light YAMAHA DT125R 2002 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: DT125R, Model: YAMAHA DT125R 2002Pages: 96, PDF Size: 2.14 MB

Page 42 of 96

6-4

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU03884

NOTE:

8The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

8Hydraulic brake service

9Regularly check and, if necessary, correct the brake fluid level.

9Every two years replace the internal components of the brake master cylinders and calipers, and change the

brake fluid.

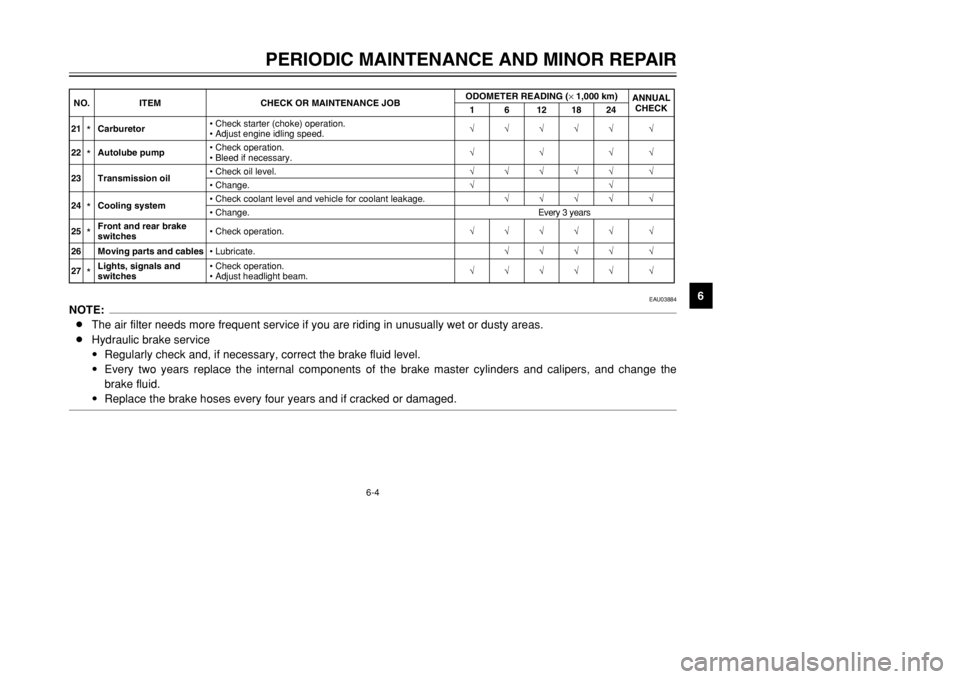

9Replace the brake hoses every four years and if cracked or damaged.21

*Carburetor•Check starter (choke) operation.

•Adjust engine idling speed.√√√√√ √

22*Autolube pump•Check operation.

•Bleed if necessary.√√√√

23 Transmission oil•Check oil level.√√√√√ √

•Change.√√

24*Cooling system•Check coolant level and vehicle for coolant leakage.√√√√ √

•Change.Every 3 years

25*Front and rear brake

switches•Check operation.√√√√√ √

26 Moving parts and cables•Lubricate.√√√√ √

27*Lights, signals and

switches•Check operation.

•Adjust headlight beam.√√√√√ √ NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING (× 1,000 km)

ANNUAL

CHECK

1 6 12 18 24

3MB-9-E8 6/13/01 10:55 AM Page 41

Page 47 of 96

6-9

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU01833

Checking the spark plugThe spark plug is an important

engine component, which is easy to

check. Since heat and deposits will

cause any spark plug to slowly erode,

the spark plug should be removed

and checked in accordance with the

periodic maintenance and lubrication

chart. In addition, the condition of the

spark plug can reveal the condition of

the engine.

