sensor TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 832 of 3000

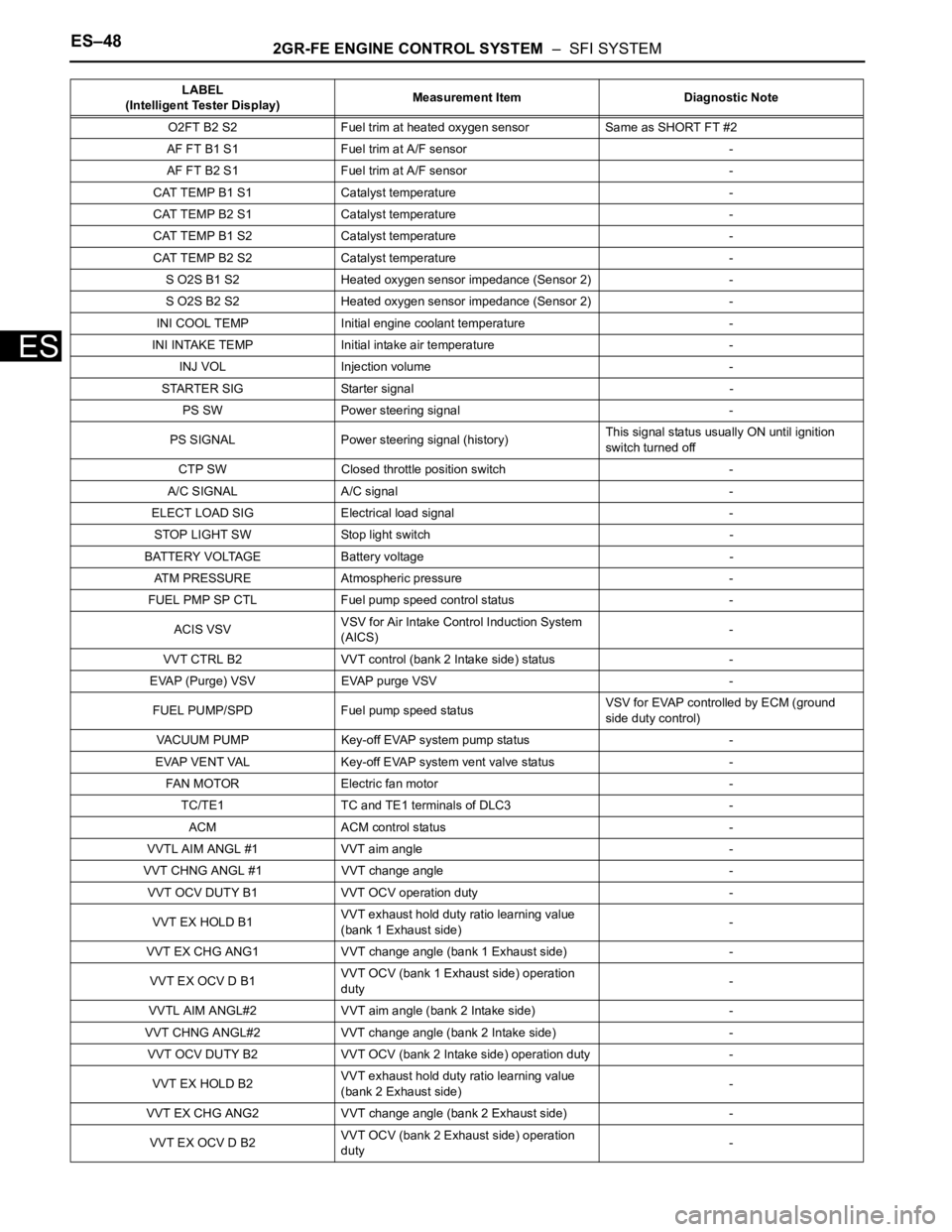

ES–482GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

O2FT B2 S2 Fuel trim at heated oxygen sensor Same as SHORT FT #2

AF FT B1 S1 Fuel trim at A/F sensor -

AF FT B2 S1 Fuel trim at A/F sensor -

CAT TEMP B1 S1 Catalyst temperature -

CAT TEMP B2 S1 Catalyst temperature -

CAT TEMP B1 S2 Catalyst temperature -

CAT TEMP B2 S2 Catalyst temperature -

S O2S B1 S2 Heated oxygen sensor impedance (Sensor 2) -

S O2S B2 S2 Heated oxygen sensor impedance (Sensor 2) -

INI COOL TEMP Initial engine coolant temperature -

INI INTAKE TEMP Initial intake air temperature -

INJ VOL Injection volume -

STARTER SIG Starter signal -

PS SW Power steering signal -

PS SIGNAL Power steering signal (history)This signal status usually ON until ignition

switch turned off

CTP SW Closed throttle position switch -

A/C SIGNAL A/C signal -

ELECT LOAD SIG Electrical load signal -

STOP LIGHT SW Stop light switch -

BATTERY VOLTAGE Battery voltage -

ATM PRESSURE Atmospheric pressure -

FUEL PMP SP CTL Fuel pump speed control status -

ACIS VSVVSV for Air Intake Control Induction System

(AICS)-

VVT CTRL B2 VVT control (bank 2 Intake side) status -

EVAP (Purge) VSV EVAP purge VSV -

FUEL PUMP/SPD Fuel pump speed statusVSV for EVAP controlled by ECM (ground

side duty control)

