YAMAHA VX110 2005 Owners Manual

VX110 2005

YAMAHA

YAMAHA

https://www.carmanualsonline.info/img/51/57494/w960_57494-0.png

YAMAHA VX110 2005 Owners Manual

Page 203 of 347

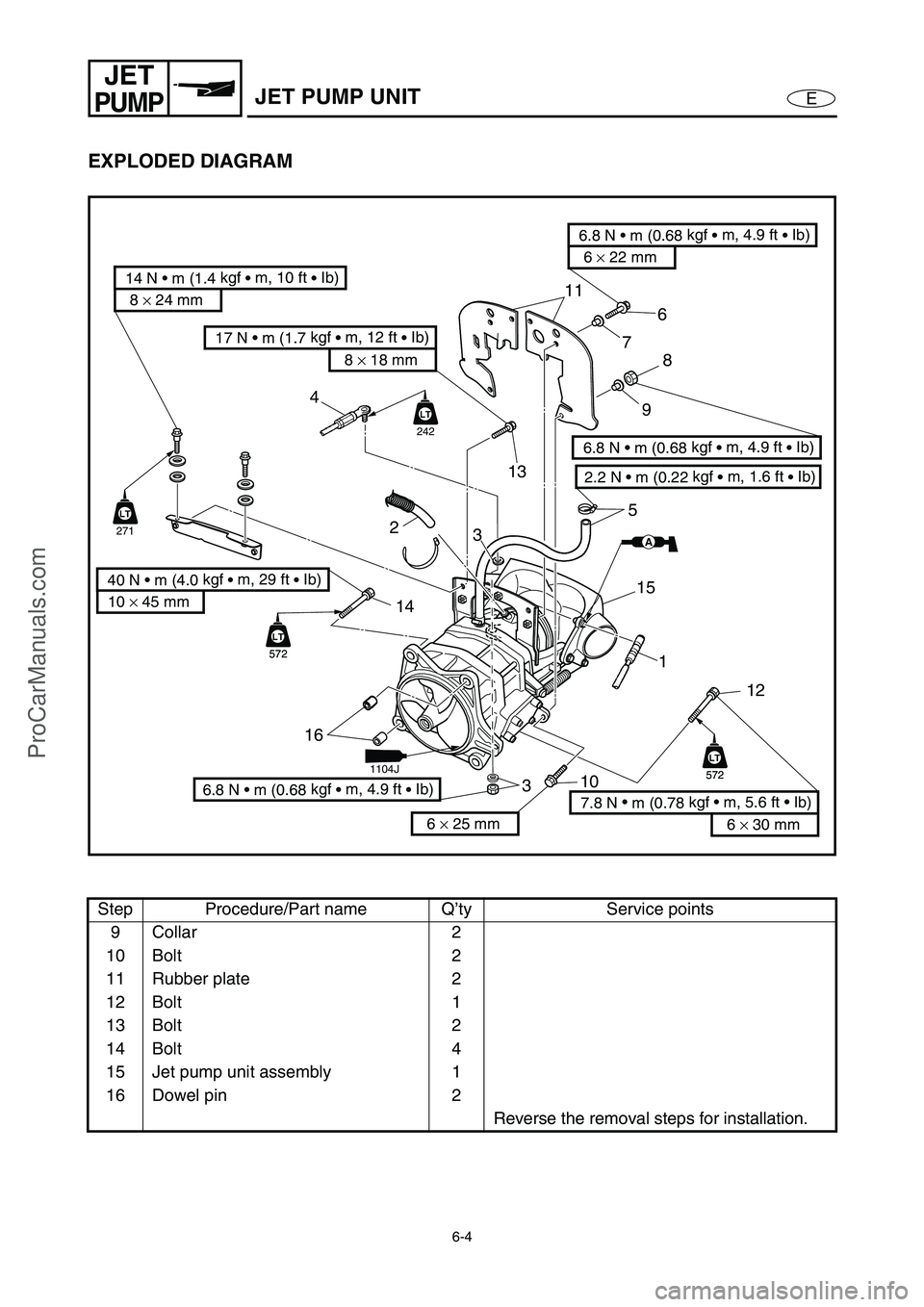

6-4

E

JET

PUMPJET PUMP UNIT

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

9 Collar 2

10 Bolt 2

11 Rubber plate 2

12 Bolt 1

13 Bolt 2

14 Bolt 4

15 Jet pump unit assembly 1

16 Dowel pin 2

Reverse the removal steps for installation.

8 × 24 mm

14 N • m (1.4 kgf

• m, 10 ft

• Ib)

6 × 22 mm

6.8 N • m (0.68 kgf

• m, 4.9 ft

• Ib)

2.2 N • m (0.22 kgf

• m, 1.6 ft

• Ib)

6.8 N • m (0.68 kgf

• m, 4.9 ft

• Ib)

10 × 45 mm

40 N • m (4.0 kgf

• m, 29 ft

• Ib)

11

76

5

3

16

312 1 15

LT

572

LT

572

LT

572

LT

572

LT

242

AA

LT

271

LT

4

14

2

10

13

6.8 N • m (0.68 kgf

• m, 4.9 ft

• Ib)

8

9

6 × 30 mm

7.8 N •

m (0.78 kgf • m, 5.6 ft • Ib) 8 × 18 mm

17 N • m (1.7 kgf

• m, 12 ft

• Ib)

