YAMAHA WR 250F 2009 Owners Manual

Manufacturer: YAMAHA, Model Year: 2009, Model line: WR 250F, Model: YAMAHA WR 250F 2009Pages: 224, PDF Size: 13.93 MB

Page 131 of 224

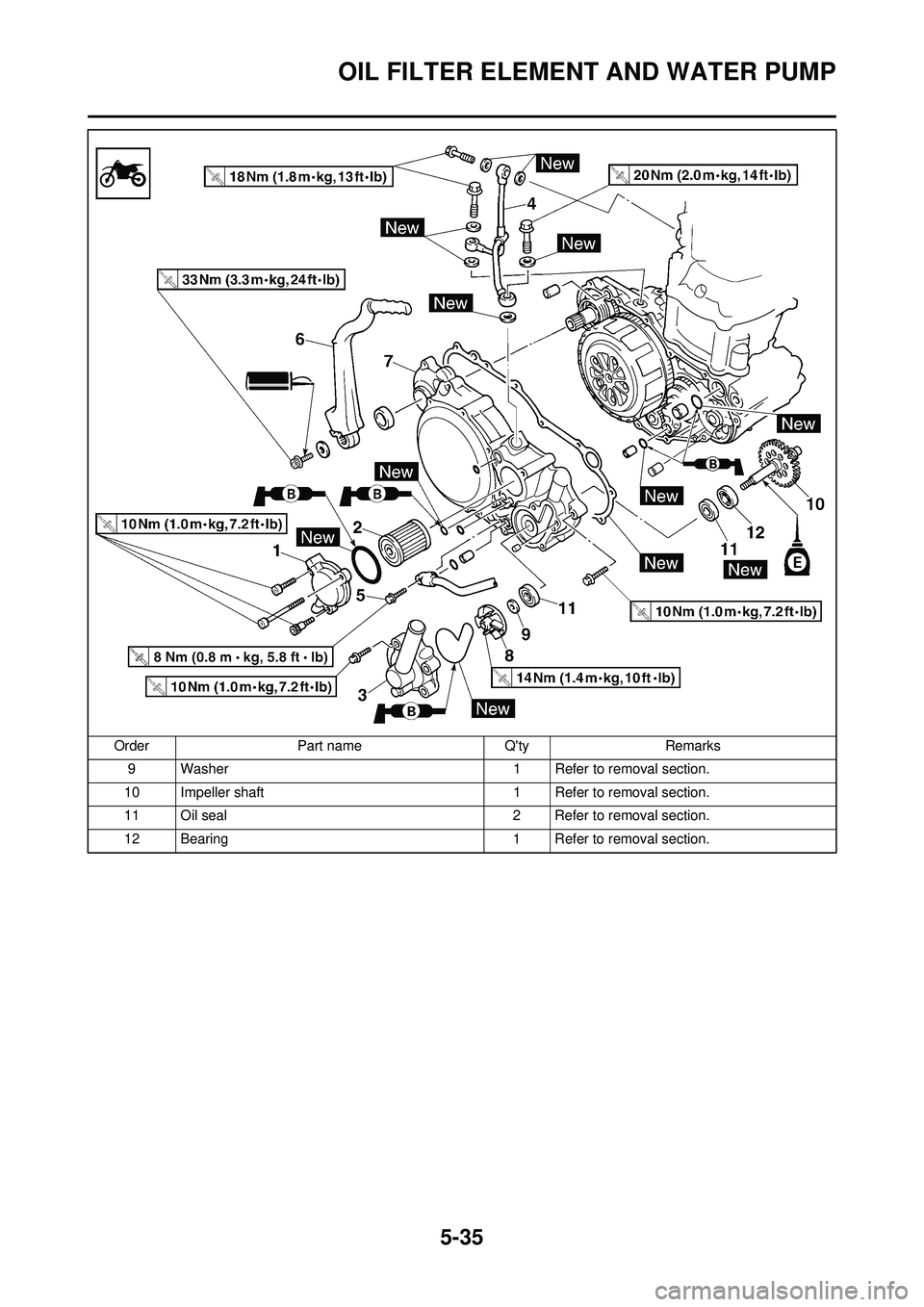

5-35

OIL FILTER ELEMENT AND WATER PUMP

9 Washer1 Refer to removal section.

10 Impeller shaft 1 Refer to removal section.

11 Oil seal 2 Refer to removal section.

12 Bearing 1 Refer to removal section.

Order

Part name Q'tyRemarks

Page 132 of 224

5-36

OIL FILTER ELEMENT AND WATER PUMP

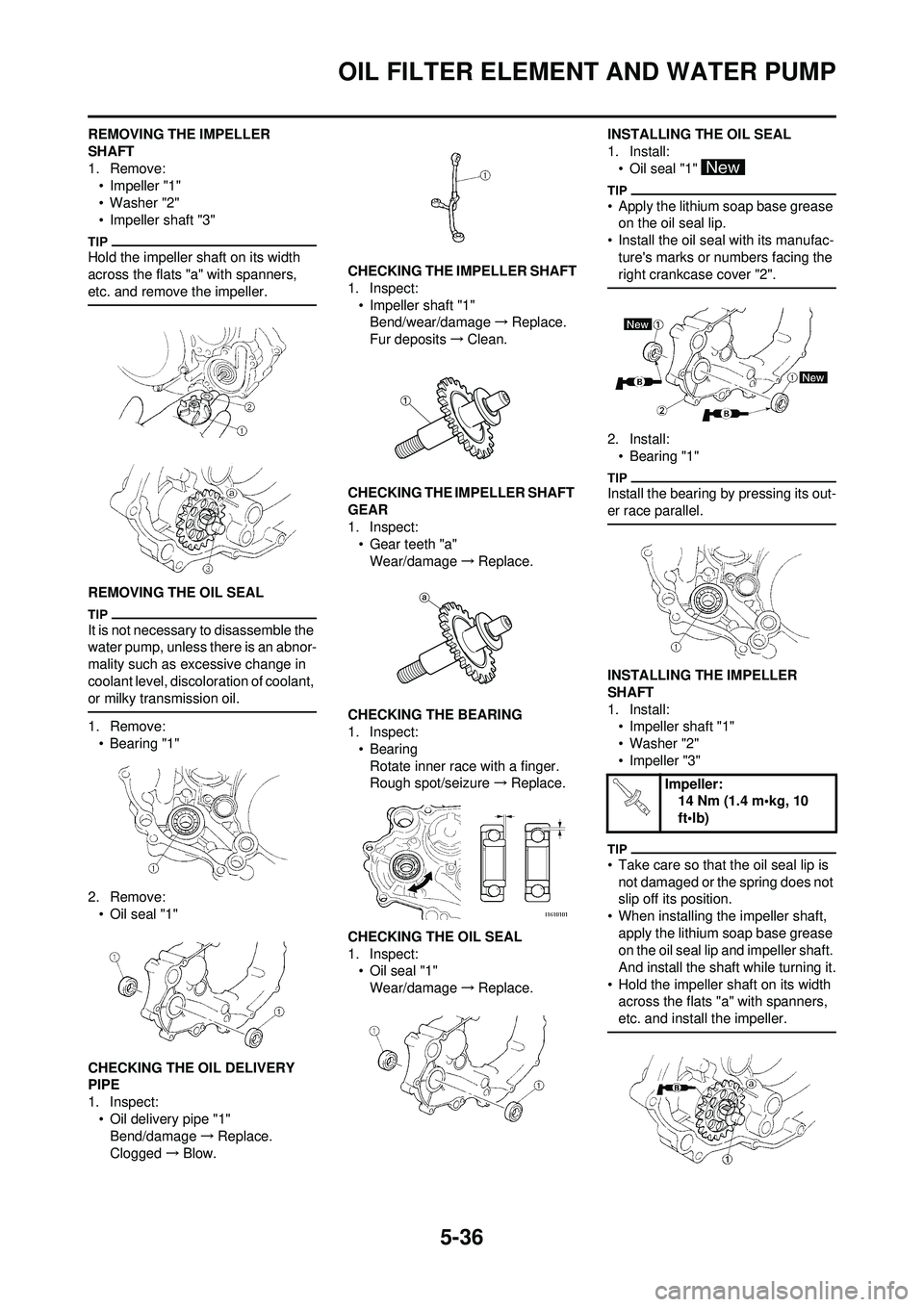

REMOVING THE IMPELLER

SHAFT

1. Remove:•Impeller "1"

• Washer "2"

• Impeller shaft "3"

Hold the impeller shaft on its width

across the flats "a" with spanners,

etc. and remove the impeller.

REMOVING THE OIL SEAL

It is not necessary to disassemble the

water pump, unless there is an abnor-

mality such as excessive change in

coolant level, discoloration of coolant,

or milky transmission oil.

1. Remove:

• Bearing "1"

2. Remove: •Oil seal "1"

CHECKING THE OIL DELIVERY

PIPE

1. Inspect: • Oil delivery pipe "1"Bend/damage →Replace.

Clogged →Blow. CHECKING THE IMPELLER SHAFT

