TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 541 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–235

ES

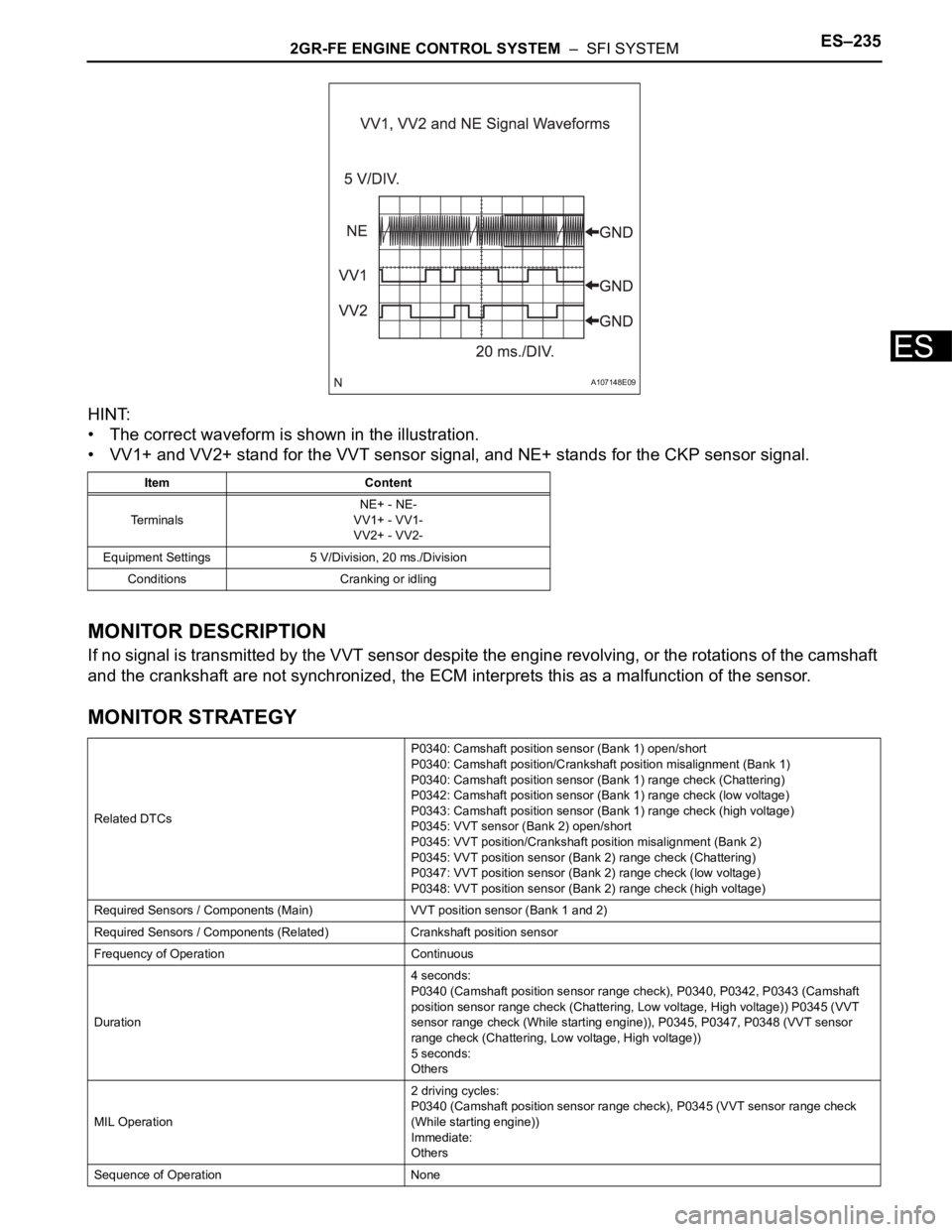

HINT:

• The correct waveform is shown in the illustration.

• VV1+ and VV2+ stand for the VVT sensor signal, and NE+ stands for the CKP sensor signal.

MONITOR DESCRIPTION

If no signal is transmitted by the VVT sensor despite the engine revolving, or the rotations of the camshaft

and the crankshaft are not synchronized, the ECM interprets this as a malfunction of the sensor.

MONITOR STRATEGY

Item Content

TerminalsNE+ - NE-

VV1+ - VV1-

VV2+ - VV2-

Equipment Settings 5 V/Division, 20 ms./Division

Conditions Cranking or idling

Related DTCsP0340: Camshaft position sensor (Bank 1) open/short

P0340: Camshaft position/Crankshaft position misalignment (Bank 1)

P0340: Camshaft position sensor (Bank 1) range check (Chattering)

P0342: Camshaft position sensor (Bank 1) range check (low voltage)

P0343: Camshaft position sensor (Bank 1) range check (high voltage)

P0345: VVT sensor (Bank 2) open/short

P0345: VVT position/Crankshaft position misalignment (Bank 2)

P0345: VVT position sensor (Bank 2) range check (Chattering)

P0347: VVT position sensor (Bank 2) range check (low voltage)

P0348: VVT position sensor (Bank 2) range check (high voltage)

Required Sensors / Components (Main) VVT position sensor (Bank 1 and 2)

