lock YAMAHA SR400 2016 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: SR400, Model: YAMAHA SR400 2016Pages: 96, PDF Size: 2.52 MB

Page 62 of 96

Periodic maintenance and adjustment

6-24

1

2

3

4

5

6

7

8

9

10

11

12

13

14 when refilling. Water will signifi-

cantly lower the boiling point of

the fluid and may result in vapor

lock.

NOTICE

ECA17641

Brake fluid may damage painted sur-

faces or plastic parts. Always clean

up spilled fluid immediately.

As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake sys-

tem leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. If the brake

fluid level goes down suddenly, have a

Yamaha dealer check the cause before

further riding.

EAU22724

Changing the brake fluid

Have a Yamaha dealer change the

brake fluid at the intervals specified in

the periodic maintenance and lubrica-

tion chart. In addition, have the oil seals

of the brake master cylinder and caliper

as well as the brake hose replaced at

the intervals listed below or whenever

they are damaged or leaking.

Oil seals: Replace every two

years.

Brake hose: Replace every four

years.

2RD-28199-E1.book 24 ページ 2015年9月3日 木曜日 午後3時42分

Page 63 of 96

Periodic maintenance and adjustment

6-25

1

2

3

4

5

6

7

8

9

10

11

12

13

14

EAU22762

Drive chain slack

The drive chain slack should be

checked before each ride and adjusted

if necessary.

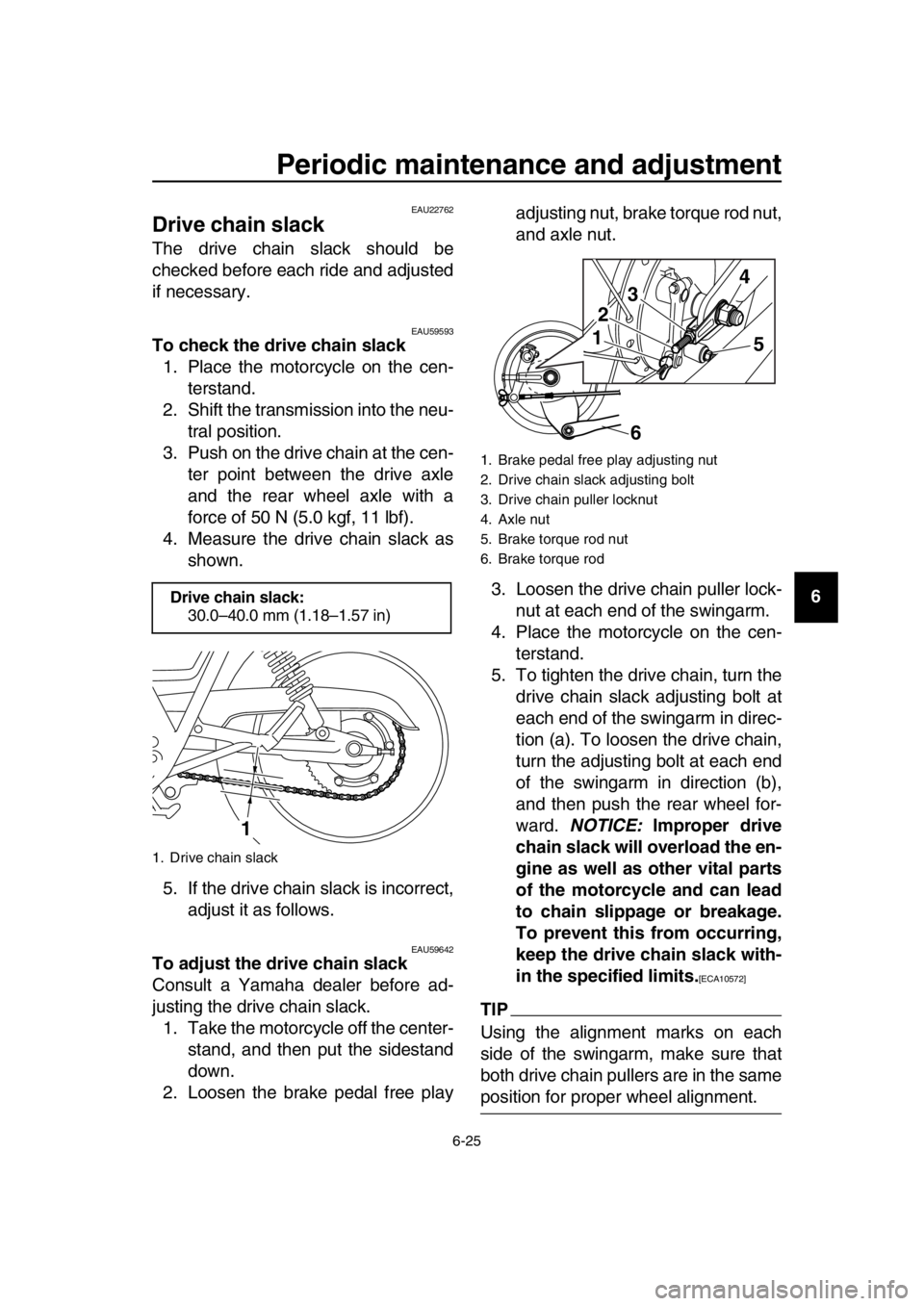

EAU59593To check the drive chain slack 1. Place the motorcycle on the cen- terstand.

