TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 741 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–455

ES

INSPECTION PROCEDURE

(a) Check that the Malfunction Indicator Lamp (MIL) lights

up when turning the ignition switch to the ON position.

OK:

MIL lights up.

OK

NG

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Check the communication between the tester and ECM.

Result

A

B

(a) Disconnect the throttle body connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

Result

(d) Reconnect the throttle body connector.

A

B

(a) Disconnect the accelerator pedal position sensor

connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

1CHECK MIL

GO TO MIL CIRCUIT (See page ES-478)

2CHECK CONNECTION BETWEEN INTELLIGENT TESTER AND ECM

Result Proceed to

Communication is possible A

Communication is not possible B

GO TO MIL CIRCUIT (See page ES-478)

3CHECK THROTTLE BODY (CHECK MIL ILLUMINATED)

Result Proceed to

MIL illuminates A

MIL does not illuminate B

REPLACE THROTTLE BODY (See page ES-

493)

4CHECK ACCELERATOR PEDAL ROD (CHECK MIL ILLUMINATED)

Page 742 of 3000

ES–4562GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

Result

(d) Reconnect the accelerator pedal position sensor

connector.

A

B

(a) Disconnect the VVT sensor for intake camshaft bank 1

connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

Result

(d) Reconnect the VVT sensor for intake camshaft bank 1

connector.

A

B

(a) Disconnect the VVT sensor for exhaust camshaft bank 1

connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

Result

(d) Reconnect the VVT sensor for exhaust camshaft bank 1

connector.

A

B

Result Proceed to

MIL illuminates A

MIL does not illuminate B

REPLACE ACCELERATOR PEDAL ROD (See

page ES-502)

5CHECK VVT SENSOR FOR INTAKE CAMSHAFT BANK 1 (CHECK MIL ILLUMINATED)

Result Proceed to

MIL illuminates A

MIL does not illuminate B

REPLACE VVT SENSOR FOR INTAKE

CAMSHAFT BANK 1 (See page ES-509)

6CHECK VVT SENSOR FOR EXHAUST CAMSHAFT BANK 1 (CHECK MIL ILLUMINAT E D )

Result Proceed to

MIL illuminates A

MIL does not illuminate B

REPLACE VVT SENSOR FOR EXHAUST

CAMSHAFT BANK 1 (See page ES-509)

Page 743 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–457

ES

(a) Disconnect the VVT sensor for intake camshaft bank 2

connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

Result

(d) Reconnect the VVT sensor for intake camshaft bank 2

connector.

A

B

(a) Disconnect the VVT sensor for exhaust camshaft bank 2

connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

Result

(d) Reconnect the VVT sensor for exhaust camshaft bank 2

connector.

A

B

(a) Disconnect the canister pump module connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

Result

(d) Reconnect the canister pump module connector.

A

7CHECK VVT SENSOR FOR INTAKE CAMSHAFT BANK 2 (CHECK MIL ILLUMINATED)

Result Proceed to

MIL illuminates A

MIL does not illuminate B

REPLACE VVT SENSOR FOR INTAKE

CAMSHAFT BANK 2 (See page ES-509)

8CHECK VVT SENSOR FOR EXHAUST CAMSHAFT BANK 2 (CHECK MIL ILLUMINAT E D )

Result Proceed to

MIL illuminates A

MIL does not illuminate B

REPLACE VVT SENSOR FOR EXHAUST

CAMSHAFT BANK 2 (See page ES-509)

9CHECK CHARCOAL CANISTER ASSEMBLY (CHECK MIL ILLUMINATED)

Result Proceed to

MIL illuminates A

MIL does not illuminate B

REPLACE CHARCOAL CANISTER

ASSEMBLY (See page EC-8)

