TOYOTA TERCEL 1985 Repair Manual

Manufacturer: TOYOTA, Model Year: 1985, Model line: TERCEL, Model: TOYOTA TERCEL 1985Pages: 885, PDF Size: 64.52 MB

Page 541 of 885

REAR AXLE AND SUSPENSION - Differential (4WD)RA-33

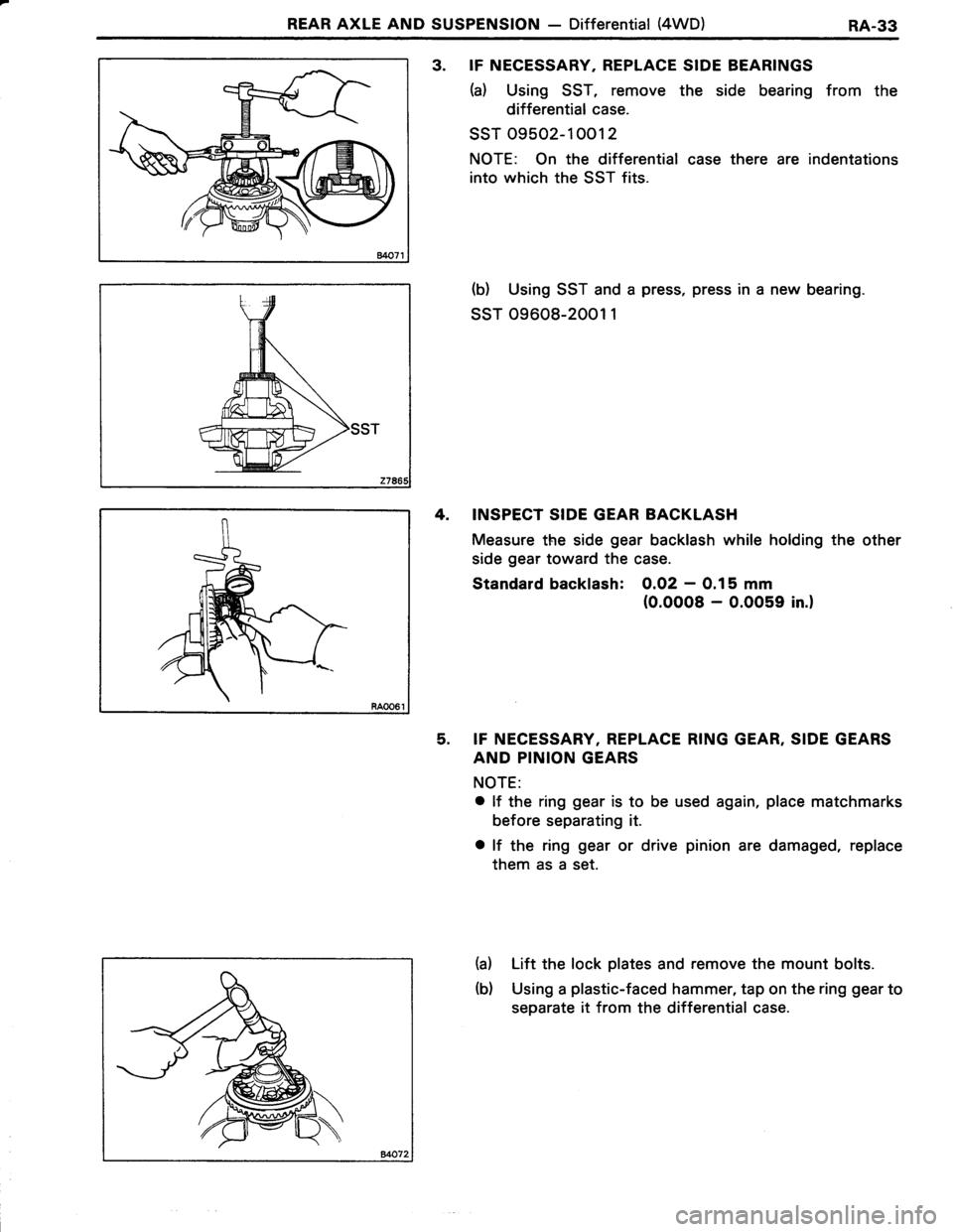

3. IF NECESSARY, REPLACE SIDE BEARINGS

(a) Using SST, remove the side bearing from the

differential case.

ssT 09502-10012

NOTE: On the differential case there are indentations

into which the ssT fits.

