YAMAHA YD110 2007 Repair Manual

Manufacturer: YAMAHA, Model Year: 2007, Model line: YD110, Model: YAMAHA YD110 2007Pages: 158, PDF Size: 2.27 MB

Page 61 of 158

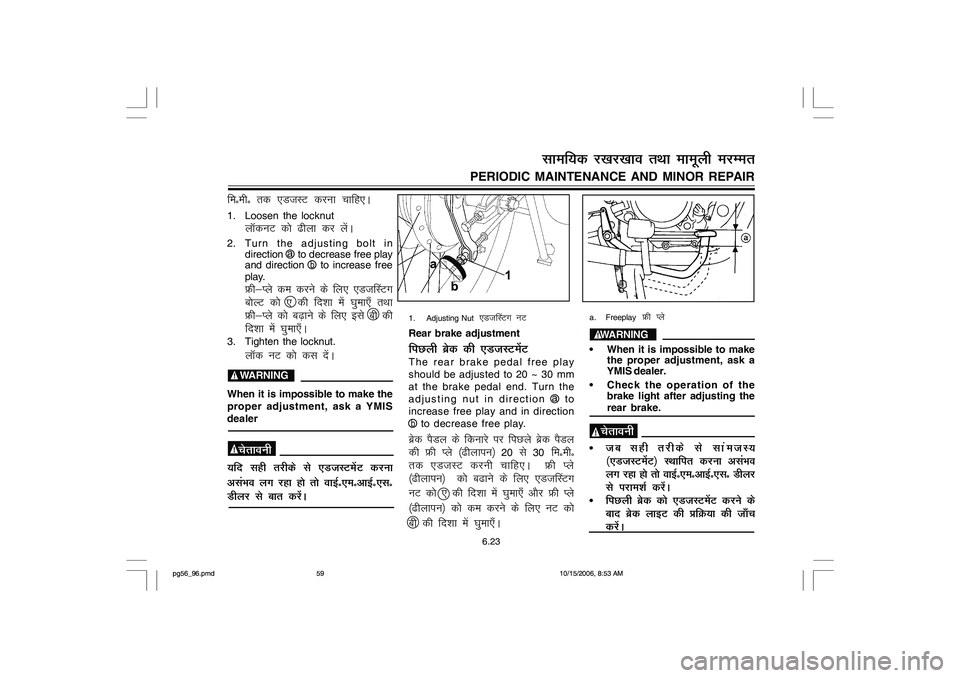

1. Adjusting Nut

,Mt¯LVx uV

Rear brake adjustment

fiNyh czsd dh ,MtLVesaVThe rear brake pedal free play

should be adjusted to 20 ~ 30 mm

at the brake pedal end. Turn the

adjusting nut in direction ç to

increase free play and in direction

è to decrease free play.czsd iSMy ds fdukjs ij fiNys czsd iSMy

dh Ýh Iys ¼

ls

30

feñehñ

rd ,MtLV djuh pkfg,A Ýh Iys

¼

¼

a. Freeplay

Ýh Iys

WARNING• When it is impossible to make

the proper adjustment, ask a

YMIS dealer.

• Check the operation of the

brake light after adjusting the

rear brake. psrkouh•

tc lgh rjhds ls lkaetL;

¼,MtLVesaV½ LFkkfir djuk vlaHko

yx jgk g¨ r¨ okbZñ,eñvkbZñ,lñ Mhyj

ls ijke'kZ djsaA

•

fiNyh czsd d¨ ,MtLVesaV djus ds

ckn czsd ykbV dh çfØ;k dh tk¡p

djsaA

6.23

PERIODIC MAINTENANCE AND MINOR REPAIR

lkef;d j[kj[kko rFkk ekewyh ejEer

feñehñ rd ,MtLV djuk pkfg,A1. Loosen the locknut

ykWduV d¨

direction ç to decrease free play

and direction è to increase free

play.

