YAMAHA TDM 900 2003 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2003, Model line: TDM 900, Model: YAMAHA TDM 900 2003Pages: 110, PDF Size: 7.38 MB

Page 51 of 110

6-5

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU01139

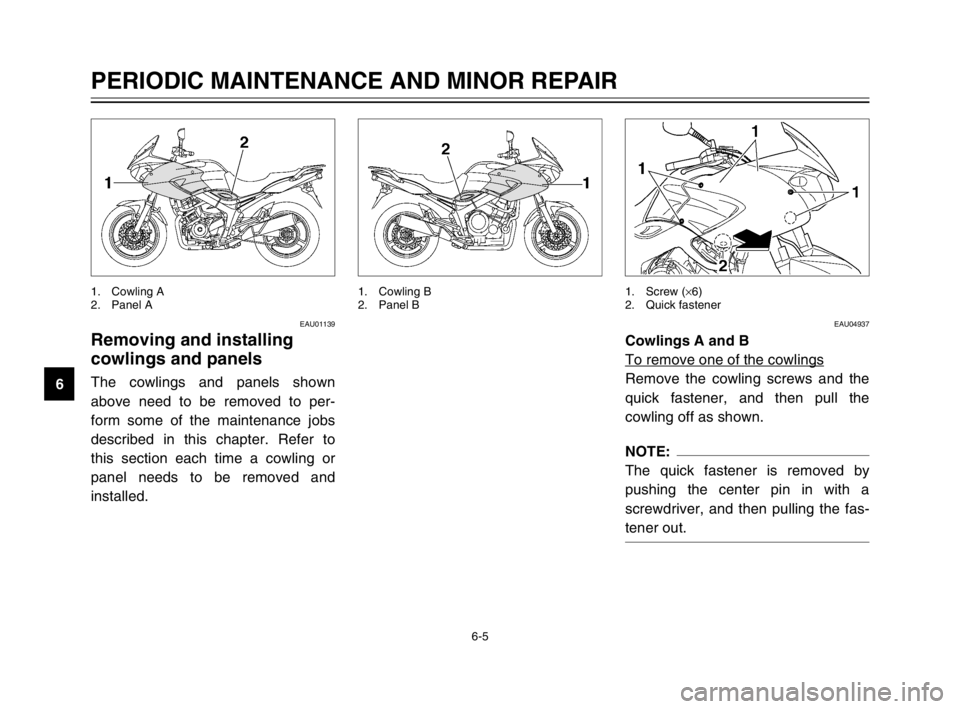

Removing and installing

cowlings and panels

Cowlings and panels, removing and installingThe cowlings and panels shown

above need to be removed to per-

form some of the maintenance jobs

described in this chapter. Refer to

this section each time a cowling or

panel needs to be removed and

installed.

1. Cowling A

2. Panel A

EAU04937

Cowlings A and B

To remove one of the cowlings

Remove the cowling screws and the

quick fastener, and then pull the

cowling off as shown.

NOTE:

The quick fastener is removed by

pushing the center pin in with a

screwdriver, and then pulling the fas-

tener out.