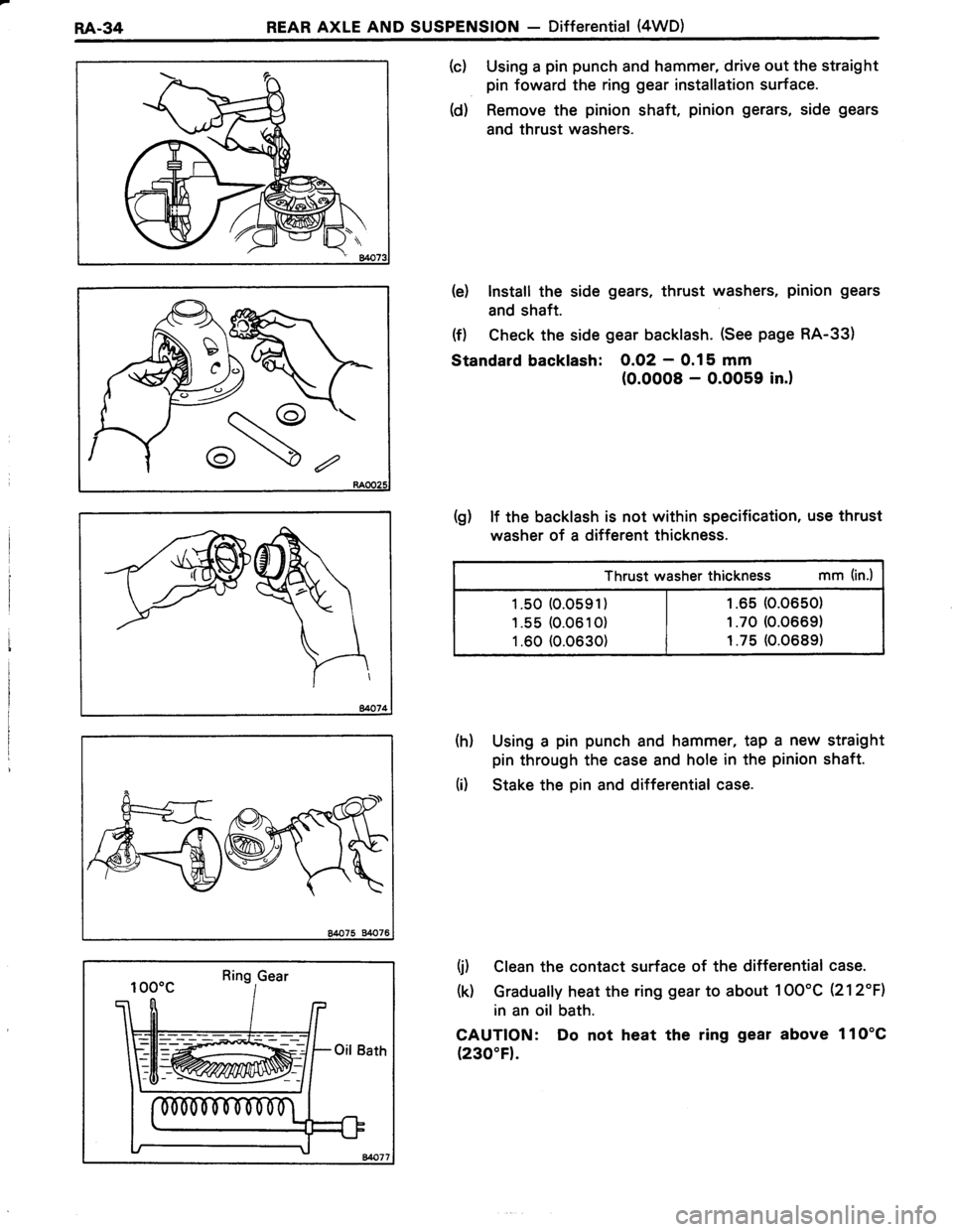

(b) Using SST and a press, press in a new bearing.

ssr 09608-2001 1

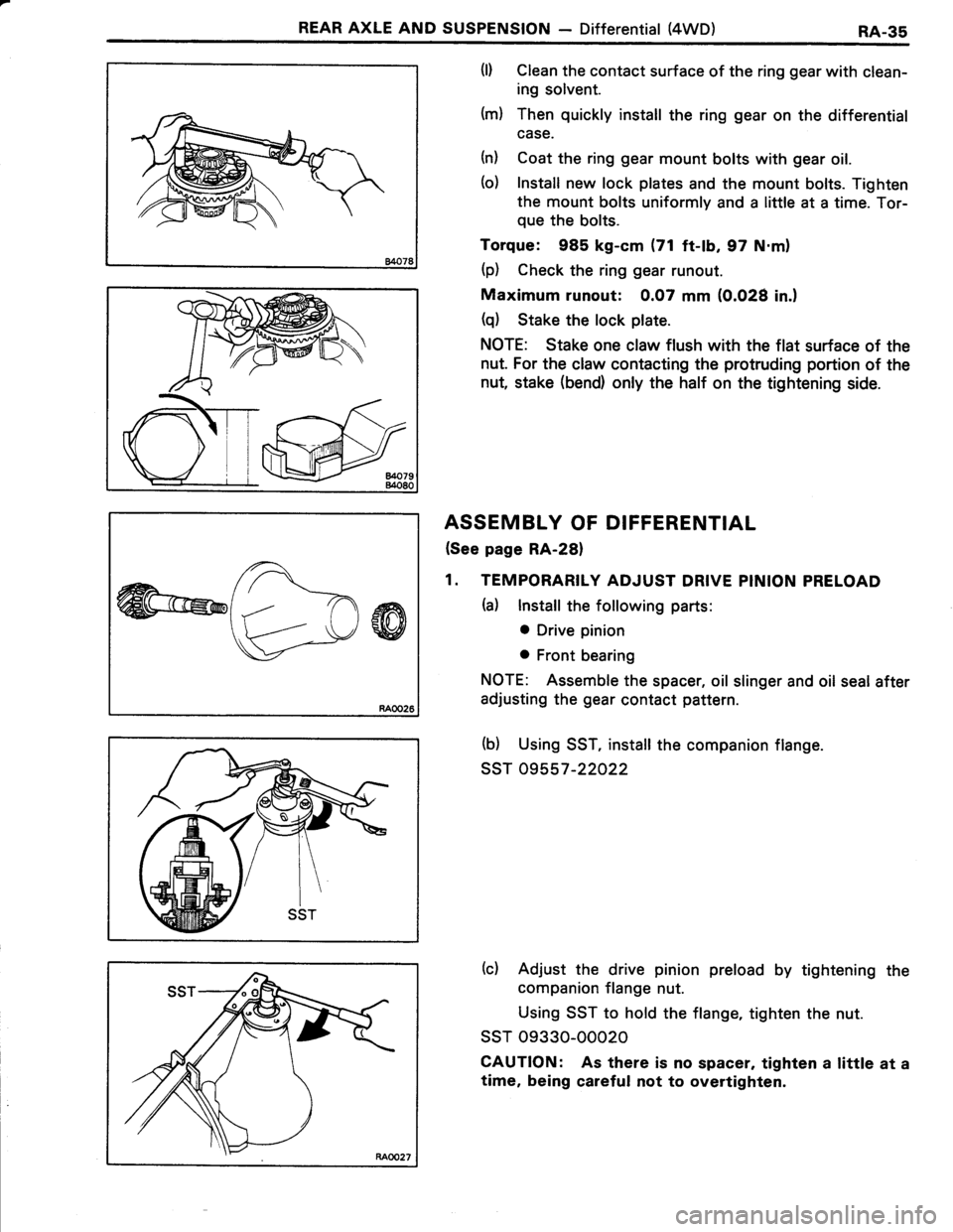

4. INSPECT SIDE GEAR BACKLASH

Measure the side gear backlash while holding the other

side gear toward the case.

Standard backlash: 0.02 - 0.15 mm

(0.0008 - 0.0059 in.)

5. IF NECESSARY, REPLACE RING GEAR, SIDE GEARS

AND PINION GEARS

NOTE:

o lf the ring gear is to be used again, place matchmarks

before separating it.

o lf the ring gear or drive pinion are damaged, replace

them as a set.

(a) Lift the lock plates and remove the mount bolts.

(b) Using a plastic-faced hammer, tap on the ring gear to

separate it from the differential case.