Required Sensors / Components (Related) Crankshaft position sensor

Frequency of Operation Continuous

Duration4 seconds:

P0340 (Camshaft position sensor range check), P0340, P0342, P0343 (Camshaft

position sensor range check (Chattering, Low voltage, High voltage)) P0345 (VVT

sensor range check (While starting engine)), P0345, P0347, P0348 (VVT sensor

range check (Chattering, Low voltage, High voltage))

5 seconds:

Others

MIL Operation2 driving cycles:

P0340 (Camshaft position sensor range check), P0345 (VVT sensor range check

(While starting engine))

Immediate:

Others

Sequence of Operation None

A107148E09

Page 542 of 3000

ES–2362GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

TYPICAL ENABLING CONDITIONS

All:

Camshaft Position Sensor Range Check:

Camshaft Position/Crankshaft Position Misalignment:

Camshaft Position Sensor Range Check (Chattering, Low voltage, High voltage):

VVT sensor range check (While starting engine):

VVT sensor range check (After starting engine):

VVT sensor range check (Chattering, Low voltage, High voltage):

TYPICAL MALFUNCTION THRESHOLDS

Camshaft Position Sensor Range Check:

Camshaft Position/Crankshaft Position Misalignment:

Camshaft Position Sensor Range Check (Fluctuating):

Camshaft Position Sensor Range Check (Low voltage):

Camshaft Position Sensor Range Check (High voltage):

VVT sensor range check (While starting engine):

VVT sensor range check (After starting engine):

The monitor will run whenever these DTCs are not

presentNone

Starter ON and not starter ON again

Minimal battery voltage while starter ON Less than 11 V

Engine RPM 600 rpm or more

Starter OFF

Starter OFF

Ignition switch ON and time after ignition switch is OFF

to ON2 seconds or more

Starter ON

Battery voltage while starter ON once at least Less than 11 V

Engine RPM 600 rpm or more

Starter OFF

Battery voltage 8 V or more

Ignition switch ON

Starter OFF

Ignition switch ON and time after ignition switch is OFF

to ON2 seconds or more

Battery voltage 8 V or more

Camshaft position signal No signal

Camshaft position and crankshaft position phase Mis-aligned

Camshaft position voltage Less than 0.3 V, or more than 4.7 V

Camshaft position voltage Less than 0.3 V

Camshaft position voltage More than 4.7 V

VVT sensor signal No signal

VVT sensor signal No signal

Page 543 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–237

ES

VVT sensor range check (Fluctuating):

VVT sensor range check (Low voltage):

VVT sensor range check (High voltage):

COMPONENT OPERATING RANGE

WIRING DIAGRAM

Refer to DTC P0335 (See page ES-222).

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of

a malfunction.