Ýh&Iys de djus ds fy, ,Mt¯LVx

c¨YV d¨ , dh fn'kk esa ?kqek,¡ rFkk

Ýh&Iys d¨ c<+kus ds fy, bls ch dh

fn'kk esa ?kqek,¡A

3. Tighten the locknut.

ykWd uV d¨ dl nsaA

WARNINGWhen it is impossible to make the

proper adjustment, ask a YMIS

dealer psrkouh;fn lgh rjhds ls ,MtLVesaV djuk

vlaHko yx jgk g¨ r¨ okbZñ,eñvkbZñ,lñ

Mhyj ls ckr djsaA

1

pg56_96.pmd10/15/2006, 8:53 AM 59

Page 62 of 158

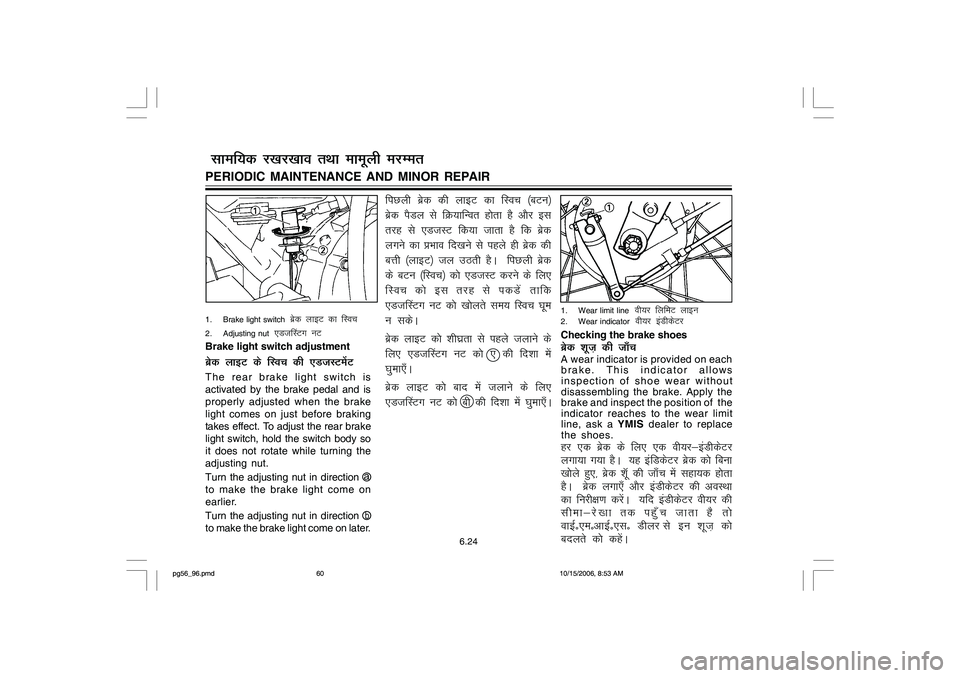

1. Wear limit line

oh;j fyfeV ykbu

2. Wear indicator

oh;j baMhdsVj

Checking the brake shoes

czsd 'kwt+ dh tk¡pA wear indicator is provided on each

brake. This indicator allows

inspection of shoe wear without

disassembling the brake. Apply the

brake and inspect the position of the

indicator reaches to the wear limit

line, ask a YMIS dealer to replace

the shoes.gj ,d czsd ds fy, ,d oh;j&baMhdsVj

yxk;k x;k gSA ;g bafMdsVj czsd d¨ fcuk

[k¨ys gq,] czsd 'kwW dh tk¡p esa lgk;d g¨rk

gSA czsd yxk,¡ v©j baMhdsVj dh voLFkk

dk fujh{k.k djsaA ;fn baMhdsVj oh;j dh

lhek&js[kk rd igq¡p tkrk gS r¨

okbZñ,eñvkbZñ,lñ Mhyj ls bu 'kwt+ d¨

cnyrs d¨ dgsaA

1. Brake light switch

czsd ykbV dk fLop

2. Adjusting nut

,Mt¯LVx uV

Brake light switch adjustment

czsd ykbV ds fLop dh ,MtLVesaVThe rear brake light switch is

activated by the brake pedal and is

properly adjusted when the brake

light comes on just before braking

takes effect. To adjust the rear brake

light switch, hold the switch body so

it does not rotate while turning the

adjusting nut.

