sensor TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1473 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–107

AX

DESCRIPTION

Shifting from 1st to 5th is performed in combination with "ON" and "OFF" operation of the shift solenoid

valves SL1, SL2, SL3, S4 and SR which are controlled by the ECM. If an open or short circuit occurs in

either of the shift solenoid valves, the ECM controls the remaining normal shift solenoid valves to allow

the vehicle to be operated smoothly (Fail safe function).

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". When there is an open or

short circuit in any shift solenoid valve circuit, the ECM detects the problem and illuminates the MIL and

stores the DTC. And the ECM performs the fail-safe function and turns the other normal shift solenoid

valves "ON/OFF" (In case of an open or short circuit, the ECM stops sending current to the circuit.)

(See page AX-30).

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

COMPONENT OPERATING RANGE

DTC P0798Pressure Control Solenoid "C" Electrical (Shift

Solenoid Valve SL3)

DTC No. DTC Detection Condition Trouble Area

P0798The ECM checks for an open or short in the shift

solenoid valve SL3 circuit while driving and shifting

gears.

(1-trip detection logic)

– Output signal duty equals to 100 %.

(NOTE: SL3 output signal duty is less than 100 %

under normal condition.)• Open or short in shift solenoid valve SL3 circuit

• Shift solenoid valve SL3

•ECM

Related DTCs P0798: Shift solenoid valve SL3/Range check

Required sensors/Components Shift solenoid valve SL3

Frequency of operation Continuous

Duration 1 sec.

MIL operation Immediate

Sequence of operation None

The monitor will run whenever this DTC is not present. None

Battery voltage10 V or more

Ignition switchON

Sta r t e rOFF

Output signal duty100%

Output signal dutyLess than 100%

Page 1477 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–111

AX

DESCRIPTION

Shifting from 1st to 5th is performed in combination with "ON" and "OFF" operation of the shift solenoid

valves SL1, SL2, SL3, S4 and SR which are controlled by the ECM. If an open or short circuit occurs in

either of the shift solenoid valves, the ECM controls the remaining normal shift solenoid valves to allow

the vehicle to be operated smoothly (Fail safe function).

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". When there is an open or

short circuit in any shift solenoid valve circuit, the ECM detects the problem and illuminates the MIL and

stores the DTC. And the ECM performs the fail-safe function and turns the other normal shift solenoid

valves "ON/OFF" (In case of an open or short circuit, the ECM stops sending current to the circuit.)

(See page AX-30).

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

P0982: Range check (Low resistance):

P0983: Range check (High resistance):

DTC P0982Shift Solenoid "D" Control Circuit Low (Shift

Solenoid Valve S4)

DTC P0983Shift Solenoid "D" Control Circuit High (Shift

Solenoid Valve S4)

DTC No. DTC Detection Condition Trouble Area

P0982ECM detects short in solenoid valve S4 circuit 2 times

when solenoid valve S4 is operated (1-trip detection

logic)• Short in shift solenoid valve S4 circuit

• Shift solenoid valve S4

•ECM

P0983ECM detects open in solenoid valve S4 circuit 2 times

when solenoid valve S4 is not operated (1-trip detection

logic)• Open in shift solenoid valve S4 circuit

• Shift solenoid valve S4

•ECM

Related DTCsP0982: Shift solenoid valve S4/Range check (Low resistance)

P0983: Shift solenoid valve S4/Range check (High resistance)

Required sensors/Components Shift solenoid valve S4

Frequency of operation Continuous

Duration 0.064 sec.

MIL operation Immediate

Sequence of operation None

The monitor will run whenever this DTC is not present. None

Shift solenoid valve S4ON

Battery voltage8 V or more

Ignition switchON

Sta r t e rOFF

The monitor will run whenever this DTC is not present. None

Shift solenoid valve S4OFF

Battery voltage8 V or more

Ignition switchON

Sta r t e rOFF

Page 1480 of 3000

AX–114U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

DESCRIPTION

Shifting from 1st to 5th is performed in combination with "ON" and "OFF" operation of the shift solenoid

valves SL1, SL2, SL3, S4 and SR which are controlled by the ECM. If an open or short circuit occurs in

either of the shift solenoid valves, the ECM controls the remaining normal shift solenoid valves to allow

the vehicle to be operated smoothly (Fail safe function).

