YAMAHA WR 250F 2015 Owners Manual

Manufacturer: YAMAHA, Model Year: 2015, Model line: WR 250F, Model: YAMAHA WR 250F 2015Pages: 430, PDF Size: 14.14 MB

Page 411 of 430

ELECTRICAL COMPONENTS

9-77

EAS2GB2397CHECKING THE SPEED SENSOR

1. Check:

• Speed sensor output voltage

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the test harness-speed sensor (3P)

to the speed sensor coupler and wire har-

ness.

b. Connect the pocket tester (DC20V) to the

test harness-speed sensor (3P).

c. Set the main switch to “ON”.

d. Elevate the front wheel and slowly turn it.

e. Measure the voltage (DC 5 V) of white and

black/white. With the front wheel slowly ro-

tating, voltage alternates between 0 V and 5

V.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲EAS2GB2398CHECKING THE FUEL SENDER

1. Drain the gasoline.

2. Disconnect:

• Fuel sender coupler

(from the fuel sender)

3. Remove:

• Fuel sender

(from the fuel tank)4. Check:

• Fuel sender resistance

Out of specification Replace the fuel

sender.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k) to the

fuel sender as shown.

b. Measure the resistance of the fuel sender.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2399CHECKING THE RESISTER

1. Disconnect:

• Resister coupler

(from the wire harness)

2. Check:

• Resister resistance

Out of specification Replace the resister.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 10) to the re-

sister as shown. Output voltage reading cycle

0.6V to 4.8V to 0.6V to 4.8V

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Test harness– speed sensor 5TJ

(3P)

90890-03228

Test harness– speed sensor 5TJ

(3P)