1. Inspect:

• Impeller shaft "1"Bend/wear/damage →Replace.

Fur deposits →Clean.

CHECKING THE IMPELLER SHAFT

GEAR

1. Inspect: • Gear teeth "a"Wear/damage →Replace.

CHECKING THE BEARING

1. Inspect: • BearingRotate inner race with a finger.

Rough spot/seizure →Replace.

CHECKING THE OIL SEAL

1. Inspect: • Oil seal "1"

Wear/damage →Replace. INSTALLING THE OIL SEAL

1. Install:

•Oil seal "1"

• Apply the lithium soap base grease on the oil seal lip.

• Install the oil seal with its manufac- ture's marks or numbers facing the

right crankcase cover "2".

2. Install:• Bearing "1"

Install the bearing by pressing its out-

er race parallel.

INSTALLING THE IMPELLER

SHAFT

1. Install:• Impeller shaft "1"

• Washer "2"

• Impeller "3"

• Take care so that the oil seal lip is

not damaged or the spring does not

slip off its position.

• When installing the impeller shaft, apply the lithium soap base grease

on the oil seal lip and impeller shaft.

And install the shaft while turning it.

• Hold the impeller shaft on its width across the flats "a" with spanners,

etc. and install the impeller.

Impeller: 14 Nm (1.4 m•kg, 10

ft•lb)

