TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 571 of 3000

ES–2782GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

MONITOR DESCRIPTION

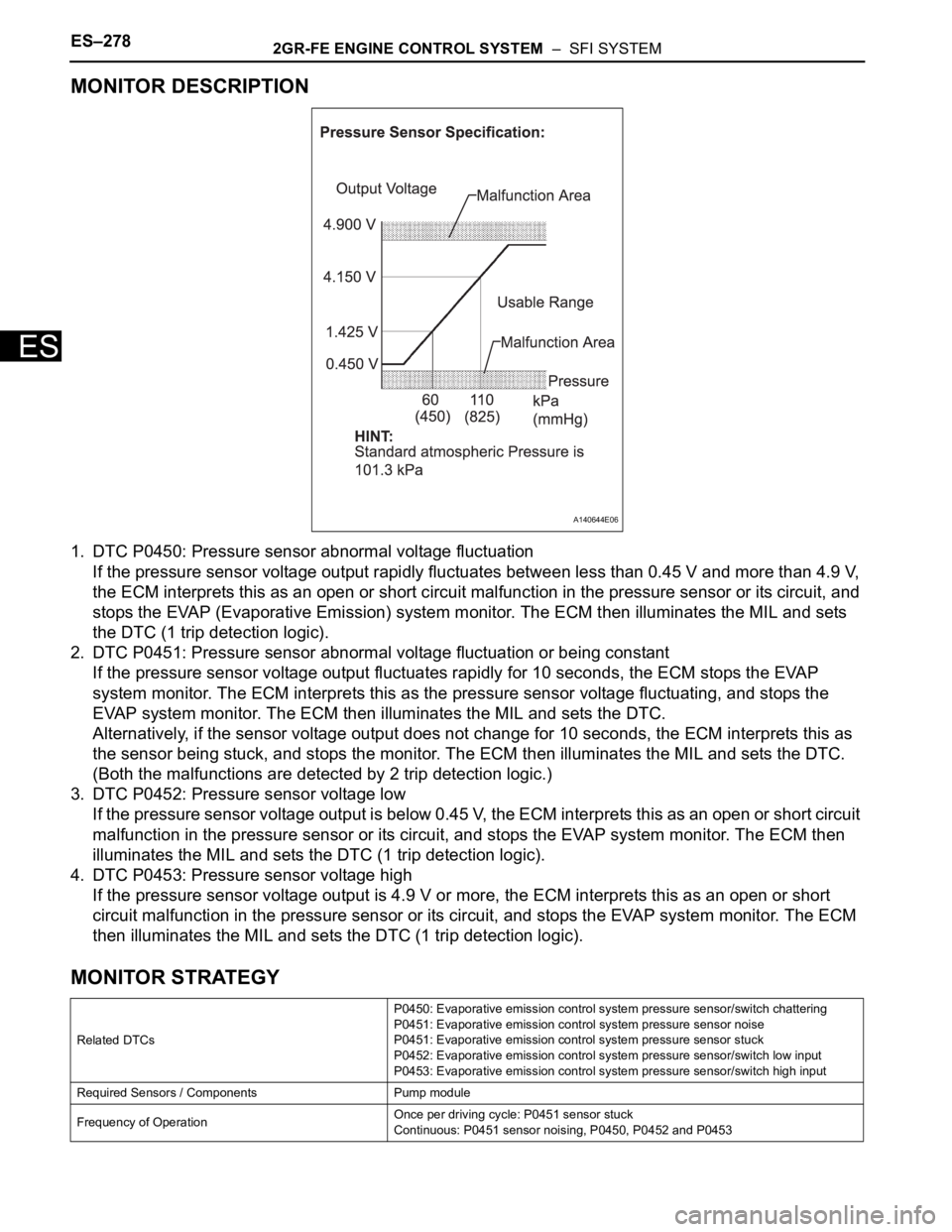

1. DTC P0450: Pressure sensor abnormal voltage fluctuation

If the pressure sensor voltage output rapidly fluctuates between less than 0.45 V and more than 4.9 V,

the ECM interprets this as an open or short circuit malfunction in the pressure sensor or its circuit, and

stops the EVAP (Evaporative Emission) system monitor. The ECM then illuminates the MIL and sets

the DTC (1 trip detection logic).

2. DTC P0451: Pressure sensor abnormal voltage fluctuation or being constant

If the pressure sensor voltage output fluctuates rapidly for 10 seconds, the ECM stops the EVAP

system monitor. The ECM interprets this as the pressure sensor voltage fluctuating, and stops the

EVAP system monitor. The ECM then illuminates the MIL and sets the DTC.

Alternatively, if the sensor voltage output does not change for 10 seconds, the ECM interprets this as

the sensor being stuck, and stops the monitor. The ECM then illuminates the MIL and sets the DTC.

(Both the malfunctions are detected by 2 trip detection logic.)

3. DTC P0452: Pressure sensor voltage low

If the pressure sensor voltage output is below 0.45 V, the ECM interprets this as an open or short circuit

malfunction in the pressure sensor or its circuit, and stops the EVAP system monitor. The ECM then

illuminates the MIL and sets the DTC (1 trip detection logic).

4. DTC P0453: Pressure sensor voltage high

If the pressure sensor voltage output is 4.9 V or more, the ECM interprets this as an open or short

circuit malfunction in the pressure sensor or its circuit, and stops the EVAP system monitor. The ECM

then illuminates the MIL and sets the DTC (1 trip detection logic).