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". When there is an open or

short circuit in any shift solenoid valve circuit, the ECM detects the problem and illuminates the MIL and

stores the DTC. And the ECM performs the fail-safe function and turns the other normal shift solenoid

valves "ON/OFF" (In case of an open or short circuit, the ECM stops sending current to the circuit.)

(See page AX-30).

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

P0985: Range check (Low resistance):

P0986: Range check (High resistance):

DTC P0985Shift Solenoid "E" Control Circuit Low (Shift

Solenoid Valve SR)

DTC P0986Shift Solenoid "E" Control Circuit High (Shift

Solenoid Valve SR)

DTC No. DTC Detection Condition Trouble Area

P0985ECM detects short in solenoid valve SR circuit 2 times

when solenoid valve SR is operated (1-trip detection

logic)• Short in shift solenoid valve SR circuit

• Shift solenoid valve SR

•ECM

P0986ECM detects open in solenoid valve SR circuit 2 times

when solenoid valve SR is not operated (1-trip

detection logic)• Open in shift solenoid valve SR circuit

• Shift solenoid valve SR

•ECM

Related DTCsP0985: Shift solenoid valve SR/Range check (Low resistance)

P0986: Shift solenoid valve SR/Range check (High resistance)

Required sensors/Components Shift solenoid valve SR

Frequency of operation Continuous

Duration 0.064 sec.

