engine YAMAHA WR 400F 2000 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: WR 400F, Model: YAMAHA WR 400F 2000Pages: 654, PDF Size: 60.12 MB

Page 430 of 654

4 - 84

ENGCRANKCASE AND CRANKSHAFT

EC4N4101

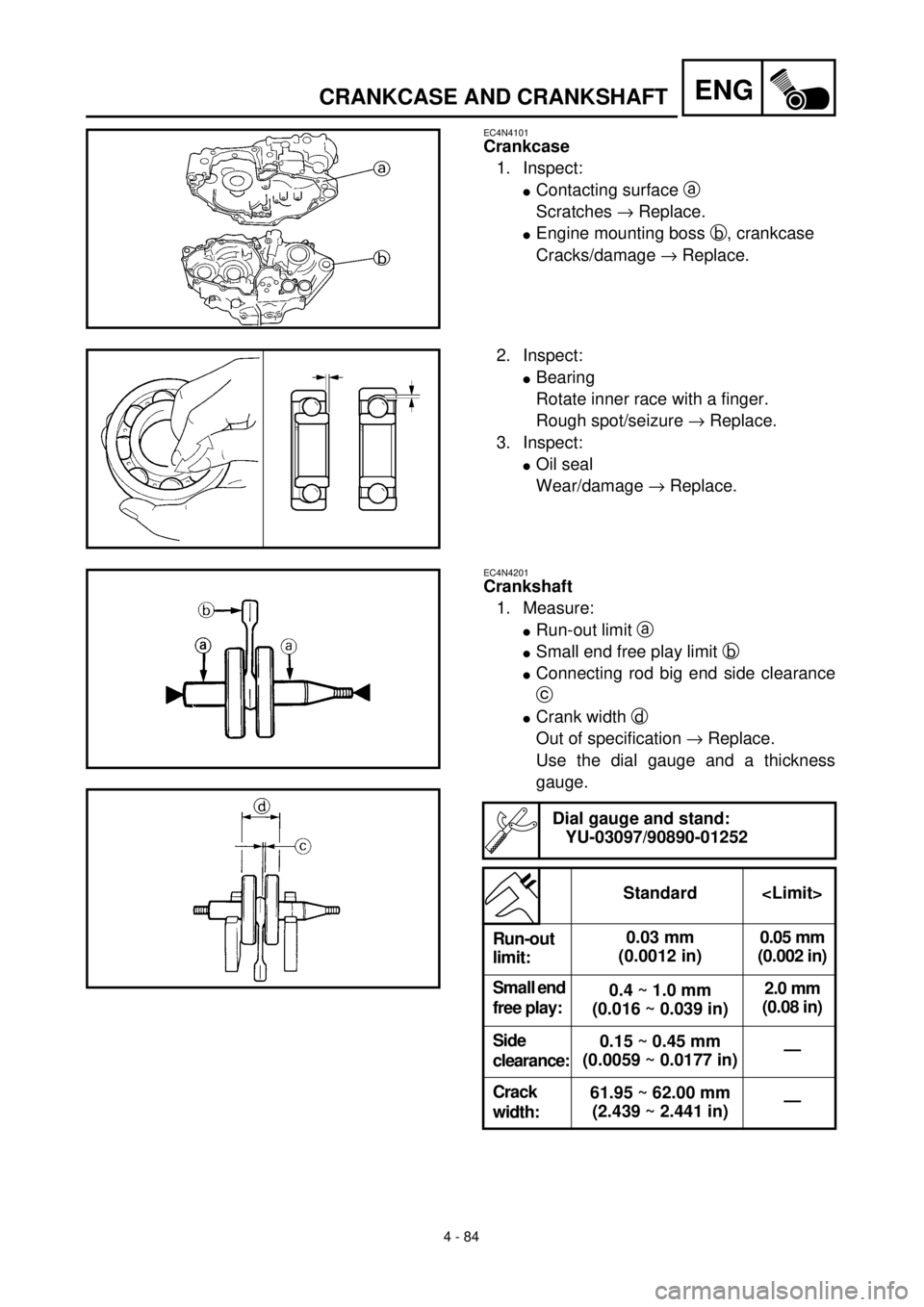

Crankcase

1. Inspect:

lContacting surface a

Scratches ® Replace.

lEngine mounting boss b, crankcase

Cracks/damage ® Replace.

2. Inspect:

lBearing

Rotate inner race with a finger.

Rough spot/seizure ® Replace.

3. Inspect:

lOil seal

Wear/damage ® Replace.

EC4N4201

Crankshaft

1. Measure:

lRun-out limit a

lSmall end free play limit b

lConnecting rod big end side clearance

c

lCrank width d

Out of specification ® Replace.

Use the dial gauge and a thickness

gauge.

Dial gauge and stand:

YU-03097/90890-01252

Standard

Run-out

limit:0.03 mm

(0.0012 in)0.05 mm

(0.002 in)

Small end

free play:0.4 ~ 1.0 mm

(0.016 ~ 0.039 in)2.0 mm

(0.08 in)

