YAMAHA XT600E 2002 Service Manual

Manufacturer: YAMAHA, Model Year: 2002, Model line: XT600E, Model: YAMAHA XT600E 2002Pages: 100, PDF Size: 2.1 MB

Page 41 of 100

6-3

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU03685

Periodic maintenance and lubrication chart

Periodic maintenance and lubrication chartNOTE:

8The annual checks must be performed every year, except if a kilometer-based maintenance is performed instead.

8From 50,000 km, repeat the maintenance intervals starting from 10,000 km.

8Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools, data and

technical skills.NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING (× 1,000 km)

ANNUAL

CHECK

1 10203040

1

*Fuel line•Check fuel hoses for cracks or damage.√√√√ √

2 Spark plug•Check condition.

•Clean and regap.√√

•Replace.√√

3*Valves•Check valve clearance.

•Adjust.√√√√

4 Air filter element•Clean.√√

•Replace.√√

5 Clutch•Check operation.

•Adjust.√√√√√

6*Front brake•Check operation, fluid level and vehicle for fluid leakage.

(See NOTE on page 6-5.)√√√√√ √

•Replace brake pads.Whenever worn to the limit

7*Rear brake•Check operation, fluid level and vehicle for fluid leakage.

(See NOTE on page 6-5.)√√√√√ √

•Replace brake pads.Whenever worn to the limit

4PT-E7 (English) 6/29/01 9:13 AM Page 40

Page 42 of 100

6-4

PERIODIC MAINTENANCE AND MINOR REPAIR

6

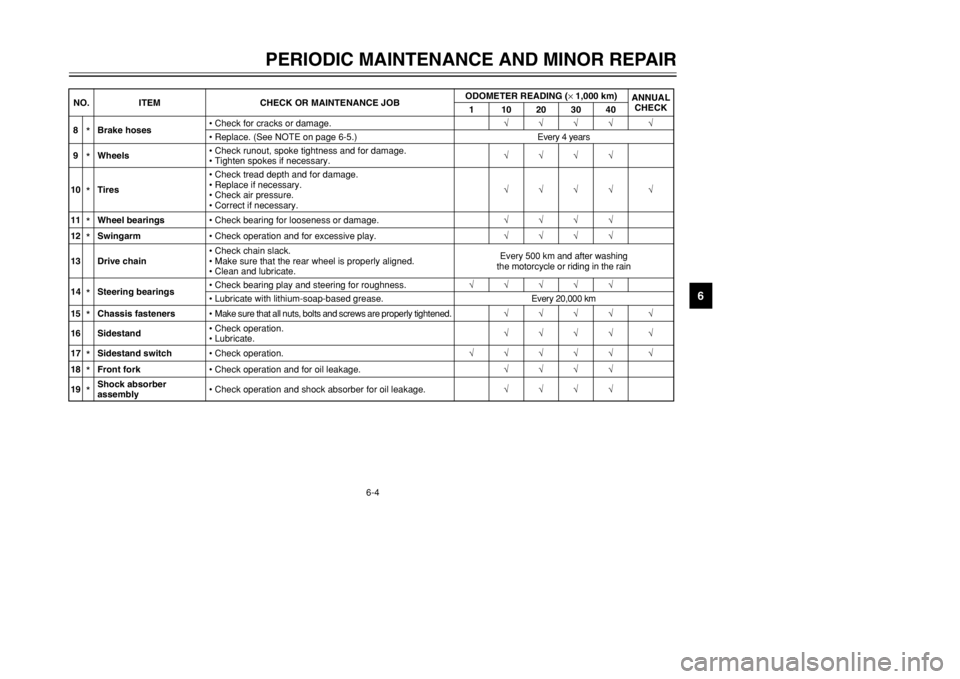

8

*Brake hoses•Check for cracks or damage.√√√√ √

•Replace. (See NOTE on page 6-5.)Every 4 years

9*Wheels•Check runout, spoke tightness and for damage.

•Tighten spokes if necessary.√√√√

10*Tires•Check tread depth and for damage.

•Replace if necessary.

•Check air pressure.

•Correct if necessary.√√√√ √

11*Wheel bearings•Check bearing for looseness or damage.√√√√

12*Swingarm•Check operation and for excessive play.√√√√

13 Drive chain•Check chain slack.

•Make sure that the rear wheel is properly aligned.