2. Shift the transmission into the neu- tral position.

3. Push on the drive chain at the cen- ter point between the drive axle

and the rear wheel axle with a

force of 50 N (5.0 kgf, 11 lbf).

4. Measure the drive chain slack as shown.

5. If the drive chain slack is incorrect, adjust it as follows.

EAU59642To adjust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack.1. Take the motorcycle off the center- stand, and then put the sidestand

down.

2. Loosen the brake pedal free play adjusting nut, brake torque rod nut,

and axle nut.

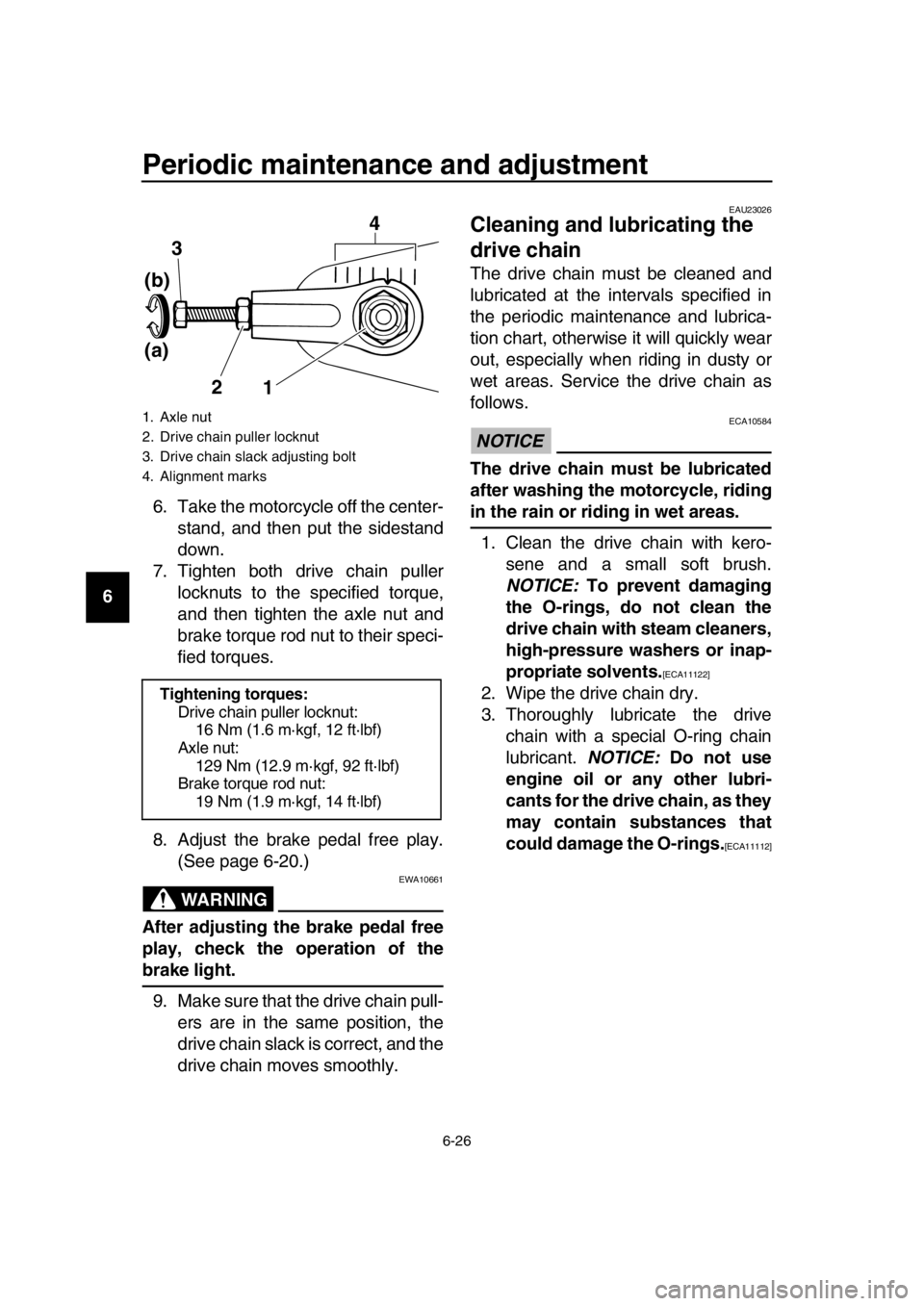

3. Loosen the drive chain puller lock- nut at each end of the swingarm.

4. Place the motorcycle on the cen- terstand.

5. To tighten the drive chain, turn the drive chain slack adjusting bolt at

each end of the swingarm in direc-

tion (a). To loosen the drive chain,

turn the adjusting bolt at each end

of the swingarm in direction (b),

and then push the rear wheel for-

ward. NOTICE: Improper drive

chain slack will overload the en-

gine as well as other vital parts

of the motorcycle and can lead

to chain slippage or breakage.

To prevent this from occurring,

keep the drive chain slack with-

in the specified limits.[ECA10572]

TIP

Using the alignment marks on each

side of the swingarm, make sure that

both drive chain pullers are in the same

position for proper wheel alignment.