Side

clearance:0.15 ~ 0.45 mm

(0.0059 ~ 0.0177 in)—

Crack

width:61.95 ~ 62.00 mm

(2.439 ~ 2.441 in)—

Page 436 of 654

4 - 87

ENGCRANKCASE AND CRANKSHAFT

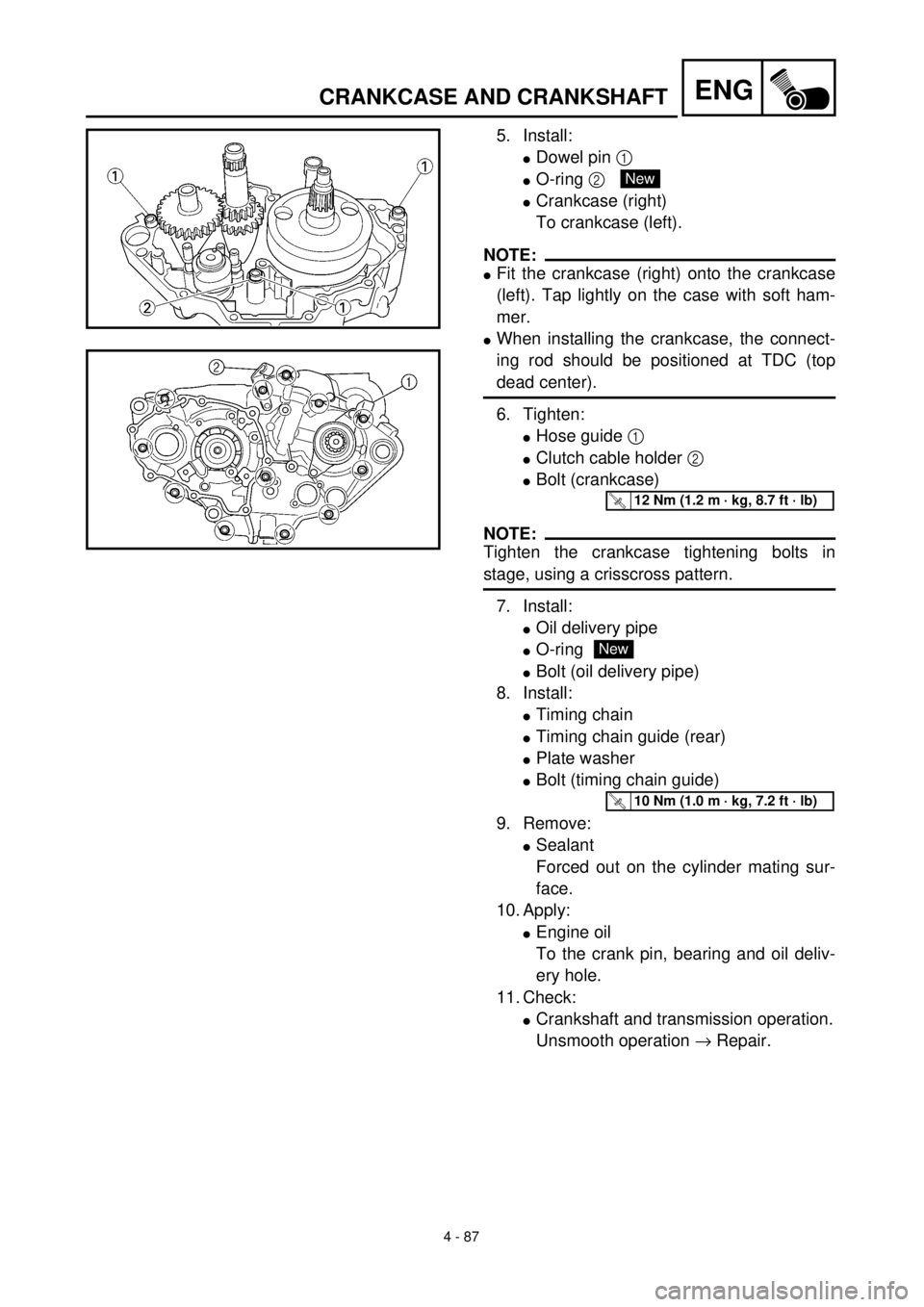

5. Install:

lDowel pin 1

lO-ring 2

lCrankcase (right)

To crankcase (left).

NOTE:

lFit the crankcase (right) onto the crankcase

(left). Tap lightly on the case with soft ham-

mer.

lWhen installing the crankcase, the connect-

ing rod should be positioned at TDC (top

dead center).

6. Tighten:

lHose guide 1

lClutch cable holder 2

lBolt (crankcase)

NOTE:

Tighten the crankcase tightening bolts in

stage, using a crisscross pattern.

7. Install:

lOil delivery pipe

lO-ring

lBolt (oil delivery pipe)

8. Install:

lTiming chain

lTiming chain guide (rear)

lPlate washer

lBolt (timing chain guide)

9. Remove:

lSealant

Forced out on the cylinder mating sur-

face.

10. Apply:

lEngine oil

To the crank pin, bearing and oil deliv-

ery hole.

11. Check:

lCrankshaft and transmission operation.

Unsmooth operation ® Repair.

New

T R..12 Nm (1.2 m · kg, 8.7 ft · lb)