Page 542 of 885

RA.34REAR AXLE AND SUSPENSION - Differential (4WD)

(c) Using a pin punch and hammer, drive out the straight

pin foward the ring gear installation surface.

(d) Remove the pinion shaft, pinion gerars, side gears

and thrust washers.

te) Install the side gears, thrust washers, pinion gears

and shaft.

(f) Check the side gear backlash. (See page RA-33)

Standard backlash: O.O2 - 0.15 mm

(0.0008 - O.OO59 in.)

(g) lf the backlash is not within specification, use thrust

washer of a different thickness.

Thrust washer thickness mm (in.)

1.50 (0.0591) | r.65 (0.0650)

1 .s5 (0.061 0) | t .70 (0.0669)

1.60 (0.0630) | r.75 (0.0689)

(h) Using a pin punch and hammer, tap a new straight

pin through the case and hole in the pinion shaft.

(i) Stake the pin and differential case.

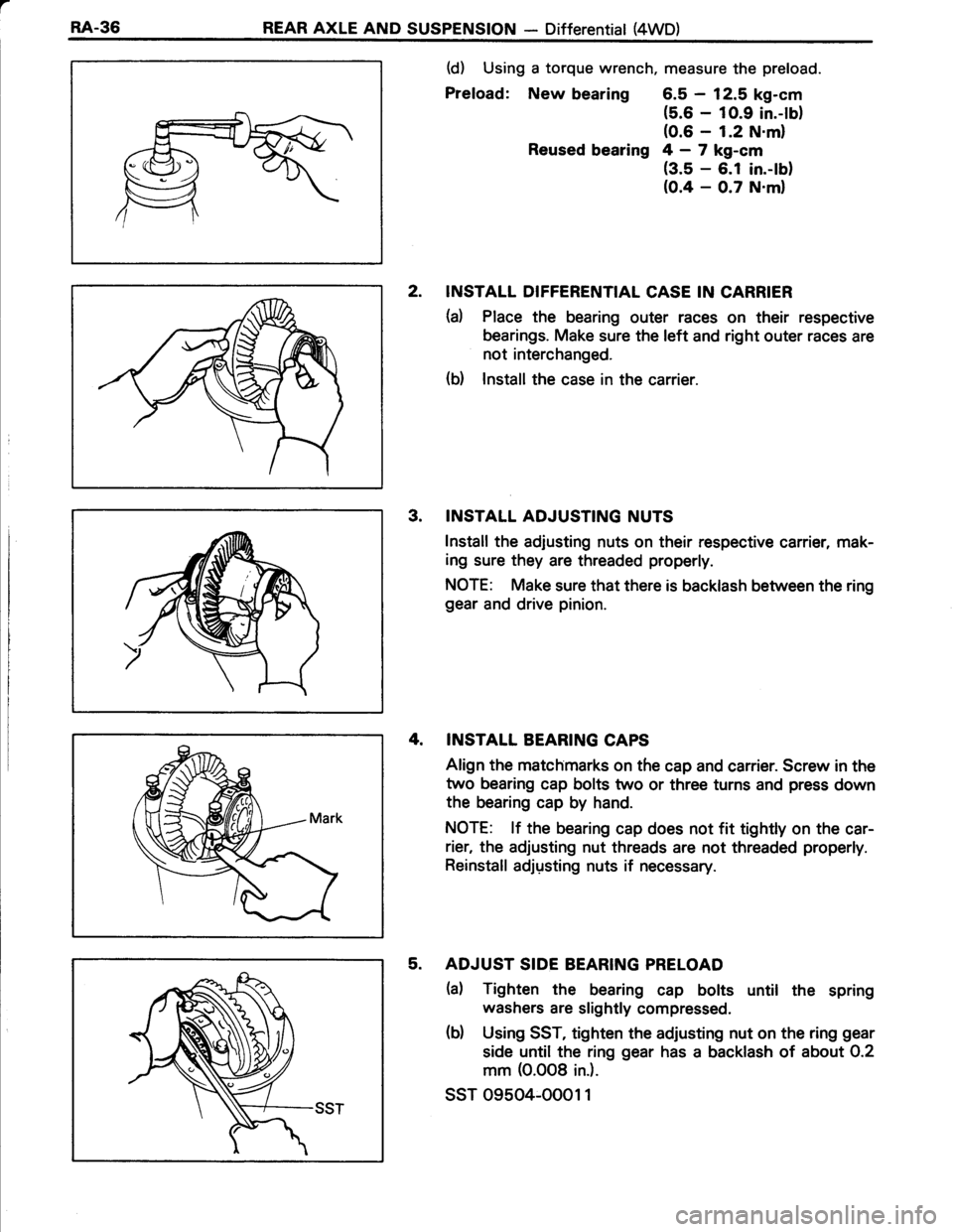

(j) Clean the contact surface of the differential case.

(0 Gradually heat the ring gear to about 1OO'C (212"F1

in an oil bath.

CAUTION: Do not heat the ring gear above 1lO'C

(230"F).

Ring Gear

=-_-

&

Page 543 of 885

REAR AXIE AND SUSPENSION - Differential (4WD)RA-35

(l) Clean the contact surface of the ring gear with clean-

ing solvent.

(m) Then quickly install the ring gear on the differential

case.

(n) Coat the ring gear mount bolts with gear oil.

(o) Install new lock plates and the mount bolts. Tighten

the mount bolts uniformly and a little at a time. Tor-

que the bolts.

Torque: 985 kg-cm (71 ft-lb, 97 N.m)

(p) Check the ring gear runout.

Maximum runout: 0.07 mm (0.028 in.)

(q) Stake the lock plate.

NOTE: Stake one claw flush with the flat surface of the

nut. For the claw contacting the protruding portion of the

nut, stake (bend) only the half on the tightening side.

ASSEMBLY OF DIFFERENTIAL

(See page RA-28)

1. TEMPORARILY ADJUST DRIVE PINION PRELOAD

(a) lnstall the following parts:

o Drive pinion

o Front bearing

NOTE: Assemble the spacer, oil slinger and oil seal after

adjusting the gear contact pattern.

(b) Using SST, install the companion flange.

ssT 09557-22022

(c) Adjust the drive pinion preload by tightening the

companion flange nut.

Using SST to hold the flange, tighten the nut.

ssT 09330-00020

CAUTION: As there is no spacer, taghten a little at a

time, being careful not to overtighten.