MONITOR STRATEGY

Related DTCsP0450: Evaporative emission control system pressure sensor/switch chattering

P0451: Evaporative emission control system pressure sensor noise

P0451: Evaporative emission control system pressure sensor stuck

P0452: Evaporative emission control system pressure sensor/switch low input

P0453: Evaporative emission control system pressure sensor/switch high input

Required Sensors / Components Pump module

Frequency of OperationOnce per driving cycle: P0451 sensor stuck

Continuous: P0451 sensor noising, P0450, P0452 and P0453

A140644E06

Page 572 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–279

ES

TYPICAL ENABLING CONDITIONS

All:

P0451 (Noise monitor):

P0451 (Stuck monitor):

P0450, P0452 and P0453:

TYPICAL MALFUNCTION THRESHOLDS

(a) P0450: Pressure sensor chattering

(b) P0451: Pressure sensor noise

(c) P0451: Pressure sensor stuck

(d) P0452: Pressure sensor low voltage

(e) P0453: Pressure sensor high voltage

DurationLess than 15 seconds: P0451 (Pressure sensor noise)

Within 2 minutes: P0451 (Pressure sensor stuck)

0.5 seconds: P0450, P0452, P0453

MIL OperationImmediate: P0450, P0452, P0453

2 driving cycles: P0451

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentNone

Atmospheric pressure 70 to 110 kPa (525 to 825 mmHg)

Battery voltage 10.5 V or more

IAT 4.4 to 35

C (40 to 95F)

EVAP pressure sensor malfunction (P0450, P0452,

P0453)Not detected

Either of the following conditions 1 or 2 is met -

1. Engine condition Running

2. Time after key-off 5 or 7 or 9.5 hours

Battery voltage 10.5 V or more

IAT 4.4 to 35

C (40 to 95F)

EVAP pressure sensor malfunction (P0450, P0452,

P0453)Not detected

Atmospheric pressure 70 to 110 kPa (525 to 825 mmHg)

Time after key-off 5 or 7 or 9.5 hours

Ignition switch ON

Battery voltage 8 V or more

Sta r t e r OF F

EVAP pressure Less than 42.11 kPa (316 mmHg), or more than 123.761 kPa (928 mmHg)

Frequency that EVAP pressure change is 0.3 kPa (2.25

mmHg) or more10 times or more in 10 seconds

EVAP pressure change during reference pressure

measurementLess than 0.65 kPa (4.876 mmHg)

EVAP pressure Less than 42.11 kPa (316 mmHg)

EVAP pressure More than 123.761 kPa (928 mmHg)

