YAMAHA WR 250F 2009 Owners Manual

Manufacturer: YAMAHA, Model Year: 2009, Model line: WR 250F, Model: YAMAHA WR 250F 2009Pages: 224, PDF Size: 13.93 MB

Page 101 of 224

5-5

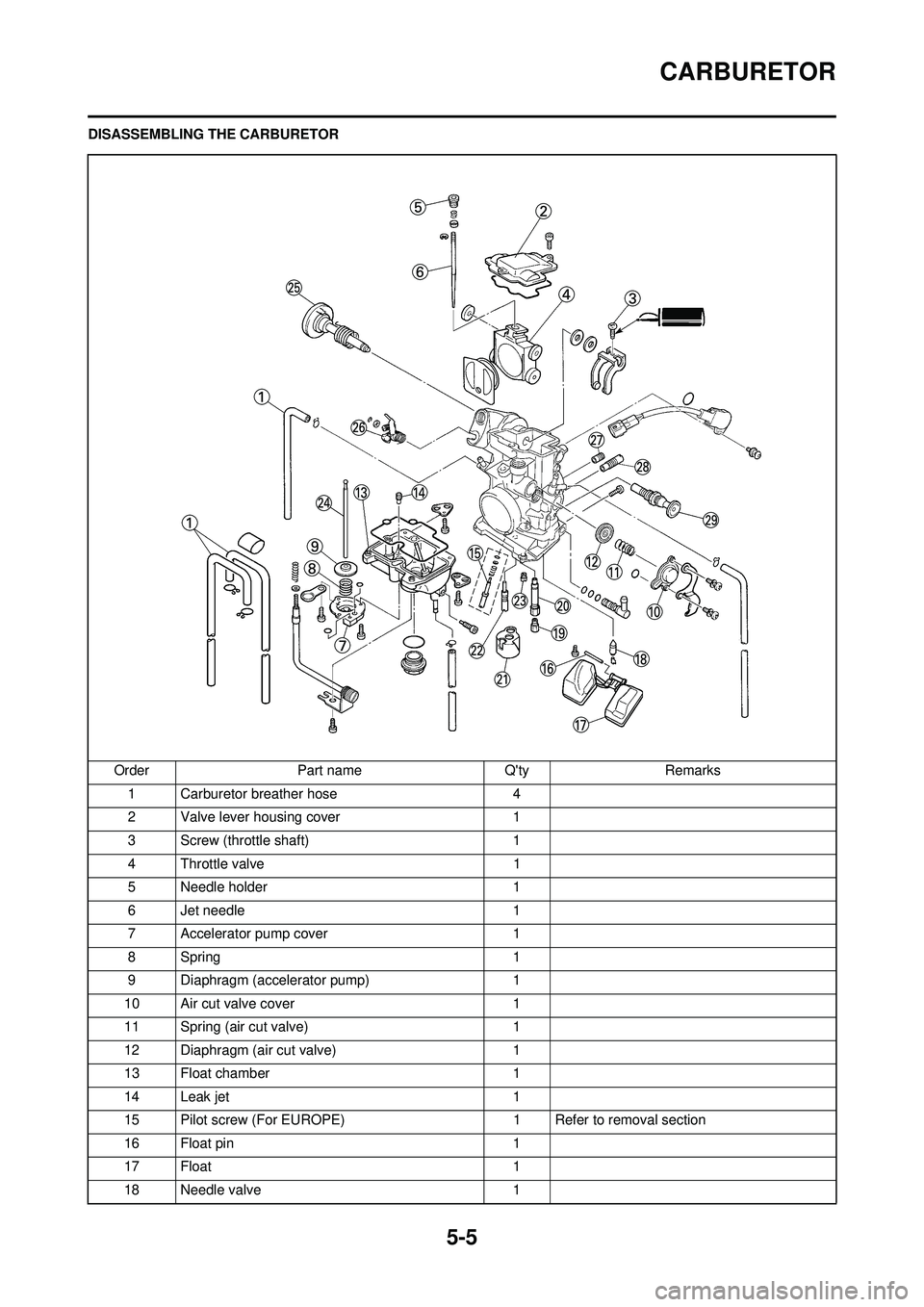

CARBURETOR

DISASSEMBLING THE CARBURETOROrder Part name Q'ty Remarks1 Carburetor breather hose 4