Page 133 of 224

5-37

OIL FILTER ELEMENT AND WATER PUMP

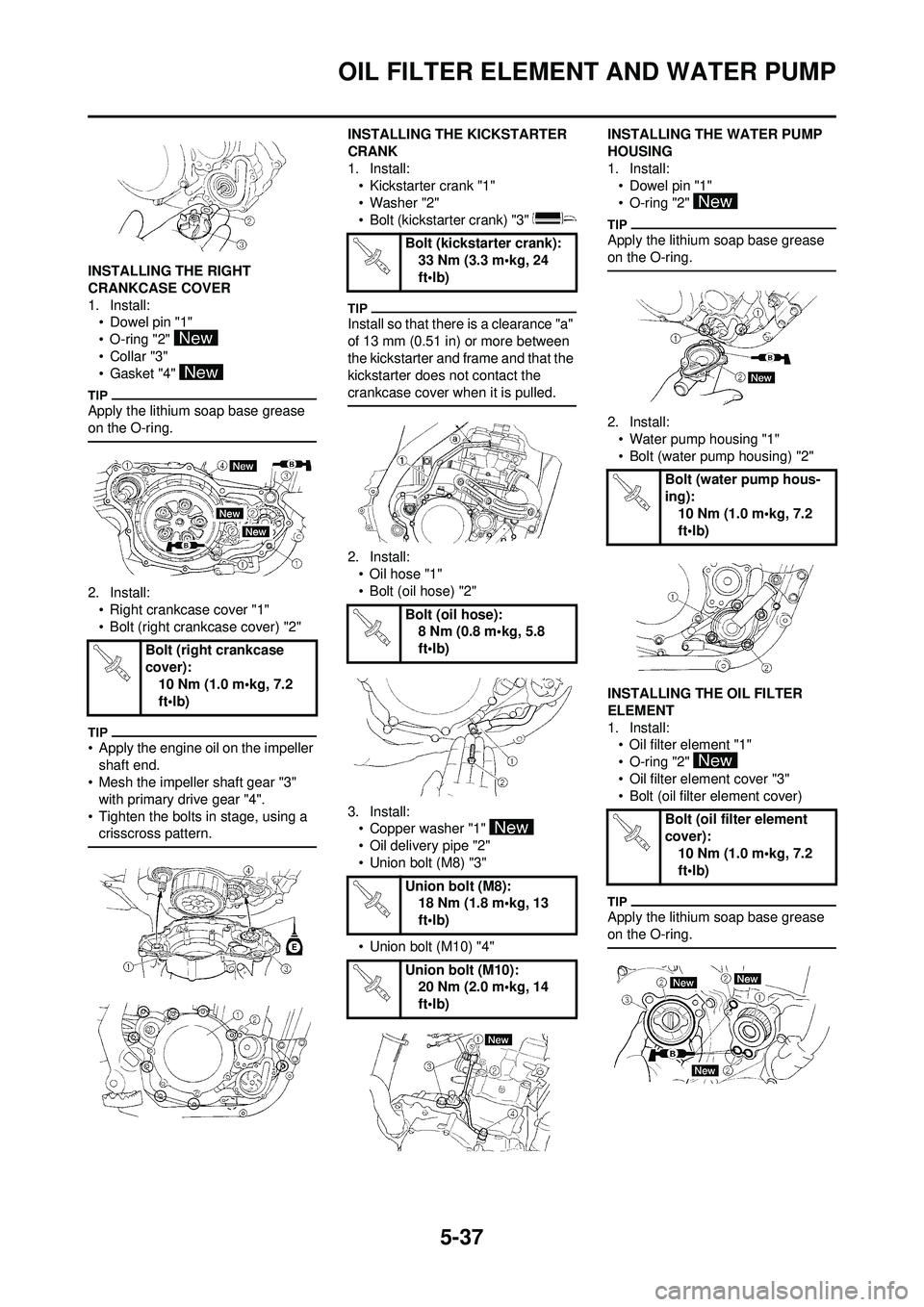

INSTALLING THE RIGHT

CRANKCASE COVER

1. Install:• Dowel pin "1"

• O-ring "2"

•Collar "3"

•Gasket "4"

Apply the lithium soap base grease

on the O-ring.

2. Install:• Right crankcase cover "1"

• Bolt (right crankcase cover) "2"

• Apply the engine oil on the impeller

shaft end.

• Mesh the impeller shaft gear "3"

with primary drive gear "4".

• Tighten the bolts in stage, using a crisscross pattern.

INSTALLING THE KICKSTARTER

CRANK

1. Install:• Kickstarter crank "1"

•Washer "2"

• Bolt (kickstarter crank) "3"

Install so that there is a clearance "a"

of 13 mm (0.51 in) or more between

the kickstarter and frame and that the

kickstarter does not contact the

crankcase cover when it is pulled.

2. Install:

• Oil hose "1"

• Bolt (oil hose) "2"

3. Install: • Copper washer "1"

• Oil delivery pipe "2"

• Union bolt (M8) "3"

• Union bolt (M10) "4" INSTALLING THE WATER PUMP

HOUSING

1. Install:

• Dowel pin "1"

• O-ring "2"

Apply the lithium soap base grease

on the O-ring.

2. Install:

• Water pump housing "1"

• Bolt (water pump housing) "2"

INSTALLING THE OIL FILTER

ELEMENT

1. Install: • Oil filter element "1"

• O-ring "2"

• Oil filter element cover "3"

• Bolt (oil filter element cover)

Apply the lithium soap base grease

on the O-ring.

Bolt (right crankcase

cover): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (kickstarter crank):33 Nm (3.3 m•kg, 24

ft•lb)

Bolt (oil hose): 8 Nm (0.8 m•kg, 5.8

ft•lb)

Union bolt (M8): 18 Nm (1.8 m•kg, 13

ft•lb)

Union bolt (M10): 20 Nm (2.0 m•kg, 14

ft•lb)

