Power on TOYOTA VERSO 2014 Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2014, Model line: VERSO, Model: TOYOTA VERSO 2014Pages: 650, PDF Size: 36.61 MB

Page 556 of 650

556 5-2. Steps to take in an emergency

Before performing emergency repair

Check the degree of the tire

damage.

• Do not remove the nail or

screw from the tire. Removing

the object may widen the

opening and prevent emer-

gency repair with the repair kit.

• Type A: To avoid sealant leak-

age, move the vehicle until the

area of the puncture, if known,

is positioned at the top of the

tire.

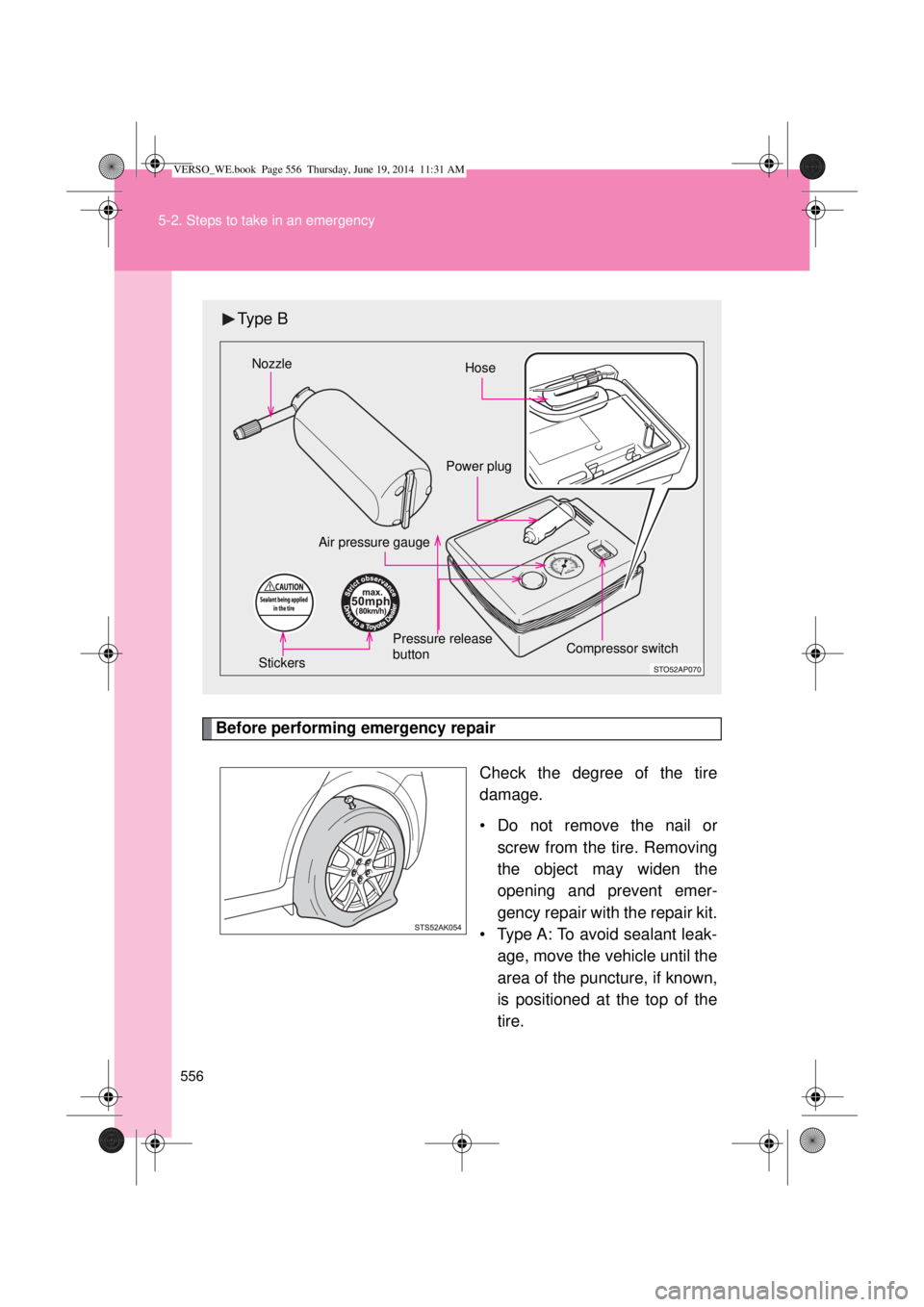

Type B

Power plug

Compressor switch

Air pressure gauge

