YAMAHA WR 250F 2009 Owners Manual

Manufacturer: YAMAHA, Model Year: 2009, Model line: WR 250F, Model: YAMAHA WR 250F 2009Pages: 224, PDF Size: 13.93 MB

Page 121 of 224

5-25

CYLINDER AND PISTON

CYLINDER AND PISTON

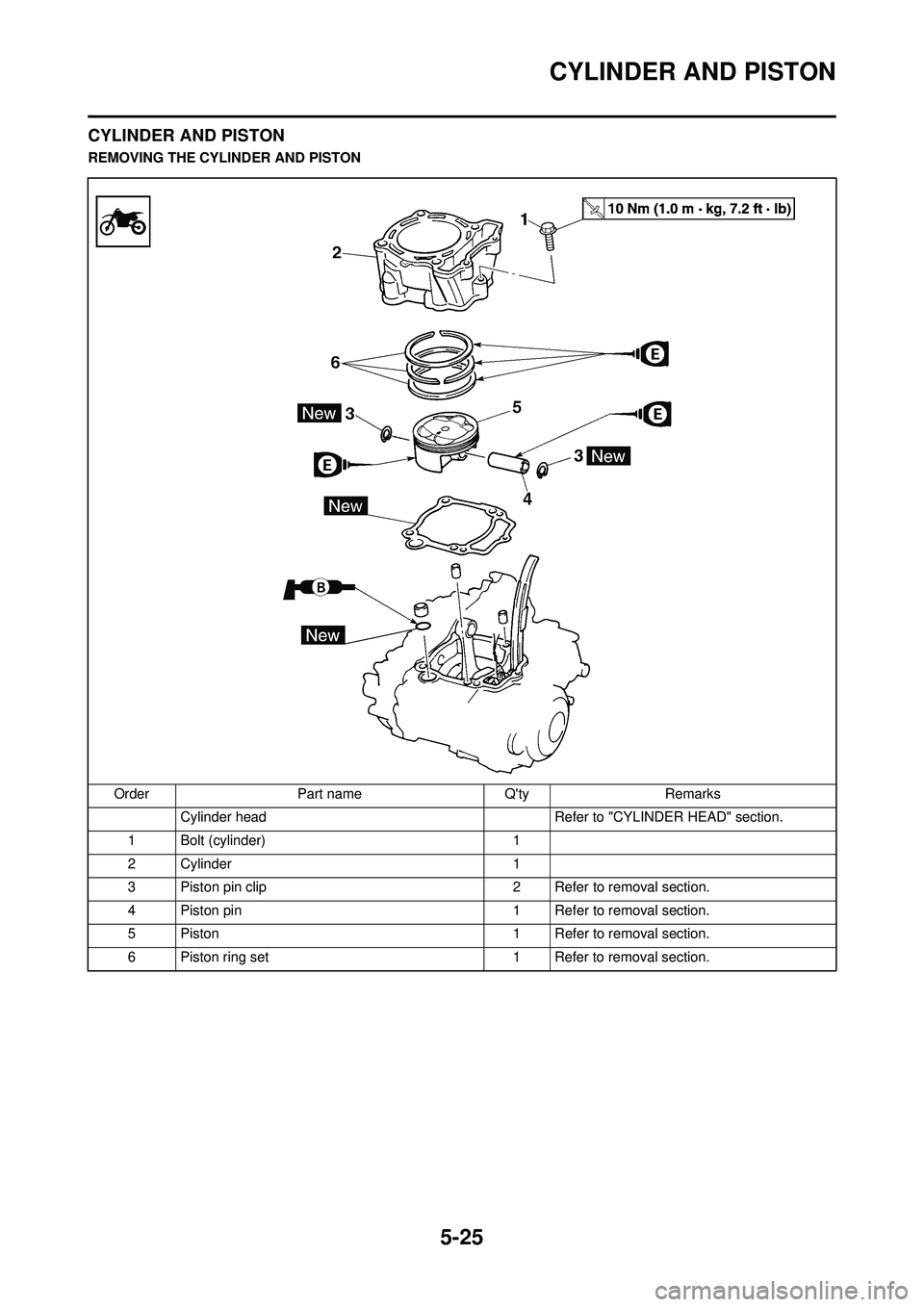

REMOVING THE CYLINDER AND PISTONOrder Part name Q'ty Remarks Cylinder head Refer to "CYLINDER HEAD" section.

1 Bolt (cylinder) 1

2Cylinder 1

3 Piston pin clip 2 Refer to removal section.

4 Piston pin 1 Refer to removal section.

5 Piston 1 Refer to removal section.

6 Piston ring set 1 Refer to removal section.

Page 122 of 224

5-26

CYLINDER AND PISTON

REMOVING THE PISTON AND

PISTON RING

1. Remove:• Piston pin clip "1"

• Piston pin "2"

•Piston "3"

• Put identification marks on each piston head for reference during re-

installation.

• Before removing each piston pin, deburr the clip groove and pin hole

area. If the piston pin groove is de-

burred and the piston pin is still dif-

ficult to remove, use the piston pin

puller set "4".

Do not use a hammer to drive the

piston pin out.

2. Remove:

• Piston ring "1"

Spread the end gaps apart while at

the same time lifting the piston ring

over the top of the piston crown, as

shown in the illustration.