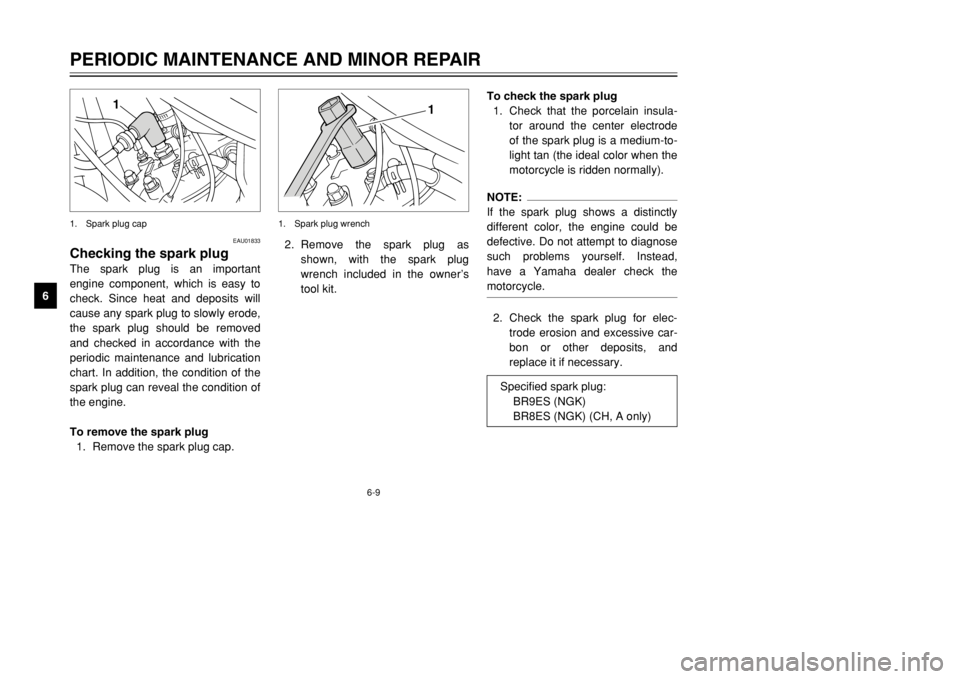

To remove the spark plug

1. Remove the spark plug cap.

1

1. Spark plug cap

To check the spark plug

1. Check that the porcelain insula-

tor around the center electrode

of the spark plug is a medium-to-

light tan (the ideal color when the

motorcycle is ridden normally).NOTE:

If the spark plug shows a distinctly

different color, the engine could be

defective. Do not attempt to diagnose

such problems yourself. Instead,

have a Yamaha dealer check the

motorcycle.2. Check the spark plug for elec-

trode erosion and excessive car-

bon or other deposits, and

replace it if necessary. 2. Remove the spark plug as

shown, with the spark plug

wrench included in the owner’s

tool kit.

1

1. Spark plug wrench

Specified spark plug:

BR9ES (NGK)

BR8ES (NGK) (CH, A only)

3MB-9-E8 6/13/01 10:55 AM Page 46

Page 48 of 96

6-10

PERIODIC MAINTENANCE AND MINOR REPAIR

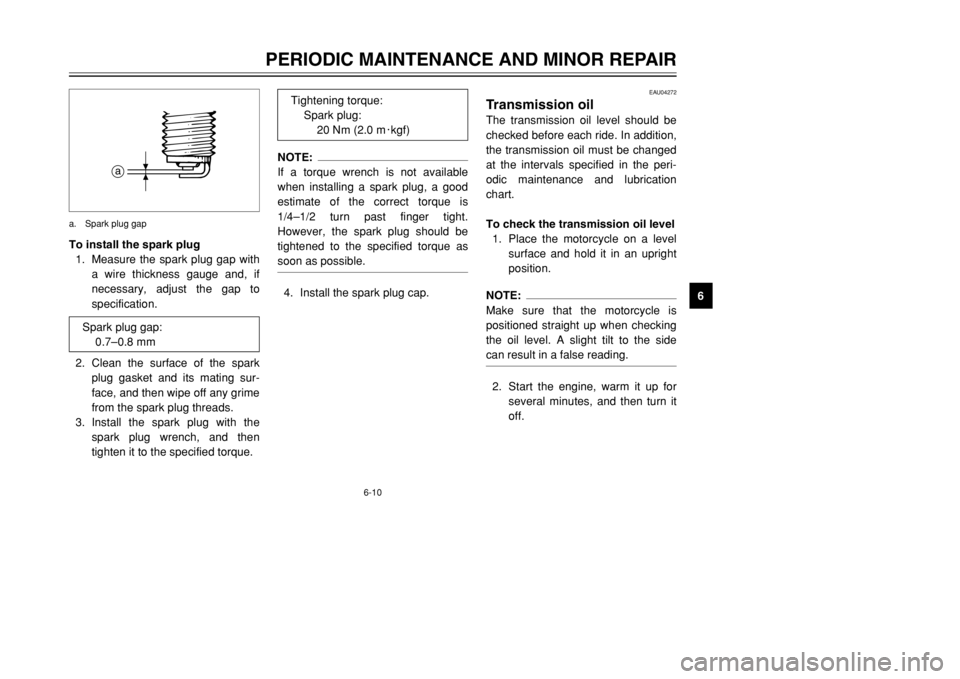

6 To install the spark plug

1. Measure the spark plug gap with

a wire thickness gauge and, if

necessary, adjust the gap to

specification.