Drive chain slack: 30.0–40.0 mm (1.18–1.57 in)

1. Drive chain slack

1

1. Brake pedal free play adjusting nut

2. Drive chain slack adjusting bolt

3. Drive chain puller locknut

4. Axle nut

5. Brake torque rod nut

6. Brake torque rod

6

12

3

4

5

2RD-28199-E1.book 25 ページ 2015年9月3日 木曜日 午後3時42分

Page 64 of 96

Periodic maintenance and adjustment

6-26

1

2

3

4

5

6

7

8

9

10

11

12

13

14 6. Take the motorcycle off the center-

stand, and then put the sidestand

down.

7. Tighten both drive chain puller locknuts to the specified torque,

and then tighten the axle nut and

brake torque rod nut to their speci-

fied torques.

8. Adjust the brake pedal free play. (See page 6-20.)

WARNING

EWA10661

After adjusting the brake pedal free

play, check the operation of the

brake light.

9. Make sure that the drive chain pull- ers are in the same position, the

drive chain slack is correct, and the

drive chain moves smoothly.

EAU23026

Cleaning and lubricating the

drive chain

The drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.

NOTICE

ECA10584

The drive chain must be lubricated

after washing the motorcycle, riding

in the rain or riding in wet areas.

1. Clean the drive chain with kero- sene and a small soft brush.

NOTICE: To prevent damaging

the O-rings, do not clean the

drive chain with steam cleaners,

high-pressure washers or inap-

propriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

engine oil or any other lubri-

cants for the drive chain, as they

may contain substances that

could damage the O-rings.

[ECA11112]

1. Axle nut

2. Drive chain puller locknut

3. Drive chain slack adjusting bolt

4. Alignment marks

Tightening torques: Drive chain puller locknut:16 Nm (1.6 m·kgf, 12 ft·lbf)

Axle nut: 129 Nm (12.9 m·kgf, 92 ft·lbf)

Brake torque rod nut:

19 Nm (1.9 m·kgf, 14 ft·lbf)

1

2

(a) (b)

