lock YAMAHA WR 450F 2016 Workshop Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 243 of 426

CAMSHAFT

6-16

EAS2GC1242CHECKING THE DECOMPRESSION SYS-

TEM

1. Check:• Decompression system

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

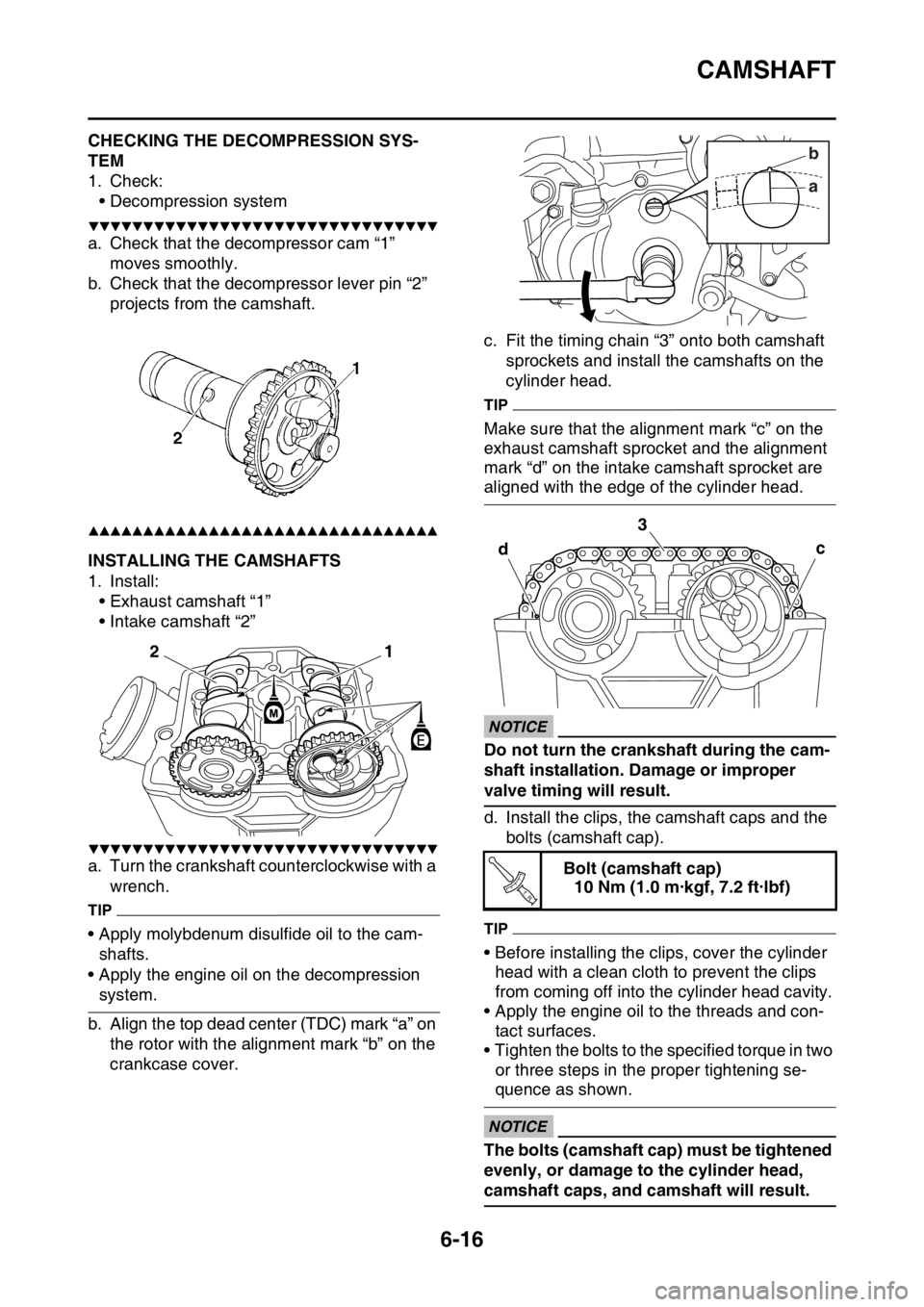

a. Check that the decompressor cam “1”

moves smoothly.

b. Check that the decompressor lever pin “2” projects from the camshaft.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GC1243INSTALLING THE CAMSHAFTS

1. Install:• Exhaust camshaft “1”

• Intake camshaft “2”

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the crankshaft counterclockwise with a

wrench.

TIP

• Apply molybdenum disulfide oil to the cam-shafts.

• Apply the engine oil on the decompression

system.

b. Align the top dead center (TDC) mark “a” on the rotor with the alignment mark “b” on the

crankcase cover. c. Fit the timing chain “3” onto both camshaft

sprockets and install the camshafts on the

cylinder head.

TIP

Make sure that the alignment mark “c” on the

exhaust camshaft sprocket and the alignment

mark “d” on the intake camshaft sprocket are

aligned with the edge of the cylinder head.

ECA

NOTICE

Do not turn the crankshaft during the cam-

shaft installation. Damage or improper

valve timing will result.

d. Install the clips, the camshaft caps and the bolts (camshaft cap).

TIP

• Before installing the clips, cover the cylinder head with a clean cloth to prevent the clips

from coming off into the cylinder head cavity.

• Apply the engine oil to the threads and con- tact surfaces.

• Tighten the bolts to the specified torque in two or three steps in the proper tightening se-

quence as shown.

ECA

NOTICE

The bolts (camshaft cap) must be tightened

evenly, or damage to the cylinder head,

camshaft caps, and camshaft will result.

1

2

Bolt (camshaft cap)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

ab

c

3

d

T R..

