TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 621 of 3000

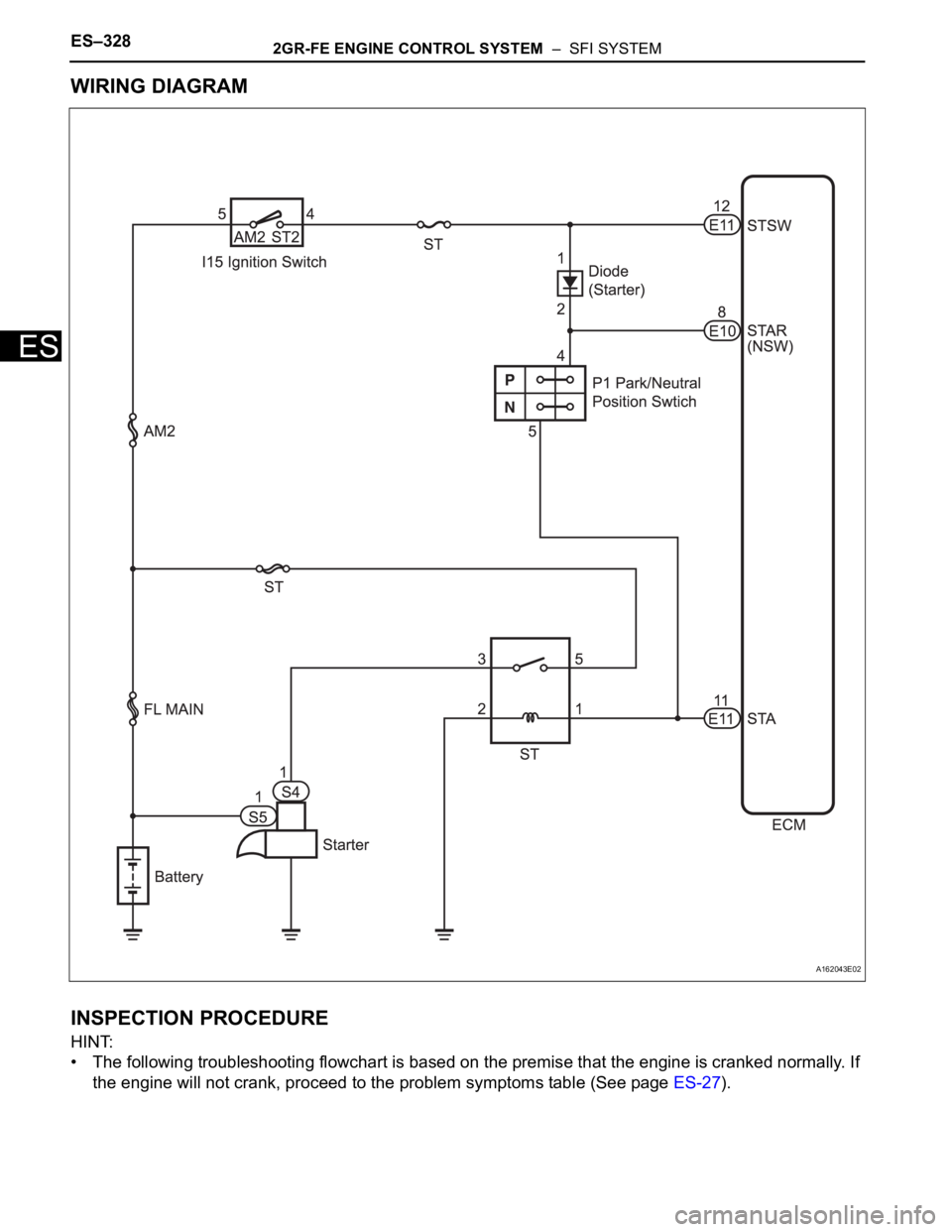

ES–3282GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

• The following troubleshooting flowchart is based on the premise that the engine is cranked normally. If

the engine will not crank, proceed to the problem symptoms table (See page ES-27).

A162043E02

Page 622 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–329

ES

• Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame

data can be helpful in determining whether the vehicle was running or stopped, whether the engine

was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the

time of a malfunction.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST / ALL / STARTER SIG.

(d) Check the value displayed on the tester when the

ignition switch is turned to the ON position and START

position.