New

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 438 of 654

ENG

4 - 88

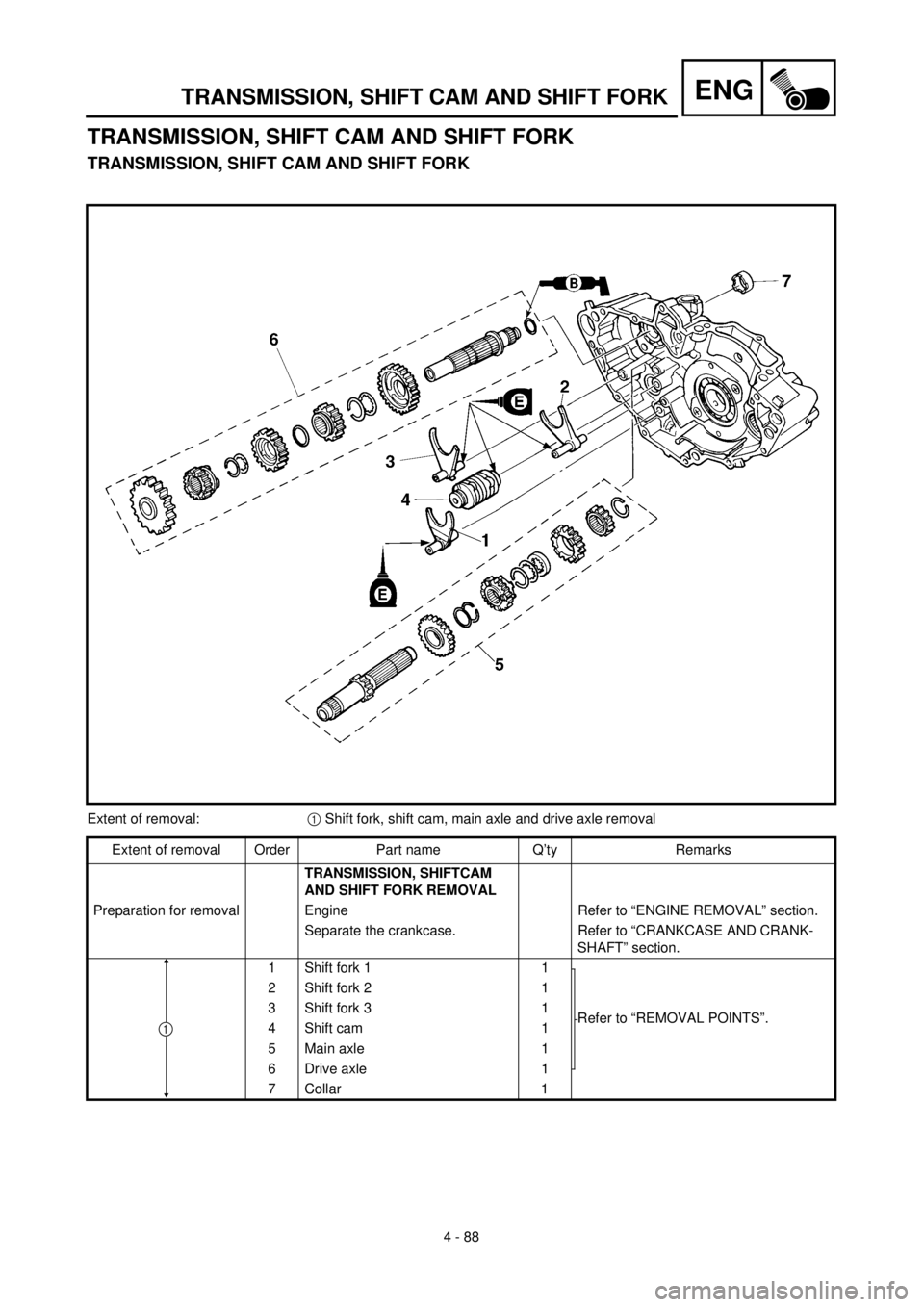

TRANSMISSION, SHIFT CAM AND SHIFT FORK

TRANSMISSION, SHIFT CAM AND SHIFT FORK

TRANSMISSION, SHIFT CAM AND SHIFT FORK

Extent of removal:1 Shift fork, shift cam, main axle and drive axle removal

Extent of removal Order Part name Q’ty Remarks

TRANSMISSION, SHIFTCAM

AND SHIFT FORK REMOVAL

Preparation for removal Engine Refer to “ENGINE REMOVAL” section.

Separate the crankcase. Refer to “CRANKCASE AND CRANK-

SHAFT” section.