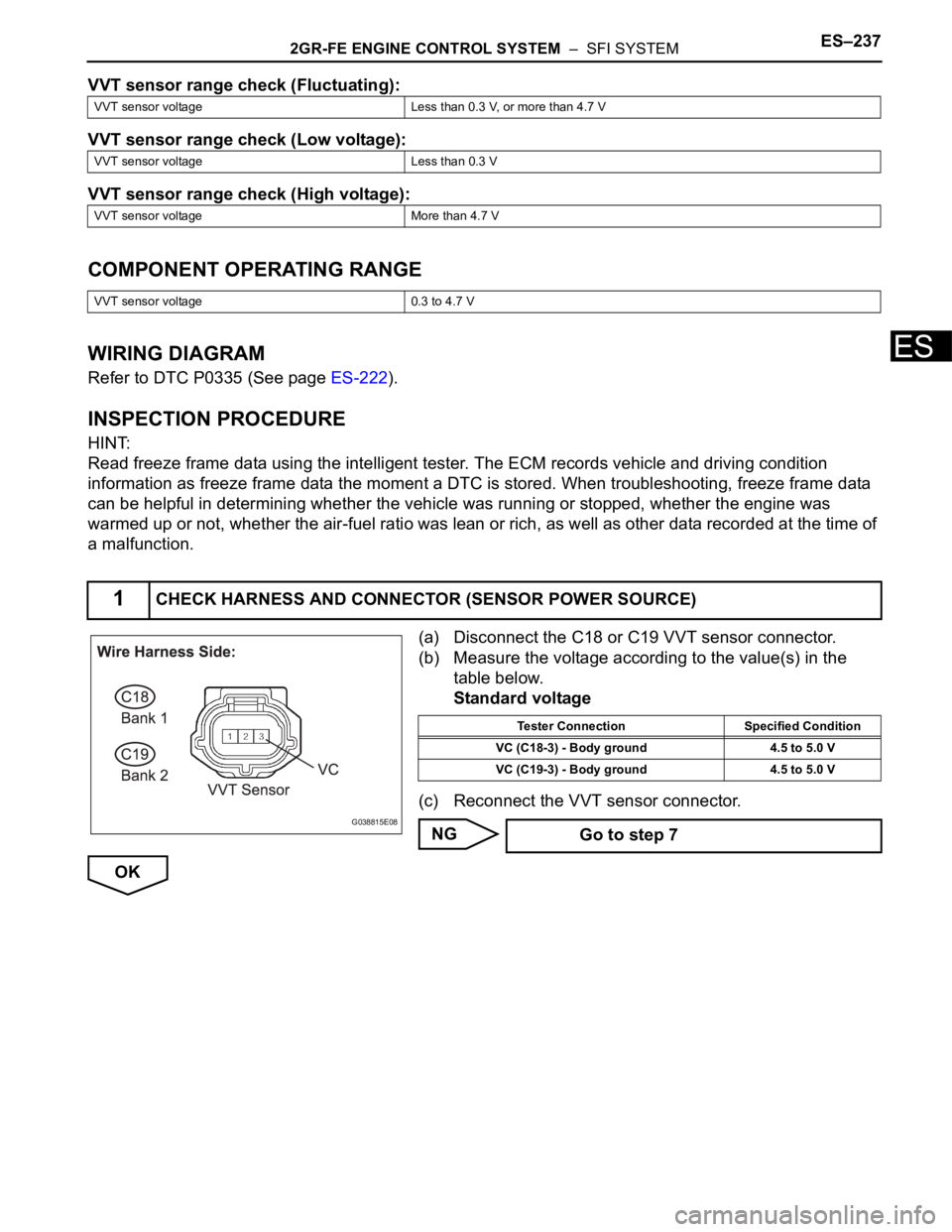

(a) Disconnect the C18 or C19 VVT sensor connector.

(b) Measure the voltage according to the value(s) in the

table below.

Standard voltage

(c) Reconnect the VVT sensor connector.

NG

OK

VVT sensor voltage Less than 0.3 V, or more than 4.7 V

VVT sensor voltage Less than 0.3 V

VVT sensor voltage More than 4.7 V

VVT sensor voltage 0.3 to 4.7 V

1CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE)

G038815E08

Tester Connection Specified Condition

VC (C18-3) - Body ground 4.5 to 5.0 V

VC (C19-3) - Body ground 4.5 to 5.0 V

Go to step 7

Page 544 of 3000

ES–2382GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

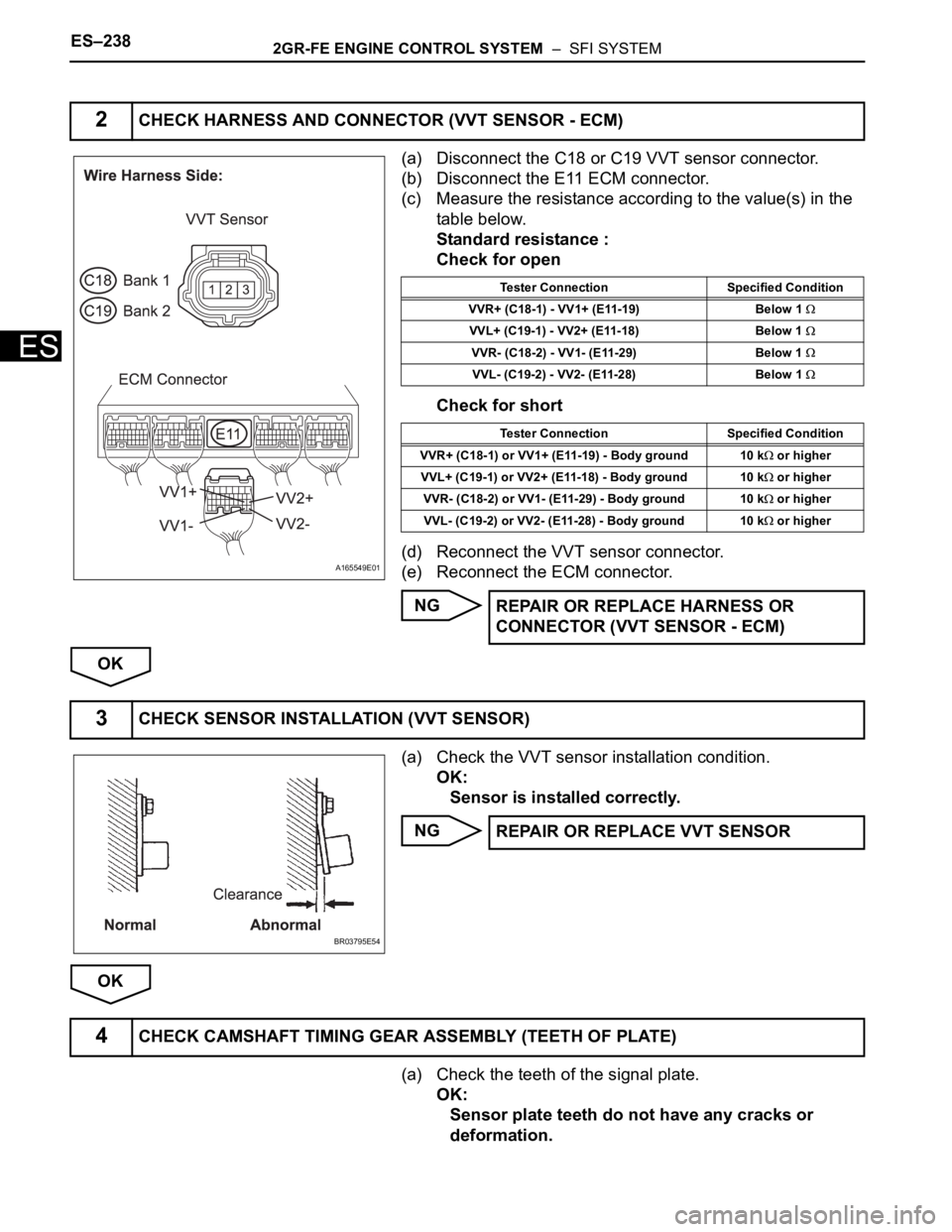

(a) Disconnect the C18 or C19 VVT sensor connector.

