TOYOTA TERCEL 1985 Repair Manual

Manufacturer: TOYOTA, Model Year: 1985, Model line: TERCEL, Model: TOYOTA TERCEL 1985Pages: 885, PDF Size: 64.52 MB

Page 561 of 885

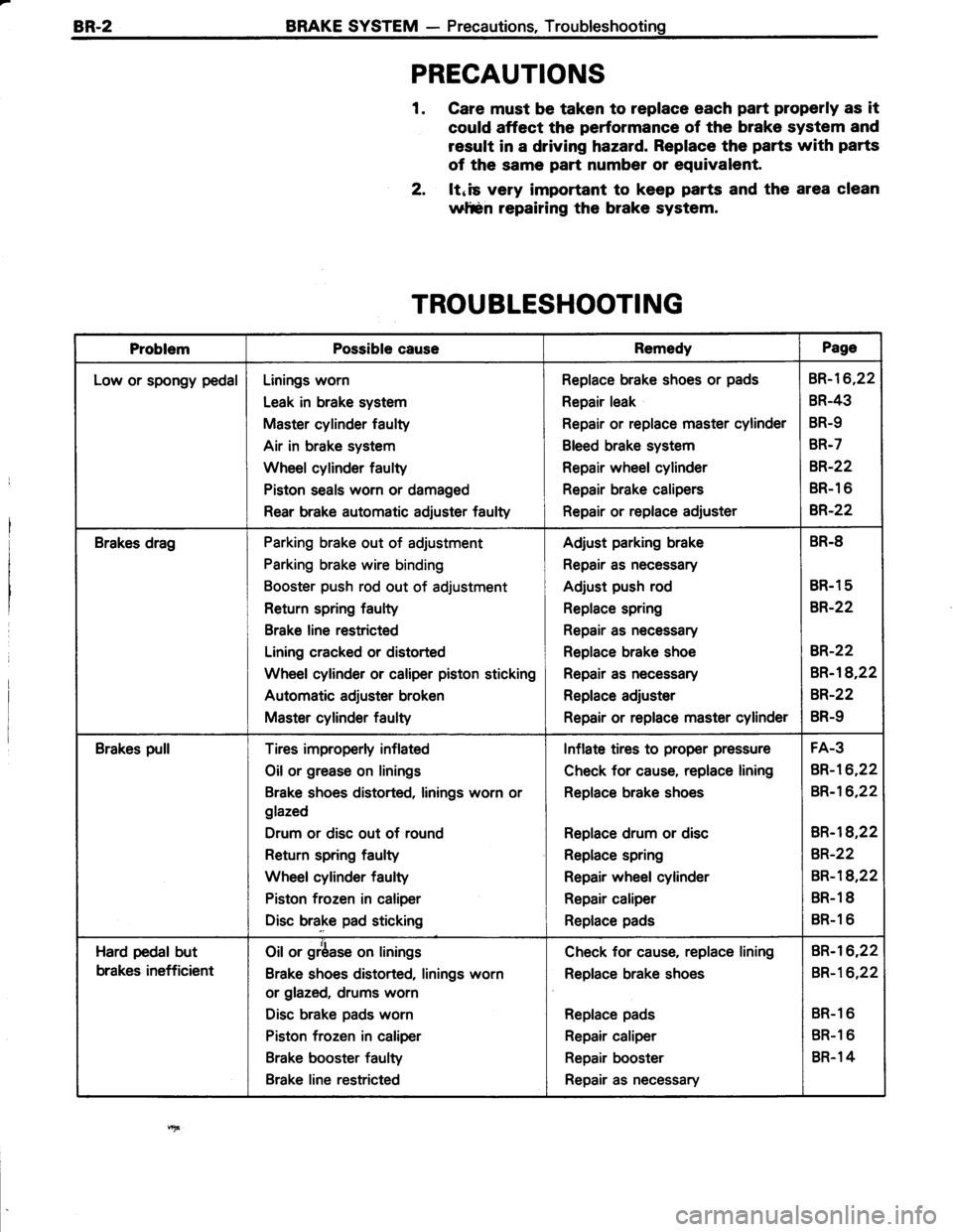

BR-2BRAKE SYSTEM - Precautions, Troubleshooting

PRECAUTIONS

1. Care must be taken to replace each part properly as it

could affect the performance of the brake system and

result in a driving hazard. Replace the parts with parts

of the same part number or equivalent.

2, ltnis very important to keep parts and the area clean

wltsn repairing the brake system.