Bolt (water pump hous-

ing):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (oil filter element

cover): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 134 of 224

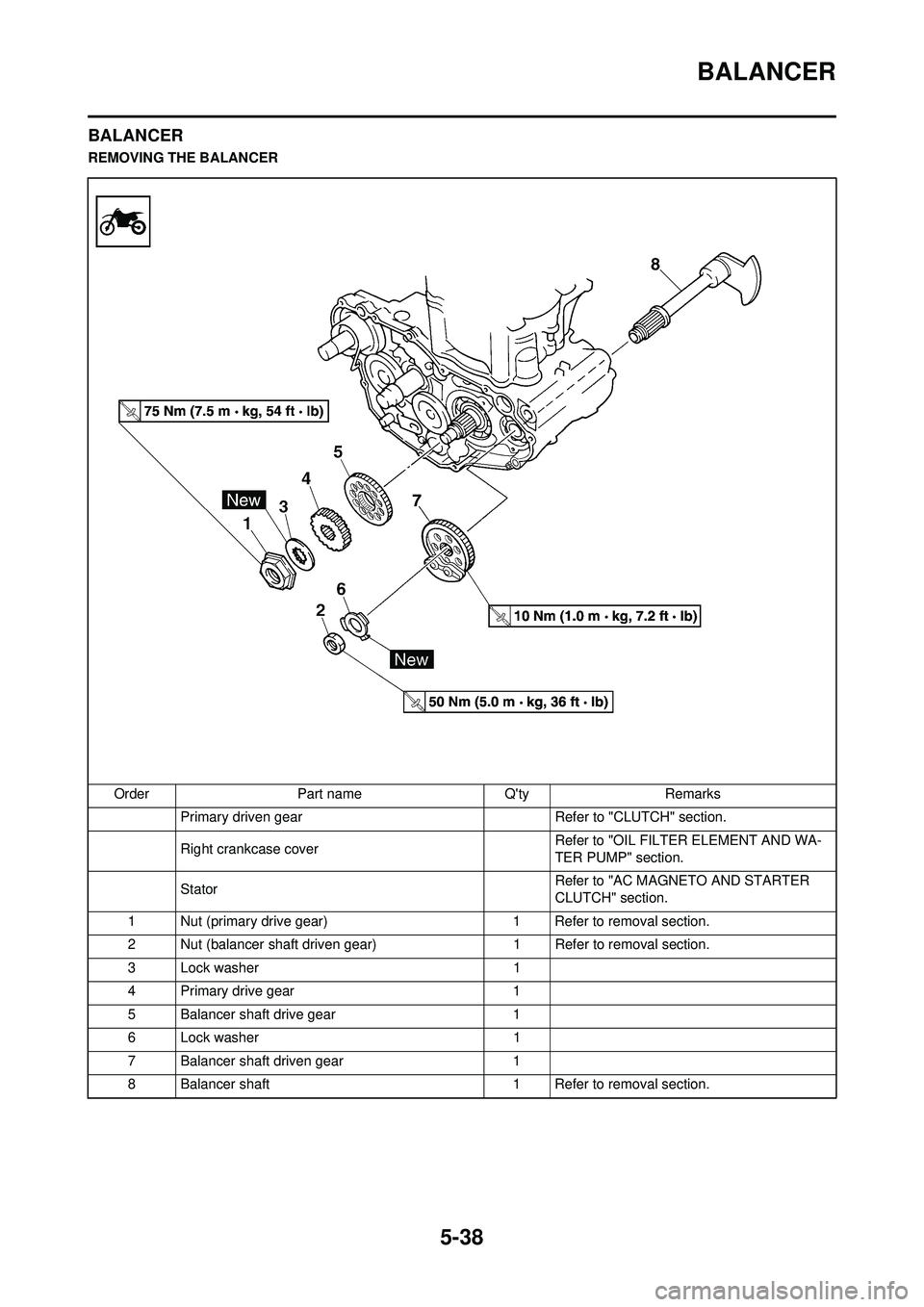

5-38

BALANCER

BALANCER

REMOVING THE BALANCEROrder Part name Q'ty Remarks Primary driven gear Refer to "CLUTCH" section.

Right crankcase cover Refer to "OIL FILTER ELEMENT AND WA-

TER PUMP" section.

Stator Refer to "AC MAGNETO AND STARTER

CLUTCH" section.

1 Nut (primary drive gear) 1 Refer to removal section.

2 Nut (balancer shaft driven gear) 1 Refer to removal section.

3 Lock washer 1

4 Primary drive gear 1

5 Balancer shaft drive gear 1

6 Lock washer 1

7 Balancer shaft driven gear 1

8 Balancer shaft 1 Refer to removal section.

Page 135 of 224

5-39

BALANCER

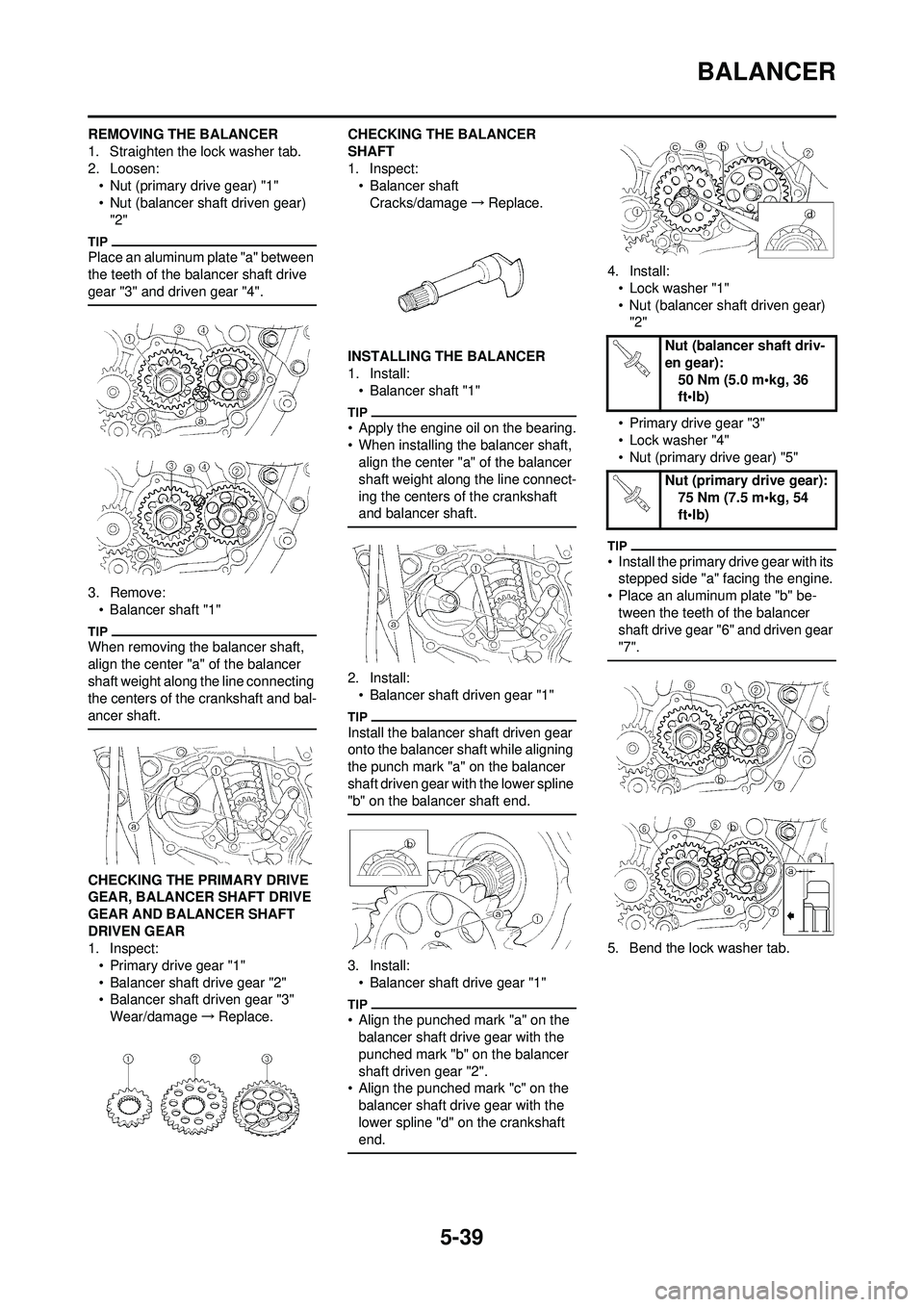

REMOVING THE BALANCER

1. Straighten the lock washer tab.

2. Loosen:• Nut (primary drive gear) "1"

• Nut (balancer shaft driven gear)

"2"

Place an aluminum plate "a" between

the teeth of the balancer shaft drive

gear "3" and driven gear "4".

3. Remove:• Balancer shaft "1"

When removing the balancer shaft,

align the center "a" of the balancer

shaft weight along the line connecting

the centers of the crankshaft and bal-

ancer shaft.