(b) Disconnect the E11 ECM connector.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance :

Check for open

Check for short

(d) Reconnect the VVT sensor connector.

(e) Reconnect the ECM connector.

NG

OK

(a) Check the VVT sensor installation condition.

OK:

Sensor is installed correctly.

NG

OK

(a) Check the teeth of the signal plate.

OK:

Sensor plate teeth do not have any cracks or

deformation.

2CHECK HARNESS AND CONNECTOR (VVT SENSOR - ECM)

A165549E01

Tester Connection Specified Condition

VVR+ (C18-1) - VV1+ (E11-19) Below 1

VVL+ (C19-1) - VV2+ (E11-18) Below 1

VVR- (C18-2) - VV1- (E11-29) Below 1

VVL- (C19-2) - VV2- (E11-28) Below 1

Tester Connection Specified Condition

VVR+ (C18-1) or VV1+ (E11-19) - Body ground 10 k

or higher

VVL+ (C19-1) or VV2+ (E11-18) - Body ground 10 k

or higher

VVR- (C18-2) or VV1- (E11-29) - Body ground 10 k

or higher

VVL- (C19-2) or VV2- (E11-28) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (VVT SENSOR - ECM)

3CHECK SENSOR INSTALLATION (VVT SENSOR)

BR03795E54

REPAIR OR REPLACE VVT SENSOR

4CHECK CAMSHAFT TIMING GEAR ASSEMBLY (TEETH OF PLATE)

Page 545 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–239

ES

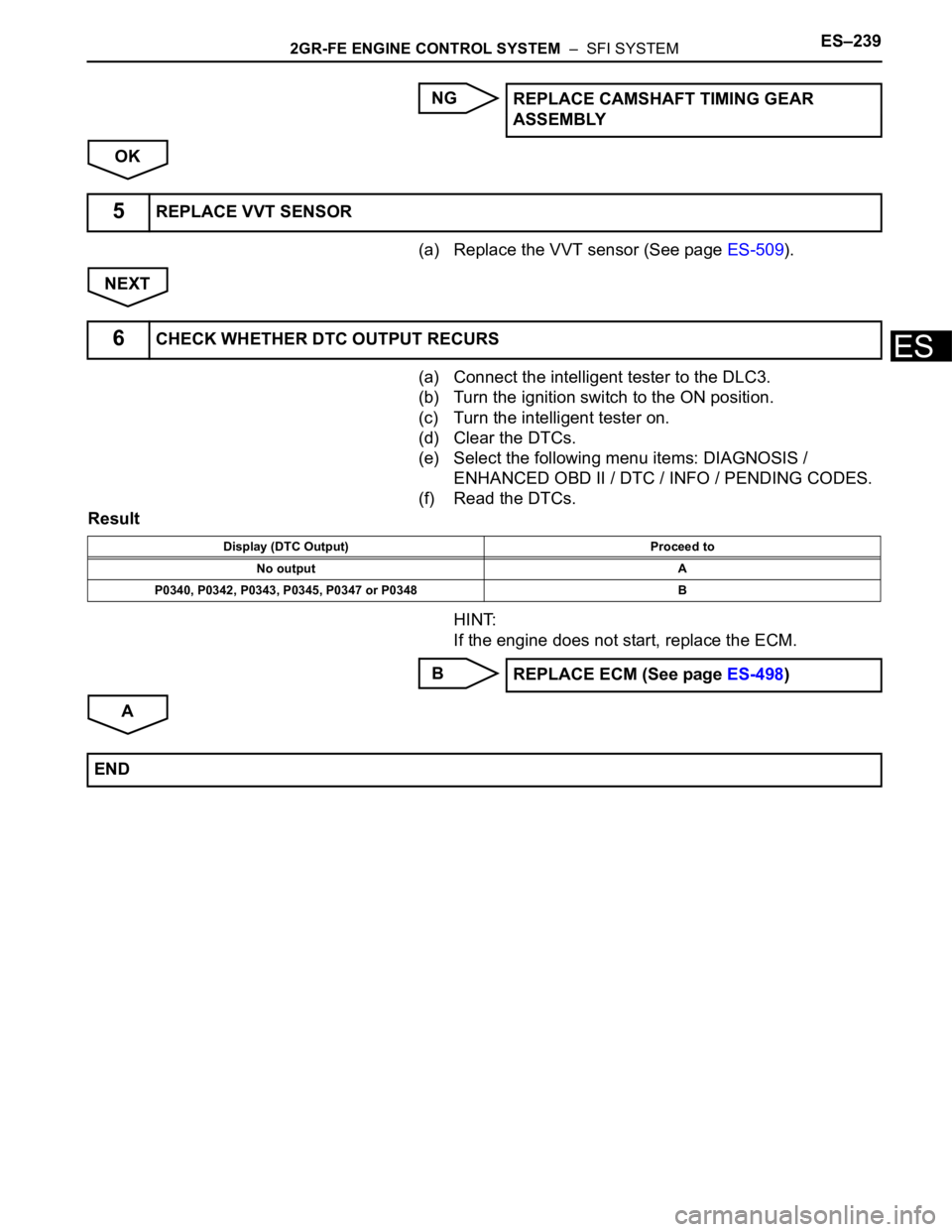

NG

OK

(a) Replace the VVT sensor (See page ES-509).