•Clean and lubricate.Every 500 km and after washing

the motorcycle or riding in the rain

14*Steering bearings•Check bearing play and steering for roughness.√√√√√

•Lubricate with lithium-soap-based grease.Every 20,000 km

15*Chassis fasteners•Make sure that all nuts, bolts and screws are properly tightened.√√√√ √

16 Sidestand•Check operation.

•Lubricate.√√√√ √

17*Sidestand switch•Check operation.√√√√√ √

18*Front fork•Check operation and for oil leakage.√√√√

19*Shock absorber

assembly•Check operation and shock absorber for oil leakage.√√√√ NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING (× 1,000 km)

ANNUAL

CHECK

1 10203040

4PT-E7 (English) 6/29/01 9:13 AM Page 41

Page 43 of 100

6-5

PERIODIC MAINTENANCE AND MINOR REPAIR

6

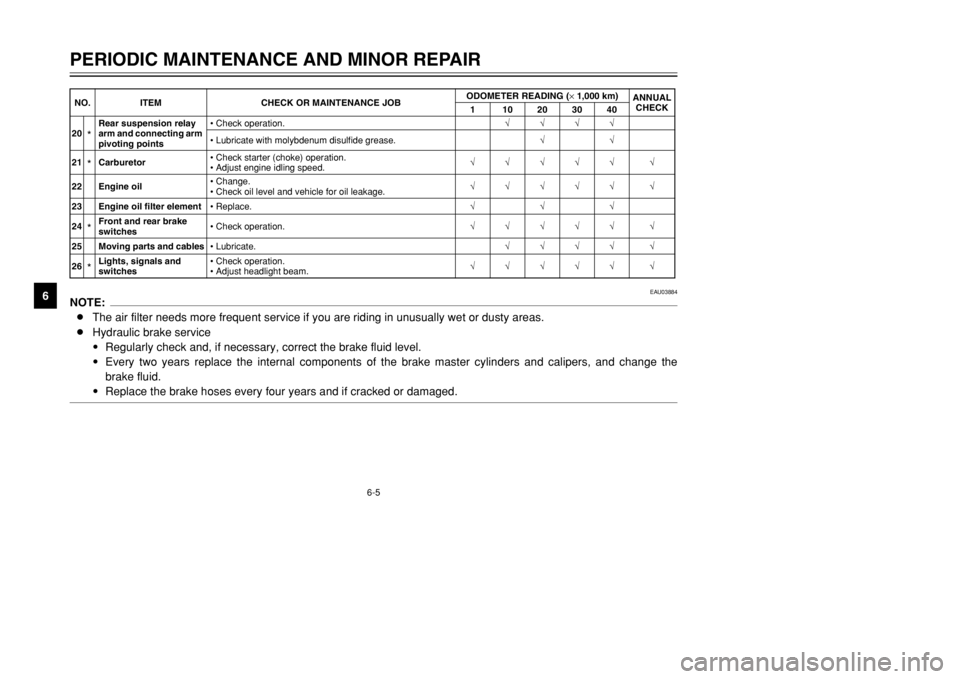

EAU03884

NOTE:

8The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

8Hydraulic brake service

9Regularly check and, if necessary, correct the brake fluid level.

9Every two years replace the internal components of the brake master cylinders and calipers, and change the

brake fluid.

9Replace the brake hoses every four years and if cracked or damaged.20

*Rear suspension relay

arm and connecting arm

pivoting points•Check operation.√√√√

•Lubricate with molybdenum disulfide grease.√√

21*Carburetor•Check starter (choke) operation.

•Adjust engine idling speed.√√√√√ √

22 Engine oil•Change.

•Check oil level and vehicle for oil leakage.√√√√√ √

23 Engine oil filter element•Replace.√√√

24*Front and rear brake

switches•Check operation.√√√√√ √

25 Moving parts and cables•Lubricate.√√√√ √

26*Lights, signals and

switches•Check operation.

•Adjust headlight beam.√√√√√ √ NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING (× 1,000 km)

ANNUAL

CHECK

1 10203040

4PT-E7 (English) 6/29/01 9:13 AM Page 42

Page 44 of 100

6-6

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU03516

Removing and installing the

cowling and panelsCowling and panels, removing and installingThe cowling and panels shown above

need to be removed to perform some

of the maintenance jobs described in

this chapter.

1

1. Cowling A

1

1. Panel B

Refer to this section each time the

cowling or a panel needs to be

removed and installed.

1

1. Panel A

4PT-E7 (English) 6/29/01 9:13 AM Page 43

Page 45 of 100

6-7

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU01145

Cowling A

To remove the cowlingRemove the screw, and then pull the

cowling off as shown.