HoseNozzle

Stickers

Pressure release

button

VERSO_WE.book Page 556 Thursday, June 19, 2014 11:31 AM

Page 560 of 650

560 5-2. Steps to take in an emergency

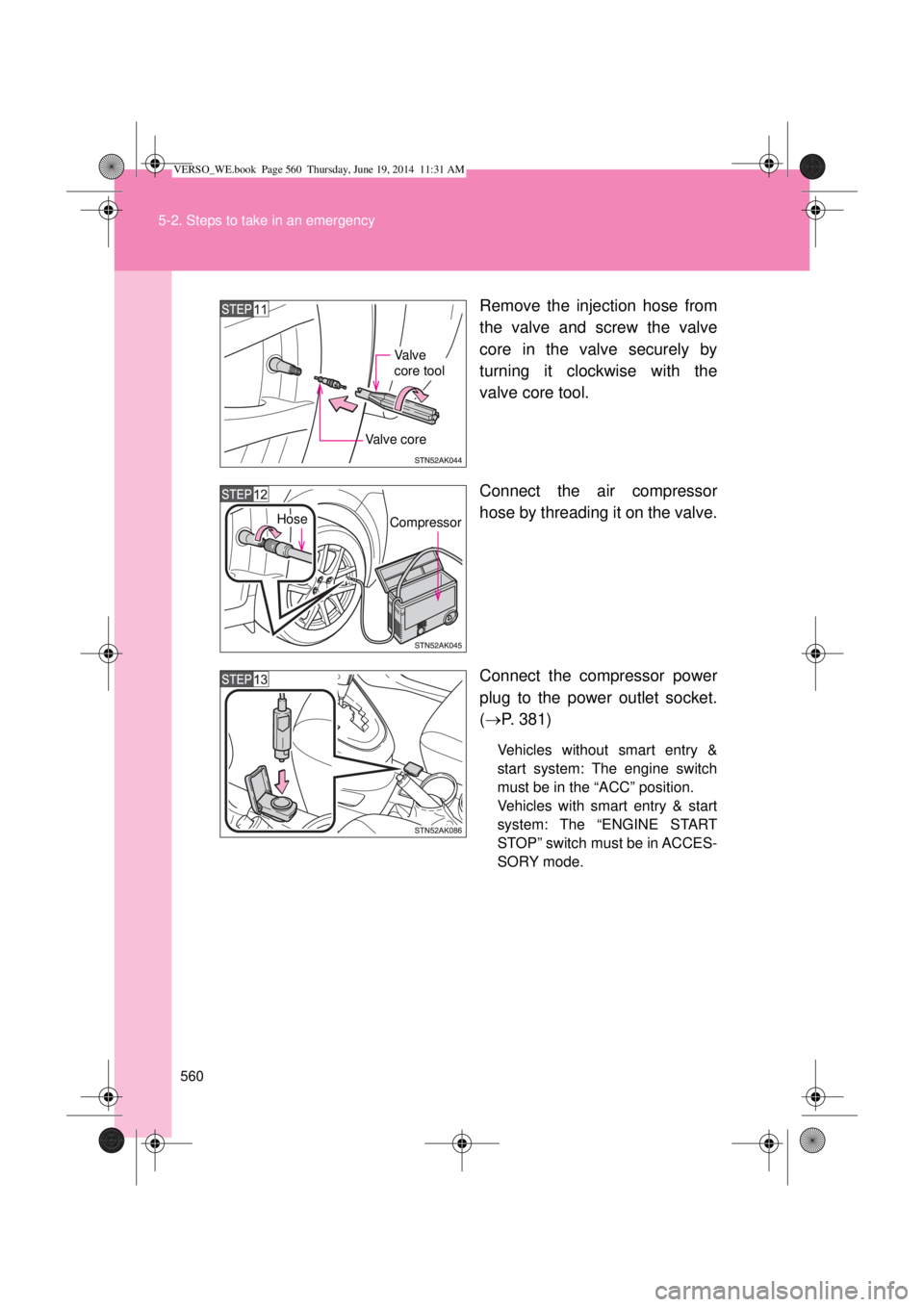

Remove the injection hose from

the valve and screw the valve

core in the valve securely by

turning it clockwise with the

valve core tool.

Connect the air compressor

hose by threading it on the valve.

Connect the compressor power

plug to the power outlet socket.

(P. 381)

Vehicles without smart entry &

start system: The engine switch

must be in the “ACC” position.

Vehicles with smart entry & start

system: The “ENGINE START

STOP” switch must be in ACCES-

SORY mode.