1. Screw (×6)

2. Quick fastener1. Cowling B

2. Panel B

5PS-28199-E1 8/29/02 9:16 AM Page 50

Page 52 of 110

6-6

PERIODIC MAINTENANCE AND MINOR REPAIR

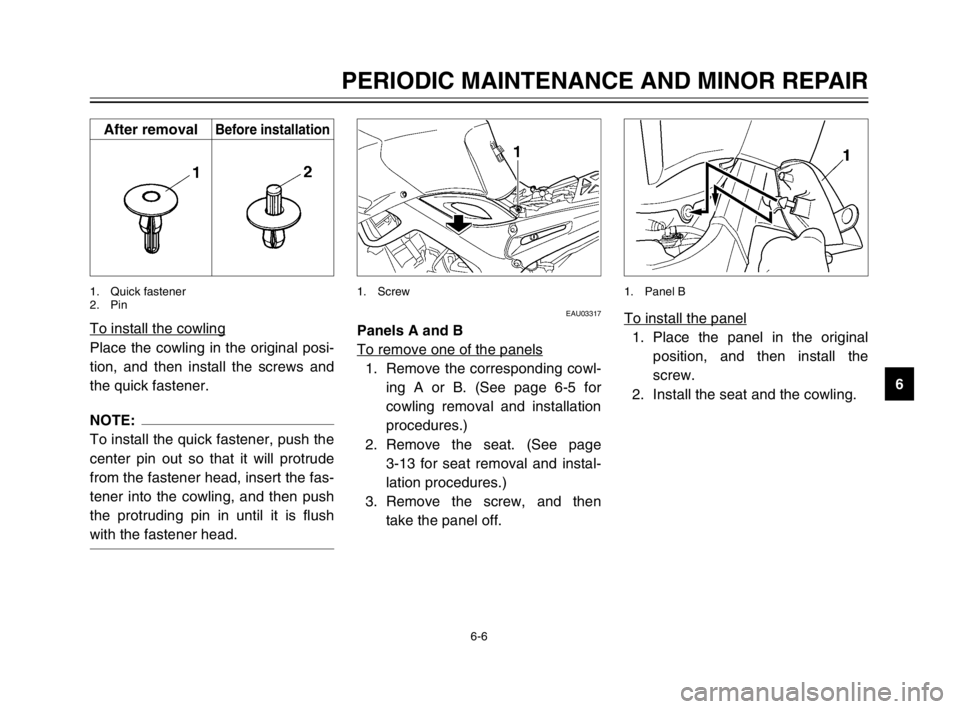

6 To install the cowling

Place the cowling in the original posi-

tion, and then install the screws and

the quick fastener.

NOTE:

To install the quick fastener, push the

center pin out so that it will protrude

from the fastener head, insert the fas-

tener into the cowling, and then push

the protruding pin in until it is flush

with the fastener head.

1. Quick fastener

2. Pin

To install the panel

1. Place the panel in the original

position, and then install the

screw.

2. Install the seat and the cowling.

1. Panel B

EAU03317

Panels A and B

To remove one of the panels

1. Remove the corresponding cowl-

ing A or B. (See page 6-5 for

cowling removal and installation

procedures.)

2. Remove the seat. (See page

3-13 for seat removal and instal-

lation procedures.)

3. Remove the screw, and then

take the panel off.

1. Screw

After removalBefore installation

5PS-28199-E1 8/29/02 9:16 AM Page 51

Page 53 of 110

6-7

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU01880

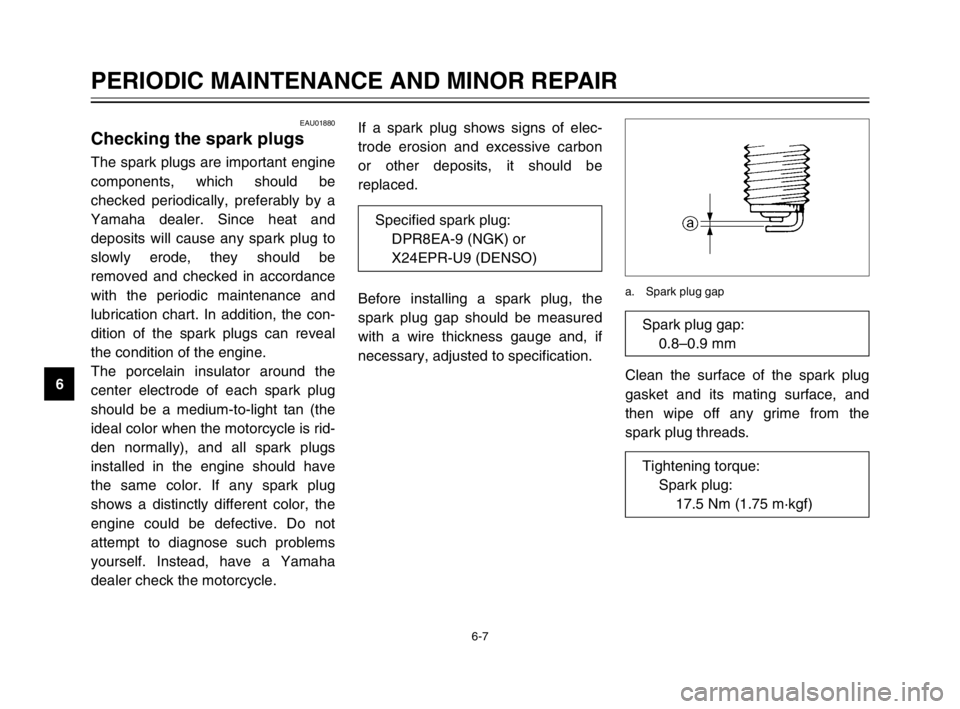

Checking the spark plugsSpark plugs, checkingThe spark plugs are important engine

components, which should be

checked periodically, preferably by a

Yamaha dealer. Since heat and

deposits will cause any spark plug to

slowly erode, they should be

removed and checked in accordance

with the periodic maintenance and

lubrication chart. In addition, the con-

dition of the spark plugs can reveal

the condition of the engine.