Page 244 of 426

CAMSHAFT

6-17

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

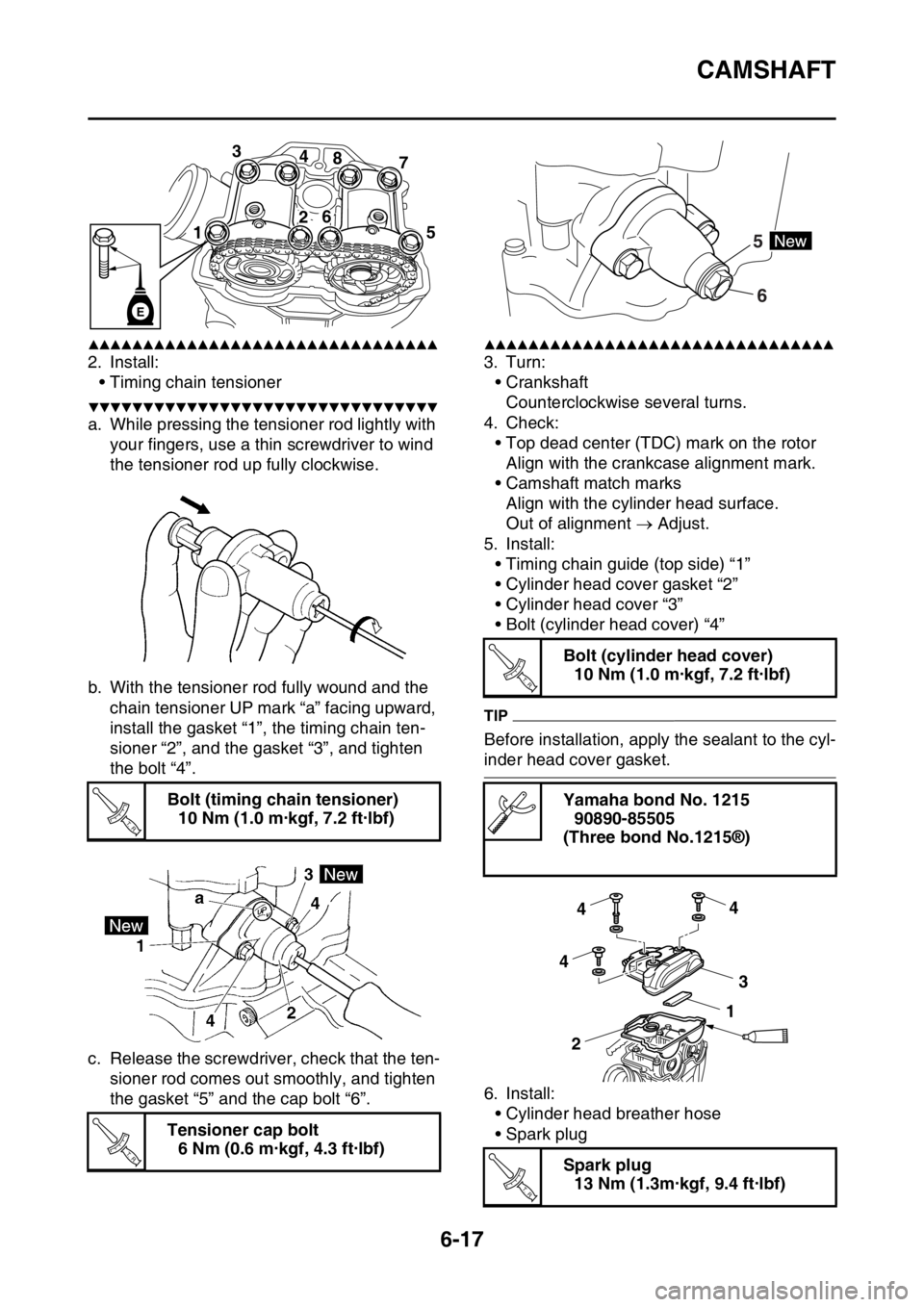

2. Install:• Timing chain tensioner

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. While pressing the tensioner rod lightly with

your fingers, use a thin screwdriver to wind

the tensioner rod up fully clockwise.

b. With the tensioner rod fully wound and the chain tensioner UP mark “a” facing upward,

install the gasket “1”, the timing chain ten-

sioner “2”, and the gasket “3”, and tighten

the bolt “4”.

c. Release the screwdriver, check that the ten- sioner rod comes out smoothly, and tighten

the gasket “5” and the cap bolt “6”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Turn:• Crankshaft

Counterclockwise several turns.

4. Check: • Top dead center (TDC) mark on the rotor

Align with the crankcase alignment mark.

• Camshaft match marks Align with the cylinder head surface.

Out of alignment Adjust.

5. Install: • Timing chain guide (top side) “1”

• Cylinder head cover gasket “2”

• Cylinder head cover “3”

• Bolt (cylinder head cover) “4”

TIP

Before installation, apply the sealant to the cyl-

inder head cover gasket.

6. Install:• Cylinder head breather hose

• Spark plug

Bolt (timing chain tensioner)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Tensioner cap bolt 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

3 48

7

1 5

26

E

T R..

T R..

Bolt (cylinder head cover)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Yamaha bond No. 1215 90890-85505

(Three bond No.1215®)

Spark plug 13 Nm (1.3m·kgf, 9.4 ft·lbf)

6

5

T R..

4

4

4 3

2 1

T R..

