YAMAHA FJR1300A 2013 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2013, Model line: FJR1300A, Model: YAMAHA FJR1300A 2013Pages: 118, PDF Size: 3.28 MB

Page 51 of 118

INSTRUMENT AND CONTROL FUNCTIONS

3-36

3

WARNING

EWA14420

●

Do not exceed the load limit of 1

kg (2 lb) for storage compart-

ment A.

●

Do not exceed the load limit of 3

kg (7 lb) for storage compart-

ment B.

●

Do not exceed the maximum

load of 215 kg (474 lb) for the ve-

hicle.

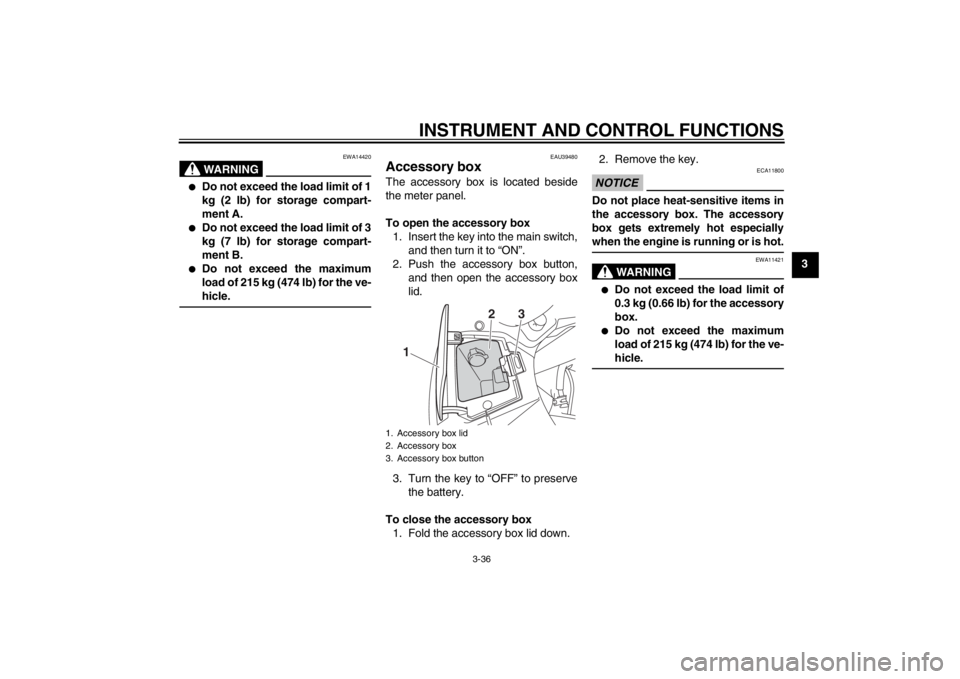

EAU39480

Accessory box The accessory box is located beside

the meter panel.

To open the accessory box1. Insert the key into the main switch, and then turn it to “ON”.

2. Push the accessory box button, and then open the accessory box

lid.

3. Turn the key to “OFF” to preserve the battery.

To close the accessory box 1. Fold the accessory box lid down. 2. Remove the key.

NOTICE

ECA11800

Do not place heat-sensitive items in

the accessory box. The accessory

box gets extremely hot especially

when the engine is running or is hot.

WARNING

EWA11421

●

Do not exceed the load limit of

0.3 kg (0.66 lb) for the accessory

box.

●

Do not exceed the maximum

load of 215 kg (474 lb) for the ve-

hicle.

