service YAMAHA VX110 2005 Manual PDF

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 159 of 347

5-60

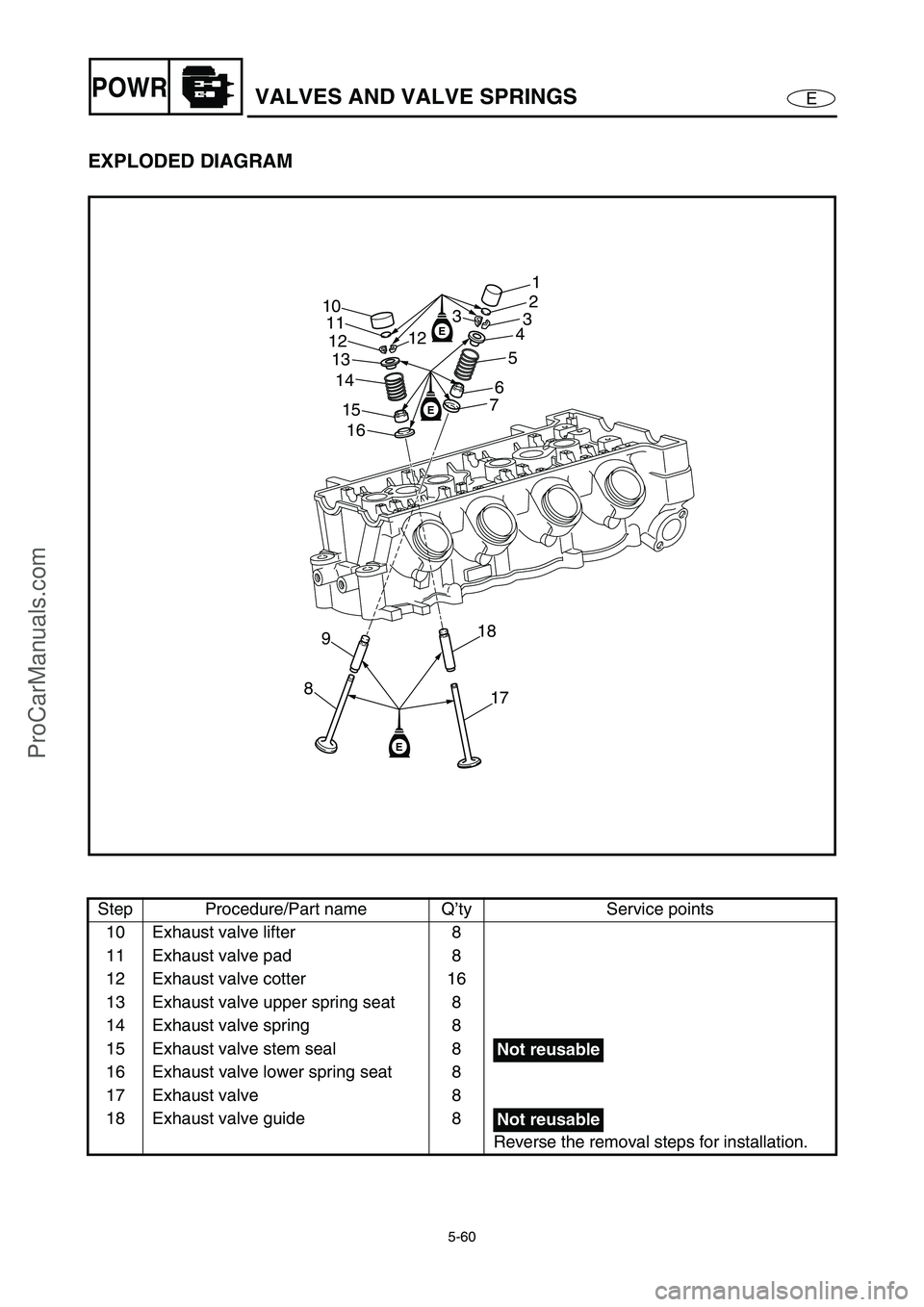

EPOWRVALVES AND VALVE SPRINGS

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

10 Exhaust valve lifter 8

11 Exhaust valve pad 8

12 Exhaust valve cotter 16

13 Exhaust valve upper spring seat 8

14 Exhaust valve spring 8

15 Exhaust valve stem seal 8

16 Exhaust valve lower spring seat 8

17 Exhaust valve 8

18 Exhaust valve guide 8

Reverse the removal steps for installation.

E

E

E

89

17 18 16 15 14 13 10

11

121

2

3

4

5

6

7 3

12

Not reusable

Not reusable

ProCarManuals.com

Page 160 of 347

5-61

EPOWRVALVES AND VALVE SPRINGS

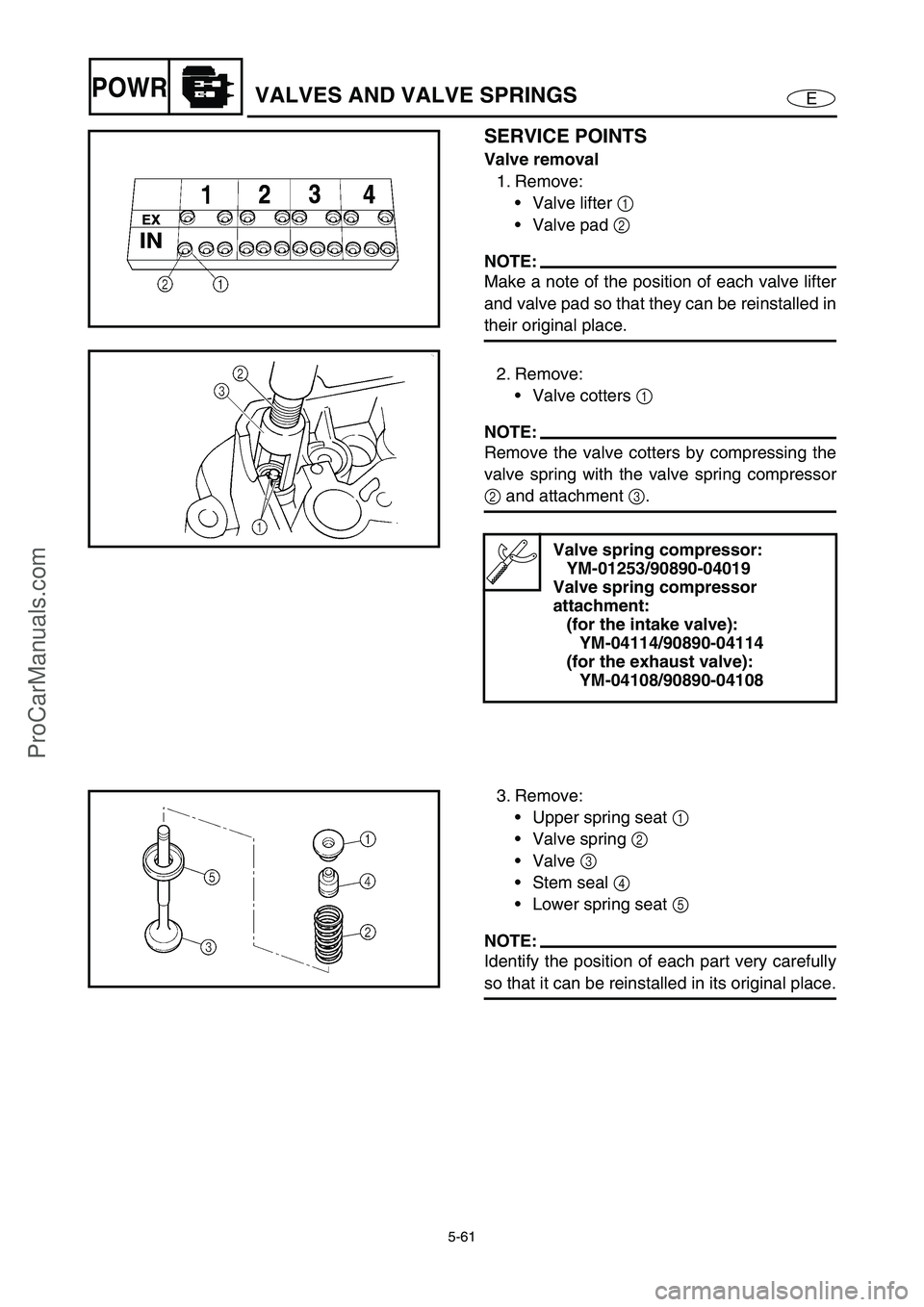

SERVICE POINTS

Valve removal

1. Remove:

Valve lifter 1

Valve pad 2

NOTE:

Make a note of the position of each valve lifter

and valve pad so that they can be reinstalled in

their original place.

2. Remove:

Valve cotters 1

NOTE:

Remove the valve cotters by compressing the

valve spring with the valve spring compressor

2

and attachment 3

.

Valve spring compressor:

YM-01253/90890-04019

Valve spring compressor

attachment:

(for the intake valve):

YM-04114/90890-04114

(for the exhaust valve):

YM-04108/90890-04108

3. Remove:

Upper spring seat 1

Valve spring 2

Valve 3

Stem seal 4

Lower spring seat 5

NOTE:

Identify the position of each part very carefully

so that it can be reinstalled in its original place.

ProCarManuals.com

Page 163 of 347

5-64

EPOWRVALVES AND VALVE SPRINGS

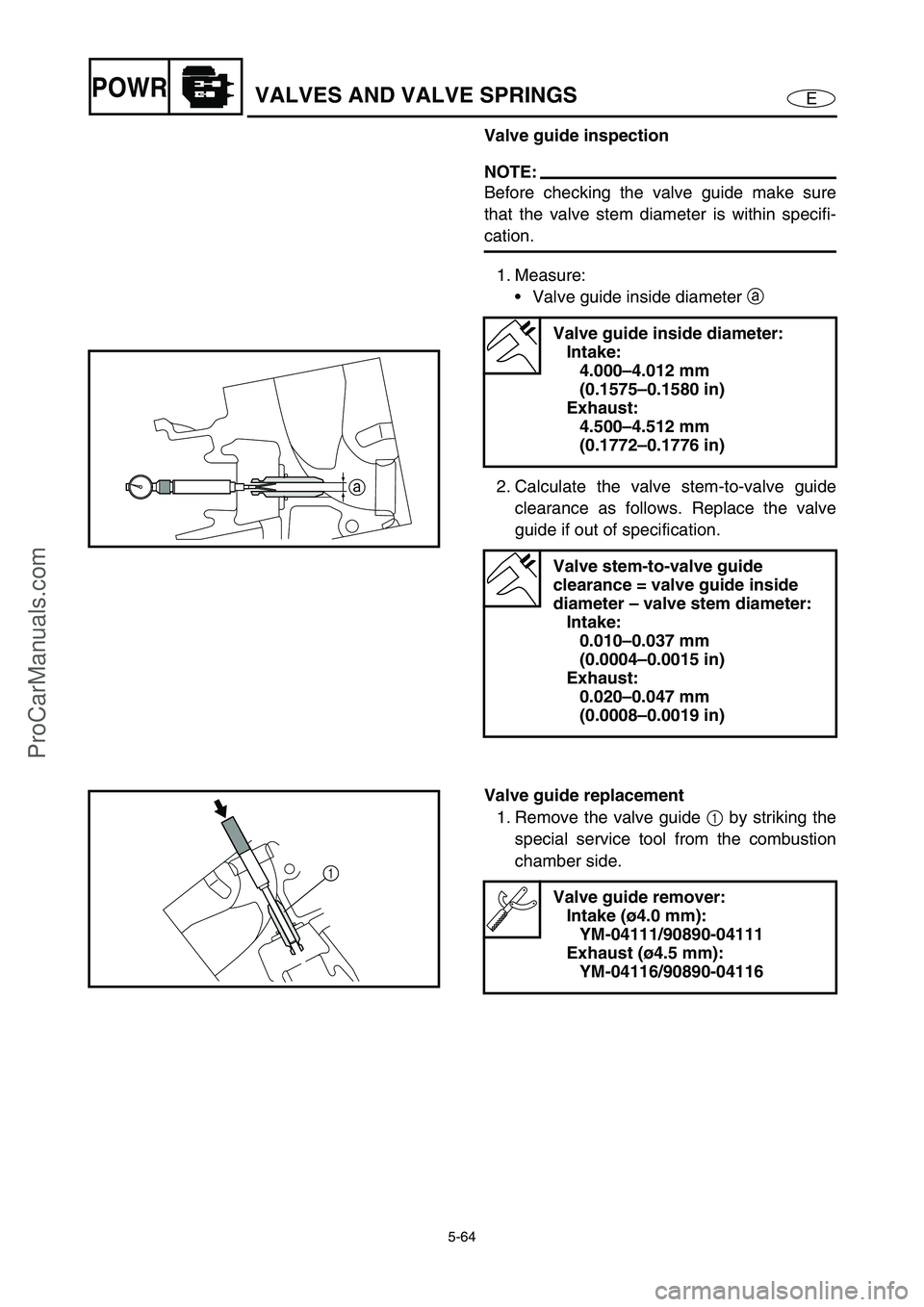

Valve guide inspection

NOTE:

Before checking the valve guide make sure

that the valve stem diameter is within specifi-

cation.

1. Measure:

Valve guide inside diameter a

2. Calculate the valve stem-to-valve guide

clearance as follows. Replace the valve

guide if out of specification.

Valve guide inside diameter:

Intake:

4.000–4.012 mm

(0.1575–0.1580 in)

Exhaust:

4.500–4.512 mm

(0.1772–0.1776 in)

Valve stem-to-valve guide

clearance = valve guide inside

diameter – valve stem diameter:

Intake:

0.010–0.037 mm

(0.0004–0.0015 in)

Exhaust:

0.020–0.047 mm

(0.0008–0.0019 in)

a

Valve guide replacement

1. Remove the valve guide 1

by striking the

special service tool from the combustion

chamber side.

Valve guide remover:

Intake (ø4.0 mm):

YM-04111/90890-04111

Exhaust (ø4.5 mm):

YM-04116/90890-04116

1

ProCarManuals.com

Page 164 of 347

5-65

EPOWRVALVES AND VALVE SPRINGS

2. Install the new valve guide 2

by striking

the special service tool from the camshaft

side until the valve guide clip 3

contacts

the cylinder head.

NOTE:

Apply engine oil to the surface of the new

valve guide.

Valve guide remover:

Intake (ø4.0 mm):

YM-04111/90890-04111

Exhaust (ø4.5 mm):

YM-04116/90890-04116

Valve guide installer:

Intake (ø4.0 mm):

YM-04112/90890-04112

Exhaust (ø4.5 mm):

YM-04117/90890-04117

3

E

2

3. Insert the special service tool into the

valve guide 2

, and then ream the valve

guide.

NOTE:

Turn the valve guide reamer clockwise to

ream the valve guide.

Do not turn the reamer counterclockwise

when removing the reamer.

4. Measure:

Valve guide inside diameter

Valve guide reamer:

Intake (ø4.0 mm):

YM-04113/90890-04113

Exhaust (ø4.5 mm):

YM-04118/90890-04118

Valve guide inside diameter:

Intake:

4.000–4.012 mm

(0.1575–0.1580 in)

Exhaust:

4.500–4.512 mm

(0.1772–0.1776 in)

2

ProCarManuals.com

Page 170 of 347

5-71

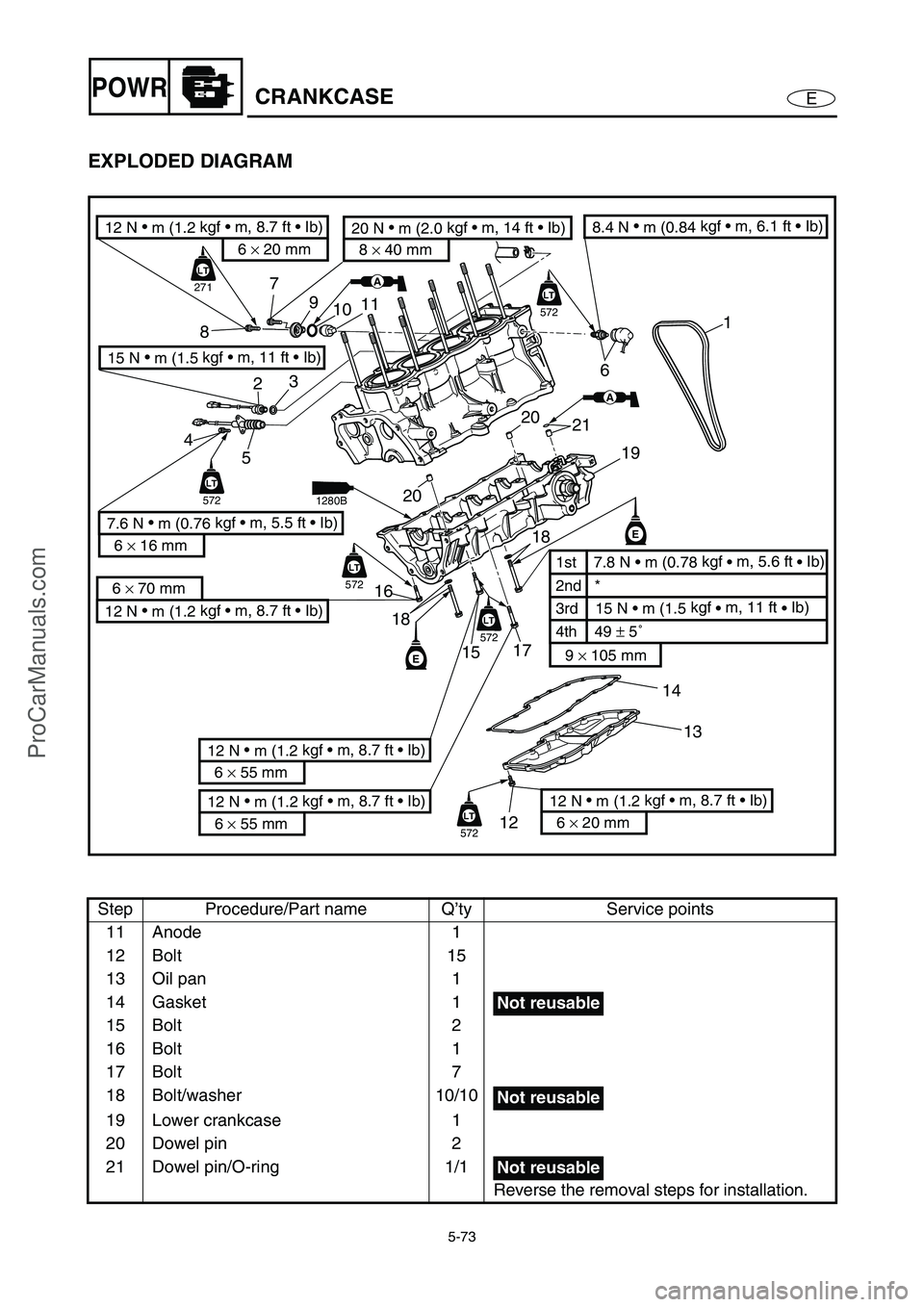

EPOWRCRANKCASE

CRANKCASE

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

OIL PAN AND CRANKCASE

REMOVALFollow the left “Step” for removal.

Engine unit Refer to “ENGINE UNIT”.

Intake assembly Refer to “FUEL INJECTION SYSTEM” in

Chapter 4.

Exhaust pipes 1 and 2 Refer to “EXHAUST PIPES 1 AND 2”.

Exhaust manifold Refer to “EXHAUST MANIFOLD”.

Generator cover Refer to “GENERATOR AND STARTER

MOTOR”.

Oil tank Refer to “OIL TANK”.

Oil pump Refer to “OIL PUMP”.

*: Loosen completely

6

21 20

20 11

10 9

87

23

4

5

16

151718

13 14

1219

1

LT

271

LT

LT

572

LT

LT

572

LT

LT

572

LT

LT

572

LT

LT

572

LT

E

E

AA

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 70 mm

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 20 mm

20 N •

m (2.0 kgf • m, 14 ft • Ib)

8 × 40 mm

2nd *

3rd 15 N • m (1.5 kgf

• m, 11 ft

• Ib) 1st 7.8 N • m (0.78 kgf

• m, 5.6 ft

• Ib)

9 × 105 mm

4th 49 ± 5˚

8.4 N •

m (0.84 kgf • m, 6.1 ft • Ib)

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 55 mm

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 55 mm

7.6 N •

m (0.76 kgf • m, 5.5 ft • Ib)

6 × 16 mm

15 N •

m (1.5 kgf • m, 11 ft • Ib)

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 20 mm

18

AA

1280B

ProCarManuals.com

Page 171 of 347

5-72

EPOWRCRANKCASE

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

Reduction drive gear case Refer to “REDUCTION DRIVE GEAR”.

Cylinder head Refer to “CAMSHAFTS”.

1 Timing chain 1

2 Engine temperature sensor 1

3 Washer 1

4Bolt 2

5 Thermoswitch (engine) 1

6 Oil pressure switch 1

7Bolt 1

8Bolt 1

9 Anode cover 1

10 Grommet 1

6

21 20

20 11

10 9

87

23

4

5

16

151718

13 14

1219

1

LT

271

LT

LT

572

LT

LT

572

LT

LT

572

LT

LT

572

LT

LT

572

LT

E

E

AA

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 70 mm

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 20 mm

20 N •

m (2.0 kgf • m, 14 ft • Ib)

8 × 40 mm

2nd *

3rd 15 N • m (1.5 kgf

• m, 11 ft

• Ib) 1st 7.8 N • m (0.78 kgf

• m, 5.6 ft

• Ib)

9 × 105 mm

4th 49 ± 5˚

8.4 N •

m (0.84 kgf • m, 6.1 ft • Ib)

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 55 mm

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 55 mm

7.6 N •

m (0.76 kgf • m, 5.5 ft • Ib)

6 × 16 mm

15 N •

m (1.5 kgf • m, 11 ft • Ib)

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 20 mm

18

AA

1280B

ProCarManuals.com

Page 172 of 347

5-73

EPOWRCRANKCASE

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

11 Anode 1

12 Bolt 15

13 Oil pan 1

14 Gasket 1

15 Bolt 2

16 Bolt 1

17 Bolt 7

18 Bolt/washer 10/10

19 Lower crankcase 1

20 Dowel pin 2

21 Dowel pin/O-ring 1/1

Reverse the removal steps for installation.

6

21 20

20 11

10 9

87

23

4

5

16

151718

13 14

1219

1

LT

271

LT

LT

572

LT

LT

572

LT

LT

572

LT

LT

572

LT

LT

572

LT

E

E

AA

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 70 mm

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 20 mm

20 N •

m (2.0 kgf • m, 14 ft • Ib)

8 × 40 mm

2nd *

3rd 15 N • m (1.5 kgf

• m, 11 ft

• Ib) 1st 7.8 N • m (0.78 kgf

• m, 5.6 ft

• Ib)

9 × 105 mm

4th 49 ± 5˚

8.4 N •

m (0.84 kgf • m, 6.1 ft • Ib)

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 55 mm

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 55 mm

7.6 N •

m (0.76 kgf • m, 5.5 ft • Ib)

6 × 16 mm

15 N •

m (1.5 kgf • m, 11 ft • Ib)

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 20 mm

18

AA

1280B

Not reusable

Not reusable

Not reusable

ProCarManuals.com

Page 173 of 347

5-74

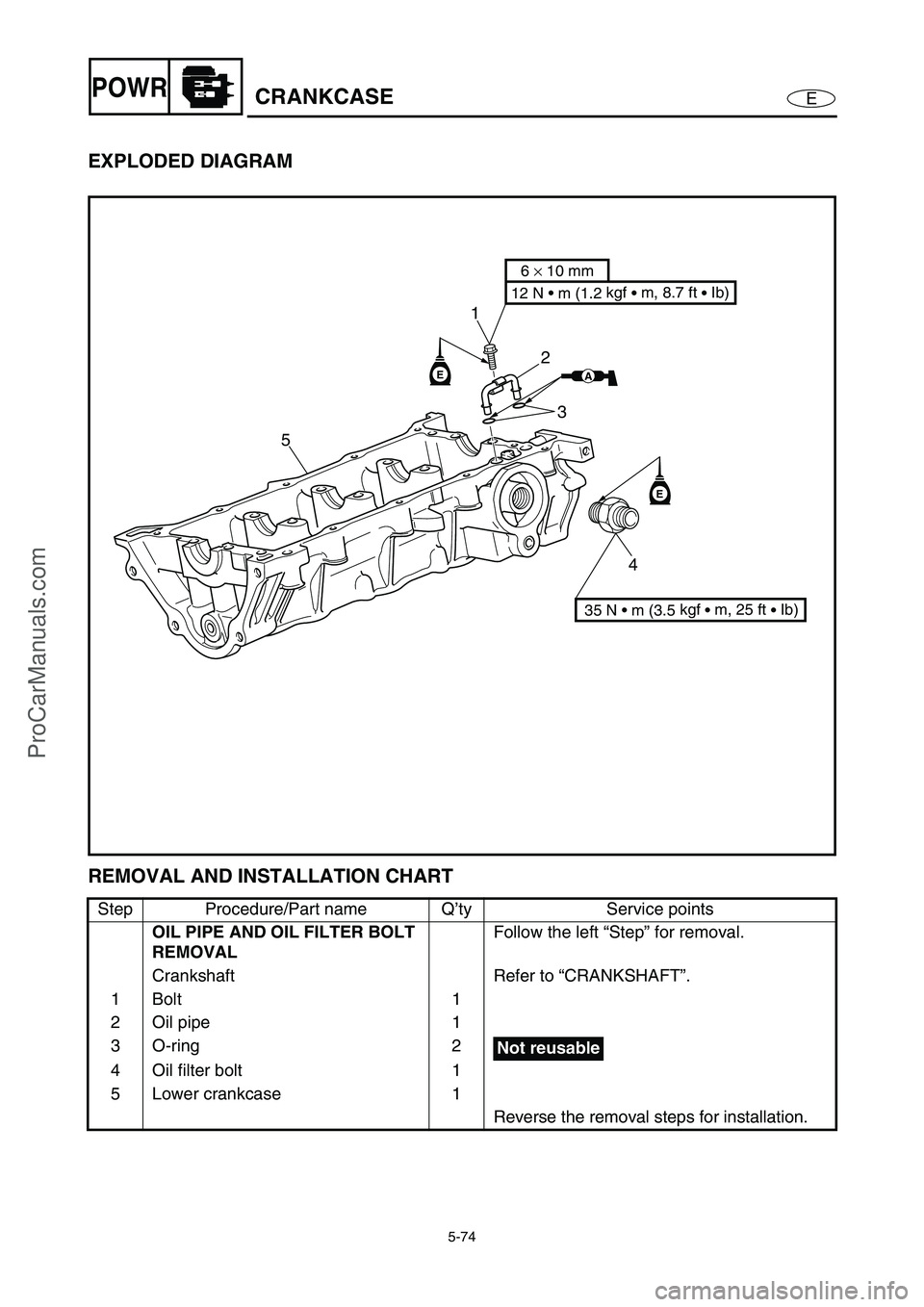

EPOWRCRANKCASE

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

OIL PIPE AND OIL FILTER BOLT

REMOVALFollow the left “Step” for removal.

Crankshaft Refer to “CRANKSHAFT”.

1Bolt 1

2 Oil pipe 1

3 O-ring 2

4 Oil filter bolt 1

5 Lower crankcase 1

Reverse the removal steps for installation.

E

E

51

2

3

4

AA

6 × 10 mm

12 N • m (1.2 kgf

• m, 8.7 ft

• Ib)

35 N • m (3.5 kgf

• m, 25 ft

• Ib)

Not reusable

ProCarManuals.com

Page 174 of 347

5-75

EPOWRCRANKCASE

SERVICE POINTS

Crankcase disassembly

1. Remove:

Oil pan bolts

NOTE:

Loosen each bolt 1/4 of a turn at a time, in

stages and in a crisscross pattern. After all of

the bolts are fully loosened, remove them.

Loosen the bolts in decreasing numerical

order (refer to the numbers in the illustra-

tion).

The numbers embossed on the oil pan indi-

cate the oil pan tightening sequence.

106

24812

15

11

7

3 1 5 9

13 14

2. Remove:

Crankcase bolts

NOTE:

Loosen each bolt 1/4 of a turn at a time, in

stages and in a crisscross pattern. After all of

the bolts are fully loosened, remove them.

Loosen the bolts in decreasing numerical

order (refer to the numbers in the illustra-

tion).

The numbers embossed on the crankcase

indicate the crankcase tightening sequence.

3. Remove:

Lower crankcase

CAUTION:

Tap on one side of the crankcase with a

soft-face hammer. Tap only on reinforced

portions of the crankcase, not on the

crankcase mating surfaces. Work slowly

and carefully and make sure the crankcase

halves separate evenly.

M9

× 105 mm bolts:

1–

0

M6

× 55 mm bolts:

A–

H,

J

M6

× 70 mm bolts:

I

15397

ICAEG

86240

HFBDJ

ProCarManuals.com

Page 179 of 347

5-80

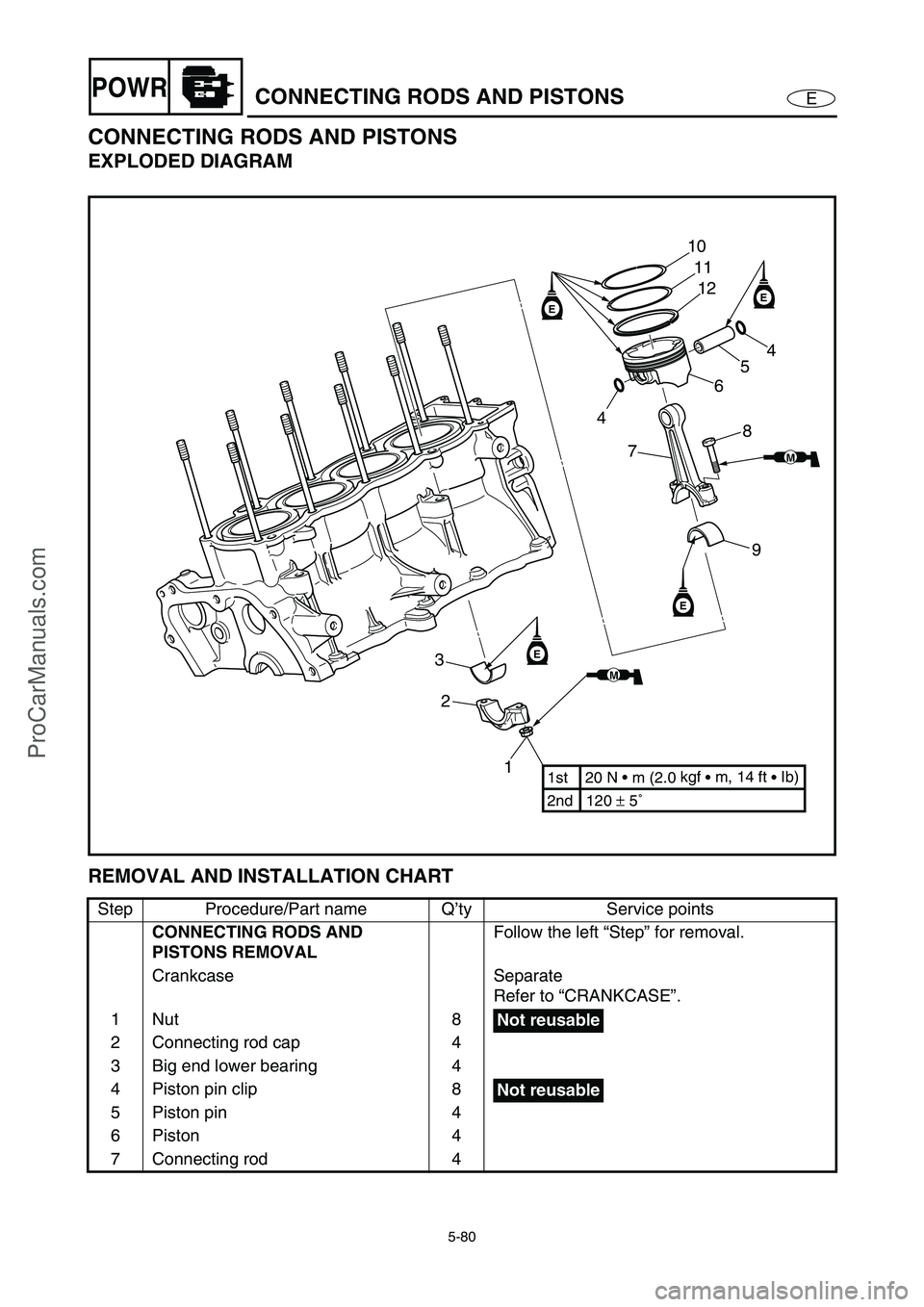

EPOWRCONNECTING RODS AND PISTONS

CONNECTING RODS AND PISTONS

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

CONNECTING RODS AND

PISTONS REMOVALFollow the left “Step” for removal.

Crankcase Separate

Refer to “CRANKCASE”.

1Nut 8

2 Connecting rod cap 4

3 Big end lower bearing 4

4 Piston pin clip 8

5 Piston pin 4

6Piston 4

7 Connecting rod 4

EE

E

E

1 2 310

11

12

4

5

6

8

7

9

2nd 120 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

MM

MM

4

Not reusable

Not reusable

ProCarManuals.com