TROUBLESHOOTING

ProblemPossible causeRemedyPage

Low or spongy pedalLinings worn

Leak in brake system

Master cylinder faulty

Air in brake system

Wheel cylinder faulty

Piston seals worn or damaged

Rear brake automatic adiuster faulty

Replace brake shoes or pads

Repair leak

Repair or replace master cylinder

Bleed brake system

Repair wheel cylinder

Repair brake calipers

Repair or replace adjuster

BR-16,22

BR-43

BR-9

BR-7

8R.22

BR-1 6

B,R.22

Brakes dragParking brake out of adjustment

Parking brake wire binding

Booster push rod out of adjustment

Return spring faulty

Brake line restricted

Lining cracked or distorted

Wheel cylinder or caliper piston sticking

Automatic adjuster broken

Master cylinder faulty

Adjust parking brake

Repair as necessary

Adjust push rod

Replace spring

Repair as necessary

Replace brake shoe

Repair as necessary

Replace adjuster

Repair or replace master cylinder

BR.8

BR.1 5

BR-22

BR-22

BR-18,22

BR-22

BR-9

Brakes pullTires improperly inflated

Oil or grease on linings

Brake shoes distorted, linings worn or

glazed

Drum or disc out of round

Return spring faulty

Wheel cylinder faulty

Piston frozen in caliper

Disc brake pad sticking

Inflate tires to proper pressure

Check for cause, replace lining

Replace brake shoes

Replace drum or disc

Replace spring

Repair wheel cylinder

Repair caliper

Replace pads

FA-3

BR-16,22

BR-16,22

BR-l8,22

BR-22

BR-18,22

BR.1 8

BR-1 6

Hard pedal but

brakes inefficient

Oil or grbase on linings

Brake shoes distorted, linings worn

or glazed, drums worn

Disc brake pads worn

Piston frozen in caliper

Brake booster faulty

Brake line restricted

Check for cause, replace lining

Replace brake shoes

Replace pads

Repair caliper

Repair booster

Repair as necessary

BR-I6,22

BR-16,22

BR-1 6

BR-1 6

BR.1 4

Page 562 of 885

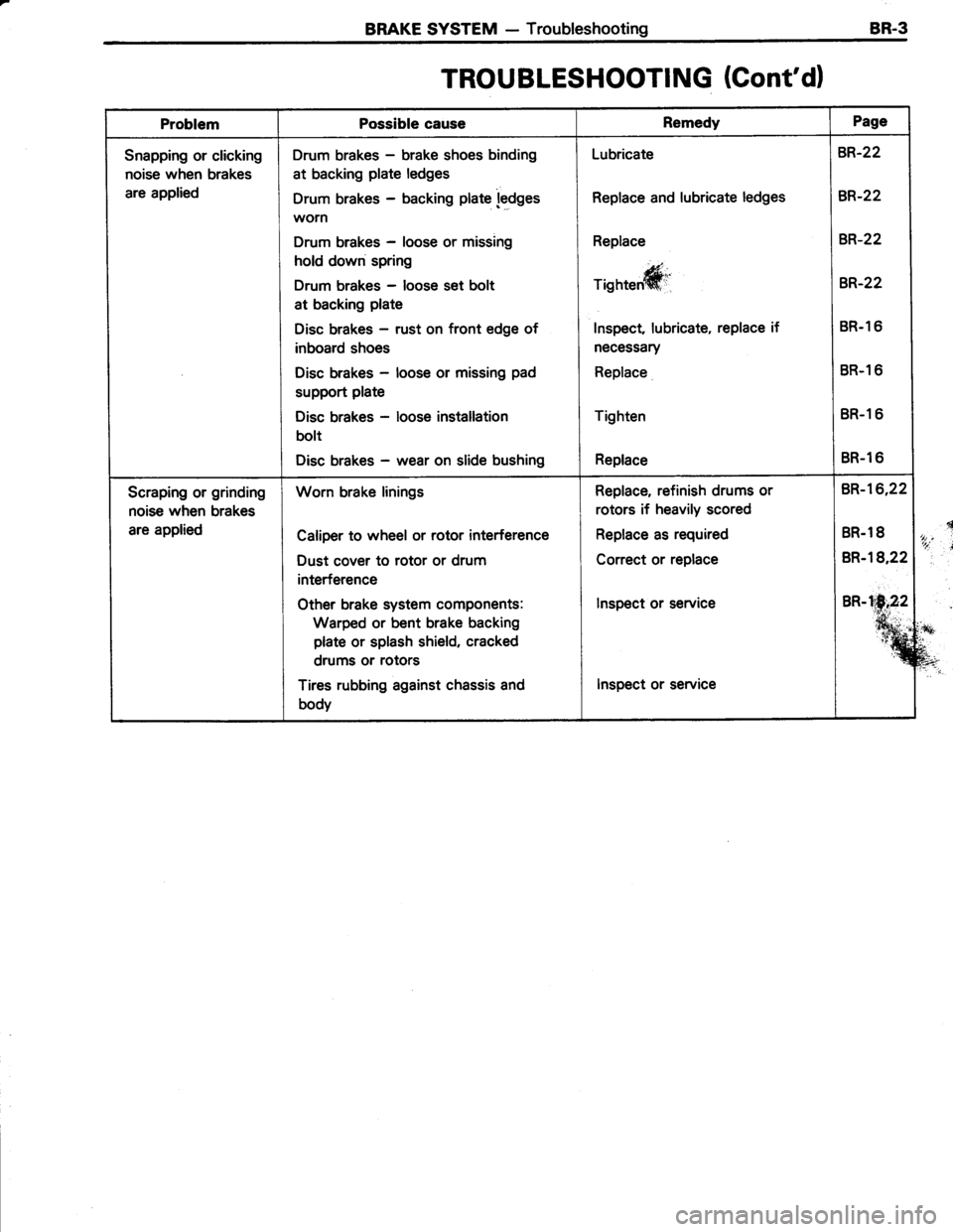

BRAKE SYSTEM - TroubleshootingBR.3

TROU BLESHOOTING (Cont'd)

ProblemPossible causeRemedyPage

r+i

:?*

a?"t

Snapping or clicking

noise when brakes

are applied

Drum brakes - brake shoes binding

at backing plate ledges

Drum brakes - backing plate ledgesworn

Drum brakes - loose or missing

hold down spring

Drum brakes - loose set bolt

at backing plate

Disc brakes - rust on front edge of

inboard shoes

Disc brakes - loose or missing pad

support plate

Disc brakes - loose installation

bolt

Disc brakes - wear on slide bushing

Lubricate

Replace and lubricate ledges

Replace

E,

Tisnteffit'

Inspect lubricate, replace if

necessary

Replace

Tighten

Replace

BR-22

BR-22

BR-22

BR-22

BR.1 6

BR-1 6

BR-1 6

BR-1 6

Scraping or grinding

noise when brakes

are applied

Worn brake linings

Caliper to wheel or rotor interference

Dust cover to rotor or drum

interference

other brake system components:

Warped or bent brake backing

plate or splash shield, cracked

drums or rotors

Tires rubbing against chassis and

body

Replace, refinish drums or

rotors if heavily scored

Replace as required

Correct or replace

lnspect or service

Inspect or service

BR-16,22

BR.1 8

BR-l8,22

BR-h1N,22

%

Page 563 of 885

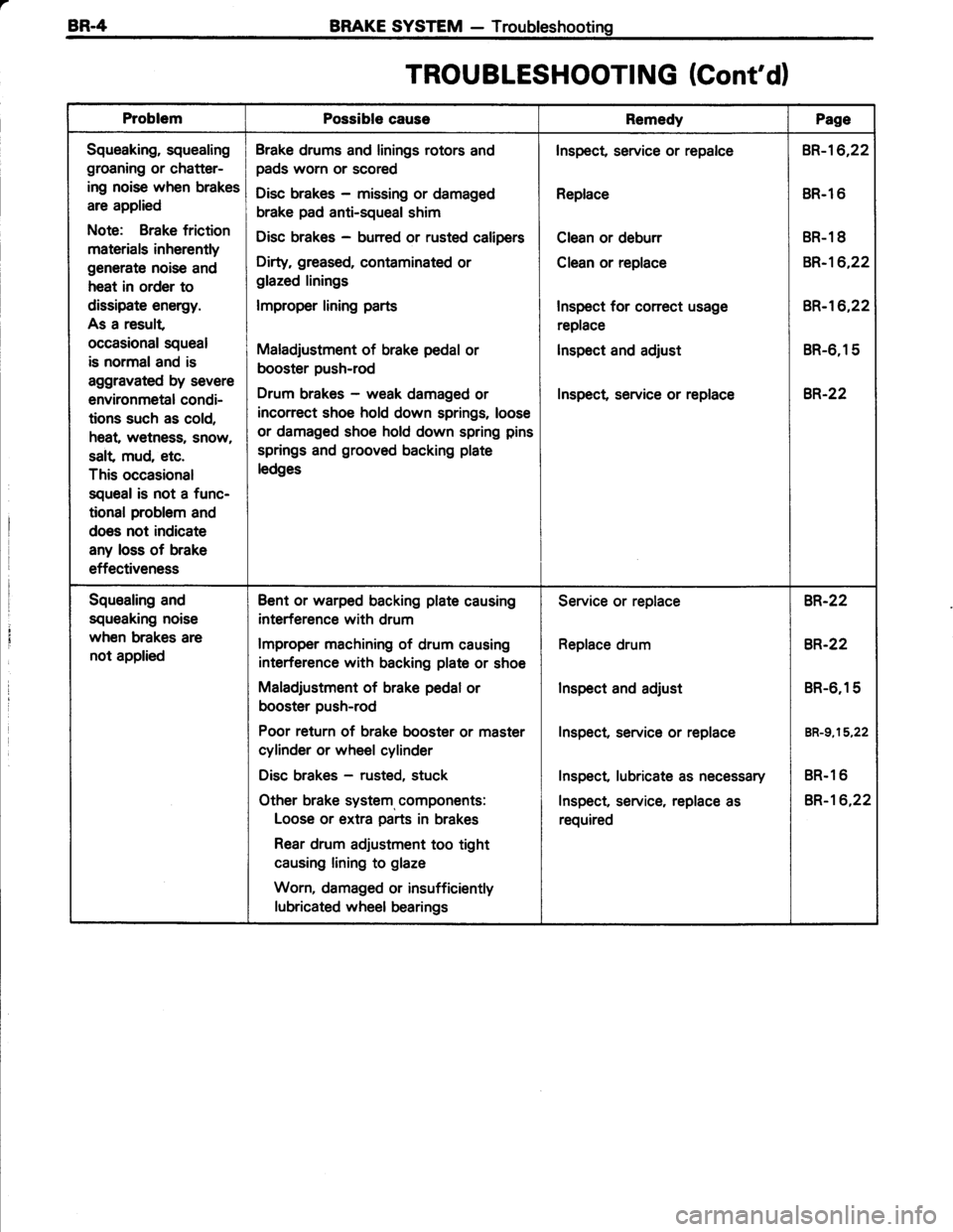

BR-4 BRAKE SYSTEM - Troubleshooting

TROU BLESHOOTI NG (Cont'd)

ProblemPossible causeRemedyPage

Squeaking, squealing

groaning or chatter-

ing noise when brakes

are applied

Note: Brake friction

materials inherently

generate noise and

heat in order to

dissipate energy.

As a result

occasional squeal

is normaland is

aggravated by severe

environmetal condi-

tions such as cold,

heat, wetness, snow,

salt mud, etc.

This occasional

squeal is not a func-

tional problem and

does not indicate

any loss of brake

effectiveness

Brake drums and linings rotors and

pads worn or scored

Disc brakes - missing or damaged

brake pad anti-squeal shim

Disc brakes - burred or rusted calipers

Dirty, greased, contaminated or

glazed linings

lmproper lining parts

Maladjustment of brake pedal or

booster push-rod

Drum brakes - weak damaged or

incorrect shoe hold down springs, loose

or damaged shoe hold down spring pins

springs and grooved backing plate

ledges

Inspect, service or repalce

Replace

Clean or deburr

Clean or replace

Inspect for conect usage

replace

lnspect and adjust

Inspect service or replace

BR-16,22

BR.l 6

BR-1 8

BR-16,22

BR-'�t6,22

BR-6,15

8R.22

Squealing and

squeaking noise

when brakes are

not applied

Bent or warped backing plate causing

interference with drum

lmproper machining of drum causing

interference with backing plate or shoe

Maladjustment of brake pedal or

booster push-rod

Poor return of brake booster or master

cylinder or wheel cylinder

Disc brakes - rusted, stuck

Other brake system, components:

Loose or extra parts in brakes

Rear drum adjustment too tight

causing lining to glaze

Worn, damaged or insufficiently

lubricated wheel bearings

Service or replace

Replace drum

Inspect and adjust

Inspect, service or replace

Inspect lubricate as necessary

Inspect, service, replace as

required

BR-22

8R.22

BR-6,15

BR-g,15,22

BR.1 6

BR-16,22

Page 564 of 885

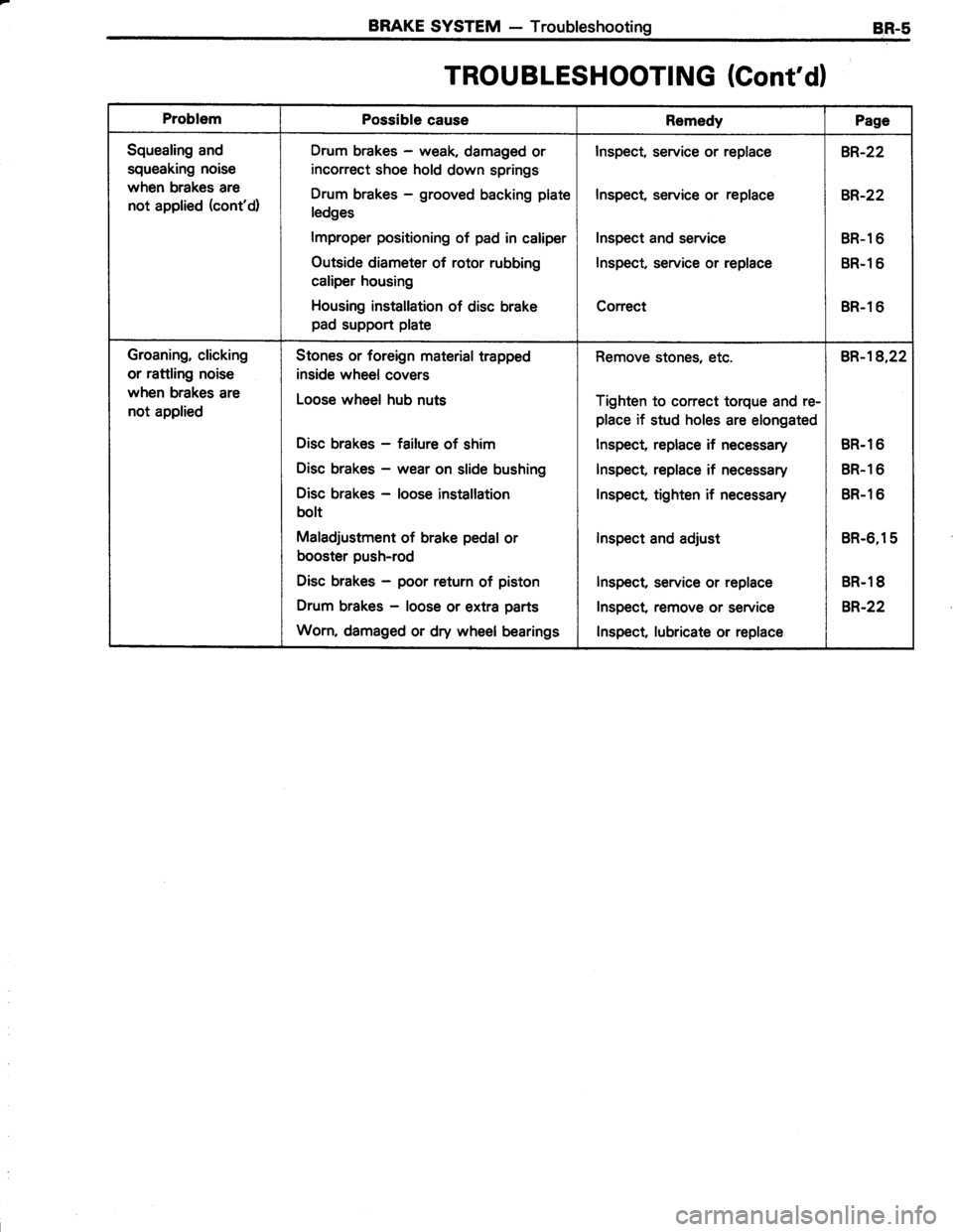

BRAKE SYSTEM - TroubleshootingBR-5

TROUBLESHOOTING (Cont'dl

ProblemPossible causeRemedyPage

Squealing and

squeaking noise

when brakes are

not applied (cont'd)

Drum brakes - weak, damaged or

incorrect shoe hold down springs

Drum brakes - grooved backing plate

ledges

lmproper positioning of pad in caliper

Outside diameter of rotor rubbing

caliper housing

Housing installation of disc brake

pad support plate

Inspect, service or replace

Inspect, service or replace

Inspect and service

Inspect, service or replace

Correct

BR-22

BR-22

BR-l 6

BR-l 6

BR-1 6

Groaning, clicking

or rattling noise

when brakes are

not applied

Stones or foreign material trapped

inside wheel covers

Loose wheel hub nuts

Disc brakes - failure of shim

Disc brakes - wear on slide bushing

Disc brakes - loose installation

bolt

Maladjustment of brake pedal or

booster push-rod

Disc brakes - poor return of piston

Drum brakes - loose or extra parts

Worn, damaged or dry wheel bearings

Remove stones, etc.

Tighten to correct torque and re-

place if stud holes are elongated

lnspect, replace if necessary

Inspect, replace if necessary

Inspect, tighten if necessary

lnspect and adjust

Inspect, service or replace

Inspect remove or service

lnspect lubricate or replace

BR-18,22

BR.1 6

BR.1 6

BR-1 6

BR-6,15

BR.1 8

B,R.22

Page 565 of 885

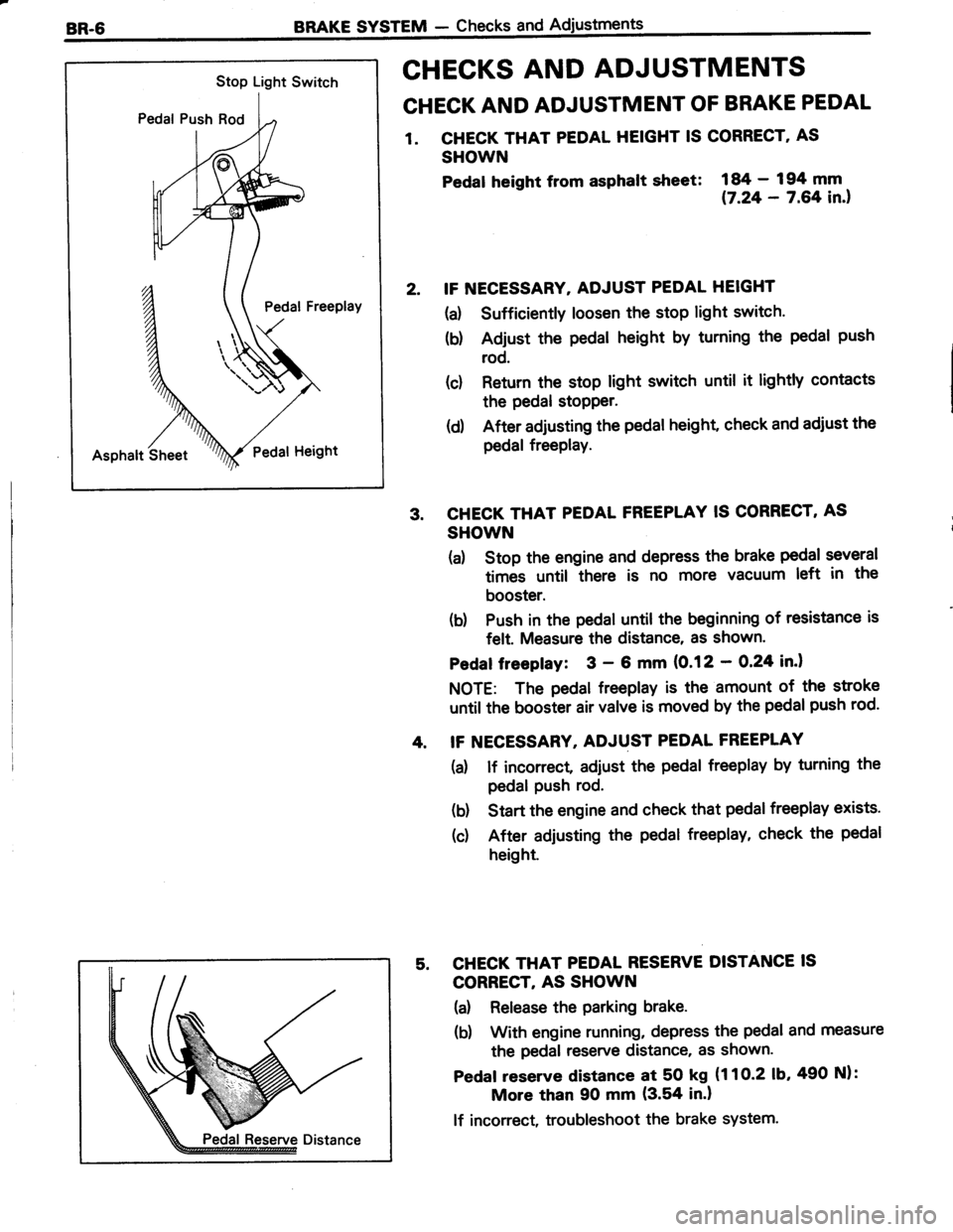

Stop Light Switch

Pedal Push Rod

Pedal Freeplay

Asphalt SheetPedat Height

BRAKE SYSTEM - Checks and

CHECKS AND ADJUSTMENTS

CHECK AND ADJUSTMENT OF BRAKE PEDAL

1. CHECK THAT PEDAL HEIGHT IS CORRECT' AS

SHOWN

Pedat heisht from asphalt slreet:

i#;:?ifil.,

IF NECESSARY. ADJUST PEDAL HEIGHT

(a) Sufficiently loosen the stop light switch.