Page 544 of 885

a

RA-36REAR AXLE AND SUSPENSION - Differential (4WD)

(d) Using a torque wrench, measure the preload.

Preload: New bearing 6.5 - 12.5 kg-cm

(5.6 - 1O.9 in.-lb)(0.6 - 1.2 N.ml

Reused bearing 4 - 7 kg-cm(3.5 - 6.1 in.-lb)(0.4 - 0.7 N.ml

2. INSTALL DIFFERENTIAL CASE IN CARRIER

(d Place the bearing outer races on their respective

bearings. Make sure the left and right outer races are

not interchanged.

(b) Install the case in the carrier.

3. INSTALL ADJUSTING NUTS

Install the adjusting nuts on their respective carrier, mak-

ing sure they are threaded properly.

NOTE: Make sure that there is backlash between the ring

gear and drive pinion.

4, INSTALL BEARING CAPS

Align the matcfimarks on the cap and carrier. Screw in the

two bearing cap bolts two or three turns and press down

the bearing cap by hand.

NOTE: lf the bearing cap does not fit tightly on the car-

rier, the adjusting nut threads are not threaded properly.

Reinstall adjusting nuts if necessary.

5. ADJUST SIDE BEARING PRELOAD

(a) Tighten the bearing cap bolts until the spring

washers are slightly compressed.

(b) Using SST, tighten the adjusting nut on the ring gear

side until the ring gear has a backlash of about 0.2

mm (0.0O8 in.).

ssr 09504-oool 1

Page 545 of 885

REAR AXLE AND SUSPENSION - Differential (4WD)RA.37

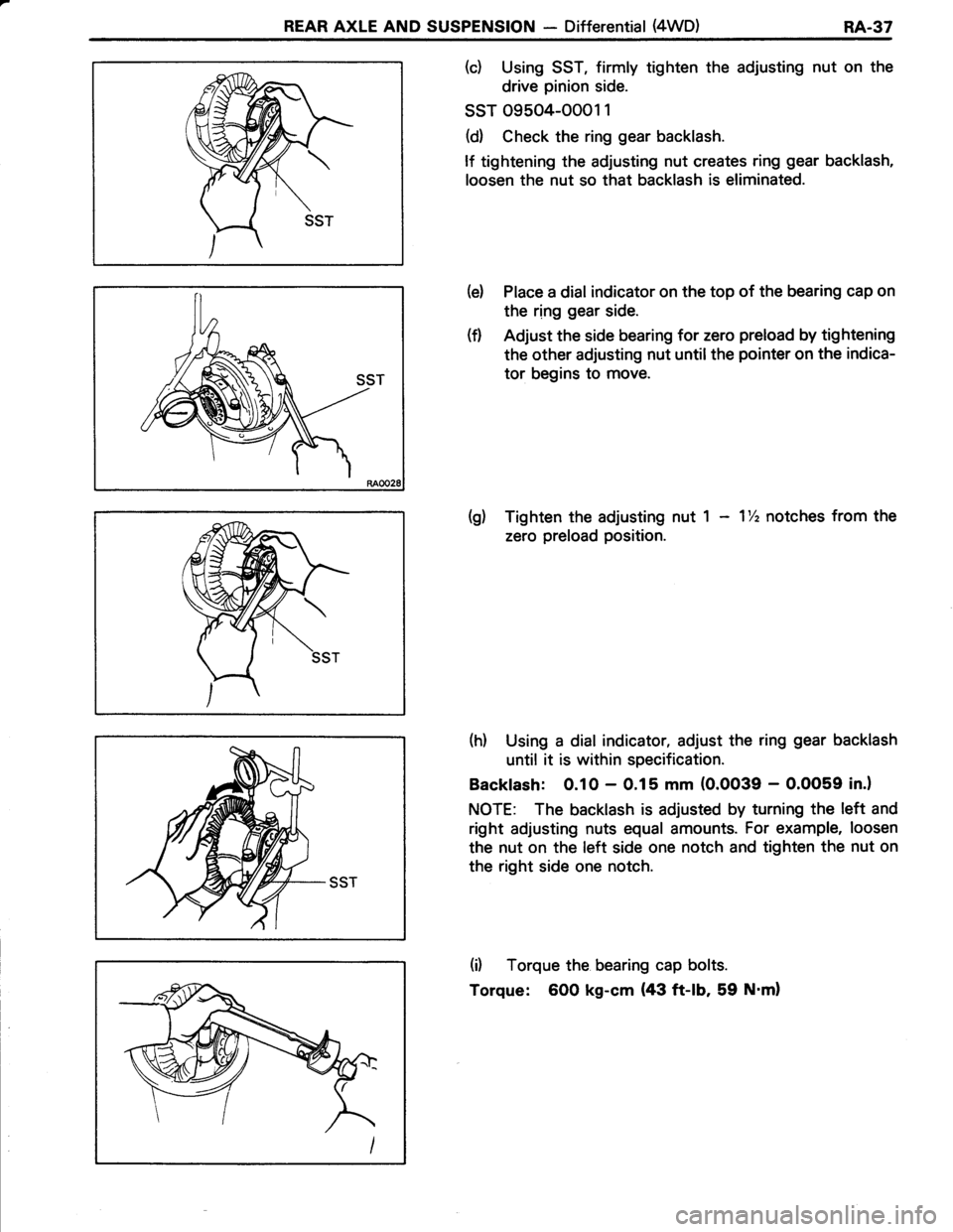

(c) Using SST, firmly tighten the adjusting nut on the

drive pinion side.

ssr o9504-ooo1 1

(d) Check the ring gear backlash.

lf tightening the adjusting nut creates ring gear backlash,

loosen the nut so that backlash is eliminated.

(e) Place a dial indicator on the top of the bearing cap on

the ring gear side.

(f) Adjust the side bearing for zero preload by tightening

the other adjusting nut until the pointer on the indica-

tor begins to move.

(g) Tighten the adjusting nut 1 - 1llz notches from the

zero preload position.

(h) Using a dial indicator, adjust the ring gear backlash

until it is within specification.

Backlash: 0.10 - 0,15 mm (O.OO39 - O.OO59 in.l

NOTE: The backlash is adjusted by turning the left and

right adjusting nuts equal amounts. For example, loosen

the nut on the left side one notch and tighten the nut on

the right side one notch.

(i) Torque the bearing cap bolts.