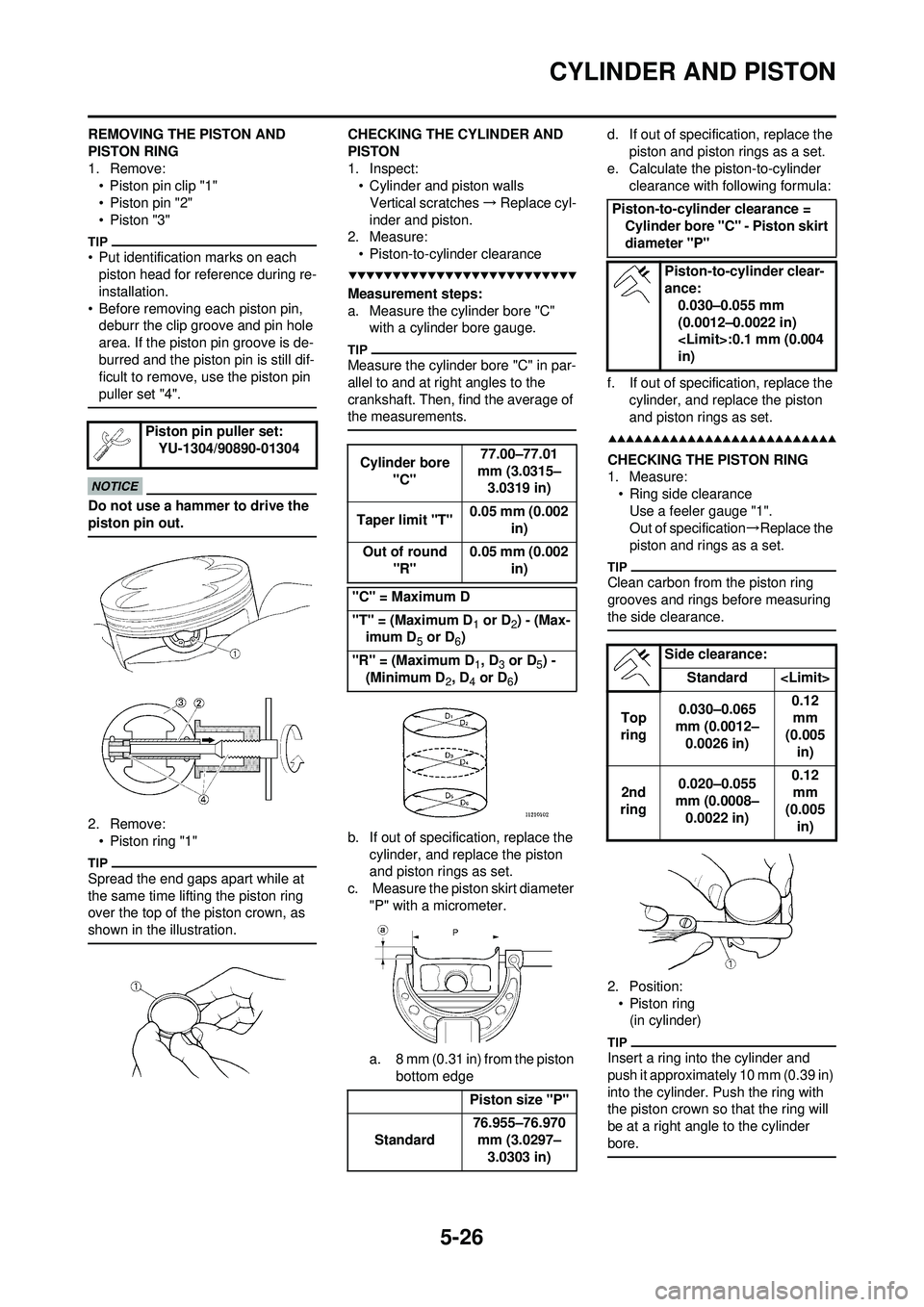

CHECKING THE CYLINDER AND

PISTON

1. Inspect:• Cylinder and piston walls

Vertical scratches →Replace cyl-

inder and piston.

2. Measure:

• Piston-to-cylinder clearance

Measurement steps:

a. Measure the cylinder bore "C" with a cylinder bore gauge.

Measure the cylinder bore "C" in par-

allel to and at right angles to the

crankshaft. Then, find the average of

the measurements.

b. If out of specification, replace the

cylinder, and replace the piston

and piston rings as set.

c. Measure the piston skirt diameter "P" with a micrometer.

a. 8 mm (0.31 in) from the piston bottom edge d. If out of specification, replace the

piston and piston rings as a set.

e. Calculate the piston-to-cylinder clearance with following formula:

f. If out of specification, replace the cylinder, and replace the piston

and piston rings as set.

CHECKING THE PISTON RING

1. Measure:

• Ring side clearanceUse a feeler gauge "1".

Out of specification →Replace the

piston and rings as a set.

Clean carbon from the piston ring

grooves and rings before measuring

the side clearance.

2. Position: • Piston ring(in cylinder)

Insert a ring into the cylinder and

push it approximately 10 mm (0.39 in)

into the cylinder. Push the ring with

the piston crown so that the ring will

be at a right angle to the cylinder

bore.

Piston pin puller set:

YU-1304/90890-01304

Cylinder bore "C" 77.00–77.01

mm (3.0315– 3.0319 in)

Taper limit "T" 0.05 mm (0.002

in)

Out of round "R" 0.05 mm (0.002

in)

"C" = Maximum D

"T" = (Maximum D

1 or D2) - (Max-

imum D

5 or D6)

"R" = (Maximum D

1, D3 or D5) -

(Minimum D

2, D4 or D6)

Piston size "P"

Standard 76.955–76.970

mm (3.0297– 3.0303 in)

Piston-to-cylinder clearance =

Cylinder bore "C" - Piston skirt

diameter "P"

Piston-to-cylinder clear-

ance:0.030–0.055 mm

(0.0012–0.0022 in)

in)

Side clearance: Standard

Top

ring 0.030–0.065

mm (0.0012– 0.0026 in) 0.12

mm

(0.005 in)

2nd

ring 0.020–0.055

mm (0.0008– 0.0022 in) 0.12

mm

(0.005 in)