VACUUM PUMP Key-off EVAP system pump status -

EVAP VENT VAL Key-off EVAP system vent valve status -

FAN MOTOR Electric fan motor -

TC/TE1 TC and TE1 terminals of DLC3 -

ACM ACM control status -

VVTL AIM ANGL #1 VVT aim angle -

VVT CHNG ANGL #1 VVT change angle -

VVT OCV DUTY B1 VVT OCV operation duty -

VVT EX HOLD B1VVT exhaust hold duty ratio learning value

(bank 1 Exhaust side)-

VVT EX CHG ANG1 VVT change angle (bank 1 Exhaust side) -

VVT EX OCV D B1VVT OCV (bank 1 Exhaust side) operation

duty-

VVTL AIM ANGL#2 VVT aim angle (bank 2 Intake side) -

VVT CHNG ANGL#2 VVT change angle (bank 2 Intake side) -

VVT OCV DUTY B2 VVT OCV (bank 2 Intake side) operation duty -

VVT EX HOLD B2VVT exhaust hold duty ratio learning value

(bank 2 Exhaust side)-

VVT EX CHG ANG2 VVT change angle (bank 2 Exhaust side) -

VVT EX OCV D B2VVT OCV (bank 2 Exhaust side) operation

duty- LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

Page 834 of 3000