1 Shift fork 1 1

Refer to “REMOVAL POINTS”. 2 Shift fork 2 1

3 Shift fork 3 1

4 Shift cam 1

5 Main axle 1

6 Drive axle 1

7Collar

1

1

Page 446 of 654

4 - 92

ENGTRANSMISSION, SHIFT CAM AND SHIFT FORK

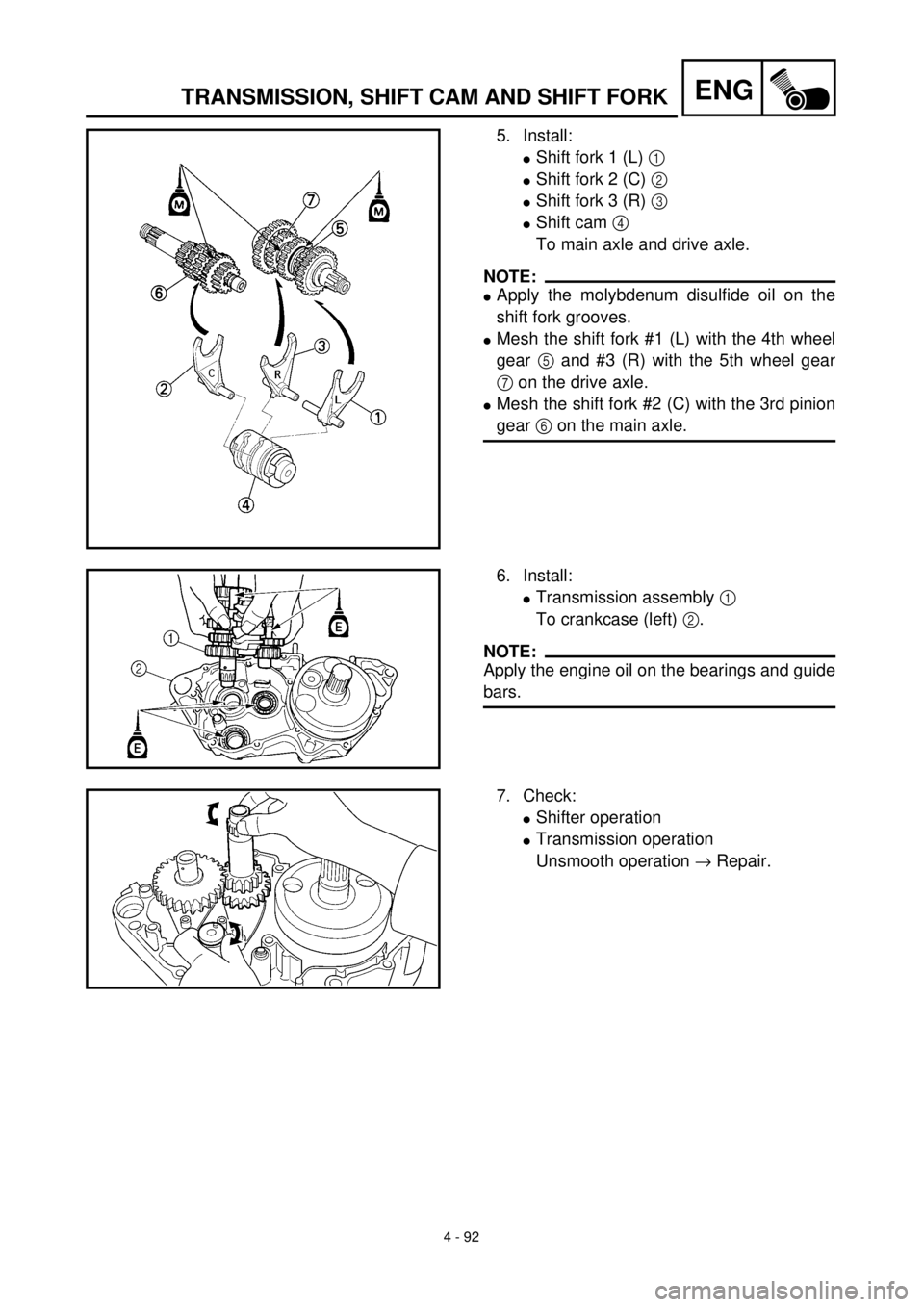

5. Install:

lShift fork 1 (L) 1

lShift fork 2 (C) 2

lShift fork 3 (R) 3

lShift cam 4

To main axle and drive axle.

NOTE:

lApply the molybdenum disulfide oil on the

shift fork grooves.

lMesh the shift fork #1 (L) with the 4th wheel

gear 5 and #3 (R) with the 5th wheel gear

7 on the drive axle.

lMesh the shift fork #2 (C) with the 3rd pinion

gear 6 on the main axle.

6. Install:

lTransmission assembly 1

To crankcase (left) 2.

NOTE:

Apply the engine oil on the bearings and guide

bars.

7. Check:

lShifter operation

lTransmission operation

Unsmooth operation ® Repair.

Page 448 of 654

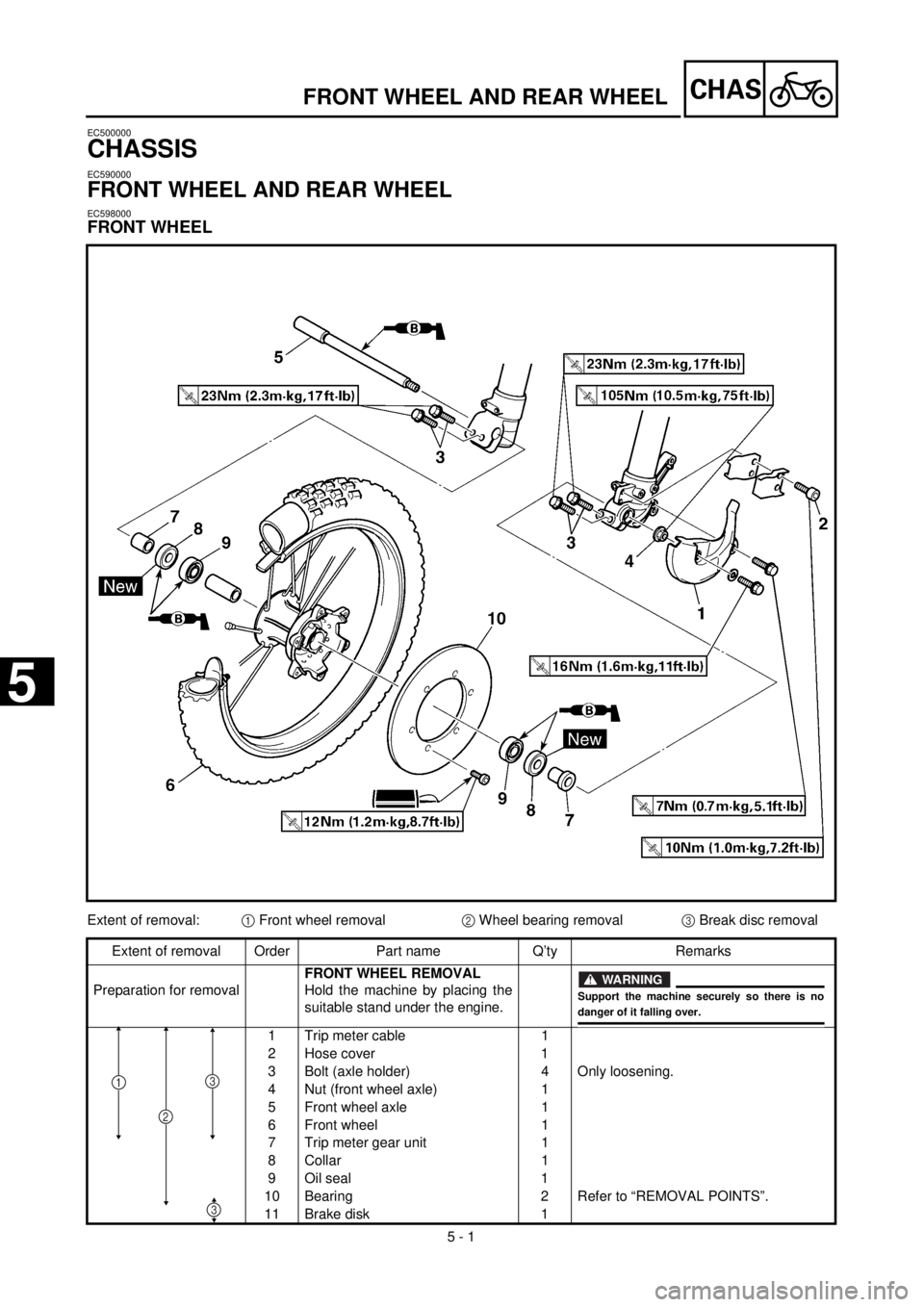

5 - 1

CHAS

EC500000

CHASSIS

EC590000

FRONT WHEEL AND REAR WHEEL

EC598000

FRONT WHEEL

FRONT WHEEL AND REAR WHEEL

Extent of removal:

1

Front wheel removal

2

Wheel bearing removal

3

Break disc removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removal

FRONT WHEEL REMOVAL

Hold the machine by placing the

suitable stand under the engine.