2 Valve lever housing cover 1

3 Screw (throttle shaft) 1

4 Throttle valve 1

5 Needle holder 1

6 Jet needle 1

7 Accelerator pump cover 1

8Spring 1

9 Diaphragm (accelerator pump) 1

10 Air cut valve cover 1

11 Spring (air cut valve) 1

12 Diaphragm (air cut valve) 1

13 Float chamber 1

14 Leak jet 1

15 Pilot screw (For EUROPE) 1 Refer to removal section

16 Float pin 1

17 Float 1

18 Needle valve 1

Page 102 of 224

5-6

CARBURETOR

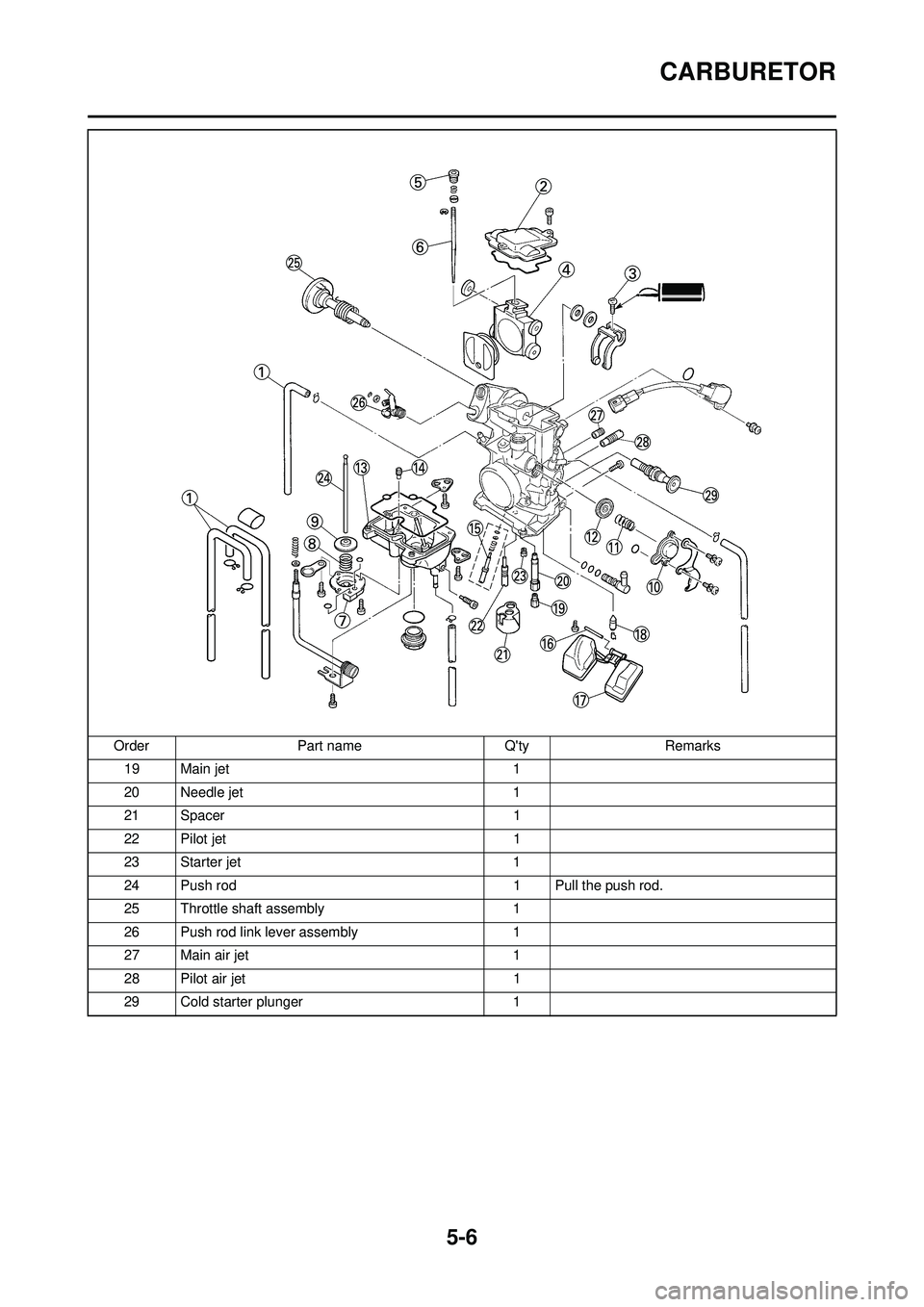

19 Main jet1

20 Needle jet 1

21 Spacer 1

22 Pilot jet 1

23 Starter jet 1

24 Push rod 1 Pull the push rod.

25 Throttle shaft assembly 1

26 Push rod link lever assembly 1

27 Main air jet 1

28 Pilot air jet 1

29 Cold starter plunger 1

Order

Part name Q'tyRemarks

Page 103 of 224

5-7

CARBURETOR

HANDLING NOTE

Do not loosen the screw (throttle

position sensor) "1" except when

changing the throttle position sen-

sor due to failure because it will

cause a drop in engine perfor-

mance.

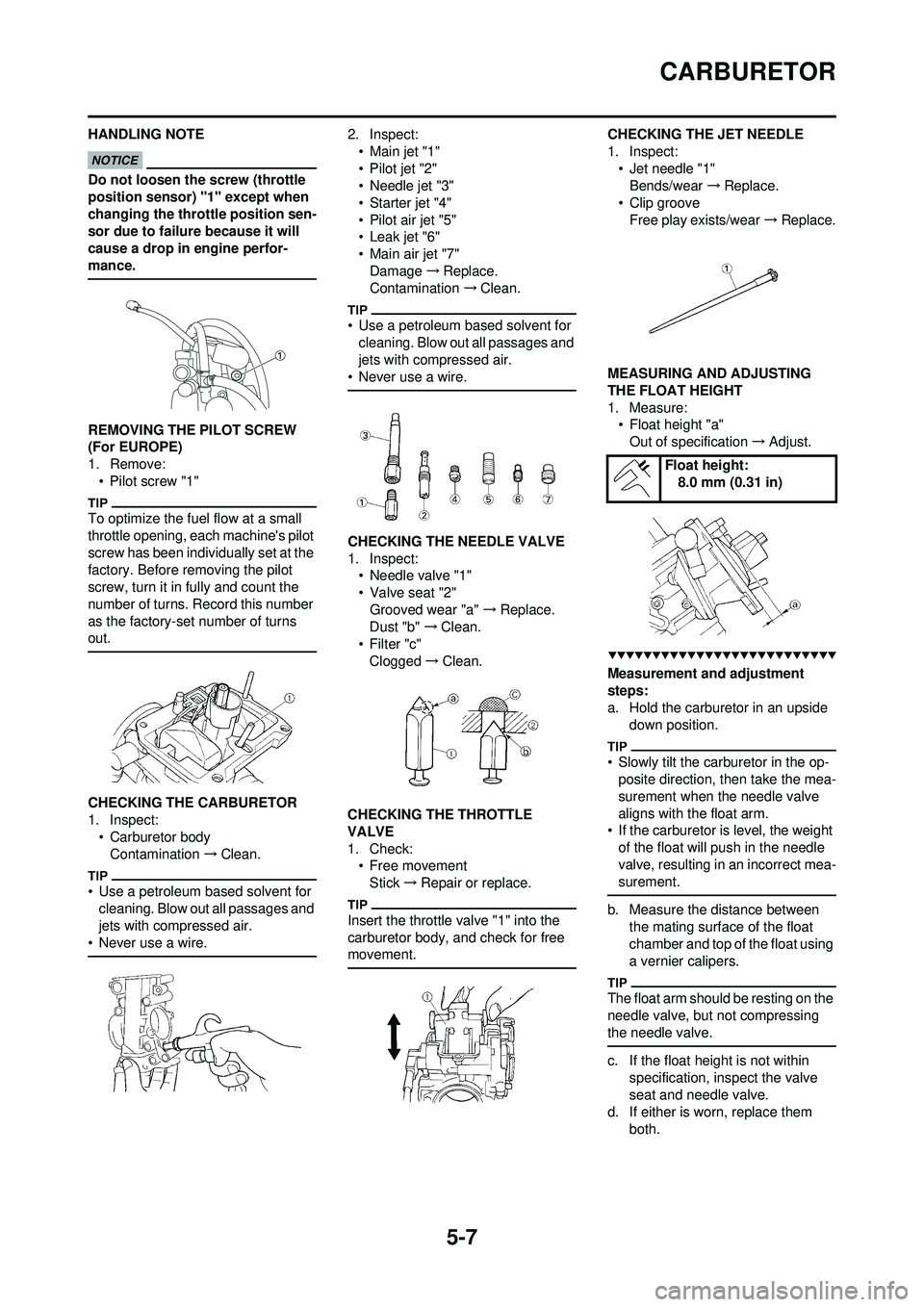

REMOVING THE PILOT SCREW

(For EUROPE)

1. Remove:• Pilot screw "1"

To optimize the fuel flow at a small

throttle opening, each machine's pilot

screw has been individually set at the

factory. Before removing the pilot

screw, turn it in fully and count the

number of turns. Record this number

as the factory-set number of turns

out.

