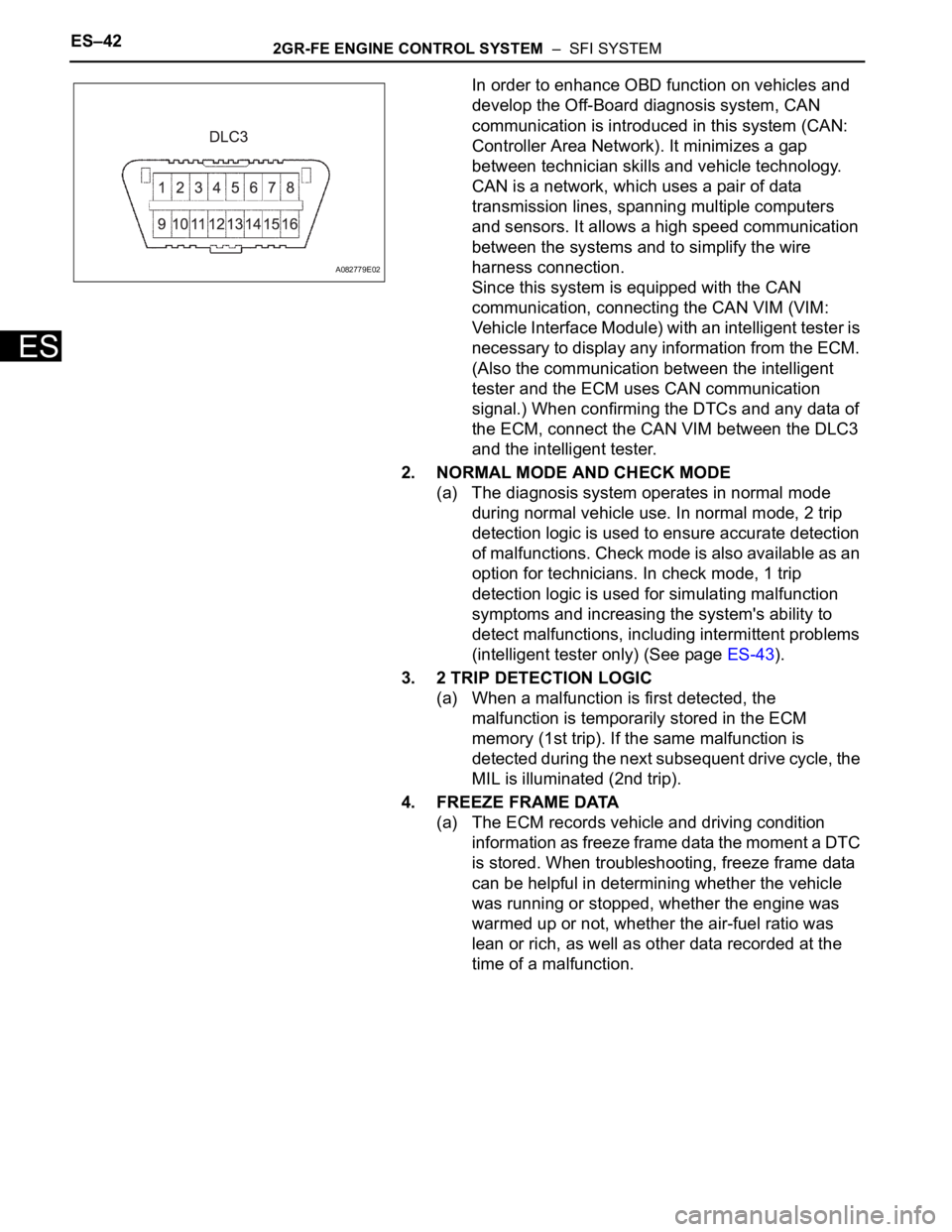

In order to enhance OBD function on vehicles and

develop the Off-Board diagnosis system, CAN

communication is introduced in this system (CAN:

Controller Area Network). It minimizes a gap

between technician skills and vehicle technology.

CAN is a network, which uses a pair of data

transmission lines, spanning multiple computers

and sensors. It allows a high speed communication

between the systems and to simplify the wire

harness connection.

Since this system is equipped with the CAN

communication, connecting the CAN VIM (VIM:

Vehicle Interface Module) with an intelligent tester is

necessary to display any information from the ECM.