MIL operation Immediate

Sequence of operation None

The monitor will run whenever this DTC is not present. None

Shift solenoid valve SRON

Battery voltage8 V or more

Ignition switchON

StarterOFF

The monitor will run whenever this DTC is not present. None

Shift solenoid valve SROFF

Battery voltage8 V or more

Ignition switchON

StarterOFF

Page 1483 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–117

AX

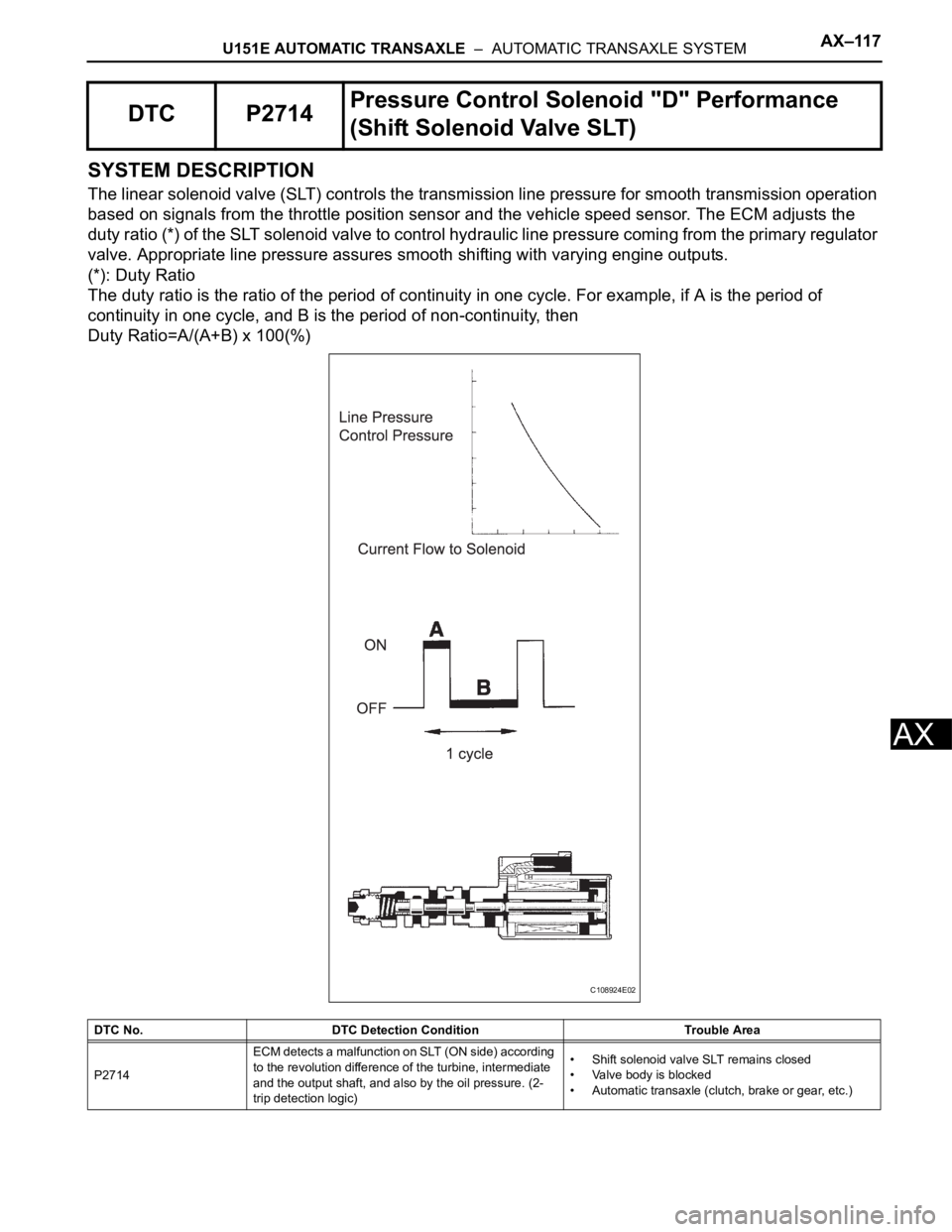

SYSTEM DESCRIPTION

The linear solenoid valve (SLT) controls the transmission line pressure for smooth transmission operation

based on signals from the throttle position sensor and the vehicle speed sensor. The ECM adjusts the

duty ratio (*) of the SLT solenoid valve to control hydraulic line pressure coming from the primary regulator

valve. Appropriate line pressure assures smooth shifting with varying engine outputs.

(*): Duty Ratio

The duty ratio is the ratio of the period of continuity in one cycle. For example, if A is the period of

continuity in one cycle, and B is the period of non-continuity, then

Duty Ratio=A/(A+B) x 100(%)

DTC P2714Pressure Control Solenoid "D" Performance

(Shift Solenoid Valve SLT)

DTC No. DTC Detection Condition Trouble Area

P2714ECM detects a malfunction on SLT (ON side) according

to the revolution difference of the turbine, intermediate

and the output shaft, and also by the oil pressure. (2-

trip detection logic)• Shift solenoid valve SLT remains closed

• Valve body is blocked

• Automatic transaxle (clutch, brake or gear, etc.)

C108924E02

Page 1484 of 3000

AX–118U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

MONITOR DESCRIPTION

In any forward position, when the difference between the revolutions of the turbine, Intermediate and

output shaft exceeds the specified value (varies with Intermediate, output speed) determined by the ECM,

the ECM illuminates the MIL and store the DTC.

When shift solenoid valve SLT remains on, the oil pressure goes down and the clutch engagement force

decreases.

NOTICE:

If you continue driving under these conditions, the clutch will burn out and the vehicle will no

longer be drivable.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

ON malfunction:

ON malfunction (A):

Related DTCs P2714: Shift solenoid valve SLT/ON malfunction

Required sensors/ComponentsShift solenoid valve SLT, Speed sensor (NT), Speed sensor (NC),

Crankshaft position sensor (NE)

Frequency of operation Continuous

Duration 0.5 sec.

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present. None

Transmission range"D"

TFT (Transmission fluid temperature) -20

C (-4F) or more

TFT sensor circuitNot circuit malfunction

Turbine speed sensor circuit Not circuit malfunction

Intermediate shaft speed sensor circuit Not circuit malfunction

Output speed sensor circuitNot circuit malfunction

Shift solenoid valve SL1 circuit Not circuit malfunction

Shift solenoid valve SL2 circuit Not circuit malfunction

Shift solenoid valve SL3 circuit Not circuit malfunction

Shift solenoid valve S4 circuit Not circuit malfunction

Shift solenoid valve SR circuit Not circuit malfunction

Shift solenoid valve DSL circuit Not circuit malfunction

Shift solenoid valve SLT circuit Not circuit malfunction

Electronic throttle systemNot circuit malfunction

ECM selected gear 1st

Temporary MAIN gear 1st or 2nd or 3rd or 4th

NT - NC x Temporary MAIN gear ratio

NT: Input (turbine) speed

NC: Intermediate shaft speed100 rpm or more at Intermediate shaft speed 1,000 rpm