1. Accessory box lid

2. Accessory box

3. Accessory box button

1

2

3

U1MCE0E0.book Page 36 Thursday, July 19, 2012 6:59 PM

Page 52 of 118

INSTRUMENT AND CONTROL FUNCTIONS

3-37

3

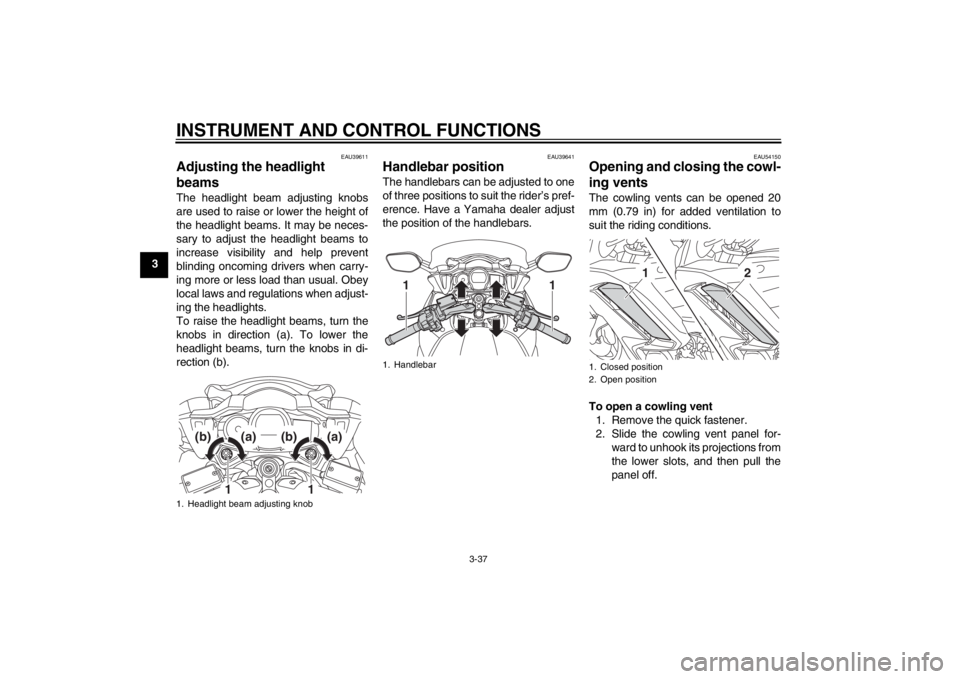

EAU39611

Adjusting the headlight

beams The headlight beam adjusting knobs

are used to raise or lower the height of

the headlight beams. It may be neces-

sary to adjust the headlight beams to

increase visibility and help prevent

blinding oncoming drivers when carry-

ing more or less load than usual. Obey

local laws and regulations when adjust-

ing the headlights.

To raise the headlight beams, turn the

knobs in direction (a). To lower the

headlight beams, turn the knobs in di-

rection (b).

EAU39641

Handlebar position The handlebars can be adjusted to one

of three positions to suit the rider’s pref-

erence. Have a Yamaha dealer adjust

the position of the handlebars.

EAU54150

Opening and closing the cowl-

ing vents The cowling vents can be opened 20

mm (0.79 in) for added ventilation to

suit the riding conditions.

To open a cowling vent1. Remove the quick fastener.

2. Slide the cowling vent panel for- ward to unhook its projections from

the lower slots, and then pull the

panel off.

1. Headlight beam adjusting knob

1

1

(b)

(a)

(b)

(a)