2. Clean the surface of the spark

plug gasket and its mating sur-

face, and then wipe off any grime

from the spark plug threads.

3. Install the spark plug with the

spark plug wrench, and then

tighten it to the specified torque.

a

a. Spark plug gap

EAU04272

Transmission oilThe transmission oil level should be

checked before each ride. In addition,

the transmission oil must be changed

at the intervals specified in the peri-

odic maintenance and lubrication

chart.

To check the transmission oil level

1. Place the motorcycle on a level

surface and hold it in an upright

position.NOTE:

Make sure that the motorcycle is

positioned straight up when checking

the oil level. A slight tilt to the side

can result in a false reading.2. Start the engine, warm it up for

several minutes, and then turn it

off.

NOTE:

If a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is

1/4–1/2 turn past finger tight.

However, the spark plug should be

tightened to the specified torque as

soon as possible.4. Install the spark plug cap.

Spark plug gap:

0.7–0.8 mmTightening torque:

Spark plug:

20 Nm (2.0 m0kgf)

3MB-9-E8 6/13/01 10:55 AM Page 47

Page 50 of 96

6-12

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EC000077

cC8In order to prevent clutch slip-

page (since the transmission

oil also lubricates the clutch),

do not mix any chemical addi-

tives with the oil.

8Make sure that no foreign

material enters the transmis-

sion.6. Start the engine, and then let it

idle for several minutes while

checking the transmission for oil

leakage. If oil is leaking, immedi-

ately turn off the engine and

check for the cause.

EAU01808

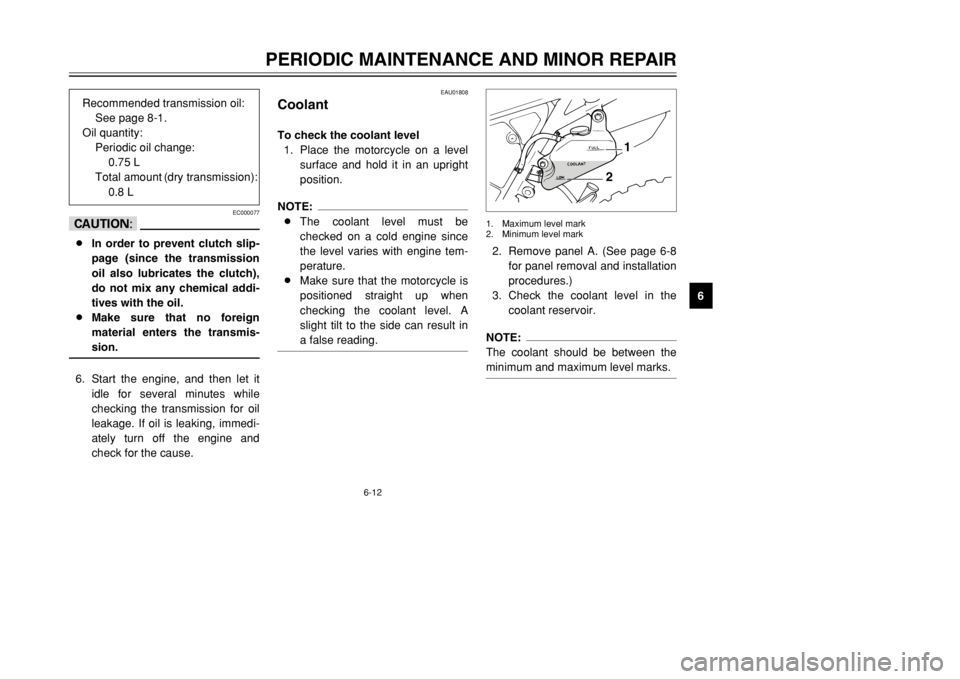

CoolantTo check the coolant level

1. Place the motorcycle on a level

surface and hold it in an upright

position.NOTE:

8The coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

8Make sure that the motorcycle is

positioned straight up when

checking the coolant level. A

slight tilt to the side can result in

a false reading.