Page 744 of 3000

ES–4582GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

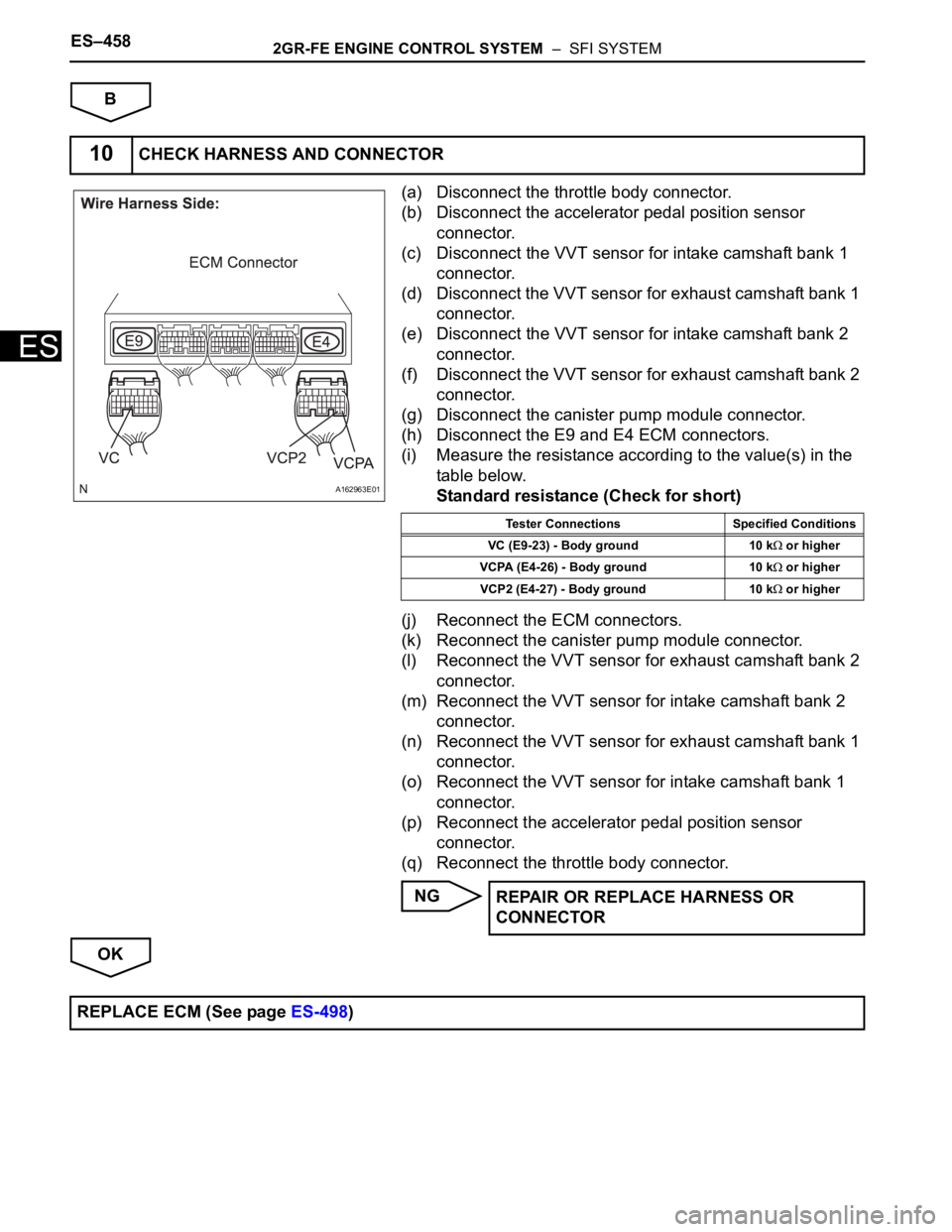

B

(a) Disconnect the throttle body connector.

(b) Disconnect the accelerator pedal position sensor

connector.

(c) Disconnect the VVT sensor for intake camshaft bank 1

connector.

(d) Disconnect the VVT sensor for exhaust camshaft bank 1

connector.

(e) Disconnect the VVT sensor for intake camshaft bank 2

connector.

(f) Disconnect the VVT sensor for exhaust camshaft bank 2

connector.

(g) Disconnect the canister pump module connector.

(h) Disconnect the E9 and E4 ECM connectors.

(i) Measure the resistance according to the value(s) in the

table below.

Standard resistance (Check for short)

(j) Reconnect the ECM connectors.

(k) Reconnect the canister pump module connector.

(l) Reconnect the VVT sensor for exhaust camshaft bank 2

connector.

(m) Reconnect the VVT sensor for intake camshaft bank 2

connector.

(n) Reconnect the VVT sensor for exhaust camshaft bank 1

connector.

(o) Reconnect the VVT sensor for intake camshaft bank 1

connector.

(p) Reconnect the accelerator pedal position sensor

connector.

(q) Reconnect the throttle body connector.