1 Trip meter cable 1

2 Hose cover 1

3 Bolt (axle holder) 4 Only loosening.

4 Nut (front wheel axle) 1

5 Front wheel axle 1

6 Front wheel 1

7 Trip meter gear unit 1

8 Collar 1

9 Oil seal 1

10 Bearing 2 Refer to “REMOVAL POINTS”.

11 Brake disk 1

WARNING

Support the machine securely so there is nodanger of it falling over.

2

31

3

5

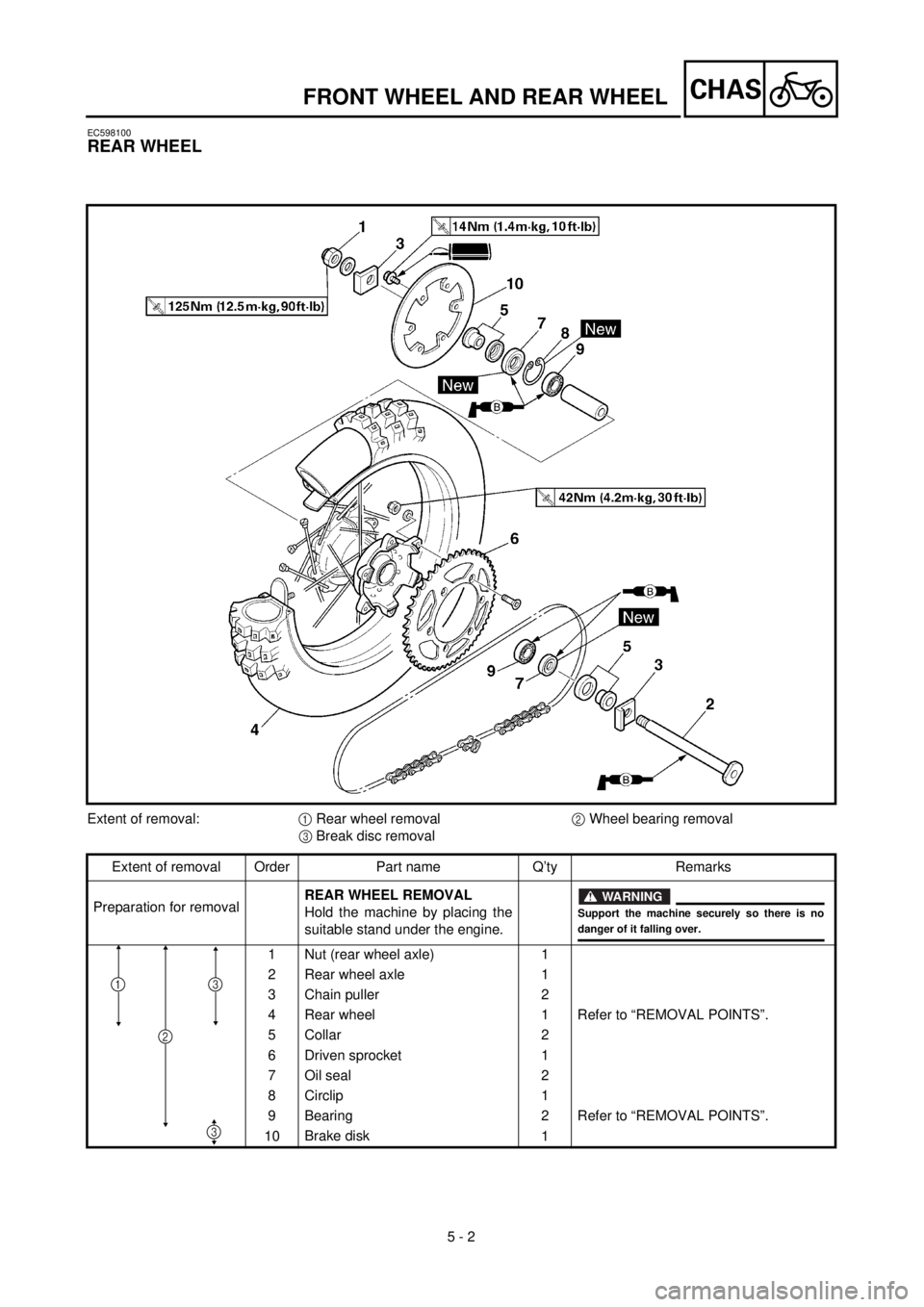

Page 450 of 654

5 - 2

CHAS

EC598100

REAR WHEEL

Extent of removal:

1

Rear wheel removal

2

Wheel bearing removal

3

Break disc removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removal

REAR WHEEL REMOVAL

Hold the machine by placing the

suitable stand under the engine.

1 Nut (rear wheel axle) 1

2 Rear wheel axle 1

3 Chain puller 2

4 Rear wheel 1 Refer to “REMOVAL POINTS”.

5 Collar 2

6 Driven sprocket 1

7 Oil seal 2

8 Circlip 1

9 Bearing 2 Refer to “REMOVAL POINTS”.

10Brake disk

1

WARNING

Support the machine securely so there is nodanger of it falling over.