Valve core

Valve

core tool

CompressorHose

VERSO_WE.book Page 560 Thursday, June 19, 2014 11:31 AM

Page 562 of 650

562 5-2. Steps to take in an emergency

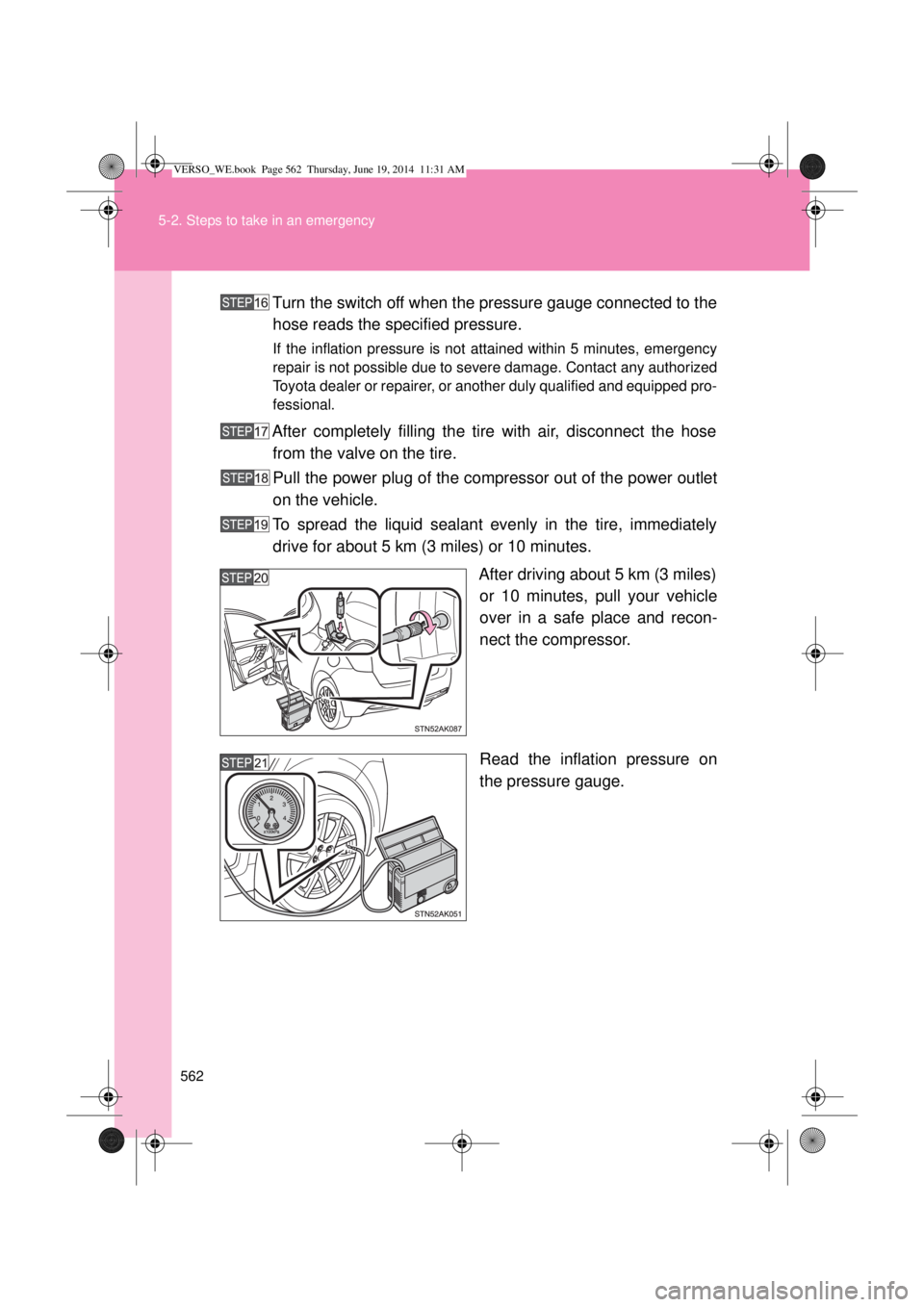

Turn the switch off when the pressure gauge connected to the

hose reads the specified pressure.

If the inflation pressure is not attained within 5 minutes, emergency

repair is not possible due to severe damage. Contact any authorized

Toyota dealer or repairer, or another duly qualified and equipped pro-

fessional.

After completely filling the tire with air, disconnect the hose

from the valve on the tire.

Pull the power plug of the compressor out of the power outlet

on the vehicle.

To spread the liquid sealant evenly in the tire, immediately

drive for about 5 km (3 miles) or 10 minutes.

After driving about 5 km (3 miles)

or 10 minutes, pull your vehicle

over in a safe place and recon-

nect the compressor.

Read the inflation pressure on

the pressure gauge.