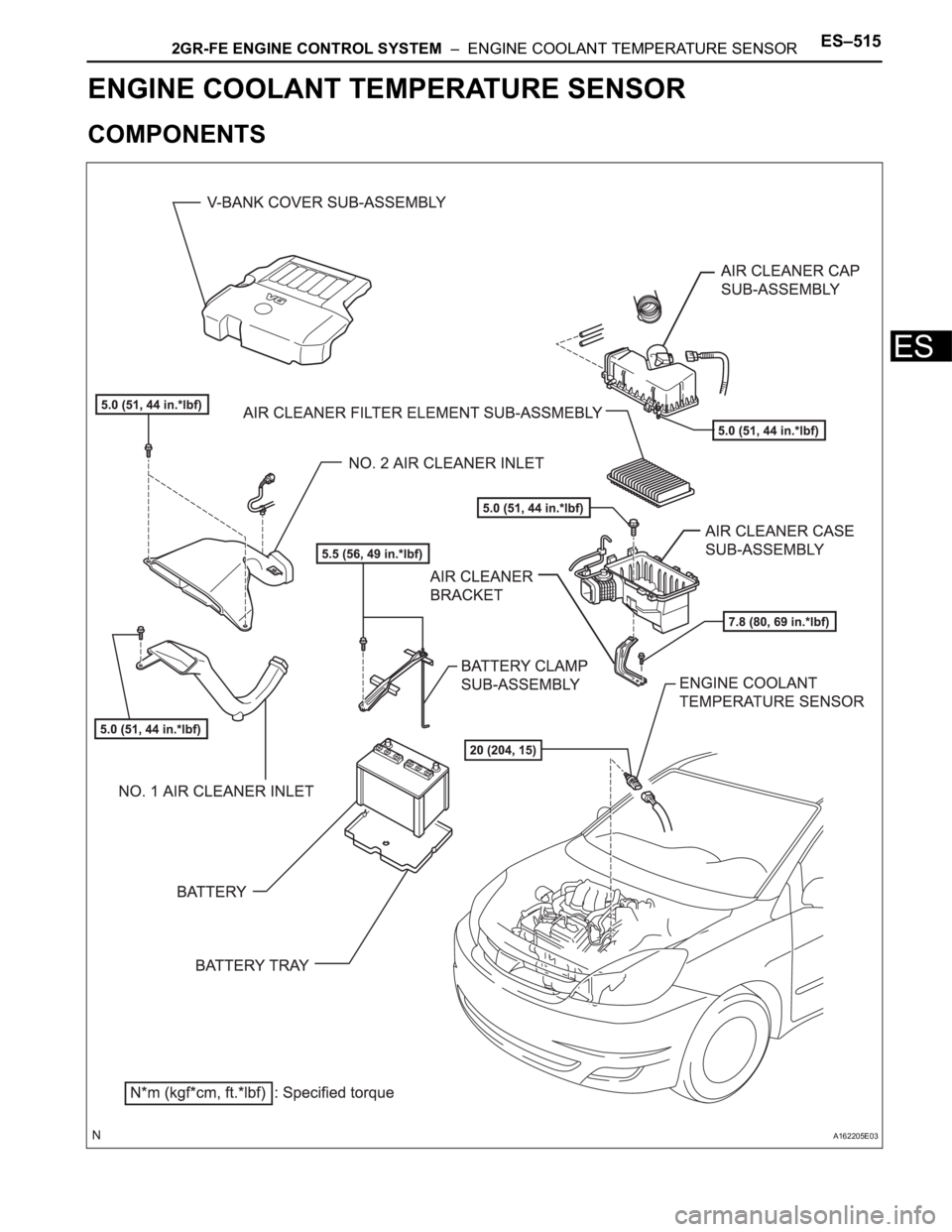

2GR-FE ENGINE CONTROL SYSTEM – ENGINE COOLANT TEMPERATURE SENSORES–515

ES

ENGINE

2GR-FE ENGINE CONTROL SYSTEM

ENGINE COOLANT TEMPERATURE SENSOR

COMPONENTS

A162205E03

Page 835 of 3000

ES–5162GR-FE ENGINE CONTROL SYSTEM – ENGINE COOLANT TEMPERATURE SENSOR

ES

REMOVAL

1. DRAIN ENGINE COOLANT (See page CO-6)

2. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

3. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

4. REMOVE NO. 1 AIR CLEANER INLET (See page EM-

28)

5. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-493)

6. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-28)

7. REMOVE ENGINE COOLANT TEMPERATURE

SENSOR

(a) Remove the engine coolant temperature sensor

connector.

(b) Remove the engine coolant temperature sensor.

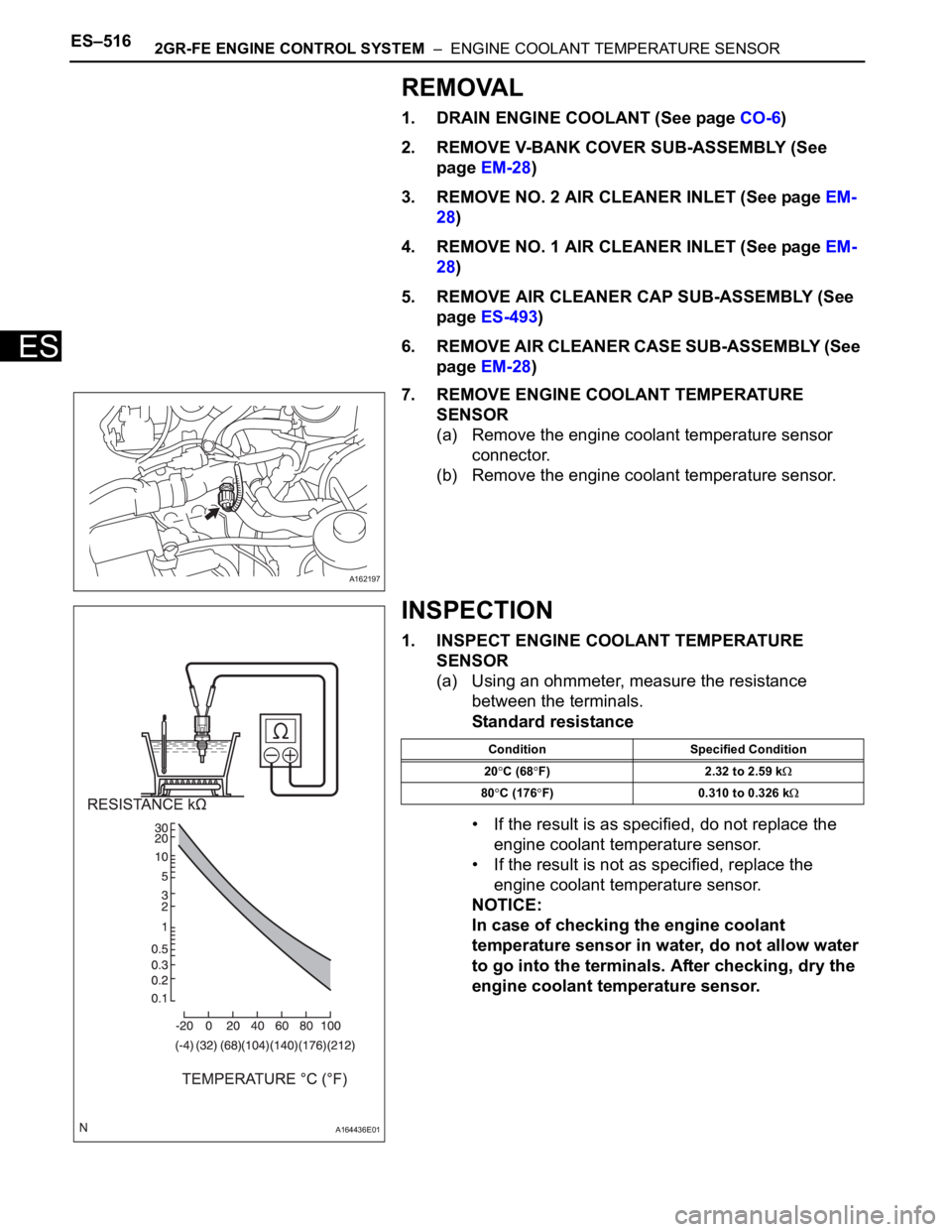

INSPECTION

1. INSPECT ENGINE COOLANT TEMPERATURE

SENSOR

(a) Using an ohmmeter, measure the resistance

between the terminals.