6 × 25 mm

1104J

ProCarManuals.com

Page 204 of 347

6-5

E

JET

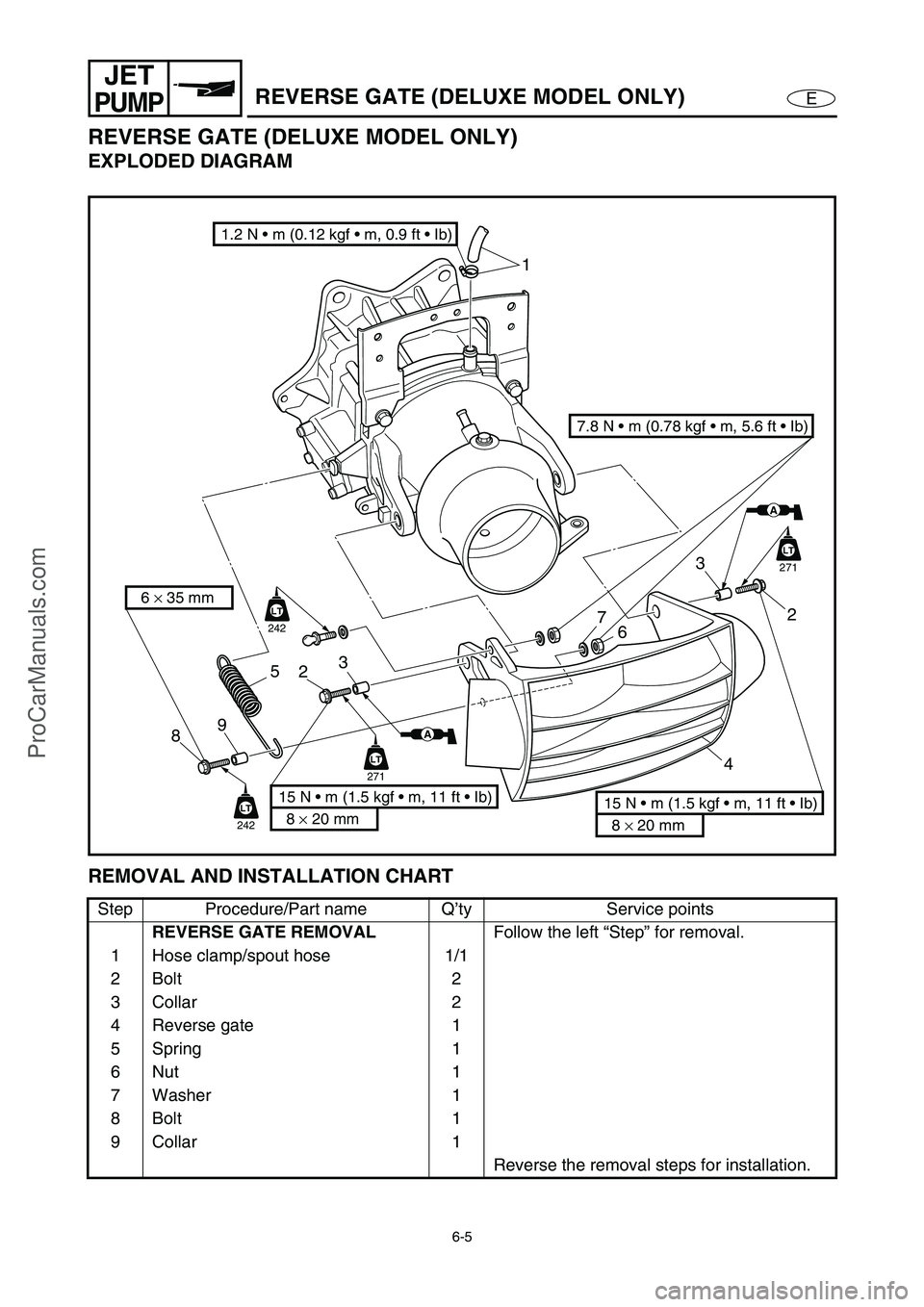

PUMPREVERSE GATE (DELUXE MODEL ONLY)

REVERSE GATE (DELUXE MODEL ONLY)

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

REVERSE GATE REMOVAL

Follow the left “Step” for removal.

1 Hose clamp/spout hose 1/1

2Bolt 2

3 Collar 2

4 Reverse gate 1

5Spring 1

6Nut 1

7 Washer 1

8Bolt 1

9 Collar 1

Reverse the removal steps for installation.