CHECKING THE PRIMARY DRIVE

GEAR, BALANCER SHAFT DRIVE

GEAR AND BALANCER SHAFT

DRIVEN GEAR

1. Inspect:

• Primary drive gear "1"

• Balancer shaft drive gear "2"

• Balancer shaft driven gear "3"Wear/damage →Replace. CHECKING THE BALANCER

SHAFT

1. Inspect:

• Balancer shaft

Cracks/damage →Replace.

INSTALLING THE BALANCER

1. Install: • Balancer shaft "1"

• Apply the engine oil on the bearing.

• When installing the balancer shaft, align the center "a" of the balancer

shaft weight along the line connect-

ing the centers of the crankshaft

and balancer shaft.

2. Install:

• Balancer shaft driven gear "1"

Install the balancer shaft driven gear

onto the balancer shaft while aligning

the punch mark "a" on the balancer

shaft driven gear with the lower spline

"b" on the balancer shaft end.

3. Install:• Balancer shaft drive gear "1"

• Align the punched mark "a" on the balancer shaft drive gear with the

punched mark "b" on the balancer

shaft driven gear "2".

• Align the punched mark "c" on the

balancer shaft drive gear with the

lower spline "d" on the crankshaft

end.

4. Install:• Lock washer "1"

• Nut (balancer shaft driven gear) "2"

• Primary drive gear "3"

• Lock washer "4"

• Nut (primary drive gear) "5"

• Install the primary drive gear with its stepped side "a" facing the engine.

• Place an aluminum plate "b" be- tween the teeth of the balancer

shaft drive gear "6" and driven gear

"7".

5. Bend the lock washer tab.

Nut (balancer shaft driv-

en gear): 50 Nm (5.0 m•kg, 36

ft•lb)

Nut (primary drive gear): 75 Nm (7.5 m•kg, 54

ft•lb)

Page 136 of 224

5-40

OIL PUMP

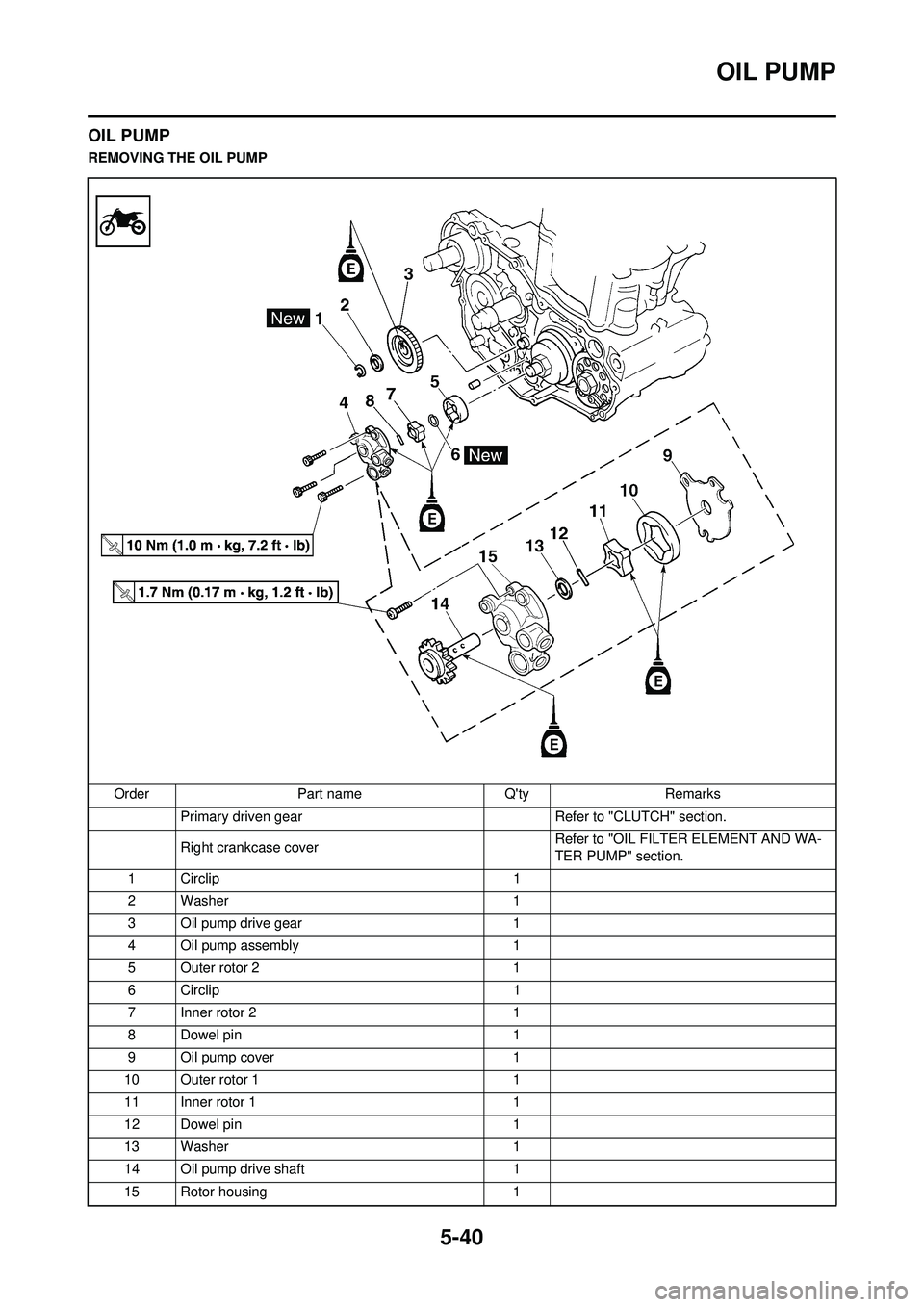

OIL PUMP

REMOVING THE OIL PUMPOrder Part name Q'ty Remarks Primary driven gear Refer to "CLUTCH" section.

Right crankcase cover Refer to "OIL FILTER ELEMENT AND WA-

TER PUMP" section.