VERSO_WE.book Page 562 Thursday, June 19, 2014 11:31 AM

Page 566 of 650

566 5-2. Steps to take in an emergency

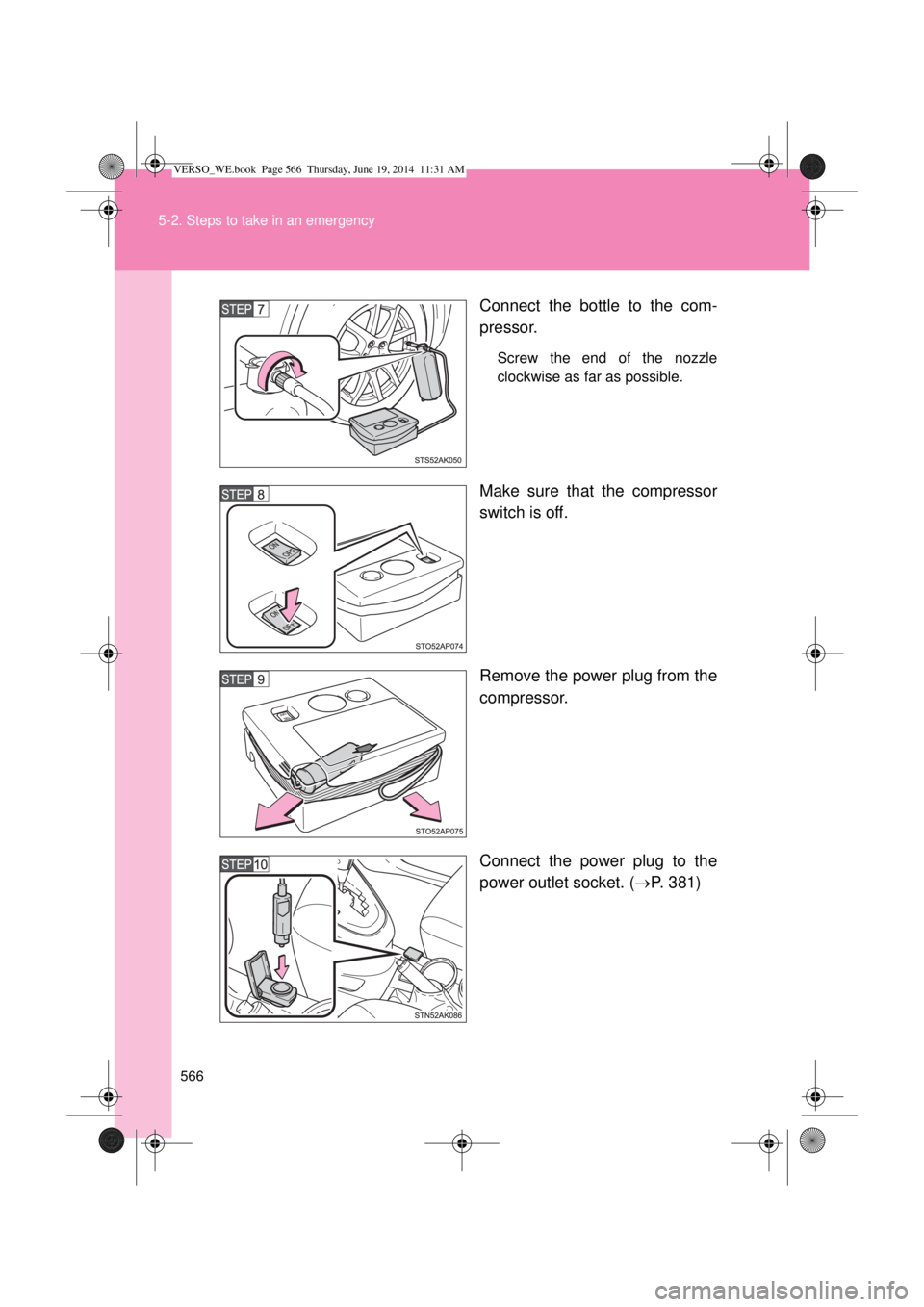

Connect the bottle to the com-

pressor.

Screw the end of the nozzle

clockwise as far as possible.

Make sure that the compressor

switch is off.

Remove the power plug from the

compressor.

Connect the power plug to the

power outlet socket. (P. 381)

VERSO_WE.book Page 566 Thursday, June 19, 2014 11:31 AM

Page 569 of 650

5

569 5-2. Steps to take in an emergency

When trouble arises

Disconnect the nozzle from the valve on the tire and then pull

out the power plug from the power outlet socket.

Some sealant may leak when the hose is removed.

Install the valve cap onto the valve of the repaired tire.

Disconnect the hose from the

bottle and attach the cap to the

bottle.

Place the bottle in the original bag

and zip it.

Temporarily store the bottle and compressor in the luggage

compartment.

To spread the liquid sealant evenly within the tire, immediately

drive safely for about 5 km (3 miles) below 80 km/h (50 mph).

After driving for about 5 km (3

miles), stop your vehicle in a

safe place on a hard, flat surface

and connect the compressor.

VERSO_WE.book Page 569 Thursday, June 19, 2014 11:31 AM

Page 575 of 650

5

575 5-2. Steps to take in an emergency

When trouble arises

NOTICE

When performing an emergency repair

A tire should only be repaired with the emergency tire puncture repair kit if

the damage is caused by a sharp object such as nail or screw passing

through the tire tread.

Do not remove the sharp object from the tire. Removing the object may

widen the opening and disenable emergency repair with the repair kit.

The repair kit is not waterproof. Make sure that the repair kit is not

exposed to water, such as when it is being used in the rain.

Do not put the repair kit directly onto dusty ground such as sand at the

side of the road. If the repair kit vacuums up dust etc., a malfunction may

occur.

Precautions for the emergency tire puncture repair kit

The repair kit power source should be 12 V DC suitable for vehicle use. Do

not connect the repair kit to any other source.

If gasoline splatters on the repair kit, the repair kit may deteriorate. Take

care not to allow gasoline to contact it.

Place the repair kit in a storage to prevent it from being exposed to dirt or

water.

Store the repair kit in the luggage room out of reach of children.

Do not disassemble or modify the repair kit. Do not subject parts such as

the air pressure indicator to impacts. This may cause a malfunction.