Standard resistance

• If the result is as specified, do not replace the

engine coolant temperature sensor.

• If the result is not as specified, replace the

engine coolant temperature sensor.

NOTICE:

In case of checking the engine coolant

temperature sensor in water, do not allow water

to go into the terminals. After checking, dry the

engine coolant temperature sensor.

A162197

A164436E01

Condition Specified Condition

20

C (68F) 2.32 to 2.59 k

80C (176F) 0.310 to 0.326 k

Page 836 of 3000

2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–521

ES

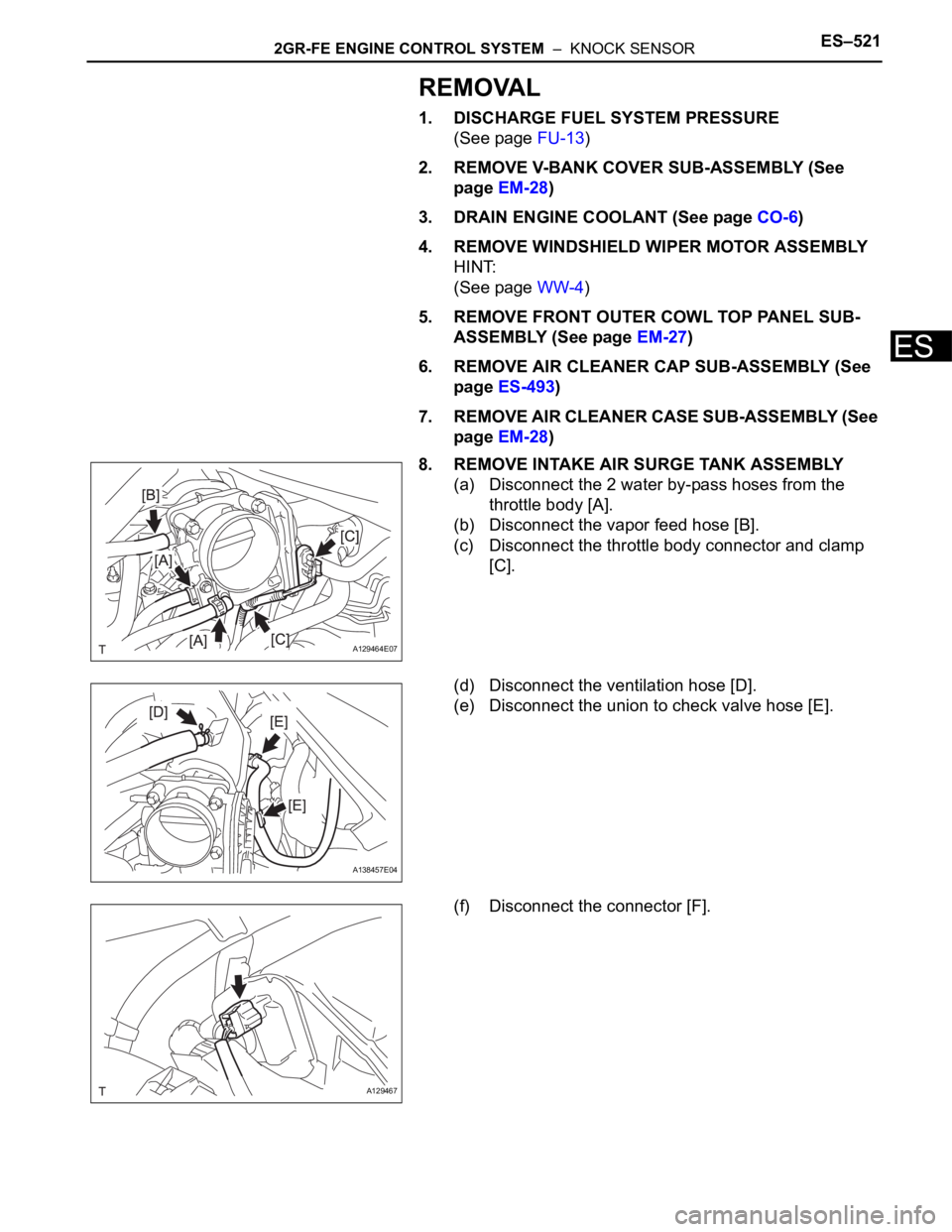

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

(See page FU-13)

2. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

3. DRAIN ENGINE COOLANT (See page CO-6)

4. REMOVE WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-4)

5. REMOVE FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-27)

6. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-493)

7. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-28)

8. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

(a) Disconnect the 2 water by-pass hoses from the

throttle body [A].

(b) Disconnect the vapor feed hose [B].

(c) Disconnect the throttle body connector and clamp

[C].

(d) Disconnect the ventilation hose [D].