1. Handlebar

11

1. Closed position

2. Open position

1

2

U1MCE0E0.book Page 37 Thursday, July 19, 2012 6:59 PM

Page 53 of 118

INSTRUMENT AND CONTROL FUNCTIONS

3-38

3

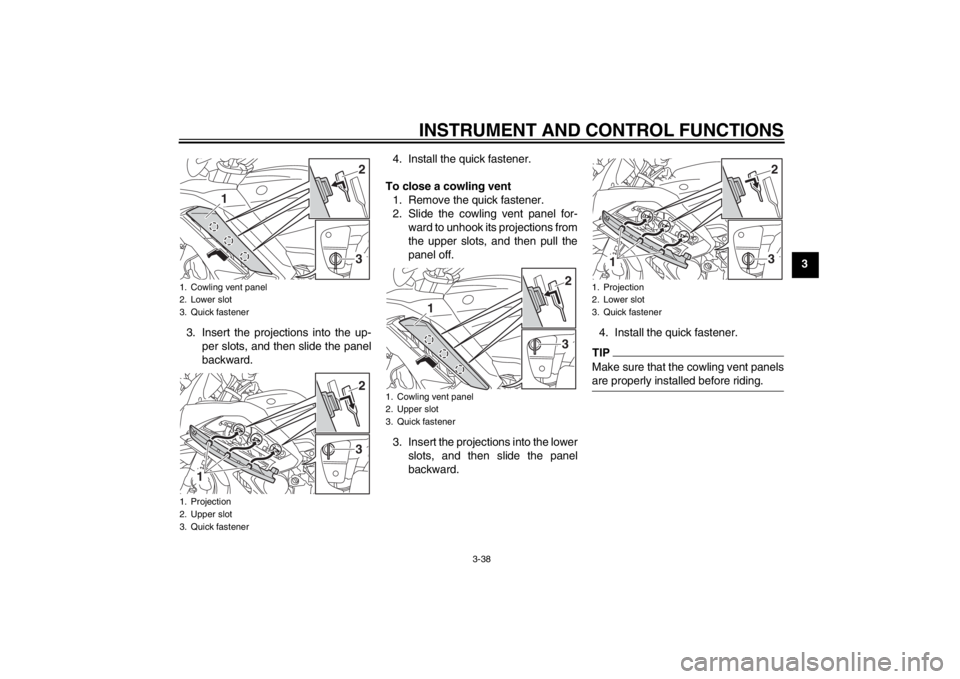

3. Insert the projections into the up- per slots, and then slide the panel

backward. 4. Install the quick fastener.

To close a cowling vent 1. Remove the quick fastener.

2. Slide the cowling vent panel for- ward to unhook its projections from

the upper slots, and then pull the

panel off.

3. Insert the projections into the lower slots, and then slide the panel

backward. 4. Install the quick fastener.

TIPMake sure that the cowling vent panels

are properly installed before riding.

1. Cowling vent panel

2. Lower slot

3. Quick fastener

1. Projection

2. Upper slot

3. Quick fastener

3

1

2

1

32

1. Cowling vent panel

2. Upper slot

3. Quick fastener

3

1

2

1. Projection

2. Lower slot

3. Quick fastener

1

32

U1MCE0E0.book Page 38 Thursday, July 19, 2012 6:59 PM

Page 54 of 118

INSTRUMENT AND CONTROL FUNCTIONS

3-39

3

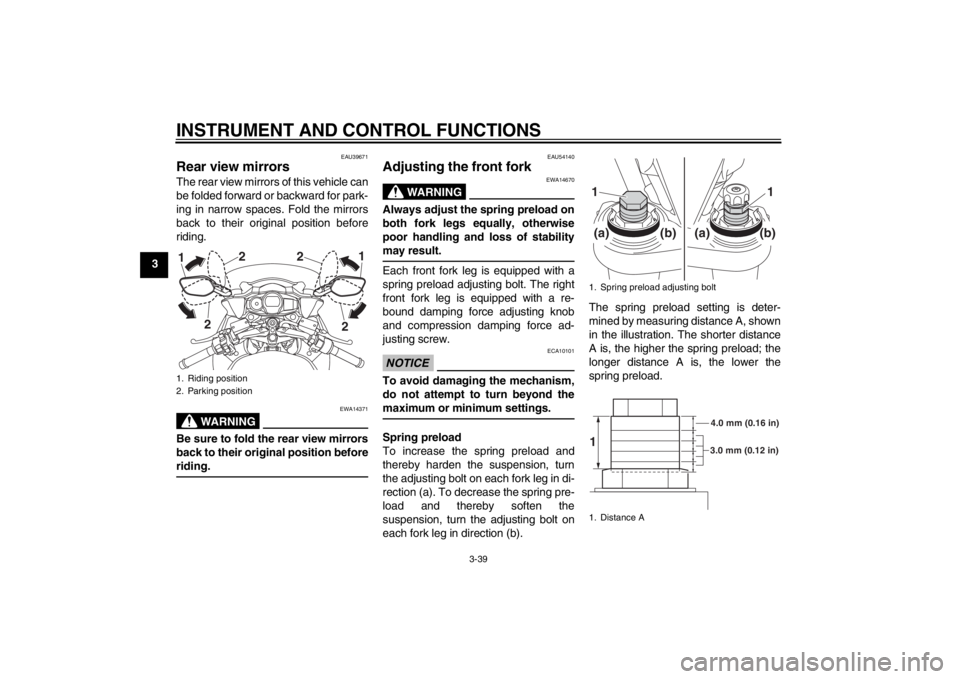

EAU39671

Rear view mirrors The rear view mirrors of this vehicle can

be folded forward or backward for park-

ing in narrow spaces. Fold the mirrors

back to their original position before

riding.