To avoid damage to the tire pressure warning valves and transmitters

(vehicles with the tire pressure warning system)

When a tire is repaired with liquid sealants, the tire pressure warning valve

and transmitter may not operate properly. If a liquid sealant is used, contact

any authorized Toyota dealer or repairer, or another duly qualified and

equipped professional or other qualified service shop as soon as possible.

Make sure to replace the tire pressure warning valve and transmitter when

replacing the tire. (P. 444)

VERSO_WE.book Page 575 Thursday, June 19, 2014 11:31 AM

Page 589 of 650

5

589

5-2. Steps to take in an emergency

When trouble arises

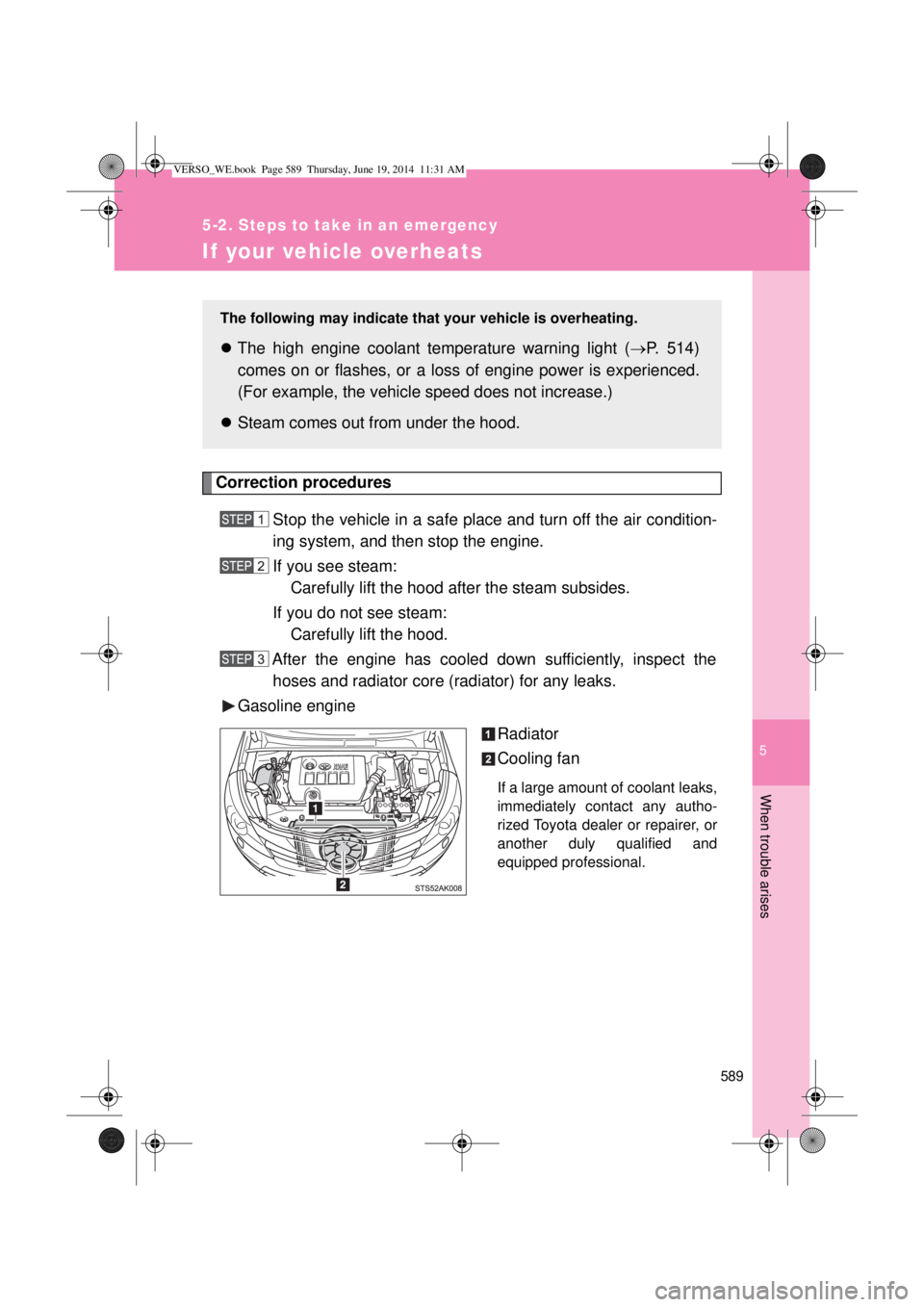

If your vehicle overheats

Correction procedures

Stop the vehicle in a safe place and turn off the air condition-

ing system, and then stop the engine.

If you see steam:

Carefully lift the hood after the steam subsides.

If you do not see steam:

Carefully lift the hood.

After the engine has cooled down sufficiently, inspect the

hoses and radiator core (radiator) for any leaks.

Gasoline engine

Radiator

Cooling fan

If a large amount of coolant leaks,

immediately contact any autho-

rized Toyota dealer or repairer, or

another duly qualified and

equipped professional.