The porcelain insulator around the

center electrode of each spark plug

should be a medium-to-light tan (the

ideal color when the motorcycle is rid-

den normally), and all spark plugs

installed in the engine should have

the same color. If any spark plug

shows a distinctly different color, the

engine could be defective. Do not

attempt to diagnose such problems

yourself. Instead, have a Yamaha

dealer check the motorcycle.Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the

spark plug threads.

a. Spark plug gap

If a spark plug shows signs of elec-

trode erosion and excessive carbon

or other deposits, it should be

replaced.

Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification.

Tightening torque:

Spark plug:

17.5 Nm (1.75 m·kgf)

Specified spark plug:

DPR8EA-9 (NGK) or

X24EPR-U9 (DENSO)

Spark plug gap:

0.8–0.9 mm

5PS-28199-E1 8/29/02 9:16 AM Page 52

Page 54 of 110

6-8

PERIODIC MAINTENANCE AND MINOR REPAIR

6

NOTE:

If a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is

1/4–1/2 turn past finger tight.

However, the spark plug should be

tightened to the specified torque as

soon as possible.

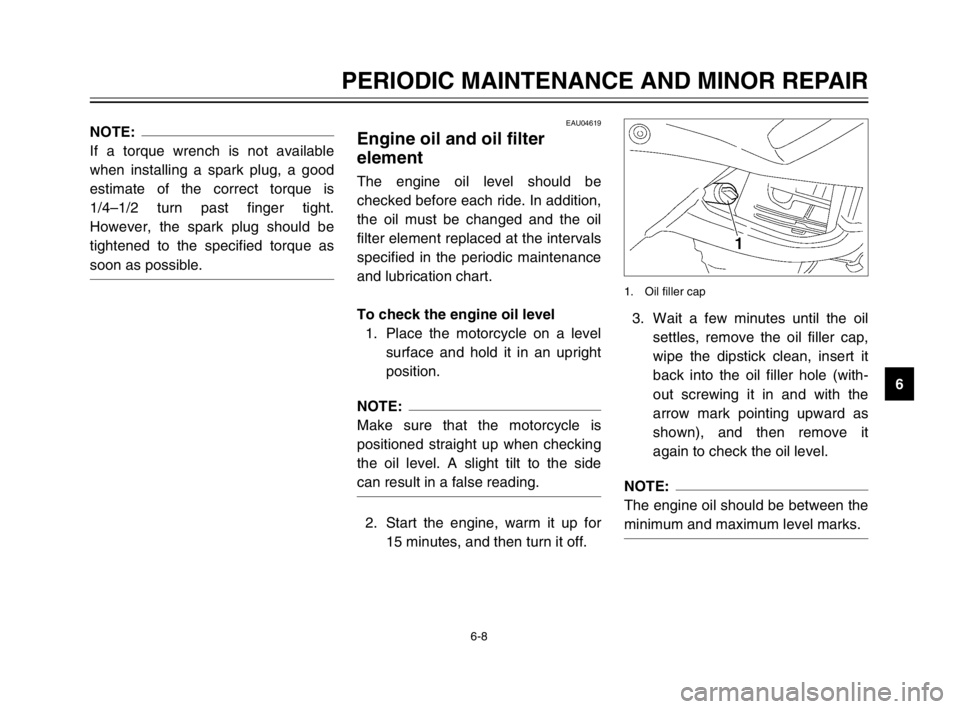

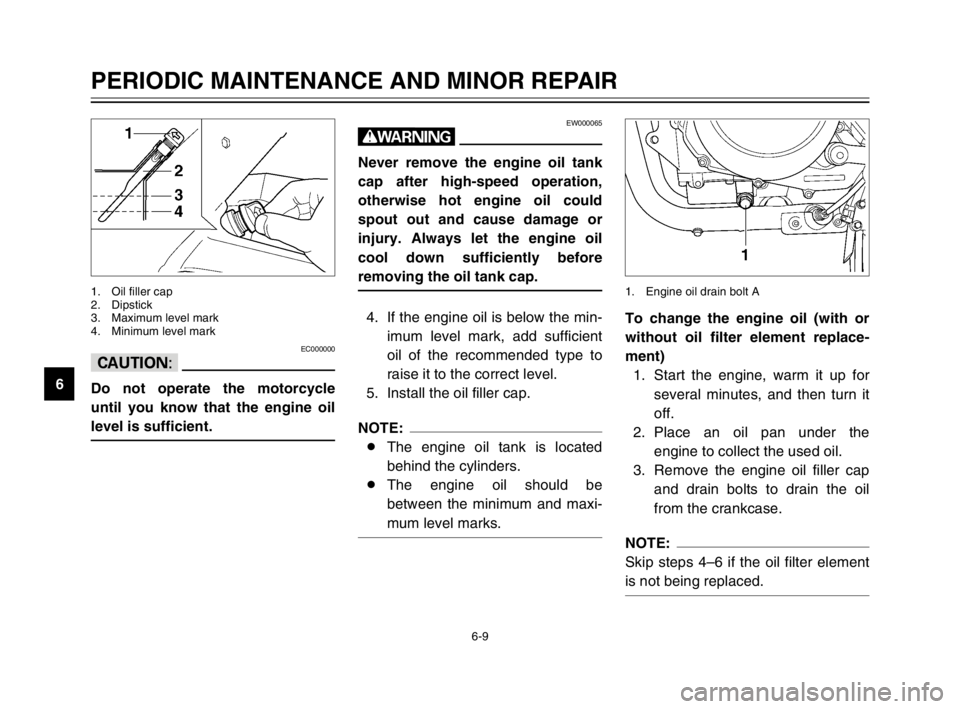

3. Wait a few minutes until the oil

settles, remove the oil filler cap,

wipe the dipstick clean, insert it

back into the oil filler hole (with-

out screwing it in and with the

arrow mark pointing upward as

shown), and then remove it

again to check the oil level.

NOTE:

The engine oil should be between the

minimum and maximum level marks.

1. Oil filler cap

EAU04619

Engine oil and oil filter

element

Engine oil and oil filter elementThe engine oil level should be

checked before each ride. In addition,