YU-03228

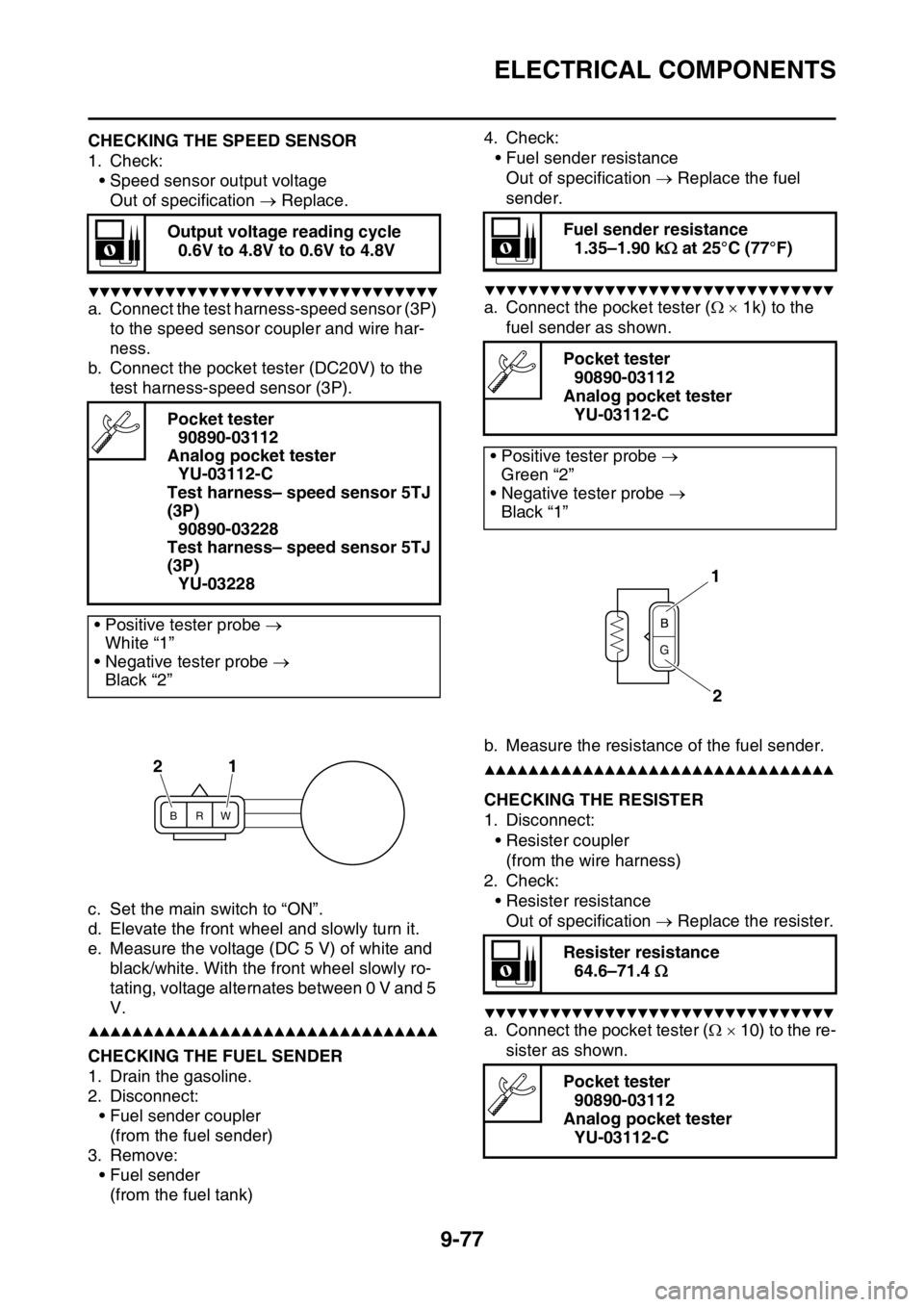

• Positive tester probe

White “1”

• Negative tester probe

Black “2”

BRW

21

Fuel sender resistance

1.35–1.90 k at 25°C (77°F)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

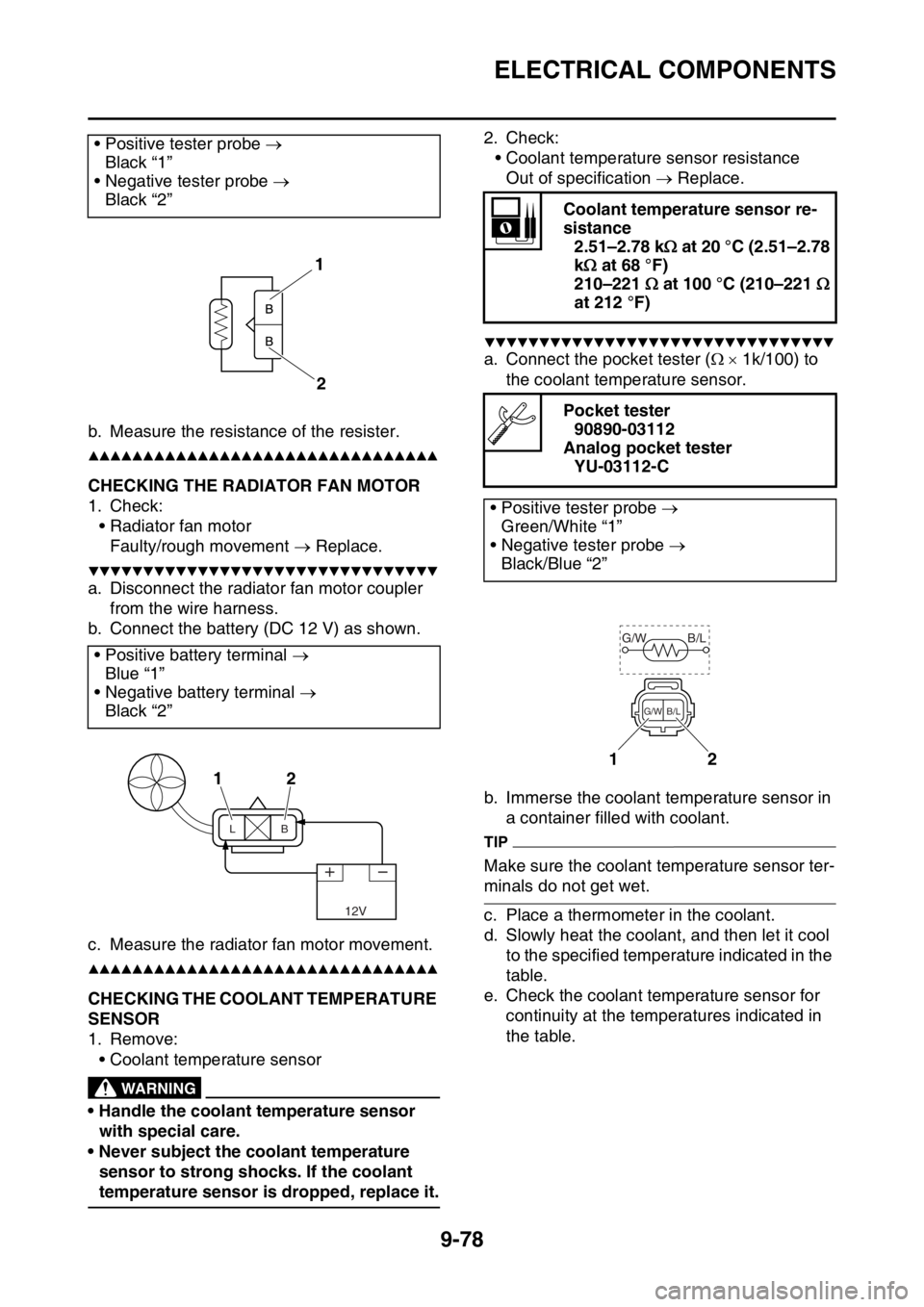

• Positive tester probe

Green “2”