Temporary U/D gear Low

NC - NO x Temporary U/D gear ratio

NO: Output speed300 rpm or more at Output speed 1,000 rpm

TT

TT: Turbine Torque900 Nm or more

NT 250 rpm or more

NC 250 rpm or more

NO 250 rpm or more

Page 1489 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–123

AX

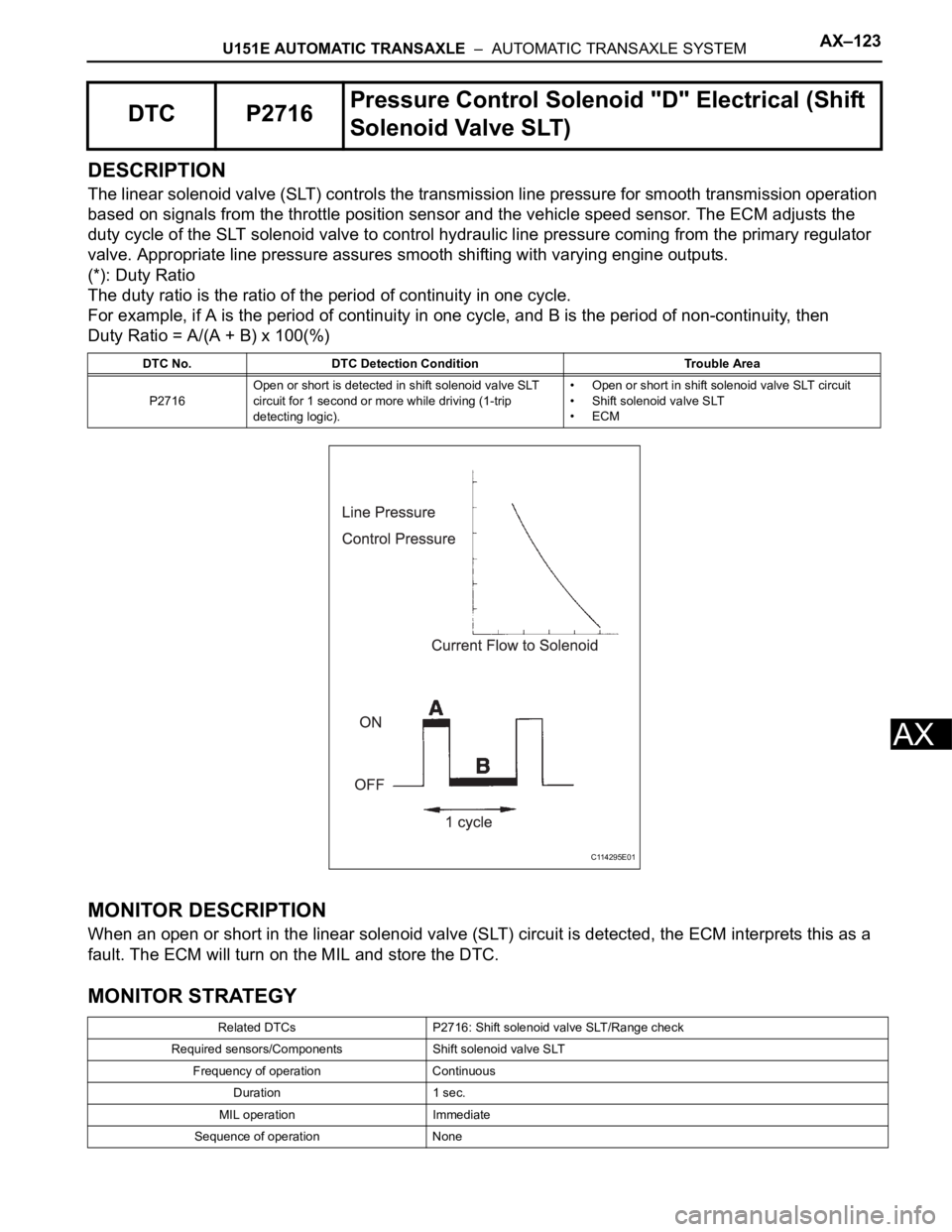

DESCRIPTION

The linear solenoid valve (SLT) controls the transmission line pressure for smooth transmission operation

based on signals from the throttle position sensor and the vehicle speed sensor. The ECM adjusts the

duty cycle of the SLT solenoid valve to control hydraulic line pressure coming from the primary regulator

valve. Appropriate line pressure assures smooth shifting with varying engine outputs.

(*): Duty Ratio

The duty ratio is the ratio of the period of continuity in one cycle.