2

31

3

FRONT WHEEL AND REAR WHEEL

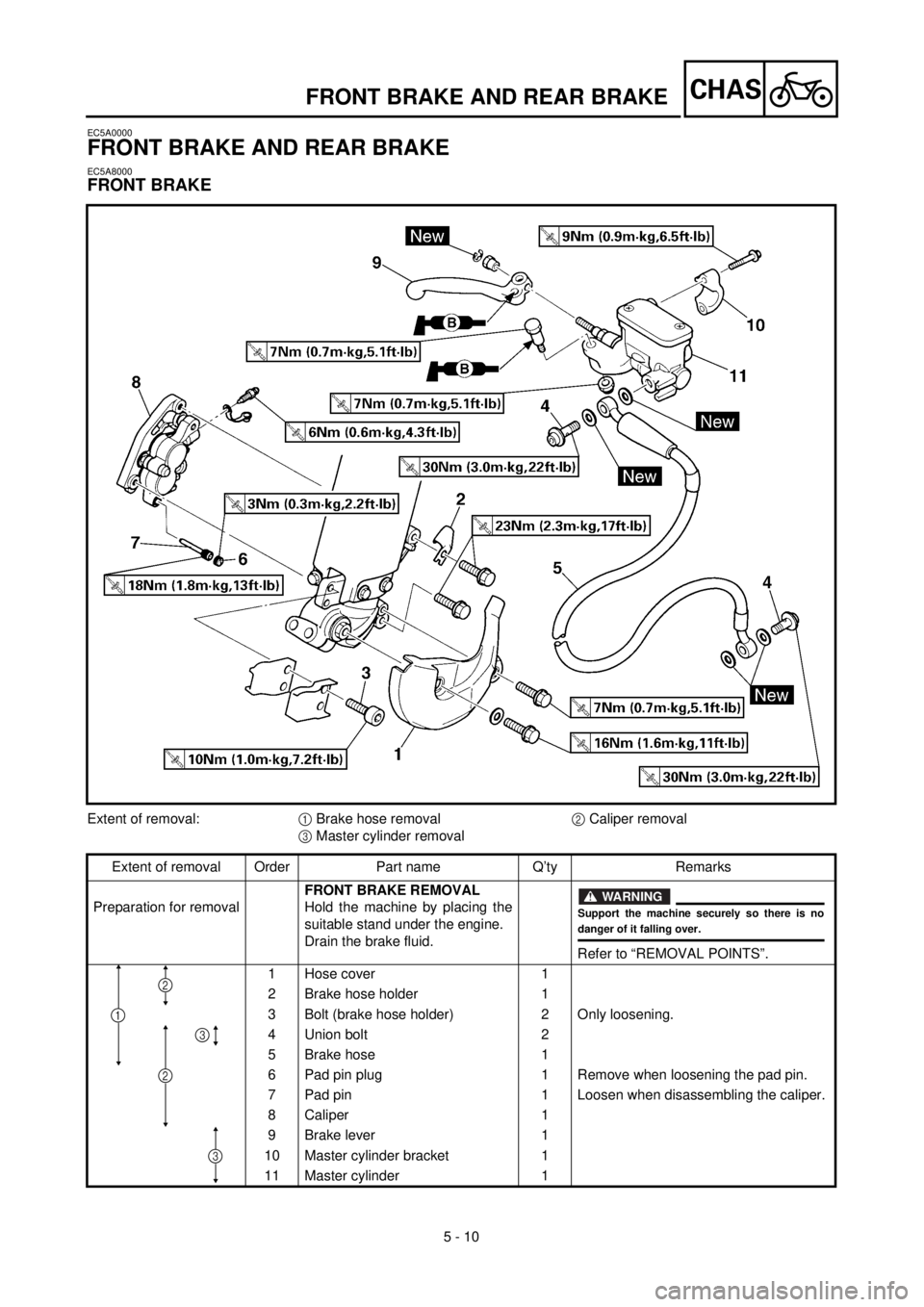

Page 466 of 654

5 - 10

CHASFRONT BRAKE AND REAR BRAKE

EC5A0000

FRONT BRAKE AND REAR BRAKE

EC5A8000

FRONT BRAKE

Extent of removal:1 Brake hose removal2 Caliper removal

3 Master cylinder removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removalFRONT BRAKE REMOVAL

Hold the machine by placing the

suitable stand under the engine.

Drain the brake fluid.

Refer to “REMOVAL POINTS”.

1 Hose cover 1

2 Brake hose holder 1

3 Bolt (brake hose holder) 2 Only loosening.

4 Union bolt 2

5 Brake hose 1

6 Pad pin plug 1 Remove when loosening the pad pin.

7 Pad pin 1 Loosen when disassembling the caliper.

8 Caliper 1

9 Brake lever 1

10 Master cylinder bracket 1

11 Master cylinder 1

WARNING

Support the machine securely so there is nodanger of it falling over.