Page 123 of 224

5-27

CYLINDER AND PISTON

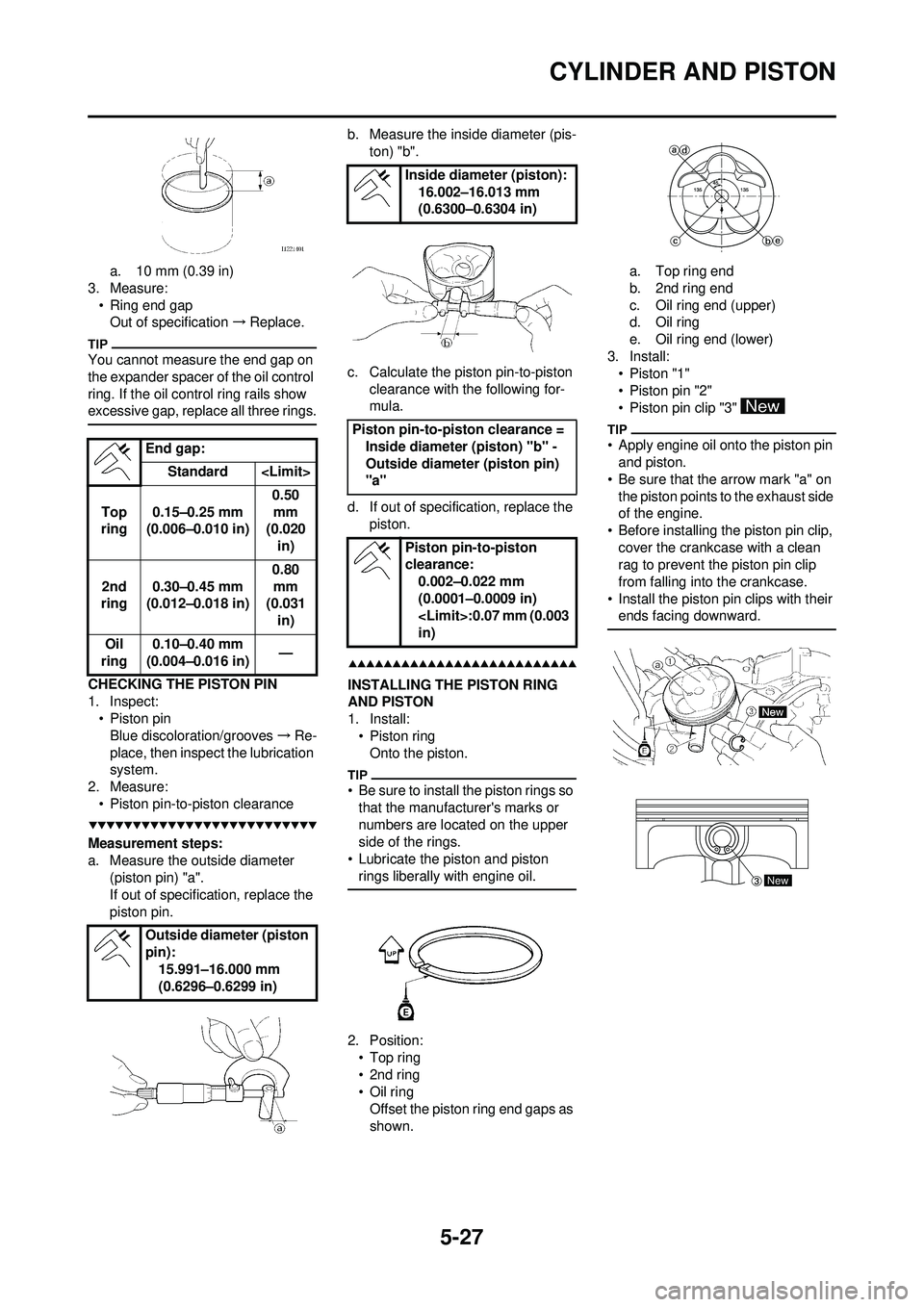

a. 10 mm (0.39 in)

3. Measure: • Ring end gapOut of specification →Replace.

You cannot measure the end gap on

the expander spacer of the oil control

ring. If the oil control ring rails show

excessive gap, replace all three rings.

CHECKING THE PISTON PIN

1. Inspect:

•Piston pin

Blue discoloration/grooves →Re-

place, then inspect the lubrication

system.

2. Measure: • Piston pin-to-piston clearance

Measurement steps:

a. Measure the outside diameter (piston pin) "a".

If out of specification, replace the

piston pin. b. Measure the inside diameter (pis-

ton) "b".

c. Calculate the piston pin-to-piston clearance with the following for-

mula.

d. If out of specification, replace the piston.

INSTALLING THE PISTON RING

AND PISTON

1. Install:• Piston ringOnto the piston.

• Be sure to install the piston rings so

that the manufacturer's marks or

numbers are located on the upper

side of the rings.

• Lubricate the piston and piston rings liberally with engine oil.

2. Position:•Top ring

•2nd ring

• Oil ringOffset the piston ring end gaps as

shown. a. Top ring end

b. 2nd ring end

c. Oil ring end (upper)

d. Oil ring

e. Oil ring end (lower)

3. Install: •Piston "1"

• Piston pin "2"

• Piston pin clip "3"

• Apply engine oil onto the piston pin and piston.

• Be sure that the arrow mark "a" on the piston points to the exhaust side

of the engine.

• Before installing the piston pin clip, cover the crankcase with a clean

rag to prevent the piston pin clip

from falling into the crankcase.

• Install the piston pin clips with their ends facing downward.End gap:

Standard

Top

ring 0.15–0.25 mm

(0.006–0.010 in) 0.50

mm

(0.020

in)

2nd

ring 0.30–0.45 mm

(0.012–0.018 in) 0.80

mm

(0.031

in)

Oil

ring 0.10–0.40 mm

(0.004–0.016 in) —

Outside diameter (piston

pin): 15.991–16.000 mm

(0.6296–0.6299 in)

Inside diameter (piston):

16.002–16.013 mm

(0.6300–0.6304 in)

Piston pin-to-piston clearance = Inside diameter (piston) "b" -

Outside diameter (piston pin)

"a"

Piston pin-to-piston

clearance:0.002–0.022 mm

(0.0001–0.0009 in)

in)