(e) Disconnect the union to check valve hose [E].

(f) Disconnect the connector [F].

A129464E07

A138457E04

A129467

Page 837 of 3000

![TOYOTA SIENNA 2007 Service Repair Manual ES–5222GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSOR

ES

(g) Using a 5 mm socket hexagon wrench, remove the

4 bolts [G].

(h) Remove the 2 nuts, 2 bolts and intake air surge tank

[H].

(i) Remove th TOYOTA SIENNA 2007 Service Repair Manual ES–5222GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSOR

ES

(g) Using a 5 mm socket hexagon wrench, remove the

4 bolts [G].

(h) Remove the 2 nuts, 2 bolts and intake air surge tank

[H].

(i) Remove th](/img/14/57466/w960_57466-836.png)

ES–5222GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSOR

ES

(g) Using a 5 mm socket hexagon wrench, remove the

4 bolts [G].

(h) Remove the 2 nuts, 2 bolts and intake air surge tank

[H].

(i) Remove the gasket from the intake air surge tank [I].

9. REMOVE FUEL MAIN TUBE SUB-ASSEMBLY (See

page EM-30)

10. REMOVE INTAKE MANIFOLD (See page EM-39)

11. REMOVE KNOCK CONTROL SENSOR

(a) Disconnect the 2 knock sensor connectors.

(b) Remove the 2 bolts and then remove the 2 knock

control sensors.

INSPECTION

1. KNOCK CONTROL SENSOR

(a) Using an ohmmeter, measure the resistance

between the terminals.

Resistance:

120 to 280 k

at 20C (68F)

If the resistance is not specified, replace the knock

control sensor.

INSTALLATION

1. INSTALL KNOCK CONTROL SENSOR

(a) Install the 2 knock control sensors with the 2 bolts

as shown in the illustration.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf)

(b) Connect the 2 knock control sensor connectors.

2. INSTALL INTAKE MANIFOLD (See page EM-49)

3. INSTALL FUEL MAIN TUBE SUB-ASSEMBLY (See

page EM-56)

4. INSTALL INTAKE AIR SURGE TANK

NOTICE:

DO NOT apply oil to the bolts listed below.

A129468E08

A129615

A065174

A132951E01

Tightening PartsTo r q u e

N*m (kgf*cm, ft.*lbf)QTY

Surge Tank and Intake Manifold 18 (184, 13) 4

No. 1 Surge Tank Stay and Surge Tank 21 (214, 15) 1

Throttle Body Bracket and Surge Tank 21 (214, 15) 1

Page 838 of 3000

![TOYOTA SIENNA 2007 Service Repair Manual 2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–523

ES

(a) Install a new gasket to the intake air surge tank [A].

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts [B].

Torque: 18 N*m ( TOYOTA SIENNA 2007 Service Repair Manual 2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–523

ES

(a) Install a new gasket to the intake air surge tank [A].

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts [B].

Torque: 18 N*m (](/img/14/57466/w960_57466-837.png)

2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–523

ES

(a) Install a new gasket to the intake air surge tank [A].

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts [B].

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

(c) Install the intake air surge tank with the 2 nuts and 2

bolts [C].

Torque: Nut

16 N*m (163 kgf*cm, 12 ft.*lbf)

Bolt

21 N*m (214 kgf*cm, 15 ft.*lbf)

(d) Connect the connector [D].

(e) Connect the union to check valve hose [E].

(f) Connect the ventilation hose No. 2 [F].

(g) Install the clamp and connect the throttle with motor

body assembly connector [G].

(h) Connect the vapor feed hose [H].

(i) Connect the 2 water by-pass hoses to the throttle

with motor body assembly [I].

5. INSTALL AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-59)

6. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-496)

7. ADD ENGINE COOLANT (See page CO-7)

8. INSPECT FOR ENGINE COOLANT LEAK (See page

CO-1)

9. INSPECT FOR FUEL LEAK (See page FU-7)

10. INSTALL FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-61)

11. INSTALL WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-5)

A129468E09

A129467

A138457E05

A129464E08

Page 839 of 3000

ES–5242GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSOR

ES

12. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-63)

Page 850 of 3000

MULTIPLEX COMMUNICATION – MULTIPLEX COMMUNICATION SYSTEMMP–7

MP

(b) Measure the voltage between the specified

terminals on the wire harness side connector.

If the result is not as specified, there may be a

malfunction on the wire harness side.

(c) Measure the resistance between the specified

terminals on the wire harness side connector.

If the result is not as specified, there may be a

malfunction on the wire harness side.