• Negative tester probe

Black “1”

Resister resistance

64.6–71.4

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

1

2

Page 412 of 430

ELECTRICAL COMPONENTS

9-78

b. Measure the resistance of the resister.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2400CHECKING THE RADIATOR FAN MOTOR

1. Check:

• Radiator fan motor

Faulty/rough movement Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Disconnect the radiator fan motor coupler

from the wire harness.

b. Connect the battery (DC 12 V) as shown.

c. Measure the radiator fan motor movement.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2401CHECKING THE COOLANT TEMPERATURE

SENSOR

1. Remove:

• Coolant temperature sensor

EWA

WARNING

• Handle the coolant temperature sensor

with special care.

• Never subject the coolant temperature

sensor to strong shocks. If the coolant

temperature sensor is dropped, replace it.2. Check:

• Coolant temperature sensor resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k/100) to

the coolant temperature sensor.

b. Immerse the coolant temperature sensor in

a container filled with coolant.

TIP

Make sure the coolant temperature sensor ter-

minals do not get wet.

c. Place a thermometer in the coolant.

d. Slowly heat the coolant, and then let it cool

to the specified temperature indicated in the

table.

e. Check the coolant temperature sensor for

continuity at the temperatures indicated in

the table. • Positive tester probe

Black “1”

• Negative tester probe

Black “2”