CHECKING THE CARBURETOR

1. Inspect:• Carburetor body

Contamination →Clean.

• Use a petroleum based solvent for

cleaning. Blow out all passages and

jets with compressed air.

• Never use a wire.

2. Inspect: •Main jet "1"

• Pilot jet "2"

• Needle jet "3"

• Starter jet "4"

• Pilot air jet "5"

•Leak jet "6"

• Main air jet "7"Damage →Replace.

Contamination →Clean.

• Use a petroleum based solvent for

cleaning. Blow out all passages and

jets with compressed air.

• Never use a wire.

CHECKING THE NEEDLE VALVE

1. Inspect: • Needle valve "1"

• Valve seat "2"

Grooved wear "a" →Replace.

Dust "b" →Clean.

•Filter "c" Clogged →Clean.

CHECKING THE THROTTLE

VALVE

1. Check: • Free movement

Stick →Repair or replace.

Insert the throttle valve "1" into the

carburetor body, and check for free

movement.

CHECKING THE JET NEEDLE

1. Inspect:

•Jet needle "1"Bends/wear →Replace.

• Clip groove Free play exists/wear →Replace.

MEASURING AND ADJUSTING

THE FLOAT HEIGHT

1. Measure: • Float height "a"

Out of specification →Adjust.

Measurement and adjustment

steps:

a. Hold the carburetor in an upside

down position.

• Slowly tilt the carburetor in the op-posite direction, then take the mea-

surement when the needle valve

aligns with the float arm.

• If the carburetor is level, the weight

of the float will push in the needle

valve, resulting in an incorrect mea-

surement.

b. Measure the distance between the mating surface of the float

chamber and top of the float using

a vernier calipers.

The float arm should be resting on the

needle valve, but not compressing

the needle valve.

c. If the float height is not within specification, inspect the valve

seat and needle valve.

d. If either is worn, replace them

both.

Float height:8.0 mm (0.31 in)

Page 104 of 224

5-8

CARBURETOR

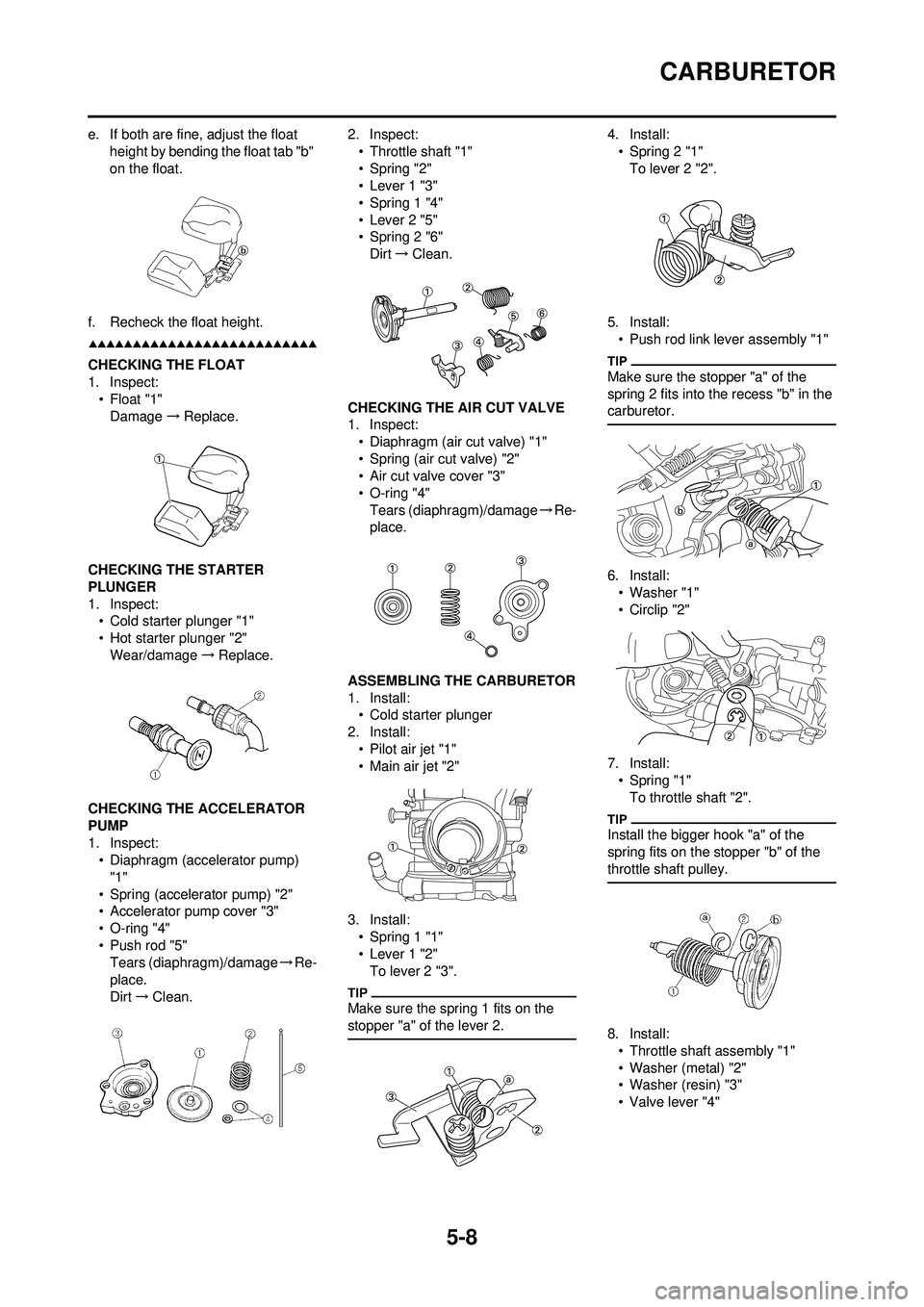

e. If both are fine, adjust the float height by bending the float tab "b"

on the float.

f. Recheck the float height.