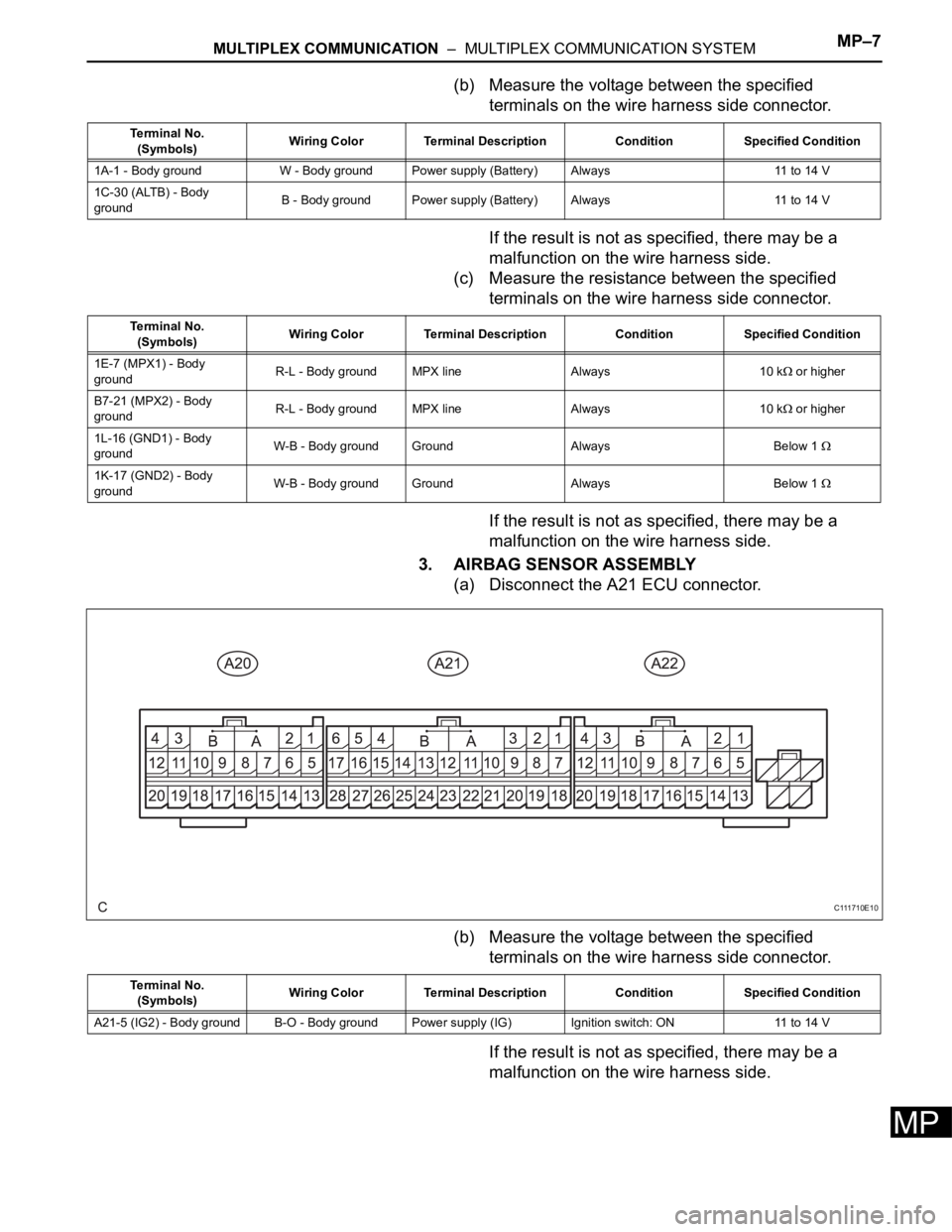

3. AIRBAG SENSOR ASSEMBLY

(a) Disconnect the A21 ECU connector.

(b) Measure the voltage between the specified

terminals on the wire harness side connector.

If the result is not as specified, there may be a

malfunction on the wire harness side.

Terminal No.

(Symbols)Wiring Color Terminal Description Condition Specified Condition

1A-1 - Body ground W - Body ground Power supply (Battery) Always 11 to 14 V

1C-30 (ALTB) - Body

groundB - Body ground Power supply (Battery) Always 11 to 14 V

Terminal No.

(Symbols)Wiring Color Terminal Description Condition Specified Condition

1E-7 (MPX1) - Body

groundR-L - Body ground MPX line Always 10 k

or higher

B7-21 (MPX2) - Body

groundR-L - Body ground MPX line Always 10 k

or higher

1L-16 (GND1) - Body

groundW-B - Body ground Ground Always Below 1

1K-17 (GND2) - Body

groundW-B - Body ground Ground Always Below 1

C111710E10

Terminal No.