Turn the adjusting nut in direction ç

to make the brake light come on

earlier.

Turn the adjusting nut in direction è

to make the brake light come on later.

fiNyh czsd dh ykbV dk fLop ¼cVu½

czsd iSMy ls fØ;kfUor g¨rk gS v©j bl

rjg ls ,MtLV fd;k tkrk gS fd czsd

yxus dk çHkko fn[kus ls igys gh czsd dh

cÙkh ¼ykbV½ ty mBrh gSA fiNyh czsd

ds cVu ¼fLop½ d¨ ,MtLV djus ds fy,

fLop d¨ bl rjg ls idMsa rkfd

,Mt¯LVx uV d¨ [k¨yrs le; fLop ?kwe

u ldsA

czsd ykbV d¨ 'kh?kzrk ls igys tykus ds

fy, ,Mt¯LVx uV d¨ , dh fn'kk esa

?kqek,¡A

czsd ykbV d¨ ckn esa tykus ds fy,

,Mt¯LVx uV d¨ ch dh fn'kk esa ?kqek,¡A

6.24

PERIODIC MAINTENANCE AND MINOR REPAIRlkef;d j[kj[kko rFkk ekewyh ejEer

pg56_96.pmd10/15/2006, 8:53 AM 60

Page 63 of 158

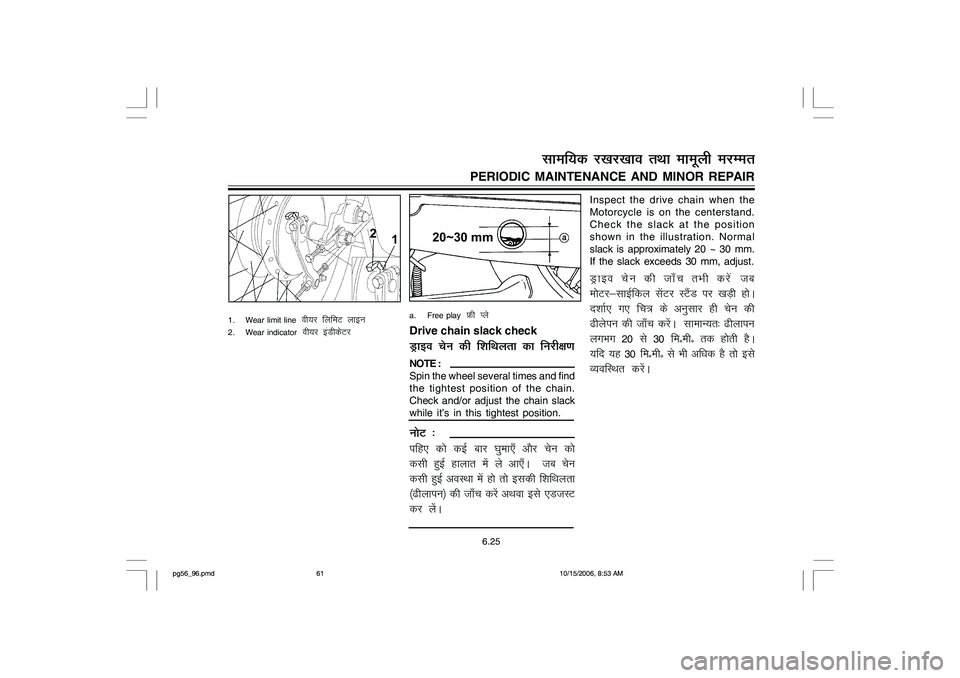

Inspect the drive chain when the

Motorcycle is on the centerstand.