CHECKING THE FLOAT

1. Inspect: •Float "1"Damage →Replace.

CHECKING THE STARTER

PLUNGER

1. Inspect: • Cold starter plunger "1"

• Hot starter plunger "2"

Wear/damage →Replace.

CHECKING THE ACCELERATOR

PUMP

1. Inspect: • Diaphragm (accelerator pump)

"1"

• Spring (accelerator pump) "2"

• Accelerator pump cover "3"

• O-ring "4"

• Push rod "5" Tears (diaphragm)/damage →Re-

place.

Dirt →Clean. 2. Inspect:

• Throttle shaft "1"

• Spring "2"

• Lever 1 "3"

• Spring 1 "4"

• Lever 2 "5"

• Spring 2 "6"Dirt →Clean.

CHECKING THE AIR CUT VALVE

1. Inspect: • Diaphragm (air cut valve) "1"

• Spring (air cut valve) "2"

• Air cut valve cover "3"

• O-ring "4"Tears (diaphragm)/damage →Re-

place.

ASSEMBLING THE CARBURETOR

1. Install: • Cold starter plunger

2. Install: • Pilot air jet "1"

• Main air jet "2"

3. Install: • Spring 1 "1"

• Lever 1 "2"

To lever 2 "3".

Make sure the spring 1 fits on the

stopper "a" of the lever 2.

4. Install:• Spring 2 "1"To lever 2 "2".

5. Install: • Push rod link lever assembly "1"

Make sure the stopper "a" of the

spring 2 fits into the recess "b" in the

carburetor.

6. Install:• Washer "1"

•Circlip "2"

7. Install: • Spring "1"To throttle shaft "2".

Install the bigger hook "a" of the

spring fits on the stopper "b" of the

throttle shaft pulley.

8. Install:

• Throttle shaft assembly "1"

• Washer (metal) "2"

• Washer (resin) "3"

• Valve lever "4"

Page 105 of 224

5-9

CARBURETOR

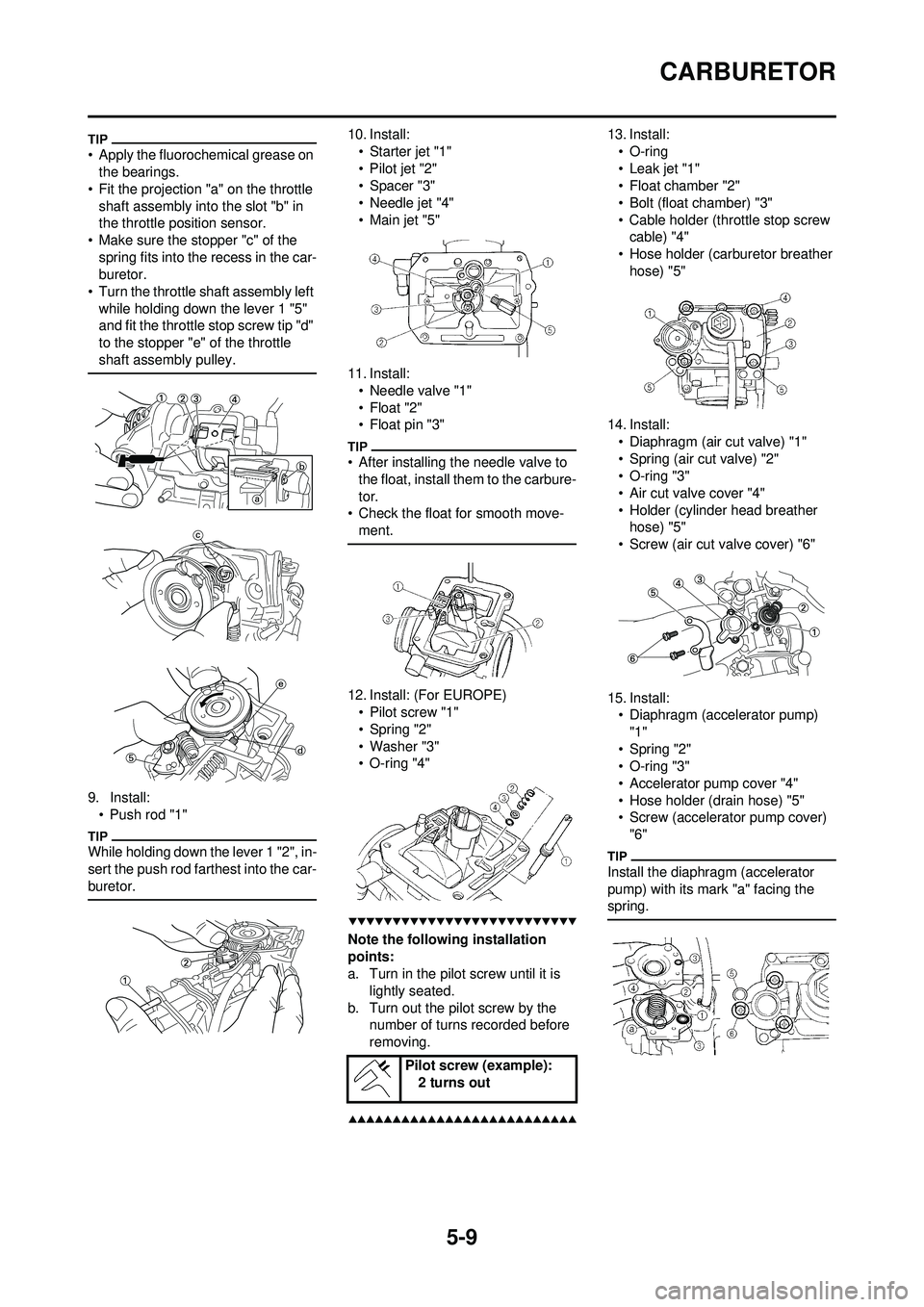

• Apply the fluorochemical grease on the bearings.

• Fit the projection "a" on the throttle shaft assembly into the slot "b" in

the throttle position sensor.

• Make sure the stopper "c" of the spring fits into the recess in the car-

buretor.

• Turn the throttle shaft assembly left while holding down the lever 1 "5"

and fit the throttle stop screw tip "d"

to the stopper "e" of the throttle

shaft assembly pulley.

9. Install:• Push rod "1"

While holding down the lever 1 "2", in-

sert the push rod farthest into the car-

buretor.