For example, if A is the period of continuity in one cycle, and B is the period of non-continuity, then

Duty Ratio = A/(A + B) x 100(%)

MONITOR DESCRIPTION

When an open or short in the linear solenoid valve (SLT) circuit is detected, the ECM interprets this as a

fault. The ECM will turn on the MIL and store the DTC.

MONITOR STRATEGY

DTC P2716Pressure Control Solenoid "D" Electrical (Shift

Solenoid Valve SLT)

DTC No. DTC Detection Condition Trouble Area

P2716Open or short is detected in shift solenoid valve SLT

circuit for 1 second or more while driving (1-trip

detecting logic).• Open or short in shift solenoid valve SLT circuit

• Shift solenoid valve SLT

•ECM

Related DTCs P2716: Shift solenoid valve SLT/Range check

Required sensors/Components Shift solenoid valve SLT

Frequency of operation Continuous

Duration 1 sec.

MIL operation Immediate

Sequence of operation None

C114295E01

Page 1493 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–127

AX

DESCRIPTION

The shift solenoid valve DSL is turned "ON" and "OFF" by signals from the ECM in order to control the

hydraulic pressure operation, the lock-up relay valve, which then controls operation of the lock-up clutch.

MONITOR DESCRIPTION

Torque converter lock-up is controlled by the ECM based on engine rpm, engine load, engine

temperature, vehicle speed, transmission temperature, and shift range selection. The ECM determines

the lock-up status of the torque converter by comparing the engine rpm (NE) to the input turbine rpm (NT).

The ECM calculates the actual transmission gear by comparing input turbine rpm (NT) to counter gear

rpm (NC). When conditions are appropriate, the ECM requests "lock-up" by applying control voltage to the

shift solenoid DSL. When the DSL is opened, it applies pressure to the lock-up relay valve and locks the

torque converter clutch. If the ECM detects an open or short in the DSL solenoid circuit, the ECM

interprets this as a fault in the DSL solenoid or circuit. The ECM will turn on the MIL and store the DTC.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

P2769: Range check (Low resistance):

P2770: Range check (High resistance):

DTC P2769Torque Converter Clutch Solenoid Circuit Low

(Shift Solenoid Valve DSL)

DTC P2770Torque Converter Clutch Solenoid Circuit High

(Shift Solenoid Valve DSL)

DTC No. DTC Detection Condition Trouble Area

P2769ECM detects short in solenoid valve DSL circuit (0.1

sec.) when solenoid valve DSL is operated (2-trip

detection logic)• Short in shift solenoid valve DSL circuit

• Shift solenoid valve DSL

•ECM

P2770ECM detects open in solenoid valve DSL circuit (0.1

sec.) when solenoid valve DSL is not operated (2-trip

detection logic)• Open in shift solenoid valve DSL circuit

• Shift solenoid valve DSL

•ECM

Related DTCsP2769: Shift solenoid valve DSL/Range check (Low resistance)

P2770: Shift solenoid valve DSL/Range check (High resistance)