OK

OK

NG

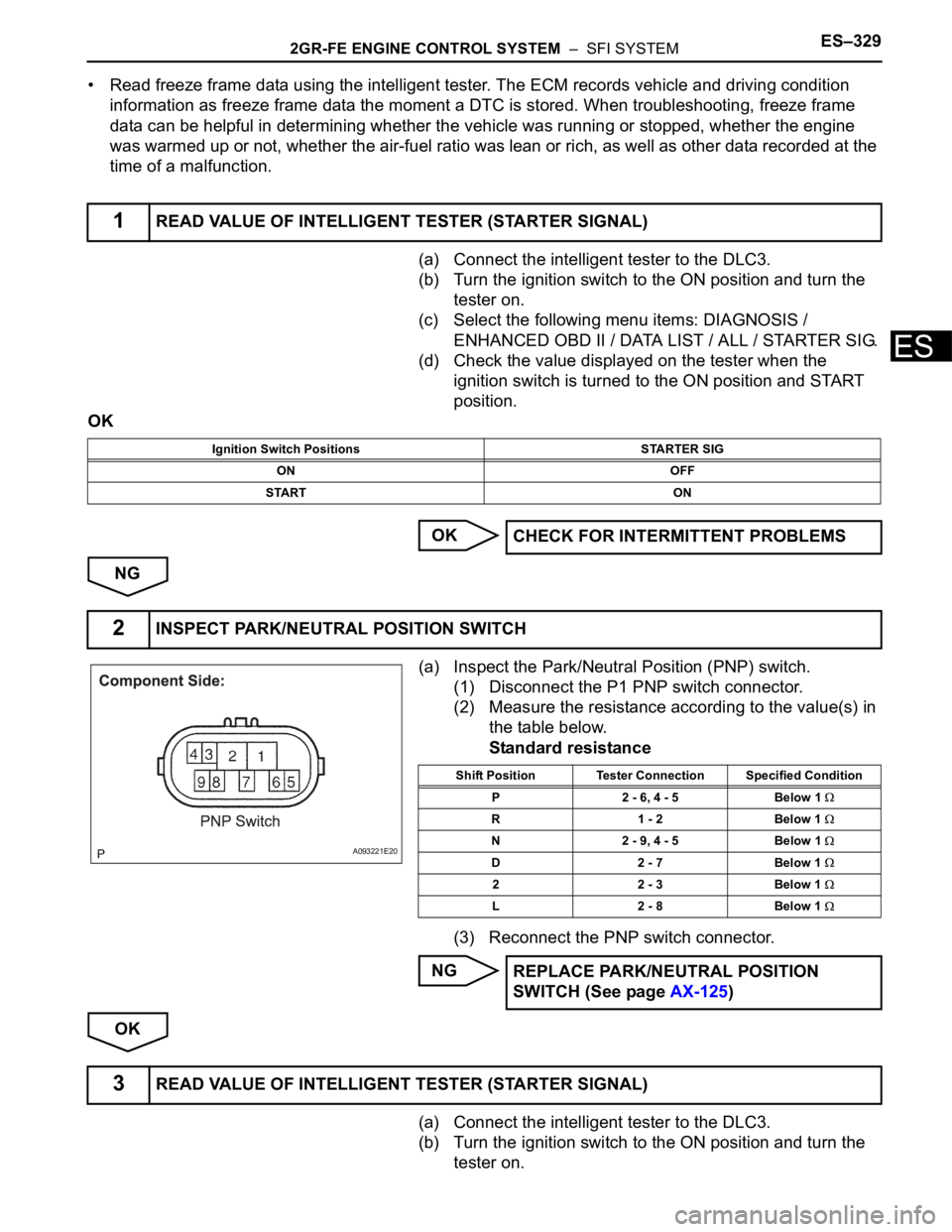

(a) Inspect the Park/Neutral Position (PNP) switch.

(1) Disconnect the P1 PNP switch connector.

(2) Measure the resistance according to the value(s) in

the table below.

Standard resistance

(3) Reconnect the PNP switch connector.

NG

OK

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

1READ VALUE OF INTELLIGENT TESTER (STARTER SIGNAL)

Ignition Switch Positions STARTER SIG

ON OFF

START ON

CHECK FOR INTERMITTENT PROBLEMS

2INSPECT PARK/NEUTRAL POSITION SWITCH

A093221E20

Shift Position Tester Connection Specified Condition

P 2 - 6, 4 - 5 Below 1

R 1 - 2 Below 1

N 2 - 9, 4 - 5 Below 1

D 2 - 7 Below 1

2 2 - 3 Below 1

L 2 - 8 Below 1

REPLACE PARK/NEUTRAL POSITION

SWITCH (See page AX-125)

3READ VALUE OF INTELLIGENT TESTER (STARTER SIGNAL)

Page 623 of 3000

ES–3302GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

(c) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST / ALL / STARTER SIG.

(d) Check the value displayed on the tester when the

ignition switch is turned to the ON position and the

START position.