10. Install:• Starter jet "1"

• Pilot jet "2"

•Spacer "3"

• Needle jet "4"

•Main jet "5"

11. Install: • Needle valve "1"

• Float "2"

• Float pin "3"

• After installing the needle valve to the float, install them to the carbure-

tor.

• Check the float for smooth move-

ment.

12. Install: (For EUROPE)• Pilot screw "1"

• Spring "2"

•Washer "3"

• O-ring "4"

Note the following installation

points:

a. Turn in the pilot screw until it is

lightly seated.

b. Turn out the pilot screw by the number of turns recorded before

removing.

13. Install:

• O-ring

• Leak jet "1"

• Float chamber "2"

• Bolt (float chamber) "3"

• Cable holder (throttle stop screw cable) "4"

• Hose holder (carburetor breather hose) "5"

14. Install: • Diaphragm (air cut valve) "1"

• Spring (air cut valve) "2"

• O-ring "3"

• Air cut valve cover "4"

• Holder (cylinder head breather hose) "5"

• Screw (air cut valve cover) "6"

15. Install: • Diaphragm (accelerator pump)

"1"

• Spring "2"

• O-ring "3"

• Accelerator pump cover "4"

• Hose holder (drain hose) "5"

• Screw (accelerator pump cover) "6"

Install the diaphragm (accelerator

pump) with its mark "a" facing the

spring.

Pilot screw (example): 2 turns out

Page 106 of 224

5-10

CARBURETOR

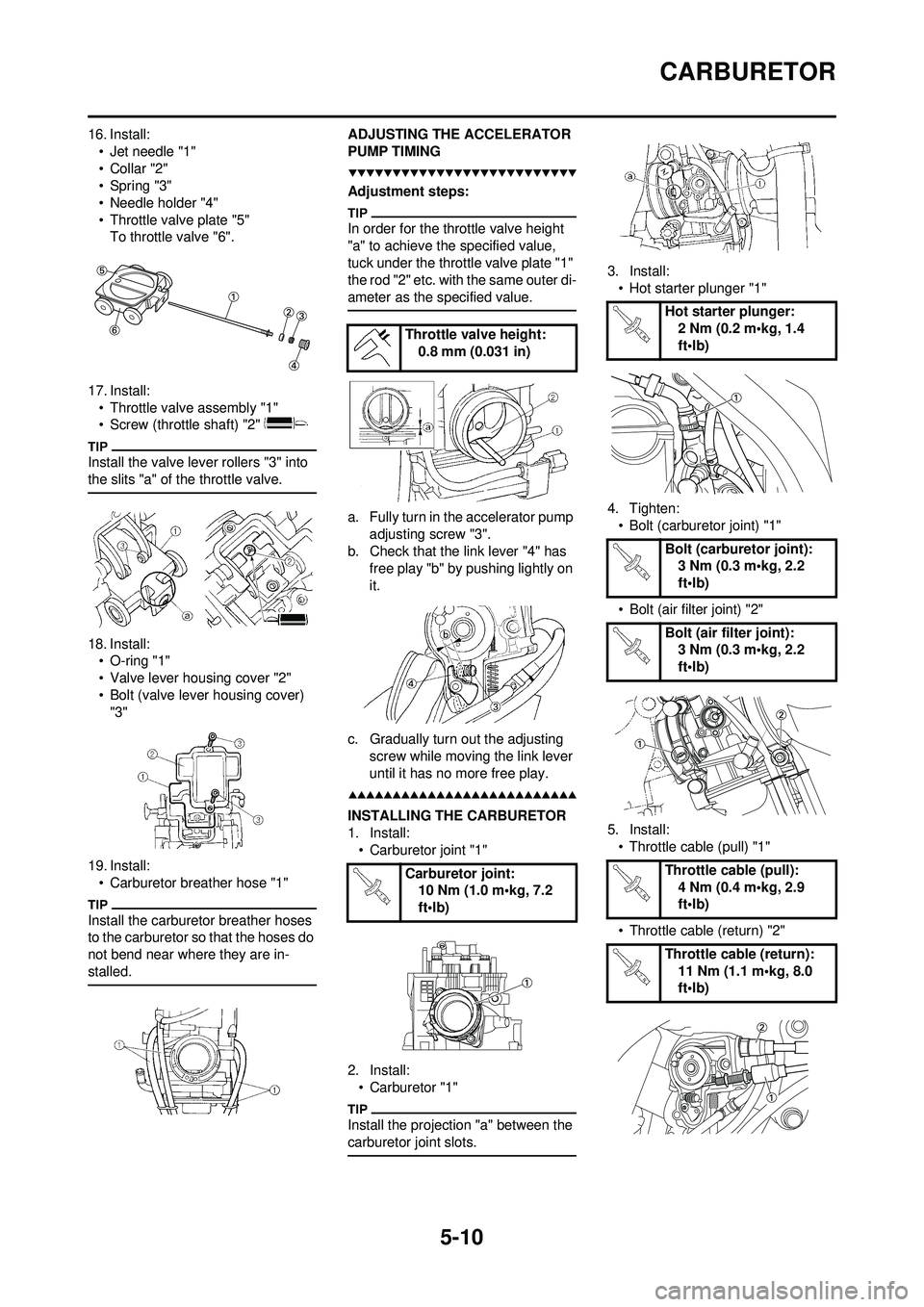

16. Install:• Jet needle "1"

•Collar "2"

• Spring "3"

• Needle holder "4"

• Throttle valve plate "5"To throttle valve "6".

17. Install: • Throttle valve assembly "1"

• Screw (throttle shaft) "2"

Install the valve lever rollers "3" into

the slits "a" of the throttle valve.

18. Install:• O-ring "1"

• Valve lever housing cover "2"

• Bolt (valve lever housing cover) "3"

19. Install: • Carburetor breather hose "1"

Install the carburetor breather hoses

to the carburetor so that the hoses do

not bend near where they are in-

stalled.

ADJUSTING THE ACCELERATOR

PUMP TIMING

Adjustment steps:

In order for the throttle valve height

"a" to achieve the specified value,

tuck under the throttle valve plate "1"

the rod "2" etc. with the same outer di-

ameter as the specified value.

a. Fully turn in the accelerator pump adjusting screw "3".

b. Check that the link lever "4" has

free play "b" by pushing lightly on

it.

c. Gradually turn out the adjusting screw while moving the link lever

until it has no more free play.

INSTALLING THE CARBURETOR

1. Install:• Carburetor joint "1"

2. Install: • Carburetor "1"

Install the projection "a" between the

carburetor joint slots.