(b) Adjust the pedal height by turning the pedal push

rod.

(c) Return the stop light switch until it lightly contacts

the pedal stopper.

(d) After adjusting the pedal height, check and adiust the

pedal freePlay.

CHECK THAT PEDAL FREEPLAY IS CORRECT, AS

SHOWN

(a) Stop the engine and depress the brake pedal several

times until there is no more vacuum left in the

booster.

(b) Push in the pedal until the beginning of resistance is

felt. Measure the distance, as shown'

Pedaf freepfay: 3 - 6 mm (0.12 - O,24 in.l

NOTE: The pedal freeplay is the amount of the stroke

until the booster air valve is moved by the pedal push rod.

IF NECESSARY, ADJUST PEDAL FREEPLAY

(a) lf incorrect adiust the pedal freeplay by turning the

pedal Push rod.

(b) Start the engine and check that pedal freeplay exists.

(c) After adjusting the pedal freeplay, check the pedal

height.

CHECK THAT PEDAL RESERVE DISTANCE IS

CORRECT, AS SHOWN

(a) Release the parking brake.

(b) With engine running, depress the pedal and measure

the pedal reserve distance, as shown.

Pedaf reserve distance at 50 kg (1 1 O-2 1b,490 Nl:

More than 90 mm (3.54 in.l

lf incorrect, troubleshoot the brake system.

Page 566 of 885

BRAKE SYSTEM - Checks and AdjustmentsBR-7

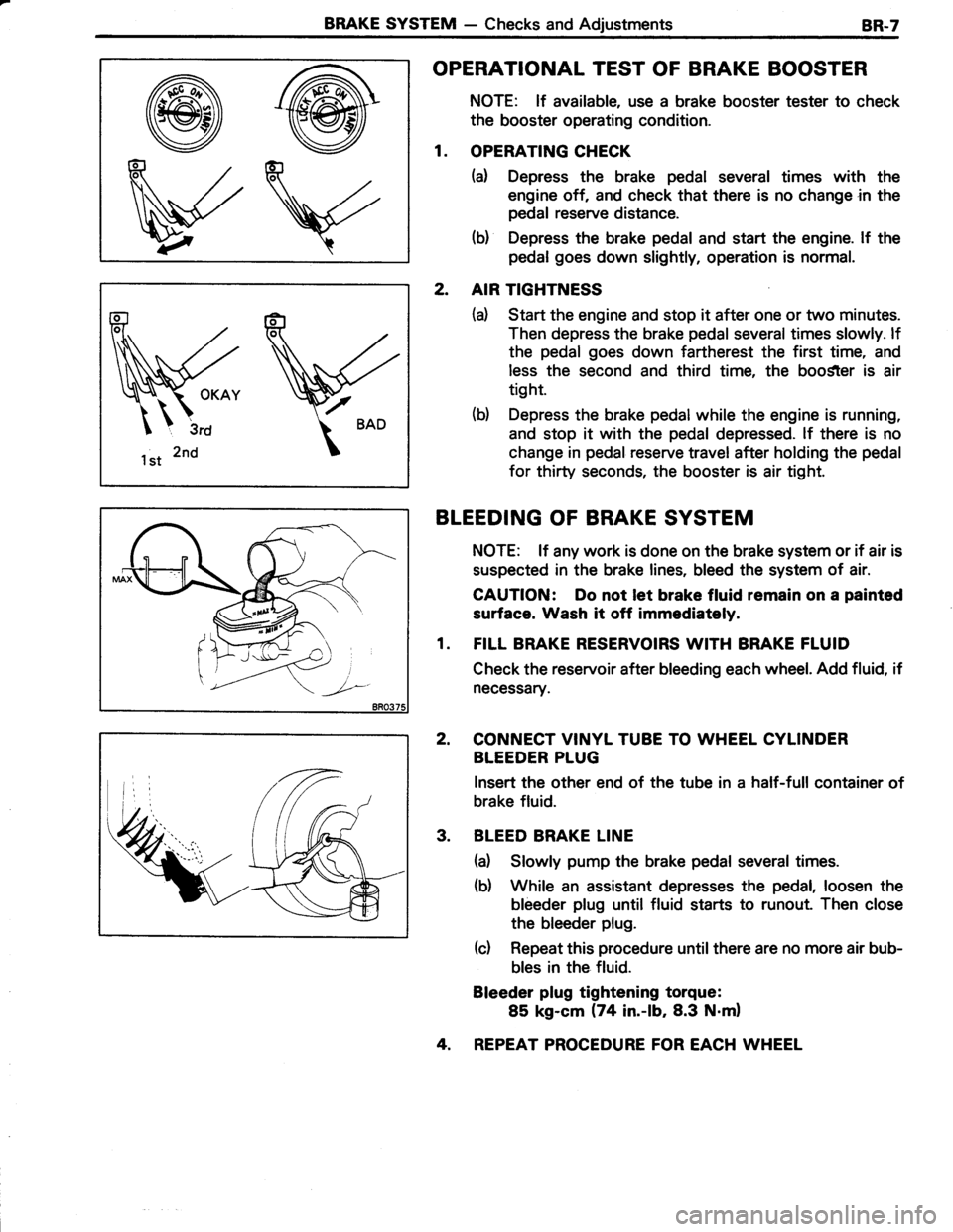

@@

VV

1 st 2nd

OPERATIONAL TEST OF BRAKE BOOSTER

NOTE: lf available, use a brake booster tester to check

the booster operating condition.

1. OPERATING CHECK

(a) Depress the brake pedal several times with the

engine off, and check that there is no change in the

pedal reserve distance.

(b) Depress the brake pedal and start the engine. lf the

pedal goes down slightly, operation is normal.

2. AIR TIGHTNESS

(d Start the engine and stop it after one or two minutes.

Then depress the brake pedal several times slowly. lf

the pedal goes down fartherest the first time, and

less the second and third time, the boo$ter is air

tight.

(b) Depress the brake pedal while the engine is running,

and stop it with the pedal depressed. lf there is no

change in pedal reserve travel after holding the pedal

for thirty seconds, the booster is air tight.

BLEEDING OF BRAKE SYSTEM

NOTE: lf any work is done on the brake system or if air is

suspected in the brake lines, bleed the system of air.

CAUTION: Do not let brake fluid remain on a painted

surface. Wash it off immediataly.