New

Page 124 of 224

5-28

CYLINDER AND PISTON

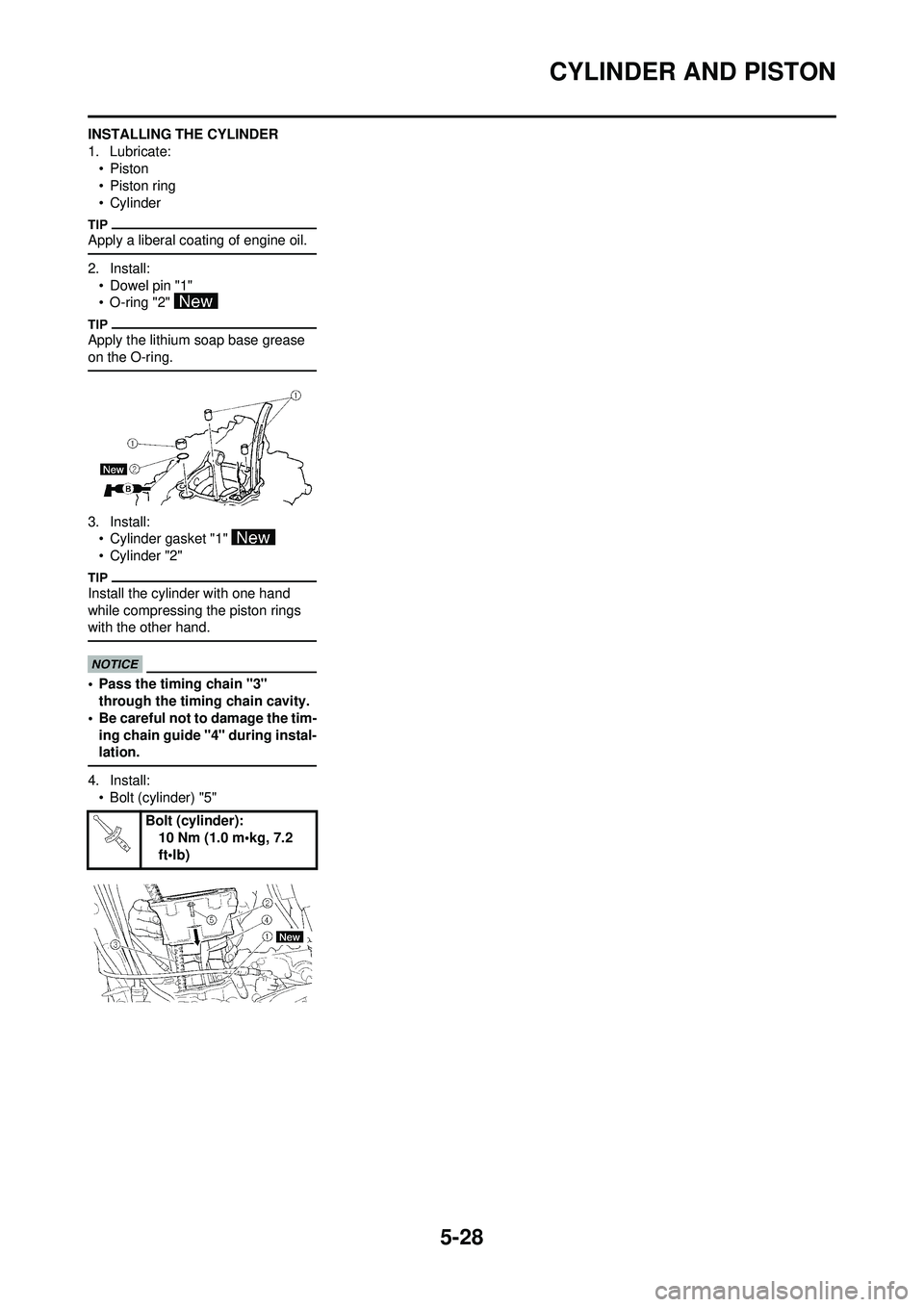

INSTALLING THE CYLINDER

1. Lubricate:•Piston

•Piston ring

•Cylinder

Apply a liberal coating of engine oil.

2. Install:• Dowel pin "1"

• O-ring "2"

Apply the lithium soap base grease

on the O-ring.

3. Install:• Cylinder gasket "1"

•Cylinder "2"

Install the cylinder with one hand

while compressing the piston rings

with the other hand.

• Pass the timing chain "3" through the timing chain cavity.

• Be careful not to damage the tim- ing chain guide "4" during instal-

lation.

4. Install:• Bolt (cylinder) "5"

Bolt (cylinder):10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 125 of 224

5-29

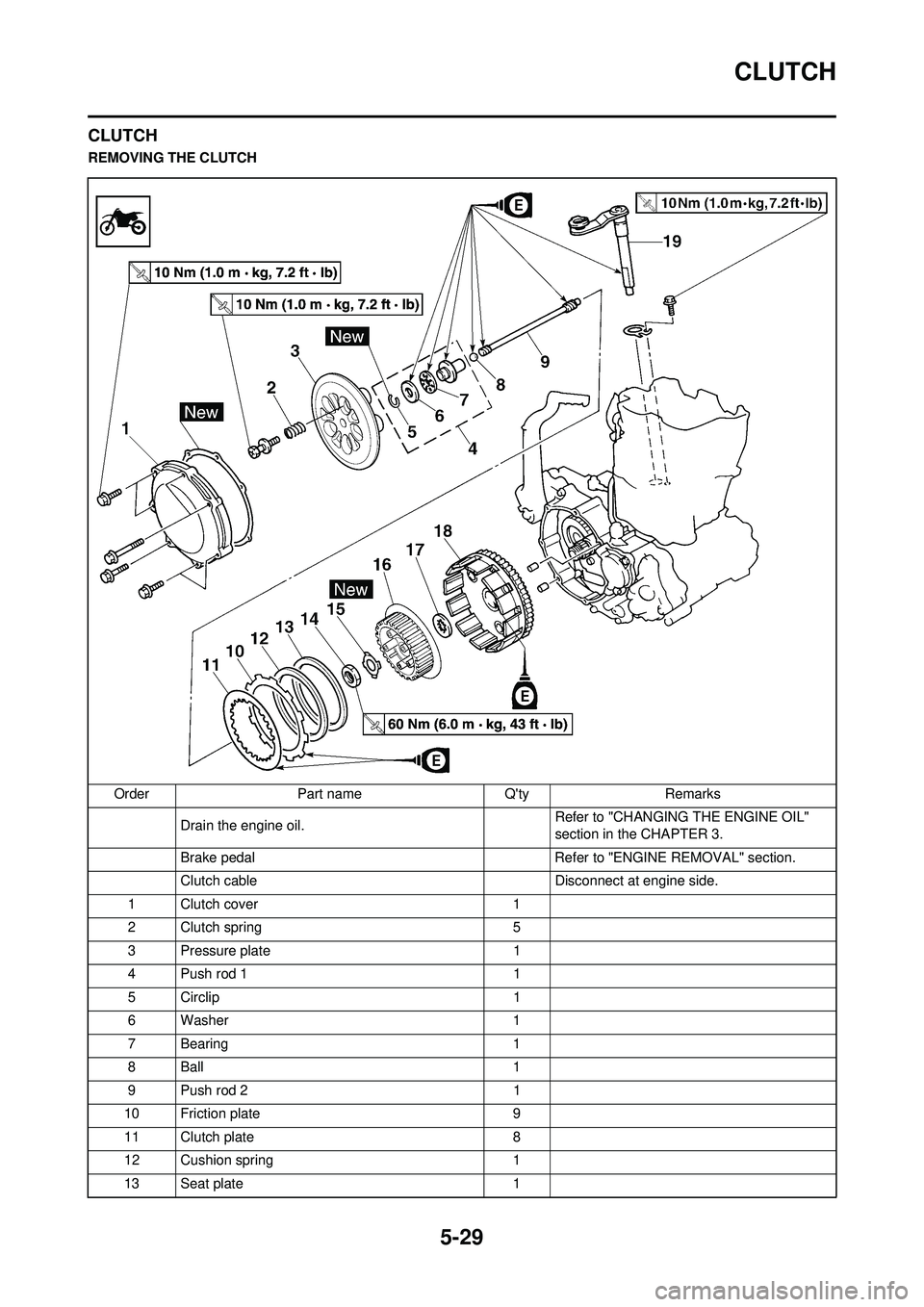

CLUTCH

CLUTCH

REMOVING THE CLUTCHOrder Part name Q'ty Remarks Drain the engine oil. Refer to "CHANGING THE ENGINE OIL"

section in the CHAPTER 3.