Page 279 of 426

KICKSTATER

6-52

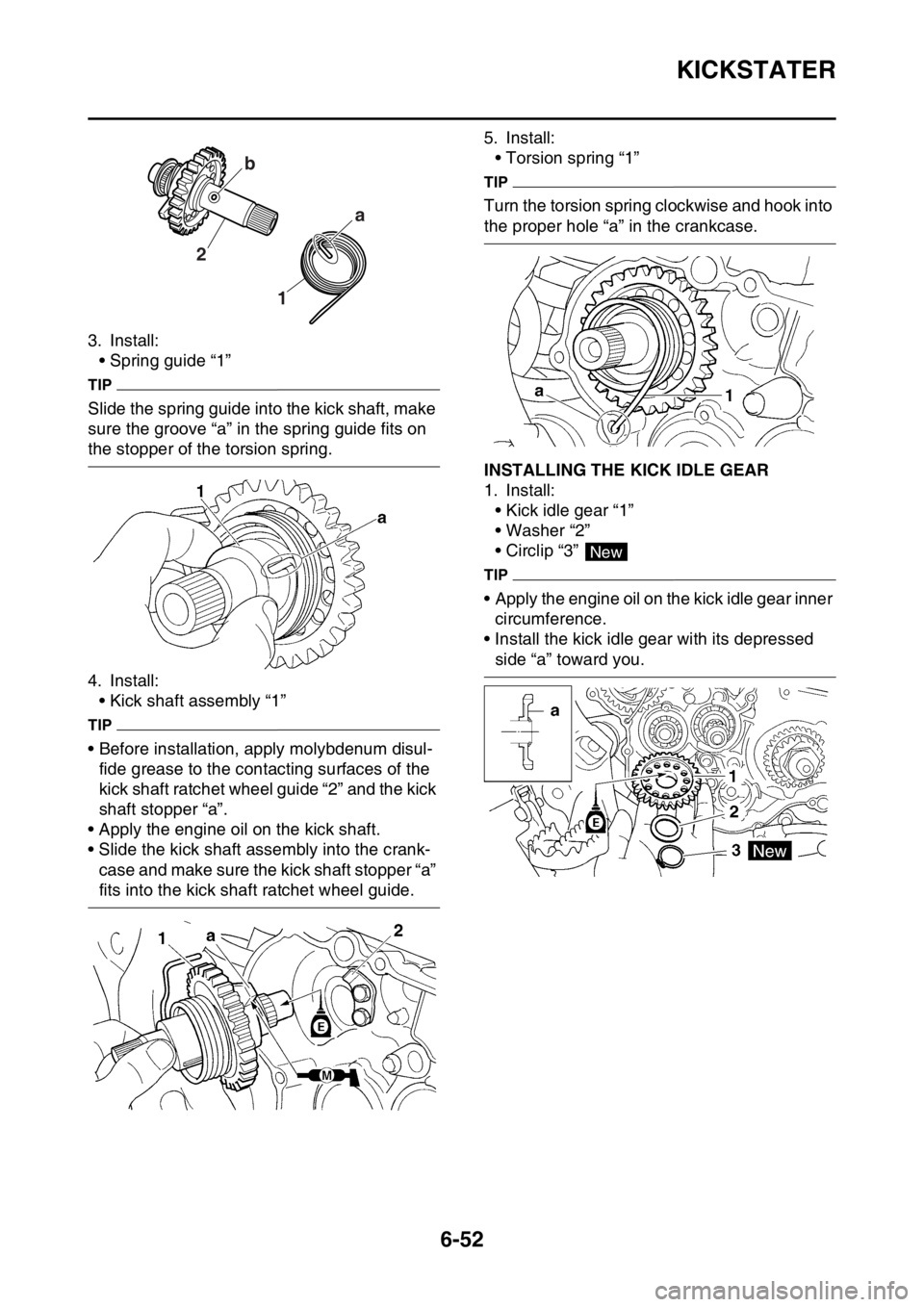

3. Install:• Spring guide “1”

TIP

Slide the spring guide into the kick shaft, make

sure the groove “a” in the spring guide fits on

the stopper of the torsion spring.

4. Install:• Kick shaft assembly “1”

TIP

• Before installation, apply molybdenum disul-fide grease to the contacting surfaces of the

kick shaft ratchet wheel guide “2” and the kick

shaft stopper “a”.

• Apply the engine oil on the kick shaft.

• Slide the kick shaft assembly into the crank-

case and make sure the kick shaft stopper “a”

fits into the kick shaft ratchet wheel guide. 5. Install:

• Torsion spring “1”

TIP

Turn the torsion spring clockwise and hook into

the proper hole “a” in the crankcase.

EAS2GC1286INSTALLING THE KICK IDLE GEAR

1. Install:• Kick idle gear “1”

• Washer “2”

• Circlip “3”

TIP

• Apply the engine oil on the kick idle gear inner circumference.

• Install the kick idle gear with its depressed

side “a” toward you.