1. FILL BRAKE RESERVOIRS WITH BRAKE FLUID

Check the reservoir after bleeding each wheel. Add fluid, if

necessary.

2, CONNECT VINYL TUBE TO WHEEL CYLINDER

BLEEDER PLUG

lnsert the other end of the tube in a half-full container of

brake fluid.

3. BLEED BRAKE LINE

(a) Slowly pump the brake pedal several times.

(b) While an assistant depresses the pedal, loosen the

bleeder plug until fluid starts to runout. Then close

the bleeder plug.

(c) Repeat this procedure until there are no more air bub-

bles in the fluid.

Bleeder plug tightening torque:

85 kg-cm (74 in.-lb,8.3 N.m)

4. REPEAT PROCEDURE FOR EACH WHEEL

Page 567 of 885

BR.8BRAKE SYSTEM - Checks and Adjustments

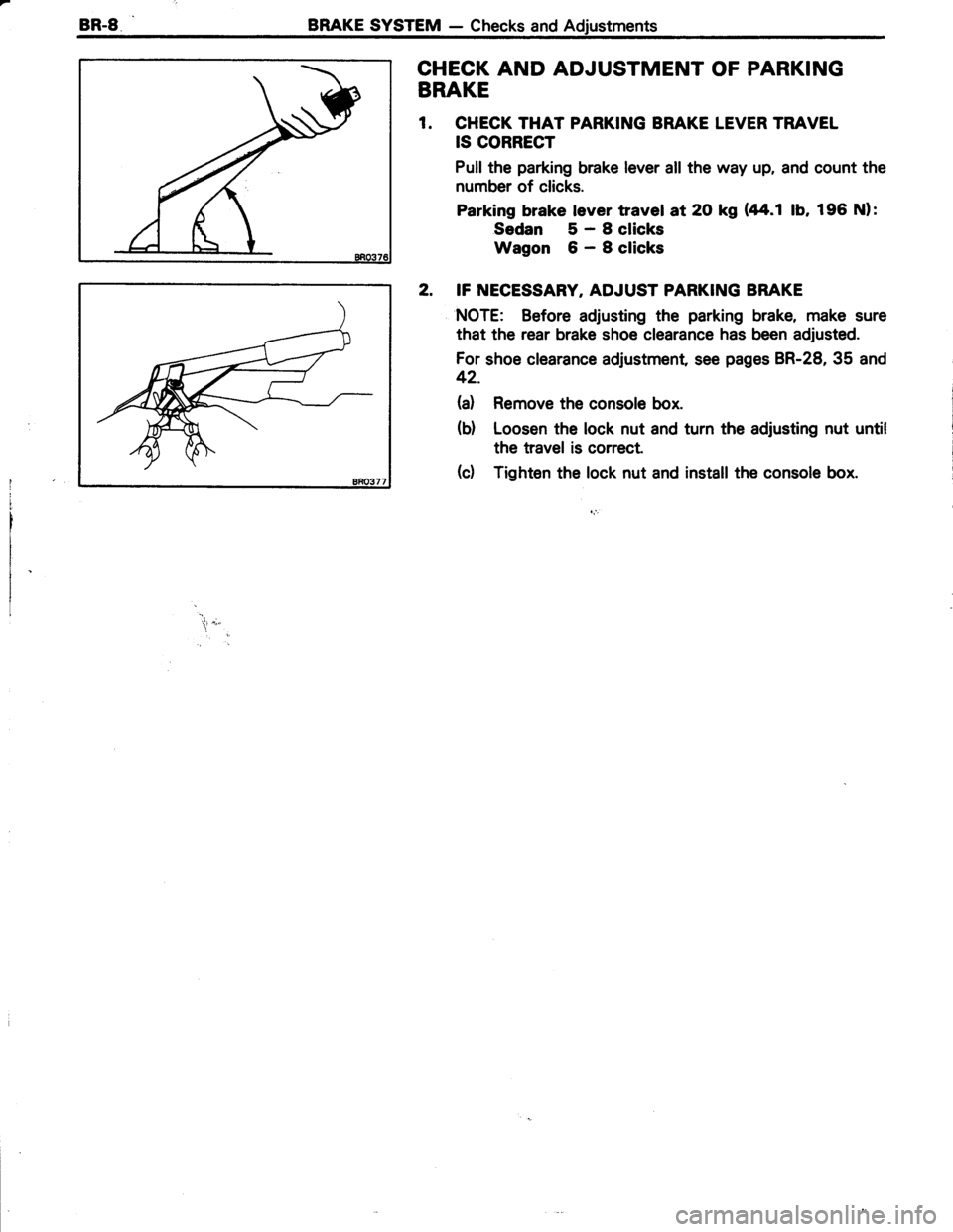

CHECK AND ADJUSTMENT OF PARKING

BRAKE

1. CHECK THAT PARKING BRAKE LEVER TRAVEL

IS CORRECT

Pull the parking brake lever all the way up, and count the

number of clicks.

Parking brake lever travel at 2O kg (44.1 lb, 196 Nl:

Sedan 5-Sclicks

Wagon 6-Sclicks

2. IF NECESSARY, ADJUST PARKING BRAKE

NOTE: Before adjusting the parking brake, make sure

that the rear brake shoe clearance has been adjusted.

For shoe clearance adjustment, see pages BR-28, 35 and

42.

(a) Remove the console box.

(d Loosen the lock nut and turn the adjusting nut until

the travel is correct.

(d Tighten the lock nut and install the console box.

*r .;"