1 Circlip 1

2 Washer 1

3 Oil pump drive gear 1

4 Oil pump assembly 1

5 Outer rotor 2 1

6 Circlip 1

7 Inner rotor 2 1

8 Dowel pin 1

9 Oil pump cover 1

10 Outer rotor 1 1

11 Inner rotor 1 1

12 Dowel pin 1

13 Washer 1

14 Oil pump drive shaft 1

15 Rotor housing 1

Page 137 of 224

5-41

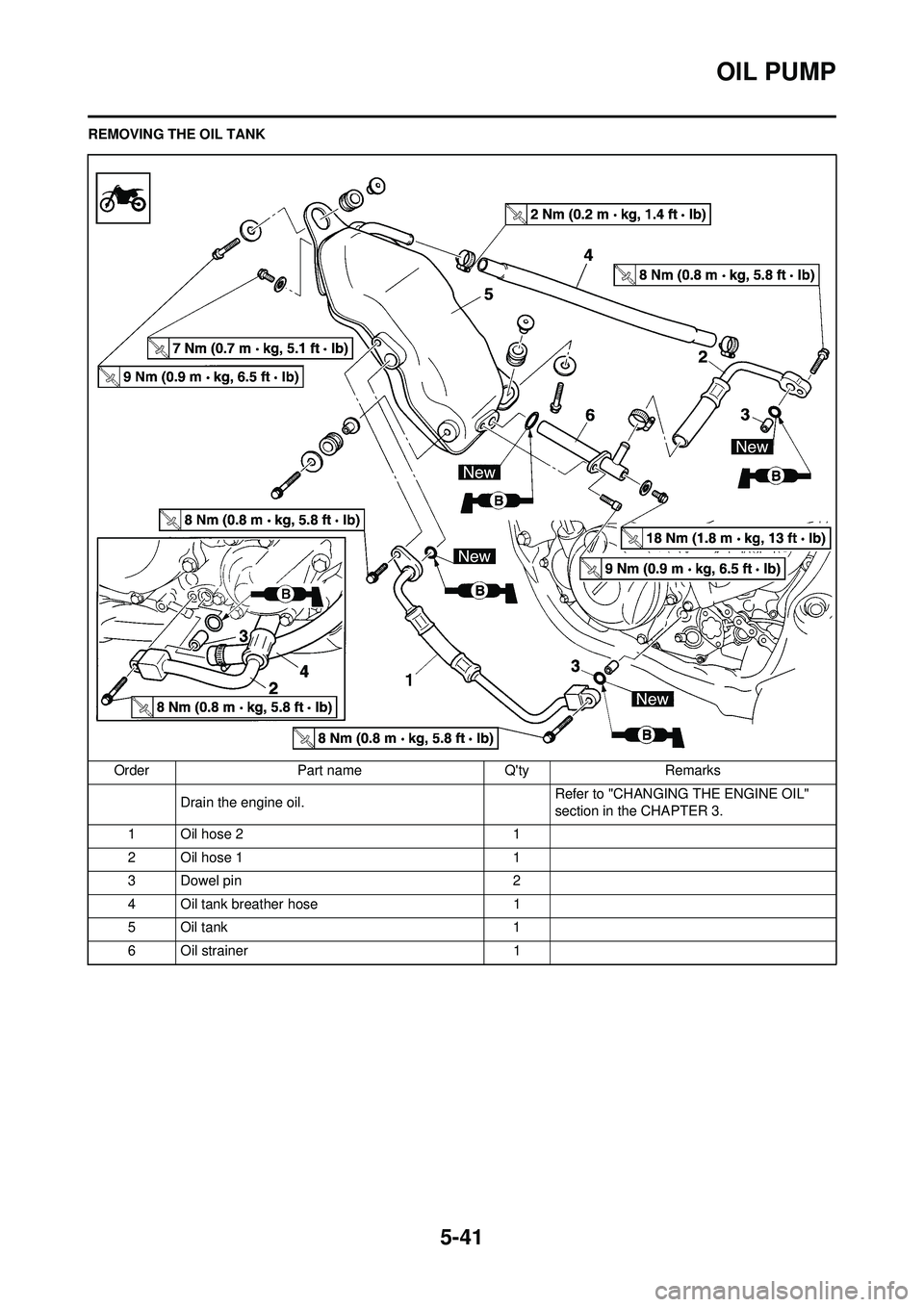

OIL PUMP

REMOVING THE OIL TANKOrder Part name Q'ty Remarks Drain the engine oil. Refer to "CHANGING THE ENGINE OIL"

section in the CHAPTER 3.