Page 573 of 3000

ES–2802GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

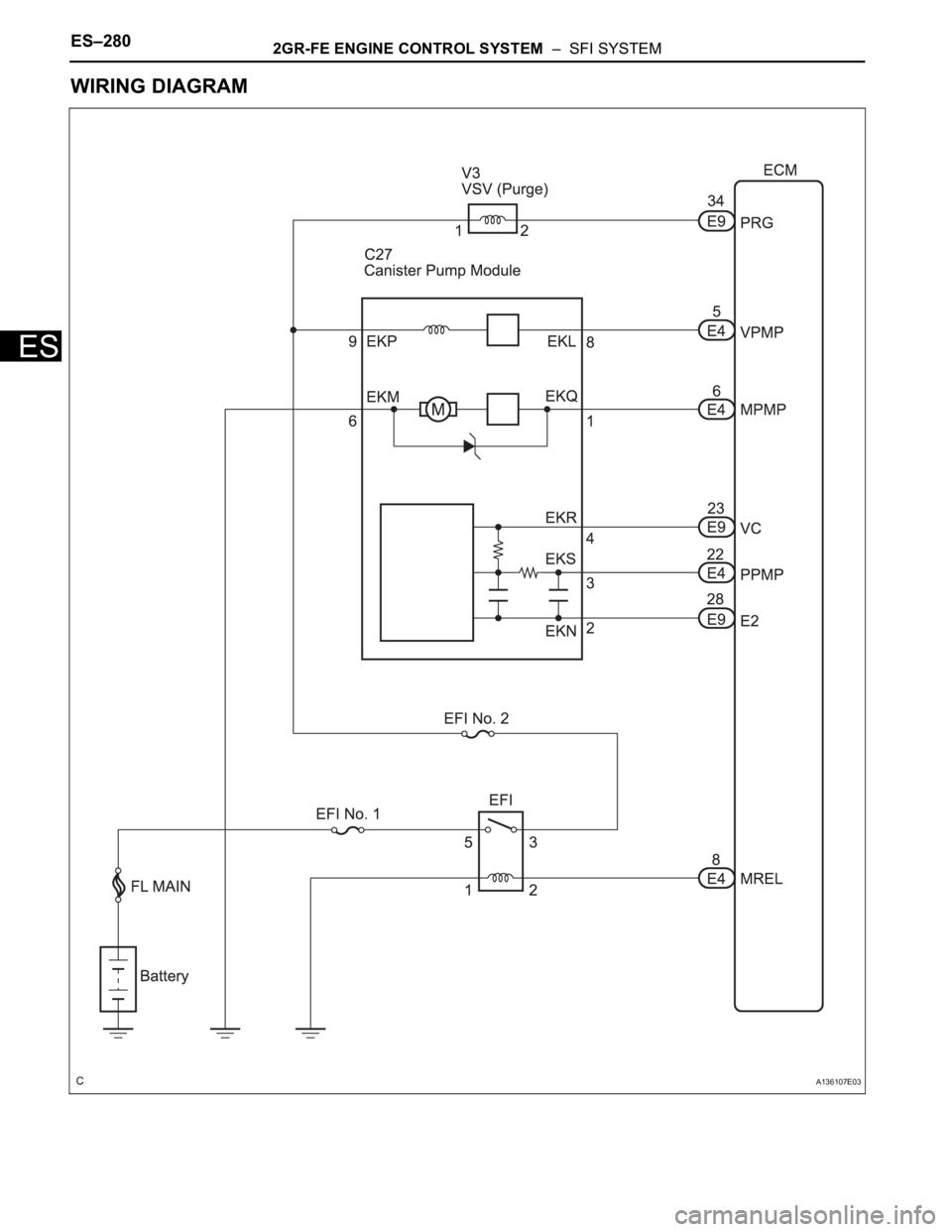

WIRING DIAGRAM

A136107E03

Page 574 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–281

ES

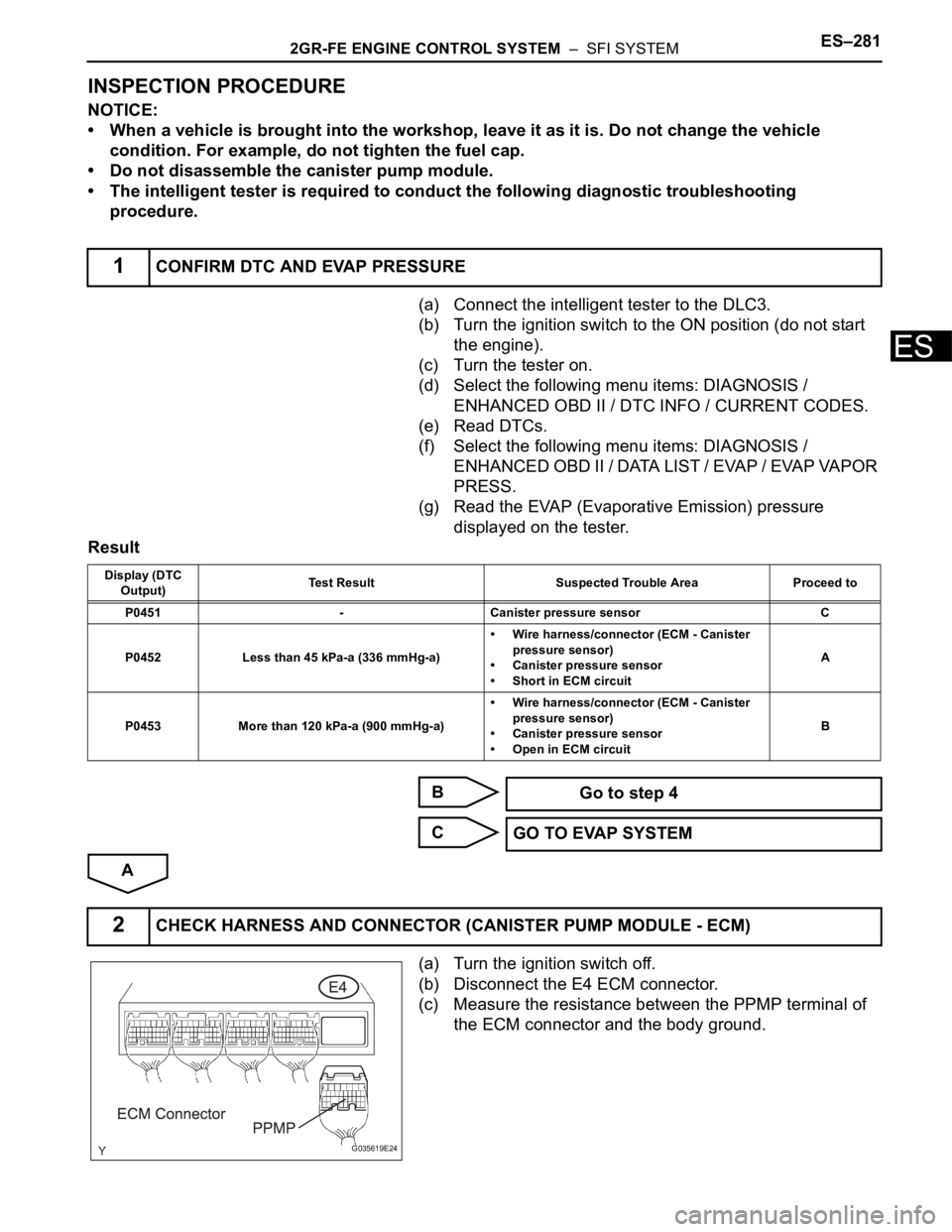

INSPECTION PROCEDURE

NOTICE:

• When a vehicle is brought into the workshop, leave it as it is. Do not change the vehicle

condition. For example, do not tighten the fuel cap.

• Do not disassemble the canister pump module.

• The intelligent tester is required to conduct the following diagnostic troubleshooting

procedure.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position (do not start

the engine).

(c) Turn the tester on.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(e) Read DTCs.

(f) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST / EVAP / EVAP VAPOR

PRESS.

(g) Read the EVAP (Evaporative Emission) pressure

displayed on the tester.

Result

B

C

A

(a) Turn the ignition switch off.