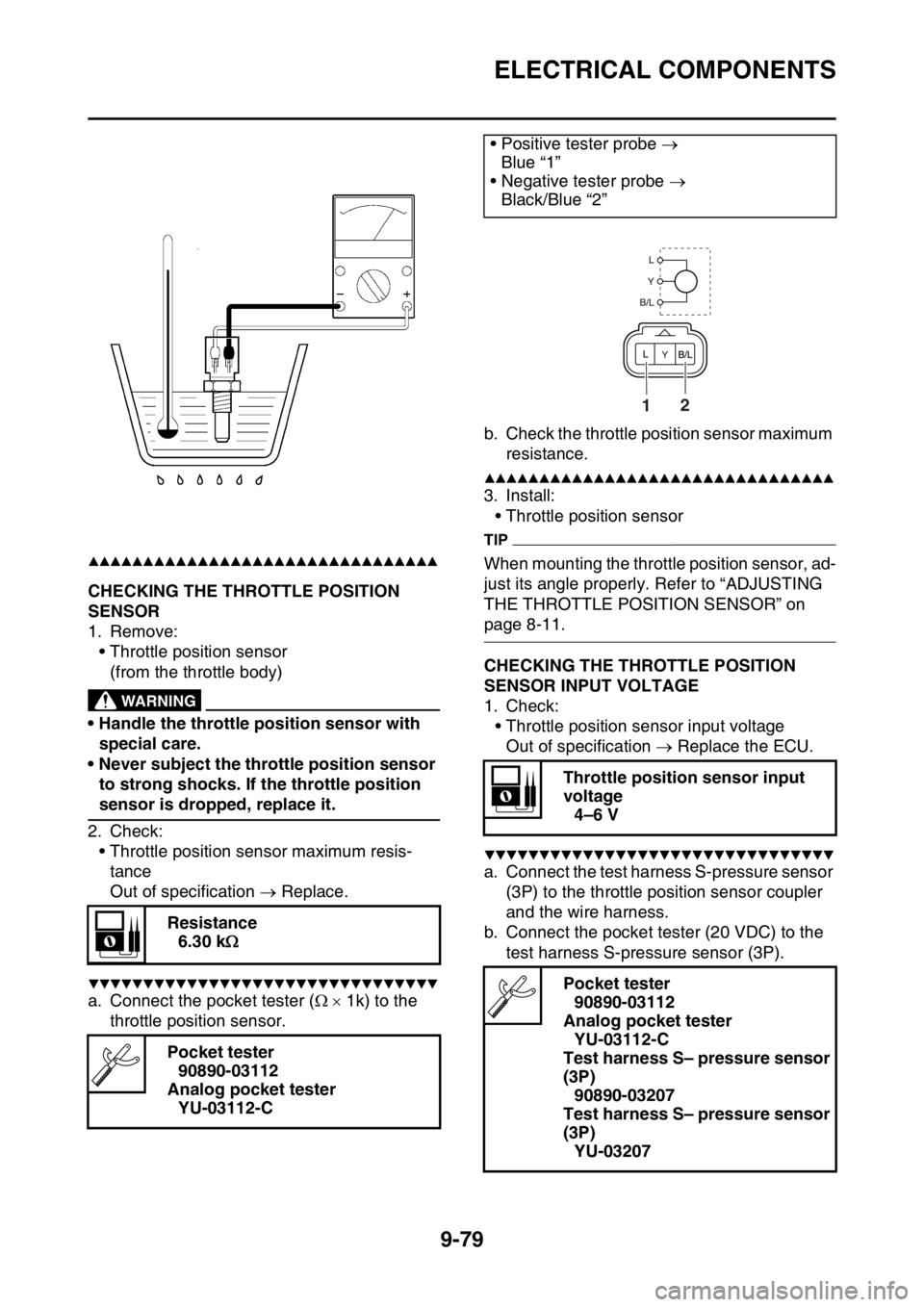

• Positive battery terminal

Blue “1”

• Negative battery terminal

Black “2”

1

2

12

12V

LB

Coolant temperature sensor re-

sistance

2.51–2.78 k at 20 °C (2.51–2.78

k at 68 °F)

210–221 at 100 °C (210–221

at 212 °F)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Green/White “1”

• Negative tester probe

Black/Blue “2”

12

G/W B/L

B/L G/W

Page 413 of 430

ELECTRICAL COMPONENTS

9-79

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2402CHECKING THE THROTTLE POSITION

SENSOR

1. Remove:

• Throttle position sensor

(from the throttle body)

EWA

WARNING

• Handle the throttle position sensor with

special care.

• Never subject the throttle position sensor

to strong shocks. If the throttle position

sensor is dropped, replace it.

2. Check:

• Throttle position sensor maximum resis-

tance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k) to the

throttle position sensor.b. Check the throttle position sensor maximum

resistance.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Install:

• Throttle position sensor

TIP

When mounting the throttle position sensor, ad-

just its angle properly. Refer to “ADJUSTING

THE THROTTLE POSITION SENSOR” on

page 8-11.

EAS2GB2403CHECKING THE THROTTLE POSITION

SENSOR INPUT VOLTAGE

1. Check:

• Throttle position sensor input voltage

Out of specification Replace the ECU.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the test harness S-pressure sensor

(3P) to the throttle position sensor coupler

and the wire harness.