WARNING

EWA14371

Be sure to fold the rear view mirrors

back to their original position before

riding.

EAU54140

Adjusting the front fork

WARNING

EWA14670

Always adjust the spring preload on

both fork legs equally, otherwise

poor handling and loss of stability

may result.Each front fork leg is equipped with a

spring preload adjusting bolt. The right

front fork leg is equipped with a re-

bound damping force adjusting knob

and compression damping force ad-

justing screw.NOTICE

ECA10101

To avoid damaging the mechanism,

do not attempt to turn beyond the

maximum or minimum settings.Spring preload

To increase the spring preload and

thereby harden the suspension, turn

the adjusting bolt on each fork leg in di-

rection (a). To decrease the spring pre-

load and thereby soften the

suspension, turn the adjusting bolt on

each fork leg in direction (b).The spring preload setting is deter-

mined by measuring distance A, shown

in the illustration. The shorter distance

A is, the higher the spring preload; the

longer distance A is, the lower the

spring preload.

1. Riding position

2. Parking position

2

2

1

2 2

1

1. Spring preload adjusting bolt

1. Distance A

(a)

(b)1

1(a)

(b)

4.0 mm (0.16 in)

3.0 mm (0.12 in)

1

U1MCE0E0.book Page 39 Thursday, July 19, 2012 6:59 PM

Page 55 of 118

INSTRUMENT AND CONTROL FUNCTIONS

3-40

3

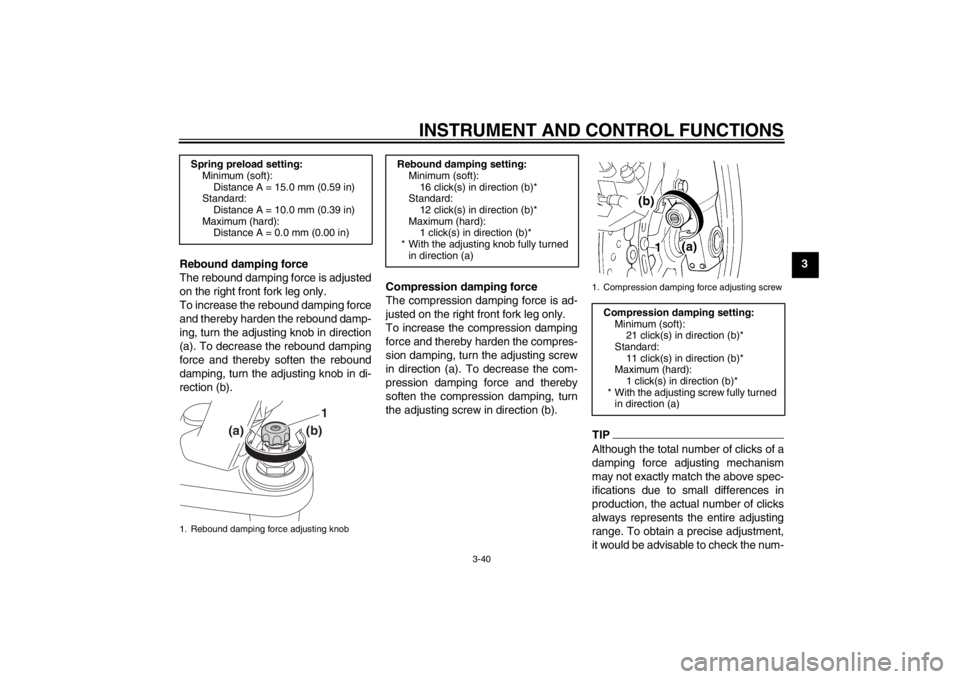

Rebound damping force

The rebound damping force is adjusted

on the right front fork leg only.

To increase the rebound damping force

and thereby harden the rebound damp-

ing, turn the adjusting knob in direction

(a). To decrease the rebound damping

force and thereby soften the rebound

damping, turn the adjusting knob in di-

rection (b). Compression damping force

The compression damping force is ad-

justed on the right front fork leg only.