3

4

2RD-28199-E1.book 26 ページ 2015年9月3日 木曜日 午後3時42分

Page 74 of 96

Periodic maintenance and adjustment

6-36

1

2

3

4

5

6

7

8

9

10

11

12

13

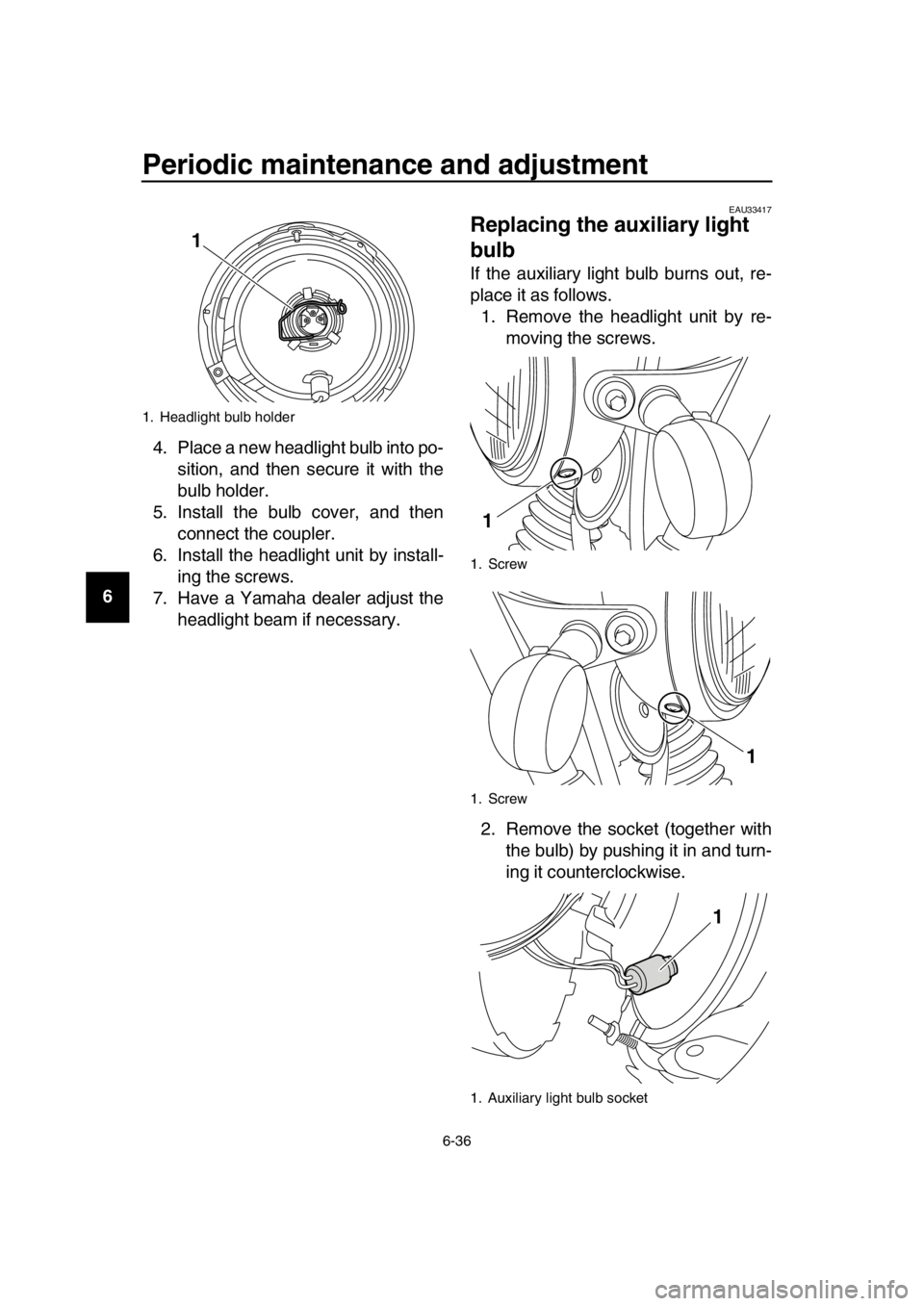

14 4. Place a new headlight bulb into po-

sition, and then secure it with the

bulb holder.

5. Install the bulb cover, and then connect the coupler.

6. Install the headlight unit by install- ing the screws.

7. Have a Yamaha dealer adjust the headlight beam if necessary.

EAU33417

Replacing the auxiliary light

bulb

If the auxiliary light bulb burns out, re-

place it as follows.1. Remove the headlight unit by re- moving the screws.

2. Remove the socket (together with the bulb) by pushing it in and turn-

ing it counterclockwise.

1. Headlight bulb holder

1

1. Screw

1. Screw

1. Auxiliary light bulb socket

1

1

1

2RD-28199-E1.book 36 ページ 2015年9月3日 木曜日 午後3時42分

Page 75 of 96

Periodic maintenance and adjustment

6-37

1

2

3

4

5

6

7

8

9

10

11

12

13

14

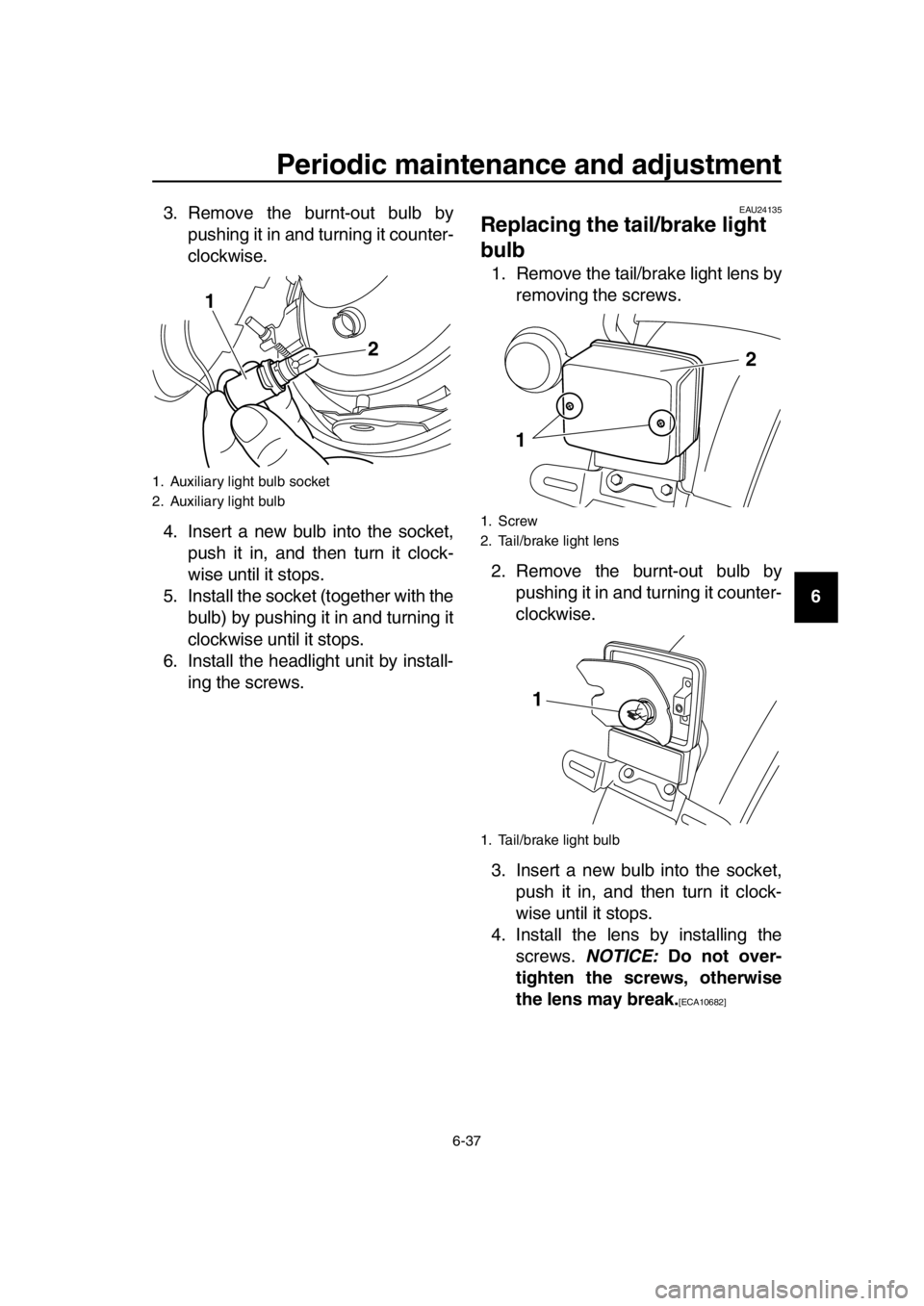

3. Remove the burnt-out bulb by

pushing it in and turning it counter-

clockwise.