OK

OK

NG

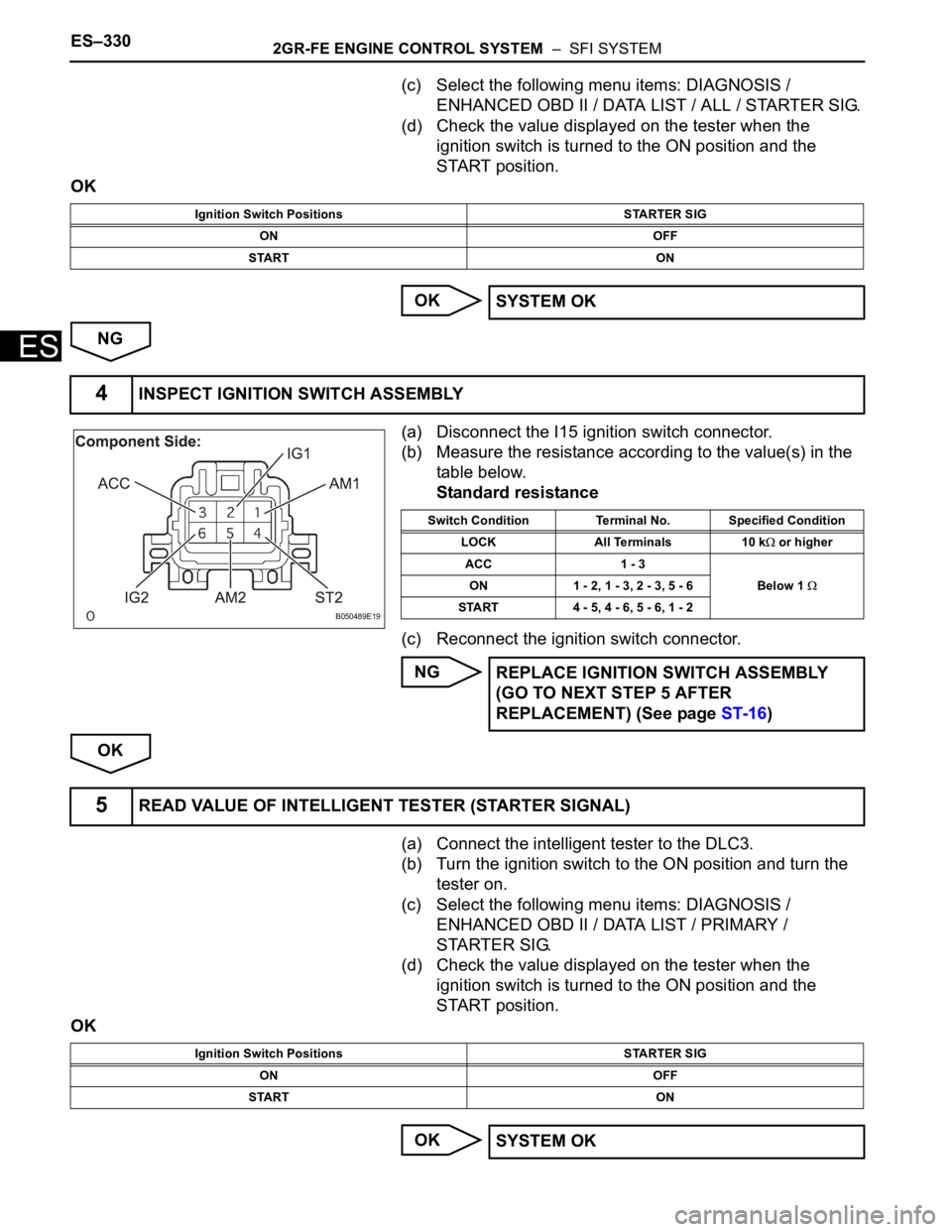

(a) Disconnect the I15 ignition switch connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

(c) Reconnect the ignition switch connector.

NG

OK

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST / PRIMARY /

STARTER SIG.

(d) Check the value displayed on the tester when the

ignition switch is turned to the ON position and the

START position.