To increase the compression damping

force and thereby harden the compres-

sion damping, turn the adjusting screw

in direction (a). To decrease the com-

pression damping force and thereby

soften the compression damping, turn

the adjusting screw in direction (b).

TIPAlthough the total number of clicks of a

damping force adjusting mechanism

may not exactly match the above spec-

ifications due to small differences in

production, the actual number of clicks

always represents the entire adjusting

range. To obtain a precise adjustment,

it would be advisable to check the num-

Spring preload setting:

Minimum (soft):

Distance A = 15.0 mm (0.59 in)

Standard:

Distance A = 10.0 mm (0.39 in)

Maximum (hard): Distance A = 0.0 mm (0.00 in)1. Rebound damping force adjusting knob

(a)

(b)

1

Rebound damping setting: Minimum (soft):

16 click(s) in direction (b)*

Standard:

12 click(s) in direction (b)*

Maximum (hard): 1 click(s) in direction (b)*

* With the adjusting knob fully turned in direction (a)

1. Compression damping force adjusting screw

Compression damping setting: Minimum (soft): 21 click(s) in direction (b)*

Standard: 11 click(s) in direction (b)*

Maximum (hard):

1 click(s) in direction (b)*

* With the adjusting screw fully turned in direction (a)

U1MCE0E0.book Page 40 Thursday, July 19, 2012 6:59 PM

Page 56 of 118

INSTRUMENT AND CONTROL FUNCTIONS

3-41

3ber of clicks of each damping force ad-

justing mechanism and to modify the

specifications as necessary.

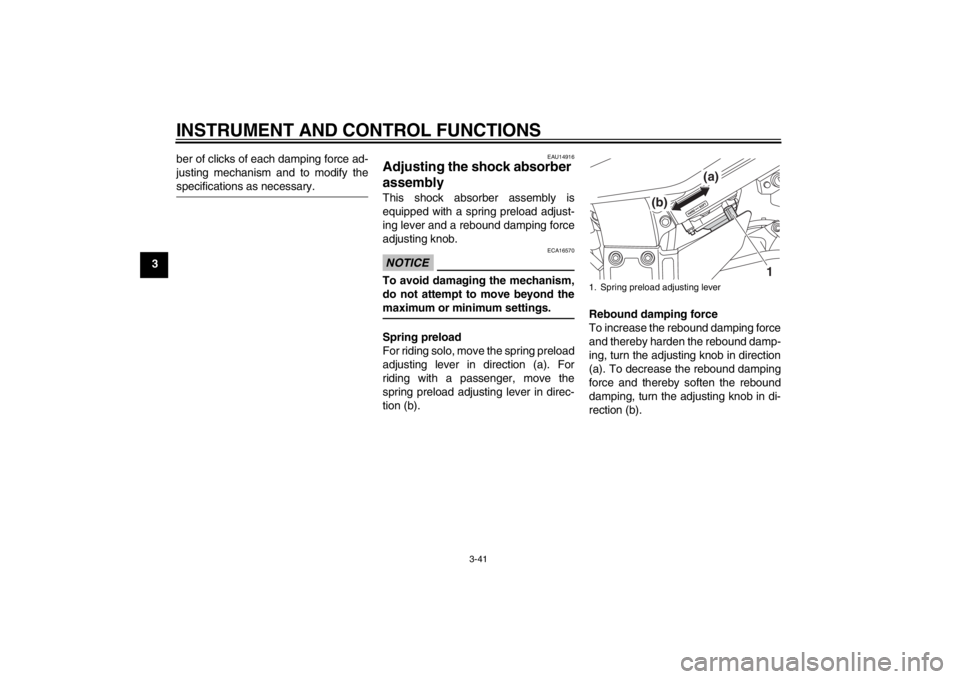

EAU14916

Adjusting the shock absorber

assembly This shock absorber assembly is

equipped with a spring preload adjust-

ing lever and a rebound damping force

adjusting knob.NOTICE

ECA16570

To avoid damaging the mechanism,

do not attempt to move beyond the

maximum or minimum settings.Spring preload

For riding solo, move the spring preload

adjusting lever in direction (a). For

riding with a passenger, move the

spring preload adjusting lever in direc-

tion (b).