The following may indicate that your vehicle is overheating.

The high engine coolant temperature warning light (P. 514)

comes on or flashes, or a loss of engine power is experienced.

(For example, the vehicle speed does not increase.)

Steam comes out from under the hood.

VERSO_WE.book Page 589 Thursday, June 19, 2014 11:31 AM

Page 596 of 650

596 5-2. Steps to take in an emergency

CAUTION

If the engine has to be turned off while driving

Power assist for the brakes and steering wheel will be lost, making the

brake pedal harder to depress and the steering wheel heavier to turn.

Decelerate as much as possible before turning off the engine.

Vehicles without smart entry & start system: Never attempt to remove the

key, as doing so will lock the steering wheel.

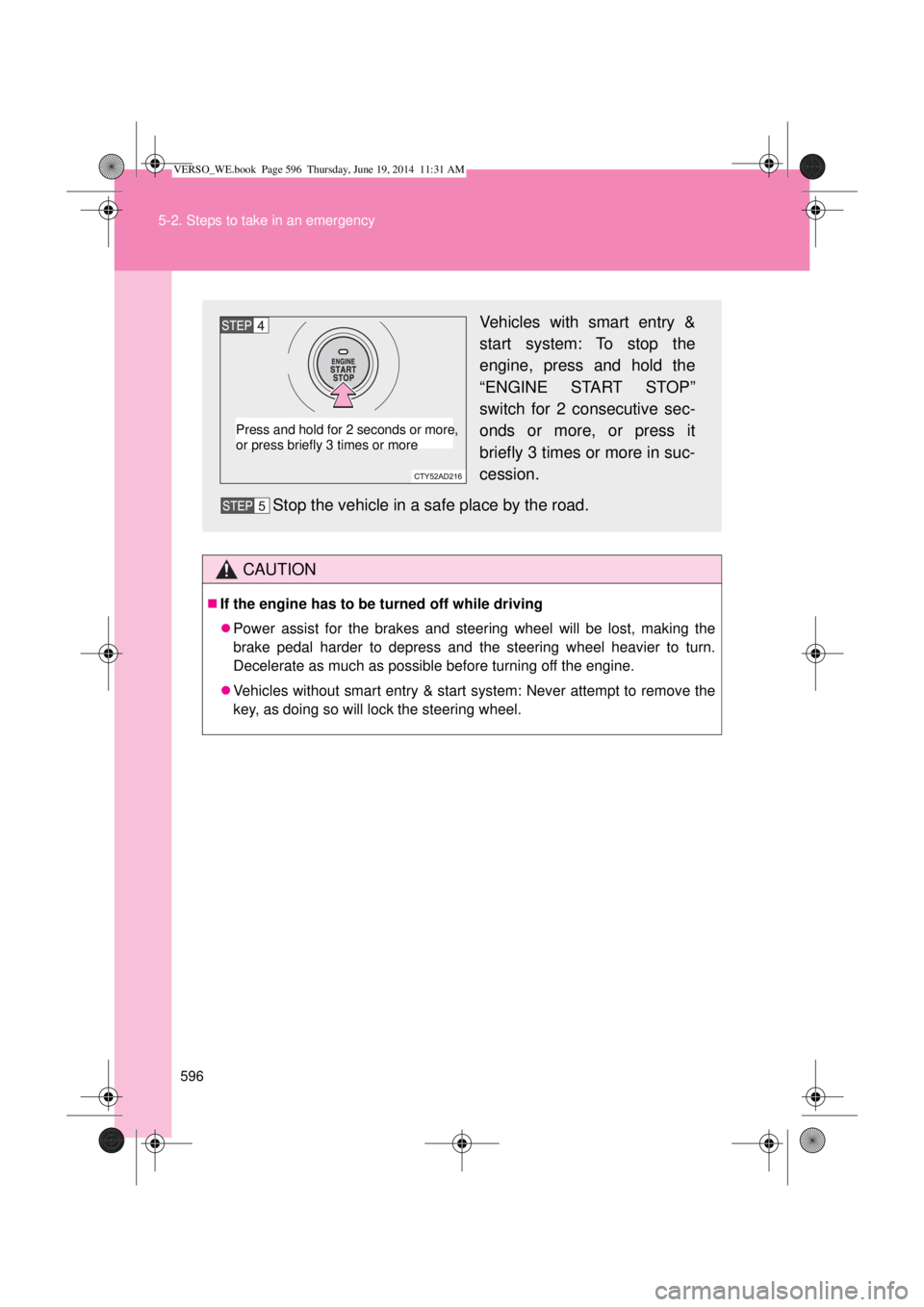

Vehicles with smart entry &

start system: To stop the

engine, press and hold the

“ENGINE START STOP”

switch for 2 consecutive sec-

onds or more, or press it

briefly 3 times or more in suc-

cession.

Stop the vehicle in a safe place by the road.