3. Install:• Hot starter plunger "1"

4. Tighten: • Bolt (carburetor joint) "1"

• Bolt (air filter joint) "2"

5. Install: • Throttle cable (pull) "1"

• Throttle cable (return) "2"

Throttle valve height: 0.8 mm (0.031 in)

Carburetor joint: 10 Nm (1.0 m•kg, 7.2

ft•lb)

Hot starter plunger:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Bolt (carburetor joint): 3 Nm (0.3 m•kg, 2.2

ft•lb)

Bolt (air filter joint): 3 Nm (0.3 m•kg, 2.2

ft•lb)

Throttle cable (pull): 4 Nm (0.4 m•kg, 2.9

ft•lb)

Throttle cable (return): 11 Nm (1.1 m•kg, 8.0

ft•lb)

Page 107 of 224

5-11

CARBURETOR

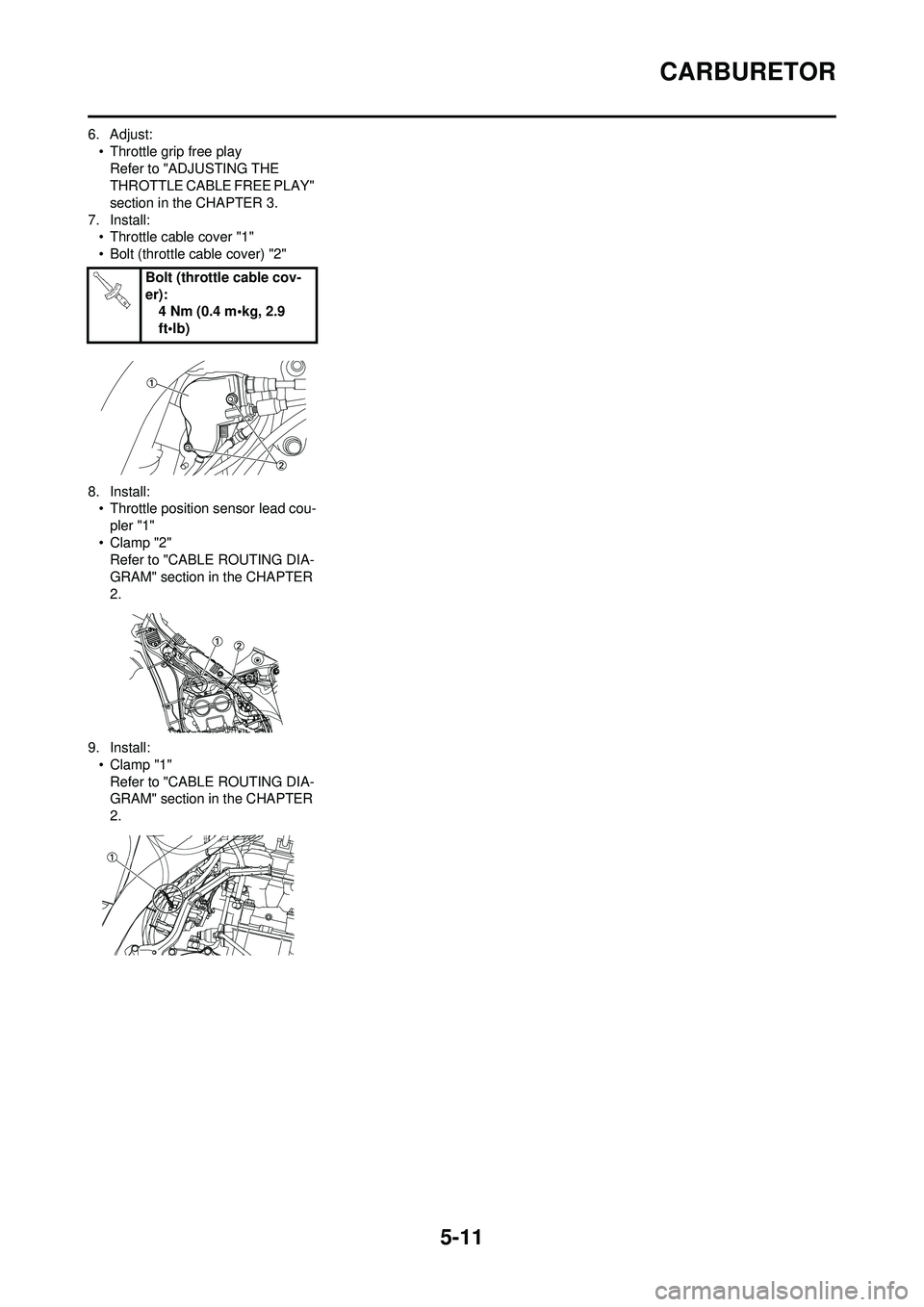

6. Adjust:• Throttle grip free playRefer to "ADJUSTING THE

THROTTLE CABLE FREE PLAY"

section in the CHAPTER 3.

7. Install: • Throttle cable cover "1"

• Bolt (throttle cable cover) "2"

8. Install: • Throttle position sensor lead cou-

pler "1"

•Clamp "2" Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2.

9. Install: •Clamp "1"Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2. Bolt (throttle cable cov-

er):

4 Nm (0.4 m•kg, 2.9

ft•lb)