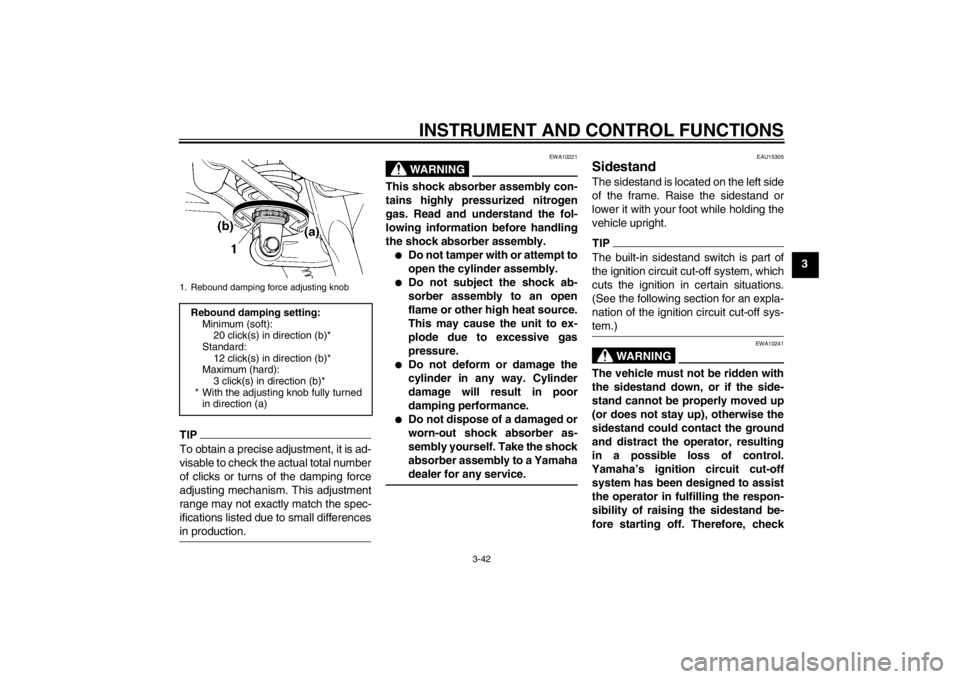

Rebound damping force

To increase the rebound damping force

and thereby harden the rebound damp-

ing, turn the adjusting knob in direction

(a). To decrease the rebound damping

force and thereby soften the rebound

damping, turn the adjusting knob in di-

rection (b).

1. Spring preload adjusting lever

1

(b)

(a)

U1MCE0E0.book Page 41 Thursday, July 19, 2012 6:59 PM

Page 57 of 118

INSTRUMENT AND CONTROL FUNCTIONS

3-42

3

TIPTo obtain a precise adjustment, it is ad-

visable to check the actual total number

of clicks or turns of the damping force

adjusting mechanism. This adjustment

range may not exactly match the spec-

ifications listed due to small differences

in production.

WARNING

EWA10221

This shock absorber assembly con-

tains highly pressurized nitrogen

gas. Read and understand the fol-

lowing information before handling

the shock absorber assembly.●

Do not tamper with or attempt to

open the cylinder assembly.

●

Do not subject the shock ab-

sorber assembly to an open

flame or other high heat source.

This may cause the unit to ex-

plode due to excessive gas

pressure.

●

Do not deform or damage the

cylinder in any way. Cylinder

damage will result in poor

damping performance.

●

Do not dispose of a damaged or

worn-out shock absorber as-

sembly yourself. Take the shock

absorber assembly to a Yamaha

dealer for any service.

EAU15305

Sidestand The sidestand is located on the left side

of the frame. Raise the sidestand or

lower it with your foot while holding the

vehicle upright.TIPThe built-in sidestand switch is part of

the ignition circuit cut-off system, which

cuts the ignition in certain situations.

(See the following section for an expla-

nation of the ignition circuit cut-off sys-

tem.)

WARNING

EWA10241

The vehicle must not be ridden with

the sidestand down, or if the side-

stand cannot be properly moved up

(or does not stay up), otherwise the

sidestand could contact the ground

and distract the operator, resulting

in a possible loss of control.