1Oil hose 2 1

2Oil hose 1 1

3 Dowel pin 2

4 Oil tank breather hose 1

5 Oil tank 1

6 Oil strainer 1

Page 138 of 224

5-42

OIL PUMP

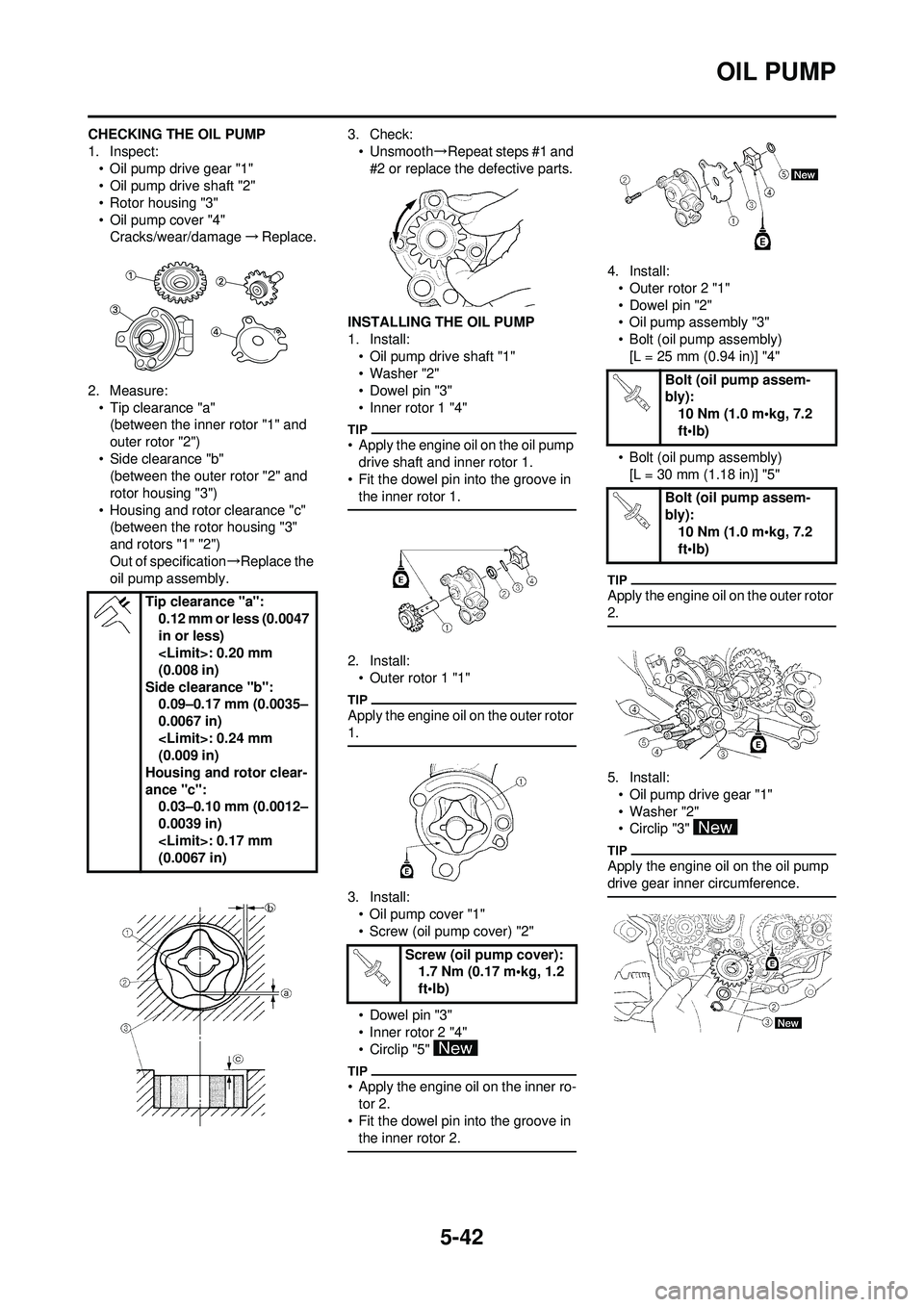

CHECKING THE OIL PUMP

1. Inspect:• Oil pump drive gear "1"

• Oil pump drive shaft "2"

• Rotor housing "3"

• Oil pump cover "4"Cracks/wear/damage →Replace.

2. Measure: • Tip clearance "a"(between the inner rotor "1" and

outer rotor "2")

• Side clearance "b" (between the outer rotor "2" and

rotor housing "3")

• Housing and rotor clearance "c" (between the rotor housing "3"

and rotors "1" "2")

Out of specification →Replace the

oil pump assembly. 3. Check:

• Unsmooth →Repeat steps #1 and

#2 or replace the defective parts.

INSTALLING THE OIL PUMP

1. Install: • Oil pump drive shaft "1"

•Washer "2"

• Dowel pin "3"

• Inner rotor 1 "4"

• Apply the engine oil on the oil pump drive shaft and inner rotor 1.

• Fit the dowel pin into the groove in the inner rotor 1.

2. Install:• Outer rotor 1 "1"

Apply the engine oil on the outer rotor

1.

3. Install:• Oil pump cover "1"

• Screw (oil pump cover) "2"

• Dowel pin "3"

• Inner rotor 2 "4"

•Circlip "5"

• Apply the engine oil on the inner ro-tor 2.

• Fit the dowel pin into the groove in

the inner rotor 2.

4. Install:• Outer rotor 2 "1"

• Dowel pin "2"

• Oil pump assembly "3"

• Bolt (oil pump assembly)[L = 25 mm (0.94 in)] "4"

• Bolt (oil pump assembly) [L = 30 mm (1.18 in)] "5"

Apply the engine oil on the outer rotor

2.

5. Install:• Oil pump drive gear "1"

• Washer "2"

• Circlip "3"

Apply the engine oil on the oil pump

drive gear inner circumference.

Tip clearance "a": 0.12 mm or less (0.0047

in or less)

(0.008 in)

Side clearance "b": 0.09–0.17 mm (0.0035–

0.0067 in)

(0.009 in)

Housing and rotor clear-

ance "c": 0.03–0.10 mm (0.0012–

0.0039 in)

(0.0067 in)

Screw (oil pump cover):1.7 Nm (0.17 m•kg, 1.2

ft•lb)