4. Insert a new bulb into the socket, push it in, and then turn it clock-

wise until it stops.

5. Install the socket (together with the bulb) by pushing it in and turning it

clockwise until it stops.

6. Install the headlight unit by install- ing the screws.

EAU24135

Replacing the tail/brake light

bulb

1. Remove the tail/brake light lens byremoving the screws.

2. Remove the burnt-out bulb by pushing it in and turning it counter-

clockwise.

3. Insert a new bulb into the socket, push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the screws. NOTICE: Do not over-

tighten the screws, otherwise

the lens may break.

[ECA10682]

1. Auxiliary light bulb socket

2. Auxiliary light bulb

1

2

1. Screw

2. Tail/brake light lens

1. Tail/brake light bulb

1 2

1

2RD-28199-E1.book 37 ページ 2015年9月3日 木曜日 午後3時42分

Page 76 of 96

Periodic maintenance and adjustment

6-38

1

2

3

4

5

6

7

8

9

10

11

12

13

14

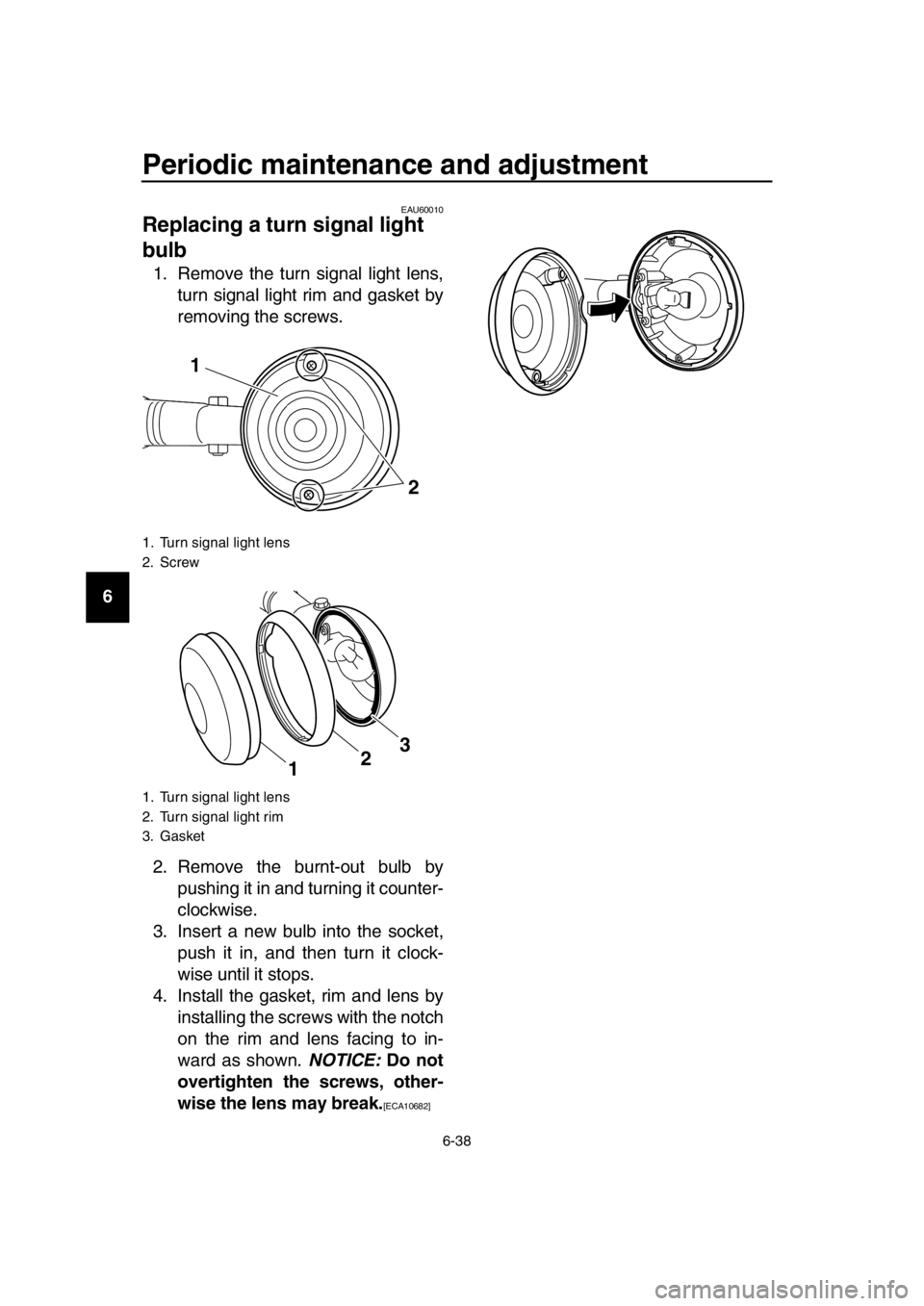

EAU60010

Replacing a turn signal light

bulb

1. Remove the turn signal light lens, turn signal light rim and gasket by

removing the screws.