1

2

a

b

New

Page 281 of 426

SHIFT SHAFT

6-54

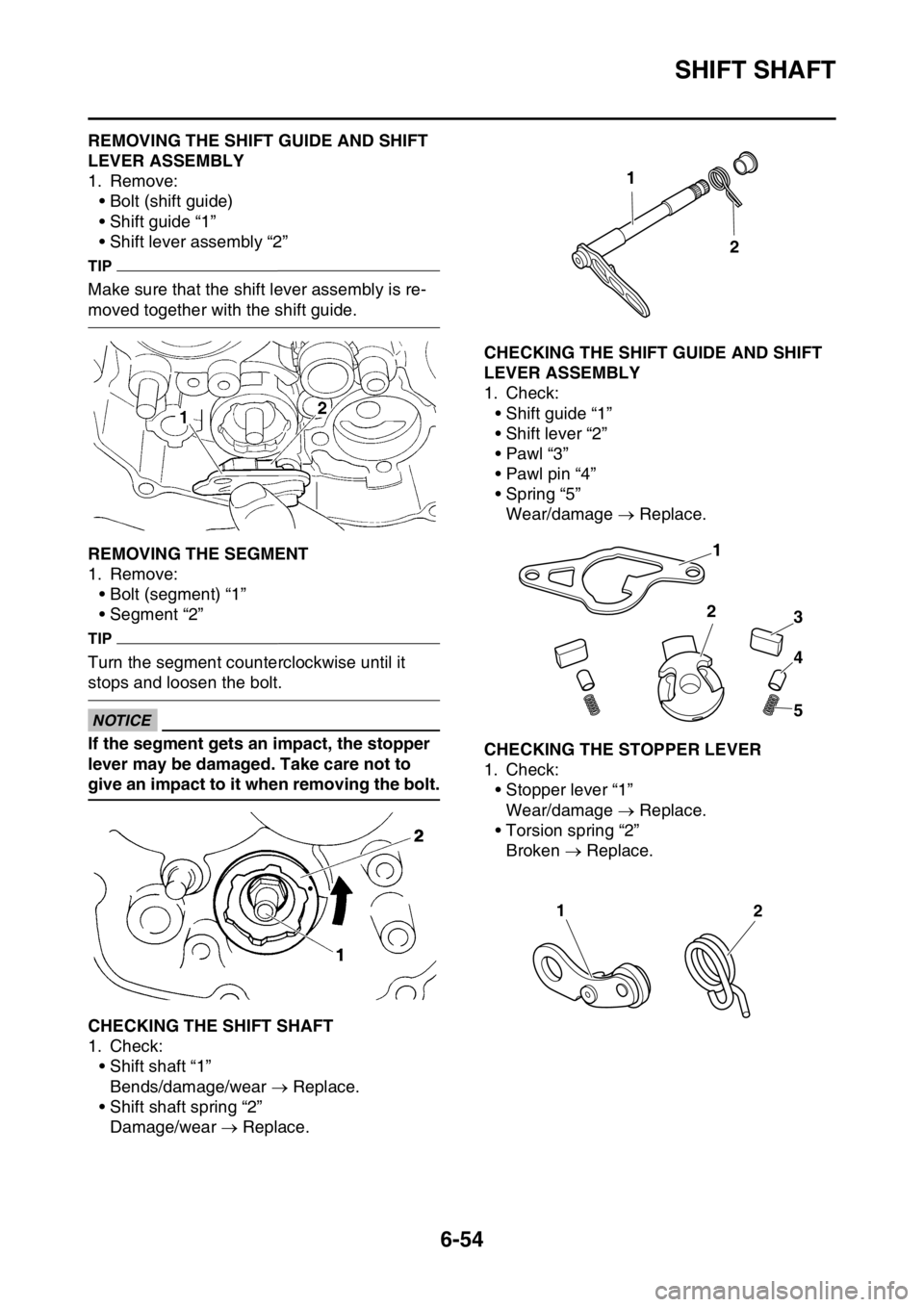

EAS2GC1288REMOVING THE SHIFT GUIDE AND SHIFT

LEVER ASSEMBLY

1. Remove:• Bolt (shift guide)

• Shift guide “1”

• Shift lever assembly “2”

TIP

Make sure that the shift lever assembly is re-

moved together with the shift guide.

EAS2GC1289REMOVING THE SEGMENT

1. Remove:

• Bolt (segment) “1”

• Segment “2”

TIP

Turn the segment counterclockwise until it

stops and loosen the bolt.

ECA

NOTICE

If the segment gets an impact, the stopper

lever may be damaged. Take care not to

give an impact to it when removing the bolt.

EAS2GC1290CHECKING THE SHIFT SHAFT

1. Check:• Shift shaft “1”

Bends/damage/wear Replace.

• Shift shaft spring “2” Damage/wear Replace.

EAS2GC1291CHECKING THE SHIFT GUIDE AND SHIFT

LEVER ASSEMBLY

1. Check:

• Shift guide “1”

• Shift lever “2”

•Pawl “3”

• Pawl pin “4”

• Spring “5”Wear/damage Replace.

EAS2GC1292CHECKING THE STOPPER LEVER

1. Check:

• Stopper lever “1”Wear/damage Replace.

• Torsion spring “2”

Broken Replace.