Press and hold for 2 seconds or more,

or press briefly 3 times or more

VERSO_WE.book Page 596 Thursday, June 19, 2014 11:31 AM

Page 615 of 650

615 6-1. Specifications

6

Vehicle specifications

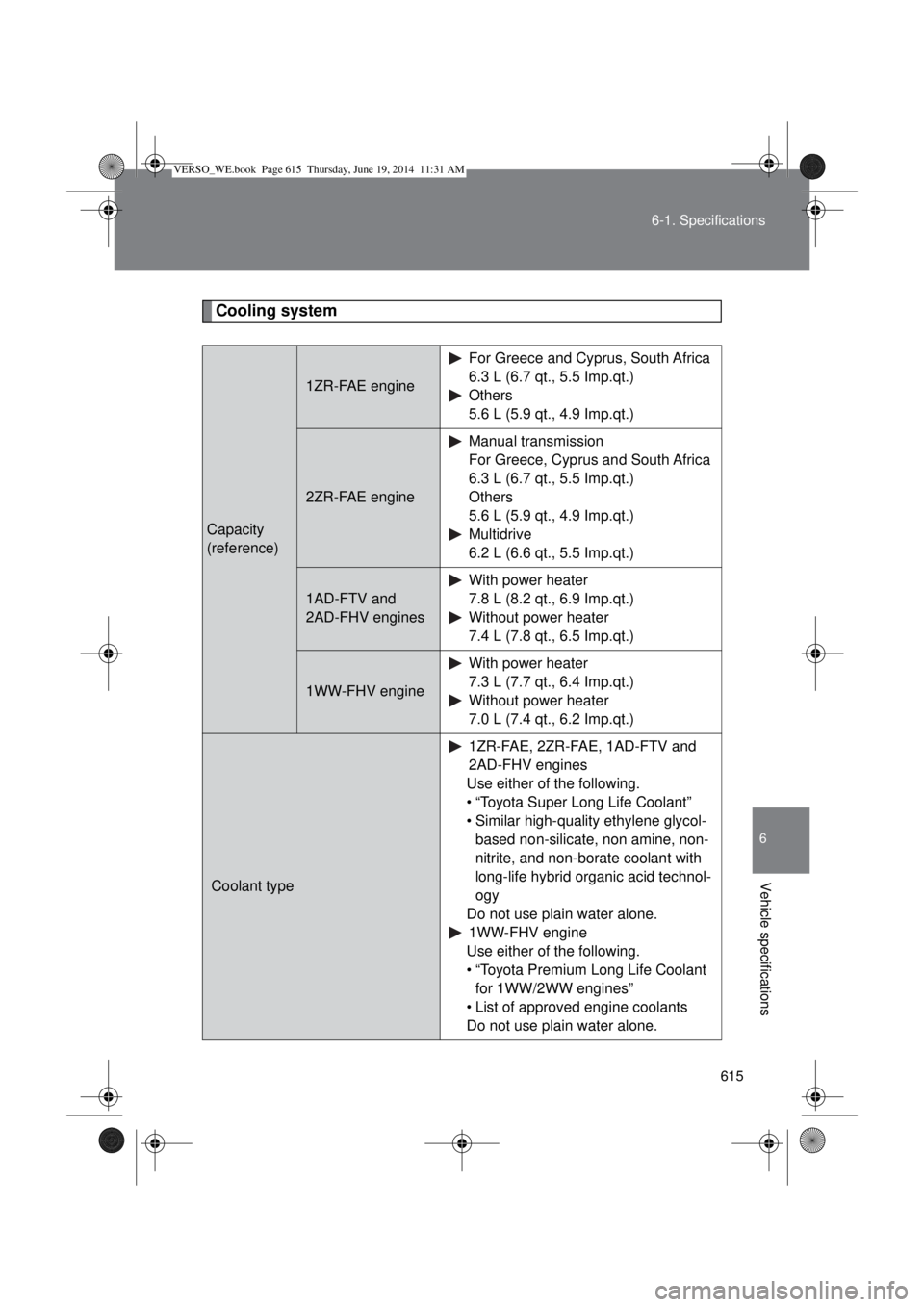

Cooling system

Capacity

(reference)

1ZR-FAE engine

For Greece and Cyprus, South Africa

6.3 L (6.7 qt., 5.5 Imp.qt.)

Others

5.6 L (5.9 qt., 4.9 Imp.qt.)

2ZR-FAE engine

Manual transmission

For Greece, Cyprus and South Africa

6.3 L (6.7 qt., 5.5 Imp.qt.)

Others

5.6 L (5.9 qt., 4.9 Imp.qt.)

Multidrive

6.2 L (6.6 qt., 5.5 Imp.qt.)

1AD-FTV and

2AD-FHV engines

With power heater

7.8 L (8.2 qt., 6.9 Imp.qt.)

Without power heater

7.4 L (7.8 qt., 6.5 Imp.qt.)

1WW-FHV engine

With power heater

7.3 L (7.7 qt., 6.4 Imp.qt.)

Without power heater

7.0 L (7.4 qt., 6.2 Imp.qt.)

Coolant type1ZR-FAE, 2ZR-FAE, 1AD-FTV and

2AD-FHV engines

Use either of the following.