b. Connect the pocket tester (20 VDC) to the

test harness S-pressure sensor (3P). Resistance

6.30 k

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

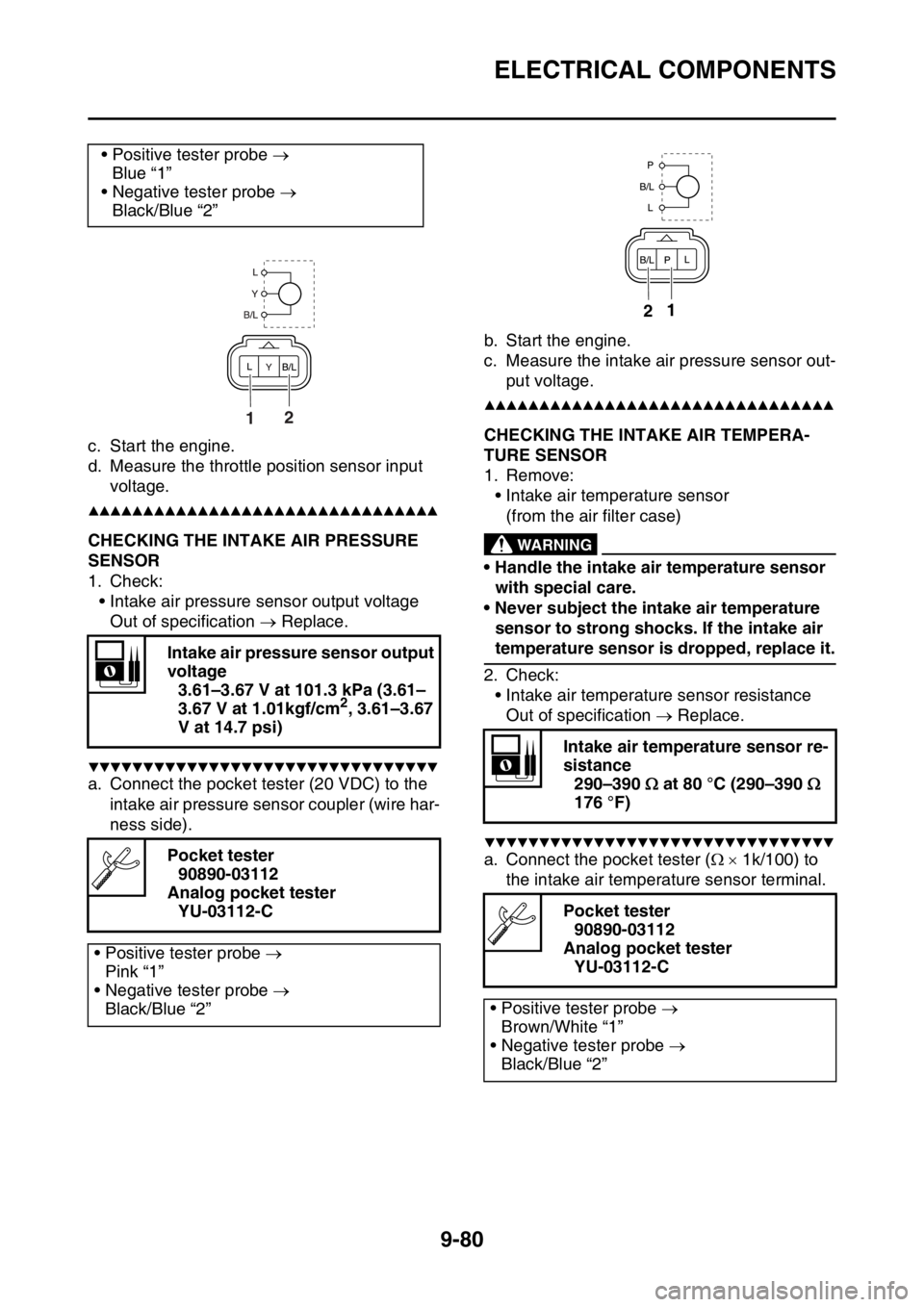

• Positive tester probe

Blue “1”

• Negative tester probe

Black/Blue “2”

Throttle position sensor input

voltage

4–6 V

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Test harness S– pressure sensor

(3P)

90890-03207

Test harness S– pressure sensor

(3P)

YU-03207

21

Page 414 of 430

ELECTRICAL COMPONENTS

9-80

c. Start the engine.

d. Measure the throttle position sensor input

voltage.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2404CHECKING THE INTAKE AIR PRESSURE

SENSOR

1. Check:

• Intake air pressure sensor output voltage

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester (20 VDC) to the

intake air pressure sensor coupler (wire har-

ness side).b. Start the engine.

c. Measure the intake air pressure sensor out-

put voltage.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2405CHECKING THE INTAKE AIR TEMPERA-

TURE SENSOR

1. Remove:

• Intake air temperature sensor

(from the air filter case)

EWA

WARNING

• Handle the intake air temperature sensor

with special care.

• Never subject the intake air temperature

sensor to strong shocks. If the intake air

temperature sensor is dropped, replace it.

2. Check:

• Intake air temperature sensor resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k/100) to

the intake air temperature sensor terminal. • Positive tester probe

Blue “1”

• Negative tester probe

Black/Blue “2”

Intake air pressure sensor output

voltage

3.61–3.67 V at 101.3 kPa (3.61–

3.67 V at 1.01kgf/cm

2, 3.61–3.67

V at 14.7 psi)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Pink “1”

• Negative tester probe

Black/Blue “2”

21

Intake air temperature sensor re-

sistance

290–390 at 80 °C (290–390

176 °F)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Brown/White “1”

• Negative tester probe

Black/Blue “2”