1

1. Screw

EAU04003

Panels A and B

To remove one of the panelsRemove the screw, and then pull the

panel off as shown.

To install the panelPlace the panel in the original posi-

tion, and then install the screw.

1

2

1. Panel A

2. Screw

To install the cowlingPlace the cowling in the original posi-

tion, and then install the screw.

4PT-E7 (English) 6/29/01 9:13 AM Page 44

Page 46 of 100

6-8

PERIODIC MAINTENANCE AND MINOR REPAIR

6

1

2

1. Panel B

2. Screw

2. Remove the spark plug as

shown, with the spark plug

wrench included in the owner’s

tool kit.

1

1. Spark plug wrench

EAU01833

Checking the spark plugSpark plug, checkingThe spark plug is an important

engine component, which is easy to

check. Since heat and deposits will

cause any spark plug to slowly erode,

the spark plug should be removed

and checked in accordance with the

periodic maintenance and lubrication

chart. In addition, the condition of the

spark plug can reveal the condition of

the engine.

To remove the spark plug

1. Remove the spark plug cap.

1

1. Spark plug cap

4PT-E7 (English) 6/29/01 9:13 AM Page 45

Page 47 of 100

6-9

PERIODIC MAINTENANCE AND MINOR REPAIR

6To check the spark plug

1. Check that the porcelain insula-

tor around the center electrode

of the spark plug is a medium-to-

light tan (the ideal color when the

motorcycle is ridden normally).

NOTE:

If the spark plug shows a distinctly

different color, the engine could be

defective. Do not attempt to diagnose

such problems yourself. Instead,

have a Yamaha dealer check the

motorcycle.2. Check the spark plug for elec-

trode erosion and excessive car-

bon or other deposits, and

replace it if necessary.3. Install the spark plug with the

spark plug wrench, and then

tighten it to the specified torque.

NOTE:

If a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4-

1/2 turn past finger tight. However,

the spark plug should be tightened to

the specified torque as soon as pos-

sible.4. Install the spark plug cap. To install the spark plug

1. Measure the spark plug gap with

a wire thickness gauge and, if

necessary, adjust the gap to

specification.

2. Clean the surface of the spark

plug gasket and its mating sur-

face, and then wipe off any grime

from the spark plug threads.

a

a. Spark plug gap

Specified spark plug:

DPR8EA-9 or

DPR9EA-9 (NGK)

Spark plug gap:

0.8–0.9 mm

Tightening torque:

Spark plug:

17.5 Nm (1.75 m0kgf)

4PT-E7 (English) 6/29/01 9:13 AM Page 46

Page 48 of 100

6-10

PERIODIC MAINTENANCE AND MINOR REPAIR

6

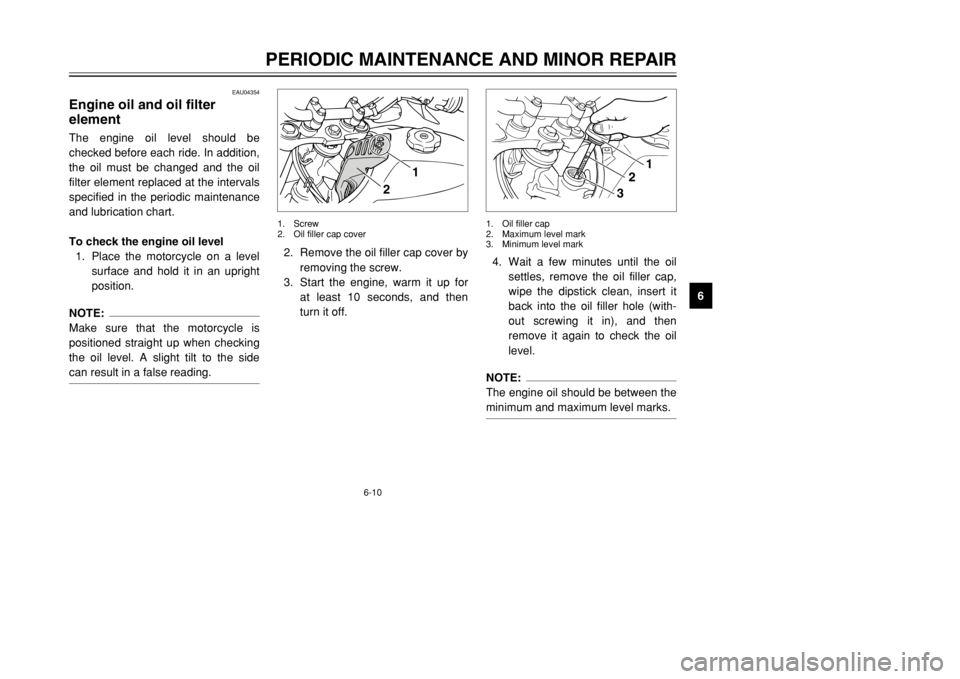

EAU04354

Engine oil and oil filter

elementEngine oil and oil filter elementThe engine oil level should be

checked before each ride. In addition,

the oil must be changed and the oil

filter element replaced at the intervals

specified in the periodic maintenance

and lubrication chart.

To check the engine oil level

1. Place the motorcycle on a level

surface and hold it in an upright

position.NOTE:

Make sure that the motorcycle is

positioned straight up when checking

the oil level. A slight tilt to the side

can result in a false reading.

4. Wait a few minutes until the oil

settles, remove the oil filler cap,

wipe the dipstick clean, insert it

back into the oil filler hole (with-

out screwing it in), and then

remove it again to check the oil

level.NOTE:

The engine oil should be between the

minimum and maximum level marks.

1

2

3

1. Oil filler cap

2. Maximum level mark

3. Minimum level mark

2. Remove the oil filler cap cover by

removing the screw.

3. Start the engine, warm it up for

at least 10 seconds, and then

turn it off.

2

1

1. Screw

2. Oil filler cap cover

4PT-E7 (English) 6/29/01 9:13 AM Page 47

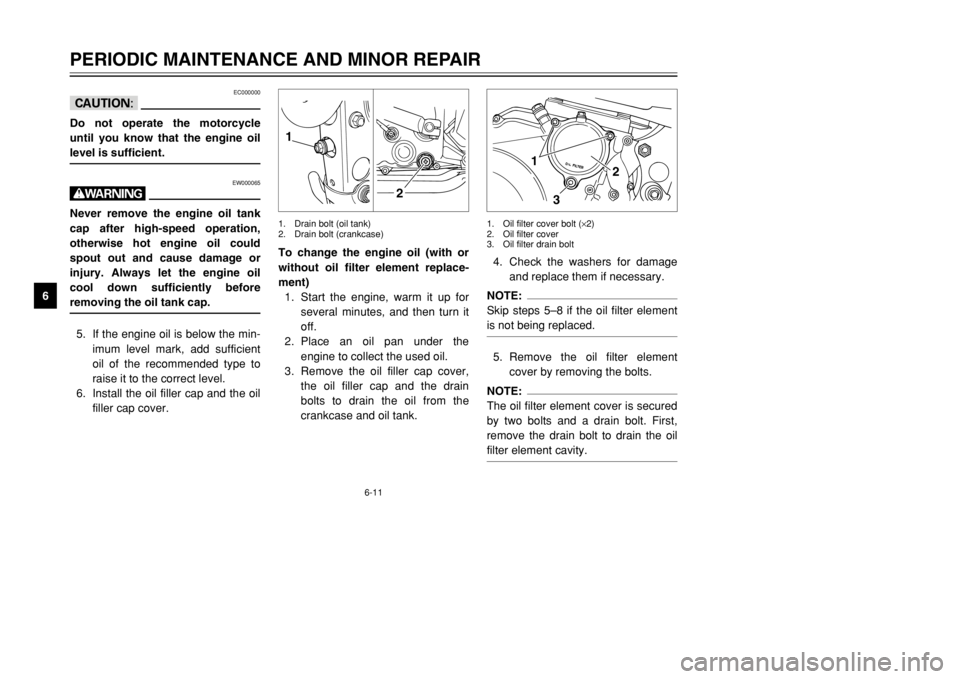

Page 49 of 100

6-11

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EC000000

cCDo not operate the motorcycle

until you know that the engine oil

level is sufficient.

EW000065

wNever remove the engine oil tank

cap after high-speed operation,

otherwise hot engine oil could

spout out and cause damage or

injury. Always let the engine oil

cool down sufficiently before

removing the oil tank cap.5. If the engine oil is below the min-

imum level mark, add sufficient

oil of the recommended type to

raise it to the correct level.

6. Install the oil filler cap and the oil

filler cap cover.4. Check the washers for damage

and replace them if necessary.