NG

OK

10CHECK HARNESS AND CONNECTOR

A162963E01

Tester Connections Specified Conditions

VC (E9-23) - Body ground 10 k

or higher

VCPA (E4-26) - Body ground 10 k

or higher

VCP2 (E4-27) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR

REPLACE ECM (See page ES-498)

Page 745 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–459

ES

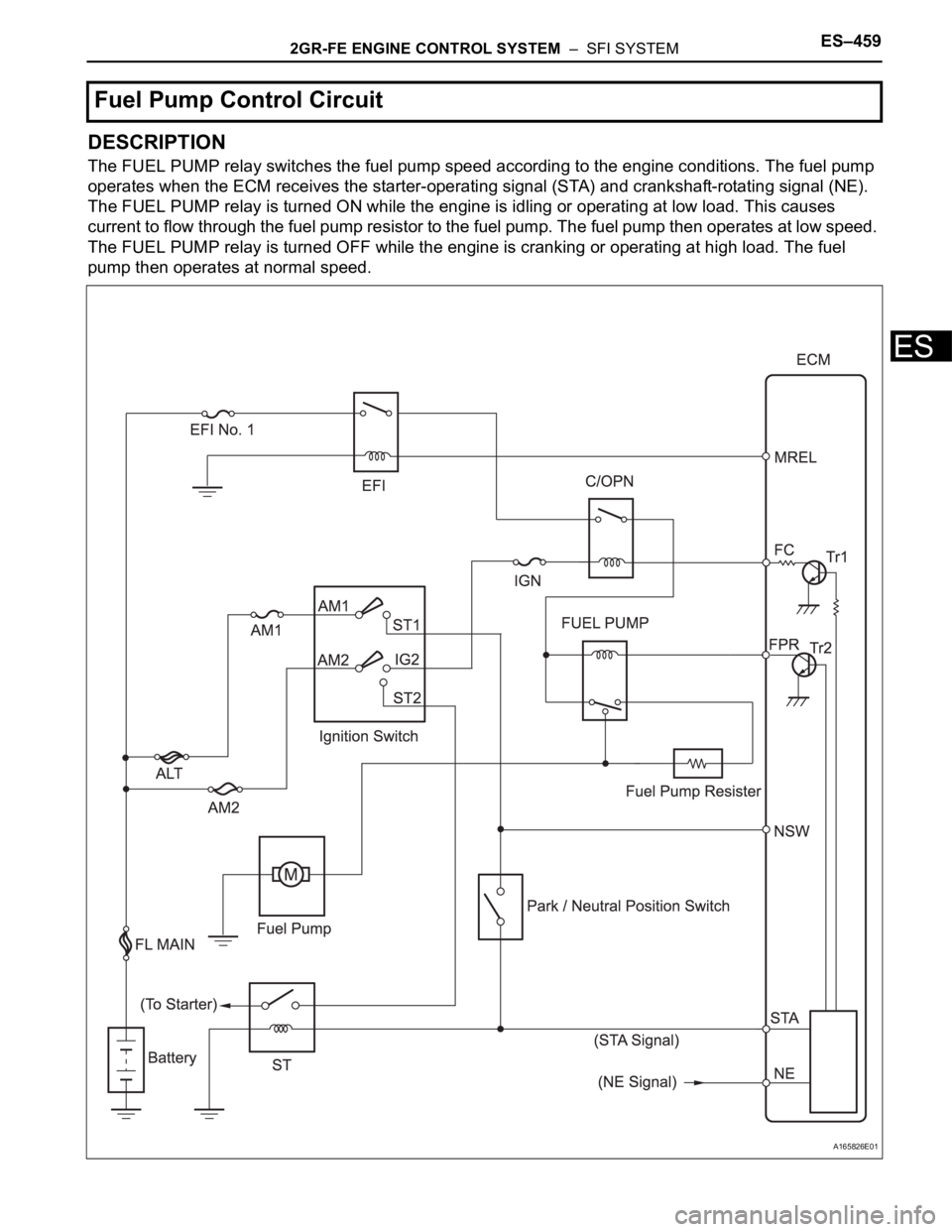

DESCRIPTION

The FUEL PUMP relay switches the fuel pump speed according to the engine conditions. The fuel pump

operates when the ECM receives the starter-operating signal (STA) and crankshaft-rotating signal (NE).

The FUEL PUMP relay is turned ON while the engine is idling or operating at low load. This causes

current to flow through the fuel pump resistor to the fuel pump. The fuel pump then operates at low speed.

The FUEL PUMP relay is turned OFF while the engine is cranking or operating at high load. The fuel

pump then operates at normal speed.