1

2

1

2 3

4

5

12

Page 285 of 426

OIL PUMP AND BALANCER GEAR

6-58

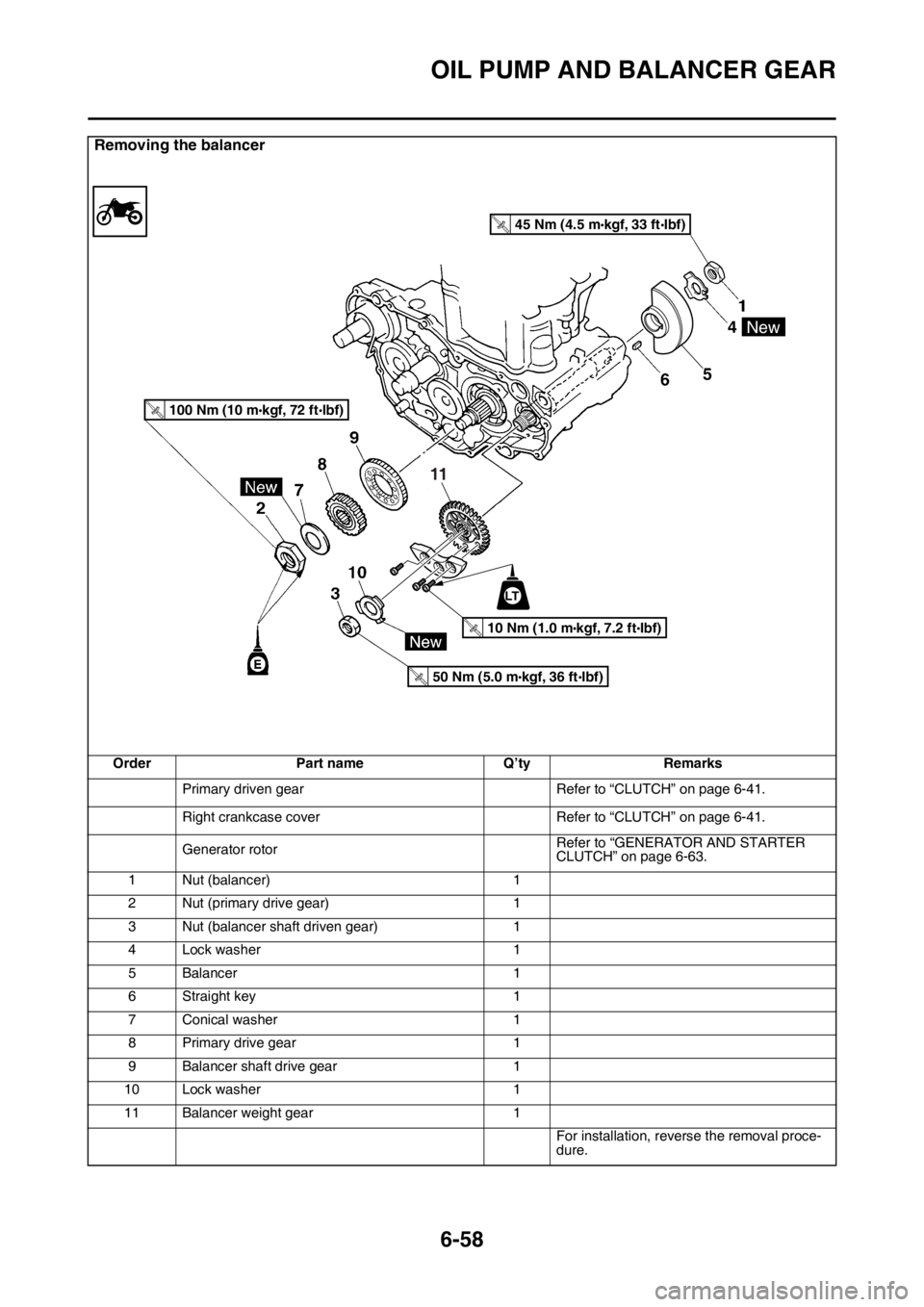

Removing the balancer

OrderPart name Q’tyRemarks

Primary driven gear Refer to “CLUTCH” on page 6-41.

Right crankcase cover Refer to “CLUTCH” on page 6-41.

Generator rotor Refer to “GENERATOR AND STARTER

CLUTCH” on page 6-63.

1 Nut (balancer) 1

2 Nut (primary drive gear) 1

3 Nut (balancer shaft driven gear) 1

4 Lock washer 1

5Balancer 1

6 Straight key 1

7 Conical washer 1

8 Primary drive gear 1

9 Balancer shaft drive gear 1

10 Lock washer 1

11 Balancer weight gear 1

For installation, reverse the removal proce-

dure.

45 Nm (4.5 m kgf, 33 ft Ibf)T.R.

100 Nm (10 m kgf, 72 ft lbf)T.R.

50 Nm (5.0 m kgf, 36 ft Ibf)T.R.

New

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.

11

LT

Page 288 of 426

OIL PUMP AND BALANCER GEAR

6-61

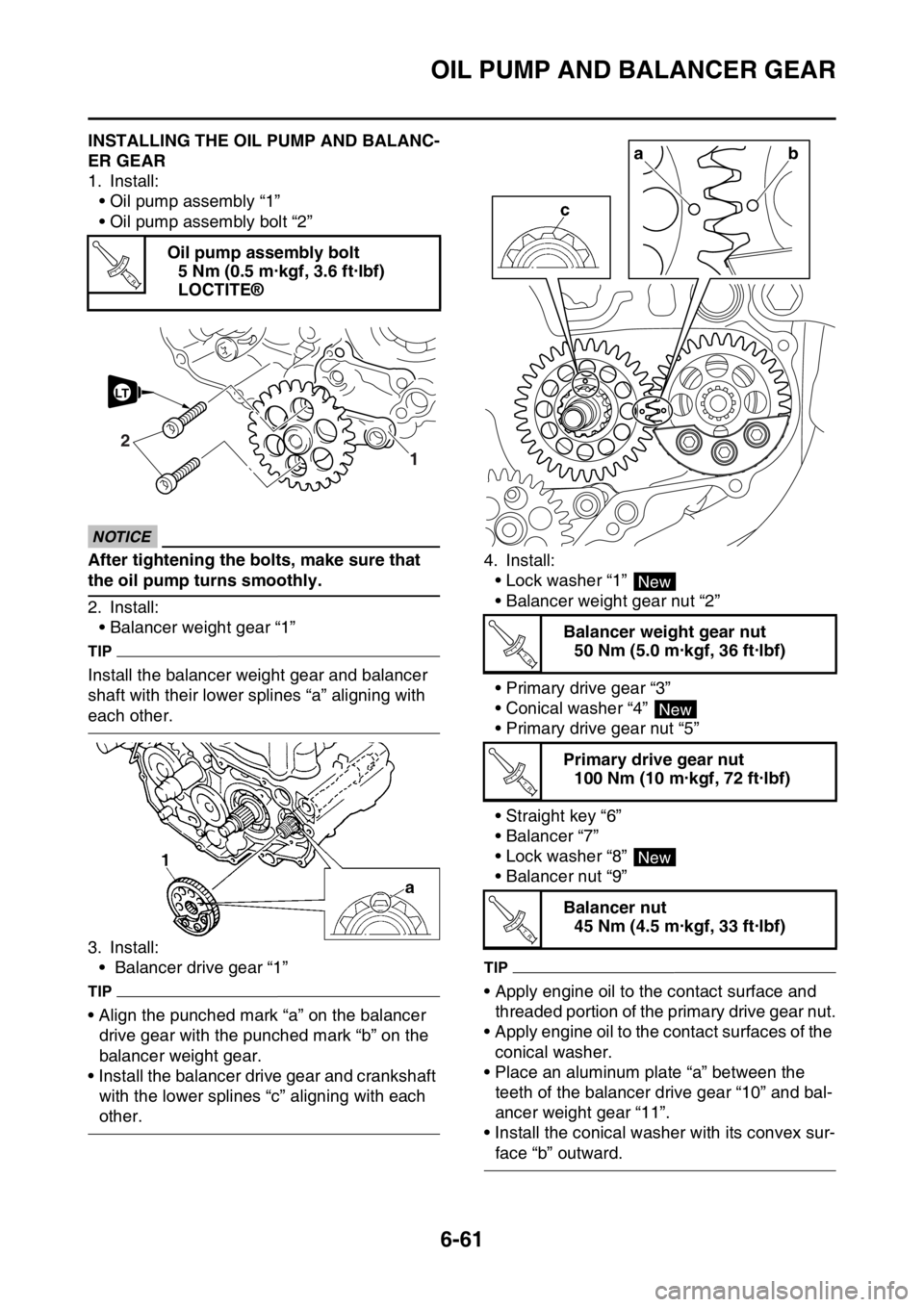

EAS2GC1304INSTALLING THE OIL PUMP AND BALANC-

ER GEAR

1. Install:• Oil pump assembly “1”

• Oil pump assembly bolt “2”

ECA1DX1023

NOTICE

After tightening the bolts, make sure that

the oil pump turns smoothly.