(Symbols)Wiring Color Terminal Description Condition Specified Condition

A21-5 (IG2) - Body ground B-O - Body ground Power supply (IG) Ignition switch: ON 11 to 14 V

Page 860 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–43

EM

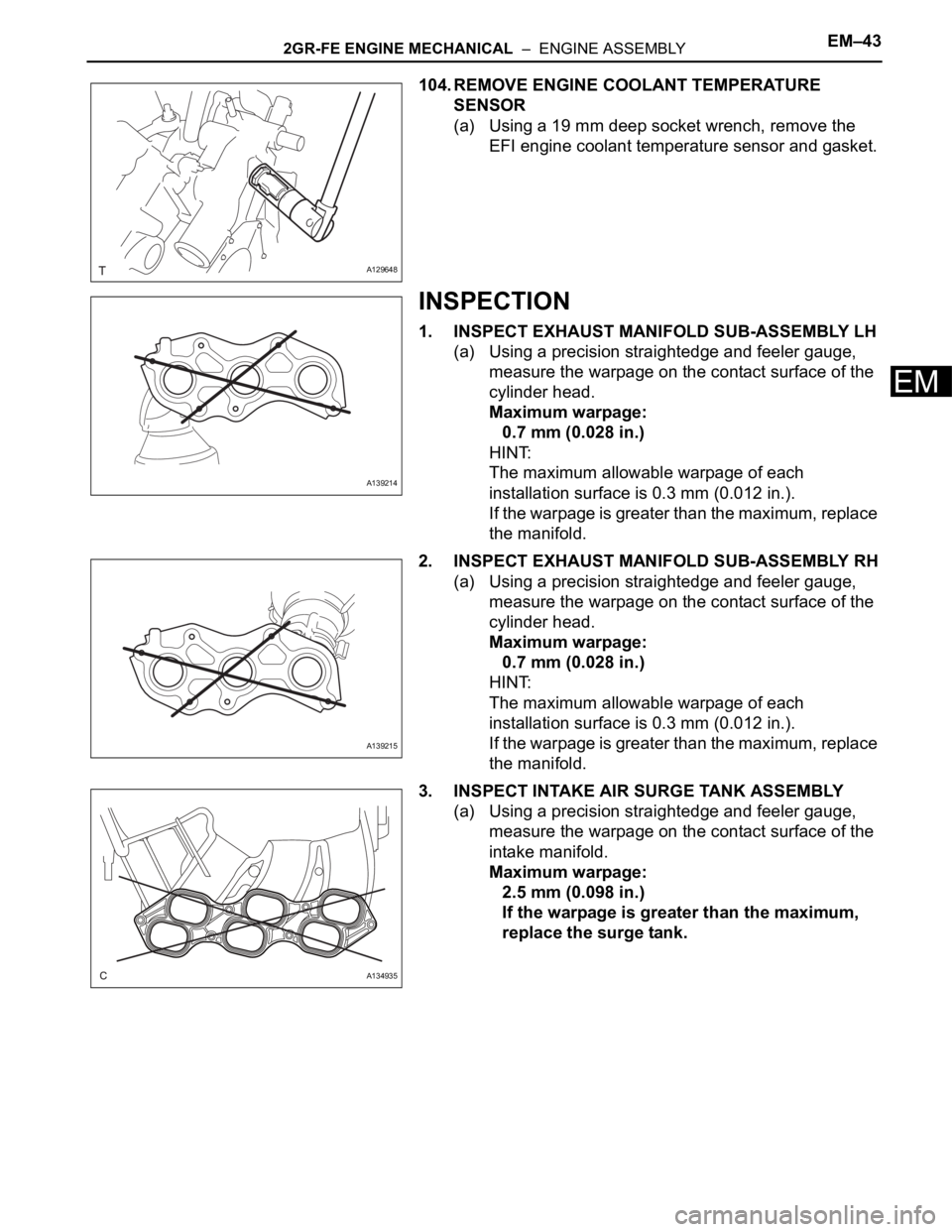

104. REMOVE ENGINE COOLANT TEMPERATURE

SENSOR

(a) Using a 19 mm deep socket wrench, remove the

EFI engine coolant temperature sensor and gasket.

INSPECTION

1. INSPECT EXHAUST MANIFOLD SUB-ASSEMBLY LH

(a) Using a precision straightedge and feeler gauge,

measure the warpage on the contact surface of the

cylinder head.

Maximum warpage:

0.7 mm (0.028 in.)

HINT:

The maximum allowable warpage of each

installation surface is 0.3 mm (0.012 in.).

If the warpage is greater than the maximum, replace

the manifold.

2. INSPECT EXHAUST MANIFOLD SUB-ASSEMBLY RH

(a) Using a precision straightedge and feeler gauge,

measure the warpage on the contact surface of the

cylinder head.

Maximum warpage:

0.7 mm (0.028 in.)

HINT:

The maximum allowable warpage of each

installation surface is 0.3 mm (0.012 in.).

If the warpage is greater than the maximum, replace

the manifold.

3. INSPECT INTAKE AIR SURGE TANK ASSEMBLY

(a) Using a precision straightedge and feeler gauge,

measure the warpage on the contact surface of the

intake manifold.

Maximum warpage:

2.5 mm (0.098 in.)

If the warpage is greater than the maximum,

replace the surge tank.