Brake pedal Refer to "ENGINE REMOVAL" section.

Clutch cable Disconnect at engine side.

1 Clutch cover 1

2 Clutch spring 5

3 Pressure plate 1

4 Push rod 1 1

5 Circlip 1

6 Washer 1

7 Bearing 1

8Ball 1

9 Push rod 2 1

10 Friction plate 9

11 Clutch plate 8

12 Cushion spring 1

13 Seat plate 1

Page 126 of 224

5-30

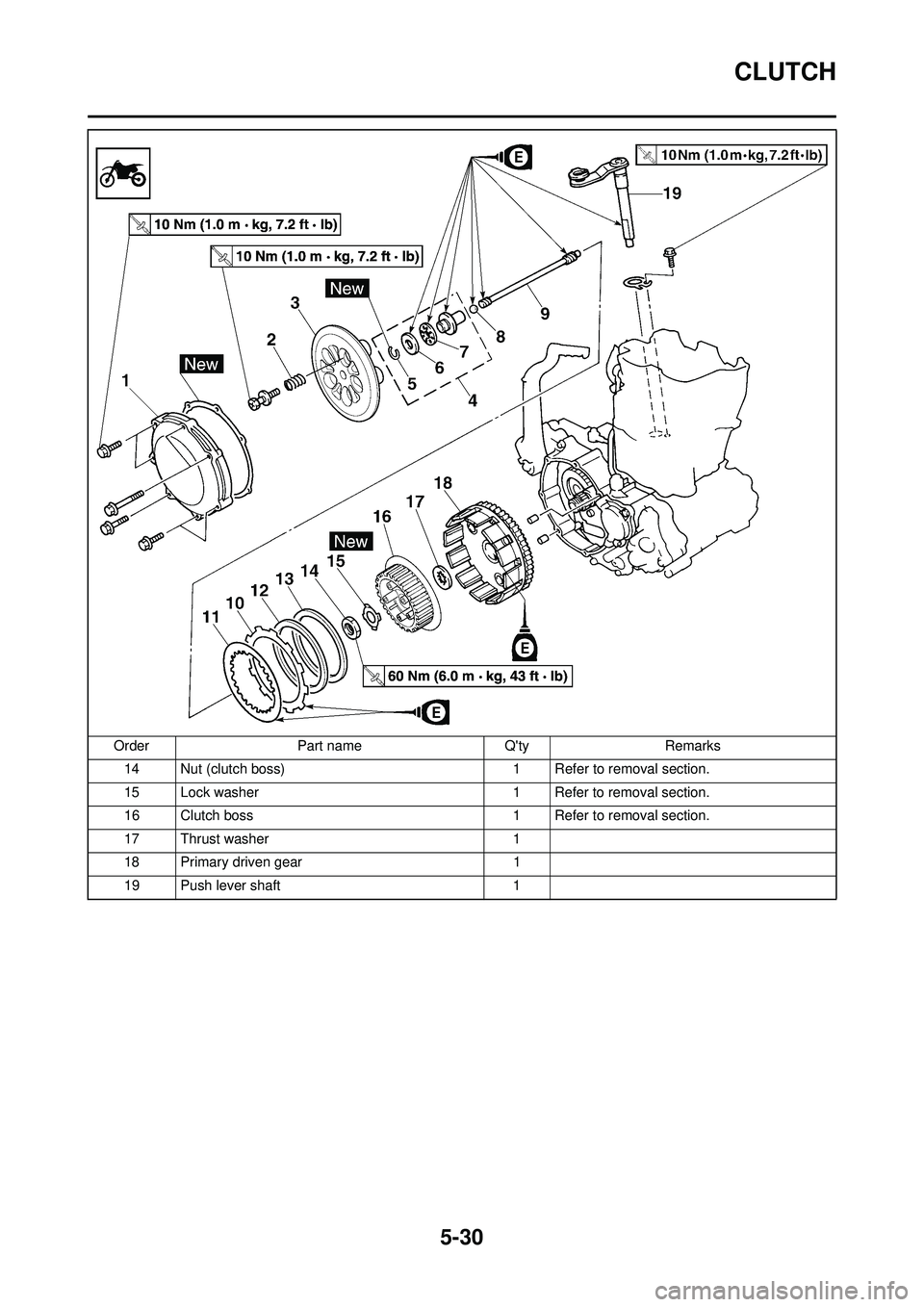

CLUTCH

14 Nut (clutch boss)1 Refer to removal section.

15 Lock washer 1 Refer to removal section.

16 Clutch boss 1 Refer to removal section.

17 Thrust washer 1

18 Primary driven gear 1

19 Push lever shaft 1

Order

Part name Q'tyRemarks

Page 127 of 224

5-31

CLUTCH

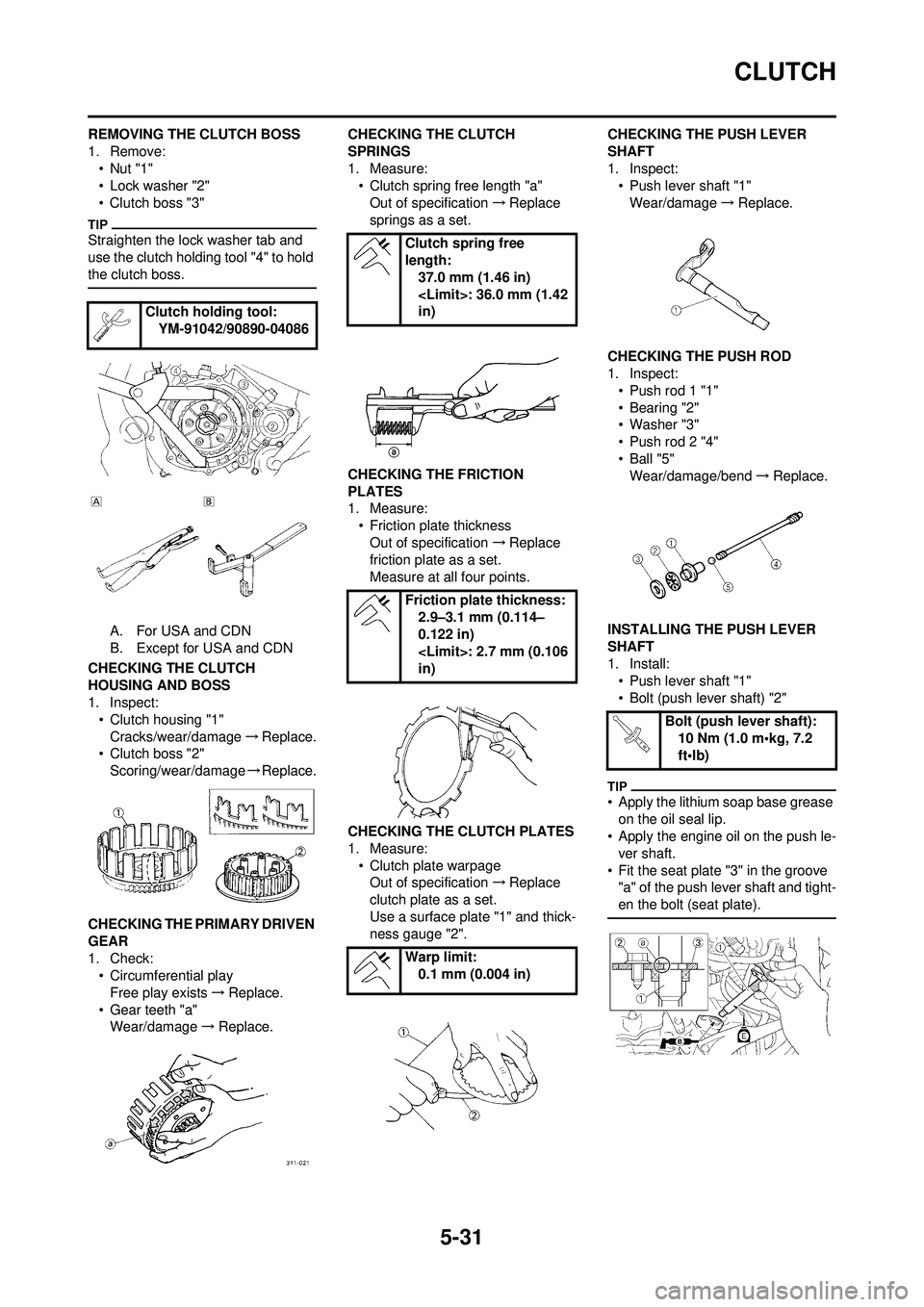

REMOVING THE CLUTCH BOSS

1. Remove:•Nut "1"

• Lock washer "2"

• Clutch boss "3"

Straighten the lock washer tab and

use the clutch holding tool "4" to hold

the clutch boss.

A. For USA and CDN

B. Except for USA and CDN

CHECKING THE CLUTCH

HOUSING AND BOSS

1. Inspect: • Clutch housing "1"Cracks/wear/damage →Replace.

• Clutch boss "2"

Scoring/wear/damage →Replace.

CHECKING THE PRIMARY DRIVEN

GEAR

1. Check: • Circumferential play

Free play exists →Replace.

• Gear teeth "a" Wear/damage →Replace. CHECKING THE CLUTCH

SPRINGS

1. Measure:

• Clutch spring free length "a"

Out of specification →Replace

springs as a set.

CHECKING THE FRICTION

PLATES

1. Measure: • Friction plate thicknessOut of specification →Replace

friction plate as a set.

Measure at all four points.

CHECKING THE CLUTCH PLATES

1. Measure: • Clutch plate warpageOut of specification →Replace

clutch plate as a set.

Use a surface plate "1" and thick-

ness gauge "2". CHECKING THE PUSH LEVER

SHAFT

1. Inspect:

• Push lever shaft "1"

Wear/damage →Replace.

CHECKING THE PUSH ROD

1. Inspect: • Push rod 1 "1"

• Bearing "2"

• Washer "3"

• Push rod 2 "4"

• Ball "5"Wear/damage/bend →Replace.

INSTALLING THE PUSH LEVER

SHAFT

1. Install: • Push lever shaft "1"

• Bolt (push lever shaft) "2"

• Apply the lithium soap base grease on the oil seal lip.

• Apply the engine oil on the push le-

ver shaft.

• Fit the seat plate "3" in the groove "a" of the push lever shaft and tight-

en the bolt (seat plate).

Clutch holding tool:

YM-91042/90890-04086

Clutch spring free

length:37.0 mm (1.46 in)

in)

Friction plate thickness: 2.9–3.1 mm (0.114–

0.122 in)

in)

Warp limit: 0.1 mm (0.004 in)

Bolt (push lever shaft):10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 128 of 224