2. Remove panel A. (See page 6-8

for panel removal and installation

procedures.)

3. Check the coolant level in the

coolant reservoir.NOTE:

The coolant should be between the

minimum and maximum level marks.

2

1

1. Maximum level mark

2. Minimum level mark

Recommended transmission oil:

See page 8-1.

Oil quantity:

Periodic oil change:

0.75 L

Total amount (dry transmission):

0.8 L

3MB-9-E8 6/13/01 10:55 AM Page 49

Page 62 of 96

6-24

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EW000109

wA soft or spongy feeling in the

brake pedal can indicate the pres-

ence of air in the hydraulic system.

If there is air in the hydraulic sys-

tem, have a Yamaha dealer bleed

the system before operating the

motorcycle. Air in the hydraulic

system will diminish the braking

performance, which may result in

loss of control and an accident.

EAU00721

Checking the front and rear

brake padsThe front and rear brake pads must

be checked for wear at the intervals

specified in the periodic maintenance

and lubrication chart.

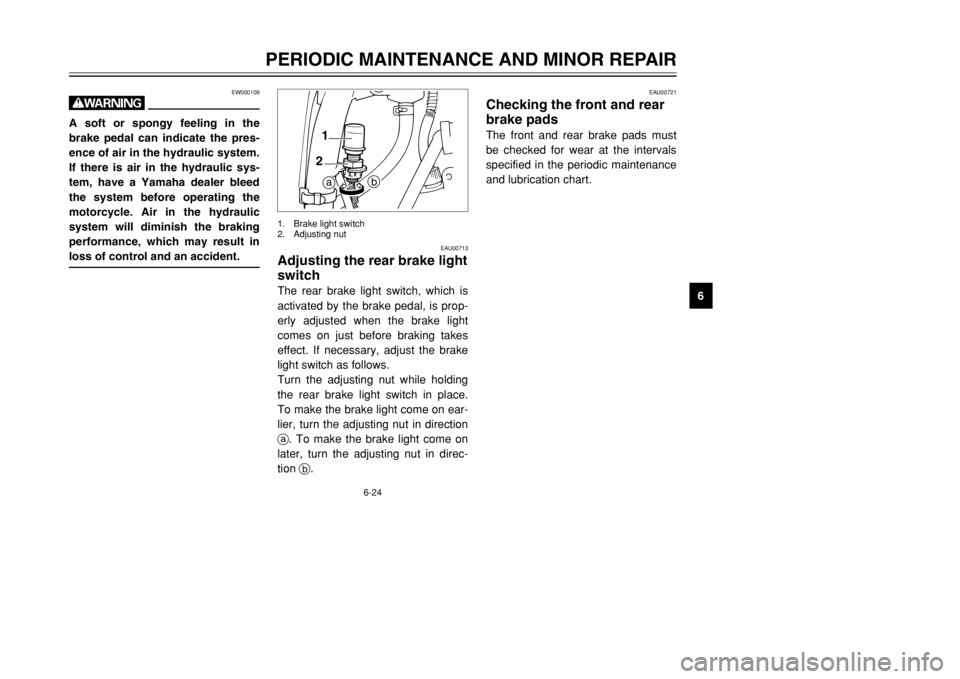

EAU00713

Adjusting the rear brake light

switchThe rear brake light switch, which is

activated by the brake pedal, is prop-

erly adjusted when the brake light

comes on just before braking takes

effect. If necessary, adjust the brake

light switch as follows.

Turn the adjusting nut while holding

the rear brake light switch in place.

To make the brake light come on ear-

lier, turn the adjusting nut in direction

a. To make the brake light come on

later, turn the adjusting nut in direc-

tion b.