Fuel Pump Control Circuit

A165826E01

Page 746 of 3000

ES–4602GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

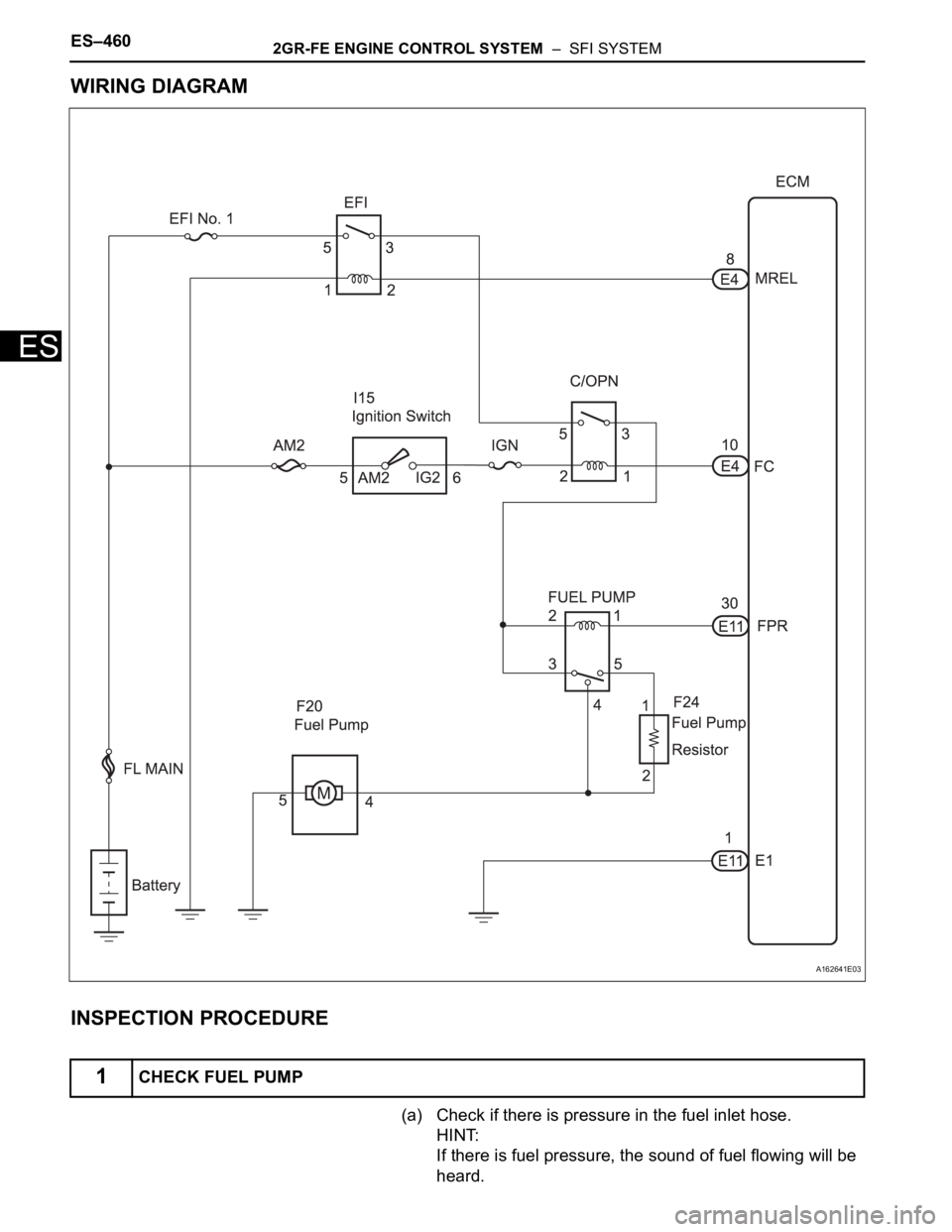

WIRING DIAGRAM

INSPECTION PROCEDURE

(a) Check if there is pressure in the fuel inlet hose.

HINT:

If there is fuel pressure, the sound of fuel flowing will be

heard.