OK

OK

Ignition Switch Positions STARTER SIG

ON OFF

START ON

SYSTEM OK

4INSPECT IGNITION SWITCH ASSEMBLY

B050489E19

Switch Condition Terminal No. Specified Condition

LOCK All Terminals 10 k

or higher

ACC 1 - 3

Below 1

ON 1 - 2, 1 - 3, 2 - 3, 5 - 6

START 4 - 5, 4 - 6, 5 - 6, 1 - 2

REPLACE IGNITION SWITCH ASSEMBLY

(GO TO NEXT STEP 5 AFTER

REPLACEMENT) (See page ST-16)

5READ VALUE OF INTELLIGENT TESTER (STARTER SIGNAL)

Ignition Switch Positions STARTER SIG

ON OFF

START ON

SYSTEM OK

Page 624 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–331

ES

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR (PNP SWITCH - STA TERMINAL OF ECM)

Page 625 of 3000

ES–3322GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

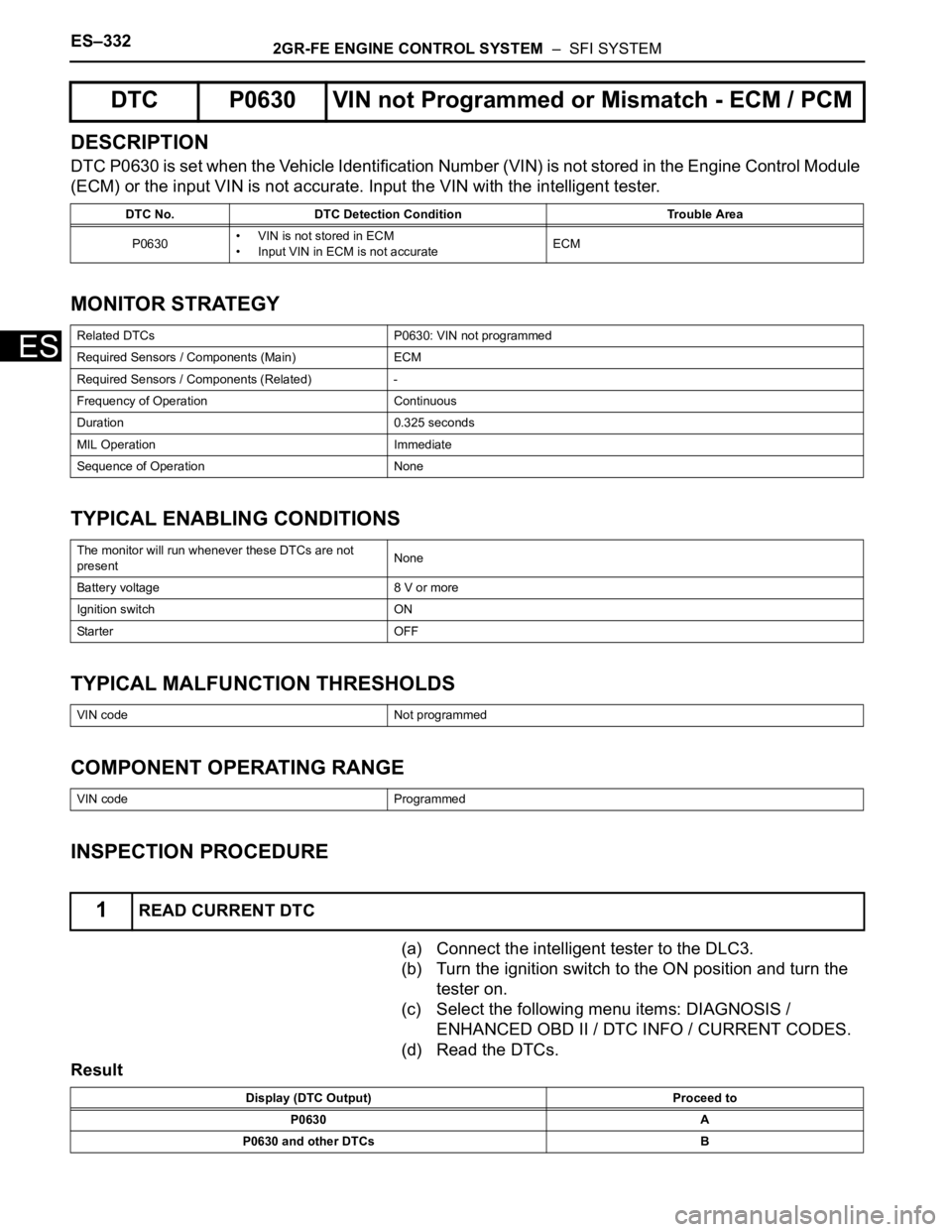

DESCRIPTION

DTC P0630 is set when the Vehicle Identification Number (VIN) is not stored in the Engine Control Module

(ECM) or the input VIN is not accurate. Input the VIN with the intelligent tester.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

COMPONENT OPERATING RANGE

INSPECTION PROCEDURE

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(d) Read the DTCs.