the oil must be changed and the oil

filter element replaced at the intervals

specified in the periodic maintenance

and lubrication chart.

To check the engine oil level

1. Place the motorcycle on a level

surface and hold it in an upright

position.

NOTE:

Make sure that the motorcycle is

positioned straight up when checking

the oil level. A slight tilt to the side

can result in a false reading.

2. Start the engine, warm it up for

15 minutes, and then turn it off.

5PS-28199-E1 8/29/02 9:16 AM Page 53

Page 55 of 110

6-9

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EC000000

cC

Do not operate the motorcycle

until you know that the engine oil

level is sufficient.

1. Oil filler cap

2. Dipstick

3. Maximum level mark

4. Minimum level mark

To change the engine oil (with or

without oil filter element replace-

ment)

1. Start the engine, warm it up for

several minutes, and then turn it

off.

2. Place an oil pan under the

engine to collect the used oil.

3. Remove the engine oil filler cap

and drain bolts to drain the oil

from the crankcase.

NOTE:

Skip steps 4–6 if the oil filter element

is not being replaced.

1. Engine oil drain bolt A

EW000065

w

Never remove the engine oil tank

cap after high-speed operation,

otherwise hot engine oil could

spout out and cause damage or

injury. Always let the engine oil

cool down sufficiently before

removing the oil tank cap.

4. If the engine oil is below the min-

imum level mark, add sufficient

oil of the recommended type to

raise it to the correct level.

5. Install the oil filler cap.

NOTE:

8The engine oil tank is located

behind the cylinders.

8The engine oil should be

between the minimum and maxi-

mum level marks.

5PS-28199-E1 8/29/02 9:16 AM Page 54

Page 56 of 110

6-10

PERIODIC MAINTENANCE AND MINOR REPAIR

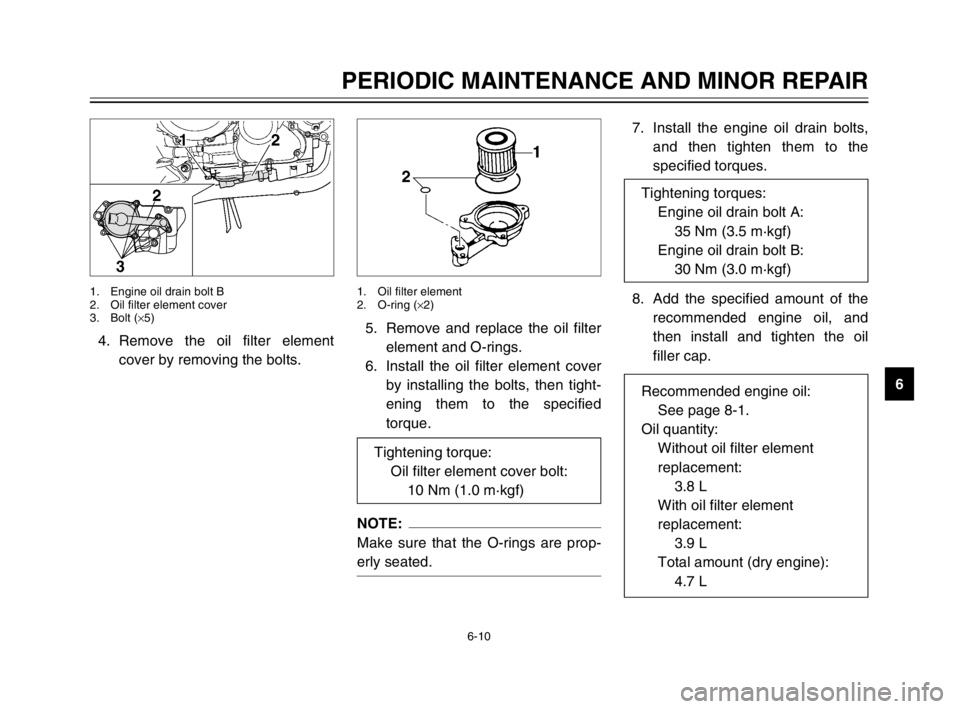

6 4. Remove the oil filter element

cover by removing the bolts.

1. Engine oil drain bolt B

2. Oil filter element cover

3. Bolt (×5)

7. Install the engine oil drain bolts,

and then tighten them to the

specified torques.

8. Add the specified amount of the

recommended engine oil, and

then install and tighten the oil

filler cap. 5. Remove and replace the oil filter

element and O-rings.

6. Install the oil filter element cover

by installing the bolts, then tight-

ening them to the specified

torque.

NOTE:

Make sure that the O-rings are prop-

erly seated.

1. Oil filter element

2. O-ring (×2)

Tightening torque:

Oil filter element cover bolt:

10 Nm (1.0 m·kgf)

Tightening torques:

Engine oil drain bolt A:

35 Nm (3.5 m·kgf)

Engine oil drain bolt B:

30 Nm (3.0 m·kgf)

Recommended engine oil:

See page 8-1.

Oil quantity:

Without oil filter element

replacement:

3.8 L

With oil filter element

replacement:

3.9 L

Total amount (dry engine):

4.7 L

5PS-28199-E1 8/29/02 9:16 AM Page 55

Page 57 of 110

6-11

PERIODIC MAINTENANCE AND MINOR REPAIR

6

ECA00133

cC

8In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

mix any chemical additives.

Do not use oils with a diesel

specification of “CD” or oils of

a higher quality than specified.

In addition, do not use oils

labeled “ENERGY CONSERV-

ING II” or higher.

8Make sure that no foreign

material enters the crankcase.

9. Start the engine, and then let it

idle for several minutes while

checking it for oil leakage. If oil is

leaking, immediately turn the

engine off and check for the

cause.

10. Turn the engine off, and then

check the oil level and correct it if

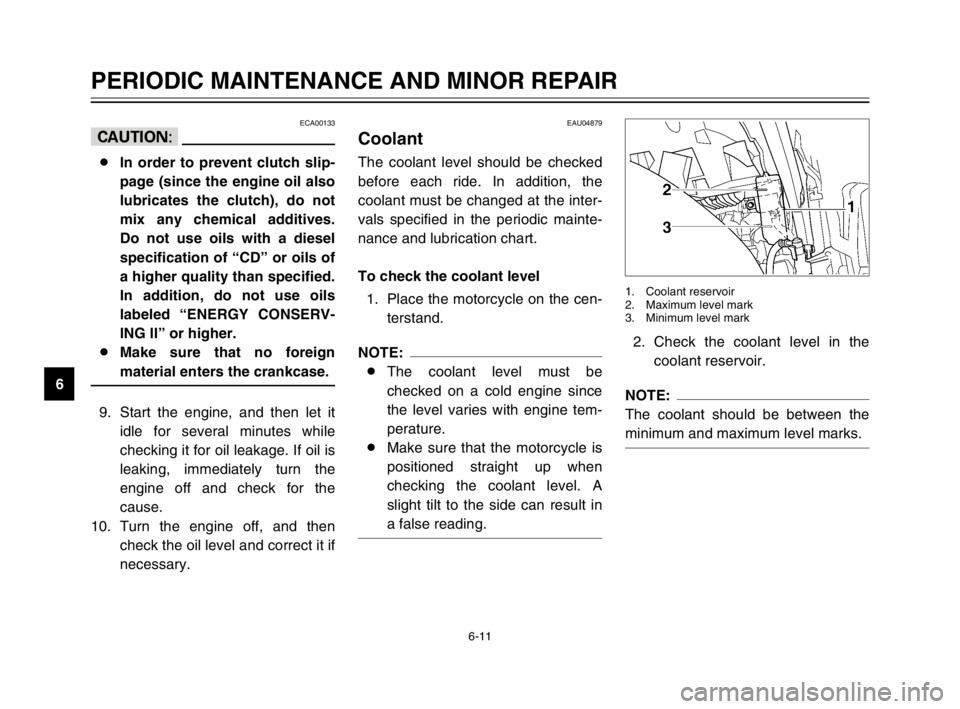

necessary.2. Check the coolant level in the

coolant reservoir.

NOTE:

The coolant should be between the

minimum and maximum level marks.

1. Coolant reservoir

2. Maximum level mark

3. Minimum level mark

EAU04879

CoolantCoolantThe coolant level should be checked

before each ride. In addition, the

coolant must be changed at the inter-

vals specified in the periodic mainte-

nance and lubrication chart.

To check the coolant level

Checking1. Place the motorcycle on the cen-

terstand.

NOTE:

8The coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

8Make sure that the motorcycle is

positioned straight up when

checking the coolant level. A

slight tilt to the side can result in

a false reading.

5PS-28199-E1 8/29/02 9:16 AM Page 56

Page 58 of 110

6-12

PERIODIC MAINTENANCE AND MINOR REPAIR

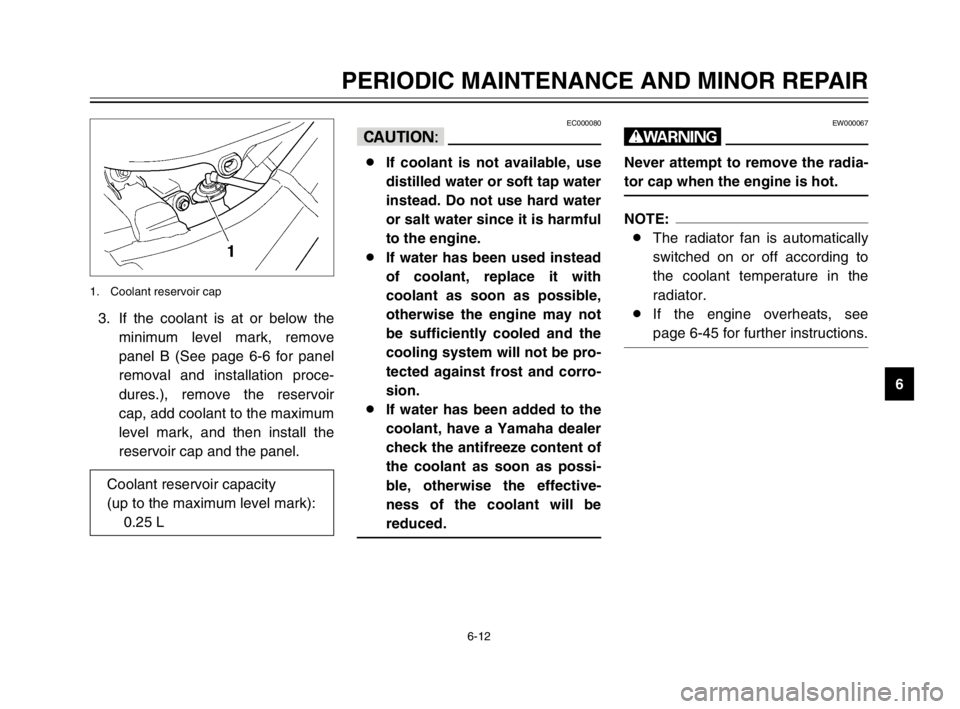

6 3. If the coolant is at or below the

minimum level mark, remove

panel B (See page 6-6 for panel

removal and installation proce-

dures.), remove the reservoir

cap, add coolant to the maximum

level mark, and then install the

reservoir cap and the panel.

1. Coolant reservoir cap

EW000067

w

Never attempt to remove the radia-

tor cap when the engine is hot.

NOTE:

8The radiator fan is automatically

switched on or off according to

the coolant temperature in the

radiator.

8If the engine overheats, see

page 6-45 for further instructions.

EC000080

cC

8If coolant is not available, use

distilled water or soft tap water

instead. Do not use hard water

or salt water since it is harmful

to the engine.

8If water has been used instead

of coolant, replace it with

coolant as soon as possible,

otherwise the engine may not

be sufficiently cooled and the

cooling system will not be pro-

tected against frost and corro-

sion.

8If water has been added to the

coolant, have a Yamaha dealer

check the antifreeze content of

the coolant as soon as possi-

ble, otherwise the effective-

ness of the coolant will be

reduced.

Coolant reservoir capacity

(up to the maximum level mark):

0.25 L

5PS-28199-E1 8/29/02 9:16 AM Page 57

Page 59 of 110

6-13

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU04461

To change the coolantChanging1. Place the motorcycle on a level

surface and let the engine cool if

necessary.

2. Remove the seat. (See page

3-13 for seat removal and instal-

lation procedures.)

3. Remove cowling B and panel B.

(See pages 6-5 and 6-6 for cowl-

ing and panel removal and instal-

lation procedures.)

4. Remove the fuel tank bolts, and

then lift the fuel tank to position it

away from the coolant reservoir.

(Do not disconnect the fuel

hoses!)

5. Place a container under the

engine to collect the used

coolant.7. Remove the coolant drain bolts

to drain the cooling system.

11

1. Coolant drain bolt (×2)

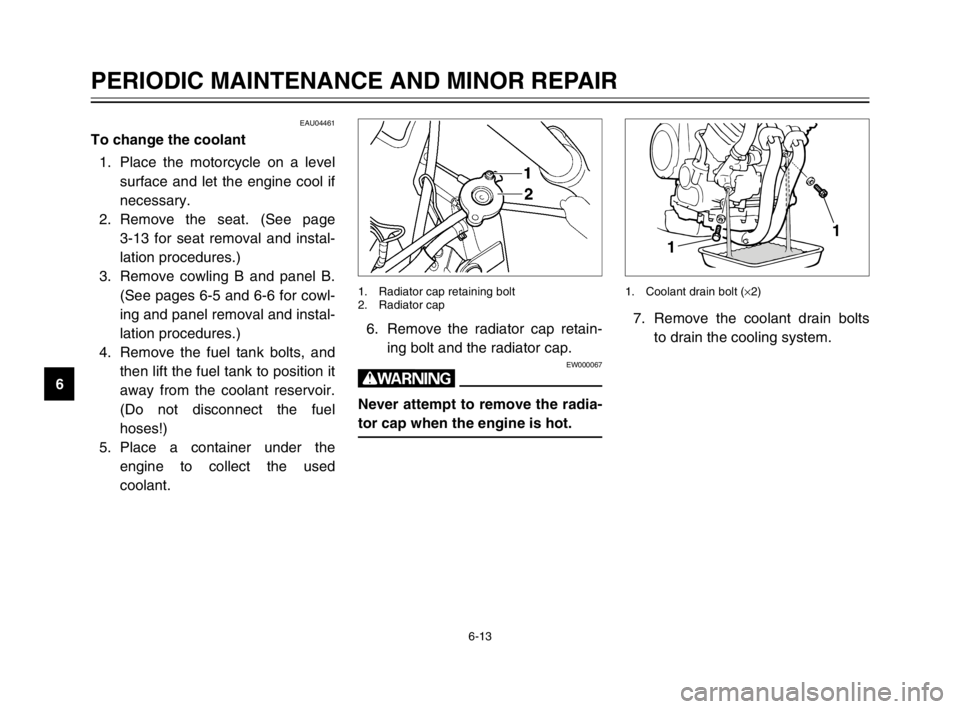

6. Remove the radiator cap retain-

ing bolt and the radiator cap.