1CHECK FUEL PUMP

A162641E03

Page 747 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–461

ES

OK

NG

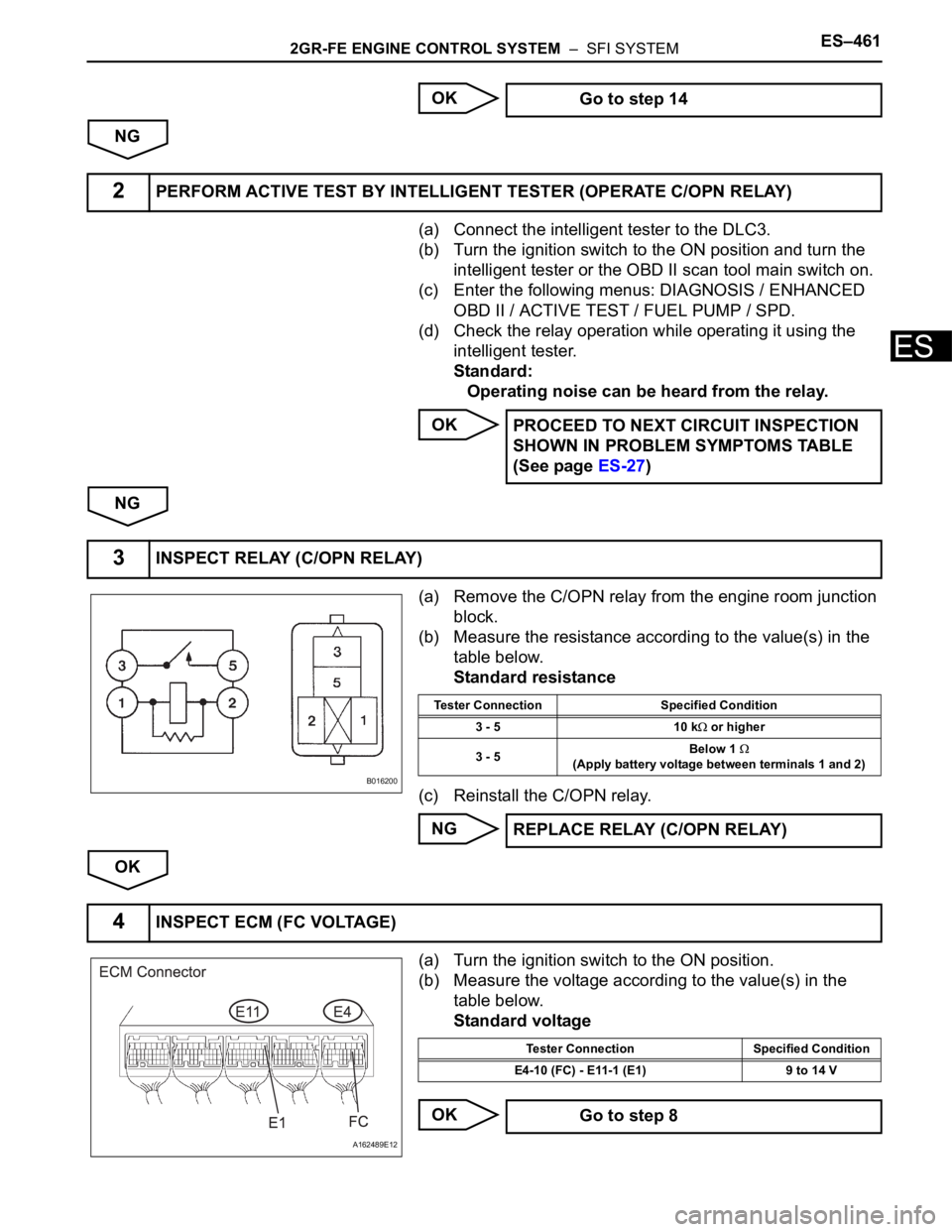

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

intelligent tester or the OBD II scan tool main switch on.

(c) Enter the following menus: DIAGNOSIS / ENHANCED

OBD II / ACTIVE TEST / FUEL PUMP / SPD.

(d) Check the relay operation while operating it using the

intelligent tester.

Standard:

Operating noise can be heard from the relay.

OK

NG

(a) Remove the C/OPN relay from the engine room junction

block.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

(c) Reinstall the C/OPN relay.

NG

OK

(a) Turn the ignition switch to the ON position.

(b) Measure the voltage according to the value(s) in the

table below.

Standard voltage

OK Go to step 14

2PERFORM ACTIVE TEST BY INTELLIGENT TESTER (OPERATE C/OPN RELAY)

PROCEED TO NEXT CIRCUIT INSPECTION

SHOWN IN PROBLEM SYMPTOMS TABLE

(See page ES-27)

3INSPECT RELAY (C/OPN RELAY)

B016200

Tester Connection Specified Condition

3 - 5 10 k

or higher

3 - 5Below 1

(Apply battery voltage between terminals 1 and 2)

REPLACE RELAY (C/OPN RELAY)

4INSPECT ECM (FC VOLTAGE)