2

3

1

3

2

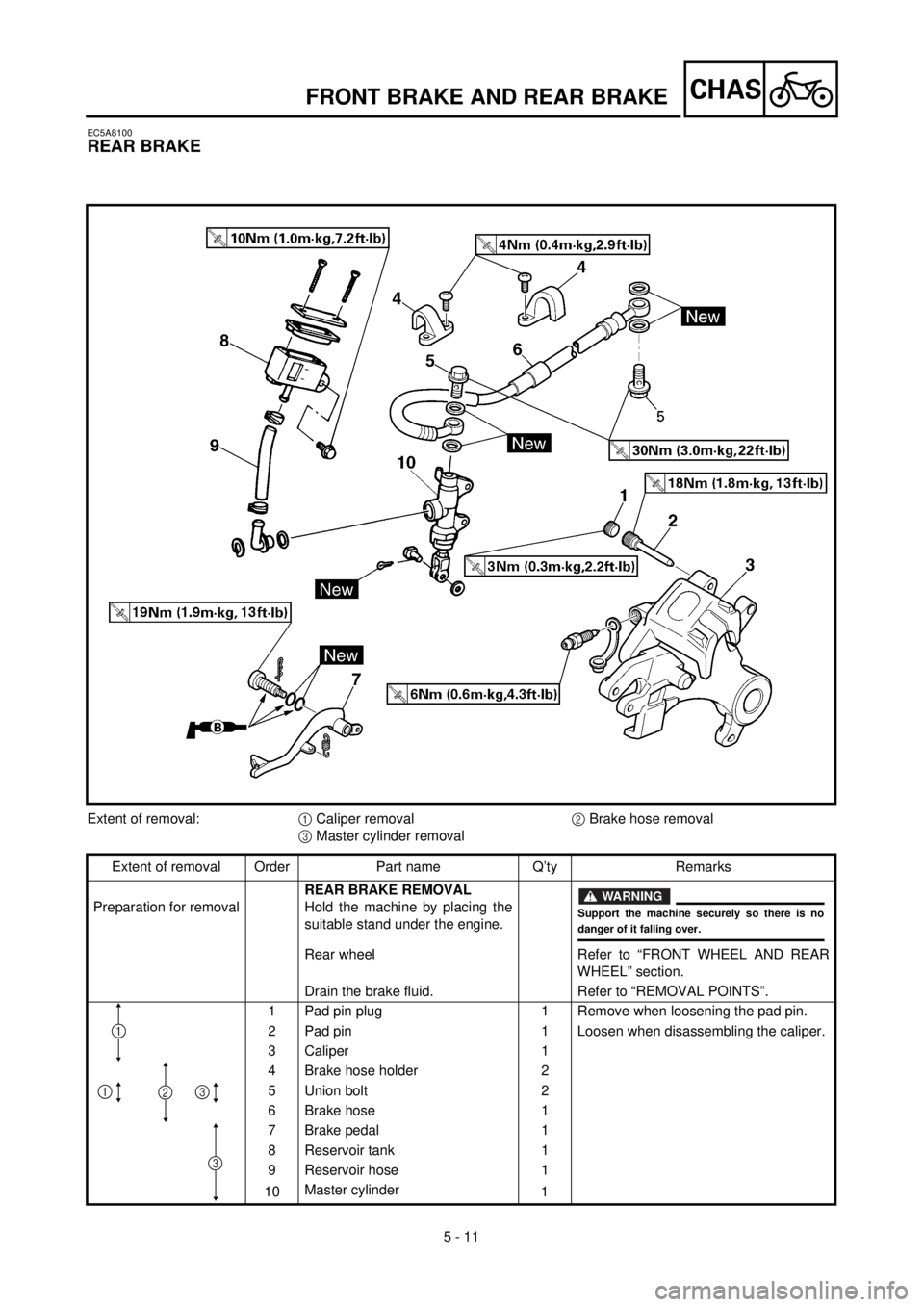

Page 468 of 654

5 - 11

CHAS

EC5A8100

REAR BRAKE

Extent of removal:1 Caliper removal2 Brake hose removal

3 Master cylinder removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removalREAR BRAKE REMOVAL

Hold the machine by placing the

suitable stand under the engine.

Rear wheel Refer to “FRONT WHEEL AND REAR

WHEEL” section.

Drain the brake fluid. Refer to “REMOVAL POINTS”.

1 Pad pin plug 1 Remove when loosening the pad pin.

2 Pad pin 1 Loosen when disassembling the caliper.

3 Caliper 1

4 Brake hose holder 2

5 Union bolt 2

6 Brake hose 1

7 Brake pedal 1

8 Reservoir tank 1

9 Reservoir hose 1

10Master cylinder

1

WARNING

Support the machine securely so there is nodanger of it falling over.

3

1

321

FRONT BRAKE AND REAR BRAKE

Page 500 of 654

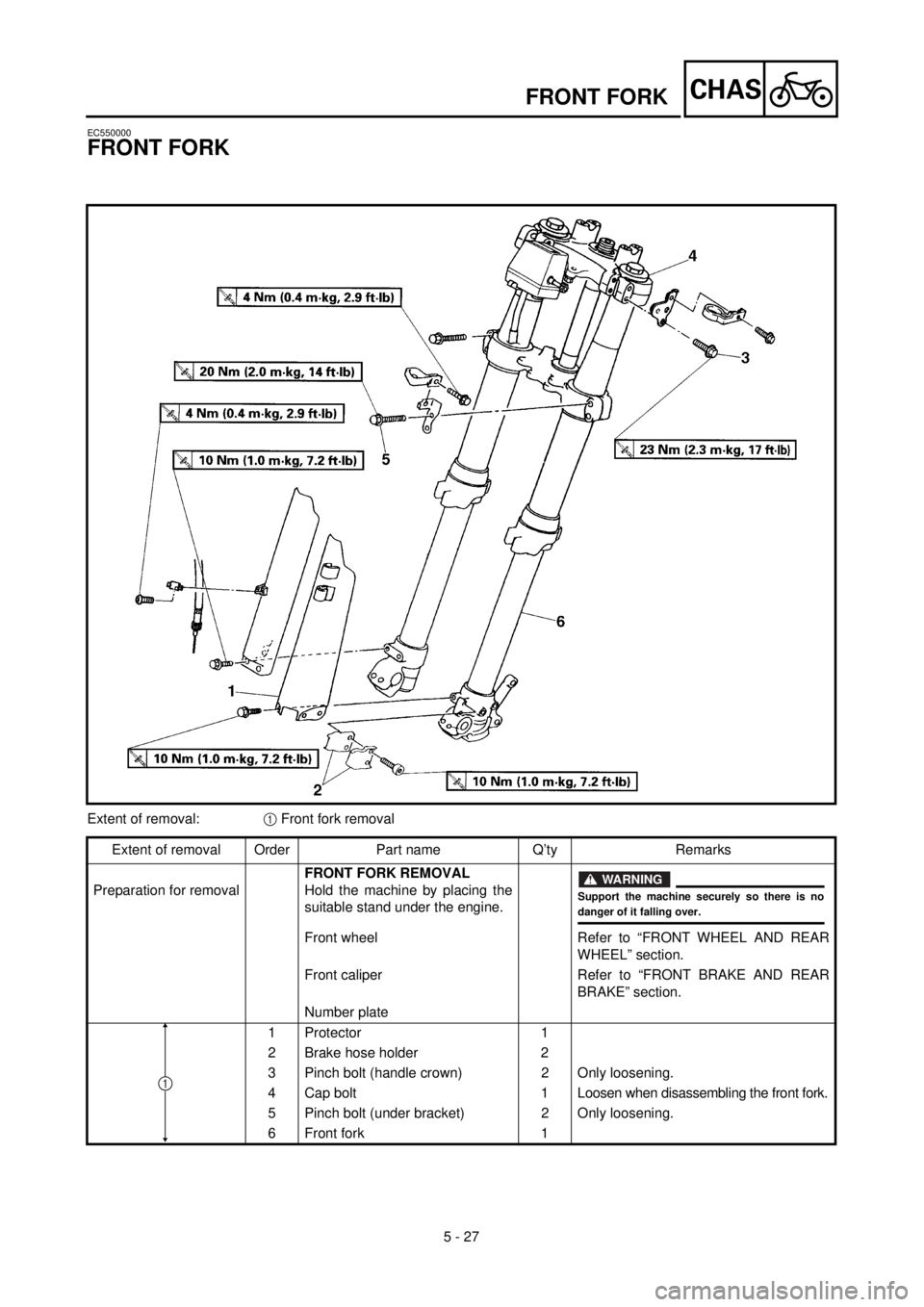

5 - 27

CHASFRONT FORK

EC550000

FRONT FORK

Extent of removal:1 Front fork removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removalFRONT FORK REMOVAL

Hold the machine by placing the

suitable stand under the engine.