b

a 1

2

1. Brake light switch

2. Adjusting nut

3MB-9-E8 6/13/01 10:55 AM Page 61

Page 74 of 96

6-36

PERIODIC MAINTENANCE AND MINOR REPAIR

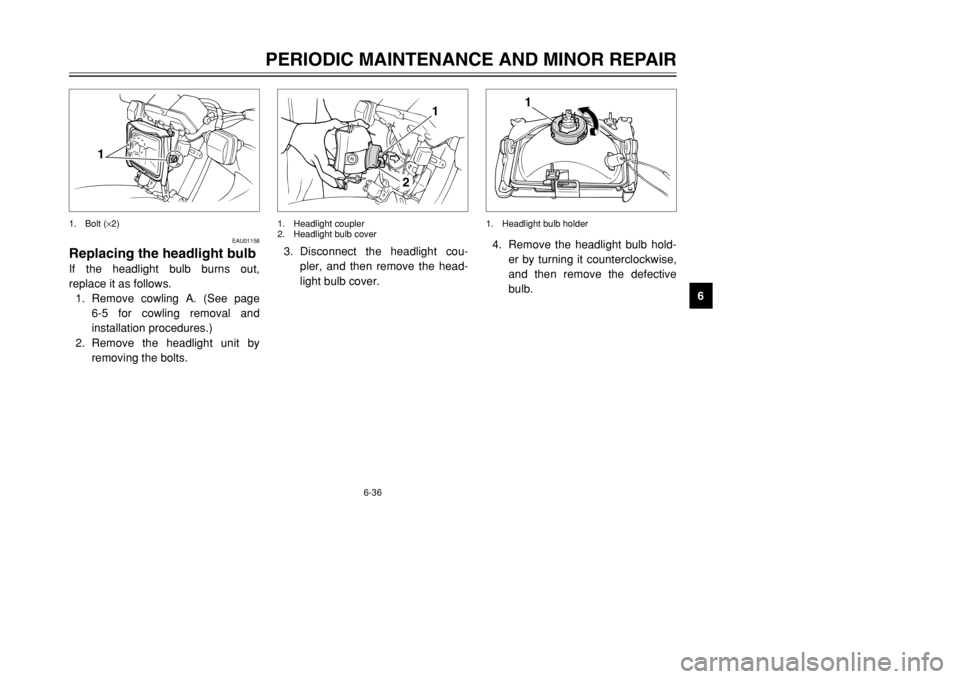

6 4. Remove the headlight bulb hold-

er by turning it counterclockwise,

and then remove the defective

bulb.

1

1. Headlight bulb holder

3. Disconnect the headlight cou-

pler, and then remove the head-

light bulb cover.

1

2

1. Headlight coupler

2. Headlight bulb cover

EAU01158

Replacing the headlight bulbIf the headlight bulb burns out,

replace it as follows.

1. Remove cowling A. (See page

6-5 for cowling removal and

installation procedures.)

2. Remove the headlight unit by

removing the bolts.

1

1. Bolt (×2)

3MB-9-E8 6/13/01 10:55 AM Page 73

Page 75 of 96

6-37

PERIODIC MAINTENANCE AND MINOR REPAIR

6

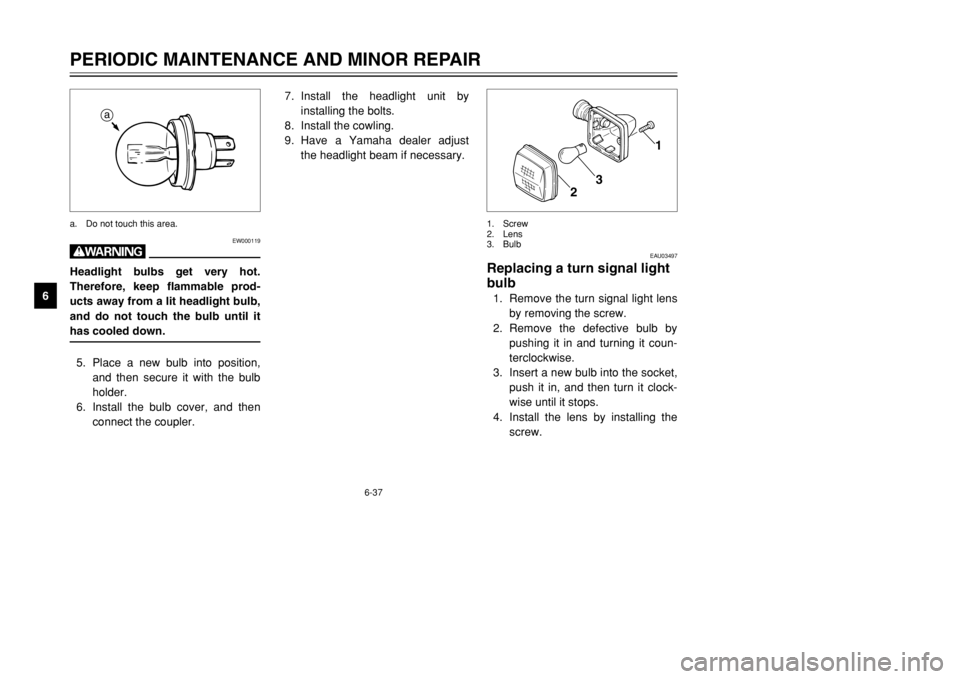

EAU03497

Replacing a turn signal light

bulb1. Remove the turn signal light lens

by removing the screw.