A162489E12

Tester Connection Specified Condition

E4-10 (FC) - E11-1 (E1) 9 to 14 V

Go to step 8

Page 748 of 3000

ES–4622GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

NG

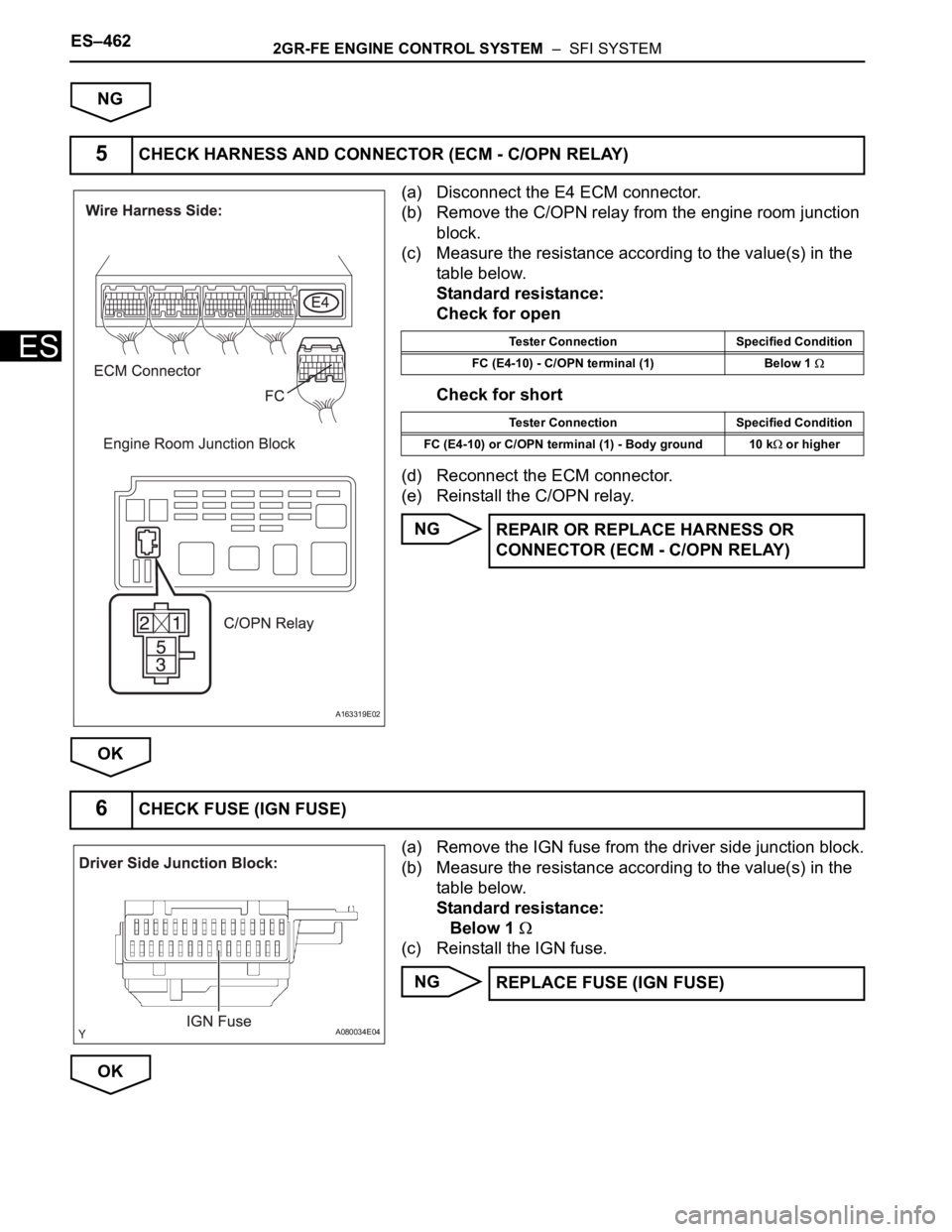

(a) Disconnect the E4 ECM connector.

(b) Remove the C/OPN relay from the engine room junction

block.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Check for open

Check for short

(d) Reconnect the ECM connector.

(e) Reinstall the C/OPN relay.

NG

OK

(a) Remove the IGN fuse from the driver side junction block.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Below 1

(c) Reinstall the IGN fuse.

NG

OK

5CHECK HARNESS AND CONNECTOR (ECM - C/OPN RELAY)

A163319E02

Tester Connection Specified Condition

FC (E4-10) - C/OPN terminal (1) Below 1

Tester Connection Specified Condition

FC (E4-10) or C/OPN terminal (1) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (ECM - C/OPN RELAY)

6CHECK FUSE (IGN FUSE)

A080034E04

REPLACE FUSE (IGN FUSE)