Check the slack at the position

shown in the illustration. Normal

slack is approximately 20 ~ 30 mm.

If the slack exceeds 30 mm, adjust.Mªkbo psu dh tk¡p rHkh djsa tc

e¨Vj&lkbZfdy lsaVj LVSaM ij [kM+h g¨A

n'kkZ, x, fp=k ds vuqlkj gh psu dh

20

ls

30 feñehñ rd g¨rh gSA

;fn ;g

30

feñehñ ls Hkh vf/kd gS r¨ bls

O;ofLFkr djsaA

1. Wear limit line

oh;j fyfeV ykbu

2. Wear indicator

oh;j baMhdsVj

a. Free play

Ýh Iys

Drive chain slack checkMªkbo psu dh f'kfFkyrk dk fujh{k.kNOTE :

Spin the wheel several times and find

the tightest position of the chain.

Check and/or adjust the chain slack

while it’s in this tightest position.u¨V %ifg, d¨ dbZ ckj ?kqek,¡ v©j psu d¨

dlh gqbZ gkykr esa ys vk,¡A tc psu

dlh gqbZ voLFkk esa g¨ r¨ bldh f'kfFkyrk

¼

6.25

PERIODIC MAINTENANCE AND MINOR REPAIR

lkef;d j[kj[kko rFkk ekewyh ejEer

1 2

20~30 mm

pg56_96.pmd10/15/2006, 8:53 AM 61

Page 64 of 158

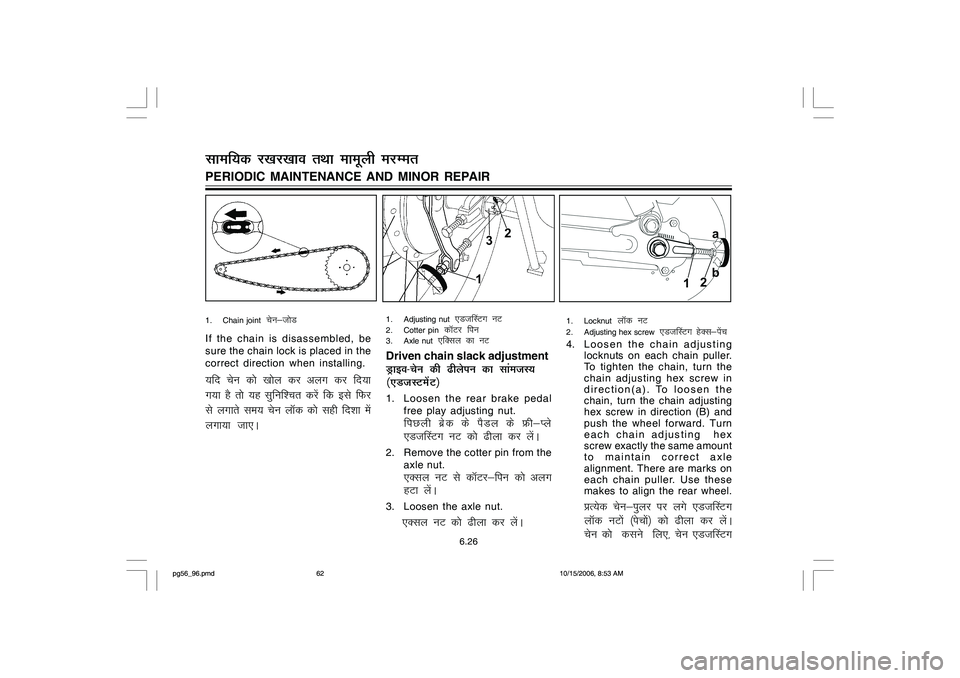

1. Chain joint

psu&t¨M

If the chain is disassembled, be

sure the chain lock is placed in the

correct direction when installing.