NOTE:

Skip steps 5–8 if the oil filter element

is not being replaced.5. Remove the oil filter element

cover by removing the bolts.NOTE:

The oil filter element cover is secured

by two bolts and a drain bolt. First,

remove the drain bolt to drain the oil

filter element cavity.

1

32

1. Oil filter cover bolt (×2)

2. Oil filter cover

3. Oil filter drain bolt

To change the engine oil (with or

without oil filter element replace-

ment)

1. Start the engine, warm it up for

several minutes, and then turn it

off.

2. Place an oil pan under the

engine to collect the used oil.

3. Remove the oil filler cap cover,

the oil filler cap and the drain

bolts to drain the oil from the

crankcase and oil tank.1. Drain bolt (oil tank)

2. Drain bolt (crankcase)1

2

4PT-E7 (English) 6/29/01 9:13 AM Page 48

Page 50 of 100

6-12

PERIODIC MAINTENANCE AND MINOR REPAIR

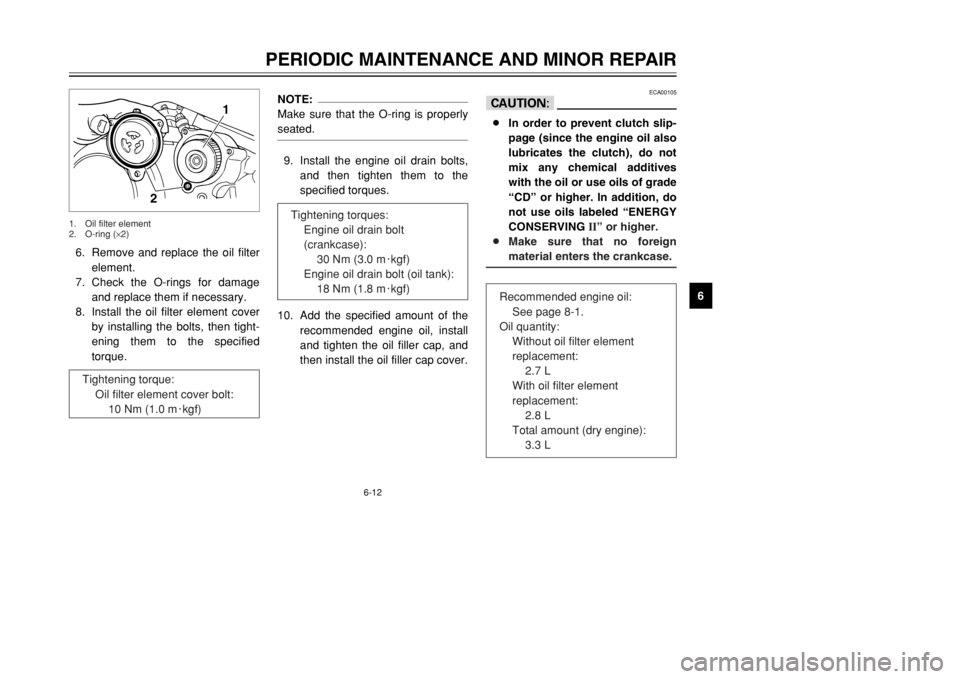

6 6. Remove and replace the oil filter

element.

7. Check the O-rings for damage

and replace them if necessary.

8. Install the oil filter element cover

by installing the bolts, then tight-

ening them to the specified

torque.

NOTE:

Make sure that the O-ring is properly

seated.9. Install the engine oil drain bolts,

and then tighten them to the

specified torques.

10. Add the specified amount of the

recommended engine oil, install

and tighten the oil filler cap, and

then install the oil filler cap cover.

ECA00105

cC8In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

mix any chemical additives

with the oil or use oils of grade

“CD” or higher. In addition, do

not use oils labeled “ENERGY

CONSERVING II” or higher.

8Make sure that no foreign

material enters the crankcase.

1

2

1. Oil filter element

2. O-ring (×2)

Tightening torque:

Oil filter element cover bolt:

10 Nm (1.0 m0kgf)

Tightening torques:

Engine oil drain bolt

(crankcase):

30 Nm (3.0 m0kgf)

Engine oil drain bolt (oil tank):

18 Nm (1.8 m0kgf)

Recommended engine oil:

See page 8-1.

Oil quantity:

Without oil filter element

replacement:

2.7 L

With oil filter element

replacement:

2.8 L

Total amount (dry engine):

3.3 L

4PT-E7 (English) 6/29/01 9:13 AM Page 49