2. Remove the burnt-out bulb by pushing it in and turning it counter-

clockwise.

3. Insert a new bulb into the socket, push it in, and then turn it clock-

wise until it stops.

4. Install the gasket, rim and lens by installing the screws with the notch

on the rim and lens facing to in-

ward as shown. NOTICE: Do not

overtighten the screws, other-

wise the lens may break.

[ECA10682]

1. Turn signal light lens

2. Screw

1. Turn signal light lens

2. Turn signal light rim

3. Gasket

1

2

3

2

1

2RD-28199-E1.book 38 ページ 2015年9月3日 木曜日 午後3時42分

Page 78 of 96

Periodic maintenance and adjustment

6-40

1

2

3

4

5

6

7

8

9

10

11

12

13

14

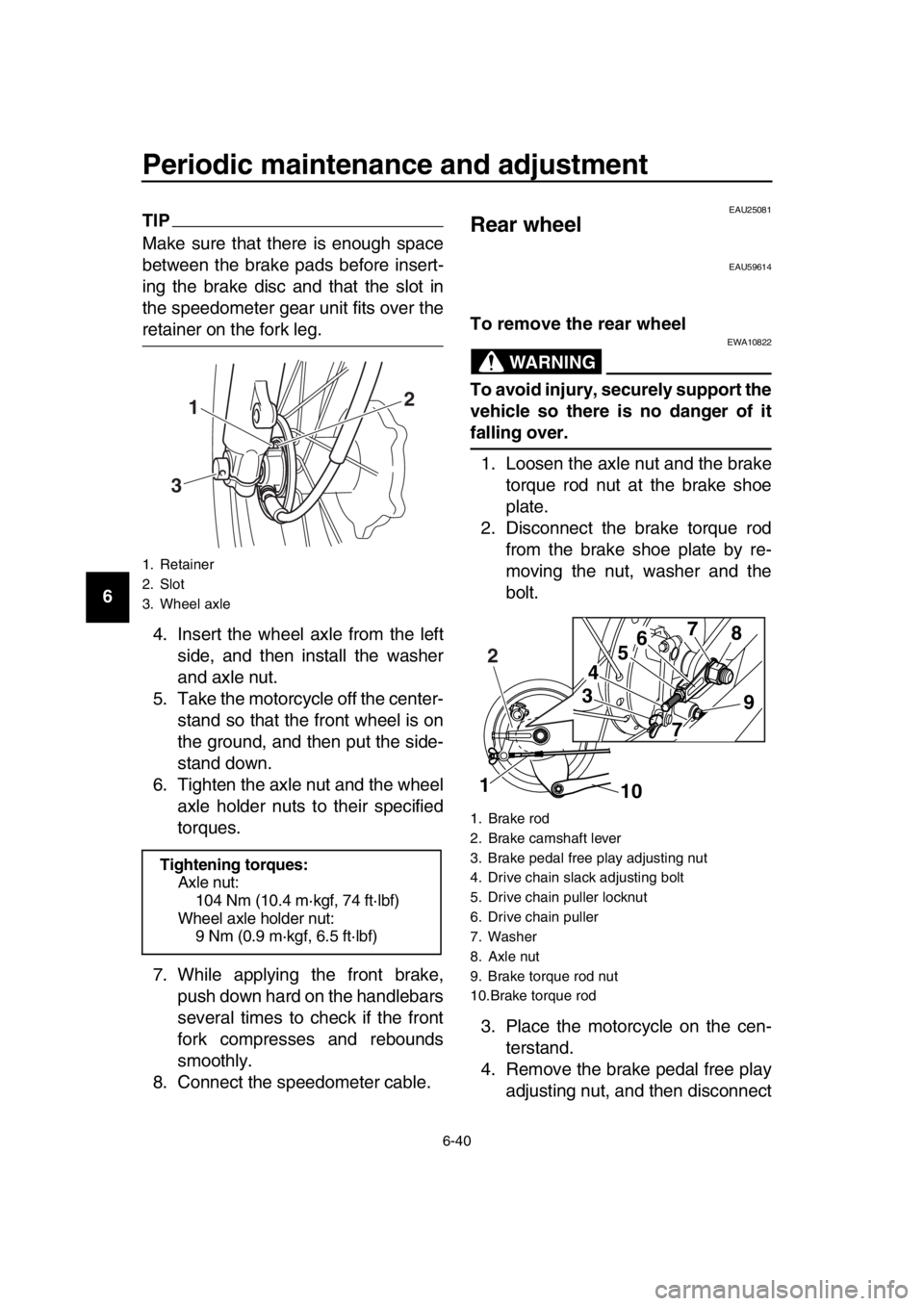

TIP

Make sure that there is enough space

between the brake pads before insert-

ing the brake disc and that the slot in

the speedometer gear unit fits over the

retainer on the fork leg.

4. Insert the wheel axle from the left side, and then install the washer

and axle nut.

5. Take the motorcycle off the center- stand so that the front wheel is on

the ground, and then put the side-

stand down.

6. Tighten the axle nut and the wheel axle holder nuts to their specified

torques.

7. While applying the front brake, push down hard on the handlebars

several times to check if the front

fork compresses and rebounds

smoothly.

8. Connect the speedometer cable.

EAU25081

Rear wheel

EAU59614

To remove the rear wheel

WARNING

EWA10822

To avoid injury, securely support the

vehicle so there is no danger of it

falling over.