Torque: 6OO kg-cm (43 ft-lb, 59 N.ml

Page 546 of 885

RA.38REAR AXLE AND SUSPENSION - Differentiat (4WD)

(j) Recheck the ring gear backlash.

(0 Using a torque meter, measure the total preload.

Total preload:

ln addition to drive pinion preload

2 - 4 kg-cm 11.7 - 3.5 in.-lb, O.2 - 0.4 N.m)

Backlash: O.1O - O.15 mm (0.0039 - 0.O059 in.)

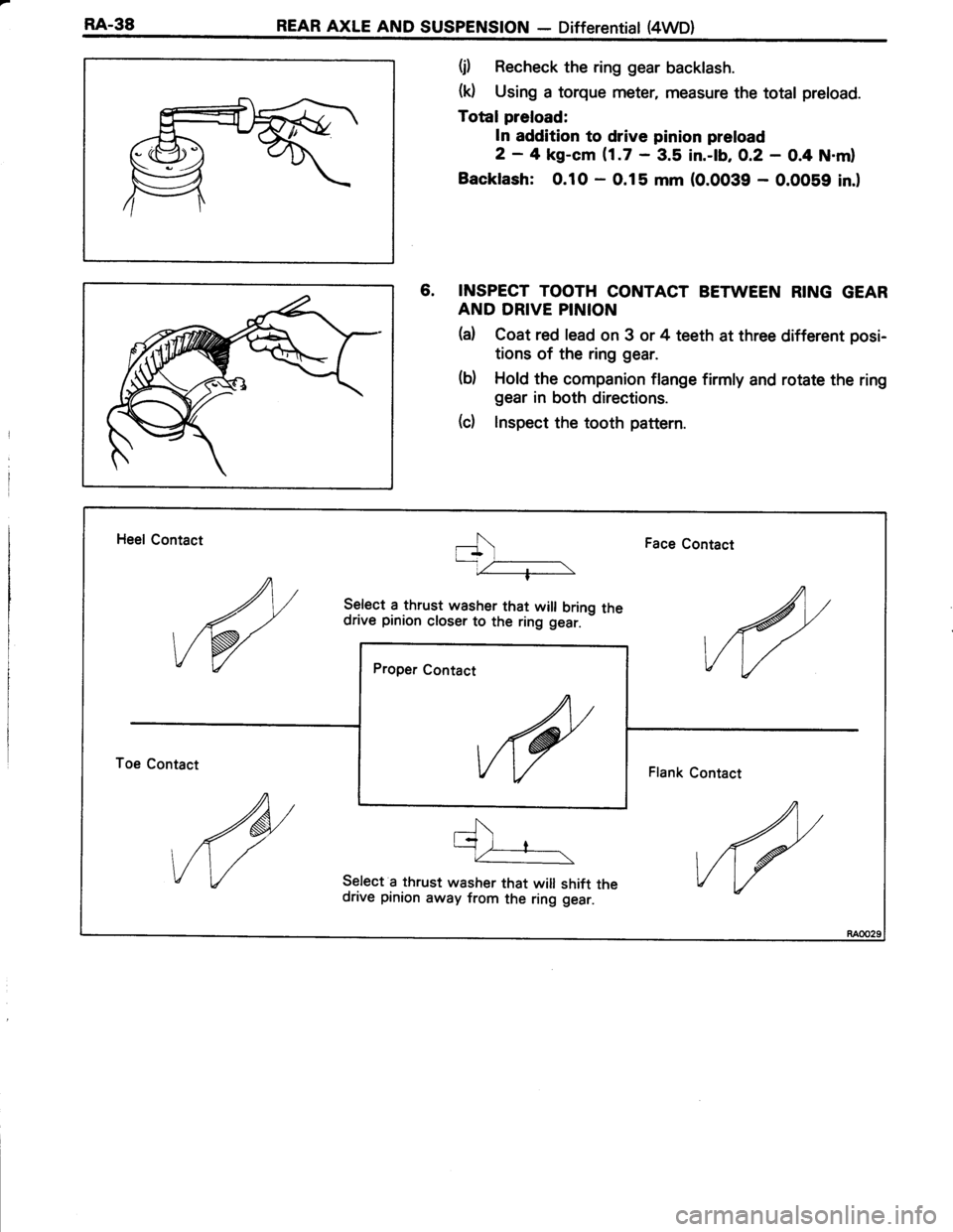

6. INSPECT TOOTH CONTACT BETWEEN RING GEAR

AND DRIVE PINION

(a) Coat red lead on 3 or 4 teeth at three different posi-

tions of the ring gear.

(b) Hold the companion flange firmly and rotate the ring

gear in both directions.

(d lnspect the tooth pattern.

Heel ContactFace Contact

Select a thrust washer that wilt brinq thedrive pinion closer to the ring gear. -

,rfl

Select a thrust washer that will shift thedrive pinion away from the ring gear.