Yamaha’s ignition circuit cut-off

system has been designed to assist

the operator in fulfilling the respon-

sibility of raising the sidestand be-

fore starting off. Therefore, check

1. Rebound damping force adjusting knobRebound damping setting:Minimum (soft):20 click(s) in direction (b)*

Standard: 12 click(s) in direction (b)*

Maximum (hard):

3 click(s) in direction (b)*

* With the adjusting knob fully turned in direction (a)

U1MCE0E0.book Page 42 Thursday, July 19, 2012 6:59 PM

Page 58 of 118

INSTRUMENT AND CONTROL FUNCTIONS

3-43

3this system regularly and have a

Yamaha dealer repair it if it does not function properly.

EAU54490

Ignition circuit cut-off system The ignition circuit cut-off system (com-

prising the sidestand switch, clutch

switch and neutral switch) has the fol-

lowing functions.●

It prevents starting when the trans-

mission is in gear and the side-

stand is up, but the clutch lever is

not pulled.

●

It prevents starting when the trans-

mission is in gear and the clutch le-

ver is pulled, but the sidestand is

still down.

●

It cuts the running engine when the

transmission is in gear and the

sidestand is moved down.

Periodically check the operation of the

ignition circuit cut-off system according

to the following procedure.

U1MCE0E0.book Page 43 Thursday, July 19, 2012 6:59 PM

Page 59 of 118

INSTRUMENT AND CONTROL FUNCTIONS

3-44

3

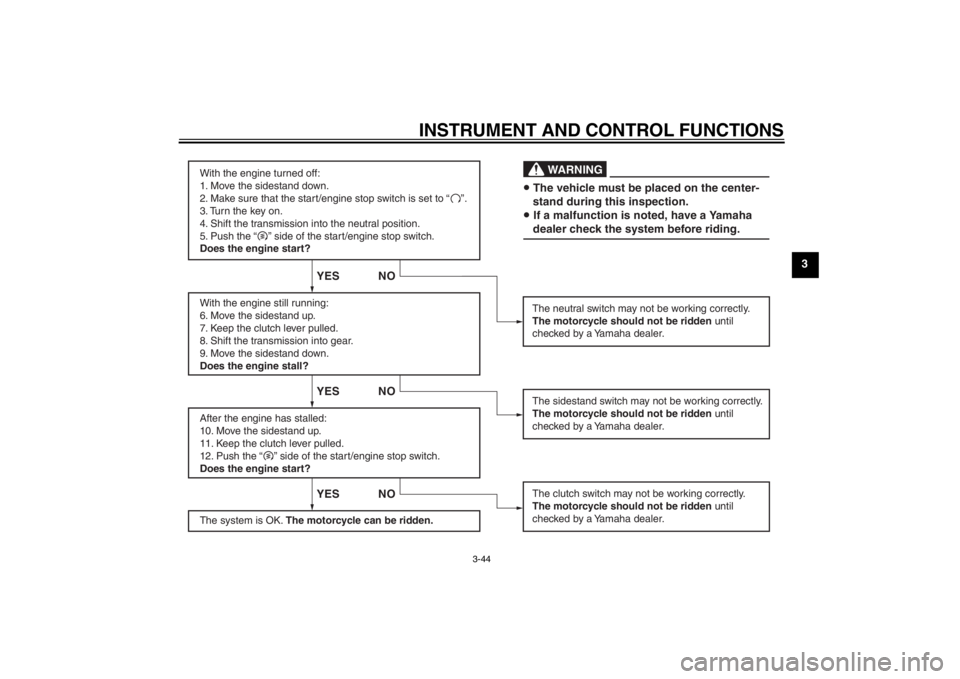

With the engine turned off:

1. Move the sidestand down.

2. Make sure that the start/engine stop switch is set to “ ”.

3. Turn the key on.

4. Shift the transmission into the neutral position.

5. Push the “ ” side of the start/engine stop switch.

Does the engine start?

With the engine still running:

6. Move the sidestand up.

7. Keep the clutch lever pulled.

8. Shift the transmission into gear.

9. Move the sidestand down.

Does the engine stall?