(b) Disconnect the E4 ECM connector.

(c) Measure the resistance between the PPMP terminal of

the ECM connector and the body ground.

1CONFIRM DTC AND EVAP PRESSURE

Display (DTC

Output)Test Result Suspected Trouble Area Proceed to

P0451 - Canister pressure sensor C

P0452 Less than 45 kPa-a (336 mmHg-a)• Wire harness/connector (ECM - Canister

pressure sensor)

• Canister pressure sensor

• Short in ECM circuitA

P0453 More than 120 kPa-a (900 mmHg-a)• Wire harness/connector (ECM - Canister

pressure sensor)

• Canister pressure sensor

• Open in ECM circuitB

Go to step 4

GO TO EVAP SYSTEM

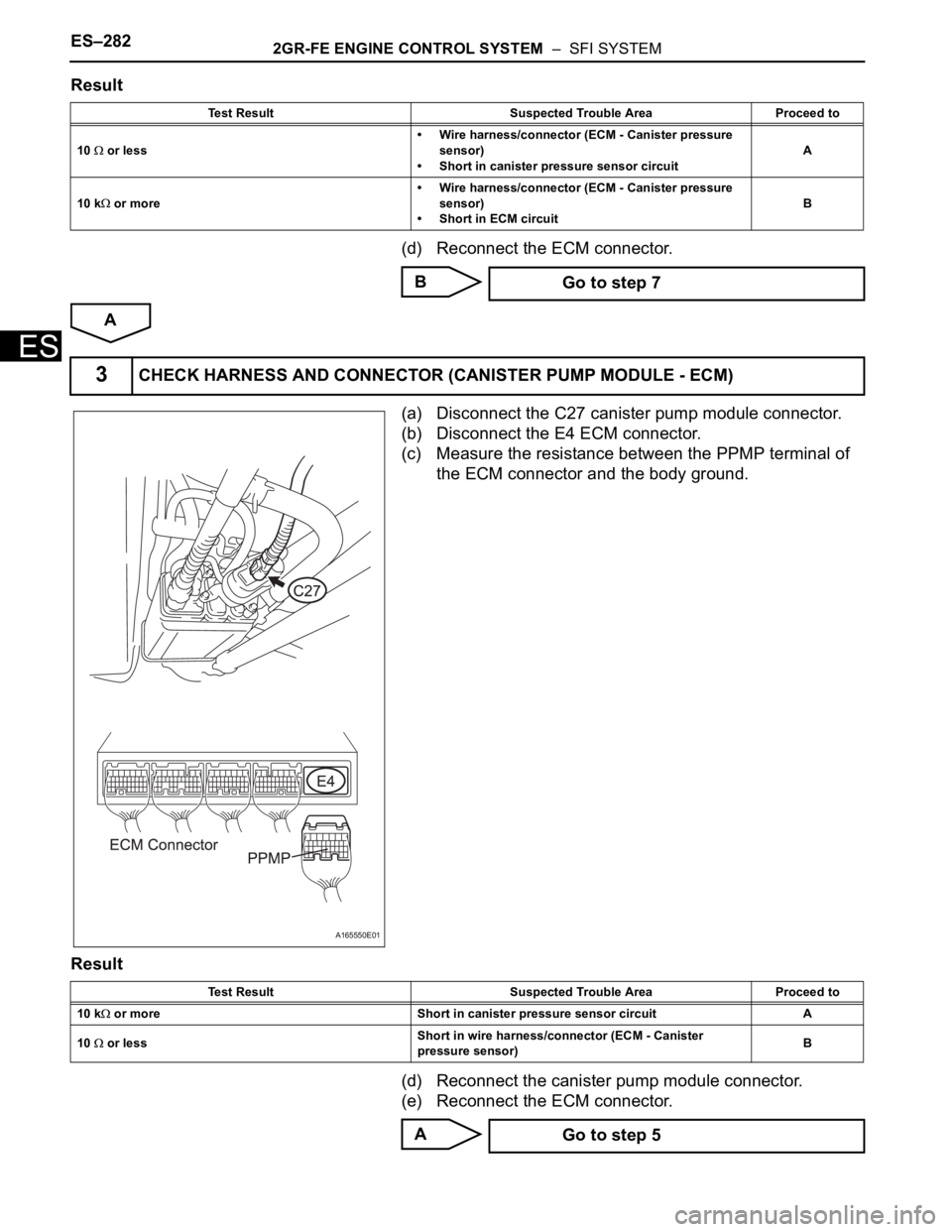

2CHECK HARNESS AND CONNECTOR (CANISTER PUMP MODULE - ECM)

G035619E24

Page 575 of 3000

ES–2822GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

Result

(d) Reconnect the ECM connector.

B

A

(a) Disconnect the C27 canister pump module connector.

(b) Disconnect the E4 ECM connector.

(c) Measure the resistance between the PPMP terminal of

the ECM connector and the body ground.

Result

(d) Reconnect the canister pump module connector.

(e) Reconnect the ECM connector.