2. Install:• Balancer weight gear “1”

TIP

Install the balancer weight gear and balancer

shaft with their lower sp lines “a” aligning with

each other.

3. Install:

• Balancer drive gear “1”

TIP

• Align the punched mark “a” on the balancer drive gear with the punched mark “b” on the

balancer weight gear.

• Install the balancer drive gear and crankshaft with the lower splines “c” aligning with each

other. 4. Install:

• Lock washer “1”

• Balancer weight gear nut “2”

• Primary drive gear “3”

• Conical washer “4”

• Primary drive gear nut “5”

• Straight key “6”

•Balancer “7”

• Lock washer “8”

• Balancer nut “9”

TIP

• Apply engine oil to the contact surface and threaded portion of the primary drive gear nut.

• Apply engine oil to the contact surfaces of the

conical washer.

• Place an aluminum plate “a” between the teeth of the balancer drive gear “10” and bal-

ancer weight gear “11”.

• Install the conical wash er with its convex sur-

face “b” outward.

Oil pump assembly bolt

5 Nm (0.5 m·kgf, 3.6 ft·lbf)

LOCTITE®

T R..

1

2

LT

Balancer weight gear nut50 Nm (5.0 m·kgf, 36 ft·lbf)

Primary drive gear nut 100 Nm (10 m·kgf, 72 ft·lbf)

Balancer nut 45 Nm (4.5 m·kgf, 33 ft·lbf)

ba

New

T R..

New

T R..

New

T R..