;fn psu d¨ [k¨y dj vyx dj fn;k

x;k gS r¨ ;g lqfuf'pr djsa fd bls fQj

ls yxkrs le; psu ykWd d¨ lgh fn'kk esa

yxk;k tk,A

1. Adjusting nut

,Mt¯LVx uV

2. Cotter pin

dkWVj fiu

3. Axle nut

,fDly dk uV

Driven chain slack adjustmentMªkbo&psu dh

free play adjusting nut.

fiNyh czsd ds iSMy ds Ýh&Iys

,Mt¯LVx uV d¨

axle nut.

,Dly uV ls dkWVj&fiu d¨ vyx

gVk ysaA

3. Loosen the axle nut.

,Dly uV d¨

1. Locknut

ykWd uV

2. Adjusting hex screw

,Mt¯LVx gsDl&isap

4. Loosen the chain adjusting

locknuts on each chain puller.

To tighten the chain, turn the

chain adjusting hex screw in

direction(a). To loosen the

chain, turn the chain adjusting

hex screw in direction (B) and

push the wheel forward. Turn

each chain adjusting hex

screw exactly the same amount

to maintain correct axle

alignment. There are marks on

each chain puller. Use these

makes to align the rear wheel.

çR;sd psu&iqyj ij yxs ,Mt¯LVx

ykWd uV¨a ¼isp¨a½ d¨

PERIODIC MAINTENANCE AND MINOR REPAIRlkef;d j[kj[kko rFkk ekewyh ejEer

1

2

3

12a

b

pg56_96.pmd10/15/2006, 8:53 AM 62

Page 65 of 158

![YAMAHA YD110 2007 Repair Manual 6.27

PERIODIC MAINTENANCE AND MINOR REPAIR

lkef;d j[kj[kko rFkk ekewyh ejEer

"kV~&isap ¼gsDl&LØ;w½ d¨ , dh fnkk

esa ?kqek,¡ rFkk bls <hyk djus] psu

,Mt¯LVx "kV~&isap ¼gsDl&LØ;w½ d¨

ch dh fn YAMAHA YD110 2007 Repair Manual 6.27

PERIODIC MAINTENANCE AND MINOR REPAIR

lkef;d j[kj[kko rFkk ekewyh ejEer

"kV~&isap ¼gsDl&LØ;w½ d¨ , dh fnkk

esa ?kqek,¡ rFkk bls <hyk djus] psu

,Mt¯LVx "kV~&isap ¼gsDl&LØ;w½ d¨

ch dh fn](/img/51/53673/w960_53673-64.png)

6.27

PERIODIC MAINTENANCE AND MINOR REPAIR

lkef;d j[kj[kko rFkk ekewyh ejEer

"kV~&isap ¼gsDl&LØ;w½ d¨ , dh fn'kk

esa ?kqek,¡ rFkk bls

ch dh fn'kk esa ?kqek,¡ v©j ifg, ij

vkxs dh v¨j ncko MkysA ,Dly dh

lgh ,ykbuesaV ¼iafDrcðrk½ d¨

çfrikfnr ¼esauVsau½ djus ds fy, çR;sd

psu ,Mt¯LVx "kV&isap ¼gsDl&LØ;ww½

d¨ Bhd rjg ls leku nwjh rd

?kqek,¡A çR;sd psu iqyj ij fu'kku

yxs gq, gSA fiNys ifg, d¨ lgh

rjg ls yxkus ds fy, bu fpUg¨ dk

ç;¨x djsaA

CAUTION :• Maintain chain slackness

within specified limits as per

specifications.

• To maintain correct axle

alignment, Ensure the notch

on the adjuster is on the same

Mark on Left and Right

Side.

lko/kkuh %•

psu dh f'kfFkyrk d¨ fo'ks"k #i ls

of.kZr fufnZ"V dh xbZ lhekv¨a esa gh

çfrikfnr ¼esauVsau½ djsaA

•

,fDly dh lgh ,ykbuesaV çfrikfnr

djus ds fy, ;g lqfuf'pr djsa fd

,MtLVj ij yxk gqvk fu'kku ckb±

rFkk nkb± v¨j ls ,d gh fpUg ¼fu'kku½

ij feyrh gSA

5. After adjusting, be sure to

tighten each chain adjusting

locknut. Then tighten the axle

nut to the specified torque.