NEXT

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the intelligent tester on.

(d) Clear the DTCs.

(e) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC / INFO / PENDING CODES.

(f) Read the DTCs.

Result

HINT:

If the engine does not start, replace the ECM.

B

AREPLACE CAMSHAFT TIMING GEAR

ASSEMBLY

5REPLACE VVT SENSOR

6CHECK WHETHER DTC OUTPUT RECURS

Display (DTC Output) Proceed to

No output A

P0340, P0342, P0343, P0345, P0347 or P0348 B

REPLACE ECM (See page ES-498)

END

Page 546 of 3000

ES–2402GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

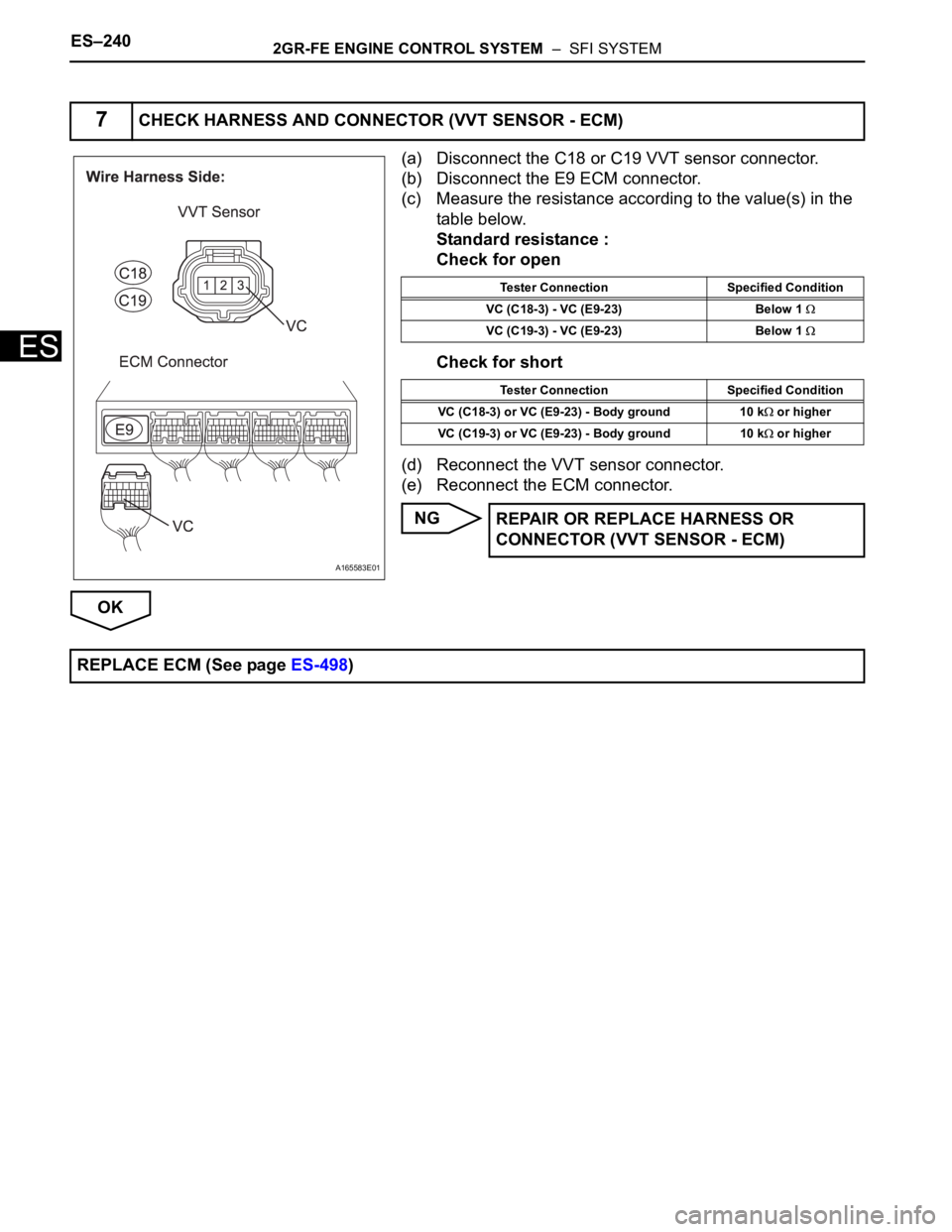

(a) Disconnect the C18 or C19 VVT sensor connector.

(b) Disconnect the E9 ECM connector.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance :

Check for open

Check for short

(d) Reconnect the VVT sensor connector.

(e) Reconnect the ECM connector.