2. Remove the defective bulb by

pushing it in and turning it coun-

terclockwise.

3. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the

screw.

1

2

3

1. Screw

2. Lens

3. Bulb

7. Install the headlight unit by

installing the bolts.

8. Install the cowling.

9. Have a Yamaha dealer adjust

the headlight beam if necessary.

EW000119

wHeadlight bulbs get very hot.

Therefore, keep flammable prod-

ucts away from a lit headlight bulb,

and do not touch the bulb until it

has cooled down.5. Place a new bulb into position,

and then secure it with the bulb

holder.

6. Install the bulb cover, and then

connect the coupler.

a

a. Do not touch this area.

3MB-9-E8 6/13/01 10:55 AM Page 74

Page 76 of 96

6-38

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EC000108

cCDo not overtighten the screws,

otherwise the lens may break.

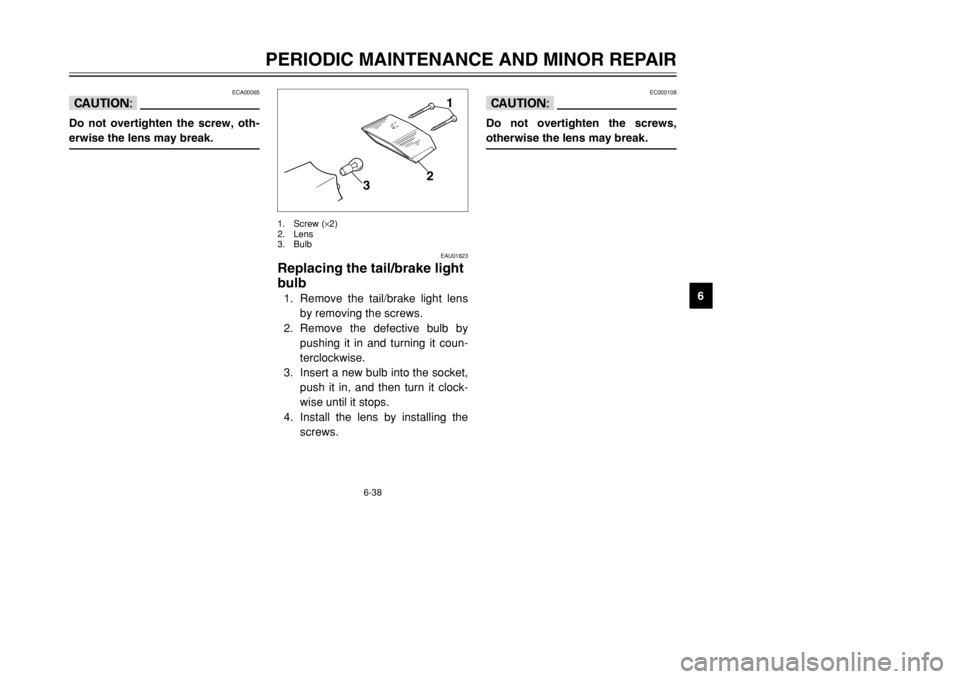

EAU01623

Replacing the tail/brake light

bulb1. Remove the tail/brake light lens

by removing the screws.

2. Remove the defective bulb by

pushing it in and turning it coun-

terclockwise.

3. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the

screws.

1

2

3

1. Screw (×2)

2. Lens

3. Bulb

ECA00065

cCDo not overtighten the screw, oth-

erwise the lens may break.

3MB-9-E8 6/13/01 10:55 AM Page 75

Page 85 of 96

7-2

MOTORCYCLE CARE AND STORAGE

78Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abra-

sive cleaning products, sol-

vent or thinner, fuel (gasoline),

rust removers or inhibitors,

brake fluid, antifreeze or elec-

trolyte.