EW000067

w

Never attempt to remove the radia-

tor cap when the engine is hot.

1. Radiator cap retaining bolt

2. Radiator cap

5PS-28199-E1 8/29/02 9:16 AM Page 58

Page 60 of 110

6-14

PERIODIC MAINTENANCE AND MINOR REPAIR

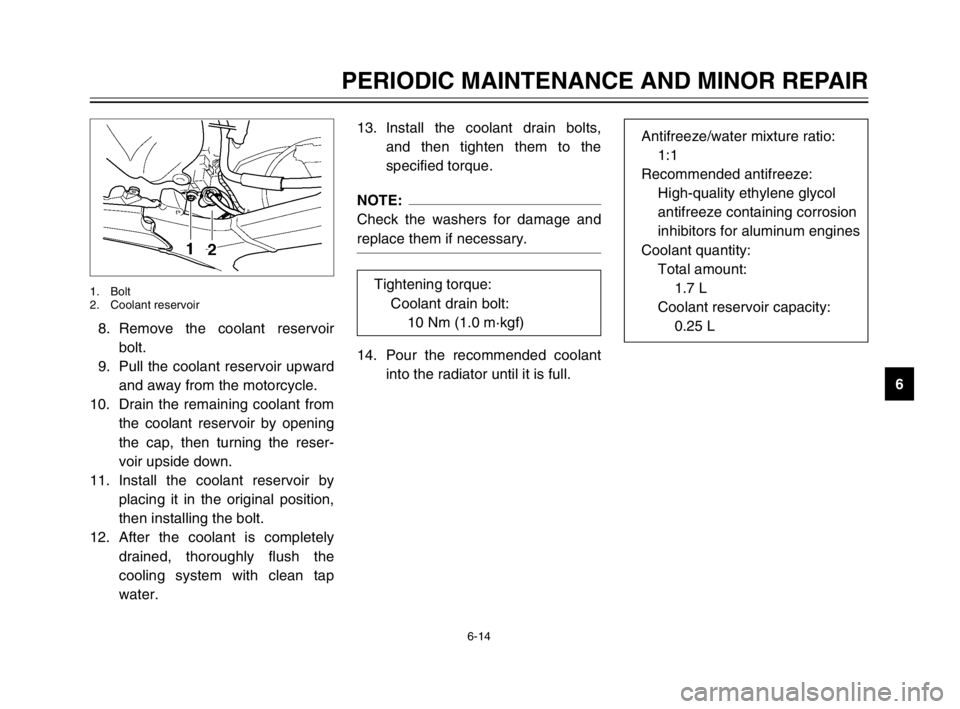

6 8. Remove the coolant reservoir

bolt.

9. Pull the coolant reservoir upward

and away from the motorcycle.

10. Drain the remaining coolant from

the coolant reservoir by opening

the cap, then turning the reser-

voir upside down.

11. Install the coolant reservoir by

placing it in the original position,

then installing the bolt.

12. After the coolant is completely

drained, thoroughly flush the

cooling system with clean tap

water.

1. Bolt

2. Coolant reservoir

13. Install the coolant drain bolts,

and then tighten them to the

specified torque.

NOTE:

Check the washers for damage and

replace them if necessary.

14. Pour the recommended coolant

into the radiator until it is full. Tightening torque:

Coolant drain bolt:

10 Nm (1.0 m·kgf)

Antifreeze/water mixture ratio:

1:1

Recommended antifreeze:

High-quality ethylene glycol

antifreeze containing corrosion

inhibitors for aluminum engines

Coolant quantity:

Total amount:

1.7 L

Coolant reservoir capacity:

0.25 L

5PS-28199-E1 8/29/02 9:16 AM Page 59