Page 108 of 224

5-12

AIR INDICTOIN SYSTEM

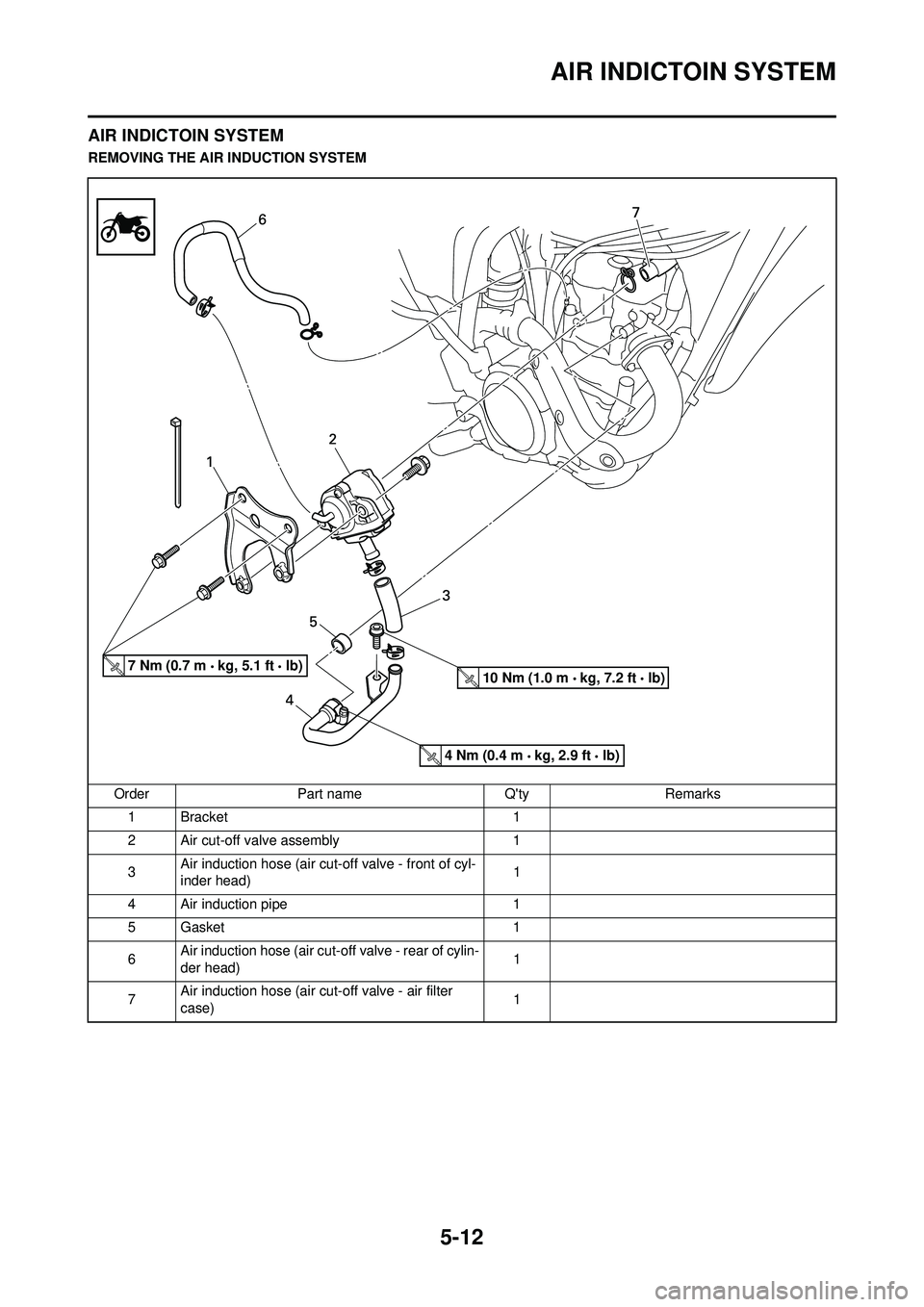

AIR INDICTOIN SYSTEM

REMOVING THE AIR INDUCTION SYSTEMOrder Part name Q'ty Remarks1Bracket 1

2 Air cut-off valve assembly 1

3 Air induction hose (air cut-off valve - front of cyl-

inder head) 1

4 Air induction pipe 1

5Gasket 1

6 Air induction hose (air cut-off valve - rear of cylin-

der head) 1

7 Air induction hose (air cut-off valve - air filter

case) 1

7 Nm (0.7 m kg, 5.1 ft lb)10 Nm (1.0 m kg, 7.2 ft lb)

4 Nm (0.4 m kg, 2.9 ft lb)

Page 109 of 224

5-13

AIR INDICTOIN SYSTEM

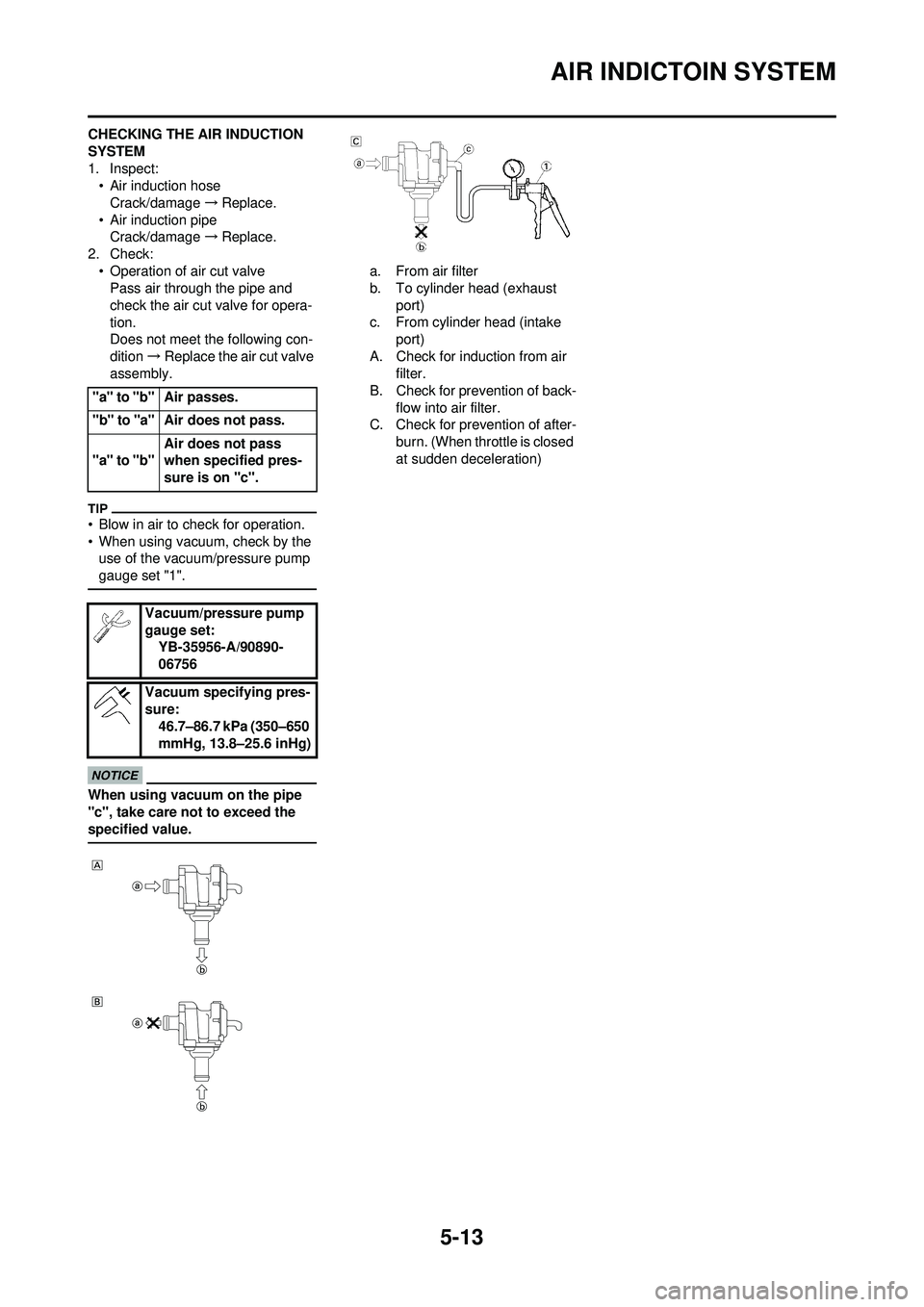

CHECKING THE AIR INDUCTION

SYSTEM

1. Inspect:• Air induction hose

Crack/damage →Replace.