A

Test Result Suspected Trouble Area Proceed to

10

or less• Wire harness/connector (ECM - Canister pressure

sensor)

• Short in canister pressure sensor circuitA

10 k

or more• Wire harness/connector (ECM - Canister pressure

sensor)

• Short in ECM circuitB

Go to step 7

3CHECK HARNESS AND CONNECTOR (CANISTER PUMP MODULE - ECM)

A165550E01

Test Result Suspected Trouble Area Proceed to

10 k

or more Short in canister pressure sensor circuit A

10

or lessShort in wire harness/connector (ECM - Canister

pressure sensor)B

Go to step 5

Page 576 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–283

ES

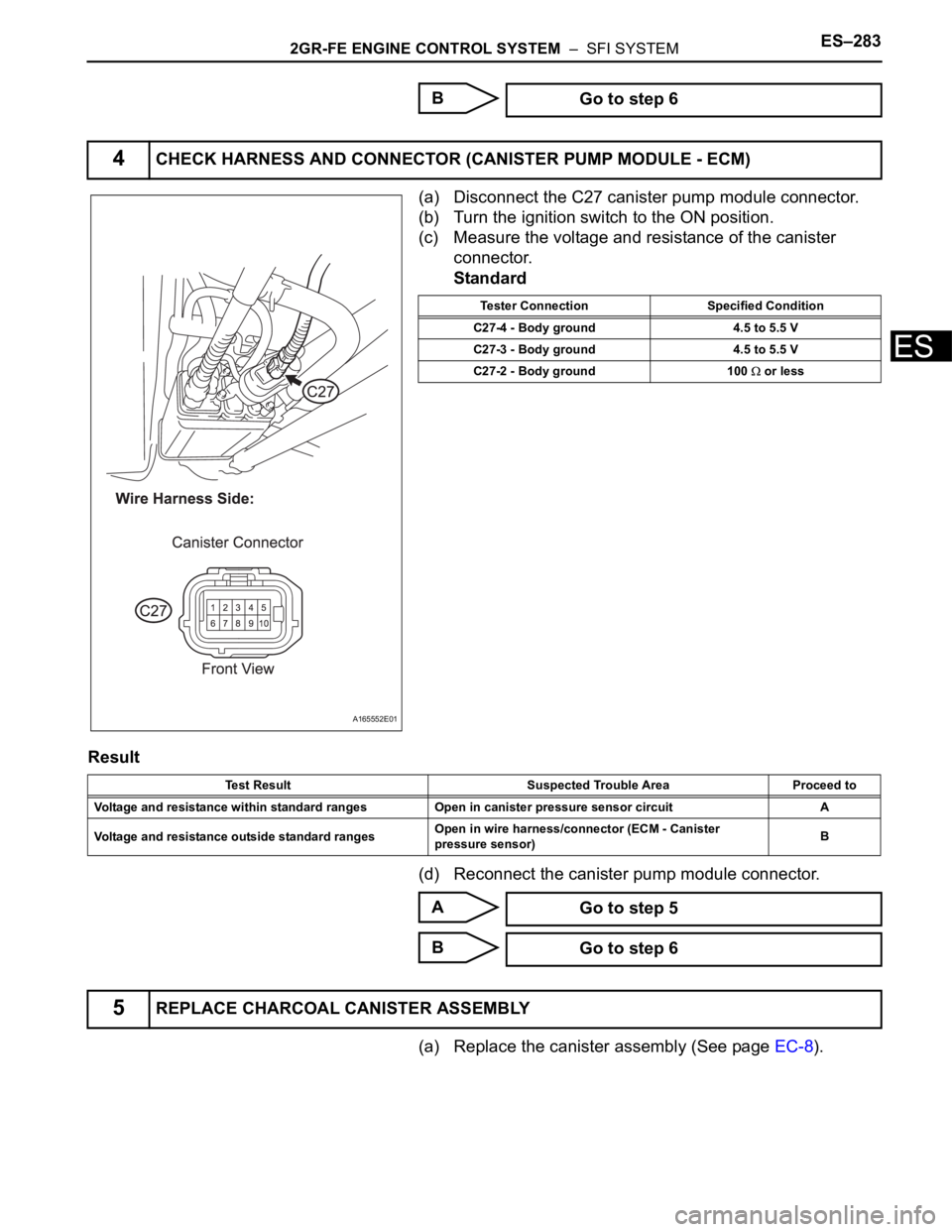

B

(a) Disconnect the C27 canister pump module connector.

(b) Turn the ignition switch to the ON position.

(c) Measure the voltage and resistance of the canister

connector.

Standard

Result

(d) Reconnect the canister pump module connector.

A

B

(a) Replace the canister assembly (See page EC-8). Go to step 6

4CHECK HARNESS AND CONNECTOR (CANISTER PUMP MODULE - ECM)

A165552E01

Tester Connection Specified Condition

C27-4 - Body ground 4.5 to 5.5 V

C27-3 - Body ground 4.5 to 5.5 V

C27-2 - Body ground 100

or less

Test Result Suspected Trouble Area Proceed to

Voltage and resistance within standard ranges Open in canister pressure sensor circuit A