12

Page 415 of 430

ELECTRICAL COMPONENTS

9-81

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

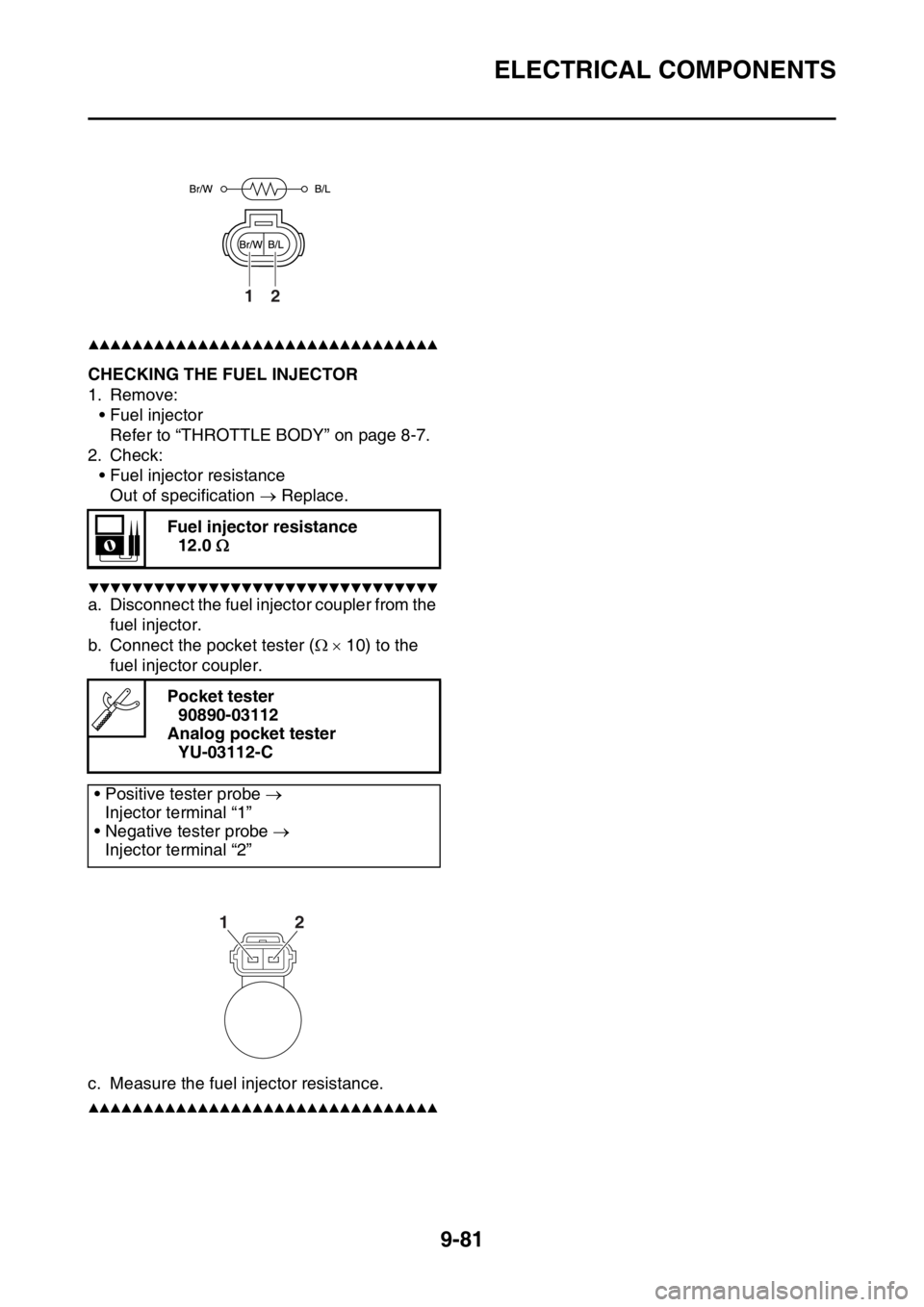

EAS2GB2406CHECKING THE FUEL INJECTOR

1. Remove:

• Fuel injector

Refer to “THROTTLE BODY” on page 8-7.

2. Check:

• Fuel injector resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Disconnect the fuel injector coupler from the

fuel injector.

b. Connect the pocket tester ( 10) to the

fuel injector coupler.

c. Measure the fuel injector resistance.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Fuel injector resistance

12.0

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Injector terminal “1”

• Negative tester probe

Injector terminal “2”