7.8 N • m (0.78 kgf • m, 5.6 ft • Ib)

1.2 N • m (0.12 kgf • m, 0.9 ft • Ib)

6 × 35 mm

8 × 20 mm

15 N • m (1.5 kgf • m, 11 ft • Ib)

AA

LT

271

LT

242

LT

242

LT

271

AA

3

2

7

6

23

5

9

81

4

8 × 20 mm

15 N • m (1.5 kgf • m, 11 ft • Ib)

ProCarManuals.com

Page 205 of 347

6-6

E

JET

PUMP

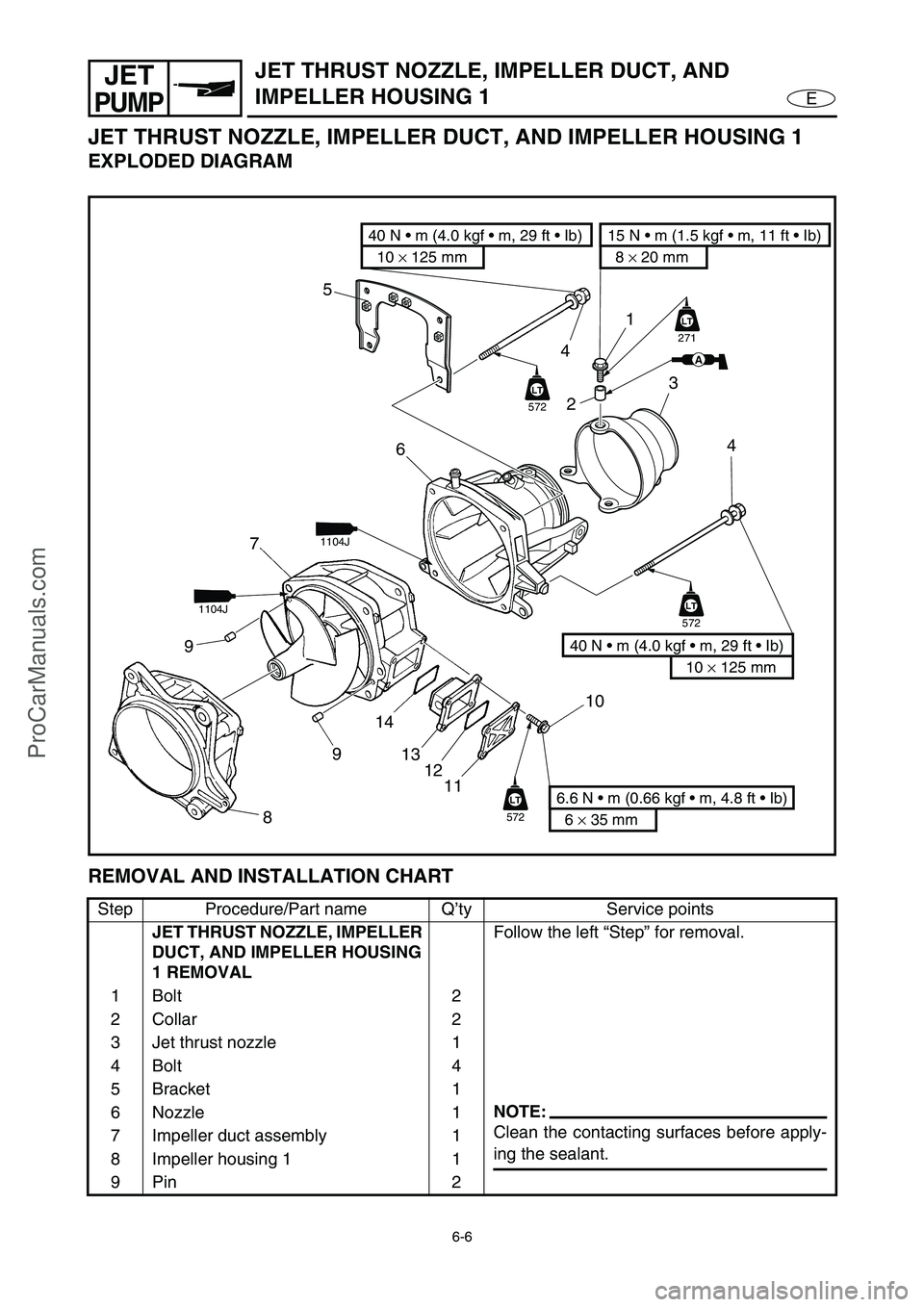

JET THRUST NOZZLE, IMPELLER DUCT, AND

IMPELLER HOUSING 1

JET THRUST NOZZLE, IMPELLER DUCT, AND IMPELLER HOUSING 1

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

JET THRUST NOZZLE, IMPELLER

DUCT, AND IMPELLER HOUSING

1 REMOVALFollow the left “Step” for removal.

1Bolt 2

2 Collar 2

3 Jet thrust nozzle 1

4Bolt 4

5Bracket 1

6Nozzle 1

NOTE:

Clean the contacting surfaces before apply-

ing the sealant. 7 Impeller duct assembly 1

8 Impeller housing 1 1

9Pin 2

10 × 125 mm

40 N • m (4.0 kgf • m, 29 ft • Ib)

6 × 35 mm

6.6 N • m (0.66 kgf • m, 4.8 ft • Ib)

10

11 12 13 14

9 97

LT

572

LT

LT

572

LT

LT

572

LT

8

10 × 125 mm

40 N • m (4.0 kgf • m, 29 ft • Ib)

1

23

4

4

6 5

8 × 20 mm

15 N • m (1.5 kgf • m, 11 ft • Ib)

LT

271

AA

1104J

1104J

ProCarManuals.com

Page 206 of 347

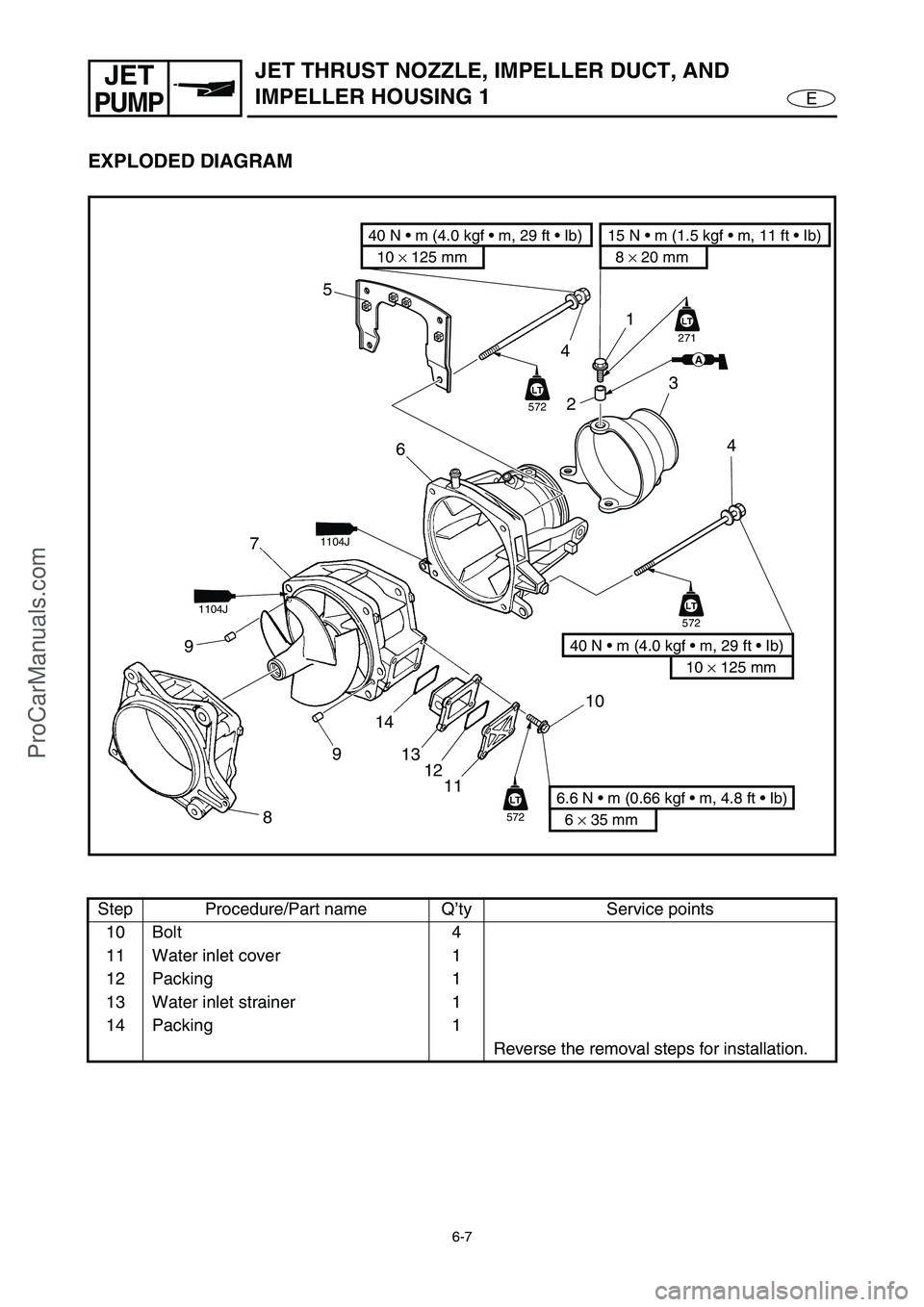

6-7

E

JET

PUMP

JET THRUST NOZZLE, IMPELLER DUCT, AND

IMPELLER HOUSING 1

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

10 Bolt 4

11 Water inlet cover 1

12 Packing 1

13 Water inlet strainer 1

14 Packing 1

Reverse the removal steps for installation.