Front wheel Refer to “FRONT WHEEL AND REAR

WHEEL” section.

Front caliper Refer to “FRONT BRAKE AND REAR

BRAKE” section.

Number plate

1 Protector 1

2 Brake hose holder 2

3 Pinch bolt (handle crown) 2 Only loosening.

4 Cap bolt 1Loosen when disassembling the front fork.

5 Pinch bolt (under bracket) 2 Only loosening.

6 Front fork 1

WARNING

Support the machine securely so there is nodanger of it falling over.

1

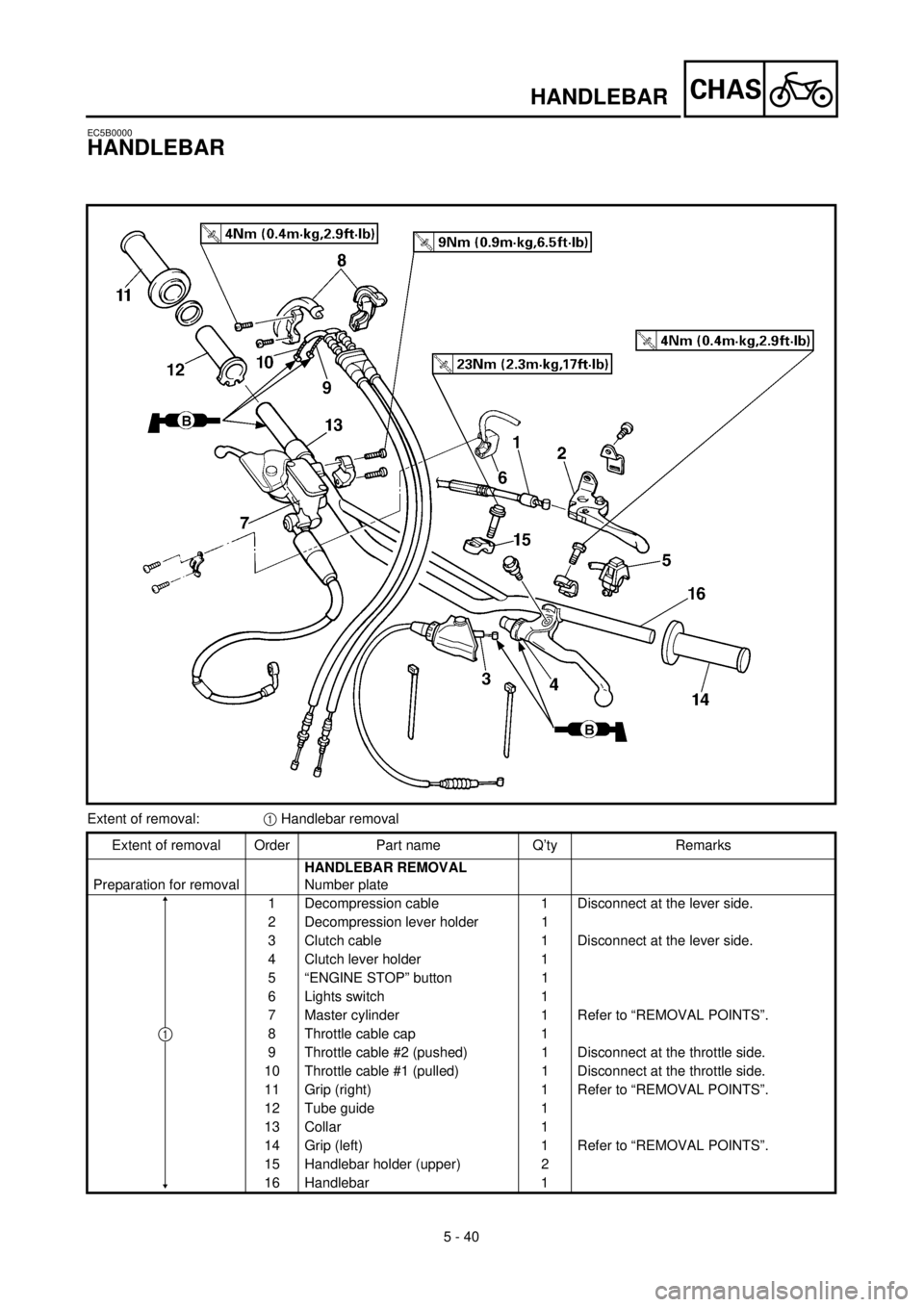

Page 526 of 654

5 - 40

CHAS

EC5B0000

HANDLEBAR

Extent of removal:1 Handlebar removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removalHANDLEBAR REMOVAL

Number plate

1 Decompression cable 1 Disconnect at the lever side.

2 Decompression lever holder 1

3 Clutch cable 1 Disconnect at the lever side.

4 Clutch lever holder 1

5 “ENGINE STOP” button 1

6 Lights switch 1

7 Master cylinder 1 Refer to “REMOVAL POINTS”.

8 Throttle cable cap 1

9 Throttle cable #2 (pushed) 1 Disconnect at the throttle side.

10 Throttle cable #1 (pulled) 1 Disconnect at the throttle side.

11 Grip (right) 1 Refer to “REMOVAL POINTS”.

12 Tube guide 1

13 Collar 1

14 Grip (left) 1 Refer to “REMOVAL POINTS”.

15 Handlebar holder (upper) 2

16 Handlebar 1

1

HANDLEBAR