Voltage and resistance outside standard rangesOpen in wire harness/connector (ECM - Canister

pressure sensor)B

Go to step 5

Go to step 6

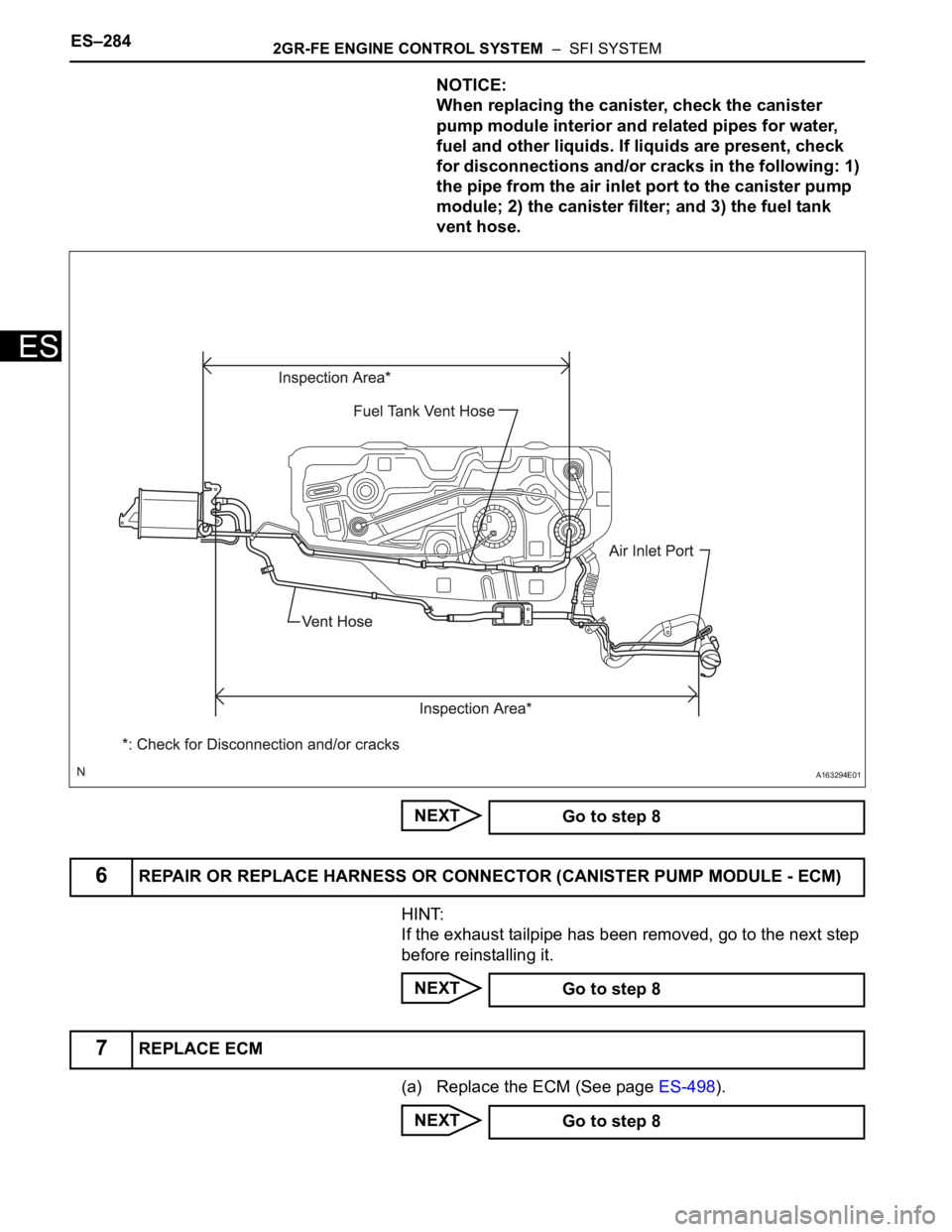

5REPLACE CHARCOAL CANISTER ASSEMBLY

Page 577 of 3000

ES–2842GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

NOTICE:

When replacing the canister, check the canister

pump module interior and related pipes for water,

fuel and other liquids. If liquids are present, check

for disconnections and/or cracks in the following: 1)

the pipe from the air inlet port to the canister pump

module; 2) the canister filter; and 3) the fuel tank

vent hose.

NEXT

HINT:

If the exhaust tailpipe has been removed, go to the next step

before reinstalling it.

NEXT

(a) Replace the ECM (See page ES-498).

NEXT

A163294E01

Go to step 8

6REPAIR OR REPLACE HARNESS OR CONNECTOR (CANISTER PUMP MODULE - ECM)

Go to step 8

7REPLACE ECM

Go to step 8

Page 578 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–285

ES

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Wait for at least 60 seconds.

(d) On the tester, select the following menu items:

DIAGNOSIS / ENHANCED OBD II / DTC INFO /

PENDING CODES.

HINT:

If no pending DTCs are displayed on the tester, the

repair has been successfully completed.

NEXT

8CHECK WHETHER DTC OUTPUT RECURS (AFTER REPAIR)

COMPLETED

Page 579 of 3000

ES–2862GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

DTC SUMMARY

DESCRIPTION

The circuit description can be found in the EVAP (Evaporative Emission) System (See page ES-409).

INSPECTION PROCEDURE

Refer to the EVAP System (See page ES-412).

MONITOR DESCRIPTION

5 hours*1 after the ignition switch is turned off, the electric vacuum pump creates negative pressure

(vacuum) in the EVAP (Evaporative Emission) system. The ECM monitors for leaks and actuator

malfunctions based on the EVAP pressure.

HINT:

*1: If the engine coolant temperature is not below 35

C (95F) 5 hours after the ignition switch is turned

off, the monitor check starts 2 hours later. If it is still not below 35

C (95F) 7 hours after the ignition switch

is turned off, the monitor check starts 2.5 hours later.