• Air induction pipe Crack/damage →Replace.

2. Check: • Operation of air cut valvePass air through the pipe and

check the air cut valve for opera-

tion.

Does not meet the following con-

dition →Replace the air cut valve

assembly.

• Blow in air to check for operation.

• When using vacuum, check by the use of the vacuum/pressure pump

gauge set "1".

When using vacuum on the pipe

"c", take care not to exceed the

specified value.

a. From air filter

b. To cylinder head (exhaust

port)

c. From cylinder head (intake

port)

A. Check for induction from air filter.

B. Check for prevention of back- flow into air filter.

C. Check for prevention of after-

burn. (When throttle is closed

at sudden deceleration)

"a" to "b" Air passes.

"b" to "a" Air does not pass.

"a" to "b"

Air does not pass

when specified pres-

sure is on "c".

Vacuum/pressure pump

gauge set: YB-35956-A/90890-

06756

Vacuum specifying pres-

sure: 46.7–86.7 kPa (350–650

mmHg, 13.8–25.6 inHg)

Page 110 of 224

5-14

CAMSHAFTS

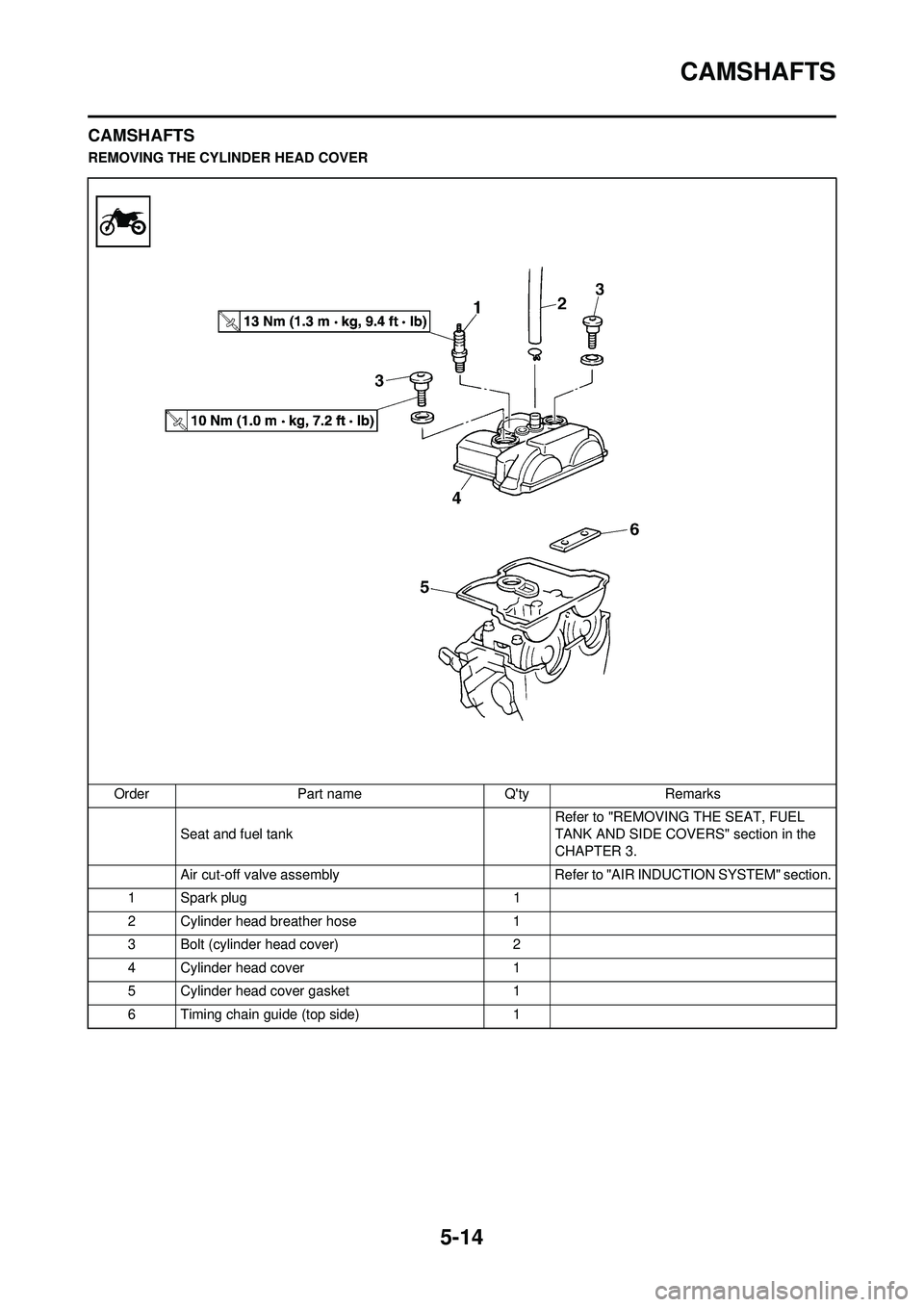

CAMSHAFTS

REMOVING THE CYLINDER HEAD COVEROrder Part name Q'ty Remarks Seat and fuel tank Refer to "REMOVING THE SEAT, FUEL

TANK AND SIDE COVERS" section in the

CHAPTER 3.

Air cut-off valve assembly Refer to "AIR INDUCTION SYSTEM" section.

1 Spark plug 1

2 Cylinder head breather hose 1

3 Bolt (cylinder head cover) 2

4 Cylinder head cover 1

5 Cylinder head cover gasket 1

6 Timing chain guide (top side) 1