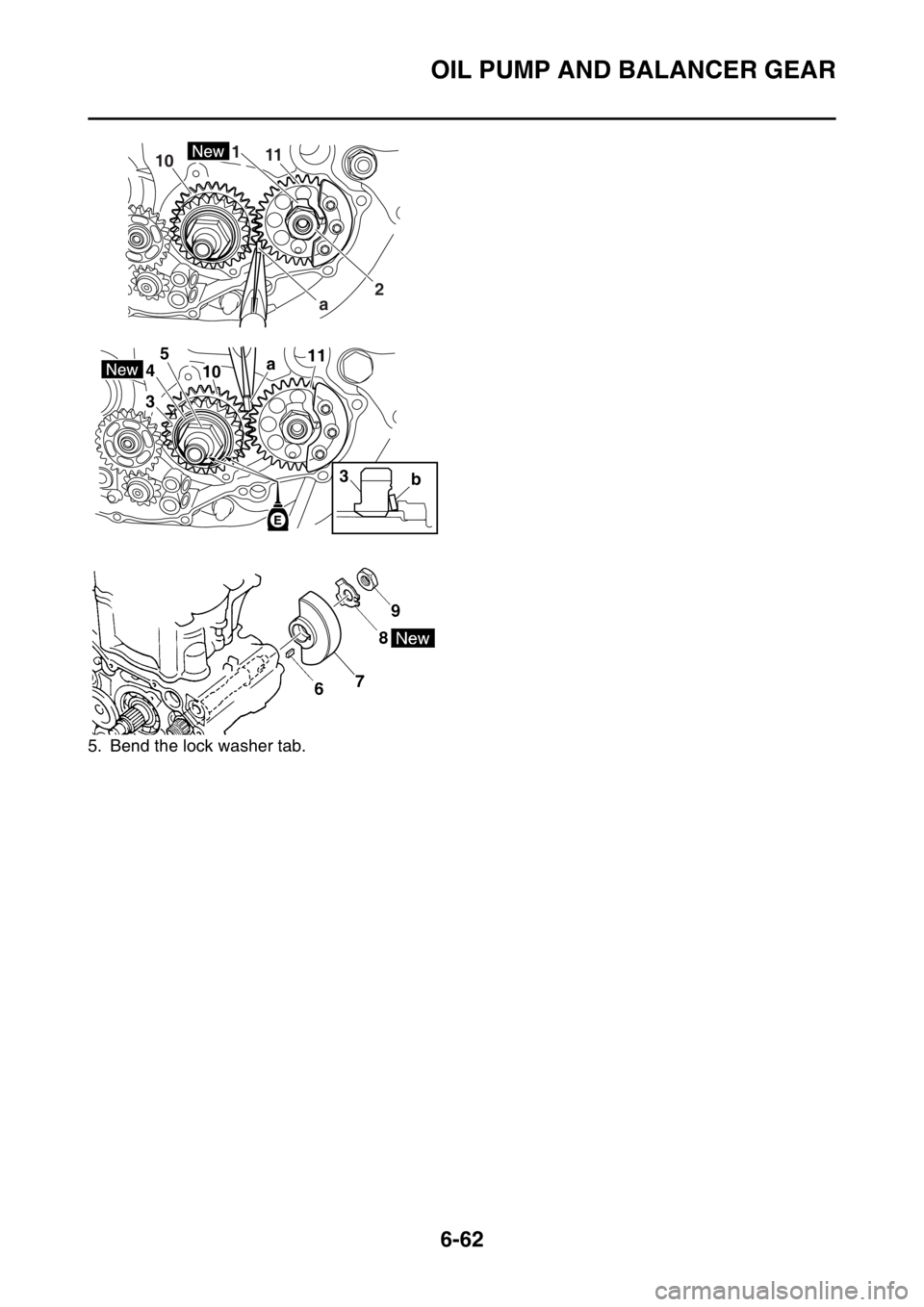

Page 289 of 426

OIL PUMP AND BALANCER GEAR

6-62

5. Bend the lock washer tab.

12

11

10

a

3 45

10 11

a

b

3

Page 292 of 426

GENERATOR AND STARTER CLUTCH

6-65

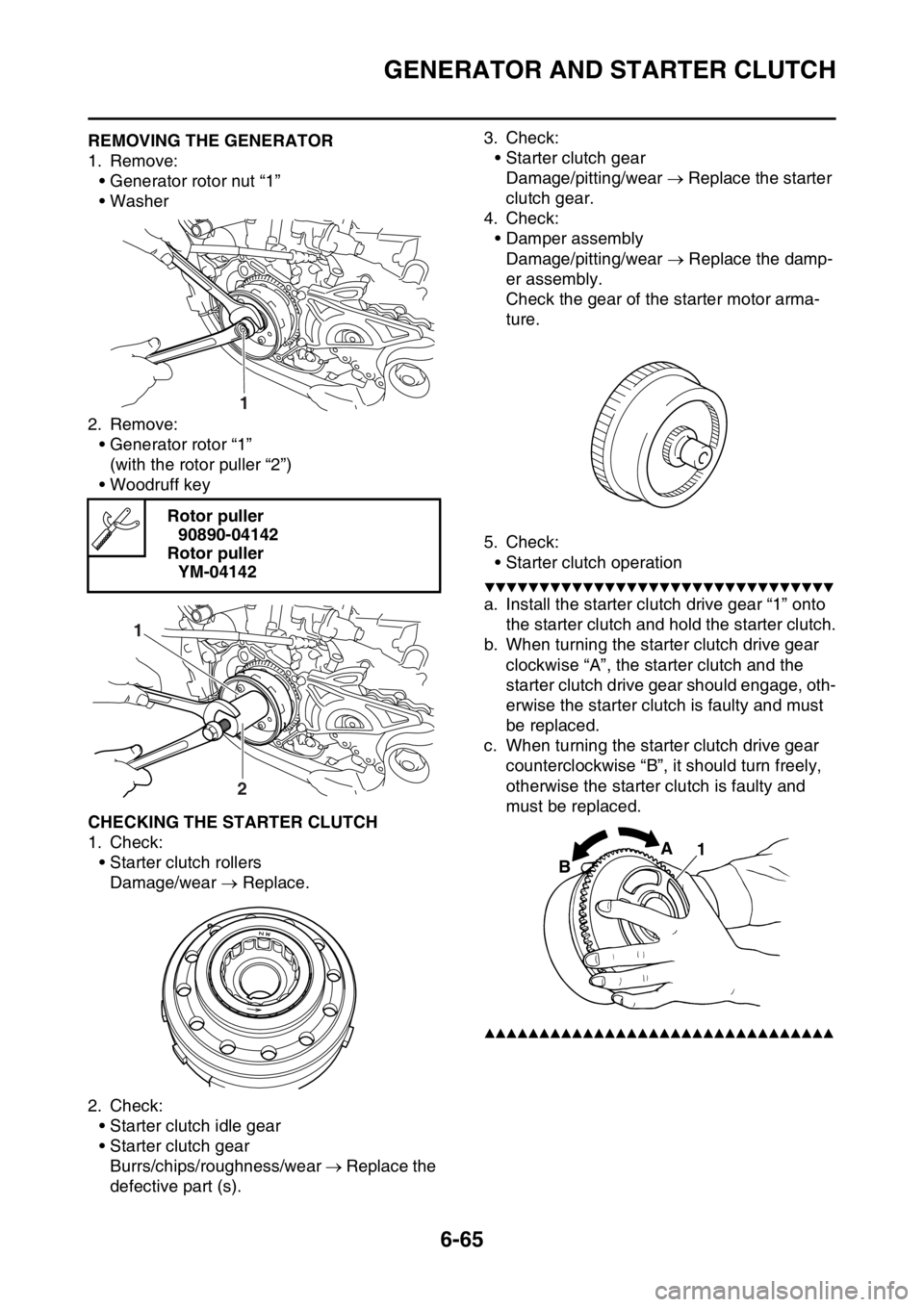

EAS2GC1306REMOVING THE GENERATOR

1. Remove:• Generator rotor nut “1”

• Washer

2. Remove: • Generator rotor “1”

(with the rotor puller “2”)

• Woodruff key

EAS2GC1307CHECKING THE STARTER CLUTCH

1. Check: • Starter clutch rollers

Damage/wear Replace.

2. Check: • Starter clutch idle gear

• Starter clutch gearBurrs/chips/roughness/wear Replace the

defective part (s). 3. Check:

• Starter clutch gearDamage/pitting/wear Replace the starter

clutch gear.

4. Check: • Damper assembly

Damage/pitting/wear Replace the damp-

er assembly.

Check the gear of the starter motor arma-

ture.

5. Check: • Starter clutch operation

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Install the starter clutch drive gear “1” onto the starter clutch and hold the starter clutch.

b. When turning the starter clutch drive gear

clockwise “A”, the starter clutch and the

starter clutch drive gear should engage, oth-

erwise the starter clutch is faulty and must

be replaced.

c. When turning the starter clutch drive gear counterclockwise “B”, it should turn freely,

otherwise the starter clutch is faulty and

must be replaced.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Rotor puller90890-04142

Rotor puller YM-04142

1

1

2

1

A

B

Page 365 of 426

FUEL INJECTION SYSTEM

9-35

6. ConditionThe current conditions are displayed. (Detected/Recovered)

7. Symptom

The symptoms of the detected malfunction are displayed.

8. Diagnosis code The diagnosis codes related to the detected malfunction are displayed.

9. FFD (only for models that can display freeze frame data) The mark “ ” is displayed when the freeze frame data is available.

10.ECU conduction time (hour: minute: second)

The total ECU conduction time (total hours the vehicle’s start switch was ON) when the malfunc-

tion was detected is displayed.

11.Number of main switch operation after detection

The number of times the meter light comes on by pushing the start switch between the malfunction

detection and code reading is displayed.