• “Toyota Super Long Life Coolant”

• Similar high-quality ethylene glycol-

based non-silicate, non amine, non-

nitrite, and non-borate coolant with

long-life hybrid organic acid technol-

ogy

Do not use plain water alone.

1WW-FHV engine

Use either of the following.

• “Toyota Premium Long Life Coolant

for 1WW/2WW engines”

• List of approved engine coolants

Do not use plain water alone.

VERSO_WE.book Page 615 Thursday, June 19, 2014 11:31 AM

Page 636 of 650

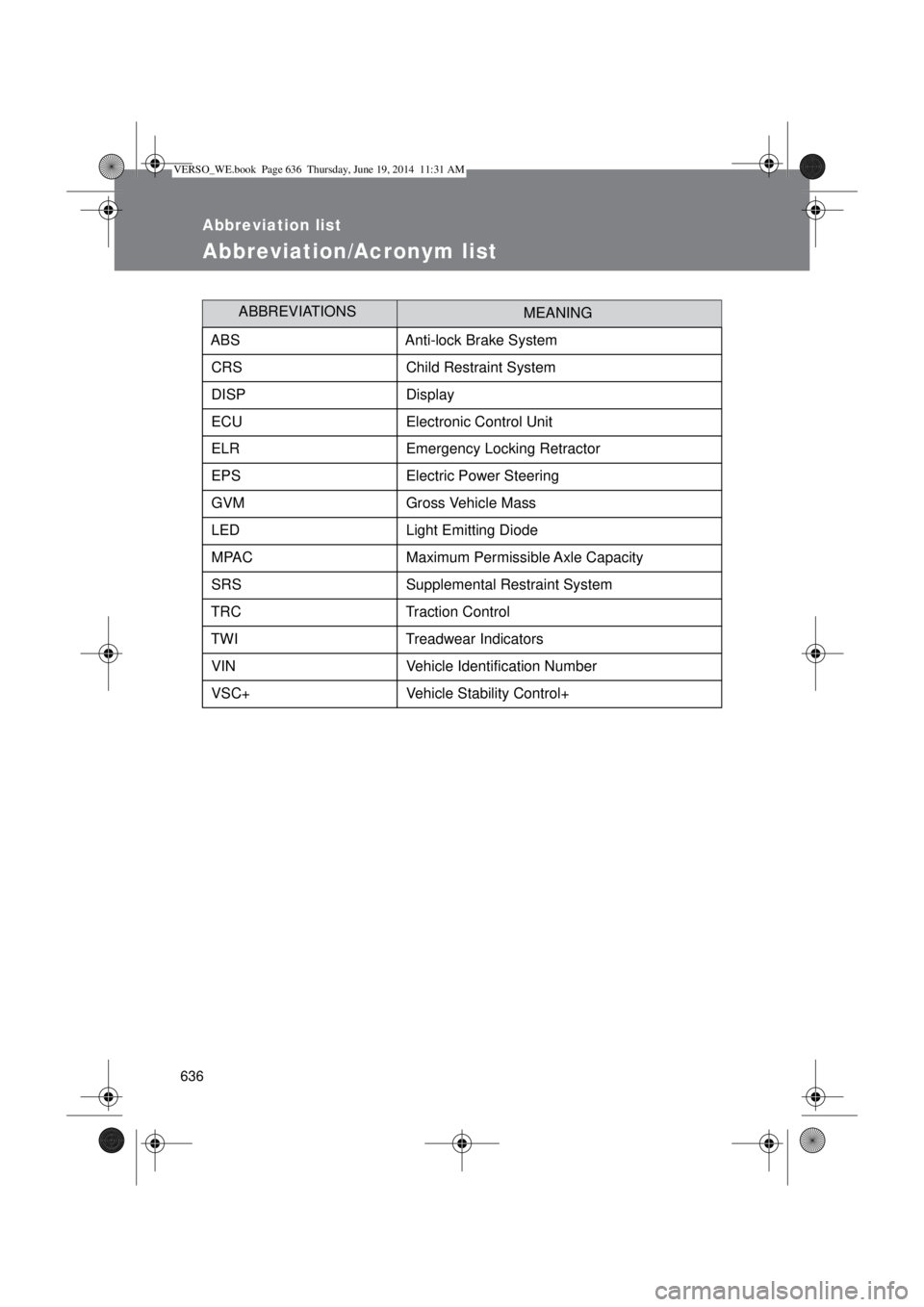

636

Abbreviation list

Abbreviation/Acronym list

ABBREVIATIONSMEANING

ABS Anti-lock Brake System

CRS Child Restraint System

DISP Display

ECU Electronic Control Unit

ELR Emergency Locking Retractor

EPS Electric Power Steering

GVM Gross Vehicle Mass

LED Light Emitting Diode

MPAC Maximum Permissible Axle Capacity

SRS Supplemental Restraint System

TRC Traction Control

TWI Treadwear Indicators

VIN Vehicle Identification Number

VSC+ Vehicle Stability Control+

VERSO_WE.book Page 636 Thursday, June 19, 2014 11:31 AM