Page 749 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–463

ES

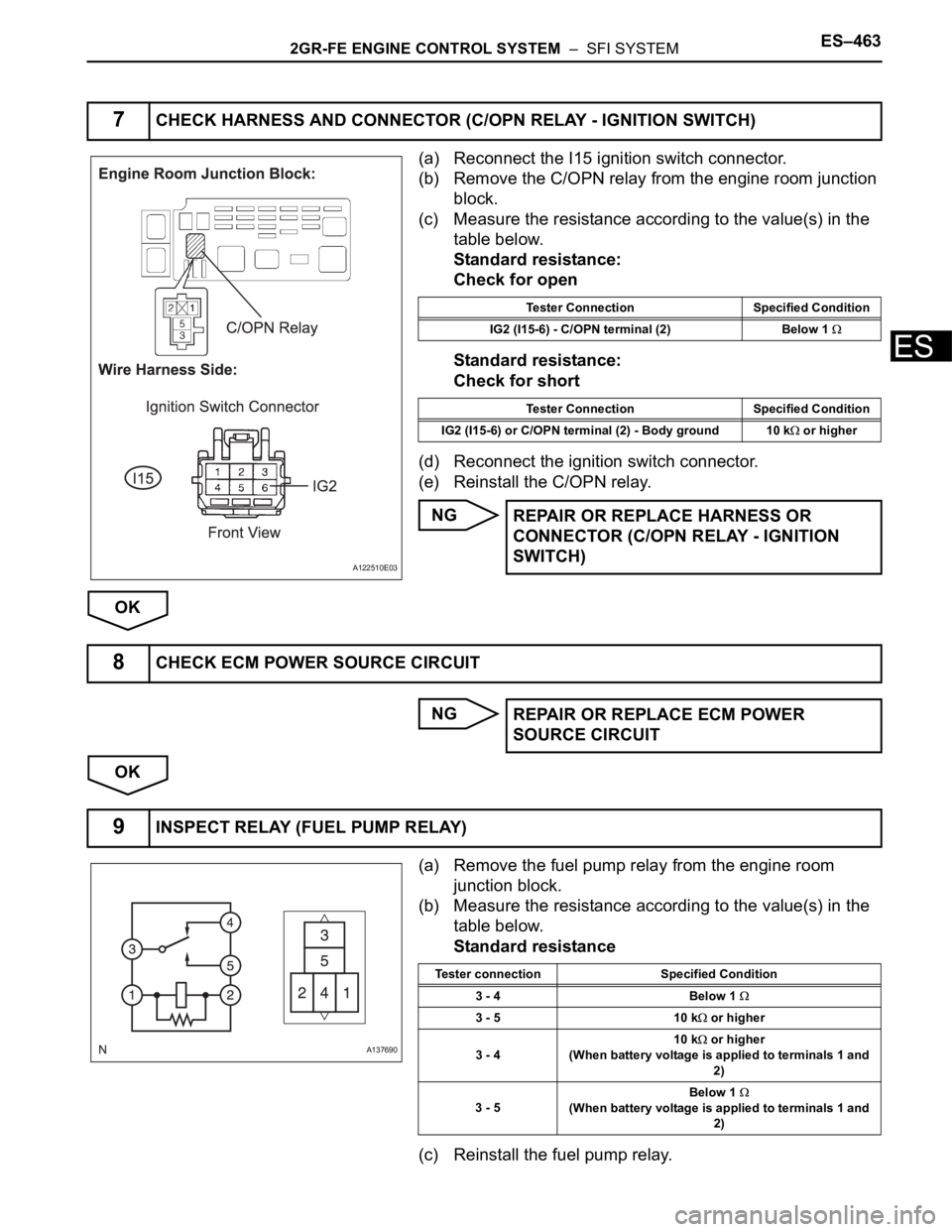

(a) Reconnect the I15 ignition switch connector.

(b) Remove the C/OPN relay from the engine room junction

block.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Check for open

Standard resistance:

Check for short

(d) Reconnect the ignition switch connector.

(e) Reinstall the C/OPN relay.

NG

OK

NG

OK

(a) Remove the fuel pump relay from the engine room

junction block.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

(c) Reinstall the fuel pump relay.

7CHECK HARNESS AND CONNECTOR (C/OPN RELAY - IGNITION SWITCH)

A122510E03

Tester Connection Specified Condition

IG2 (I15-6) - C/OPN terminal (2) Below 1

Tester Connection Specified Condition

IG2 (I15-6) or C/OPN terminal (2) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (C/OPN RELAY - IGNITION

SWITCH)

8CHECK ECM POWER SOURCE CIRCUIT

REPAIR OR REPLACE ECM POWER

SOURCE CIRCUIT

9INSPECT RELAY (FUEL PUMP RELAY)

A137690

Tester connection Specified Condition

3 - 4 Below 1

3 - 5 10 k or higher

3 - 410 k

or higher

(When battery voltage is applied to terminals 1 and

2)

3 - 5Below 1

(When battery voltage is applied to terminals 1 and

2)