Result

DTC P0630 VIN not Programmed or Mismatch - ECM / PCM

DTC No. DTC Detection Condition Trouble Area

P0630• VIN is not stored in ECM

• Input VIN in ECM is not accurateECM

Related DTCs P0630: VIN not programmed

Required Sensors / Components (Main) ECM

Required Sensors / Components (Related) -

Frequency of Operation Continuous

Duration 0.325 seconds

MIL Operation Immediate

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentNone

Battery voltage 8 V or more

Ignition switch ON

Starter OFF

VIN code Not programmed

VIN code Programmed

1READ CURRENT DTC

Display (DTC Output) Proceed to

P0630 A

P0630 and other DTCs B

Page 626 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–333

ES

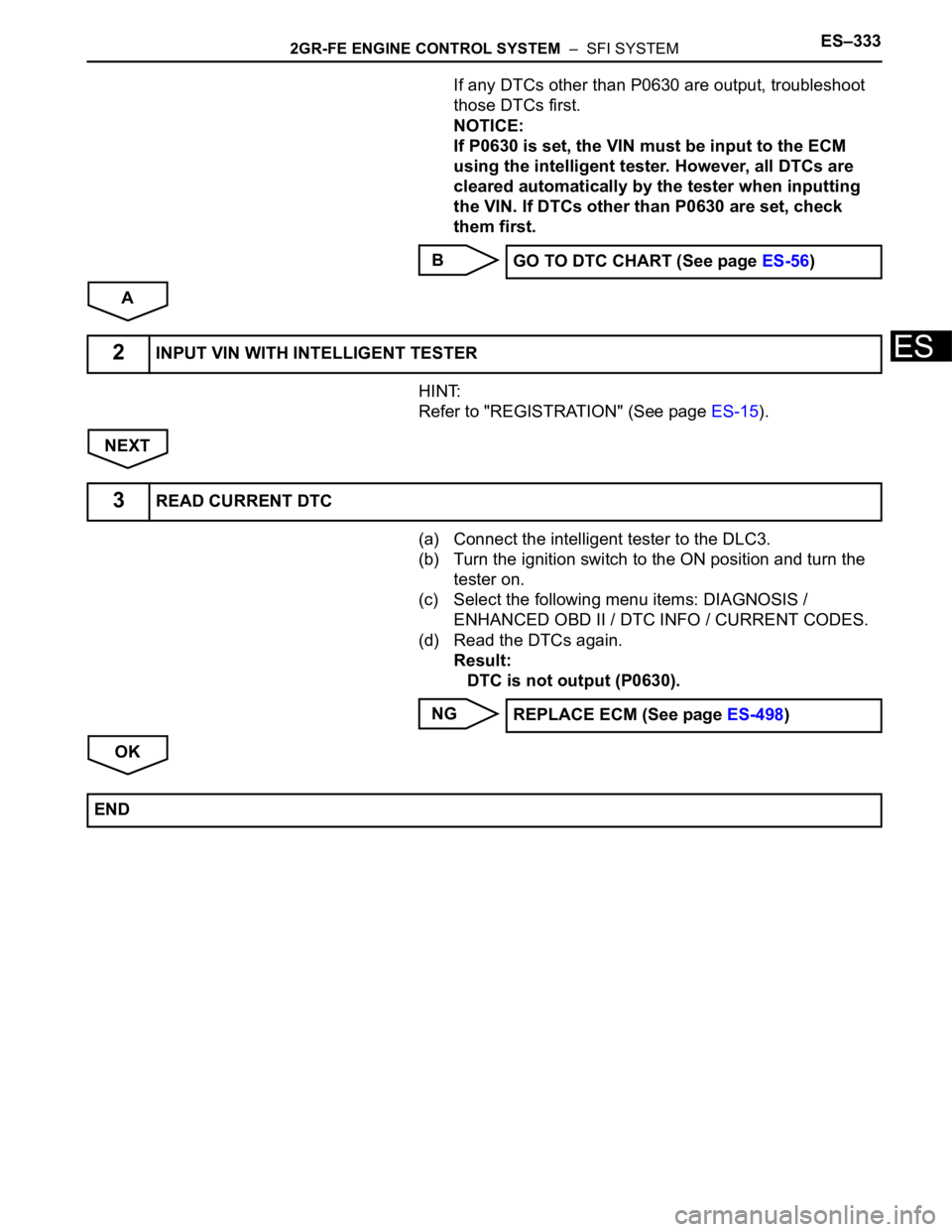

If any DTCs other than P0630 are output, troubleshoot

those DTCs first.

NOTICE:

If P0630 is set, the VIN must be input to the ECM

using the intelligent tester. However, all DTCs are

cleared automatically by the tester when inputting

the VIN. If DTCs other than P0630 are set, check

them first.