NG

OK

7CHECK HARNESS AND CONNECTOR (VVT SENSOR - ECM)

A165583E01

Tester Connection Specified Condition

VC (C18-3) - VC (E9-23) Below 1

VC (C19-3) - VC (E9-23) Below 1

Tester Connection Specified Condition

VC (C18-3) or VC (E9-23) - Body ground 10 k

or higher

VC (C19-3) or VC (E9-23) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (VVT SENSOR - ECM)

REPLACE ECM (See page ES-498)

Page 547 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–241

ES

HINT:

• These DTCs indicate malfunctions relating to the primary circuit.

• If DTC P0351 is set, check the No. 1 ignition coil with igniter circuit.

• If DTC P0352 is set, check the No. 2 ignition coil with igniter circuit.

• If DTC P0353 is set, check the No. 3 ignition coil with igniter circuit.

• If DTC P0354 is set, check the No. 4 ignition coil with igniter circuit.

• If DTC P0355 is set, check the No. 5 ignition coil with igniter circuit.

• If DTC P0356 is set, check the No. 6 ignition coil with igniter circuit.

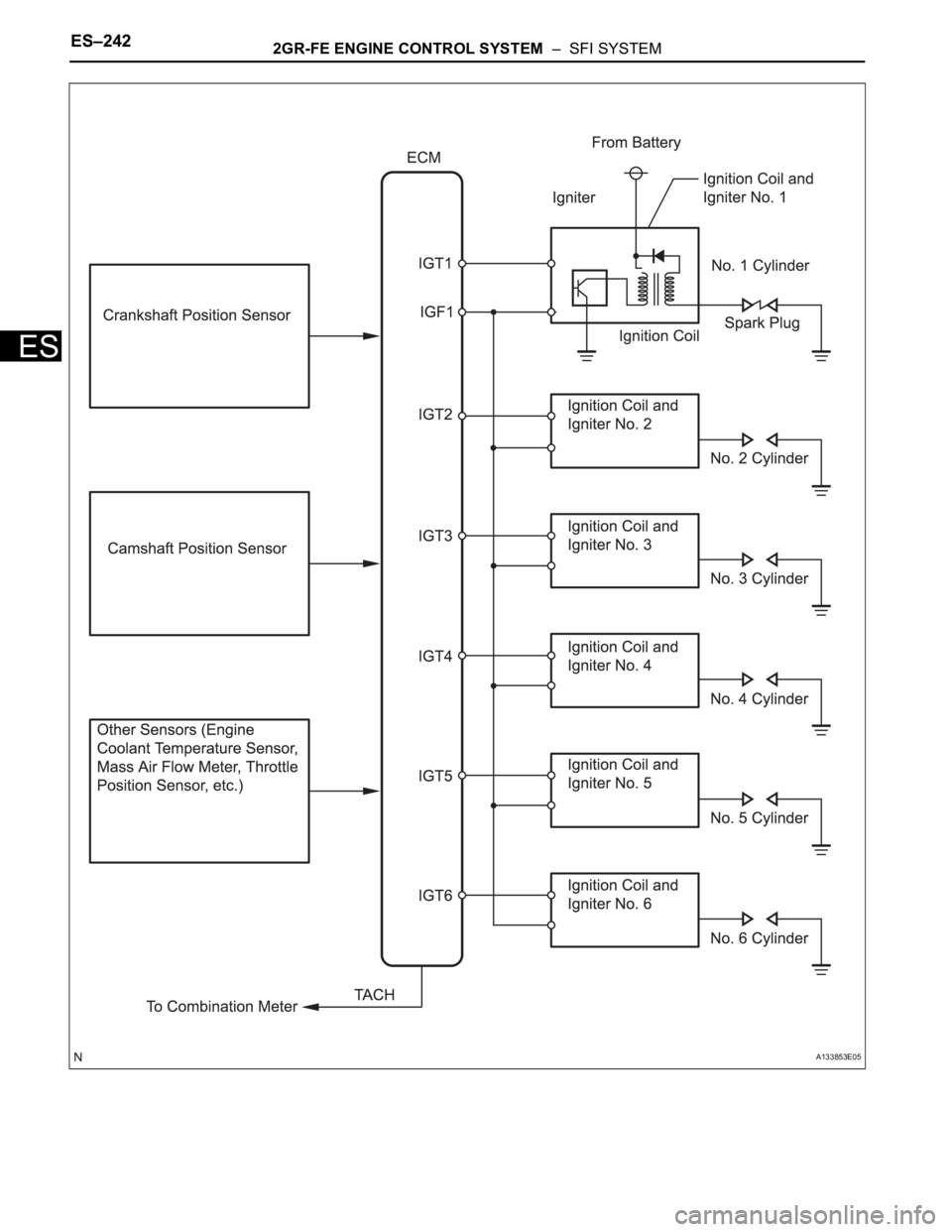

DESCRIPTION

A Direct Ignition System (DIS) is used on this vehicle.

The DIS is a 1-cylinder ignition system in which each cylinder is ignited by one ignition coil and one spark

plug is connected to the end of each secondary wiring. High-voltage is generated in the secondary wiring

and then applied directly to each spark plug. The sparks of the spark plugs pass from the center

electrodes to the ground electrodes.