10 × 125 mm

40 N • m (4.0 kgf • m, 29 ft • Ib)

6 × 35 mm

6.6 N • m (0.66 kgf • m, 4.8 ft • Ib)

10

11 12 13 14

9 97

LT

572

LT

LT

572

LT

LT

572

LT

8

10 × 125 mm

40 N • m (4.0 kgf • m, 29 ft • Ib)

1

23

4

4

6 5

8 × 20 mm

15 N • m (1.5 kgf • m, 11 ft • Ib)

LT

271

AA

1104J

1104J

ProCarManuals.com

Page 207 of 347

6-8

E

JET

PUMPIMPELLER DUCT AND DRIVE SHAFT

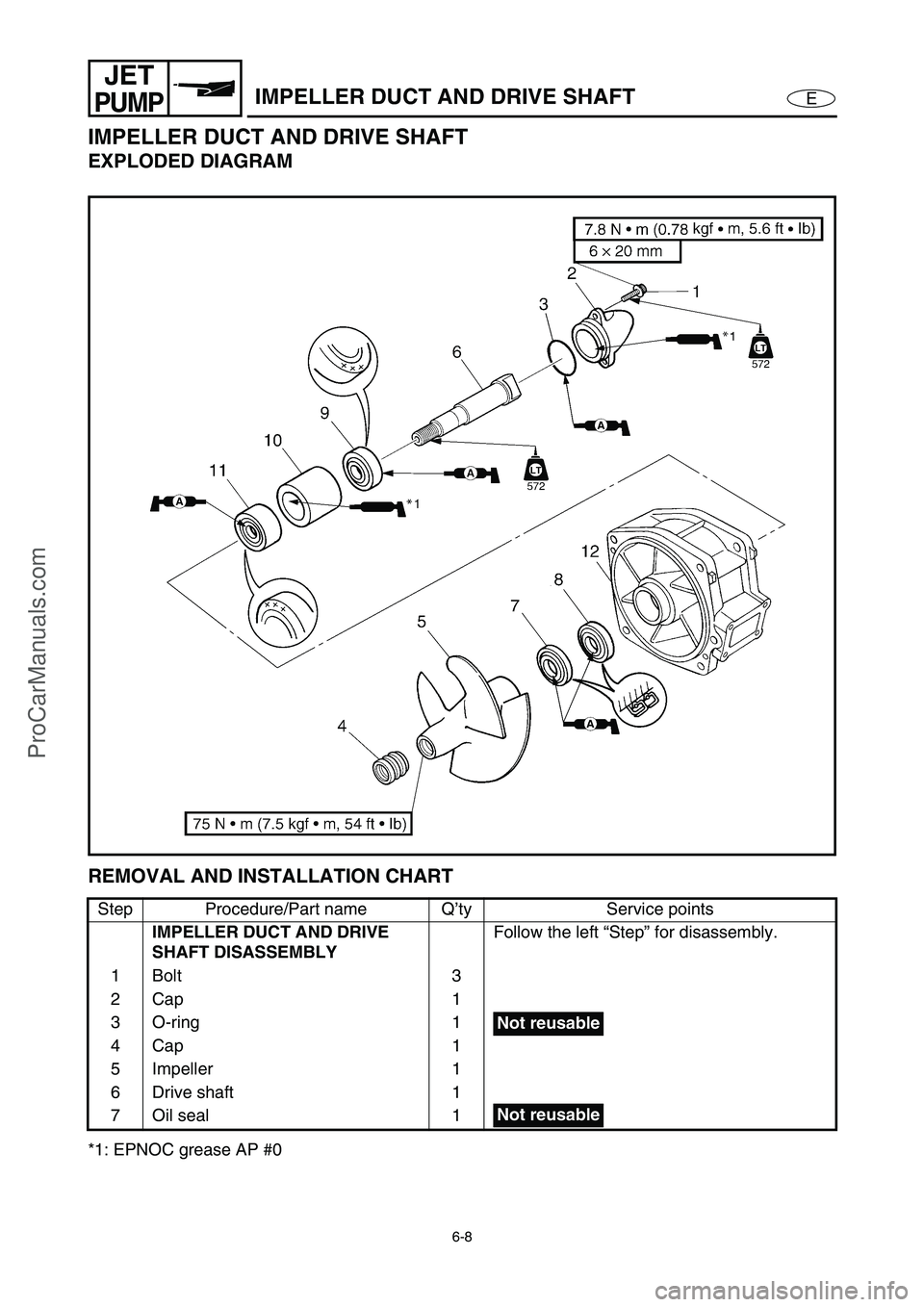

IMPELLER DUCT AND DRIVE SHAFT

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

*1: EPNOC grease AP #0Step Procedure/Part name Q’ty Service points

IMPELLER DUCT AND DRIVE

SHAFT DISASSEMBLYFollow the left “Step” for disassembly.

1Bolt 3

2Cap 1

3 O-ring 1

4Cap 1

5 Impeller 1

6 Drive shaft 1

7 Oil seal 1

Not reusable

Not reusable

ProCarManuals.com

Page 208 of 347

6-9

E

JET

PUMPIMPELLER DUCT AND DRIVE SHAFT

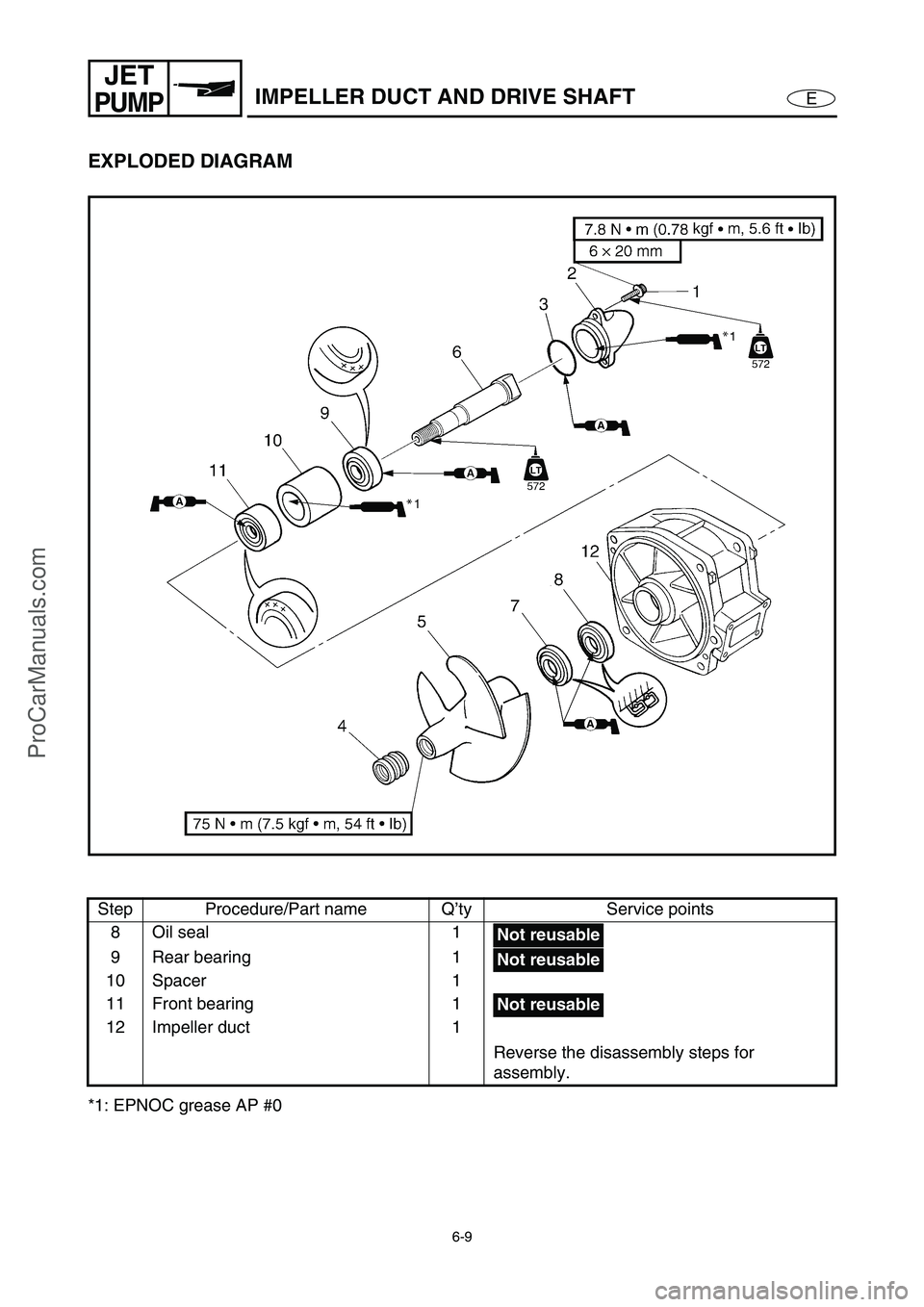

EXPLODED DIAGRAM

*1: EPNOC grease AP #0Step Procedure/Part name Q’ty Service points

8 Oil seal 1

9 Rear bearing 1

10 Spacer 1

11 Front bearing 1

12 Impeller duct 1

Reverse the disassembly steps for

assembly.