8Do not use high-pressure

washers or steam-jet cleaners

since they cause water seep-

age and deterioration in the

following areas: seals (of

wheel and swingarm bearings,

fork and brakes), electric com-

ponents (couplers, connec-

tors, instruments, switches

and lights), breather hoses

and vents.8For motorcycles equipped

with a windshield: Do not use

strong cleaners or hard

sponges as they will cause

dulling or scratching. Some

cleaning compounds for plas-

tic may leave scratches on the

windshield. Test the product

on a small hidden part of the

windshield to make sure that it

does not leave any marks. If

the windshield is scratched,

use a quality plastic polishing

compound after washing.

After normal useRemove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottle-

brush for hard-to-reach areas.

Stubborn dirt and insects will come

off more easily if the area is covered

with a wet cloth for a few minutes

before cleaning.After riding in the rain, near the sea

or on salt-sprayed roadsSince sea salt or salt sprayed on

roads during winter are extremely

corrosive in combination with water,

carry out the following steps after

each ride in the rain, near the sea or

on salt-sprayed roads.NOTE:

Salt sprayed on roads in the winter

may remain well into spring.1. Clean the motorcycle with cold

water and a mild detergent, after

the engine has cooled down.

ECA00012

cCDo not use warm water since it

increases the corrosive action of

the salt.2. Apply a corrosion protection

spray on all metal, including

chrome- and nickel-plated, sur-

faces to prevent corrosion.

3MB-9-E8 6/13/01 10:55 AM Page 84

Page 92 of 96

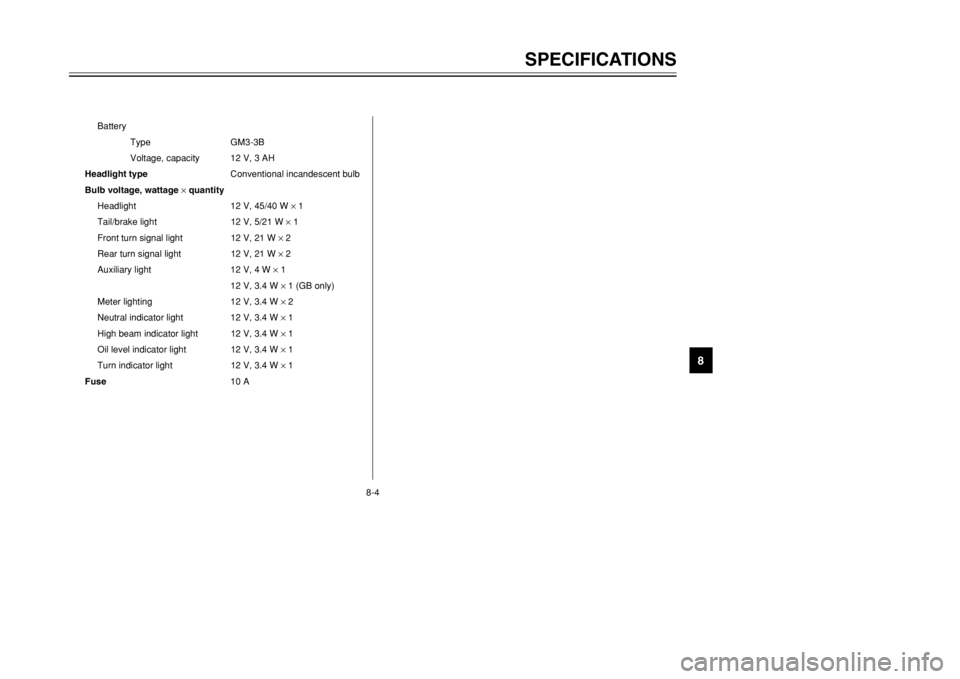

8-4

SPECIFICATIONS

8

Battery

Type GM3-3B

Voltage, capacity 12 V, 3 AH

Headlight typeConventional incandescent bulb

Bulb voltage, wattage ×quantity

Headlight 12 V, 45/40 W ×1

Tail/brake light 12 V, 5/21 W ×1

Front turn signal light 12 V, 21 W ×2

Rear turn signal light 12 V, 21 W ×2

Auxiliary light 12 V, 4 W ×1

12 V, 3.4 W ×1 (GB only)

Meter lighting 12 V, 3.4 W ×2

Neutral indicator light 12 V, 3.4 W ×1

High beam indicator light 12 V, 3.4 W ×1

Oil level indicator light 12 V, 3.4 W ×1

Turn indicator light 12 V, 3.4 W ×1

Fuse10 A

3MB-9-E8 6/13/01 10:55 AM Page 91