5-32

CLUTCH

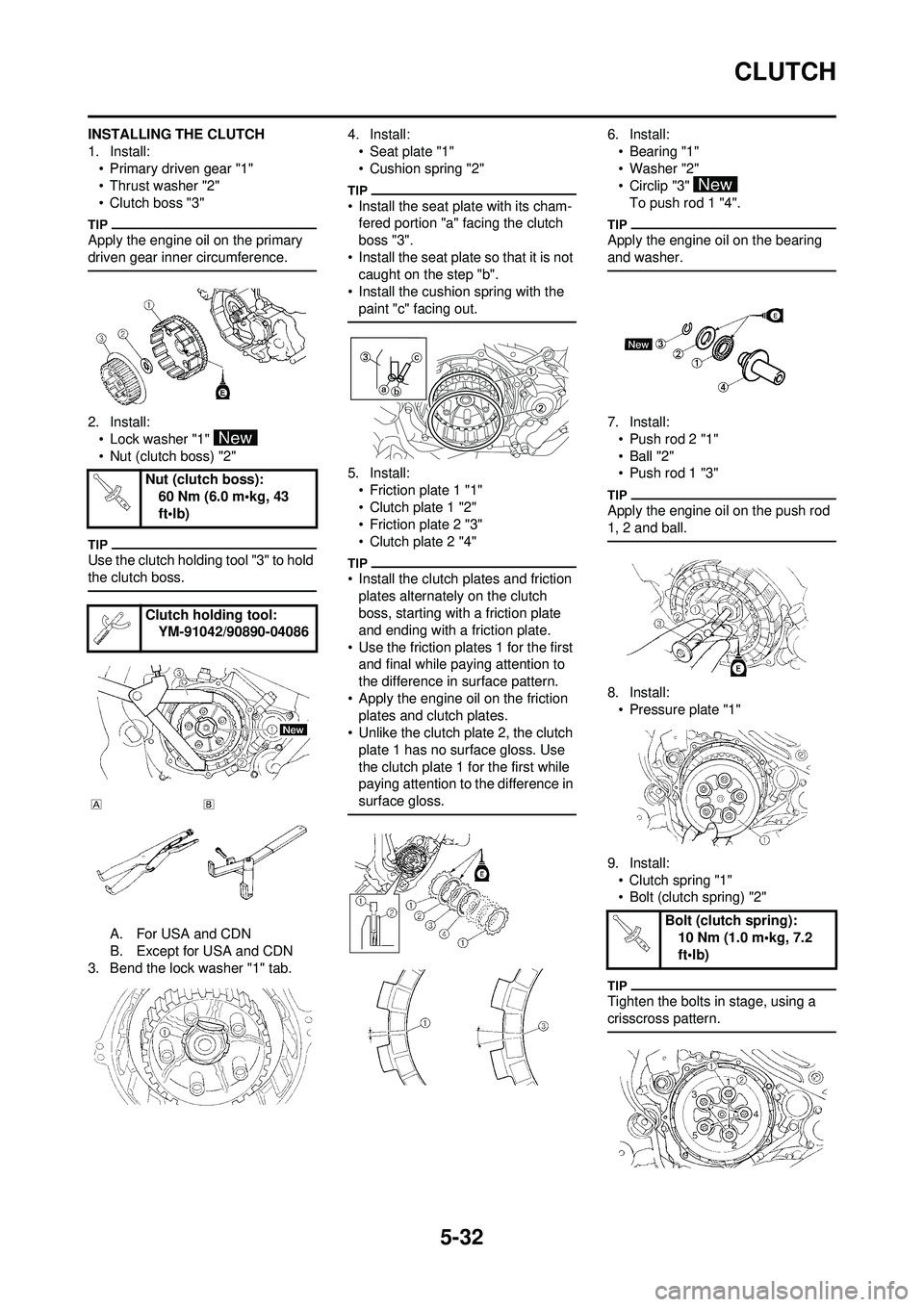

INSTALLING THE CLUTCH

1. Install:• Primary driven gear "1"

• Thrust washer "2"

• Clutch boss "3"

Apply the engine oil on the primary

driven gear inner circumference.

2. Install:• Lock washer "1"

• Nut (clutch boss) "2"

Use the clutch holding tool "3" to hold

the clutch boss.

A. For USA and CDN

B. Except for USA and CDN

3. Bend the lock washer "1" tab. 4. Install:

• Seat plate "1"

• Cushion spring "2"

• Install the seat plate with its cham-fered portion "a" facing the clutch

boss "3".

• Install the seat plate so that it is not caught on the step "b".

• Install the cushion spring with the paint "c" facing out.

5. Install:• Friction plate 1 "1"

• Clutch plate 1 "2"

• Friction plate 2 "3"

• Clutch plate 2 "4"

• Install the clutch plates and friction plates alternately on the clutch

boss, starting with a friction plate

and ending with a friction plate.

• Use the friction plates 1 for the first and final while paying attention to

the difference in surface pattern.

• Apply the engine oil on the friction plates and clutch plates.

• Unlike the clutch plate 2, the clutch plate 1 has no surface gloss. Use

the clutch plate 1 for the first while

paying attention to the difference in

surface gloss.

6. Install:• Bearing "1"

• Washer "2"

• Circlip "3" To push rod 1 "4".

Apply the engine oil on the bearing

and washer.

7. Install:• Push rod 2 "1"

• Ball "2"

• Push rod 1 "3"

Apply the engine oil on the push rod

1, 2 and ball.

8. Install:• Pressure plate "1"

9. Install: • Clutch spring "1"

• Bolt (clutch spring) "2"

Tighten the bolts in stage, using a

crisscross pattern.

Nut (clutch boss): 60 Nm (6.0 m•kg, 43

ft•lb)

Clutch holding tool: YM-91042/90890-04086

Bolt (clutch spring):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 129 of 224