12

12

Page 416 of 430

ELECTRICAL COMPONENTS

9-83

Page 417 of 430

10

TROUBLESHOOTING

TROUBLESHOOTING.................................................................................... 10-1

GENERAL INFORMATION ...................................................................... 10-1

STARTING FAILURES ............................................................................. 10-1

INCORRECT ENGINE IDLING SPEED ................................................... 10-1

POOR MEDIUM-AND-HIGH-SPEED PERFORMANCE .......................... 10-2

SHIFTING IS DIFFICULT ......................................................................... 10-2

SHIFT PEDAL DOES NOT MOVE ........................................................... 10-2

JUMPS OUT OF GEAR............................................................................ 10-2

CLUTCH SLIPS ........................................................................................ 10-2

CLUTCH DRAGS ..................................................................................... 10-2

OVERHEATING ....................................................................................... 10-2

OVERCOOLING ....................................................................................... 10-3

POOR BRAKING PERFORMANCE ......................................................... 10-3

FRONT FORK OIL LEAKING ................................................................... 10-3

FAULTY FRONT FORK LEGS ................................................................. 10-3

UNSTABLE HANDLING ........................................................................... 10-3

HEADLIGHT DOES NOT COME ON ....................................................... 10-4

HEADLIGHT BULB BURNT OUT............................................................. 10-4

TAILLIGHT DOES NOT COME ON ......................................................... 10-4

LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE ACTIONS........................... 10-5

Page 418 of 430

TROUBLESHOOTING

10-1

EAS2GB2407

TROUBLESHOOTING

EAS2GB2408GENERAL INFORMATION

TIP

The following guide for troubleshooting does

not cover all the possible causes of trouble. It

should be helpful, however, as a guide to basic

troubleshooting. Refer to the relative procedure

in this manual for checks, adjustments, and re-

placement of parts.

EAS2GB2409STARTING FAILURES

Engine

1. Cylinder and cylinder head

• Loose spark plug

• Loose cylinder head or cylinder

• Damaged cylinder head gasket

• Damaged cylinder gasket

• Worn or damaged cylinder

• Incorrect valve clearance

• Improperly sealed valve

• Incorrect valve-to-valve-seat contact

• Incorrect valve timing

• Faulty valve spring

• Seized valve

2. Piston and piston ring(s)

• Improperly installed piston ring

• Damaged, worn or fatigued piston ring

• Seized piston ring

• Seized or damaged piston

3. Air filter

• Improperly installed air filter

• Clogged air filter element

4. Crankcase and crankshaft

• Improperly assembled crankcase

• Seized crankshaft

Fuel system

1. Fuel tank

• Empty fuel tank

• Clogged fuel tank breather hose

• Deteriorated or contaminated fuel

• Clogged or damaged fuel hose

2. Fuel pump

• Faulty fuel pump

3. Throttle body

• Deteriorated or contaminated fuel

• Sucked-in air

Electrical system

1. Spark plug

• Incorrect spark plug gap• Incorrect spark plug heat range

• Fouled spark plug

• Worn or damaged electrode

• Worn or damaged insulator

2. Ignition coil

• Cracked or broken ignition coil body

• Broken or shorted primary or secondary

coils

3. Ignition system

• Faulty ECU

• Faulty crankshaft position sensor

• Broken generator rotor woodruff key

4. Switches and wiring

• Faulty ECU

• Faulty engine stop switch

• Broken or shorted wiring

• Faulty neutral switch

• Improperly grounded circuit

• Loose connections

EAS2GB2410INCORRECT ENGINE IDLING SPEED

Engine

1. Cylinder and cylinder head

• Incorrect valve clearance

• Damaged valve train components

2. Air filter

• Clogged air filter element

Fuel system

1. Throttle body

• Damaged or loose throttle body joint

• Improperly synchronized throttle bodies

• Improper throttle cable free play

• Flooded throttle body

Electrical system

1. Spark plug

• Incorrect spark plug gap

• Incorrect spark plug heat range

• Fouled spark plug

• Worn or damaged electrode

• Worn or damaged insulator

• Faulty spark plug cap

2. Ignition coil

• Broken or shorted primary or secondary

coils

• Cracked or broken ignition coil

3. Ignition system

• Faulty ECU

• Faulty crankshaft position sensor

• Broken generator rotor woodruff key

Page 419 of 430

TROUBLESHOOTING

10-2

EAS2GB2411POOR MEDIUM-AND-HIGH-SPEED PER-

FORMANCE

Refer to “STARTING FAILURES” on page 10-

1.

Engine

1. Air filter

• Clogged air filter element

Fuel system

1. Fuel pump

• Faulty fuel pump

2. Throttle body

• Defective throttle body

3. ECU

• Faulty ECU

EAS2GB2412SHIFTING IS DIFFICULT

Refer to “CLUTCH” on page 6-40.