Page 568 of 885

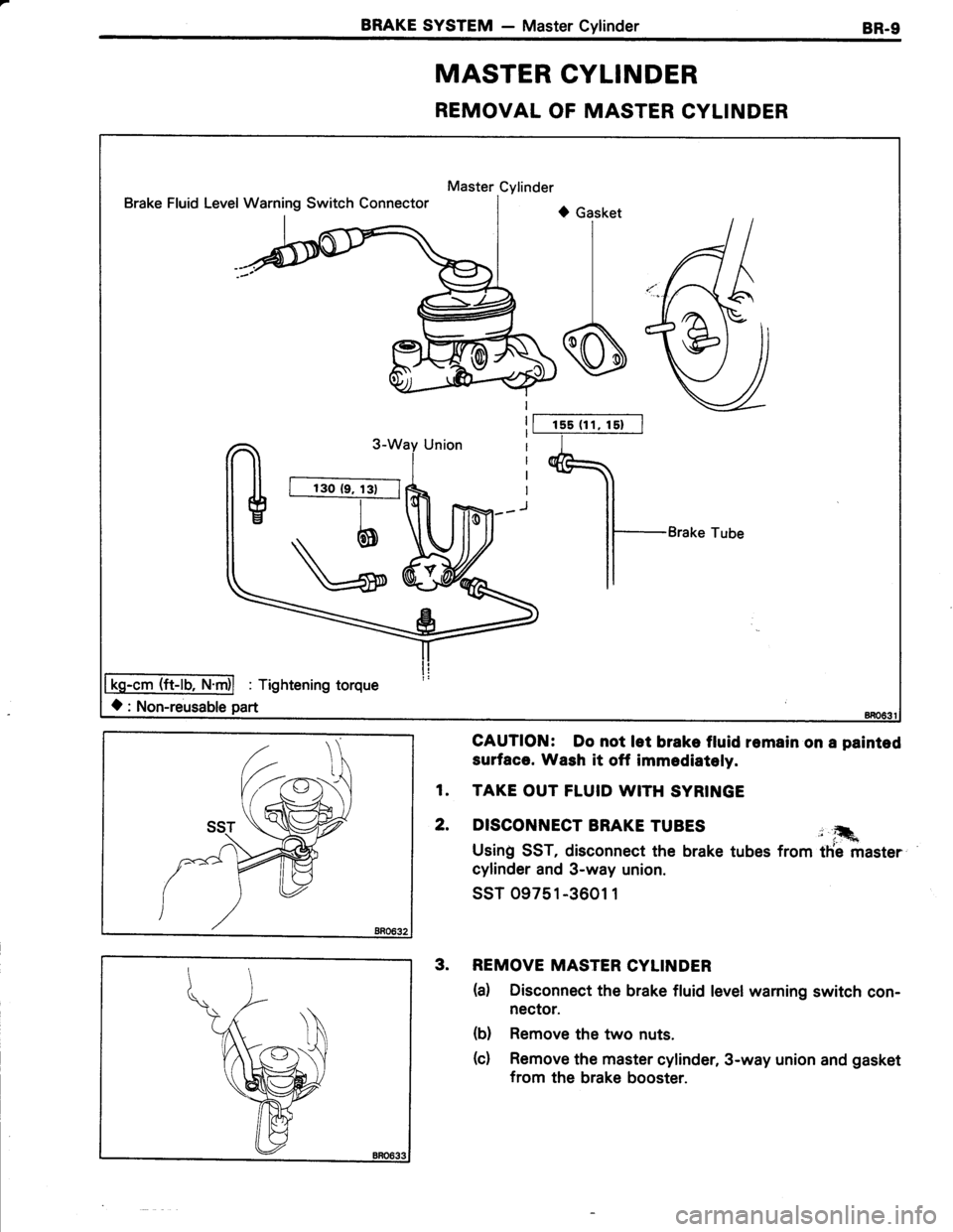

BRAKE SYSTEM - Master CylinderBR-9

MASTER CYLINDER

REMOVAL OF MASTER CYLINDER

Master Cylinder

Brake Fluid LevelWarning Switch Connectort) Gasket

I

I

s

Brake Tube

-cm (ft-lb,

O: Non-reusable part

1s5 (1 1, 15)

Tightening torque

GAUTION: Do not let brake fluid remain on a painted

surface. Wash it off immediatoly.

1. TAKE OUT FLUID WITH SYRINGE

2. DISCONNECT BRAKE TUBES j ,�.

Usin! SST, disconnect the brake tubes from tfie master

cylinder and 3-way union.

ssT 09751-3601 1

3. REMOVE MASTER CYLINDER

(d Disconnect the brake fluid level warning switch con-

nector.

(b) Remove the two nuts.

(c) Remove the master cylinder, 3-way union and gasket

from the brake booster.

Page 569 of 885

aBR.lOBRAKE SYSTEM - Master Cylinder

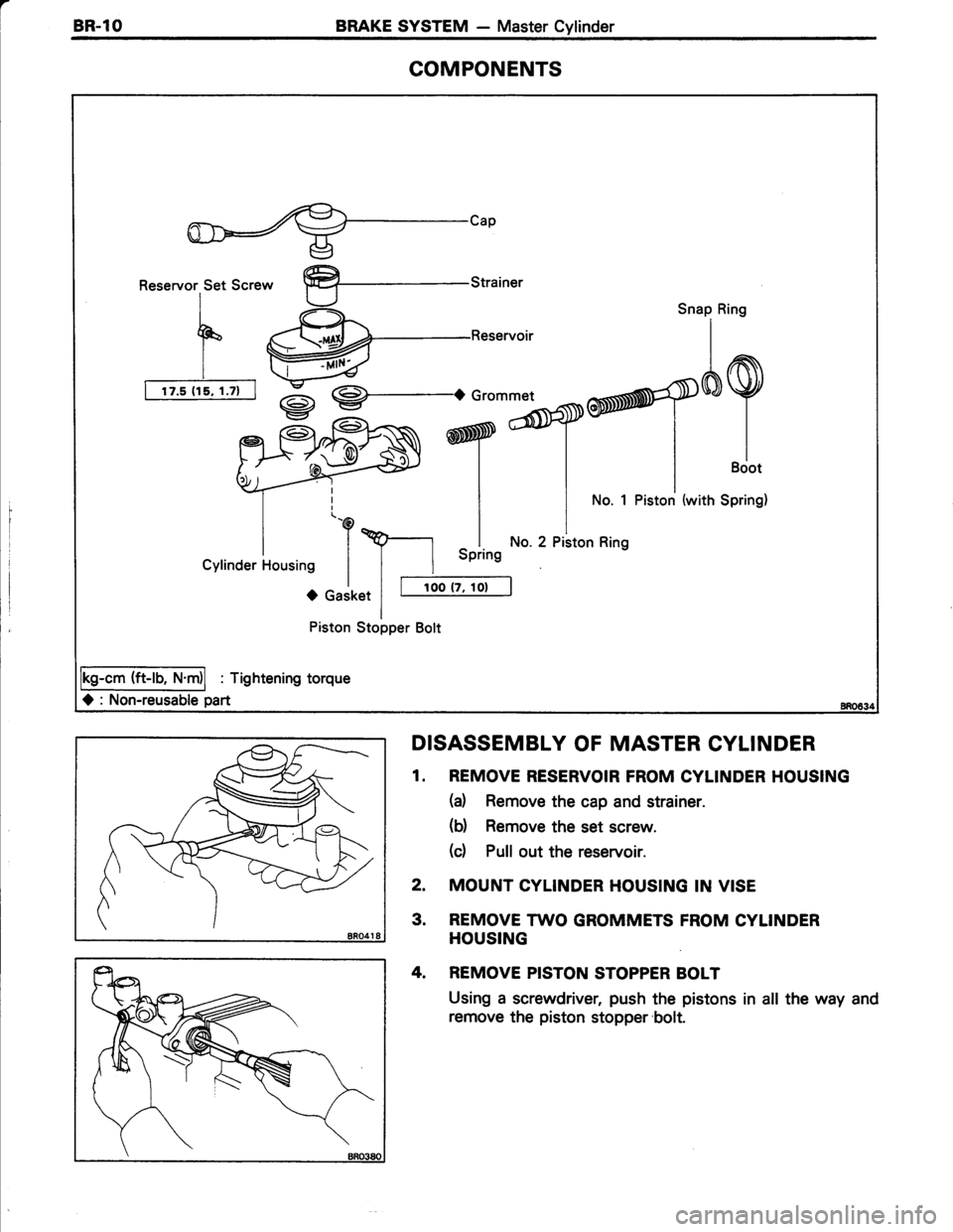

COMPONENTS

Reservor Set Screw

I

F(

Ir

I rzt{rtaz-l

%-Reservoir

I

9-.o

RN ry'jbTry^?