5-33

CLUTCH

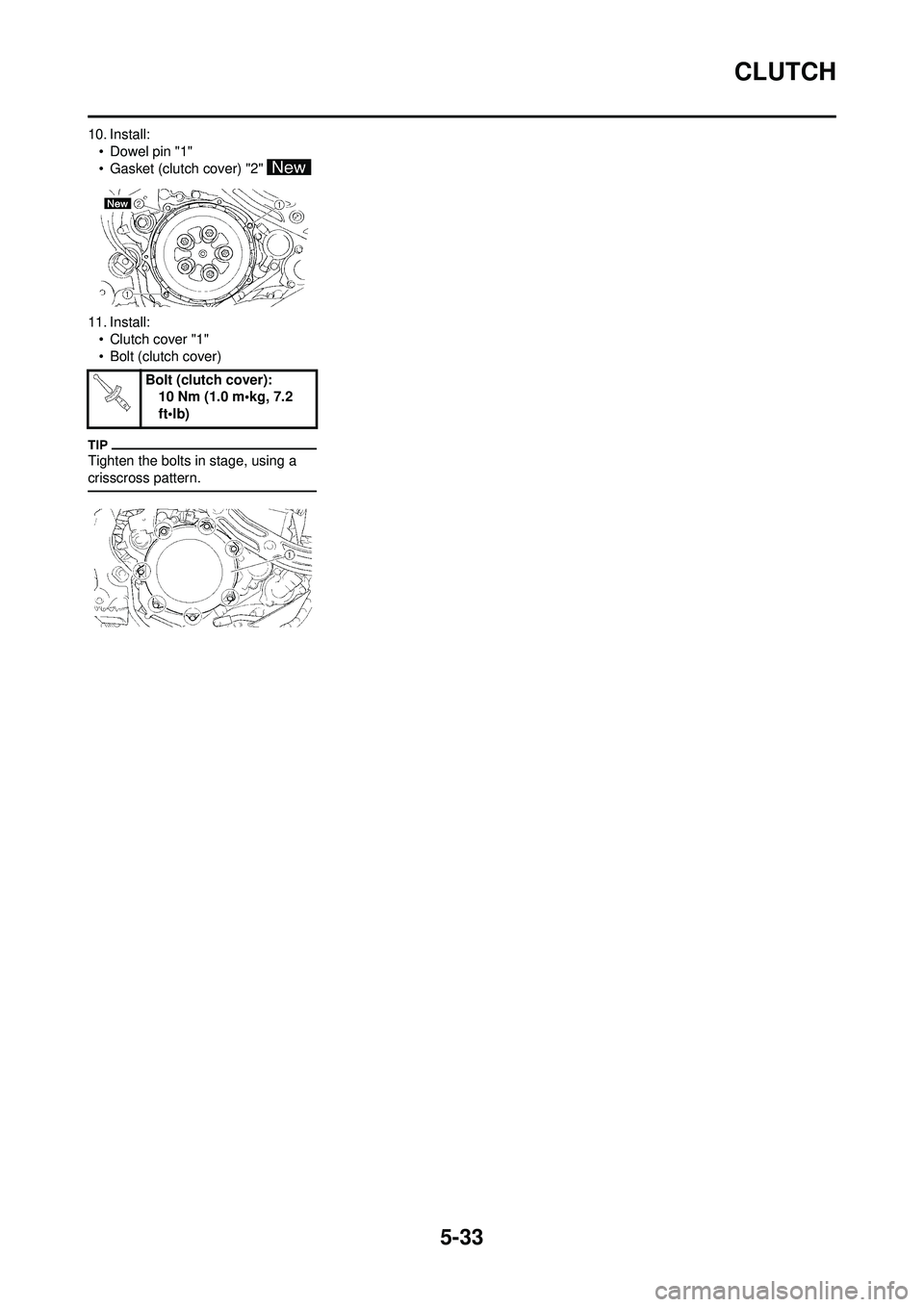

10. Install:• Dowel pin "1"

• Gasket (clutch cover) "2"

11. Install: •Clutch cover "1"

• Bolt (clutch cover)

Tighten the bolts in stage, using a

crisscross pattern.

Bolt (clutch cover): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 130 of 224

5-34

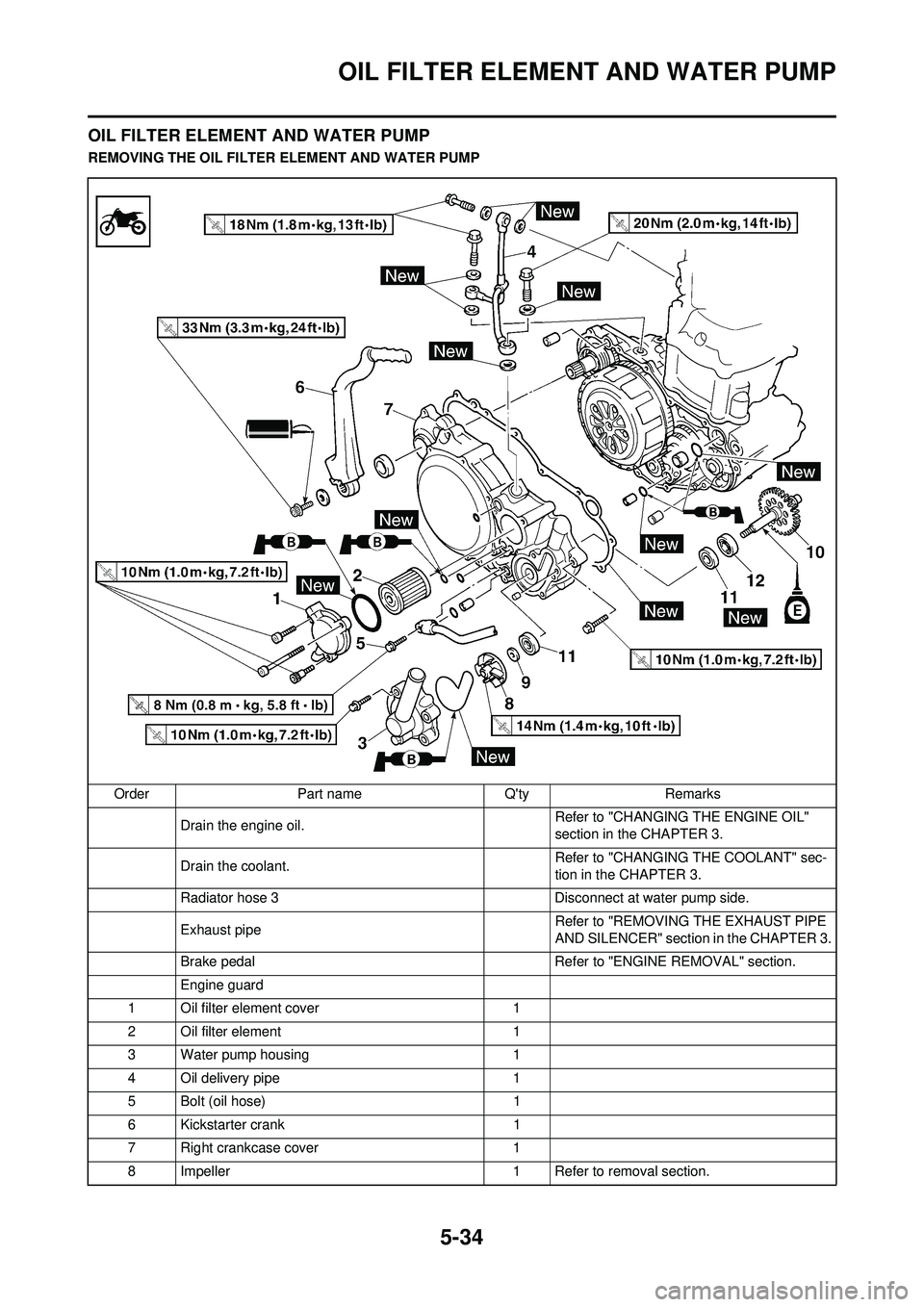

OIL FILTER ELEMENT AND WATER PUMP

OIL FILTER ELEMENT AND WATER PUMP

REMOVING THE OIL FILTER ELEMENT AND WATER PUMPOrder Part name Q'ty Remarks Drain the engine oil. Refer to "CHANGING THE ENGINE OIL"

section in the CHAPTER 3.

Drain the coolant. Refer to "CHANGING THE COOLANT" sec-

tion in the CHAPTER 3.

Radiator hose 3 Disconnect at water pump side.

Exhaust pipe Refer to "REMOVING THE EXHAUST PIPE

AND SILENCER" section in the CHAPTER 3.

Brake pedal Refer to "ENGINE REMOVAL" section.

Engine guard

1 Oil filter element cover 1

2 Oil filter element 1

3 Water pump housing 1

4 Oil delivery pipe 1

5 Bolt (oil hose) 1

6 Kickstarter crank 1

7 Right crankcase cover 1

8 Impeller 1 Refer to removal section.