Page 547 of 885

REAR AXLE AND SUSPENSION - Differential (4WD)RA.39

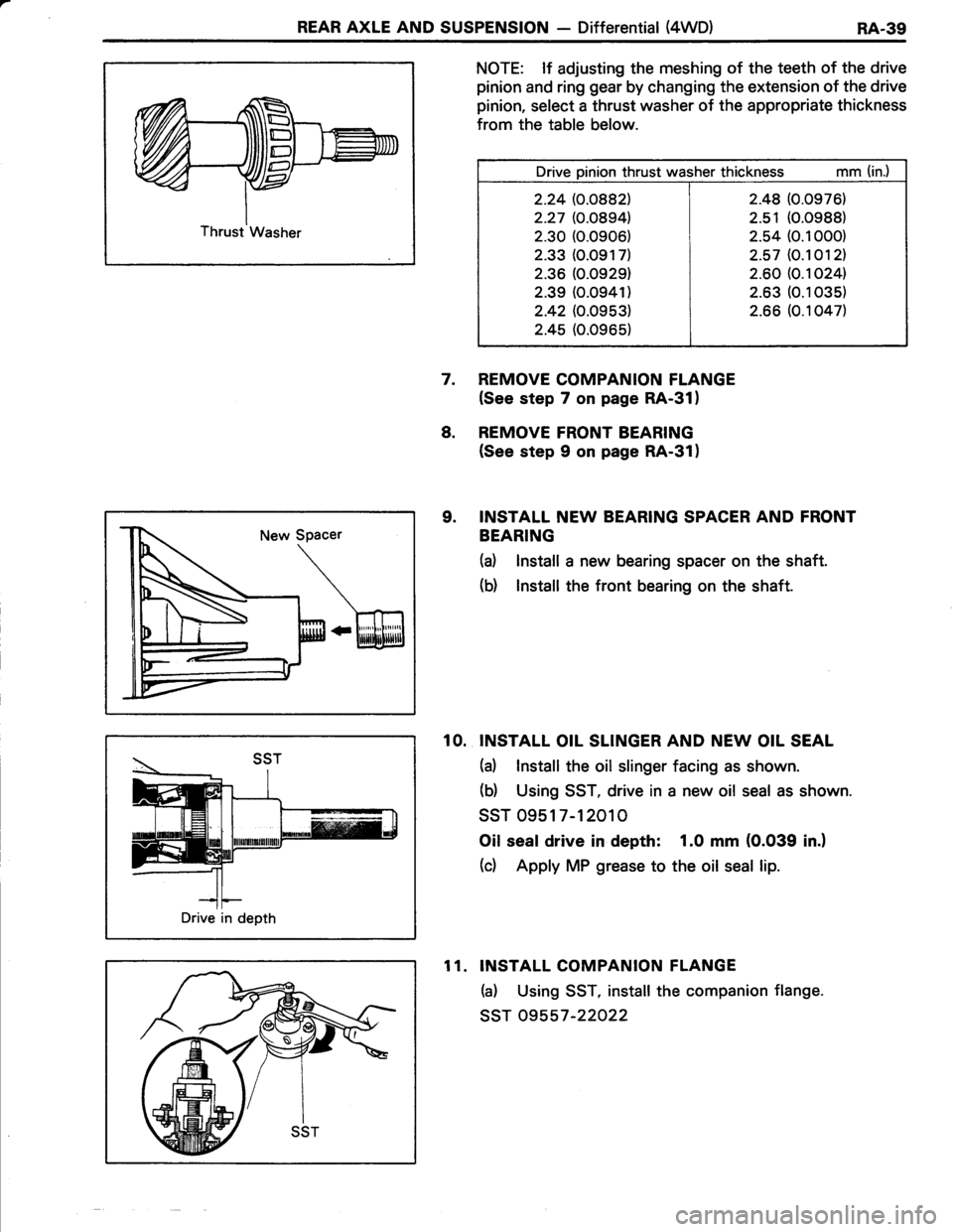

NOTE: lf adjusting the meshing of the teeth of the drive

pinion and ring gear by changing the extension of the drive

pinion, select a thrust washer of the appropriate thickness

from the table below.

REMOVE COMPANION FLANGE

(See step 7 on page RA-31)

REMOVE FRONT BEARING

(See step 9 on page RA-31)

INSTALL NEW BEARING SPACER AND FRONT

BEARING

(d lnstall a new bearing spacer on the shaft.

(b) lnstall the front bearing on the shaft.

10. INSTALL OIL SLINGER AND NEW OIL SEAL

(d Install the oil slinger facing as shown.

(b) Using SST, drive in a new oil seal as shown.

ssT 0951 7-12010

Oil seal drive in depth: 1.0 mm (0.039 in.)

(d Apply MP grease to the oil seal lip.

11. INSTALL COMPANION FLANGE

(a) Using SST, install the companion flange.

ssr 09557-22022

7.

8.

9.

Drive in depth

Drive pinion thrust washer thickness mm (in.)

2.24 (O.O882) | Z.+8 (0.0976)

2.27 l}.O8e4l I Z.S1 (0.0988)

2.30 (0.0906) I Z.S4 (0.1000)

2.33 (0.0917) | 2.57 (0.1012)

2.36 (O.Os29) | Z.A0 {0.1024)

2.39 (0.0941) I 2.63 (0.103s)

2.42 (0.0953) | Z.A6 (0.1047)

2.45 (0.096s)

Page 548 of 885

RA-/[()REAR AXLE AND SUSPENSION - Differential (4WD)