,MtLVesaV djus ds ckn gj ,d psu

,Mt¯LVx ykWd uV d¨ vo'; dl

nsaA rRi'pkr~ ,fDly uV d¨ fu£n"V

VkdZ rd dl nsaA

Tightening torque

dlk x;k VkdZ

:

Axle nut

,fDly uV %

65 ft-lb (9.05 m-kg)

1. Cotter pin

dkWVj fiu

6. Insert a new cotter pin into the axle

nut and bend the end of the cotter

pin as shown. If the notch in the

axle nut and the cotter pin hole do

not match, tighten the nut slightly

to align them.

,fDly ds uV esa ,d u;k dkWVj fiu

yxk,¡] v©j tSlk fd fp=k esa fn[kk;k

x;k gS] dkWVj fiu ds ,d fljs d¨ e¨M+

nsaA ;fn ,fDly uV dh u¨ad ¼ukWp½

rFkk dkWVj&fiu ds uksd ds lkFk fey

ugh ikrh gS r¨ bUgs vkil esa feykus ds

fy, uV d¨ /khjs&/khjs dlsaA

WARNINGAlways use a new cotter pin on the

axle nut.

pg56_96.pmd10/15/2006, 8:53 AM 63

Page 66 of 158

psrkouh

,fDly uV ds fy, ges'kk u, dkWVj fiu

dk gh ç;¨x djsaA7. Adjust the free play in the brake

pedal.