B

A

HINT:

Refer to "REGISTRATION" (See page ES-15).

NEXT

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(d) Read the DTCs again.

Result:

DTC is not output (P0630).

NG

OKGO TO DTC CHART (See page ES-56)

2INPUT VIN WITH INTELLIGENT TESTER

3READ CURRENT DTC

REPLACE ECM (See page ES-498)

END

Page 627 of 3000

ES–3342GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

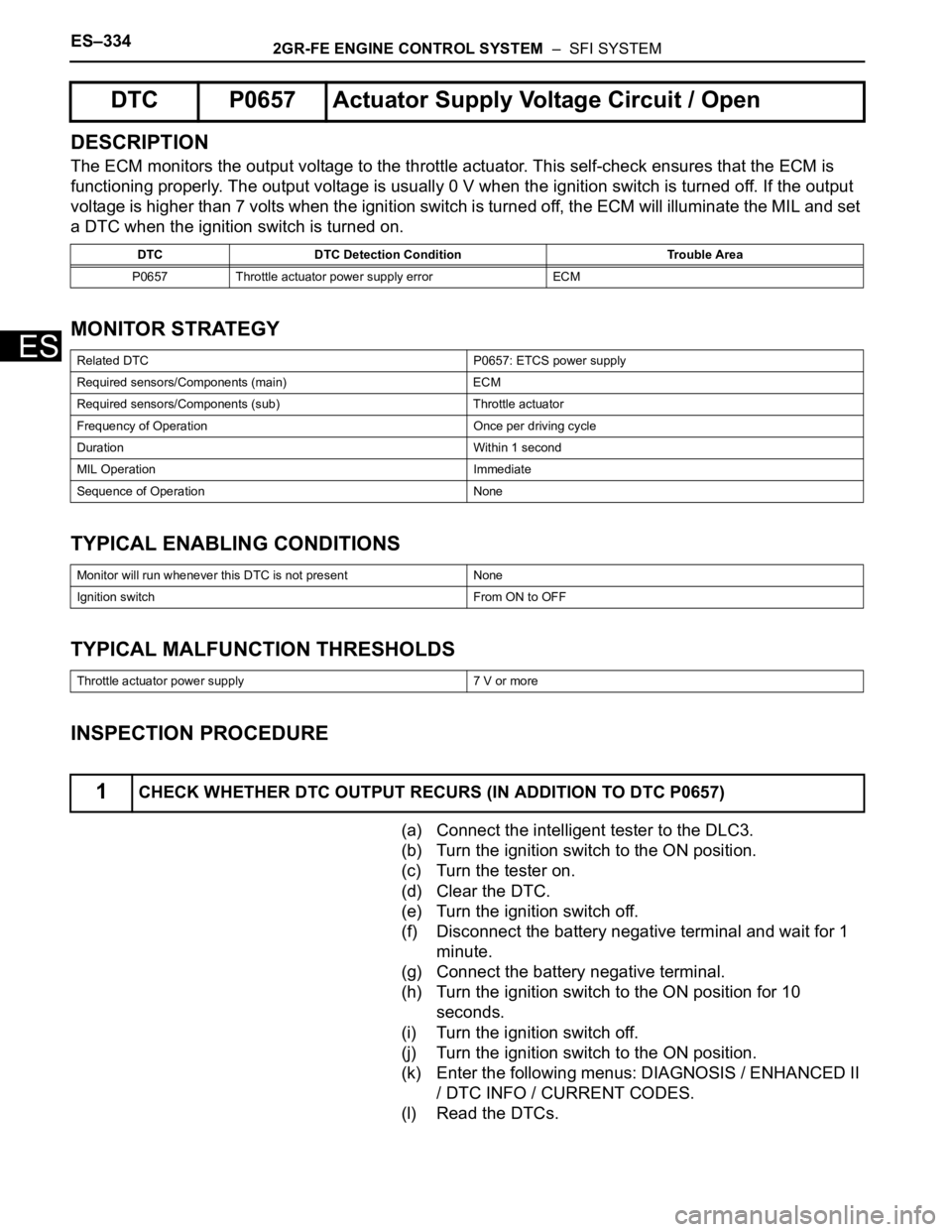

DESCRIPTION

The ECM monitors the output voltage to the throttle actuator. This self-check ensures that the ECM is

functioning properly. The output voltage is usually 0 V when the ignition switch is turned off. If the output

voltage is higher than 7 volts when the ignition switch is turned off, the ECM will illuminate the MIL and set

a DTC when the ignition switch is turned on.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

INSPECTION PROCEDURE

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Clear the DTC.