A129648

A139214

A139215

A134935

Page 861 of 3000

EM–442GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

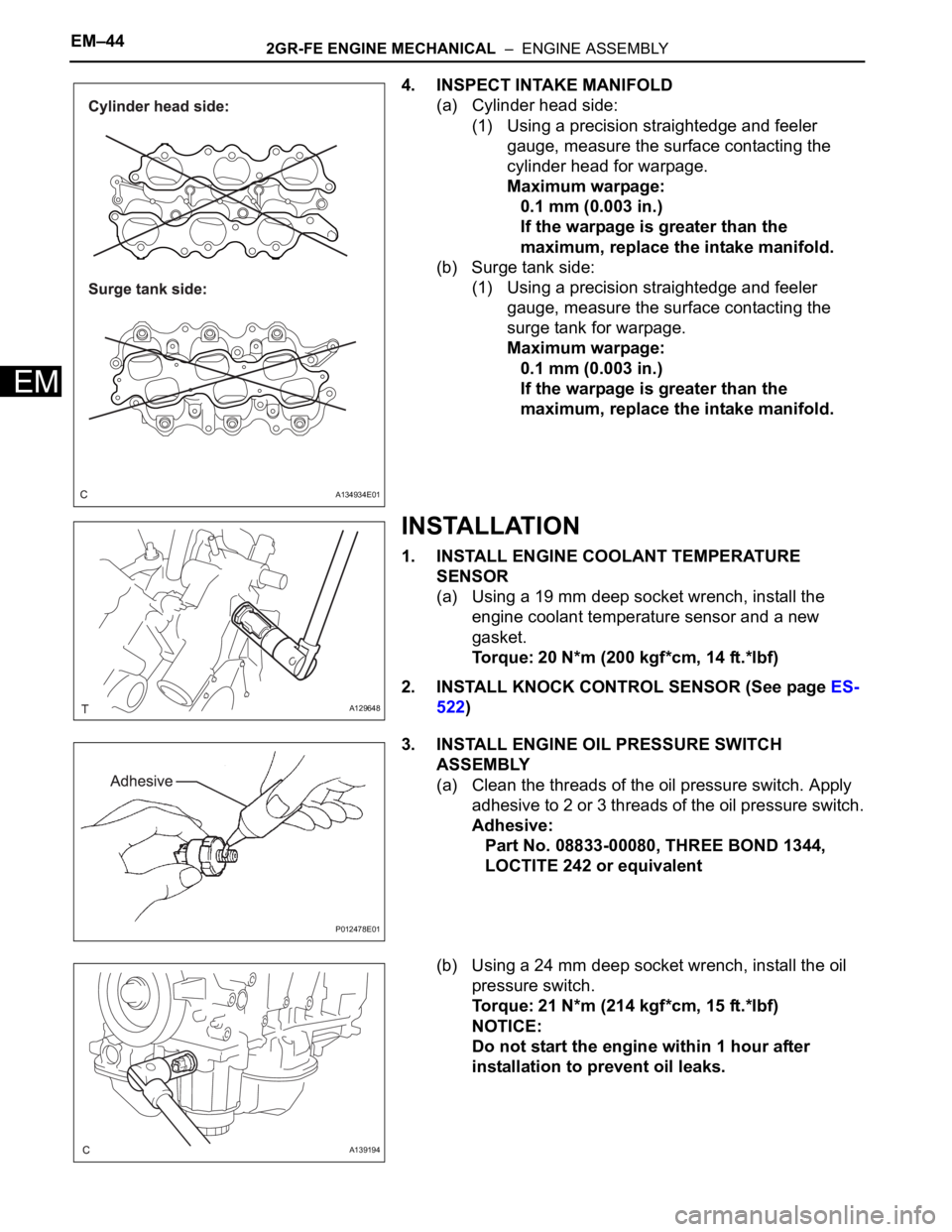

4. INSPECT INTAKE MANIFOLD

(a) Cylinder head side:

(1) Using a precision straightedge and feeler

gauge, measure the surface contacting the

cylinder head for warpage.

Maximum warpage:

0.1 mm (0.003 in.)

If the warpage is greater than the

maximum, replace the intake manifold.

(b) Surge tank side:

(1) Using a precision straightedge and feeler

gauge, measure the surface contacting the

surge tank for warpage.

Maximum warpage:

0.1 mm (0.003 in.)

If the warpage is greater than the

maximum, replace the intake manifold.

INSTALLATION

1. INSTALL ENGINE COOLANT TEMPERATURE

SENSOR

(a) Using a 19 mm deep socket wrench, install the

engine coolant temperature sensor and a new

gasket.

Torque: 20 N*m (200 kgf*cm, 14 ft.*lbf)

2. INSTALL KNOCK CONTROL SENSOR (See page ES-

522)

3. INSTALL ENGINE OIL PRESSURE SWITCH

ASSEMBLY

(a) Clean the threads of the oil pressure switch. Apply

adhesive to 2 or 3 threads of the oil pressure switch.

Adhesive:

Part No. 08833-00080, THREE BOND 1344,

LOCTITE 242 or equivalent

(b) Using a 24 mm deep socket wrench, install the oil

pressure switch.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

NOTICE:

Do not start the engine within 1 hour after

installation to prevent oil leaks.

A134934E01

A129648

P012478E01

A139194