Snap Ring

}N ryofltort""* | |-+)rlllsciot

| |

*" 1 Piston (with SPring)

\p-l ^l No.2pistonRins

I I uprrng

-^ I I roo tz, rot Ierl

(ft-rb, N

O : Non-reusable part

Piston Stopper Bolt

: Tightening torque

O Gasket

DISASSEMBLY OF MASTER CYLINDER

1. REMOVE RESERVOIR FROM CYLINDER HOUSING

(a) Remove the cap and strainer.

(d Remove the set screw.

(c) Pull out the reservoir.

2. MOUNT CYLINDER HOUSING IN VISE

3. REMOVE TWO GROMMETS FROM CYLINDER

HOUSING

4. REMOVE PISTON STOPPER BOLT

Using a screwdriver, push the pistons in all the way and

remove the piston stopper'bolt.

Page 570 of 885

BRAKE SYSTEM - Master CylinderBR-11

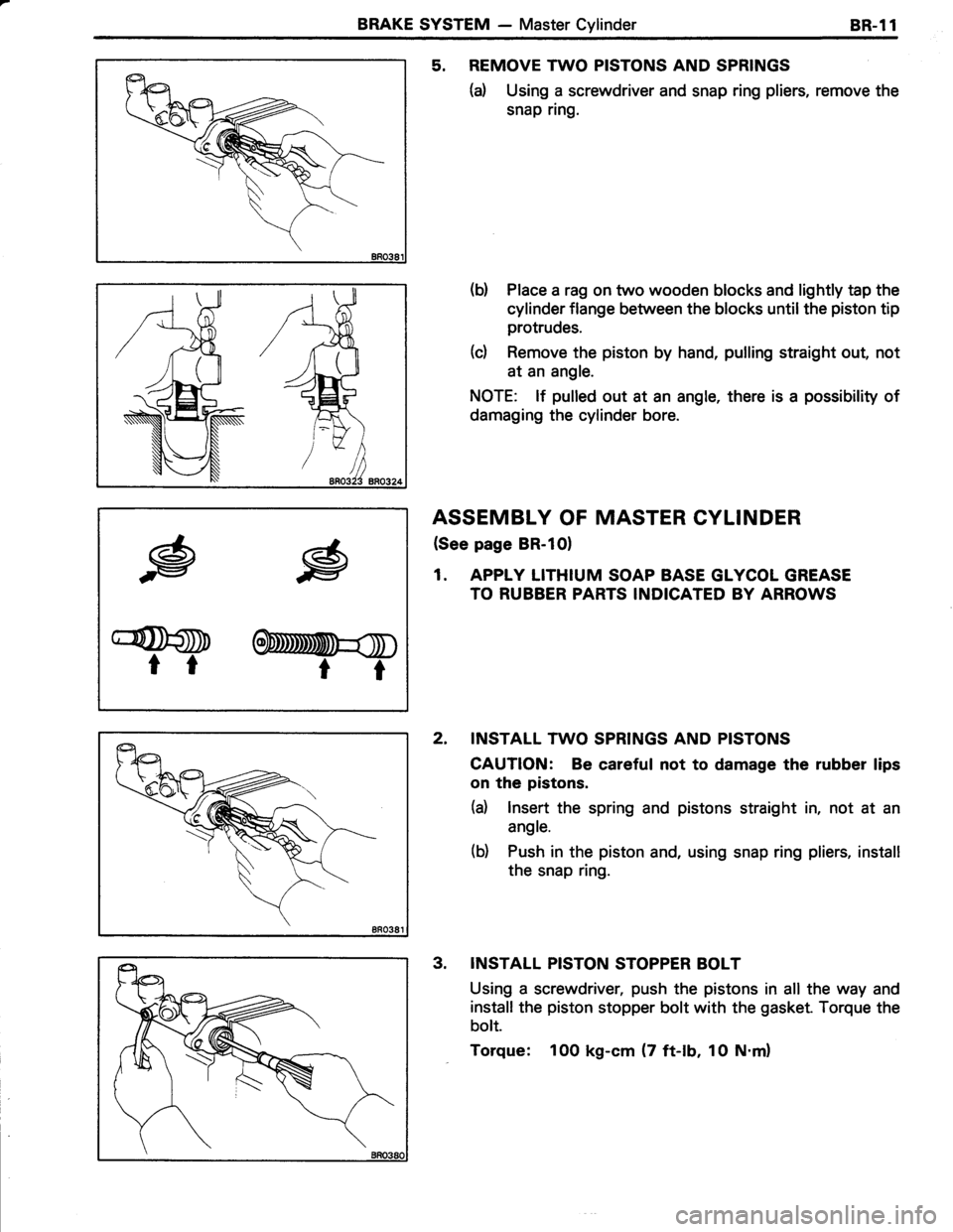

5. REMOVE TWO PISTONS AND SPRINGS

(d Using a screwdriver and snap ring pliers, remove the

snap ring.

(b) Place a rag on two wooden blocks and lightly tap the

cylinder flange between the blocks until the piston tip

protrudes.

(c) Remove the piston by hand, pulling straight out, not

at an angle.

NOTE: lf pulled out at an angle, there is a possibility of

damaging the cylinder bore.

ASSEMBLY OF MASTER CYLINDER

(See page BR-10)

1. APPLY LITHIUM SOAP BASE GLYCOL GREASE

TO RUBBER PARTS INDICATED BY ARROWS

2. INSTALL TWO SPRINGS AND PISTONS

CAUTION: Be careful not to damage the rubber lips

on the pistons.

(d lnsert the spring and pistons straight in, not at an

angle.

(b) Push in the piston and, using snap ring pliers, install

the snap ring.

INSTALL PISTON STOPPER BOLT

Using a screwdriver, push the pistons in all the way and

install the piston stopper bolt with the gasket. Torque the

bolt.

Torque: 100 kg-cm (7 ft-lb, 1O N.m)

.g

G@D

tr

.g

OnmmU=$

rt

3.