(e) Turn the ignition switch off.

(f) Disconnect the battery negative terminal and wait for 1

minute.

(g) Connect the battery negative terminal.

(h) Turn the ignition switch to the ON position for 10

seconds.

(i) Turn the ignition switch off.

(j) Turn the ignition switch to the ON position.

(k) Enter the following menus: DIAGNOSIS / ENHANCED II

/ DTC INFO / CURRENT CODES.

(l) Read the DTCs.

DTC P0657 Actuator Supply Voltage Circuit / Open

DTC DTC Detection Condition Trouble Area

P0657 Throttle actuator power supply error ECM

Related DTC P0657: ETCS power supply

Required sensors/Components (main) ECM

Required sensors/Components (sub) Throttle actuator

Frequency of Operation Once per driving cycle

Duration Within 1 second

MIL Operation Immediate

Sequence of Operation None

Monitor will run whenever this DTC is not present None

Ignition switch From ON to OFF

Throttle actuator power supply 7 V or more

1CHECK WHETHER DTC OUTPUT RECURS (IN ADDITION TO DTC P0657)

Page 628 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–335

ES

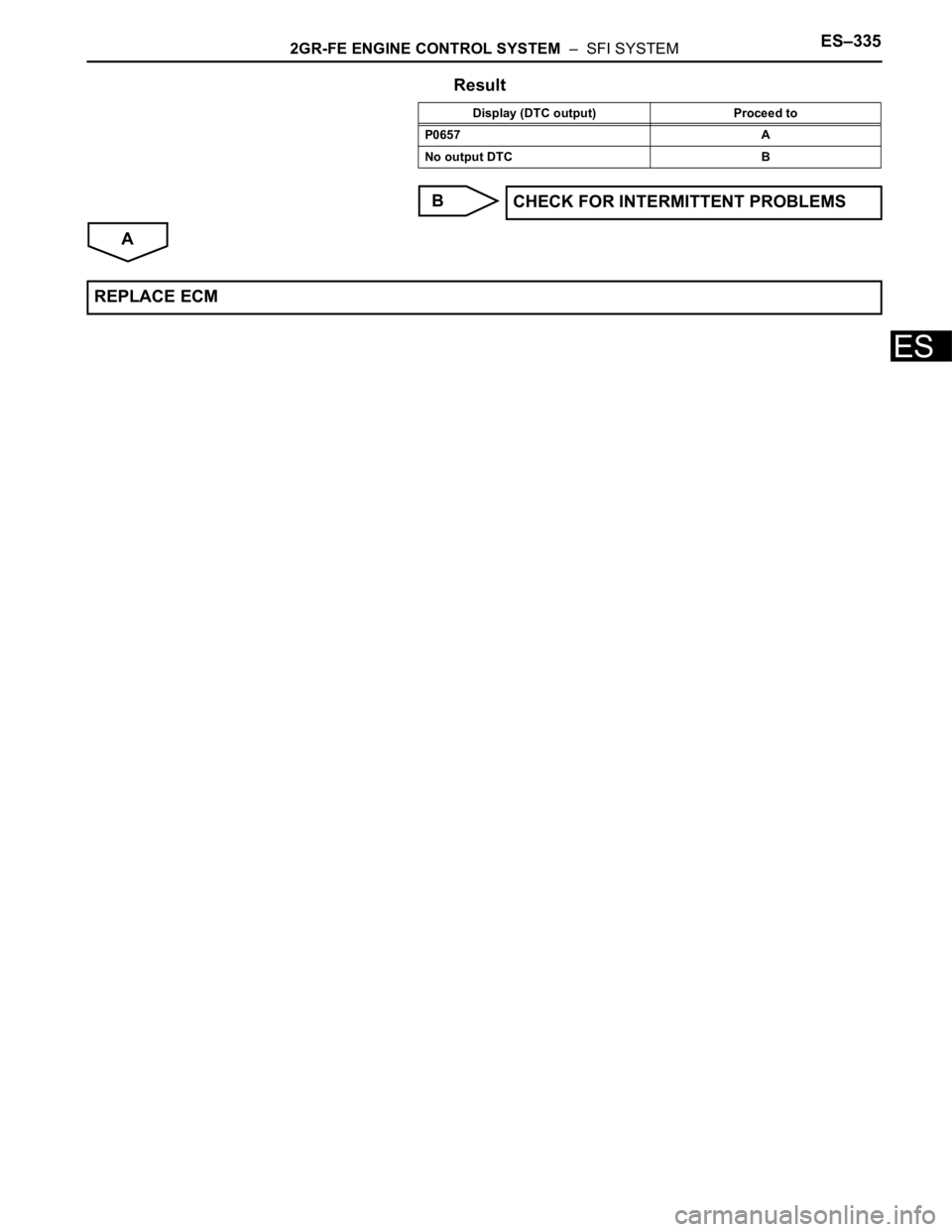

Result

B

A

Display (DTC output) Proceed to

P0657 A

No output DTC B

CHECK FOR INTERMITTENT PROBLEMS

REPLACE ECM

Page 629 of 3000

ES–3362GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

DESCRIPTION

The park/neutral position switch detects the shift lever position and sends signals to the ECM.