Bolt (oil pump assem-

bly):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (oil pump assem-

bly): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 139 of 224

5-43

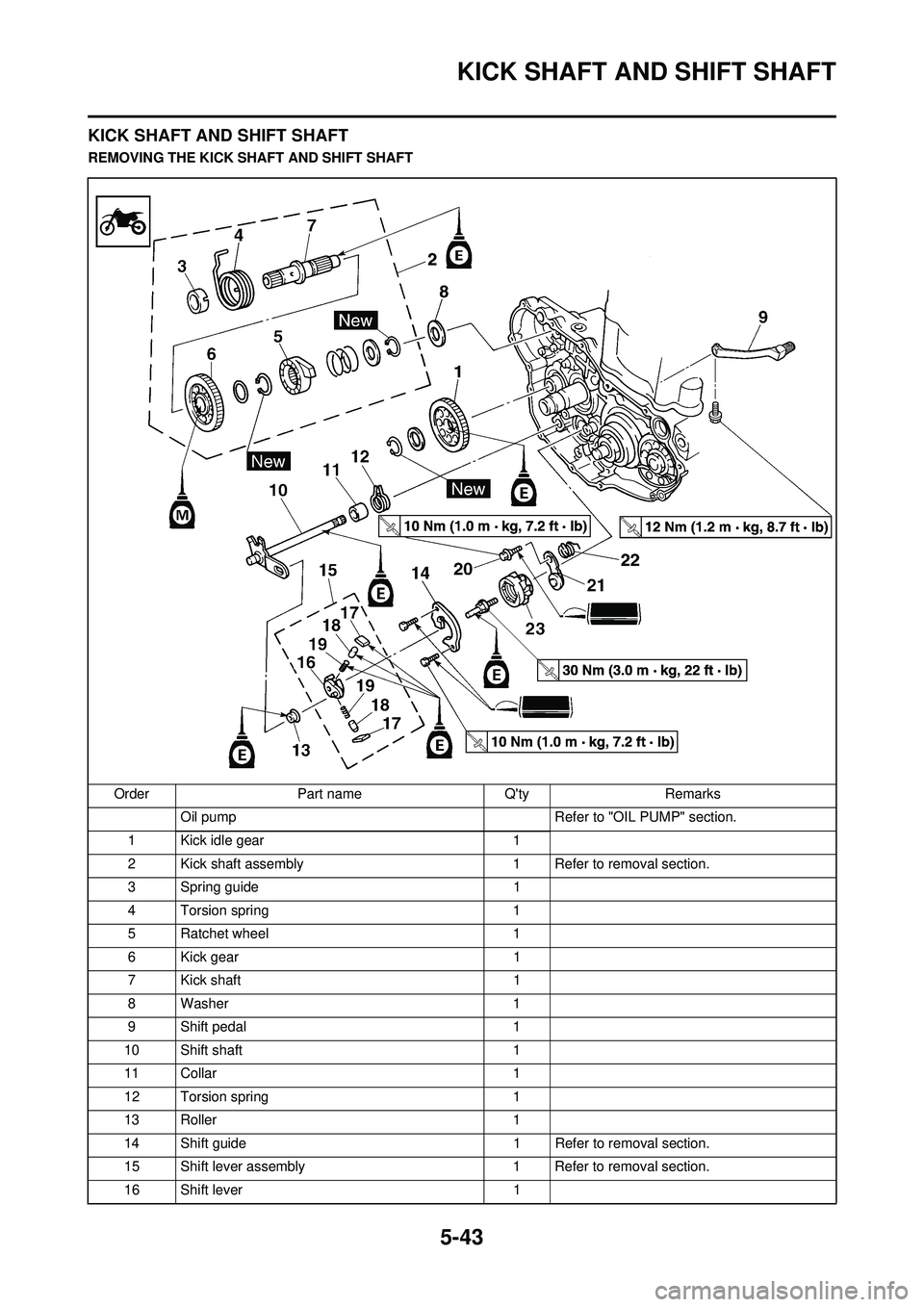

KICK SHAFT AND SHIFT SHAFT

KICK SHAFT AND SHIFT SHAFT

REMOVING THE KICK SHAFT AND SHIFT SHAFTOrder Part name Q'ty Remarks Oil pump Refer to "OIL PUMP" section.

1 Kick idle gear 1

2 Kick shaft assembly 1 Refer to removal section.

3 Spring guide 1

4 Torsion spring 1

5 Ratchet wheel 1

6 Kick gear 1

7 Kick shaft 1

8 Washer 1

9 Shift pedal 1

10 Shift shaft 1

11 Collar 1

12 Torsion spring 1

13 Roller 1

14 Shift guide 1 Refer to removal section.

15 Shift lever assembly 1 Refer to removal section.

16 Shift lever 1

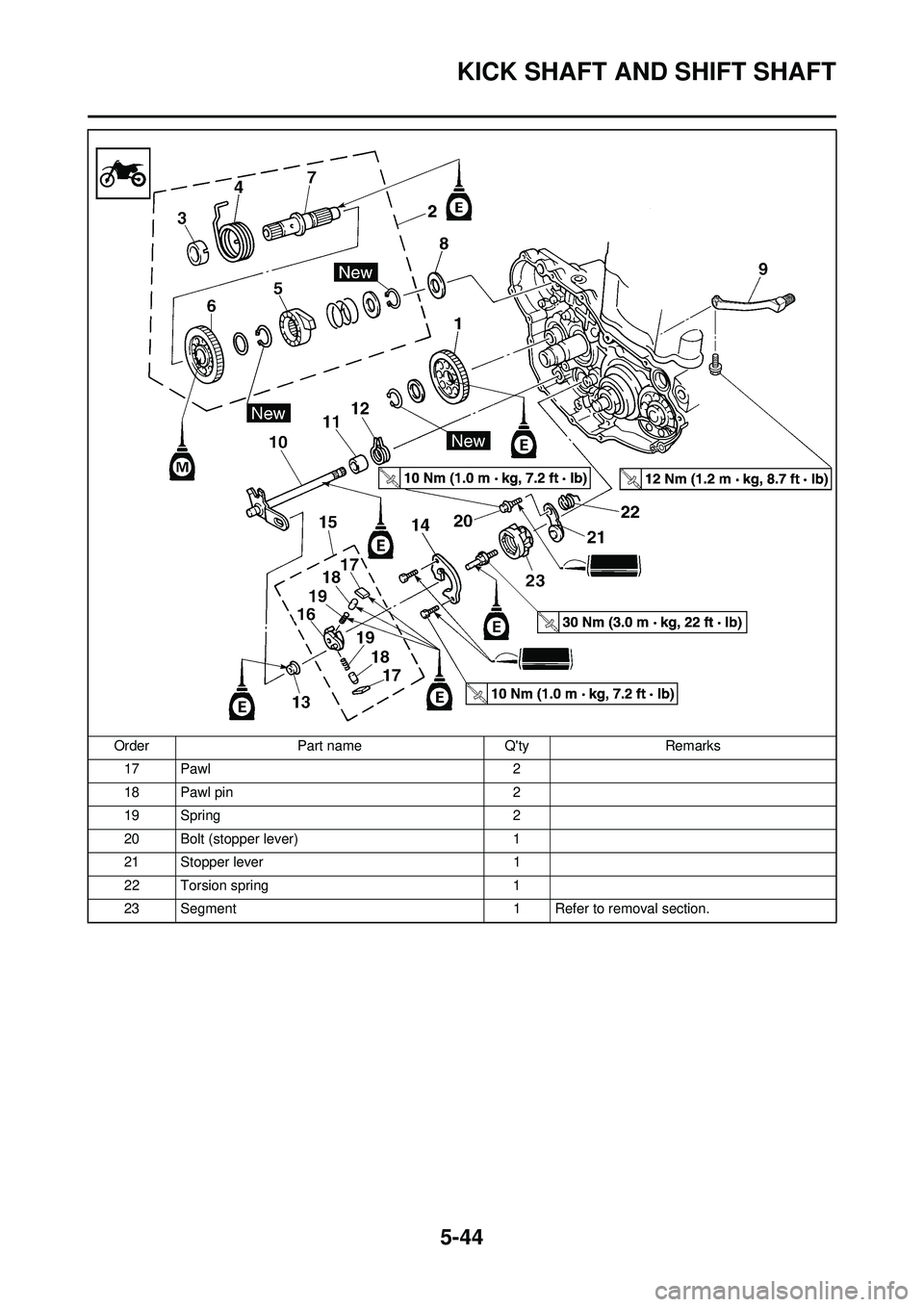

Page 140 of 224

5-44

KICK SHAFT AND SHIFT SHAFT

17 Pawl2

18 Pawl pin 2

19 Spring 2

20 Bolt (stopper lever) 1

21 Stopper lever 1

22 Torsion spring 1

23 Segment 1 Refer to removal section.

Order

Part name Q'tyRemarks