1. Loosen the axle nut and the brake torque rod nut at the brake shoe

plate.

2. Disconnect the brake torque rod from the brake shoe plate by re-

moving the nut, washer and the

bolt.

3. Place the motorcycle on the cen- terstand.

4. Remove the brake pedal free play adjusting nut, and then disconnect

1. Retainer

2. Slot

3. Wheel axle

Tightening torques:Axle nut:

104 Nm (10.4 m·kgf, 74 ft·lbf)

Wheel axle holder nut: 9 Nm (0.9 m·kgf, 6.5 ft·lbf)

1

3 2

1. Brake rod

2. Brake camshaft lever

3. Brake pedal free play adjusting nut

4. Drive chain slack adjusting bolt

5. Drive chain puller locknut

6. Drive chain puller

7. Washer

8. Axle nut

9. Brake torque rod nut

10.Brake torque rod

1

10

34

5

6

7

8

9

7

2

2RD-28199-E1.book 40 ページ 2015年9月3日 木曜日 午後3時42分

Page 79 of 96

Periodic maintenance and adjustment

6-41

1

2

3

4

5

6

7

8

9

10

11

12

13

14

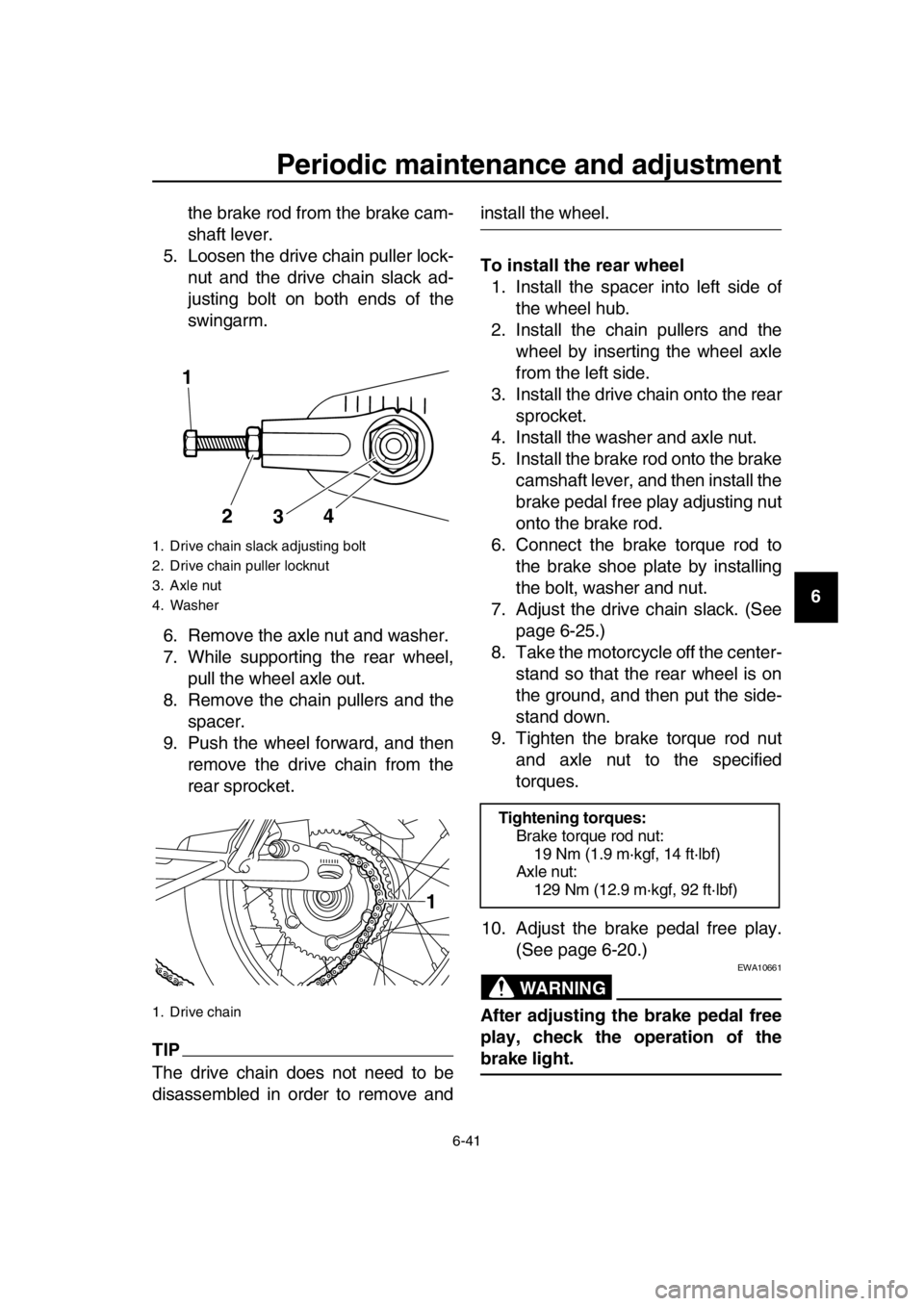

the brake rod from the brake cam-

shaft lever.

5. Loosen the drive chain puller lock- nut and the drive chain slack ad-

justing bolt on both ends of the

swingarm.