HINT:

After confirming DTC P0705, use the intelligent tester to confirm the PNP switch signal in the ALL menu

(to reach the ALL menu: DIAGNOSIS / ENHANCED OBD II / DATA LIST / ALL).

WIRING DIAGRAM

Refer to DTC P0705 for 2WD model (See page AX-40) or 4WD model (See page AX-40).

INSPECTION PROCEDURE

Refer to DTC P0705 for 2WD model (See page AX-41) or 4WD model (See page AX-41).

HINT:

Read freeze frame data using the intelligent tester or OBD II scan tool. The ECM records vehicle and

driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting,

freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up

or not, if the air-fuel ratio was LEAN or RICH, and other data from the time the malfunction occurred.

DTC P0705Transmission Range Sensor Circuit Malfunc-

tion (PRNDL Input)

DTC No. DTC Detection Condition Trouble Area

P0705(A) Any 2 or more signals of the following are ON

simultaneously (2-trip detection logic)

• P input signal is ON.

• N input signal is ON.

• R input signal is ON.

• D input signal is ON.

(B) Any 2 ore more signals of the following are ON

simultaneously (2-trip detection logic)

• NSW input signal is ON.

• R input signal is ON.

• D input signal is ON.

(C) Any of following conditions is met for 2.0 sec. or more in

the S position (2-trip detection logic).

• NSW input signal is ON.

• P input signal is ON.

• N input signal is ON.

• R input signal is ON.

(D) All switches are OFF simultaneously for NSW, P, R, N and

D.• Open or short in park/neutral position switch circuit

• Park/neutral position switch

•ECM

Page 630 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–337

ES

DESCRIPTION

The throttle actuator is operated by the ECM and opens and closes the throttle valve using gears.

The opening angle of the throttle valve is detected by the Throttle Position (TP) sensor, which is mounted

on the throttle body. The TP sensor provides feedback to the ECM. This feedback allows the ECM to

appropriately control the throttle actuator and monitor the throttle opening angle as the ECM responds to

driver inputs.

HINT:

This ETCS (Electronic Throttle Control System) does not use a throttle cable.

MONITOR DESCRIPTION

The ECM monitors the electrical current through the electronic actuator, and detects malfunctions and

open circuits in the throttle actuator based on this value. If the current is outside the standard range, the

ECM determines that there is a malfunction in the throttle actuator. In addition, if the throttle valve does

not function properly (for example, stuck on), the ECM determines that there is a malfunction. The ECM

then illuminates the MIL and sets a DTC.

Example:

When the electrical current is more than 10 A, or less than 0.5 A and the throttle actuator duty ratio

exceeds 80%, the ECM interprets this as the current being outside the standard range, and illuminates the

MIL and sets a DTC.

If the malfunction is not repaired successfully, a DTC is set when the engine is quickly revved up to a high

rpm several times after the engine has idled for 5 seconds after engine start.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

All:

DTC P2102 Throttle Actuator Control Motor Circuit Low

DTC P2103 Throttle Actuator Control Motor Circuit High

DTC No. DTC Detection Condition Trouble Area

P2102Conditions (a) and (b) continue for 2.0 seconds (1 trip

detection logic):

(a) Throttle actuator duty ratio exceeds 80% or more

(b) Throttle actuator current is 0.5 A or less• Open in throttle actuator circuit

• Throttle actuator

•ECM

P2103Either of the following conditions is met:

• Hybrid IC diagnosis signal fails

• Hybrid IC current limiter port fails• Short in throttle actuator circuit

• Throttle actuator

• Throttle valve

• Throttle body

•ECM

Related DTCsP2102: Throttle actuator current (low current)

P2103: Throttle actuator current (high current)

Required Sensors / Components (Main) Throttle actuator (throttle body)

Required Sensors / Components (Related) None

Frequency of Operation Continuous

DurationP2102: 2 seconds

P2103: 25 times or 0.6 seconds

MIL Operation Immediate

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentNone