service YAMAHA VX110 2005 Manual Online

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 180 of 347

5-81

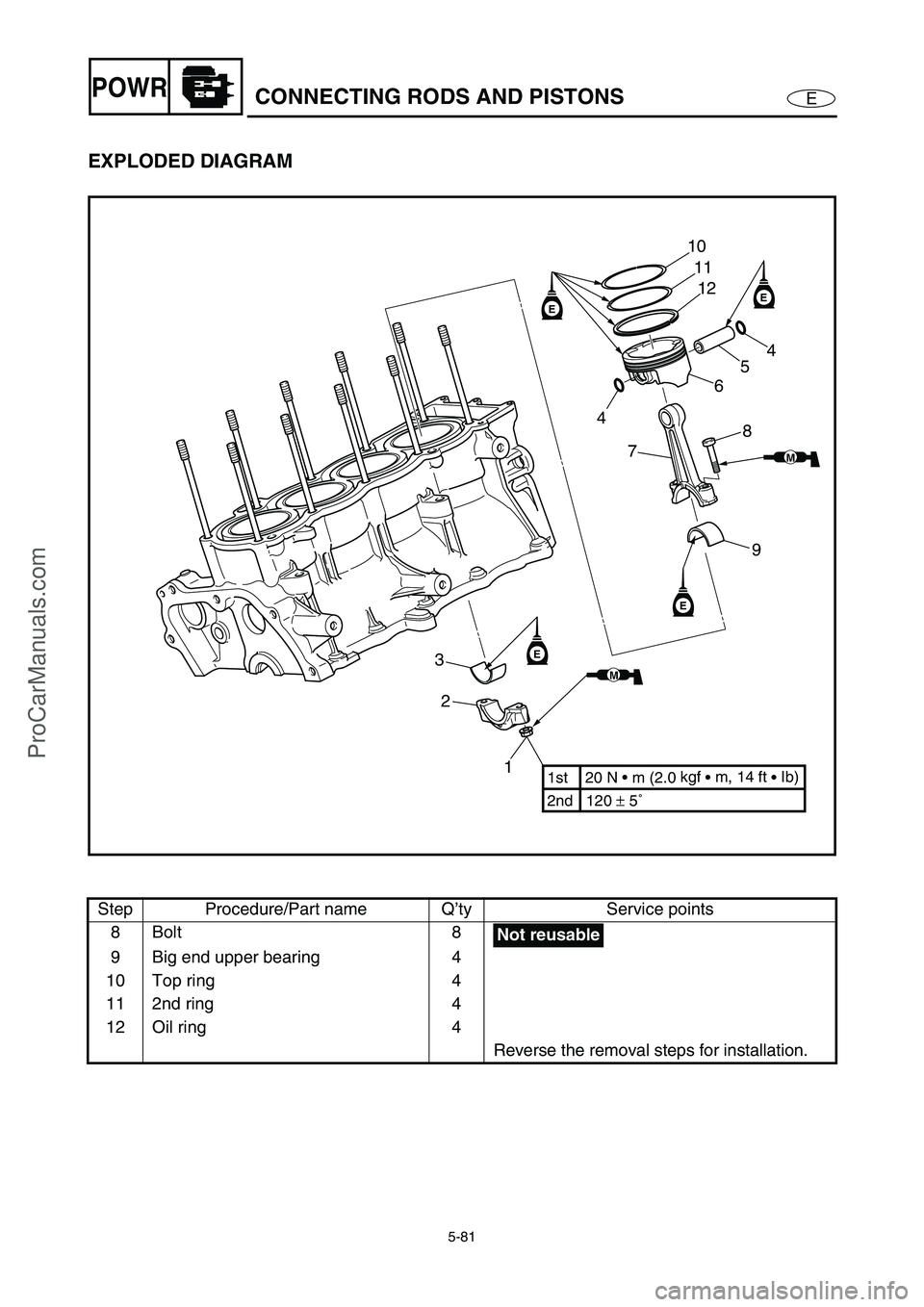

EPOWRCONNECTING RODS AND PISTONS

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

8Bolt 8

9 Big end upper bearing 4

10 Top ring 4

11 2nd ring 4

12 Oil ring 4

Reverse the removal steps for installation.

EE

E

E

1 2 310

11

12

4

5

6

8

7

9

2nd 120 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

MM

MM

4

Not reusable

ProCarManuals.com

Page 181 of 347

5-82

EPOWRCONNECTING RODS AND PISTONS

SERVICE POINTS

Connecting rod and piston removal

The following procedure applies to all of the

connecting rods and pistons.

1. Remove:

Connecting rod cap 1

Big end bearings

NOTE:

Identify the position of each big end bearing so

that it can be reinstalled in its original place.

1

2. Remove:

Piston pin clips 1

Piston pin 2

Piston 3

Connecting rod 4

CAUTION:

Do not use a hammer to drive the piston

pin out.

NOTE:

For reference during installation, put an iden-

tification number a on the piston crown.

Before removing the piston pin, deburr the

piston pin clip’s groove and the piston’s pin

bore area.

3. Remove:

Top ring

2nd ring

Oil ring

NOTE:

When removing a piston ring, open the end

gap with your fingers and lift the other side of

the ring over the piston crown.

ProCarManuals.com

Page 192 of 347

5-93

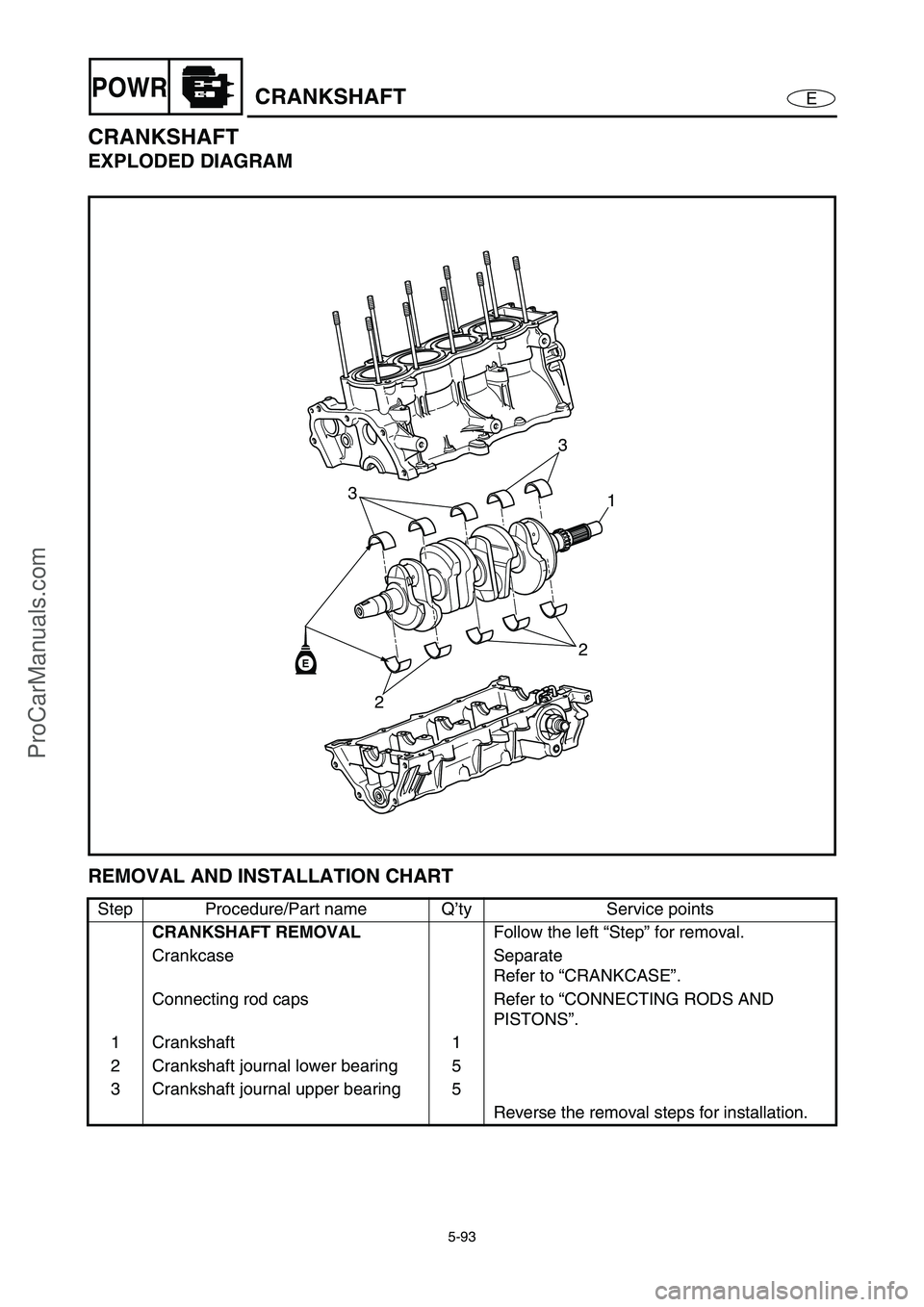

EPOWRCRANKSHAFT

CRANKSHAFT

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

CRANKSHAFT REMOVAL

Follow the left “Step” for removal.

Crankcase Separate

Refer to “CRANKCASE”.

Connecting rod caps Refer to “CONNECTING RODS AND

PISTONS”.

1 Crankshaft 1

2 Crankshaft journal lower bearing 5

3 Crankshaft journal upper bearing 5

Reverse the removal steps for installation.

2

21 33E

ProCarManuals.com

Page 193 of 347

5-94

EPOWRCRANKSHAFT

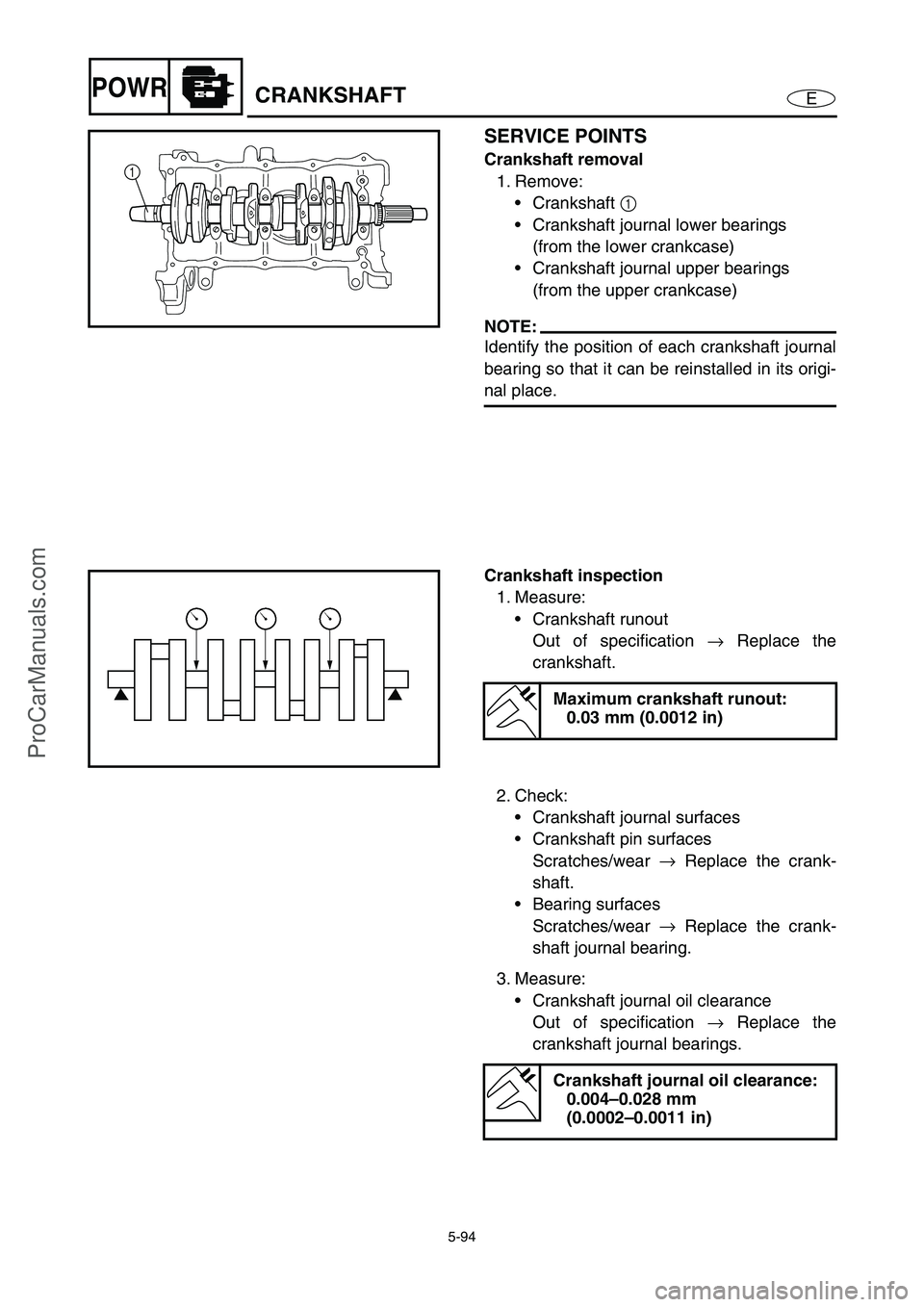

SERVICE POINTS

Crankshaft removal

1. Remove:

Crankshaft 1

Crankshaft journal lower bearings

(from the lower crankcase)

Crankshaft journal upper bearings

(from the upper crankcase)

NOTE:

Identify the position of each crankshaft journal

bearing so that it can be reinstalled in its origi-

nal place.

1

Crankshaft inspection

1. Measure:

Crankshaft runout

Out of specification →

Replace the

crankshaft.

Maximum crankshaft runout:

0.03 mm (0.0012 in)

2. Check:

Crankshaft journal surfaces

Crankshaft pin surfaces

Scratches/wear →

Replace the crank-

shaft.

Bearing surfaces

Scratches/wear →

Replace the crank-

shaft journal bearing.

3. Measure:

Crankshaft journal oil clearance

Out of specification →

Replace the

crankshaft journal bearings.

Crankshaft journal oil clearance:

0.004–0.028 mm

(0.0002–0.0011 in)

ProCarManuals.com

Page 197 of 347

5-98

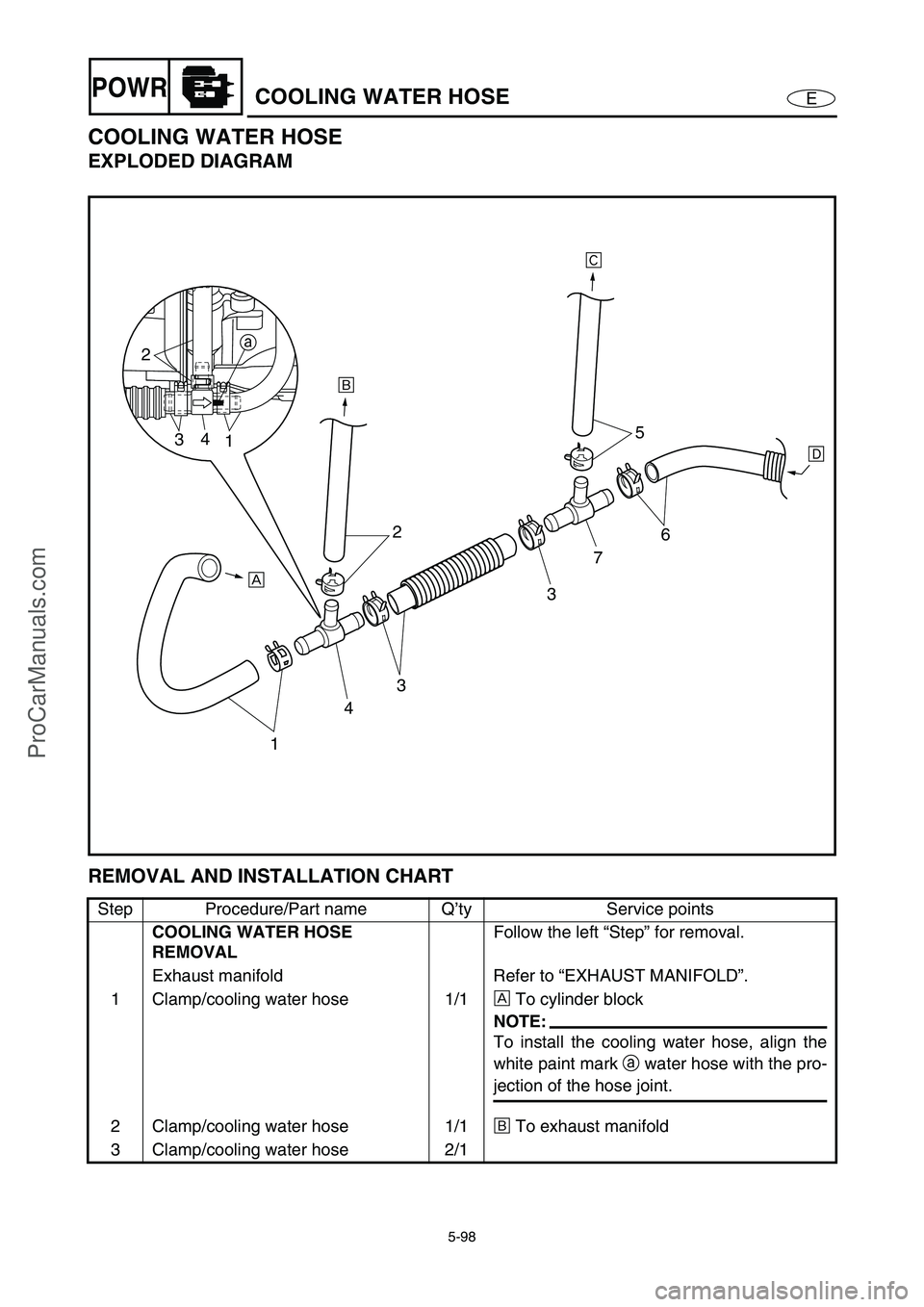

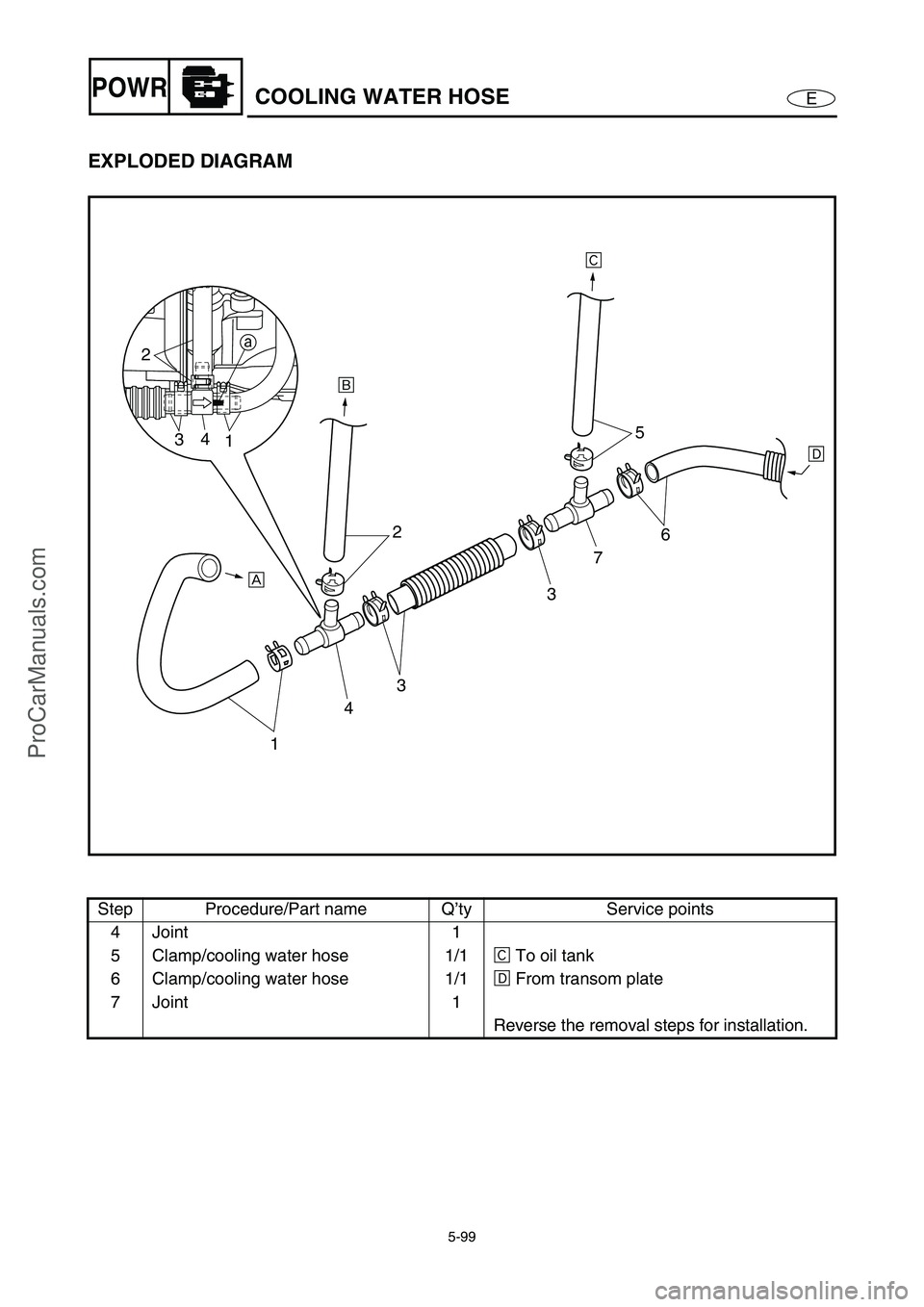

EPOWRCOOLING WATER HOSE

COOLING WATER HOSE

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

COOLING WATER HOSE

REMOVALFollow the left “Step” for removal.

Exhaust manifold Refer to “EXHAUST MANIFOLD”.

1 Clamp/cooling water hose 1/1È

To cylinder block

NOTE:

To install the cooling water hose, align the

white paint mark a

water hose with the pro-

jection of the hose joint.

2 Clamp/cooling water hose 1/1É

To exhaust manifold

3 Clamp/cooling water hose 2/1

143 2

375

6

ÈÉÊ

Ë

a

2

34

1

ProCarManuals.com

Page 198 of 347

5-99

EPOWRCOOLING WATER HOSE

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

4 Joint 1

5 Clamp/cooling water hose 1/1Ê

To oil tank

6 Clamp/cooling water hose 1/1Ë

From transom plate

7 Joint 1

Reverse the removal steps for installation.

143 2

375

6

ÈÉÊ

Ë

a

2

34

1

ProCarManuals.com

Page 199 of 347

E

JET

PUMP

1

2

3

4

5

6

7

8

9

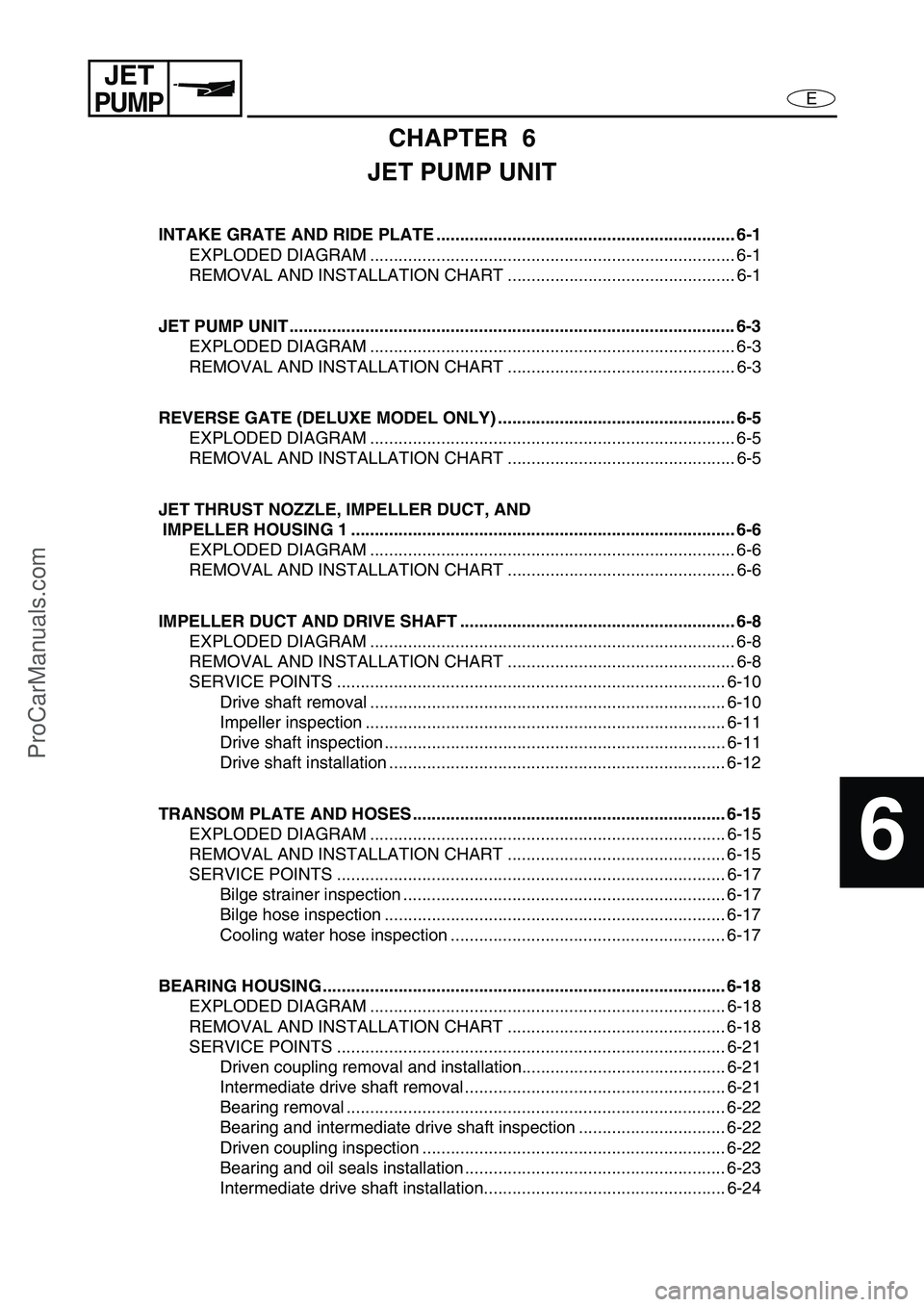

CHAPTER 6

JET PUMP UNIT

INTAKE GRATE AND RIDE PLATE ............................................................... 6-1

EXPLODED DIAGRAM ............................................................................. 6-1

REMOVAL AND INSTALLATION CHART ................................................ 6-1

JET PUMP UNIT .............................................................................................. 6-3

EXPLODED DIAGRAM ............................................................................. 6-3

REMOVAL AND INSTALLATION CHART ................................................ 6-3

REVERSE GATE (DELUXE MODEL ONLY) .................................................. 6-5

EXPLODED DIAGRAM ............................................................................. 6-5

REMOVAL AND INSTALLATION CHART ................................................ 6-5

JET THRUST NOZZLE, IMPELLER DUCT, AND

IMPELLER HOUSING 1 ................................................................................. 6-6

EXPLODED DIAGRAM ............................................................................. 6-6

REMOVAL AND INSTALLATION CHART ................................................ 6-6

IMPELLER DUCT AND DRIVE SHAFT .......................................................... 6-8

EXPLODED DIAGRAM ............................................................................. 6-8

REMOVAL AND INSTALLATION CHART ................................................ 6-8

SERVICE POINTS .................................................................................. 6-10

Drive shaft removal ........................................................................... 6-10

Impeller inspection ............................................................................ 6-11

Drive shaft inspection ........................................................................ 6-11

Drive shaft installation ....................................................................... 6-12

TRANSOM PLATE AND HOSES .................................................................. 6-15

EXPLODED DIAGRAM ........................................................................... 6-15

REMOVAL AND INSTALLATION CHART .............................................. 6-15

SERVICE POINTS .................................................................................. 6-17

Bilge strainer inspection .................................................................... 6-17

Bilge hose inspection ........................................................................ 6-17

Cooling water hose inspection .......................................................... 6-17

BEARING HOUSING ..................................................................................... 6-18

EXPLODED DIAGRAM ........................................................................... 6-18

REMOVAL AND INSTALLATION CHART .............................................. 6-18

SERVICE POINTS .................................................................................. 6-21

Driven coupling removal and installation........................................... 6-21

Intermediate drive shaft removal ....................................................... 6-21

Bearing removal ................................................................................ 6-22

Bearing and intermediate drive shaft inspection ............................... 6-22

Driven coupling inspection ................................................................ 6-22

Bearing and oil seals installation ....................................................... 6-23

Intermediate drive shaft installation................................................... 6-24

ProCarManuals.com

Page 200 of 347

6-1

E

JET

PUMP

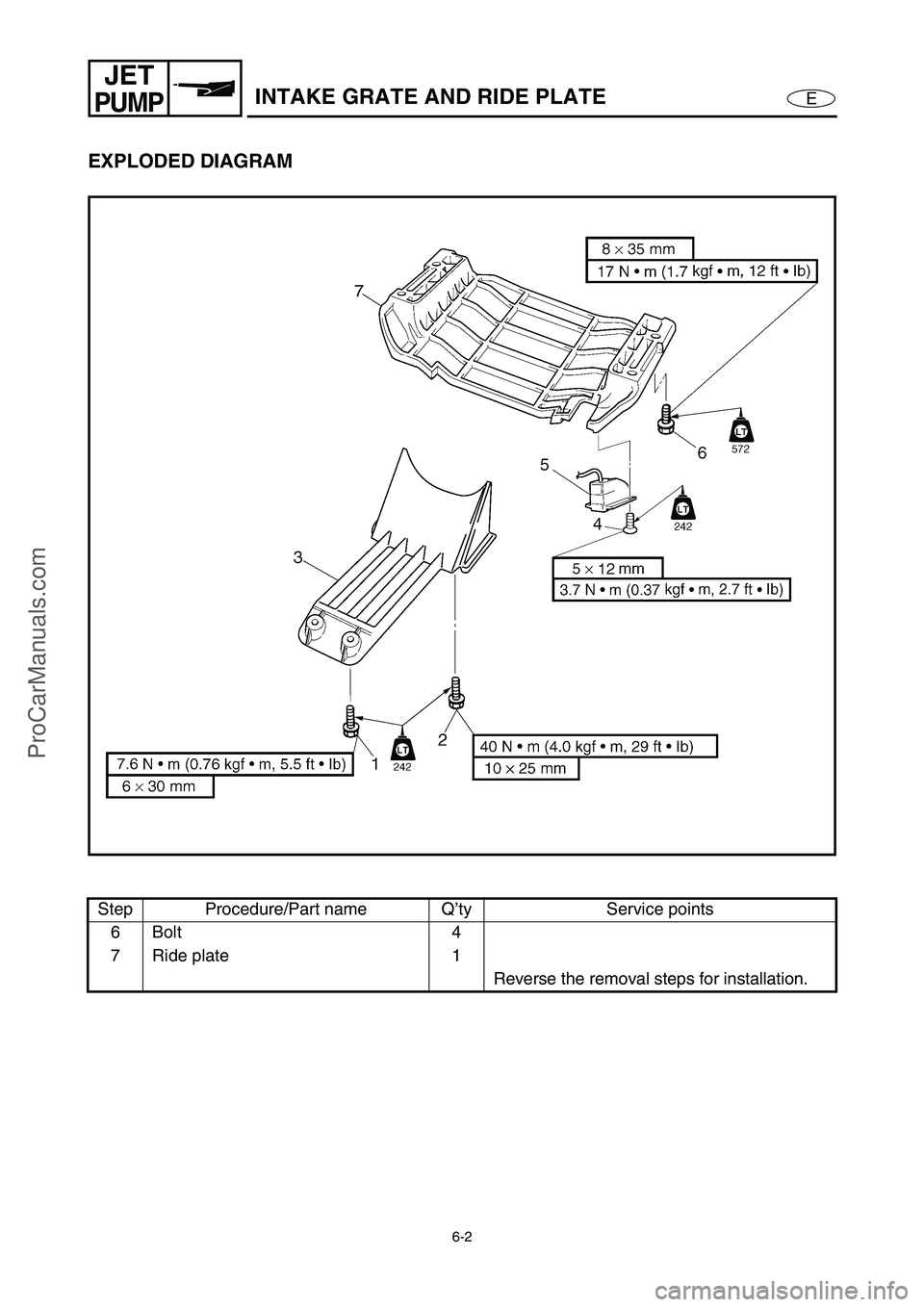

INTAKE GRATE AND RIDE PLATE

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

INTAKE GRATE, RIDE PLATE,

AND INTAKE DUCT REMOVALFollow the left “Step” for removal.

1Bolt 2

2Bolt 2

3 Intake grate 1

4Screw 4

5 Speed sensor 1

NOTE:

Route the speed sensor lead between the

jet pump unit and the bilge hose.

INTAKE GRATE AND RIDE PLATE

ProCarManuals.com

Page 201 of 347

6-2

E

JET

PUMPINTAKE GRATE AND RIDE PLATE

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

6Bolt 4

7 Ride plate 1

Reverse the removal steps for installation.

ProCarManuals.com

Page 202 of 347

6-3

E

JET

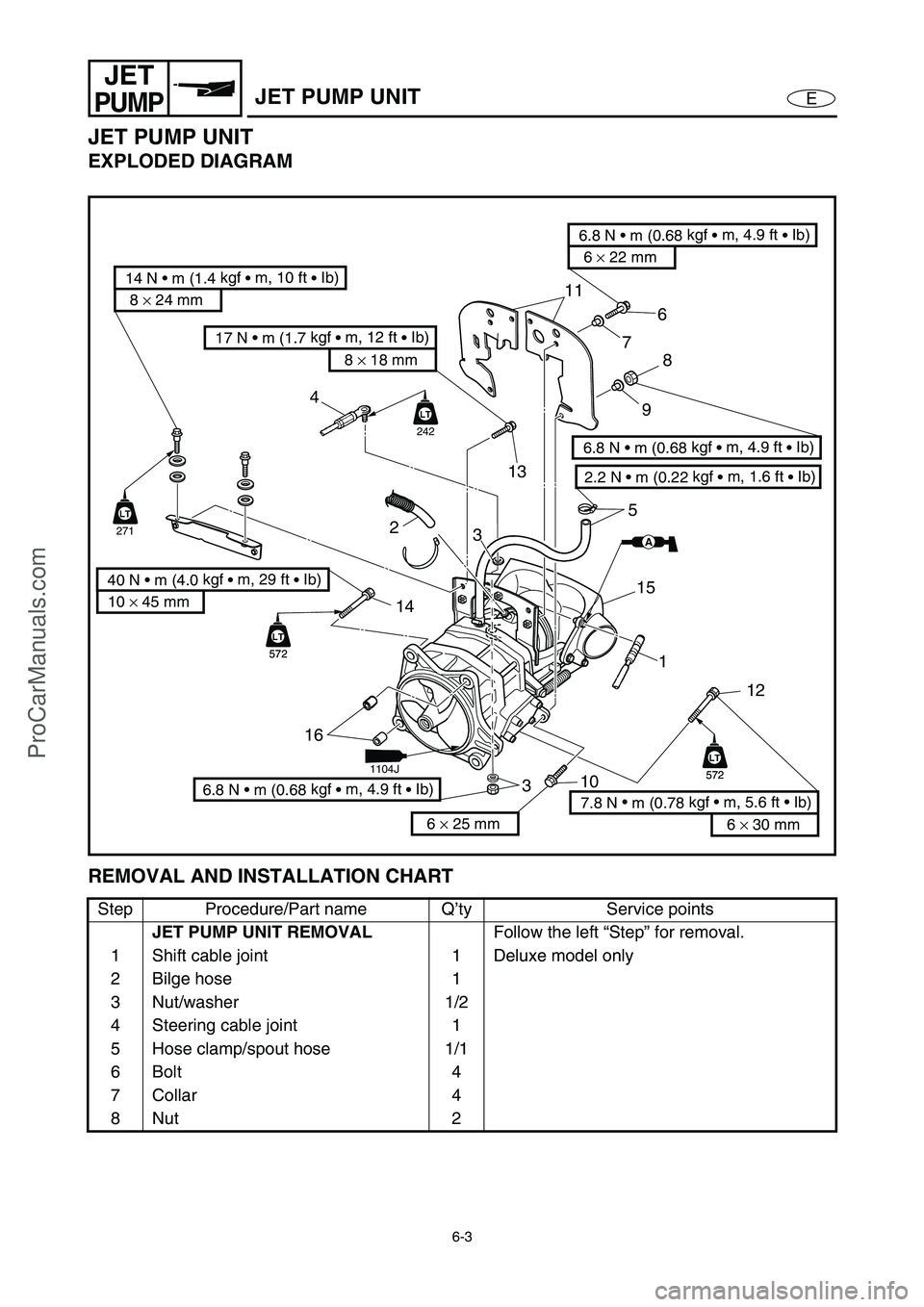

PUMPJET PUMP UNIT

JET PUMP UNIT

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

JET PUMP UNIT REMOVAL

Follow the left “Step” for removal.

1 Shift cable joint 1 Deluxe model only

2 Bilge hose 1

3 Nut/washer 1/2

4 Steering cable joint 1

5 Hose clamp/spout hose 1/1

6Bolt 4

7 Collar 4

8Nut 2

8 × 24 mm

14 N • m (1.4 kgf

• m, 10 ft

• Ib)

6 × 22 mm

6.8 N • m (0.68 kgf

• m, 4.9 ft

• Ib)

2.2 N • m (0.22 kgf

• m, 1.6 ft

• Ib)

6.8 N • m (0.68 kgf

• m, 4.9 ft

• Ib)

10 × 45 mm

40 N • m (4.0 kgf

• m, 29 ft

• Ib)

11

76

5

3

16

312 1 15

LT

572

LT

572

LT

572

LT

572

LT

242

AA

LT

271

LT

4

14

2

10

13

6.8 N • m (0.68 kgf

• m, 4.9 ft

• Ib)

8

9

6 × 30 mm

7.8 N •

m (0.78 kgf • m, 5.6 ft • Ib) 8 × 18 mm

17 N • m (1.7 kgf

• m, 12 ft

• Ib)

6 × 25 mm

1104J

ProCarManuals.com