Page 750 of 3000

ES–4642GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

NG

OK

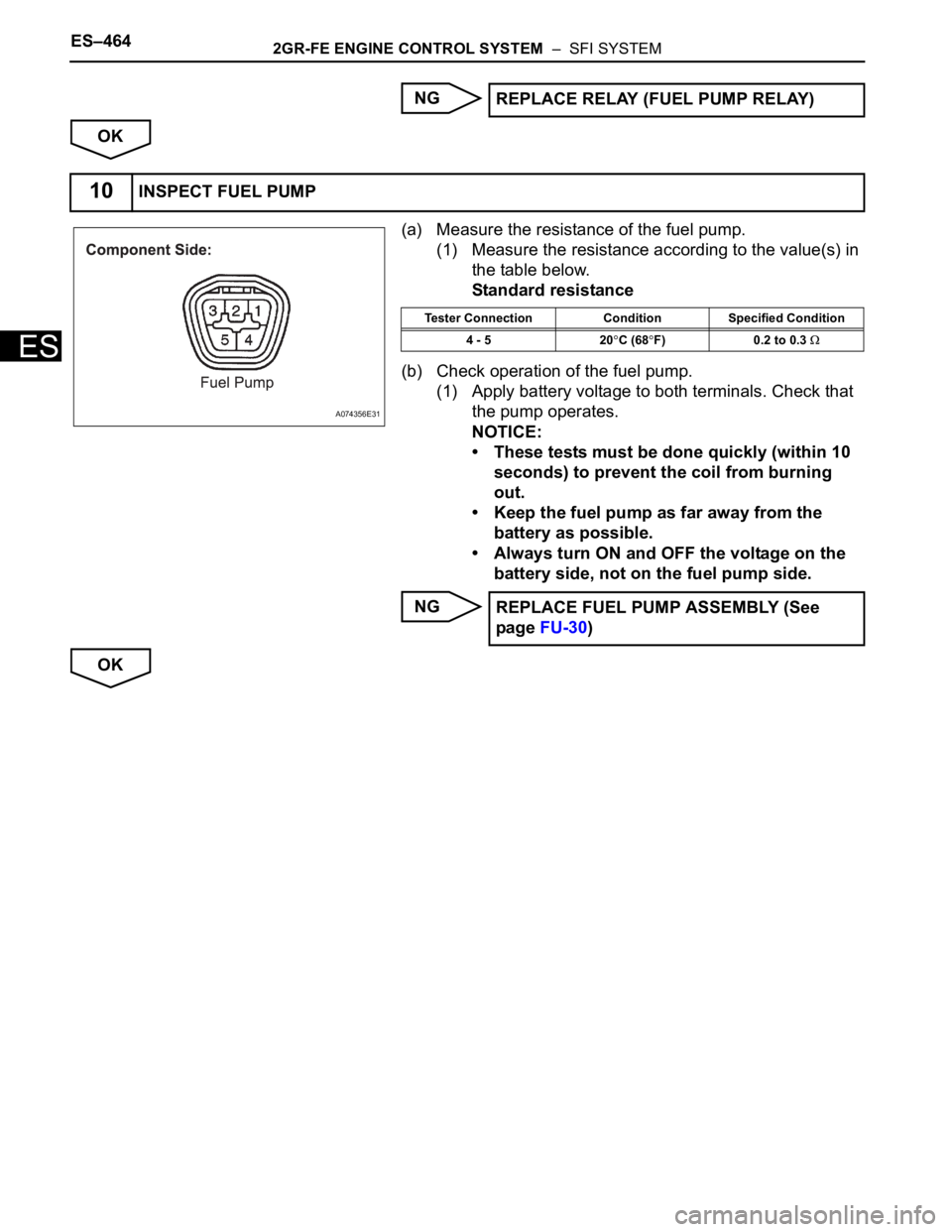

(a) Measure the resistance of the fuel pump.

(1) Measure the resistance according to the value(s) in

the table below.

Standard resistance

(b) Check operation of the fuel pump.

(1) Apply battery voltage to both terminals. Check that

the pump operates.

NOTICE:

• These tests must be done quickly (within 10

seconds) to prevent the coil from burning

out.

• Keep the fuel pump as far away from the

battery as possible.

• Always turn ON and OFF the voltage on the

battery side, not on the fuel pump side.

NG

OKREPLACE RELAY (FUEL PUMP RELAY)

10INSPECT FUEL PUMP

A074356E31

Tester Connection Condition Specified Condition

4 - 5 20

C (68F) 0.2 to 0.3

REPLACE FUEL PUMP ASSEMBLY (See

page FU-30)