czsd iSMy ds Ýh Iys d¨ ,MtLV

djsaA

p

WARNINGCheck the operation of the brake

light after adjusting the rear brake. psrkouhfiNyh czsd d¨ ,MtLV djus ds ckn

czsd dh cÙkh ¼ykbV½ dh çfØ;k d¨ tk¡p

ysaA

6.28

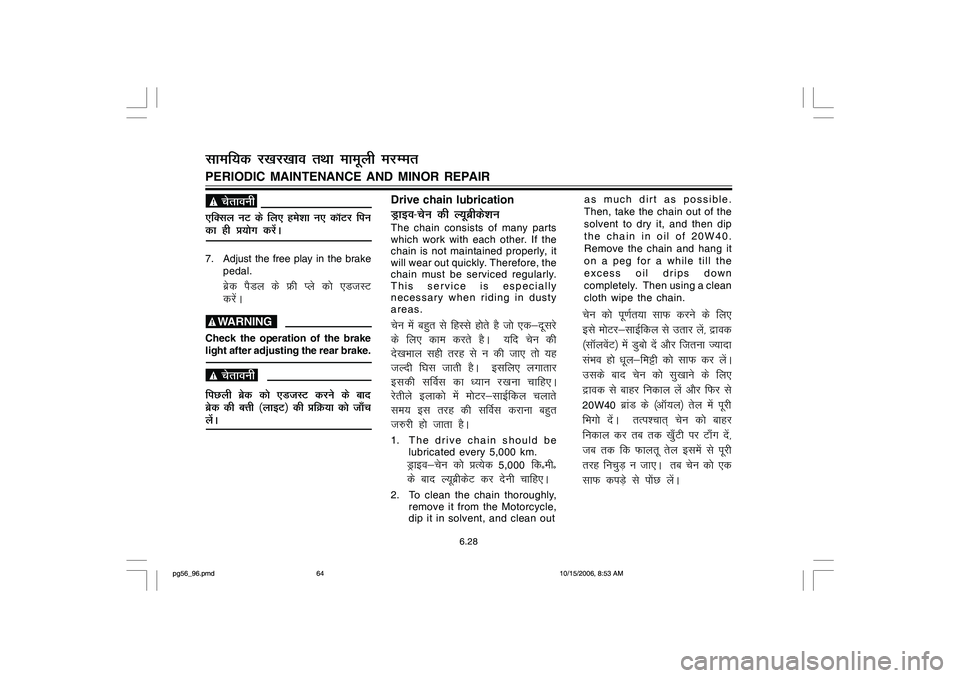

Drive chain lubricationMªkbo&psu dh Y;wczhds'kuThe chain consists of many parts

which work with each other. If the

chain is not maintained properly, it

will wear out quickly. Therefore, the

chain must be serviced regularly.

This service is especially

necessary when riding in dusty

areas.psu esa cgqr ls fgLls g¨rs gS t¨ ,d&nwljs

ds fy, dke djrs gSA ;fn psu dh

ns[kHkky lgh rjg ls u dh tk, r¨ ;g

tYnh f?kl tkrh gSA blfy, yxkrkj

bldh l£ol dk /;ku j[kuk pkfg,A

jsrhys bykd¨ esa e¨Vj&lkbZfdy pykrs

le; bl rjg dh l£ol djkuk cgqr

t#jh g¨ tkrk gSA1. The drive chain should be

lubricated every 5,000 km.

Mªkbo&psu d¨ çR;sd

5,000

fdñehñ

ds ckn Y;wczhdsV dj nsuh pkfg,A

2. To clean the chain thoroughly,

remove it from the Motorcycle,

dip it in solvent, and clean outas much dirt as possible.

Then, take the chain out of the

solvent to dry it, and then dip

the chain in oil of 20W40.

Remove the chain and hang it

on a peg for a while till the

excess oil drips down

completely. Then using a clean

cloth wipe the chain.

psu d¨ iw.kZr;k lkQ djus ds fy,

bls e¨Vj&lkbZfdy ls mrkj ysa] ækod

¼lkWyosaV½ esa Mqc¨ nsa v©j ftruk T;knk

laHko g¨ /kwy&feêh d¨ lkQ dj ysaA

mlds ckn psu d¨ lq[kkus ds fy,

ækod ls ckgj fudky ysa v©j fQj ls20W40

czkaM ds ¼vkW;y½ rsy esa iwjh

fHkx¨ nsaA rRi'pkr~ psu d¨ ckgj

fudky dj rc rd [kq¡Vh ij Vk¡x nsa]