The ECM determines the ignition timing and transmits the ignition (IGT) signals to each cylinder. Using the

IGT signal, the ECM turns the power transistor inside the igniter on and off. The power transistor, in turn,

switches on and off the current to the primary coil. When the current to the primary coil is cut off, high-

voltage is generated in the secondary coil. This voltage is applied to the spark plugs, causing them to

spark inside the cylinders. As the ECM cuts the current to the primary coil off, the igniter sends back an

ignition confirmation (IGF) signal to the ECM, for each cylinder ignition.

DTC P0351 Ignition Coil "A" Primary / Secondary Circuit

DTC P0352 Ignition Coil "B" Primary / Secondary Circuit

DTC P0353 Ignition Coil "C" Primary / Secondary Circuit

DTC P0354 Ignition Coil "D" Primary / Secondary Circuit

DTC P0355 Ignition Coil "E" Primary / Secondary Circuit

DTC P0356 Ignition Coil "F" Primary / Secondary Circuit

Page 548 of 3000

ES–2422GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

A133853E05

Page 549 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–243

ES

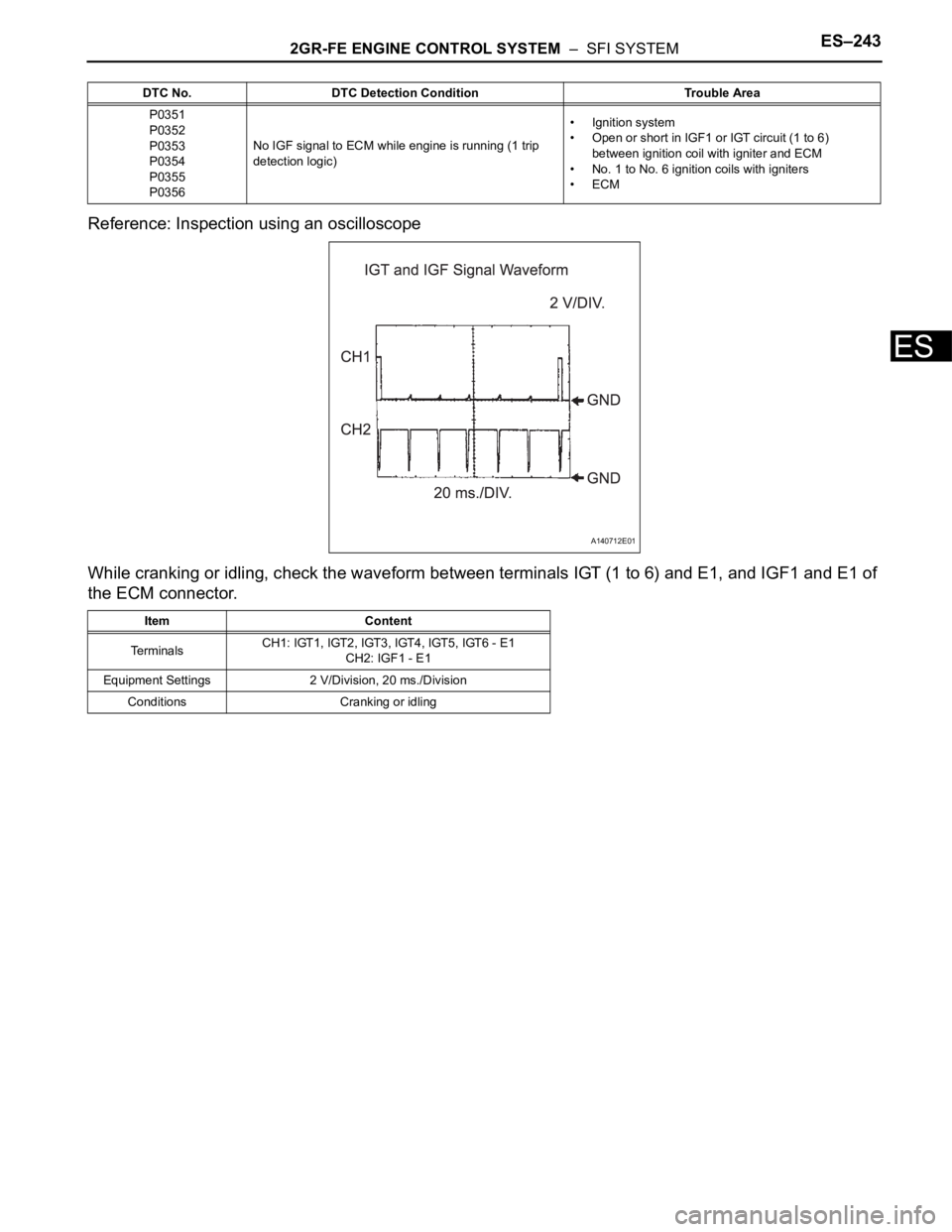

Reference: Inspection using an oscilloscope

While cranking or idling, check the waveform between terminals IGT (1 to 6) and E1, and IGF1 and E1 of

the ECM connector.