After the engine has stalled:

10. Move the sidestand up.

11. Keep the clutch lever pulled.

12. Push the “ ” side of the start/engine stop switch.

Does the engine start?

The system is OK. The motorcycle can be ridden.

YES NO YES NO YES NO

The neutral switch may not be working correctly.

The motorcycle should not be ridden until

checked by a Yamaha dealer.

The clutch switch may not be working correctly.

The motorcycle should not be ridden until

checked by a Yamaha dealer.The sidestand switch may not be working correctly.

The motorcycle should not be ridden until

checked by a Yamaha dealer. The vehicle must be placed on the center-

stand during this inspection.If a malfunction is noted, have a Yamaha

dealer check the system before riding.

WA R N I N G

U1MCE0E0.book Page 44 Thursday, July 19, 2012 6:59 PM

Page 60 of 118

INSTRUMENT AND CONTROL FUNCTIONS

3-45

3

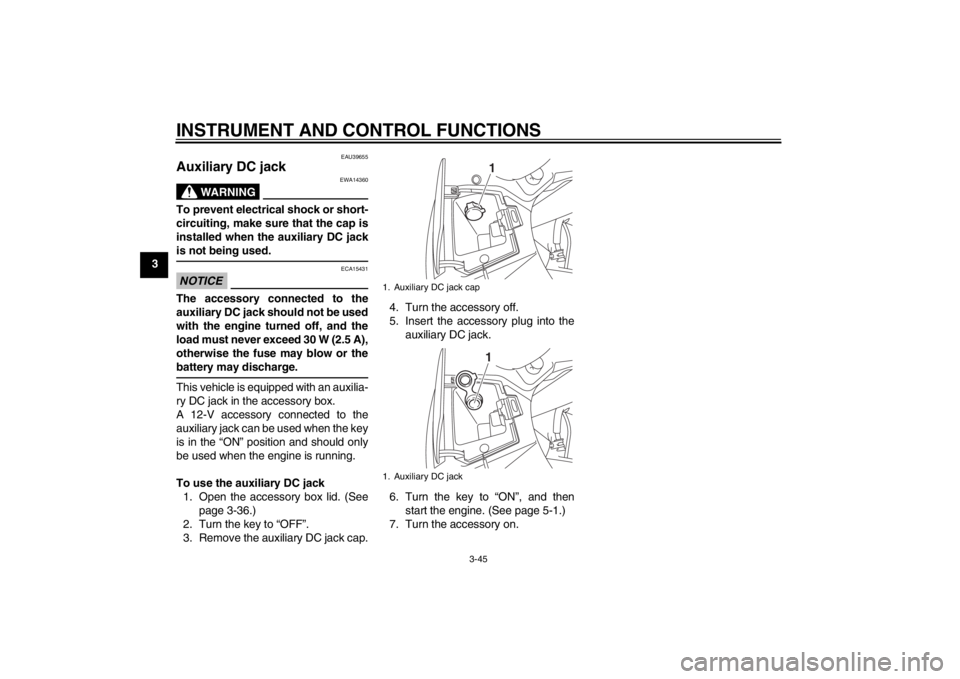

EAU39655

Auxiliary DC jack

WARNING

EWA14360

To prevent electrical shock or short-

circuiting, make sure that the cap is

installed when the auxiliary DC jack

is not being used.NOTICE

ECA15431

The accessory connected to the

auxiliary DC jack should not be used

with the engine turned off, and the

load must never exceed 30 W (2.5 A),

otherwise the fuse may blow or the

battery may discharge.This vehicle is equipped with an auxilia-

ry DC jack in the accessory box.

A 12-V accessory connected to the

auxiliary jack can be used when the key

is in the “ON” position and should only

be used when the engine is running.

To use the auxiliary DC jack1. Open the accessory box lid. (See page 3-36.)

2. Turn the key to “OFF”.

3. Remove the auxiliary DC jack cap. 4. Turn the accessory off.

5. Insert the accessory plug into the

auxiliary DC jack.

6. Turn the key to “ON”, and then start the engine. (See page 5-1.)

7. Turn the accessory on.

1. Auxiliary DC jack cap

1. Auxiliary DC jack

11

U1MCE0E0.book Page 45 Thursday, July 19, 2012 6:59 PM