12.Number of occurrences The number of malfunction occurrences between th e malfunction detection and code reading is

displayed.

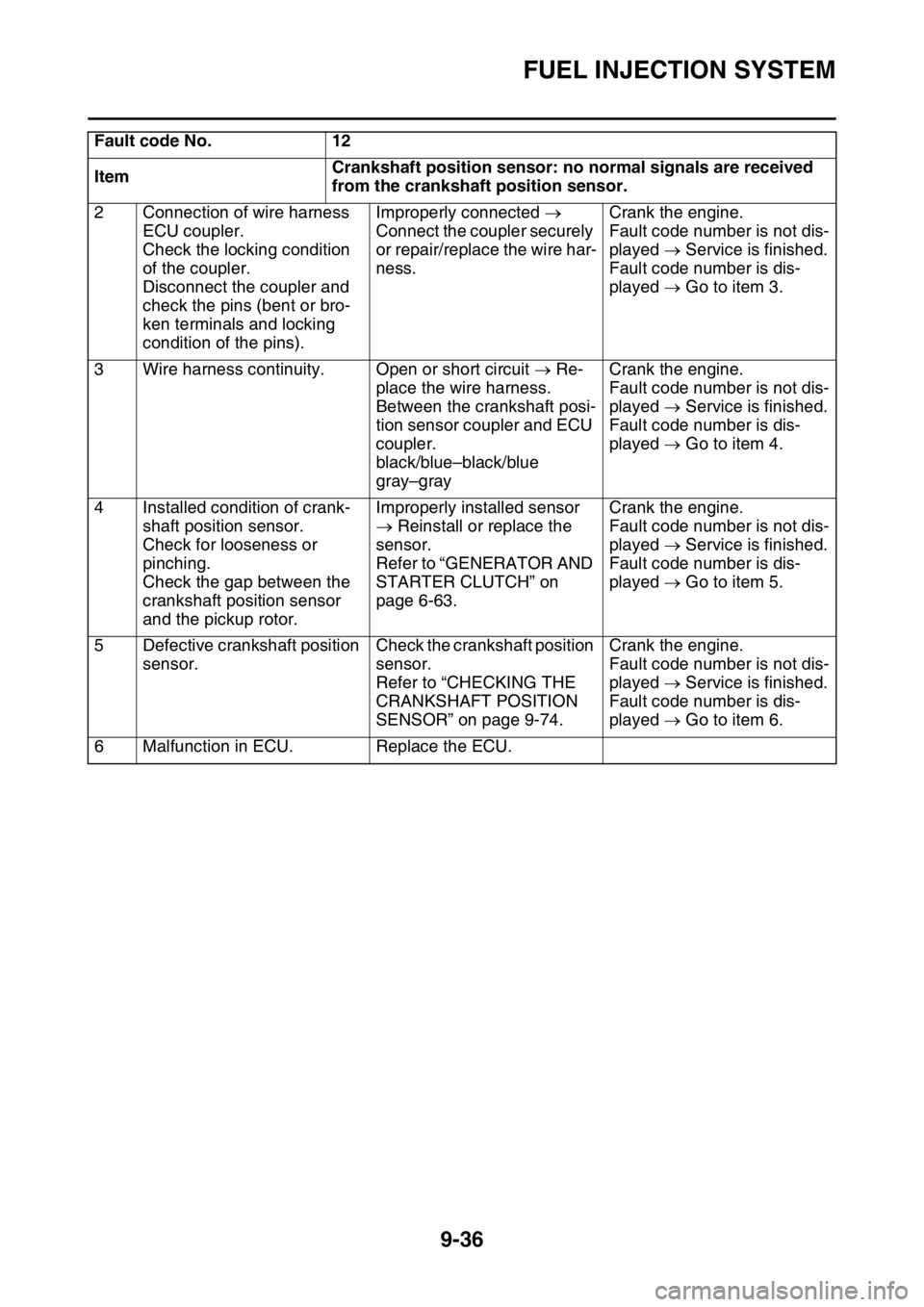

EAS2GC1378TROUBLESHOOTING DETAILS

This section describes the measures per fault c ode number displayed on the diagnostic tool. Check

and service the items or components that are the probable cause of the malfunction following the or-

der given.

After the check and service of the malfunctioning part have been completed, reset the diagnostic tool

display according to the reinstatement method.

Fault code No.:

Fault code number displayed on the diagnostic tool when the engine failed to work normally.

Diagnostic code No.:

Diagnostic code number to be used when the diagnostic mode is operated.

Fault code No. 12

Item Crankshaft position sensor: no normal signals are received

from the crankshaft position sensor.

Fail-safe system Unable to start engine

Unable to drive vehicle

Diagnostic code No. —

Diagnostic tool display —

Procedure —

Item Probable cause of malfunc-

tion and check Maintenance jobConfirmation of service

completion

1 Connection of crankshaft po- sition sensor coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins). Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness. Crank the engine.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 2.

Page 366 of 426

FUEL INJECTION SYSTEM

9-36

2 Connection of wire harness ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins). Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness. Crank the engine.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 3.

3 Wire harness continuity. Open or short circuit Re-

place the wire harness.

Between the crankshaft posi-

tion sensor coupler and ECU

coupler.

black/blue–black/blue

gray–gray Crank the engine.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 4.

4 Installed condition of crank- shaft position sensor.

Check for looseness or

pinching.

Check the gap between the

crankshaft position sensor

and the pickup rotor. Improperly installed sensor

Reinstall or replace the

sensor.

Refer to “GENERATOR AND

STARTER CLUTCH” on

page 6-63. Crank the engine.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 5.

5 Defective crankshaft position sensor. Check the crankshaft position

sensor.

Refer to “CHECKING THE

CRANKSHAFT POSITION

SENSOR” on page 9-74. Crank the engine.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 6.

6 Malfunction in ECU. Replace the ECU. Fault code No. 12

Item Crankshaft position sensor: no normal signals are received

from the crankshaft position sensor.