Required sensors/Components Shift solenoid valve DSL

Frequency of operation Continuous

Duration 0.064 sec. or more

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present. None

Shift solenoid valve DSLON

Solenoid current cut status Not cut

Battery voltage8 V or more

Ignition switchON

Sta r t e rOFF

The monitor will run whenever this DTC is not present. None

Shift solenoid valve DSLON

Battery voltage8 V or more

Ignition switchON

Page 1514 of 3000

U151E AUTOMATIC TRANSAXLE – TRANSMISSION WIREAX–131

AX

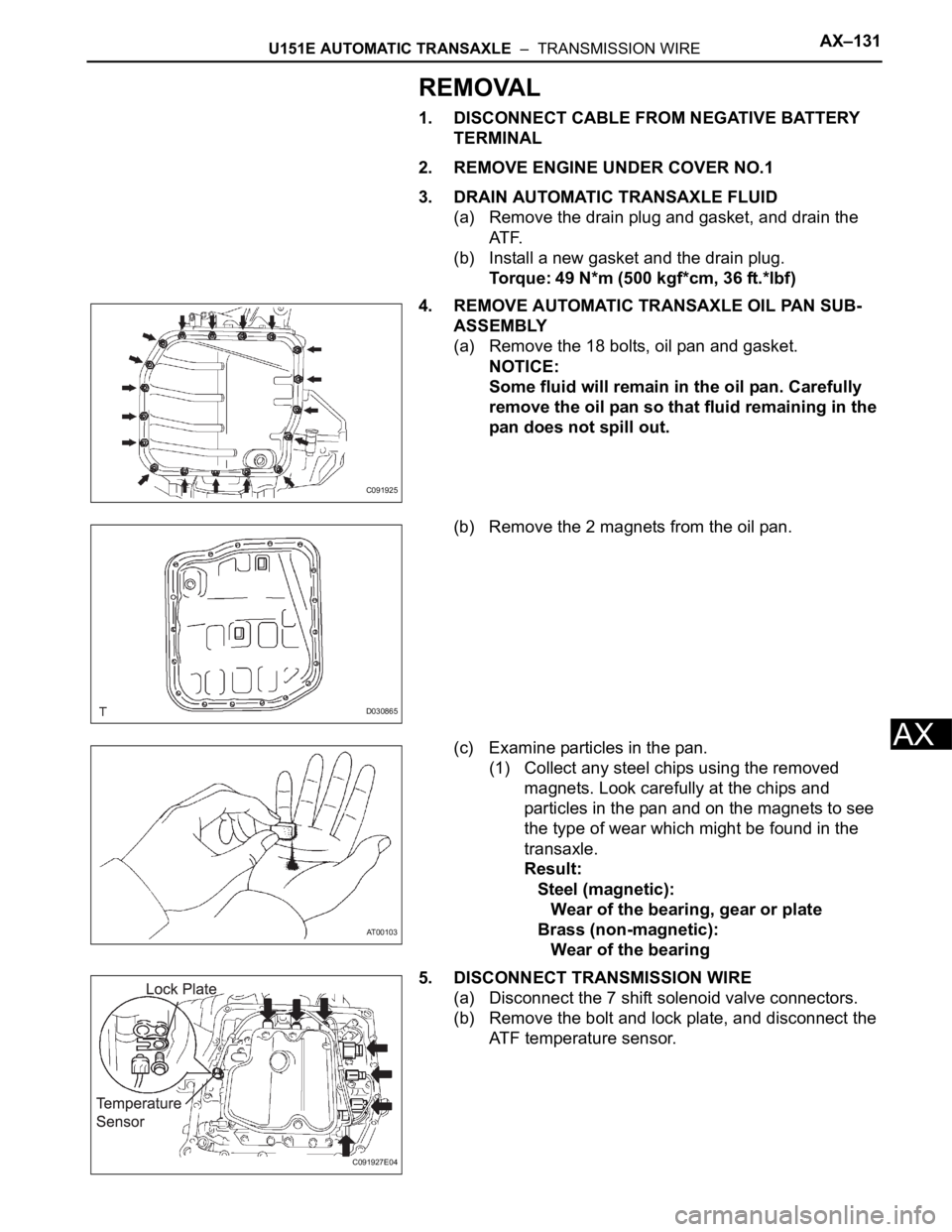

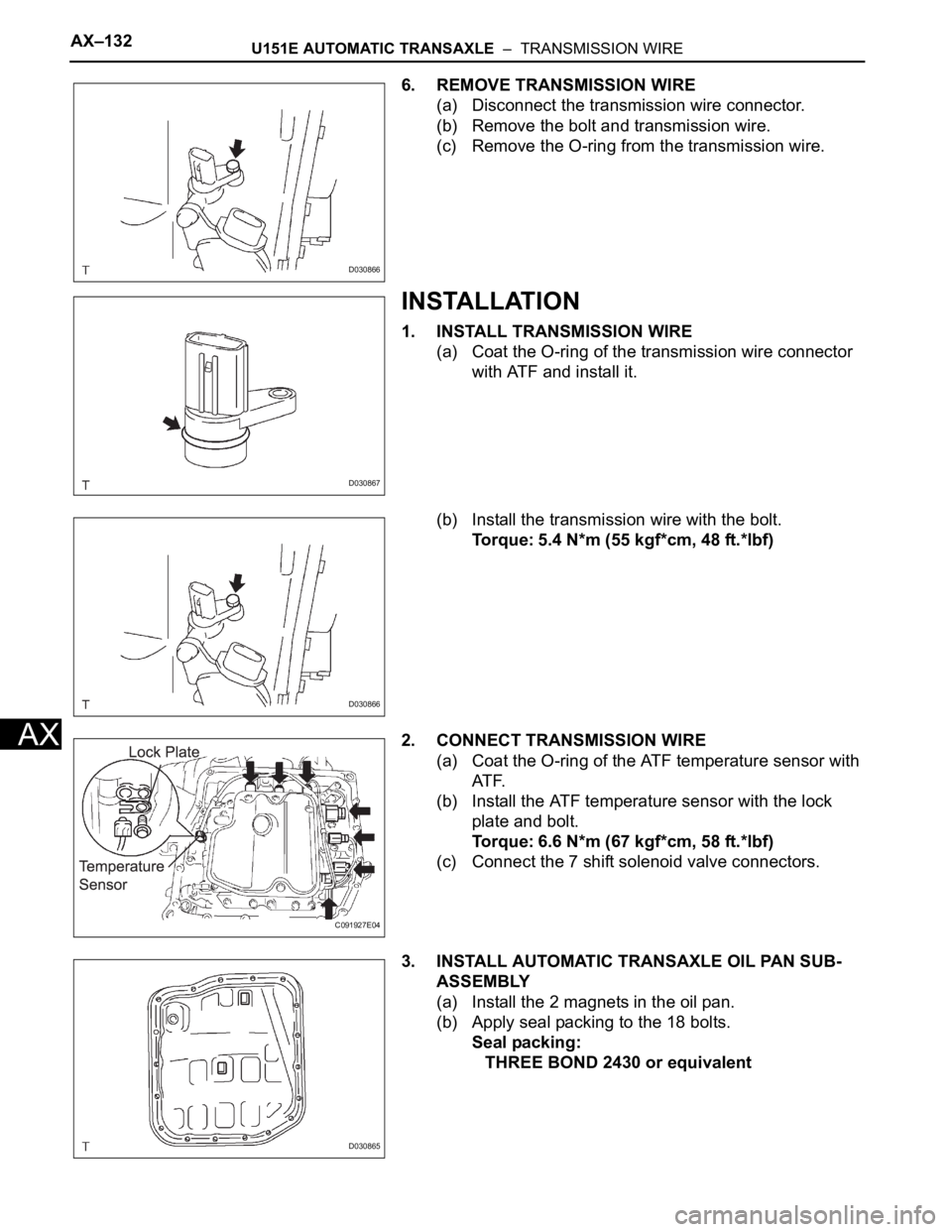

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

2. REMOVE ENGINE UNDER COVER NO.1

3. DRAIN AUTOMATIC TRANSAXLE FLUID

(a) Remove the drain plug and gasket, and drain the

AT F.

(b) Install a new gasket and the drain plug.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

4. REMOVE AUTOMATIC TRANSAXLE OIL PAN SUB-

ASSEMBLY

(a) Remove the 18 bolts, oil pan and gasket.

NOTICE:

Some fluid will remain in the oil pan. Carefully

remove the oil pan so that fluid remaining in the

pan does not spill out.

(b) Remove the 2 magnets from the oil pan.

(c) Examine particles in the pan.

(1) Collect any steel chips using the removed

magnets. Look carefully at the chips and