6. Remove the axle nut and washer.

7. While supporting the rear wheel, pull the wheel axle out.

8. Remove the chain pullers and the spacer.

9. Push the wheel forward, and then remove the drive chain from the

rear sprocket.

TIP

The drive chain does not need to be

disassembled in order to remove and

install the wheel.

To install the rear wheel1. Install the spacer into left side of the wheel hub.

2. Install the chain pullers and the wheel by inserting the wheel axle

from the left side.

3. Install the drive chain onto the rear sprocket.

4. Install the washer and axle nut.

5. Install the brake rod onto the brake camshaft lever, and then install the

brake pedal free play adjusting nut

onto the brake rod.

6. Connect the brake torque rod to the brake shoe plate by installing

the bolt, washer and nut.

7. Adjust the drive chain slack. (See page 6-25.)

8. Take the motorcycle off the center- stand so that the rear wheel is on

the ground, and then put the side-

stand down.

9. Tighten the brake torque rod nut and axle nut to the specified

torques.

10. Adjust the brake pedal free play. (See page 6-20.)

WARNING

EWA10661

After adjusting the brake pedal free

play, check the operation of the

brake light.

1. Drive chain slack adjusting bolt

2. Drive chain puller locknut

3. Axle nut

4. Washer

1. Drive chain

3

2

14

1

Tightening torques:

Brake torque rod nut: 19 Nm (1.9 m·kgf, 14 ft·lbf)

Axle nut: 129 Nm (12.9 m·kgf, 92 ft·lbf)

2RD-28199-E1.book 41 ページ 2015年9月3日 木曜日 午後3時42分

Page 92 of 96

10-1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Index

A

Air filter element, replacing ................... 6-13

Auxiliary light bulb, replacing ................ 6-36

B

Battery................................................... 6-31

Brake and clutch levers, checking and lubricating ........................................... 6-28

Brake fluid, changing ............................ 6-24

Brake fluid level, checking .................... 6-23

Brake lever .............................................. 3-7

Brake lever free play, adjusting............. 6-19

Brake light switches .............................. 6-22

Brake pads and shoes, checking .......... 6-22

Brake pedal ............................................. 3-7

Brake pedal, checking and

lubricating ........................................... 6-28

Brake pedal height and free play,

adjusting ............................................. 6-20

C

Cables, checking and lubricating .......... 6-27

Care ........................................................ 7-1

Catalytic converter ................................ 3-11

Centerstand and sidestand, checking and lubricating .................................... 6-29

Clutch lever ............................................. 3-6

Clutch lever free play, adjusting ............ 6-18

D

Decompression lever ............................ 3-12

Dimmer switch ........................................ 3-5

Drive chain, cleaning and lubricating .... 6-26

Drive chain slack ................................... 6-25

E

Engine break-in ....................................... 5-5

Engine idling speed, checking .............. 6-14

Engine oil and oil filter element ............... 6-9

Engine serial number .............................. 9-1

Engine stop switch .................................. 3-5

Engine trouble warning light.................... 3-3

F

Front fork, checking .............................. 6-30

Fuel ......................................................... 3-9

Fuel cock............................................... 3-11

Fuel consumption, tips for reducing ........ 5-5

Fuel level warning light ........................... 3-2

Fuel tank breather/overflow hose.......... 3-10

Fuel tank cap .......................................... 3-8

Fuses, replacing.................................... 6-33

H

Handlebar switches................................. 3-4

Hazard switch ......................................... 3-5 Headlight bulb, replacing ...................... 6-35

High beam indicator light ........................ 3-2

Horn switch ............................................. 3-5

I

Identification numbers ............................ 9-1

Ignition circuit cut-off system ................ 3-15

Indicator lights and warning lights .......... 3-2

K

Kickstarter ............................................ 3-12

M

Main switch/steering lock ....................... 3-1

Maintenance and lubrication, periodic .... 6-4

Maintenance, emission control system... 6-3

Matte color, caution ................................ 7-1

Model label ............................................. 9-2

N

Neutral indicator light .............................. 3-2

P

Panel, removing and installing ............... 6-7

Parking ................................................... 5-6

Part locations .......................................... 2-1

Pass switch ............................................ 3-5

S

Safety information .................................. 1-1

Seat ...................................................... 3-13

Shifting ................................................... 5-3

Shift pedal .............................................. 3-6

Shift pedal, chec

king ............................ 6-21

Shock absorber assemblies, adjusting ............................................. 3-13

Sidestand ............................................. 3-14

Spark plug, checking .............................. 6-8

Specifications ......................................... 8-1

Speedometer unit ................................... 3-3

Starting the engine ................................. 5-2

Starting the engine, trouble .................... 5-3

Steering, checking ................................ 6-30

Storage ................................................... 7-4

Swingarm pivots, lubricating ................. 6-29

T

Tachometer ............................................ 3-4

Tail/brake light bulb, replacing .............. 6-37

Throttle grip and cable, checking and

lubricating ........................................... 6-27

Throttle grip free play, checking ........... 6-14

Tires ..................................................... 6-15

Tool kit .................................................... 6-2

Troubleshooting .................................... 6-42

Troubleshooting chart ........................... 6-43

Turn signal indicator light ....................... 3-2

2RD-28199-E1.book 1 ページ 2015年9月3日 木曜日 午後3時42分