engine oil YAMAHA VX110 2005 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 97 of 347

EPOWR

1

2

3

4

5

6

7

8

9

CHAPTER 5

POWER UNIT

ENGINE UNIT .................................................................................................. 5-1

EXPLODED DIAGRAM ............................................................................. 5-1

REMOVAL AND INSTALLATION CHART ................................................ 5-1

SERVICE POINTS .................................................................................... 5-4

Compression pressure measurement ................................................. 5-4

Engine unit removal ............................................................................ 5-6

Shim removal ...................................................................................... 5-6

Engine mount inspection ..................................................................... 5-6

Coupling clearance inspection ............................................................ 5-7

EXHAUST PIPES 1 AND 2.............................................................................. 5-8

EXPLODED DIAGRAM ............................................................................. 5-8

REMOVAL AND INSTALLATION CHART ................................................ 5-8

EXHAUST MANIFOLD .................................................................................. 5-11

EXPLODED DIAGRAM ........................................................................... 5-11

REMOVAL AND INSTALLATION CHART .............................................. 5-11

OIL TANK ...................................................................................................... 5-12

EXPLODED DIAGRAM ........................................................................... 5-12

REMOVAL AND INSTALLATION CHART .............................................. 5-12

SERVICE POINTS .................................................................................. 5-17

Oil tank removal ................................................................................ 5-17

Oil strainer inspection........................................................................ 5-18

Oil tank installation ............................................................................ 5-18

OIL PUMP ...................................................................................................... 5-21

EXPLODED DIAGRAM ........................................................................... 5-21

REMOVAL AND INSTALLATION CHART .............................................. 5-21

SERVICE POINTS .................................................................................. 5-23

Oil strainer inspection........................................................................ 5-23

Oil pump installation .......................................................................... 5-23

REDUCTION DRIVE GEAR .......................................................................... 5-24

EXPLODED DIAGRAM ........................................................................... 5-24

REMOVAL AND INSTALLATION CHART .............................................. 5-24

SERVICE POINTS .................................................................................. 5-28

Drive coupling removal...................................................................... 5-28

Drive shaft removal ........................................................................... 5-28

Bearing removal ................................................................................ 5-28

Oil pump drive shaft inspection ......................................................... 5-29

Drive shaft inspection ........................................................................ 5-29

Bearing installing ............................................................................... 5-30

Drive shaft installation ....................................................................... 5-32

Drive coupling installation ................................................................. 5-32

ProCarManuals.com

Page 100 of 347

5-1

EPOWRENGINE UNIT

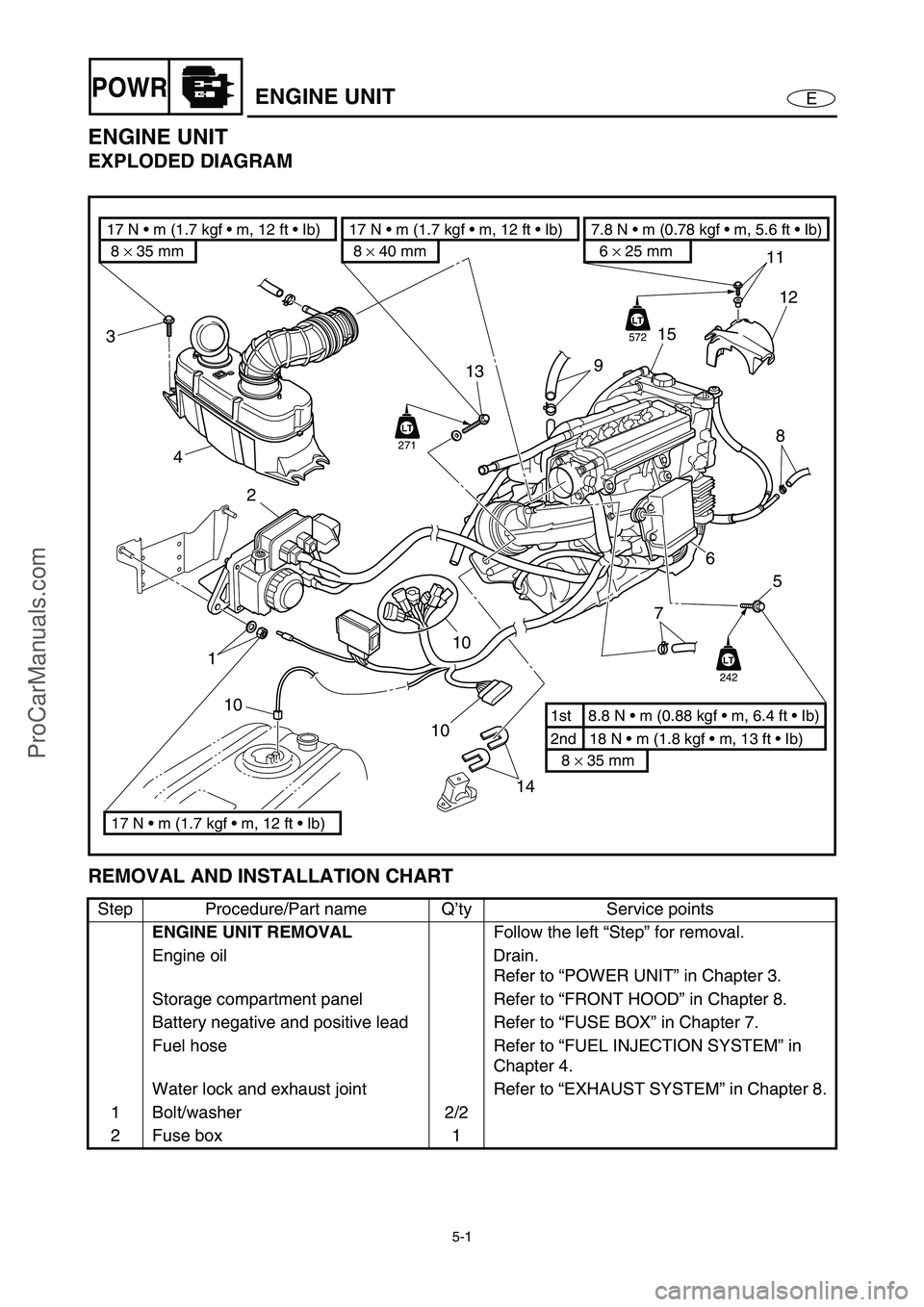

ENGINE UNIT

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

ENGINE UNIT REMOVAL

Follow the left “Step” for removal.

Engine oil Drain.

Refer to “POWER UNIT” in Chapter 3.

Storage compartment panel Refer to “FRONT HOOD” in Chapter 8.

Battery negative and positive lead Refer to “FUSE BOX” in Chapter 7.

Fuel hose Refer to “FUEL INJECTION SYSTEM” in

Chapter 4.

Water lock and exhaust joint Refer to “EXHAUST SYSTEM” in Chapter 8.

1 Bolt/washer 2/2

2 Fuse box 1

14 10

10

2

113

3

4

11

15

12

8

7

9

6

5

2nd 18 N m (1.8 kgf m, 13 ft Ib) 1st 8.8 N m (0.88 kgf m, 6.4 ft Ib)

8 × 35 mm

6 × 25 mm

7.8 N m (0.78 kgf m, 5.6 ft Ib)

8 × 35 mm 17 N m (1.7 kgf m, 12 ft Ib)

17 N m (1.7 kgf m, 12 ft Ib)8 × 40 mm

17 N m (1.7 kgf m, 12 ft Ib)

10LT

242

LT

LT

572

LT

LT

271

ProCarManuals.com

Page 103 of 347

5-4

EPOWRENGINE UNIT

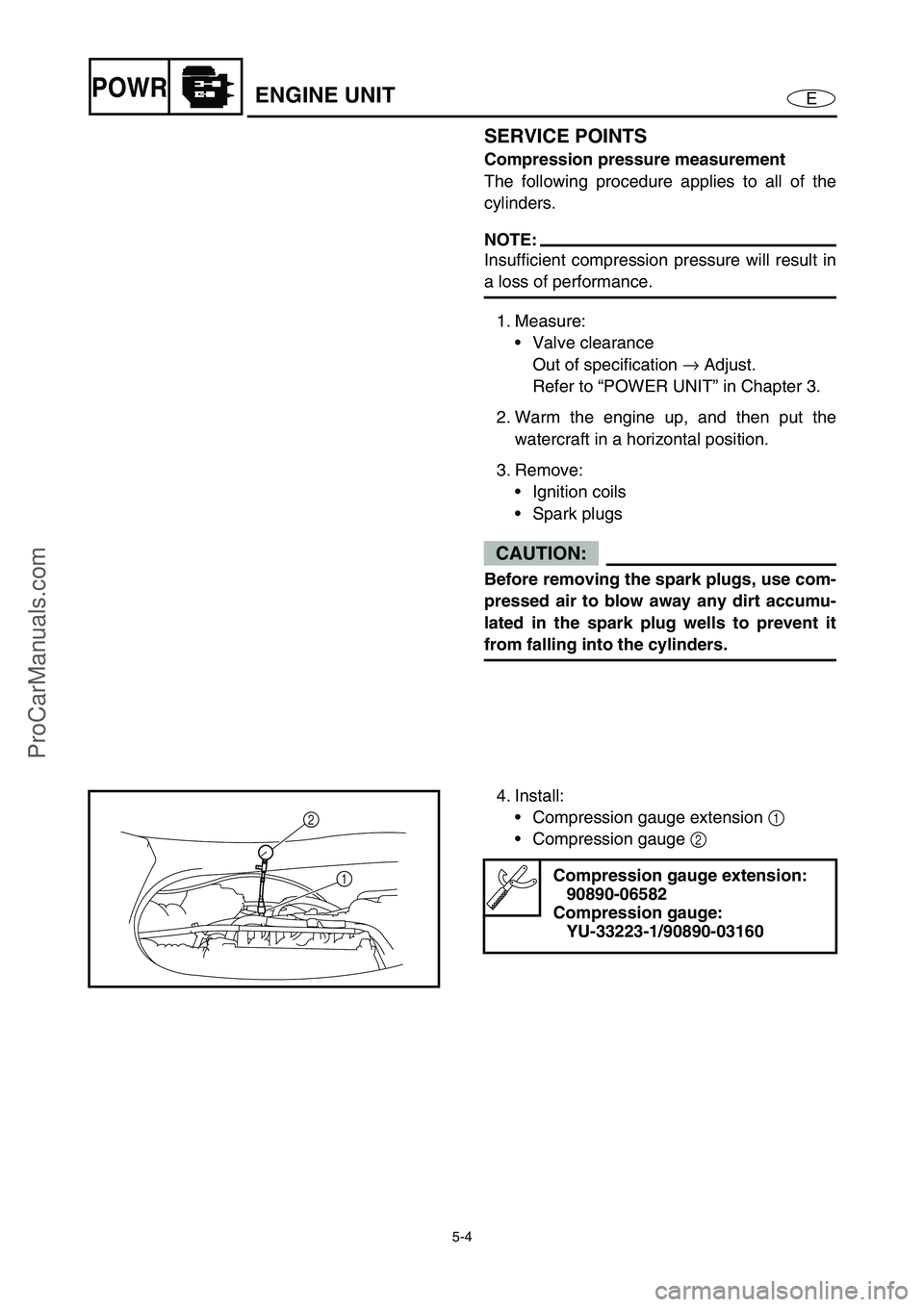

SERVICE POINTS

Compression pressure measurement

The following procedure applies to all of the

cylinders.

NOTE:

Insufficient compression pressure will result in

a loss of performance.

1. Measure:

Valve clearance

Out of specification →

Adjust.

Refer to “POWER UNIT” in Chapter 3.

2. Warm the engine up, and then put the

watercraft in a horizontal position.

3. Remove:

Ignition coils

Spark plugs

CAUTION:

Before removing the spark plugs, use com-

pressed air to blow away any dirt accumu-

lated in the spark plug wells to prevent it

from falling into the cylinders.

4. Install:

Compression gauge extension 1

Compression gauge 2

Compression gauge extension:

90890-06582

Compression gauge:

YU-33223-1/90890-03160

2

1

ProCarManuals.com

Page 104 of 347

5-5

EPOWRENGINE UNIT

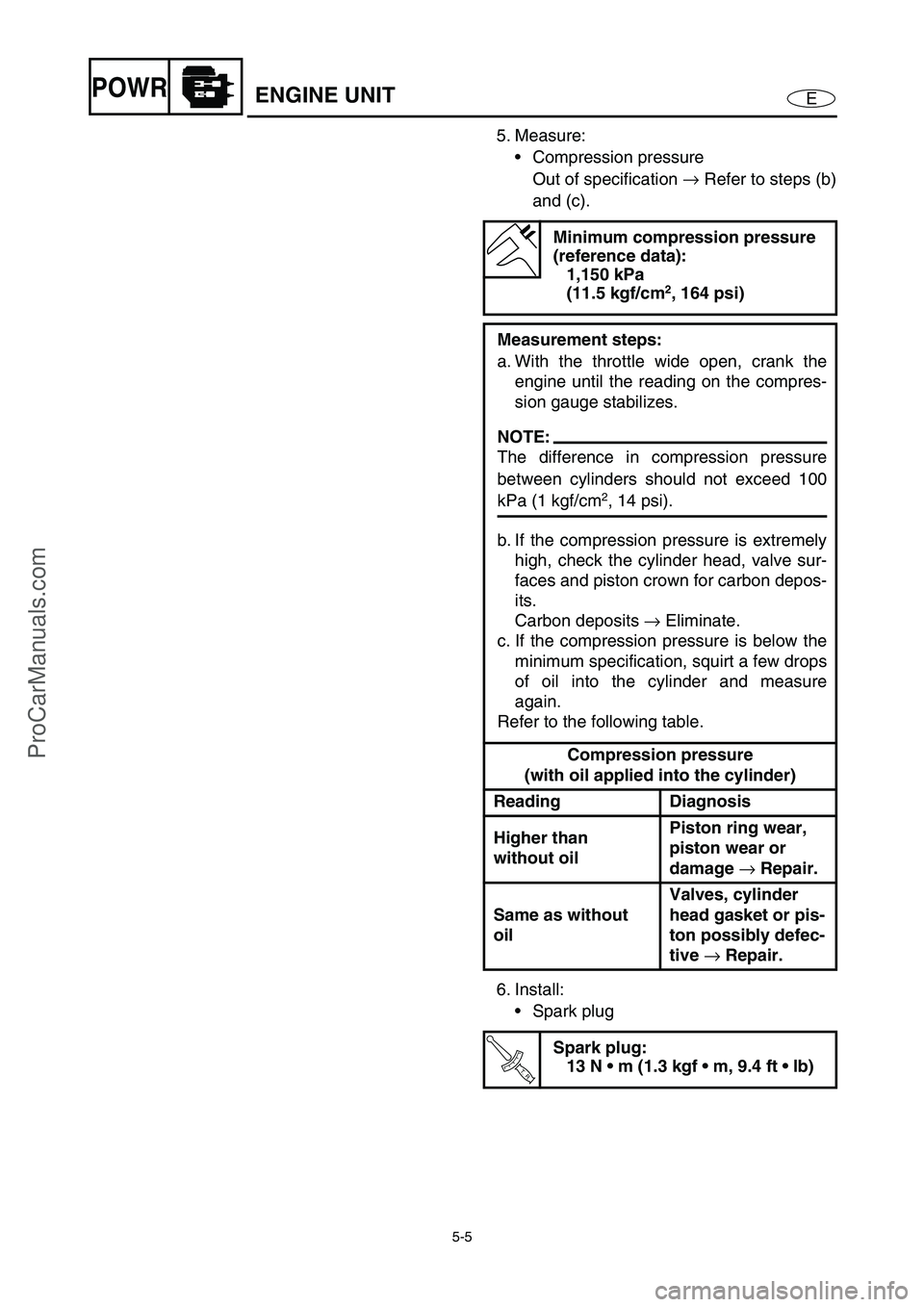

5. Measure:

Compression pressure

Out of specification →

Refer to steps (b)

and (c).

6. Install:

Spark plug

Minimum compression pressure

(reference data):

1,150 kPa

(11.5 kgf/cm

2, 164 psi)

Measurement steps:

a. With the throttle wide open, crank the

engine until the reading on the compres-

sion gauge stabilizes.

NOTE:

The difference in compression pressure

between cylinders should not exceed 100

kPa (1 kgf/cm2, 14 psi).

b. If the compression pressure is extremely

high, check the cylinder head, valve sur-

faces and piston crown for carbon depos-

its.

Carbon deposits →

Eliminate.

c. If the compression pressure is below the

minimum specification, squirt a few drops

of oil into the cylinder and measure

again.

Refer to the following table.

Compression pressure

(with oil applied into the cylinder)

Reading Diagnosis

Higher than

without oilPiston ring wear,

piston wear or

damage

→ Repair.

Same as without

oilValves, cylinder

head gasket or pis-

ton possibly defec-

tive

→ Repair.

T R..

Spark plug:

13 N m (1.3 kgf m, 9.4 ft lb)

ProCarManuals.com

Page 105 of 347

5-6

EPOWRENGINE UNIT

7. Install:

Ignition coils

T R..

Ignition coils bolt:

7.6 N m (0.76 kgf m, 5.5 ft lb)

LOCTITE 572

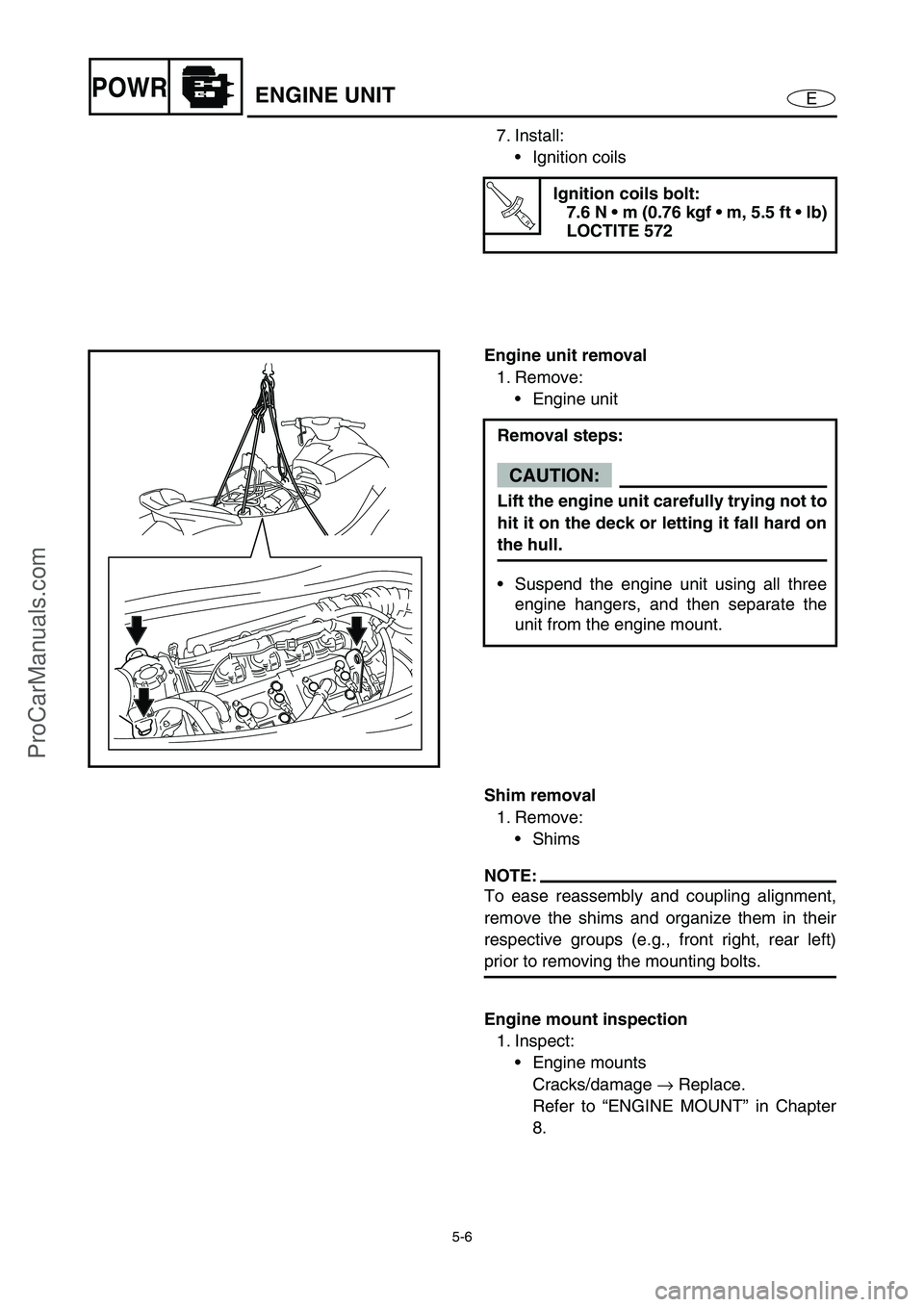

Engine unit removal

1. Remove:

Engine unit

Removal steps:

CAUTION:

Lift the engine unit carefully trying not to

hit it on the deck or letting it fall hard on

the hull.

Suspend the engine unit using all three

engine hangers, and then separate the

unit from the engine mount.

Shim removal

1. Remove:

Shims

NOTE:

To ease reassembly and coupling alignment,

remove the shims and organize them in their

respective groups (e.g., front right, rear left)

prior to removing the mounting bolts.

Engine mount inspection

1. Inspect:

Engine mounts

Cracks/damage →

Replace.

Refer to “ENGINE MOUNT” in Chapter

8.

ProCarManuals.com

Page 111 of 347

5-12

EPOWROIL TANK

OIL TANK

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

OIL TANK REMOVAL

Follow the left “Step” for removal.

Engine unit Refer to “ENGINE UNIT”.

Intake assembly Refer to “FUEL INJECTION SYSTEM” in

Chapter 4.

1 Clamp/cooling water hose 1/1È

To exhaust pipe 1

2Bolt 4

3 Water jacket 1

4Gasket 1

5 Clamp/breather hose 2/1

6 Clamp/breather hose 2/1É

To oil pump

7Bolt 2

8 Collar 2

Ì

LT

572

LT

572

LT

572

LT

572

LT

572

LT

572

23 1925 24

26

25

2116 17 15

14

1220 22

3

4

6 8

9

72

6

AA

6 × 30 mm

2nd 7.6 N m (0.76 kgf

m, 5.5 ft

Ib) 1st 3.7 N m (0.37 kgf

m, 2.7 ft

Ib)

2nd 15 N m (1.5 kgf

m, 11 ft

Ib) 1st 2.0 N m (0.2 kgf

m, 1.4 ft

Ib)

3rd 39 N m (3.9 kgf

m, 28 ft

Ib)

2nd 39 N m (3.9 kgf

m, 28 ft

Ib) 1st 15 N m (1.5 kgf

m, 11 ft

Ib)

10 × 85 mm2nd 15 N m (1.5 kgf

m, 11 ft

Ib) 1st 2.0 N m (0.2 kgf

m, 1.4 ft

Ib)

10 × 70 mm

3rd 39 N m (3.9 kgf

m, 28 ft

Ib)7.6 N

m (0.76 kgf m, 5.5 ft Ib)

6 × 35 mm

È

ÉÌ13

LT

572

LT

572

LT

572

LT

572

18

102nd 7.6 N m (0.76 kgf m, 5.5 ft Ib)

1st 3.7 N m (0.37 kgf m, 2.7 ft Ib)

6 × 20 mm

Ê

Ë

a

1

5

1111

5

6 × 35 mm

Not reusable

ProCarManuals.com

Page 120 of 347

5-21

EPOWROIL PUMP

OIL PUMP

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

OIL PUMP ASSEMBLY

REMOVALFollow the left “Step” for removal.

Oil tank Refer to “OIL TANK”.

1 Drain plug/washer 1/1 Drain engine oil.

2Bolt 6

3Bolt 2

4Bolt 2

5 Oil pump assembly 1

6Gasket 1

7Pin 2

2nd 28 N m (2.8 kgf m, 20 ft Ib) 1st 15 N m (1.5 kgf m, 11 ft Ib)

8 × 112 mm

6 × 25 mm

10 N m (1.0 kgf m, 7.2 ft Ib)

2nd 7.6 N m (0.76 kgf m, 5.5 ft Ib) 1st 3.7 N m (0.37 kgf m, 2.7 ft Ib)

6 × 16 mm

LT

572

LT

LT

572

LT

13 N m (1.3 kgf m, 9.4 ft Ib)

8 × 12 mm

LT

572

LT

1

5

7 73

4

2

6

8

8

9

2nd 28 N m (2.8 kgf m, 20 ft Ib) 1st 15 N m (1.5 kgf m, 11 ft Ib)

8 × 95 mm

Not reusable

ProCarManuals.com

Page 132 of 347

5-33

EPOWRGENERATOR AND STARTER MOTOR

GENERATOR AND STARTER MOTOR

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

GENERATOR COVER AND

FLYWHEEL MAGNETO

REMOVALFollow the left “Step” for removal.

Engine unit Refer to “ENGINE UNIT”.

1 Nut/washer 1/1

2 Starter motor lead 1

3Bolt 2

4 Battery negative lead 1

5 Starter motor 1

6 Band 1

7 Lighting coil coupler 1

4 3

2 1

5

7

89

1113 12

18 16171920 21

15 14

AA

E

E

E

LT

572

LT

572

AA

AA

8 × 30 mm

18 N m (1.8 kgf

m, 13 ft

Ib)

4.9 N

m (0.49 kgf m, 3.5 ft Ib)

10 × 47 mm

75 N m (7.5 kgf

m, 54 ft

Ib) 8 × 20 mm

24 N m (2.4 kgf

m, 17 ft

Ib)

10 × 60 mm

2nd 50 N m (5.0 kgf

m, 36 ft

Ib) 1st 15 N m (1.5 kgf

m, 11 ft

Ib)

6

2nd 50 N m (5.0 kgf

m, 36 ft

Ib) 1st 15 N m (1.5 kgf m, 11 ft Ib)

10 × 135 mm

10

LT

572

LT

572

ProCarManuals.com

Page 139 of 347

5-40

EPOWRGENERATOR AND STARTER MOTOR

Flywheel magneto installation

1. Install:

Woodruff key

Flywheel magneto

Washer

Flywheel magneto bolt

NOTE:

Clean the tapered portion of the crankshaft

and the flywheel magneto hub.

When installing the flywheel magneto, make

sure the woodruff key is properly seated in

the keyway of the crankshaft.

Lubricate the flywheel magneto bolt and

washer with engine oil.

2. Tighten:

Flywheel magneto bolt 1

NOTE:

While holding the flywheel magneto 2

with the

sheave holder 3

, tighten the flywheel mag-

neto bolt.

CAUTION:

Do not reuse the flywheel magneto bolt and

washer, always replace them with new

ones.

T R..

Flywheel magneto bolt:

75 N m (7.5 kgf m, 54 ft lb)

Sheave holder:

YS-01880-A/90890-01701

ProCarManuals.com

Page 153 of 347

5-54

EPOWRCYLINDER HEAD

CYLINDER HEAD

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

CYLINDER HEAD REMOVAL

Follow the left “Step” for removal.

Engine unit Refer to “ENGINE UNIT”.

Intake assembly Refer to “FUEL INJECTION SYSTEM” in

Chapter 4.

Exhaust pipes 1 and 2 Refer to “EXHAUST PIPES 1 AND 2”.

Oil tank Refer to “OIL TANK”.

Intake and exhaust camshaft Refer to “CAMSHAFTS”.

1Bolt 2

2 Hunger 1

3Bolt 3

EEE

E

2 4

1

855

7

9 3 6

6

LT

271

2nd 121 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 140 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

10 N •

m (1.0 kgf • m, 7.2 ft • Ib)

6 × 12 mm

10 N •

m (1.0 kgf • m, 7.2 ft • Ib)

6 × 55 mm

8 × 20 mm

6

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

E6

4

66

6

ProCarManuals.com