particles in the pan and on the magnets to see

the type of wear which might be found in the

transaxle.

Result:

Steel (magnetic):

Wear of the bearing, gear or plate

Brass (non-magnetic):

Wear of the bearing

5. DISCONNECT TRANSMISSION WIRE

(a) Disconnect the 7 shift solenoid valve connectors.

(b) Remove the bolt and lock plate, and disconnect the

ATF temperature sensor.

C091925

D030865

AT00103

C091927E04

Page 1515 of 3000

AX–132U151E AUTOMATIC TRANSAXLE – TRANSMISSION WIRE

AX

6. REMOVE TRANSMISSION WIRE

(a) Disconnect the transmission wire connector.

(b) Remove the bolt and transmission wire.

(c) Remove the O-ring from the transmission wire.

INSTALLATION

1. INSTALL TRANSMISSION WIRE

(a) Coat the O-ring of the transmission wire connector

with ATF and install it.

(b) Install the transmission wire with the bolt.

Torque: 5.4 N*m (55 kgf*cm, 48 ft.*lbf)

2. CONNECT TRANSMISSION WIRE

(a) Coat the O-ring of the ATF temperature sensor with

AT F.

(b) Install the ATF temperature sensor with the lock

plate and bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 ft.*lbf)

(c) Connect the 7 shift solenoid valve connectors.

3. INSTALL AUTOMATIC TRANSAXLE OIL PAN SUB-

ASSEMBLY

(a) Install the 2 magnets in the oil pan.