(Also the communication between the intelligent

tester and the ECM uses CAN communication

signal.) When confirming the DTCs and any data of

the ECM, connect the CAN VIM between the DLC3

and the intelligent tester.

2. NORMAL MODE AND CHECK MODE

(a) The diagnosis system operates in normal mode

during normal vehicle use. In normal mode, 2 trip

detection logic is used to ensure accurate detection

of malfunctions. Check mode is also available as an

option for technicians. In check mode, 1 trip

detection logic is used for simulating malfunction

symptoms and increasing the system's ability to

detect malfunctions, including intermittent problems

(intelligent tester only) (See page ES-43).

3. 2 TRIP DETECTION LOGIC

(a) When a malfunction is first detected, the

malfunction is temporarily stored in the ECM

memory (1st trip). If the same malfunction is

detected during the next subsequent drive cycle, the

MIL is illuminated (2nd trip).

4. FREEZE FRAME DATA

(a) The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC

is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle

was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was

lean or rich, as well as other data recorded at the

time of a malfunction.

A082779E02

Page 828 of 3000

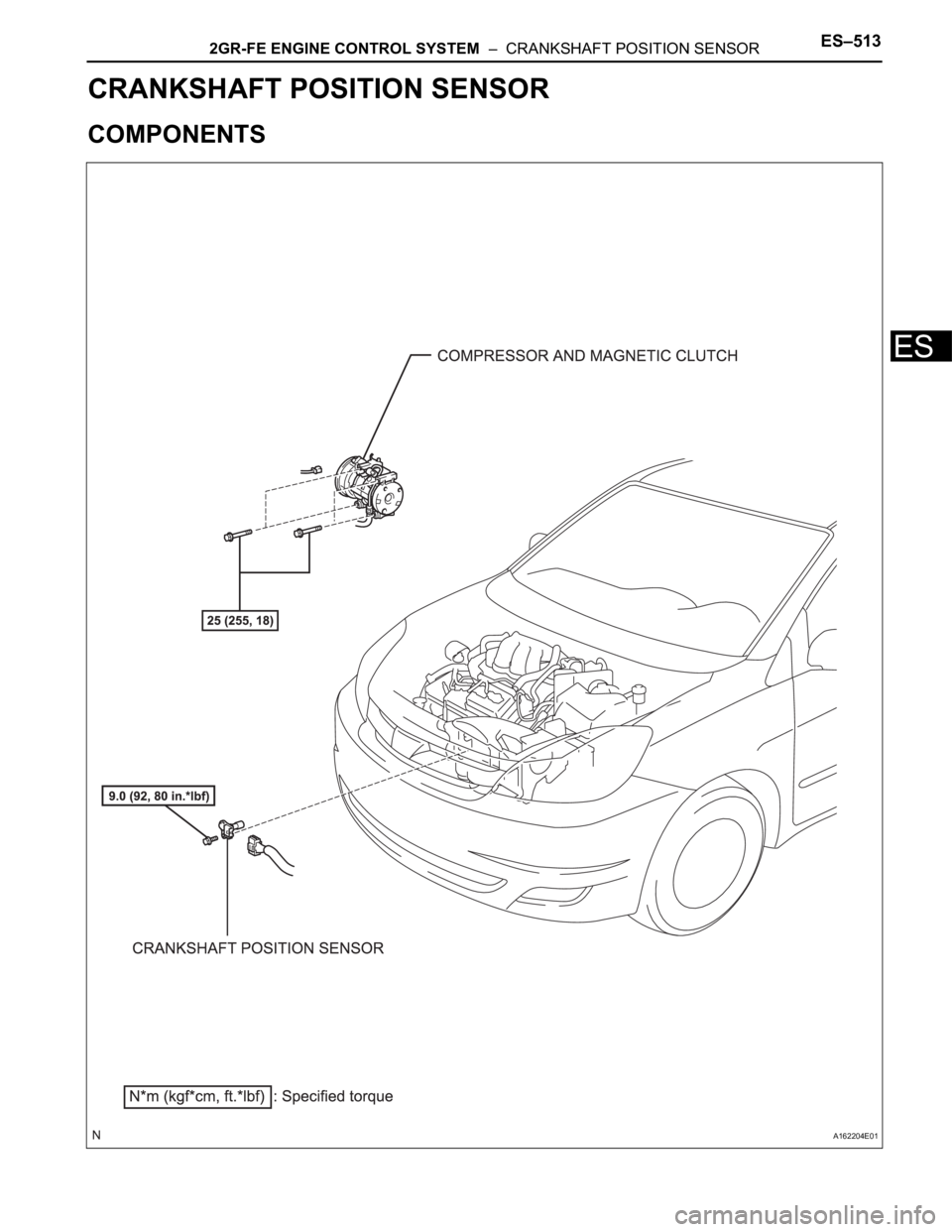

2GR-FE ENGINE CONTROL SYSTEM – CRANKSHAFT POSITION SENSORES–513

ES

ENGINE

2GR-FE ENGINE CONTROL SYSTEM

CRANKSHAFT POSITION SENSOR

COMPONENTS

A162204E01

Page 829 of 3000

ES–5142GR-FE ENGINE CONTROL SYSTEM – CRANKSHAFT POSITION SENSOR

ES

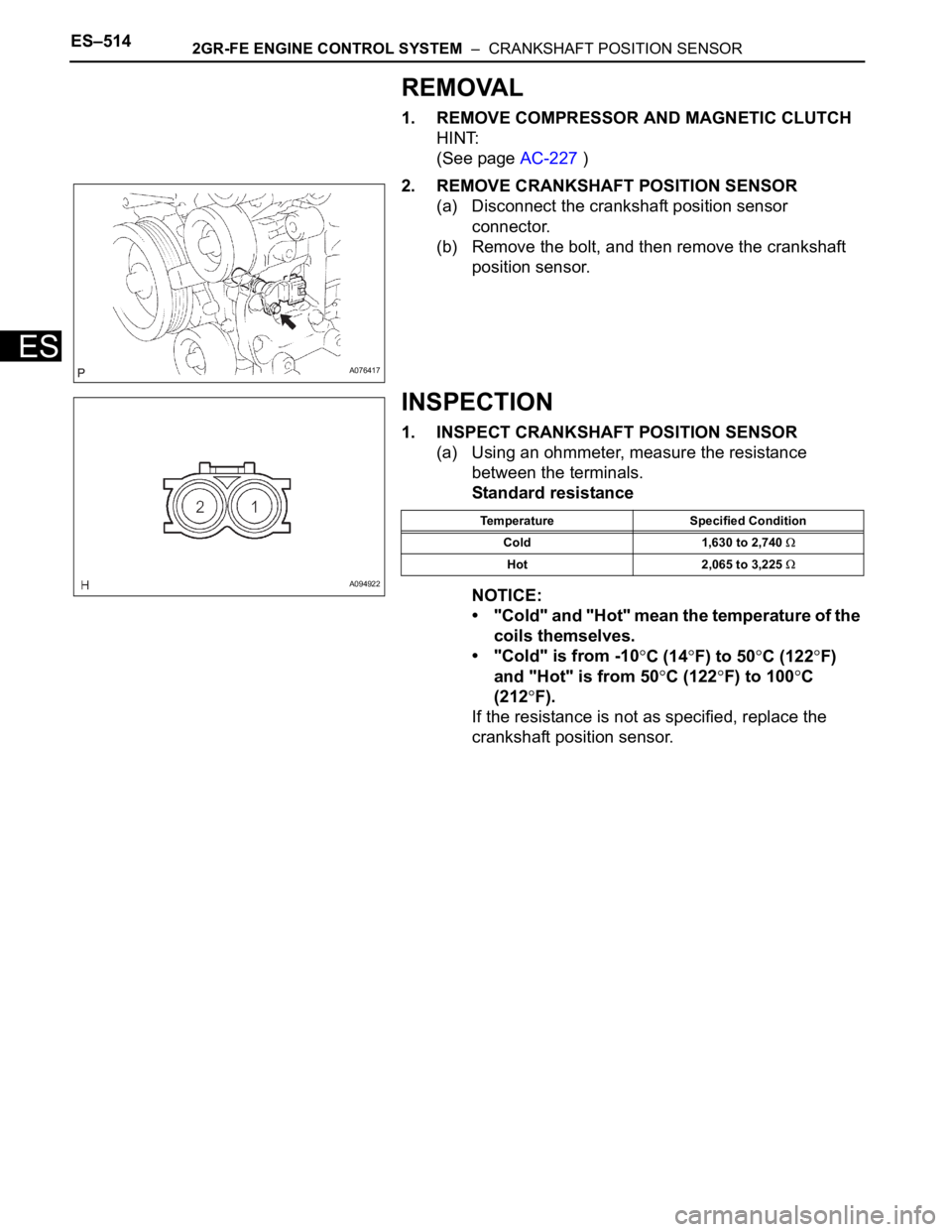

REMOVAL

1. REMOVE COMPRESSOR AND MAGNETIC CLUTCH

HINT:

(See page AC-227 )

2. REMOVE CRANKSHAFT POSITION SENSOR

(a) Disconnect the crankshaft position sensor

connector.