DTC P0455Evaporative Emission Control System Leak

Detected (Gross Leak)

DTC P0456Evaporative Emission Control System Leak

Detected (Very Small Leak)

DTCs Monitoring ItemMalfunction Detection

ConditionTrouble Area Detection TimingDetection

Logic

P0455 EVAP gross leakVacuum pump creates negative

pressure (vacuum) in EVAP

system and EVAP system

pressure is measured. 0.02 inch

leak pressure standard is

measured at start and end of leak

check.

If stabilized pressure is higher

than [second 0.02 inch leak

pressure standard x 0.2], ECM

determines that EVAP system

has a large leak.• Fuel tank cap (loose)

• Leakage from EVAP

line (Canister - Fuel

tank)

• Leakage from EVAP

line (Purge VSV -

Canister)

• Leakage from pump

module

• Leakage from fuel

tank

• Leakage from canisterWhile ignition

switch OFF2 trip

P0456 EVAP small leakVacuum pump creates negative

pressure (vacuum) in EVAP

system and EVAP system

pressure is measured. 0.02 inch

leak pressure standard measured

at start and end of leak check.

If stabilized pressure is higher

than second 0.02 inch leak

pressure standard, ECM

determines that EVAP system

has a small leak.While ignition

switch OFF2 trip

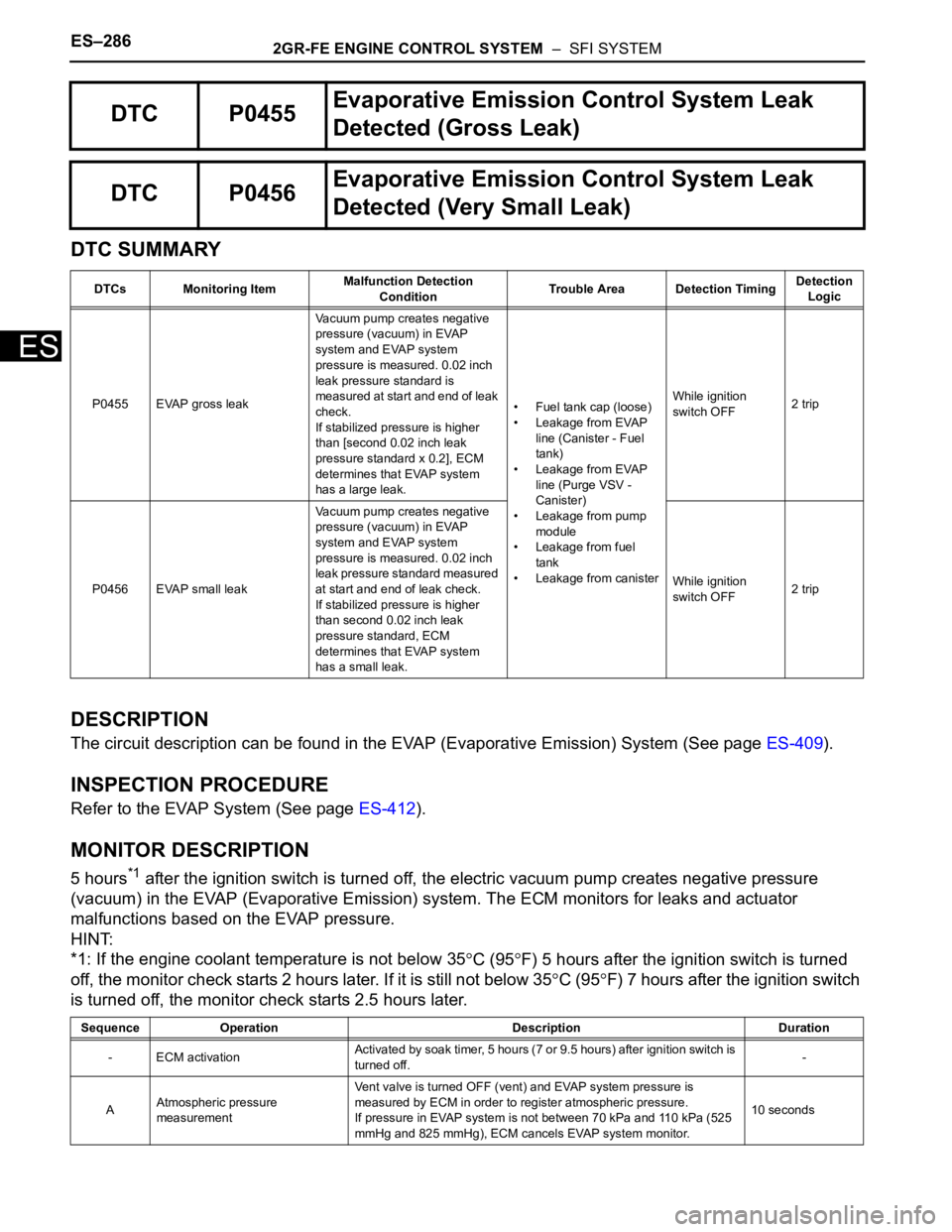

Sequence Operation Description Duration

- ECM activationActivated by soak timer, 5 hours (7 or 9.5 hours) after ignition switch is

turned off.-

AAtmospheric pressure

measurementVent valve is turned OFF (vent) and EVAP system pressure is

measured by ECM in order to register atmospheric pressure.