DTC No. DTC Detection Condition Trouble Area

P0351

P0352

P0353

P0354

P0355

P0356No IGF signal to ECM while engine is running (1 trip

detection logic)• Ignition system

• Open or short in IGF1 or IGT circuit (1 to 6)

between ignition coil with igniter and ECM

• No. 1 to No. 6 ignition coils with igniters

•ECM

Item Content

TerminalsCH1: IGT1, IGT2, IGT3, IGT4, IGT5, IGT6 - E1

CH2: IGF1 - E1

Equipment Settings 2 V/Division, 20 ms./Division

Conditions Cranking or idling

A140712E01

Page 550 of 3000

ES–2442GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

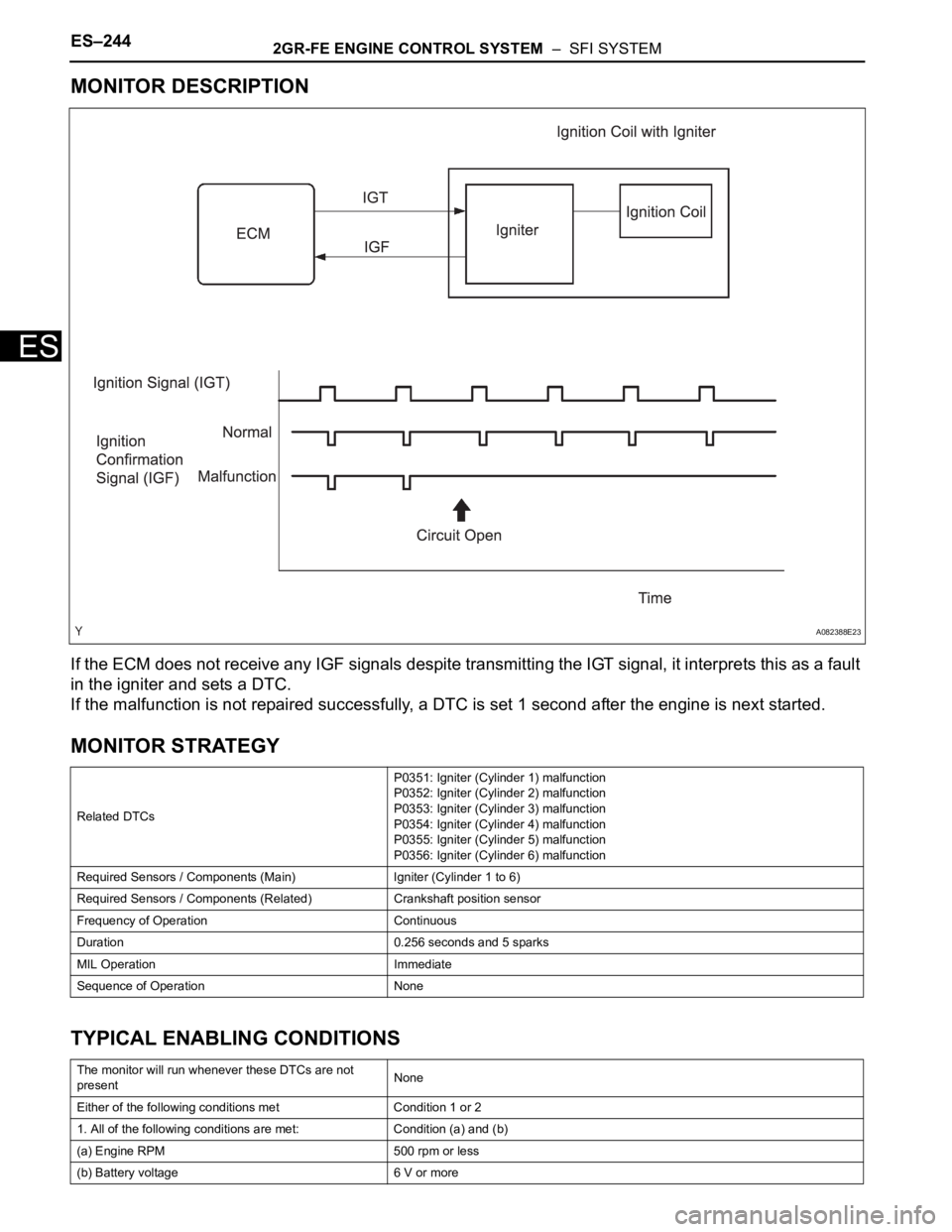

MONITOR DESCRIPTION

If the ECM does not receive any IGF signals despite transmitting the IGT signal, it interprets this as a fault

in the igniter and sets a DTC.

If the malfunction is not repaired successfully, a DTC is set 1 second after the engine is next started.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

Related DTCsP0351: Igniter (Cylinder 1) malfunction

P0352: Igniter (Cylinder 2) malfunction

P0353: Igniter (Cylinder 3) malfunction

P0354: Igniter (Cylinder 4) malfunction

P0355: Igniter (Cylinder 5) malfunction

P0356: Igniter (Cylinder 6) malfunction

Required Sensors / Components (Main) Igniter (Cylinder 1 to 6)

Required Sensors / Components (Related) Crankshaft position sensor

Frequency of Operation Continuous

Duration 0.256 seconds and 5 sparks

MIL Operation Immediate

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentNone

Either of the following conditions met Condition 1 or 2

1. All of the following conditions are met: Condition (a) and (b)

(a) Engine RPM 500 rpm or less

(b) Battery voltage 6 V or more

A082388E23