EAS2GB2413SHIFT PEDAL DOES NOT MOVE

Engine

1. Shift shaft

• Bent shift shaft

2. Shift drum and shift forks

• Foreign object in a shift drum groove

• Seized shift fork

• Bent shift fork guide bar

3. Transmission

• Seized transmission gear

• Foreign object between transmission gears

• Improperly assembled transmission

EAS2GB2414JUMPS OUT OF GEAR

Engine

1. Shift shaft

• Incorrect shift pedal position

• Improperly returned stopper lever

2. Shift forks

• Worn shift fork

3. Shift drum

• Incorrect axial play

• Worn shift drum groove

4. Transmission

• Worn gear dog

EAS2GB2415CLUTCH SLIPS

Engine

1. Clutch

• Improperly assembled clutch

• Loose or fatigued clutch spring

• Worn friction plate

• Worn clutch plate

2. Engine oil

• Incorrect oil level

• Incorrect oil viscosity (low)

• Deteriorated oil

EAS2GB2416CLUTCH DRAGS

Engine

1. Clutch

• Unevenly tensioned clutch springs

• Warped pressure plate

• Bent clutch plate

• Swollen friction plate

• Bent clutch push rod

• Damaged clutch boss

• Burnt primary driven gear bushing

2. Engine oil

• Incorrect oil level

• Incorrect oil viscosity (high)

• Deteriorated oil

EAS2GB2417OVERHEATING

Engine

1. Cylinder head and piston

• Heavy carbon buildup

• Clogged coolant passages

2. Engine oil

• Incorrect oil level

• Incorrect oil viscosity

• Inferior oil quality

Cooling system

1. Coolant

• Low coolant level

2. Radiator

• Damaged or leaking radiator

• Faulty radiator cap

• Bent or damaged radiator fin

3. Water pump

• Damaged or faulty water pump

• Damaged hose

• Improperly connected hose

• Damaged pipe

• Improperly connected pipe

Page 420 of 430

TROUBLESHOOTING

10-3

Fuel system

1. Throttle body

• Damaged or loose throttle body joint

2. Air filter

• Clogged air filter element

Chassis

1. Brake(s)

• Dragging brake

Electrical system

1. Spark plug

• Incorrect spark plug gap

• Incorrect spark plug heat range

2. Ignition system

• Faulty ECU

• Faulty coolant temperature sensor

EAS2GB2418OVERCOOLING

Cooling system

1. Coolant temperature sensor

• Faulty coolant temperature sensor

EAS2GB2419POOR BRAKING PERFORMANCE

Chassis

1. Brake(s)

• Worn brake pad

• Worn brake disc

• Air in hydraulic brake system

• Leaking brake fluid

• Defective master cylinder kit

• Faulty brake caliper kit

• Faulty brake caliper seal

• Loose union bolt

• Damaged brake hose

• Oil or grease on the brake disc

• Oil or grease on the brake pad

• Incorrect brake fluid level

EAS2GB2420FRONT FORK OIL LEAKING

Chassis

1. Front fork

• Bent, damaged, or rusty inner tube

• Cracked or damaged outer tube

• Improperly installed oil seal

• Damaged oil seal lip

• Incorrect oil level (high)

• Loose damper rod assembly bolt

• Damaged damper rod assembly bolt copper

washer

• Cracked or damaged cap bolt O-ring

EAS2GB2421FAULTY FRONT FORK LEGS

Chassis

1. Front fork

• Bent or damaged inner tube

• Bent or damaged outer tube

• Broken fork spring

• Bent or damaged damper rod

• Incorrect oil viscosity

• Incorrect oil level

EAS2GB2422UNSTABLE HANDLING

Chassis

1. Handlebar

• Bent or improperly installed handlebar

2. Steering head components

• Improperly installed upper bracket

• Improperly installed lower bracket

(improperly tightened ring nut)

• Bent steering stem

• Damaged ball bearing or bearing race

3. Front fork leg (s)

• Uneven oil levels (both front fork legs)

• Unevenly tensioned fork spring (both front

fork legs)

• Broken fork spring

• Bent or damaged inner tube

• Bent or damaged outer tube

4. Swingarm

• Worn bearing or bushing

• Bent or damaged swingarm

5. Rear shock absorber assembly (-ies)

• Faulty rear shock absorber spring

• Leaking oil or gas

6. Tire (s)

• Uneven tire pressures (front and rear)

• Incorrect tire pressure

• Uneven tire wear

7. Wheel (s)

• Incorrect wheel balance

• Broken or loose spoke

• Damaged wheel bearing

• Bent or loose wheel axle

• Excessive wheel runout

8. Frame

• Bent frame

• Damaged steering head pipe

• Improperly installed bearing race