(b) Apply seal packing to the 18 bolts.

Seal packing:

THREE BOND 2430 or equivalent

D030866

D030867

D030866

C091927E04

D030865

Page 1518 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–21

AX

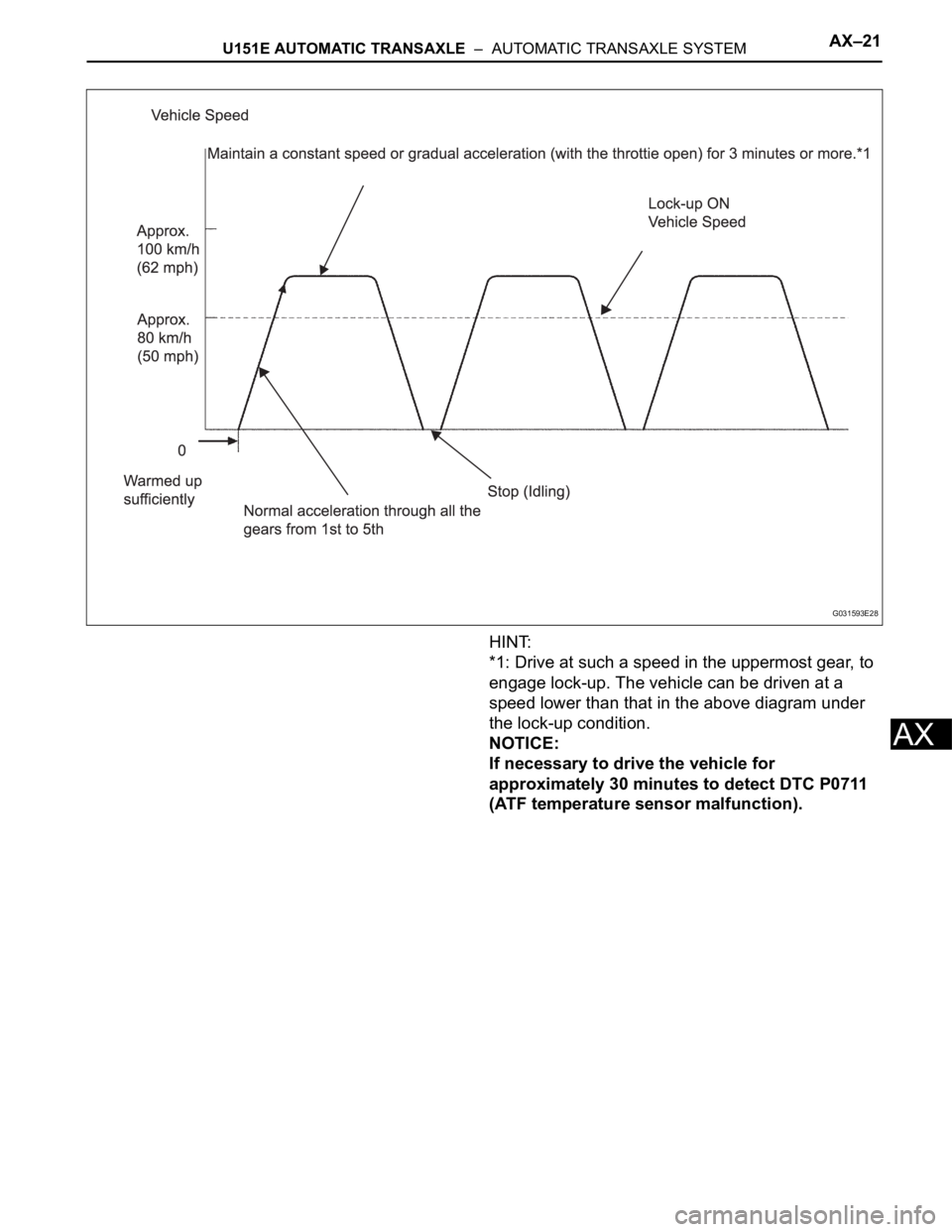

HINT:

*1: Drive at such a speed in the uppermost gear, to

engage lock-up. The vehicle can be driven at a

speed lower than that in the above diagram under

the lock-up condition.

NOTICE:

If necessary to drive the vehicle for

approximately 30 minutes to detect DTC P0711

(ATF temperature sensor malfunction).

G031593E28