If pressure in EVAP system is not between 70 kPa and 110 kPa (525

mmHg and 825 mmHg), ECM cancels EVAP system monitor.10 seconds

Page 580 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–287

ES

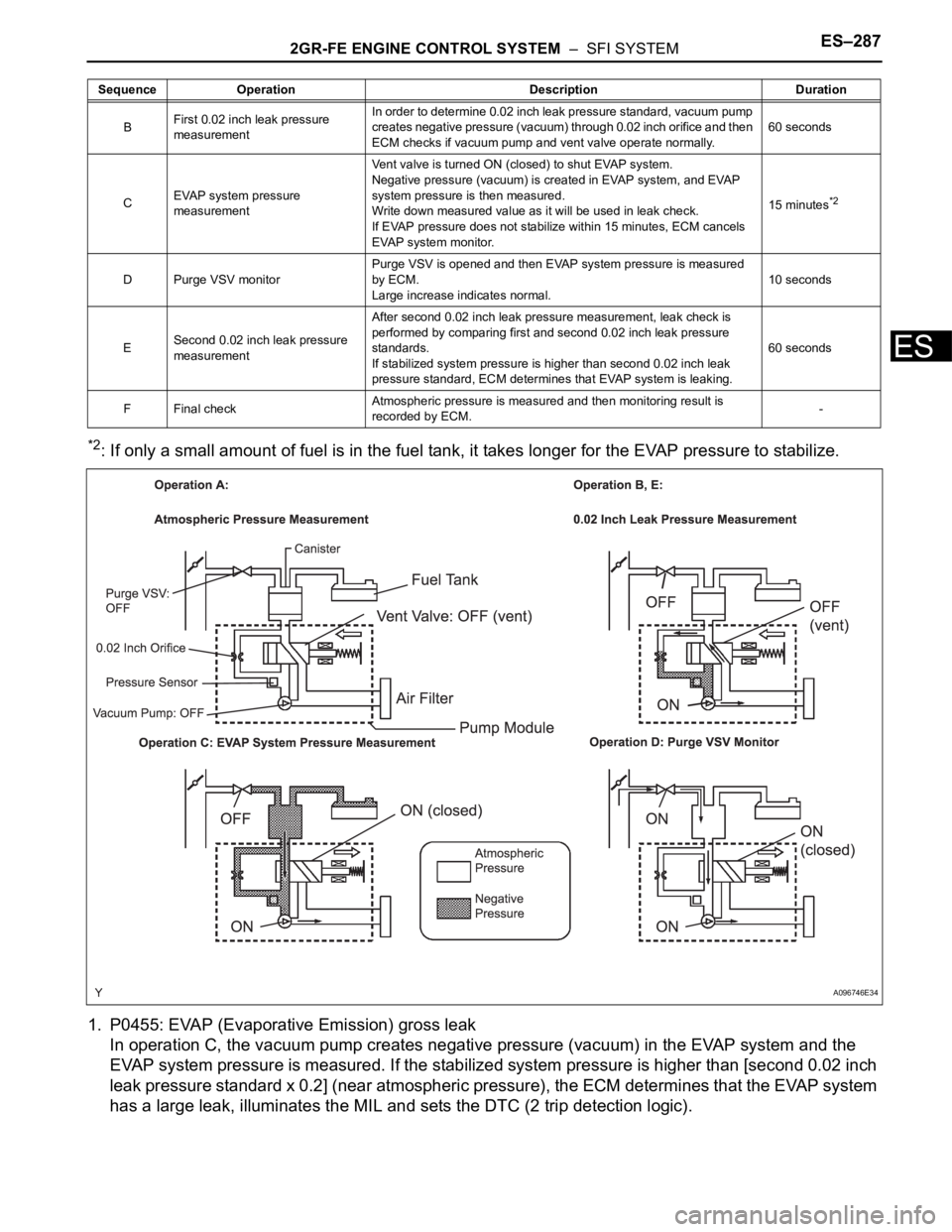

*2: If only a small amount of fuel is in the fuel tank, it takes longer for the EVAP pressure to stabilize.

1. P0455: EVAP (Evaporative Emission) gross leak

In operation C, the vacuum pump creates negative pressure (vacuum) in the EVAP system and the

EVAP system pressure is measured. If the stabilized system pressure is higher than [second 0.02 inch

leak pressure standard x 0.2] (near atmospheric pressure), the ECM determines that the EVAP system

has a large leak, illuminates the MIL and sets the DTC (2 trip detection logic).

BFirst 0.02 inch leak pressure

measurementIn order to determine 0.02 inch leak pressure standard, vacuum pump

creates negative pressure (vacuum) through 0.02 inch orifice and then

ECM checks if vacuum pump and vent valve operate normally.60 seconds

CEVAP system pressure

measurementVent valve is turned ON (closed) to shut EVAP system.

Negative pressure (vacuum) is created in EVAP system, and EVAP

system pressure is then measured.

Write down measured value as it will be used in leak check.

If EVAP pressure does not stabilize within 15 minutes, ECM cancels

EVAP system monitor.15 minutes

*2

D Purge VSV monitorPurge VSV is opened and then EVAP system pressure is measured

by ECM.

Large increase indicates normal.10 seconds

ESecond 0.02 inch leak pressure

measurementAfter second 0.02 inch leak pressure measurement, leak check is

performed by comparing first and second 0.02 inch leak pressure

standards.

If stabilized system pressure is higher than second 0.02 inch leak

pressure standard, ECM determines that EVAP system is leaking.60 seconds

F Final checkAtmospheric pressure is measured and then monitoring result is

recorded by ECM.- Sequence Operation Description Duration

A096746E34