(b) Remove the bolt, and then remove the crankshaft

position sensor.

INSPECTION

1. INSPECT CRANKSHAFT POSITION SENSOR

(a) Using an ohmmeter, measure the resistance

between the terminals.

Standard resistance

NOTICE:

• "Cold" and "Hot" mean the temperature of the

coils themselves.

• "Cold" is from -10

C (14F) to 50C (122F)

and "Hot" is from 50

C (122F) to 100C

(212

F).

If the resistance is not as specified, replace the

crankshaft position sensor.

A076417

A094922

Temperature Specified Condition

Cold 1,630 to 2,740

Hot 2,065 to 3,225

Page 830 of 3000

ES–462GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

FREEZE FRAME DATA

1. DESCRIPTION

(a) The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC

is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle

was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was

lean or rich, as well as other data recorded at the

time of a malfunction.

HINT:

If it is impossible to duplicate the problem even

though a DTC is detected, confirm the freeze frame

data.

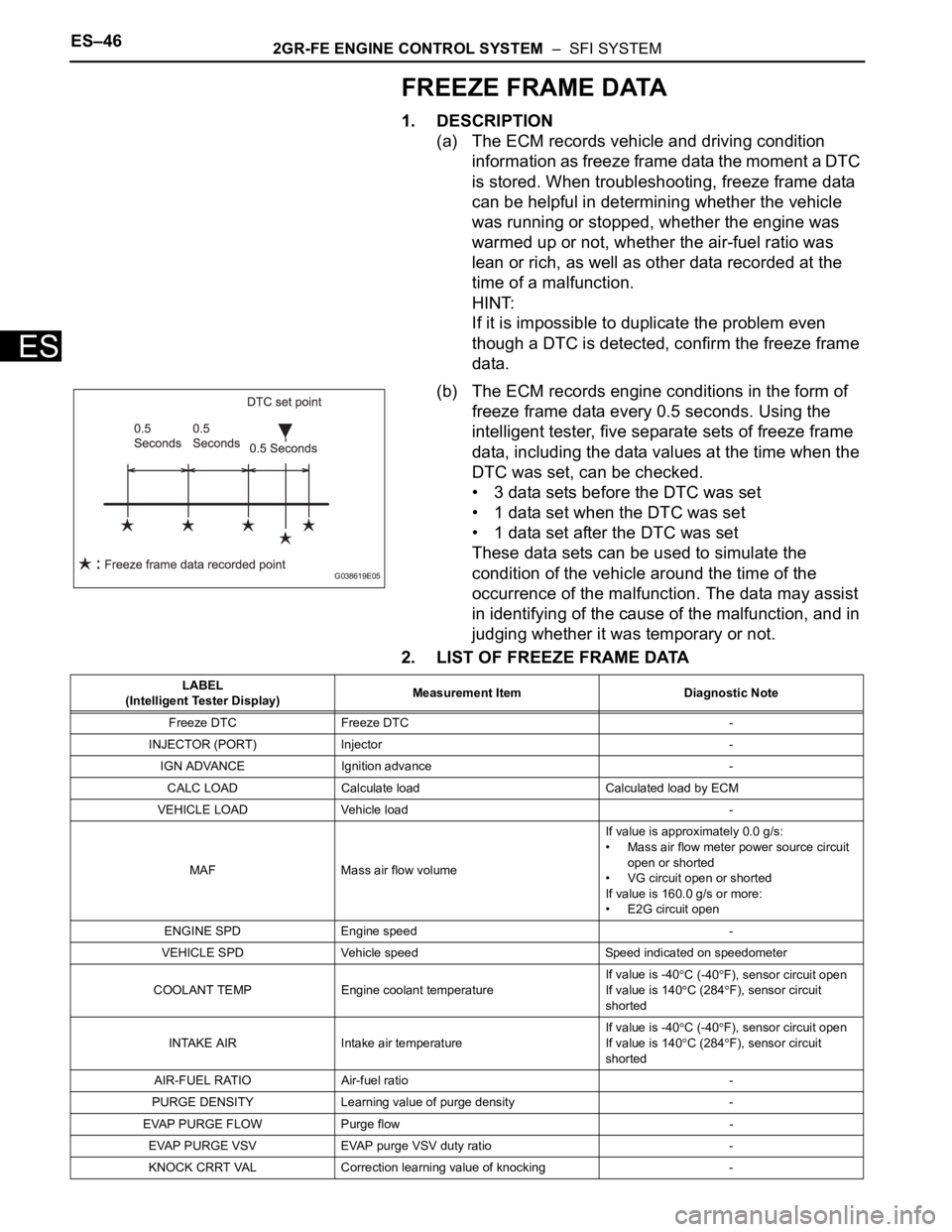

(b) The ECM records engine conditions in the form of

freeze frame data every 0.5 seconds. Using the

intelligent tester, five separate sets of freeze frame

data, including the data values at the time when the

DTC was set, can be checked.

• 3 data sets before the DTC was set

• 1 data set when the DTC was set

• 1 data set after the DTC was set

These data sets can be used to simulate the

condition of the vehicle around the time of the

occurrence of the malfunction. The data may assist

in identifying of the cause of the malfunction, and in

judging whether it was temporary or not.