Not reusable

Not reusable

Not reusable

ProCarManuals.com

Page 209 of 347

6-10

E

JET

PUMPIMPELLER DUCT AND DRIVE SHAFT

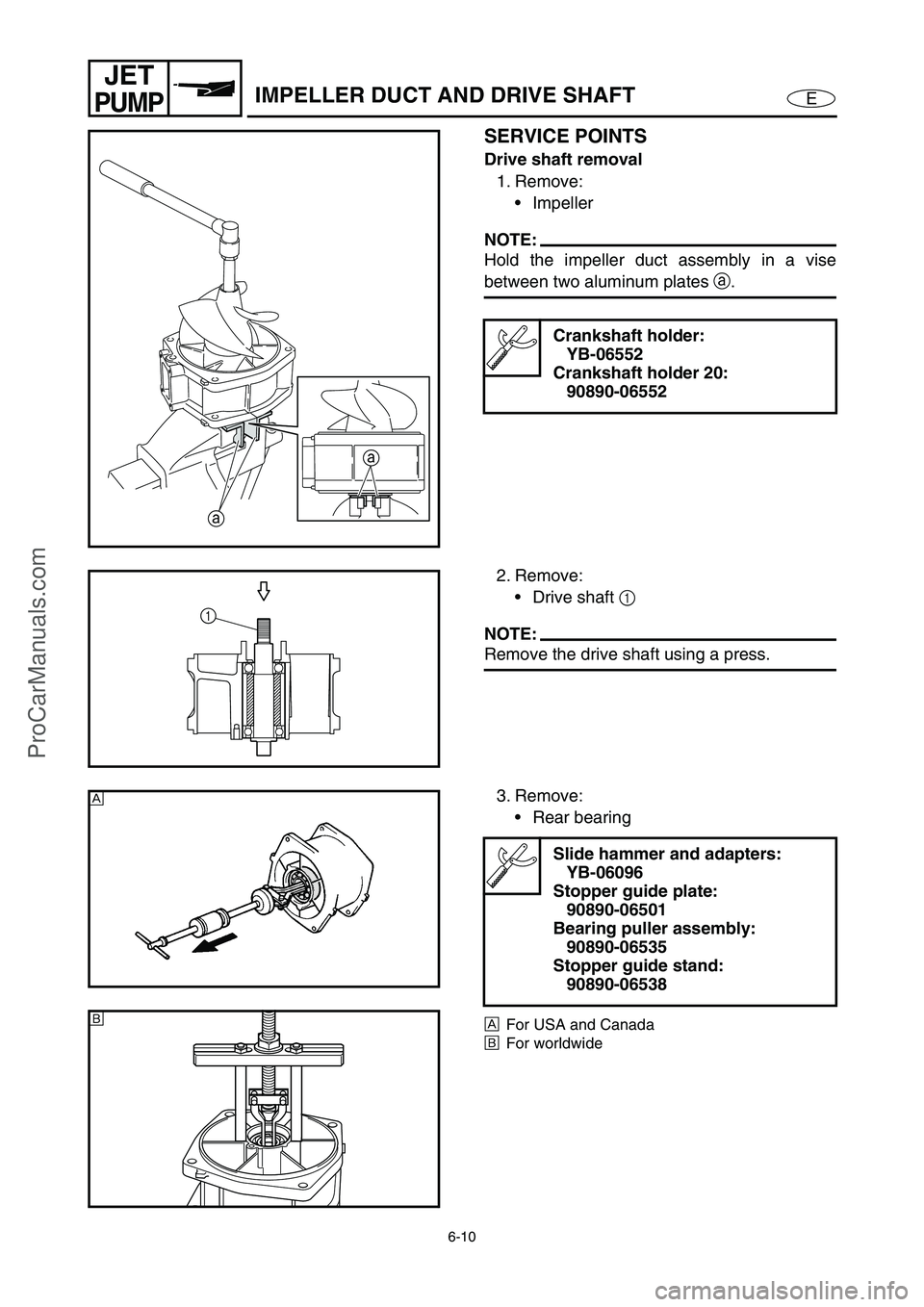

SERVICE POINTS

Drive shaft removal

1. Remove:

Impeller

NOTE:

Hold the impeller duct assembly in a vise

between two aluminum plates a

.

Crankshaft holder:

YB-06552

Crankshaft holder 20:

90890-06552

a

a

2. Remove:

Drive shaft 1

NOTE:

Remove the drive shaft using a press.

1

3. Remove:

Rear bearing

ÈFor USA and Canada

ÉFor worldwide

Slide hammer and adapters:

YB-06096

Stopper guide plate:

90890-06501

Bearing puller assembly:

90890-06535

Stopper guide stand:

90890-06538

È

É

ProCarManuals.com

Page 214 of 347

6-15

E

JET

PUMPTRANSOM PLATE AND HOSES

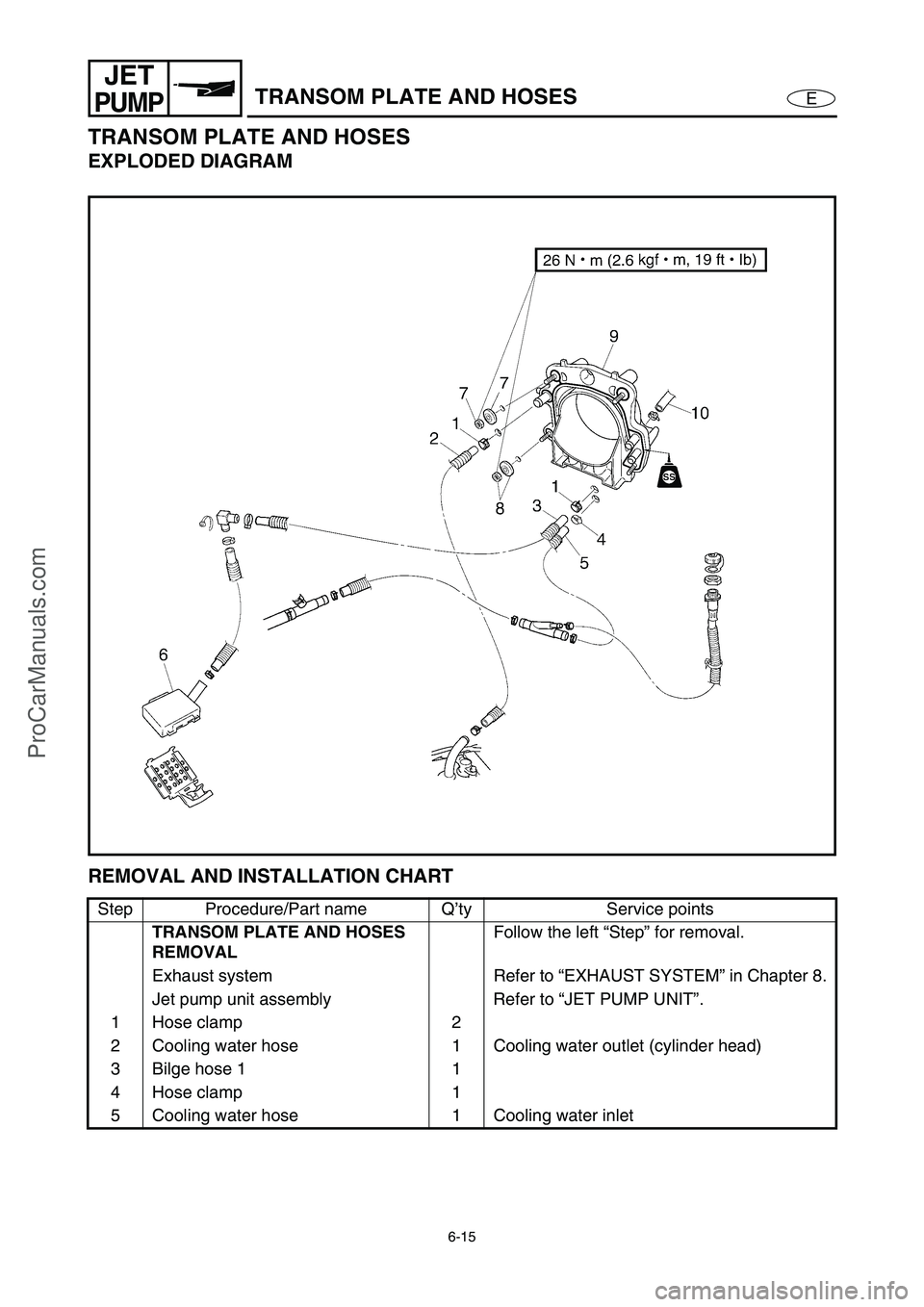

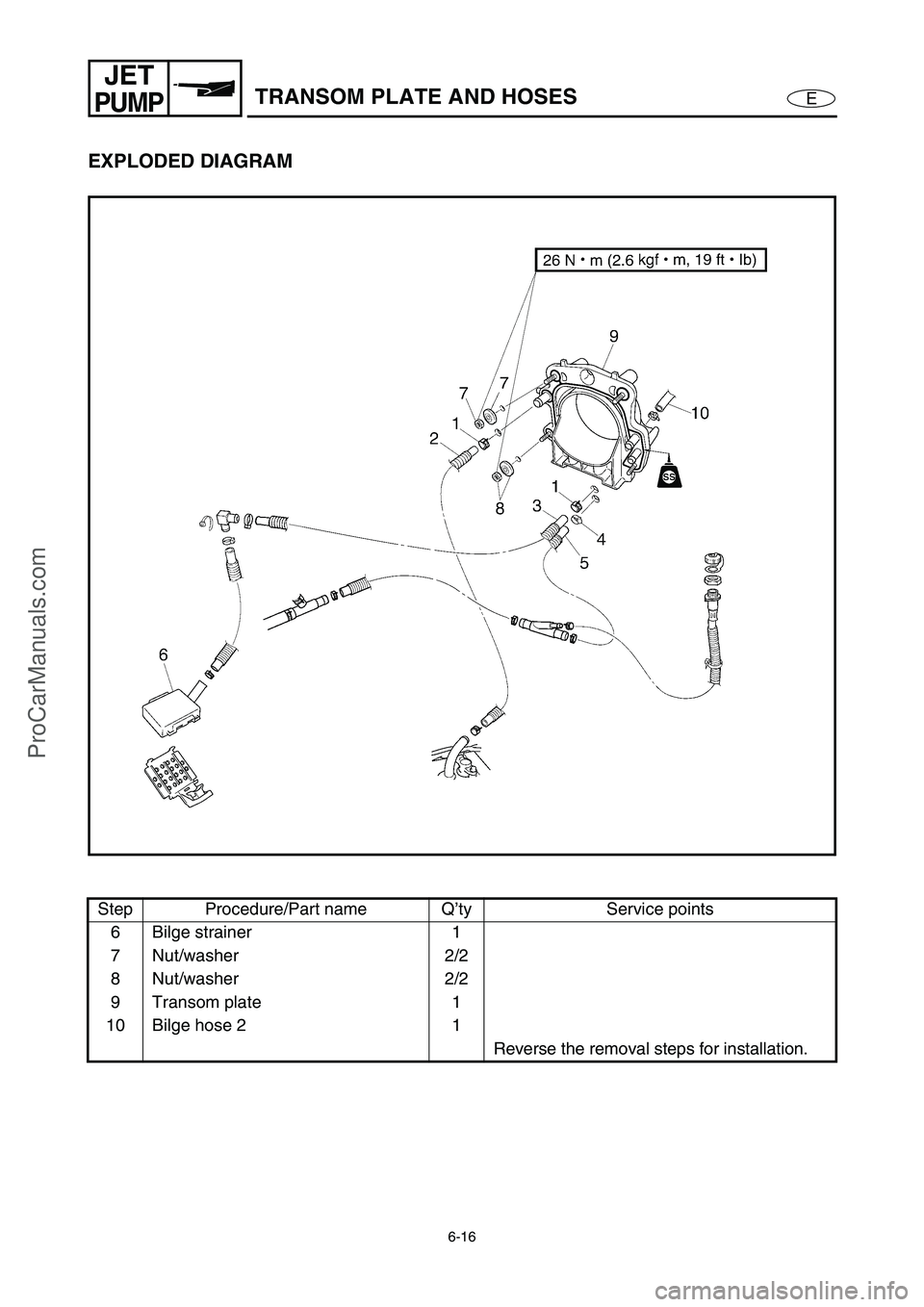

TRANSOM PLATE AND HOSES

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

TRANSOM PLATE AND HOSES

REMOVALFollow the left “Step” for removal.