RAOO3

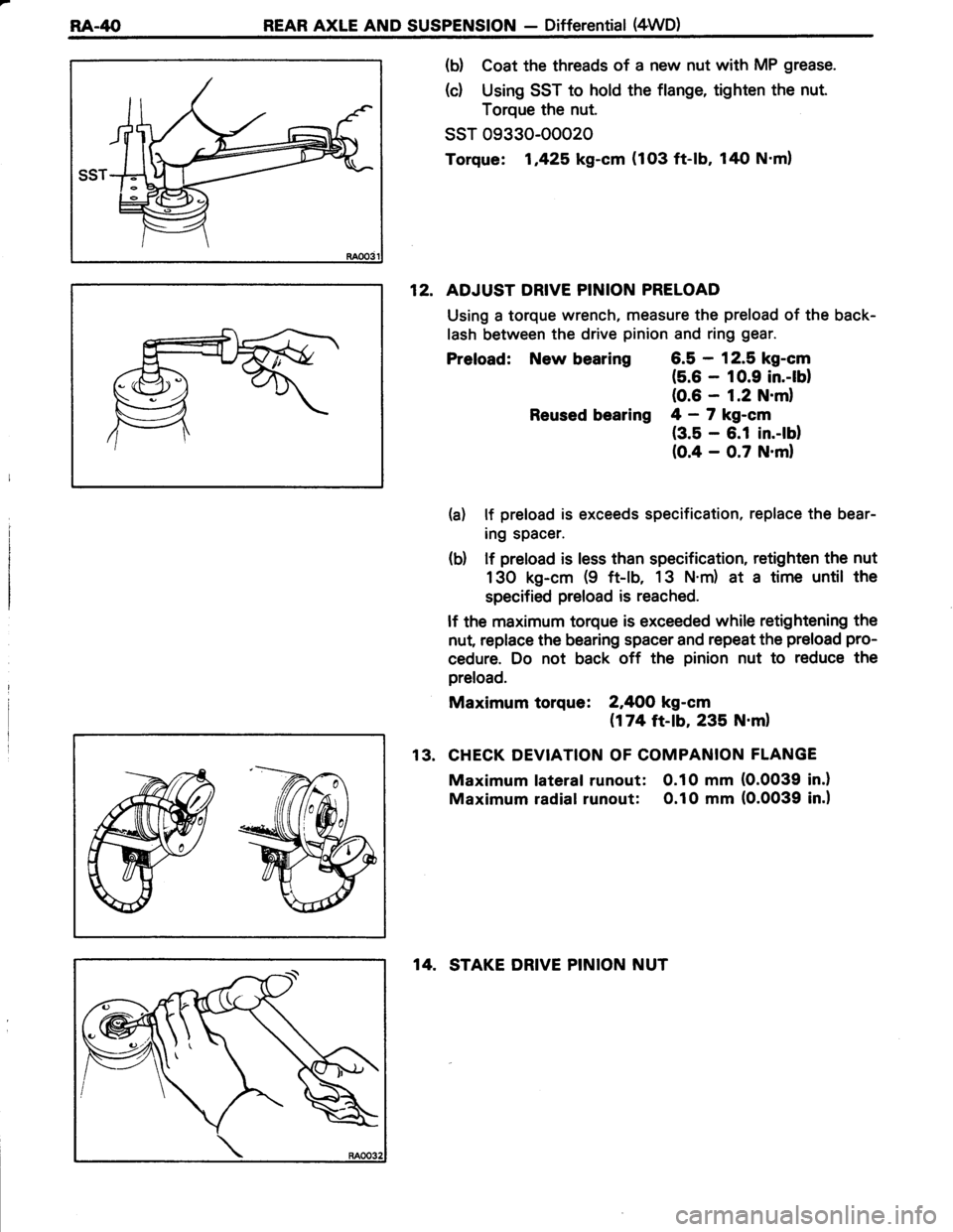

(b) Coat the threads of a new nut with MP grease.

(c) Using SST to hold the flange, tighten the nut.

Torque the nut.

ssr 09330-ooo20

Torque: 1,425 kg-cm (103 ft-lb, 140 N'ml

12. ADJUST DRIVE PINION PRELOAD

Using a torque wrench, measure the preload of the back-

lash between the drive pinion and ring gear.

Preload: New bearing 6.5 - 12.5 kg-cm

(5.6 - 10.9 in.-lbl

(0.6 - 1.2 N'ml

Reused bearing 4 - 7 kg-cm

(3.5 - 6.1 in.-lbl

(0.4 - 0.7 N'ml

lf preload is exceeds specification, replace the bear-

ing spacer.

lf preload is less than specification, retighten the nut

130 kg-cm (9 ft-lb, 13 N.m) at a time until the

specified preload is reached.

lf the maximum torque is exceeded while retightening the

nut, replace the bearing spacer and repeat the preload pro-

cedure. Do not back off the pinion nut to reduce the

preload.

Maximum torque: 2,4OO kg-cm

(174 ft-lb, 235 N'm)

CHECK DEVIATION OF COMPANION FLANGE

Maximum tateral runout: 0.10 mm (0.0039 in.l

Maximum radial runout: 0.10 mm (0.0039 in.l

14. STAKE DRIVE PINION NUT

(a)

(b)

13.

Page 549 of 885

REAR AXLE AND SUSPENSION - Differential (4WD)RA.41

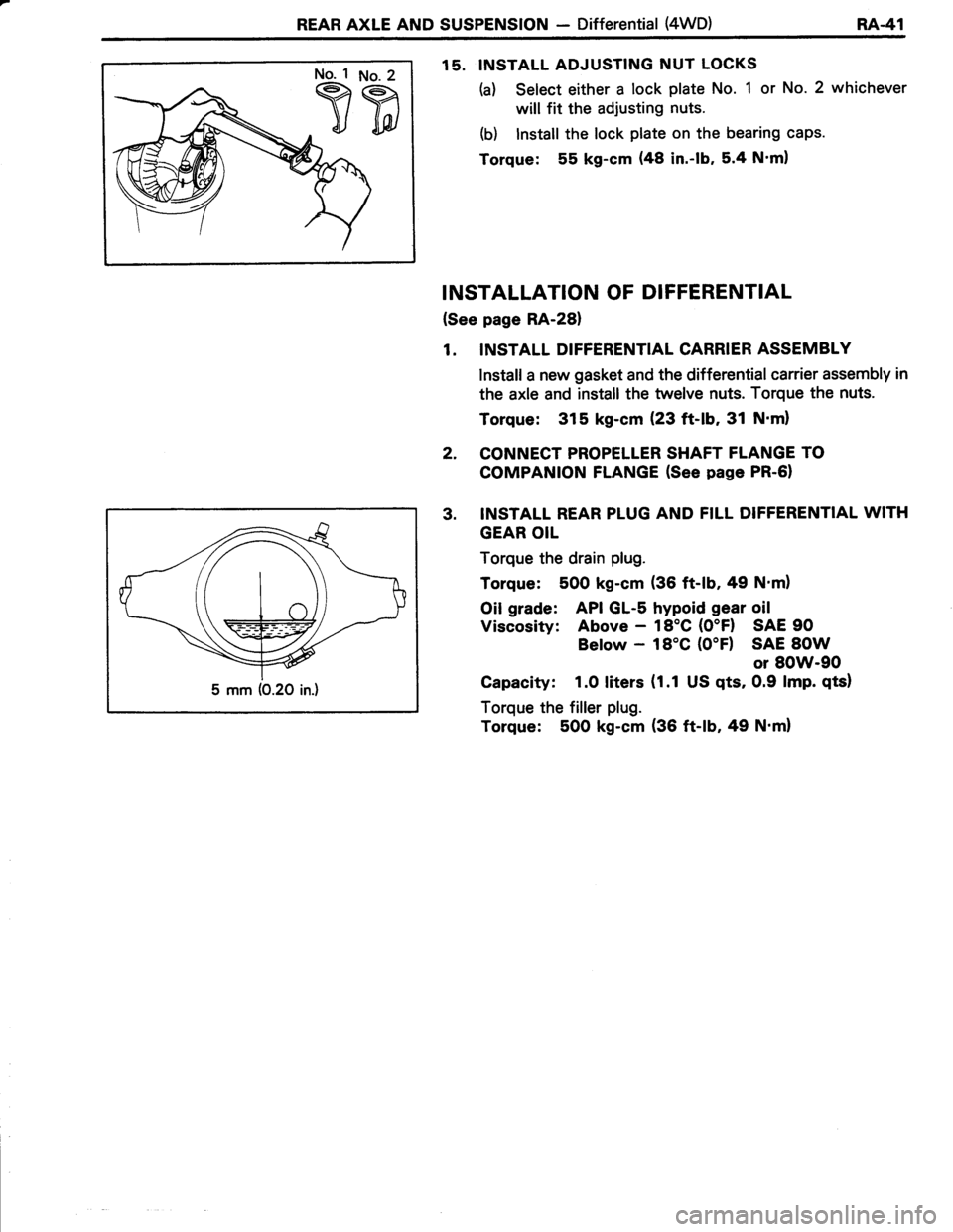

15. INSTALL ADJUSTING NUT LOCKS

(a) Select either a lock plate No. 1 or No. 2 whichever

will fit the adjusting nuts.