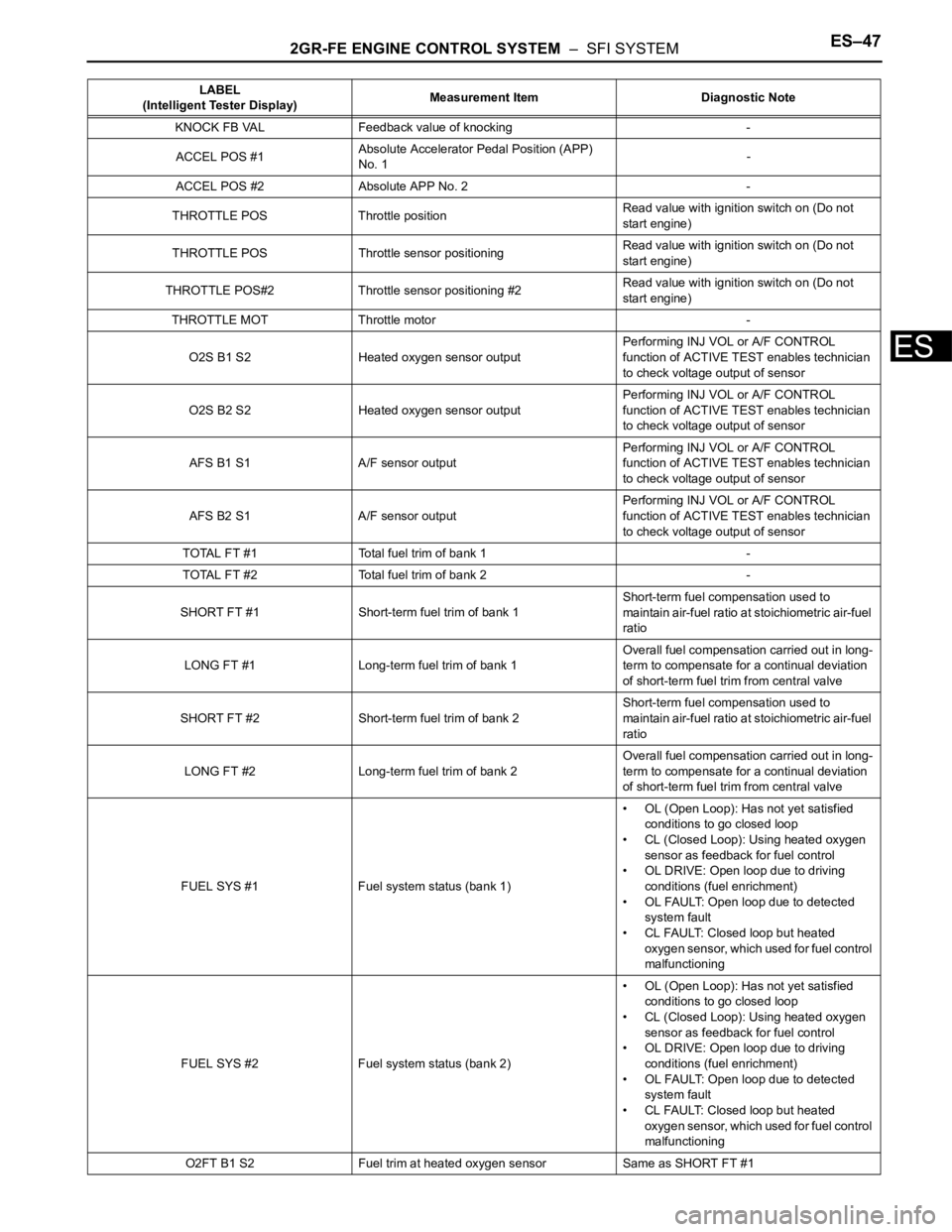

2. LIST OF FREEZE FRAME DATA

G038619E05

LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

Freeze DTC Freeze DTC -

INJECTOR (PORT) Injector -

IGN ADVANCE Ignition advance -

CALC LOAD Calculate load Calculated load by ECM

VEHICLE LOAD Vehicle load -

MAF Mass air flow volumeIf value is approximately 0.0 g/s:

• Mass air flow meter power source circuit

open or shorted

• VG circuit open or shorted

If value is 160.0 g/s or more:

• E2G circuit open

ENGINE SPD Engine speed -

VEHICLE SPD Vehicle speed Speed indicated on speedometer

COOLANT TEMP Engine coolant temperatureIf value is -40

C (-40F), sensor circuit open

If value is 140

C (284F), sensor circuit

shorted

INTAKE AIR Intake air temperatureIf value is -40

C (-40F), sensor circuit open

If value is 140C (284F), sensor circuit

shorted

AIR-FUEL RATIO Air-fuel ratio -

PURGE DENSITY Learning value of purge density -

EVAP PURGE FLOW Purge flow -

EVAP PURGE VSV EVAP purge VSV duty ratio -

KNOCK CRRT VAL Correction learning value of knocking -

Page 831 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–47

ES

KNOCK FB VAL Feedback value of knocking -

ACCEL POS #1Absolute Accelerator Pedal Position (APP)

No. 1-

ACCEL POS #2 Absolute APP No. 2 -

THROTTLE POS Throttle positionRead value with ignition switch on (Do not

start engine)

THROTTLE POS Throttle sensor positioningRead value with ignition switch on (Do not

start engine)

THROTTLE POS#2 Throttle sensor positioning #2Read value with ignition switch on (Do not

start engine)

THROTTLE MOT Throttle motor -

O2S B1 S2 Heated oxygen sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check voltage output of sensor

O2S B2 S2 Heated oxygen sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check voltage output of sensor