Exhaust system Refer to “EXHAUST SYSTEM” in Chapter 8.

Jet pump unit assembly Refer to “JET PUMP UNIT”.

1 Hose clamp 2

2 Cooling water hose 1 Cooling water outlet (cylinder head)

3 Bilge hose 1 1

4 Hose clamp 1

5 Cooling water hose 1 Cooling water inlet

ProCarManuals.com

Page 215 of 347

6-16

E

JET

PUMPTRANSOM PLATE AND HOSES

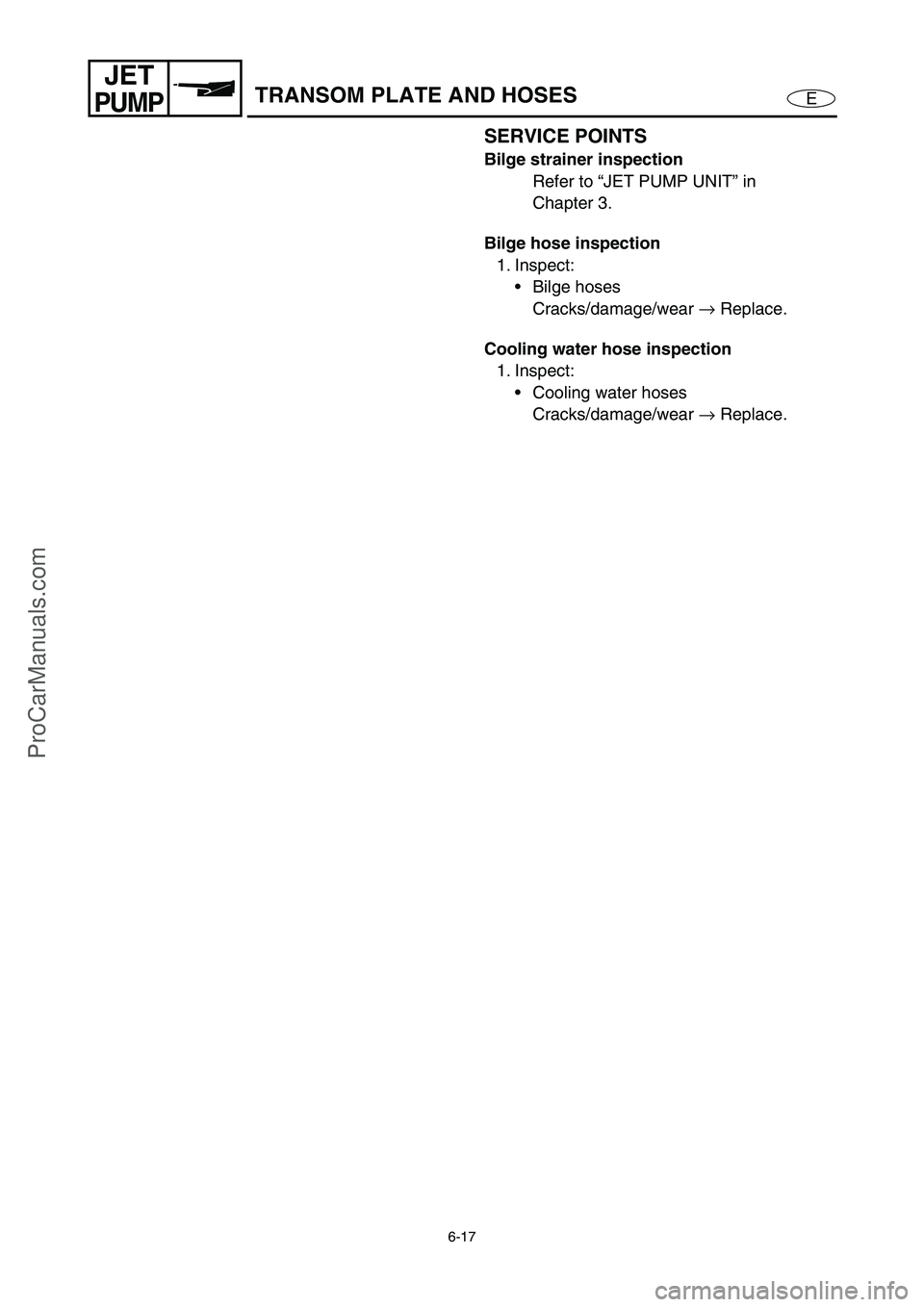

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

6 Bilge strainer 1

7 Nut/washer 2/2

8 Nut/washer 2/2

9 Transom plate 1

10 Bilge hose 2 1

Reverse the removal steps for installation.

ProCarManuals.com

Page 216 of 347

6-17

E

JET

PUMPTRANSOM PLATE AND HOSES

SERVICE POINTS

Bilge strainer inspection

Refer to “JET PUMP UNIT” in

Chapter 3.

Bilge hose inspection

1. Inspect:

Bilge hoses

Cracks/damage/wear →

Replace.

Cooling water hose inspection

1. Inspect:

Cooling water hoses

Cracks/damage/wear →

Replace.

ProCarManuals.com