(b) lnstall the lock plate on the bearing caps.

Torque: 55 kg-cm (48 in.-lb, 5.4 N'ml

INSTALLATION OF DIFFERENTIAL

(See page RA-281

1. INSTALL DIFFERENTIAL CARRIER ASSEMBLY

Install a new gasket and the differentialcarrier assembly in

the axle and install the twelve nuts. Torque the nuts.

Torque: 315 kg-cm (23 ft-lb, 31 N'm)

2. CONNECT PROPELLER SHAFT FLANGE TO

COMPANION FLANGE (See page PR-61

3. INSTALL REAR PLUG AND FILL DIFFERENTIAL WITH

GEAR OIL

Torque the drain plug.

Torque: 500 kg-cm (36 ft-|b,49 N'm)

Oil grade: API GL-s hypoid gear oil

Viscosity: Above - 18"C (O'Fl SAE 90

Below - 18'C (0"F) SAE 8OW

or 80W-90

Capacity: 1.0 liters (1.1 US qts, 0.9 lmp. qts)

Torque the filler plug.

Torque: 500 kg-cm (36 ft-|b,49 N'ml

5 mm (0.2O in.)

Page 550 of 885

RA-42 REAR AXLE AND SUSPENSION - Four Link Type Rear Suspension (4WD)

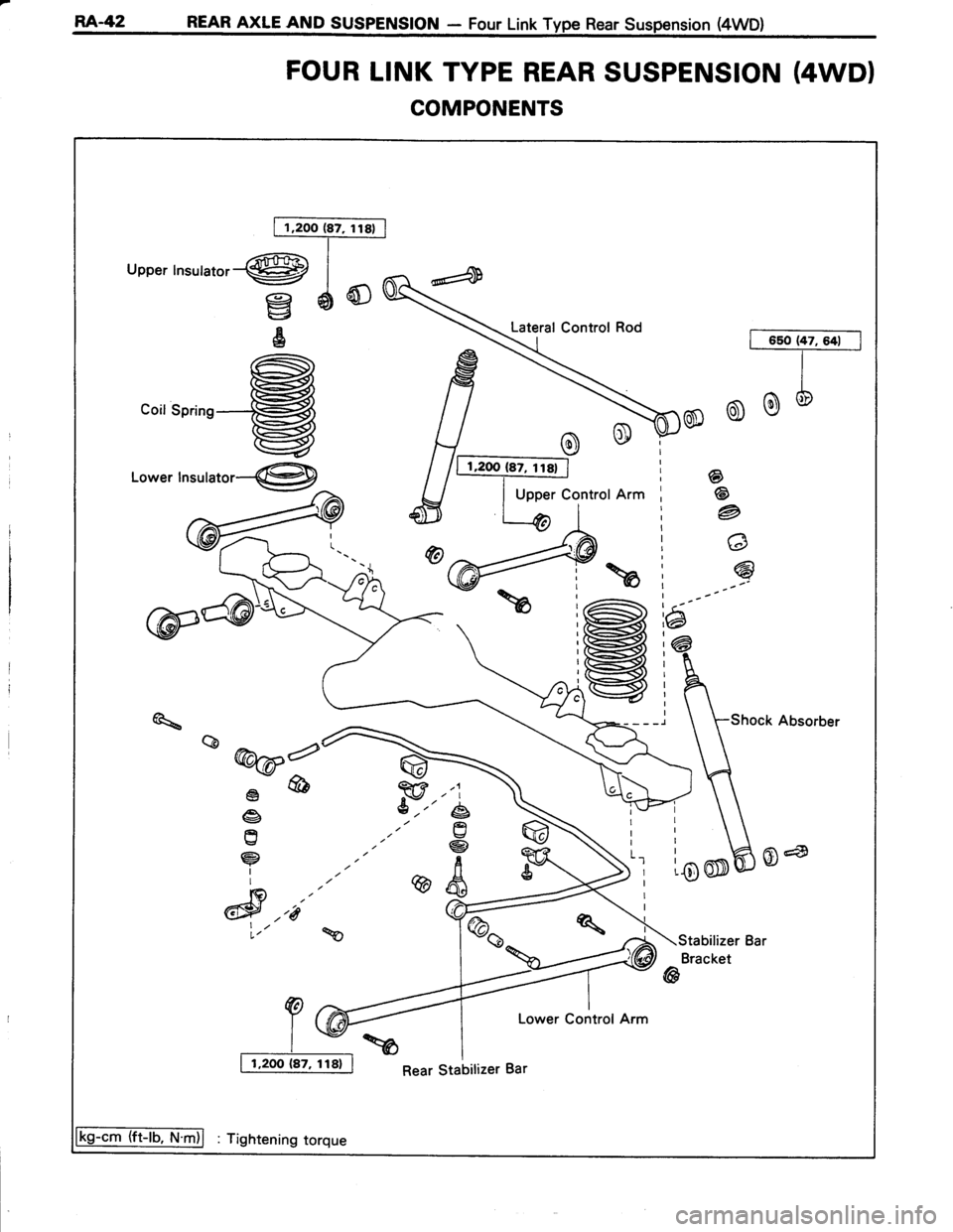

FOUR LINK TYPE REAR SUSPENSION (4WDI

COMPONENTS

fl,rooEz lrol

.ffi |Upper lnsutator-{sH9 I

€d@(

g\- Lateral Control Rod

\l l- 650 t+?,54l_l

€ ^T-

ll

ooo@

A/----_-9

a, r

f f I r,zoo raz, nat]. I a

g I uooe, Control Arm ', @

otr 11 " @

a",, ,0.,"n@

Lower tnrut.tor-@

D aia I i @v@

i o'wr=:i

b | .g

e€t,6

E i*u

,Wte

qShock Absorber

anv

%=

e@

e

Fv

? u.,r€

@.,a

i ,' a^@a

Lower Control Arm

-lb, N'm)l : Tightening torque

Rear Stabilizer Bar