AFS B1 S1 A/F sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check voltage output of sensor

AFS B2 S1 A/F sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check voltage output of sensor

TOTAL FT #1 Total fuel trim of bank 1 -

TOTAL FT #2 Total fuel trim of bank 2 -

SHORT FT #1 Short-term fuel trim of bank 1Short-term fuel compensation used to

maintain air-fuel ratio at stoichiometric air-fuel

ratio

LONG FT #1 Long-term fuel trim of bank 1Overall fuel compensation carried out in long-

term to compensate for a continual deviation

of short-term fuel trim from central valve

SHORT FT #2 Short-term fuel trim of bank 2Short-term fuel compensation used to

maintain air-fuel ratio at stoichiometric air-fuel

ratio

LONG FT #2 Long-term fuel trim of bank 2Overall fuel compensation carried out in long-

term to compensate for a continual deviation

of short-term fuel trim from central valve

FUEL SYS #1 Fuel system status (bank 1)• OL (Open Loop): Has not yet satisfied

conditions to go closed loop

• CL (Closed Loop): Using heated oxygen

sensor as feedback for fuel control

• OL DRIVE: Open loop due to driving

conditions (fuel enrichment)

• OL FAULT: Open loop due to detected

system fault

• CL FAULT: Closed loop but heated

oxygen sensor, which used for fuel control

malfunctioning

FUEL SYS #2 Fuel system status (bank 2)• OL (Open Loop): Has not yet satisfied

conditions to go closed loop

• CL (Closed Loop): Using heated oxygen

sensor as feedback for fuel control

• OL DRIVE: Open loop due to driving

conditions (fuel enrichment)

• OL FAULT: Open loop due to detected

system fault

• CL FAULT: Closed loop but heated

oxygen sensor, which used for fuel control

malfunctioning

O2FT B1 S2 Fuel trim at heated oxygen sensor Same as SHORT FT #1LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note