tc rd fd Qkyrw rsy blesa ls iwjh

rjg fupqM+ u tk,A rc psu d¨ ,d

lkQ diM+s ls i¨aN ysaA

PERIODIC MAINTENANCE AND MINOR REPAIRlkef;d j[kj[kko rFkk ekewyh ejEer

pg56_96.pmd10/15/2006, 8:53 AM 64

Page 67 of 158

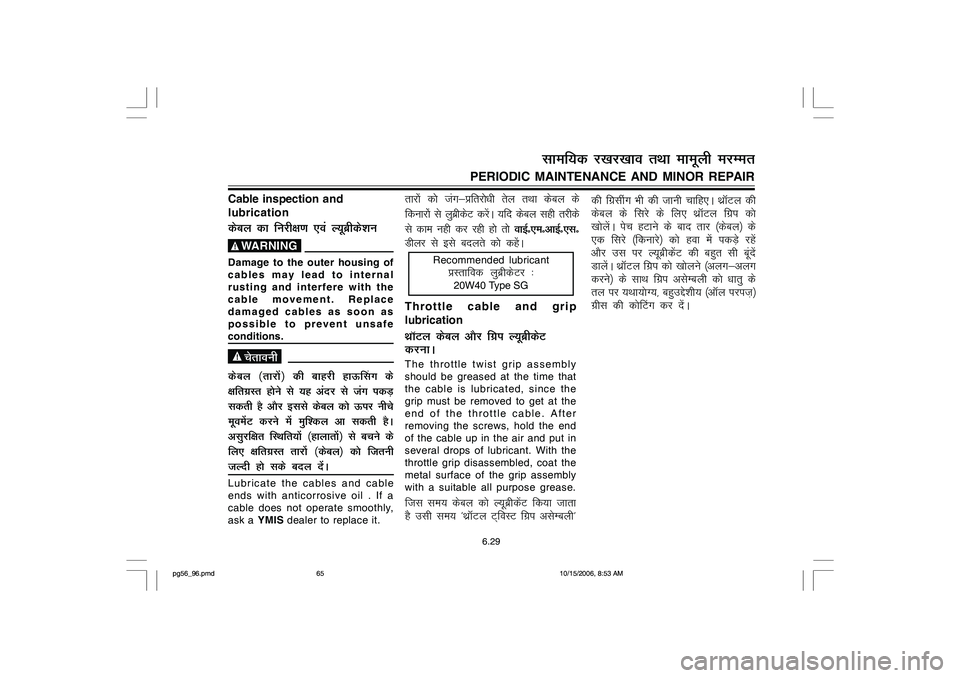

Throttle cable and grip

lubricationFkzkWVy dscy v©j fxzi Y;wczhdsV

djukAThe throttle twist grip assembly

should be greased at the time that

the cable is lubricated, since the

grip must be removed to get at the

end of the throttle cable. After

removing the screws, hold the end

of the cable up in the air and put in

several drops of lubricant. With the

throttle grip disassembled, coat the

metal surface of the grip assembly

with a suitable all purpose grease.ftl le; dscy dks Y;wczhdsaV fd;k tkrk

gS mlh le; ^FkzkWVy V~foLV fxzi vlsEcyh*rkj¨a d¨ tax&çfrj¨/kh rsy rFkk dscy ds

fdukj¨a ls yqczhdsV djsaA ;fn dscy lgh rjhds

ls dke ugh dj jgh g¨ r¨ okbZñ,eñvkbZñ,lñ

Mhyj ls bls cnyrs d¨ dgsaA

dh fxzlhax Hkh dh tkuh pkfg,A FkzkWVy dh

dscy ds fljs ds fy, FkzkWVy fxzi dks

[kksysaA isp gVkus ds ckn rkj ¼dscy½ ds

,d fljs ¼fdukjs½ dks gok esa idM+s jgsa

vkSj ml ij Y;wczhdsaV dh cgqr lh cwansa

MkysaA FkzkWVy fxzi dks [kksyus ¼vyx&vyx

djus½ ds lkFk fxzi vlsEcyh dks /kkrq ds

ry ij ;Fkk;ksX;] cgqmís'kh; ¼vkWy ijit+½

xzhl dh dks¯Vx dj nsaA

Cable inspection and

lubricationdscy dk fujh{k.k ,oa Y;wczhds'ku WARNINGDamage to the outer housing of

cables may lead to internal

rusting and interfere with the

cable movement. Replace

damaged cables as soon as

possible to prevent unsafe

conditions. psrkouhdscy ¼rkj¨a½ dh ckgjh gkůlx ds

{kfrxzLr g¨us ls ;g vanj ls tax idM+

ldrh gS v©j blls dscy d¨ Åij uhps

ewoesaV djus esa eqf'dy vk ldrh gSA

vlqjf{kr fLFkfr;¨a ¼gkykr¨aa½ ls cpus ds

fy, {kfrxzLr rkj¨a ¼dscy½ d¨ ftruh

tYnh g¨ lds cny nsaALubricate the cables and cable

ends with anticorrosive oil . If a

cable does not operate smoothly,

ask a YMIS dealer to replace it.Recommended lubricant

çLrkfod yqczhdsVj %20W40 Type SG

6.29

PERIODIC MAINTENANCE AND MINOR REPAIR

lkef;d j[kj[kko rFkk ekewyh ejEer

pg56_96.pmd10/15/2006, 8:53 AM 65

Page 68 of 158

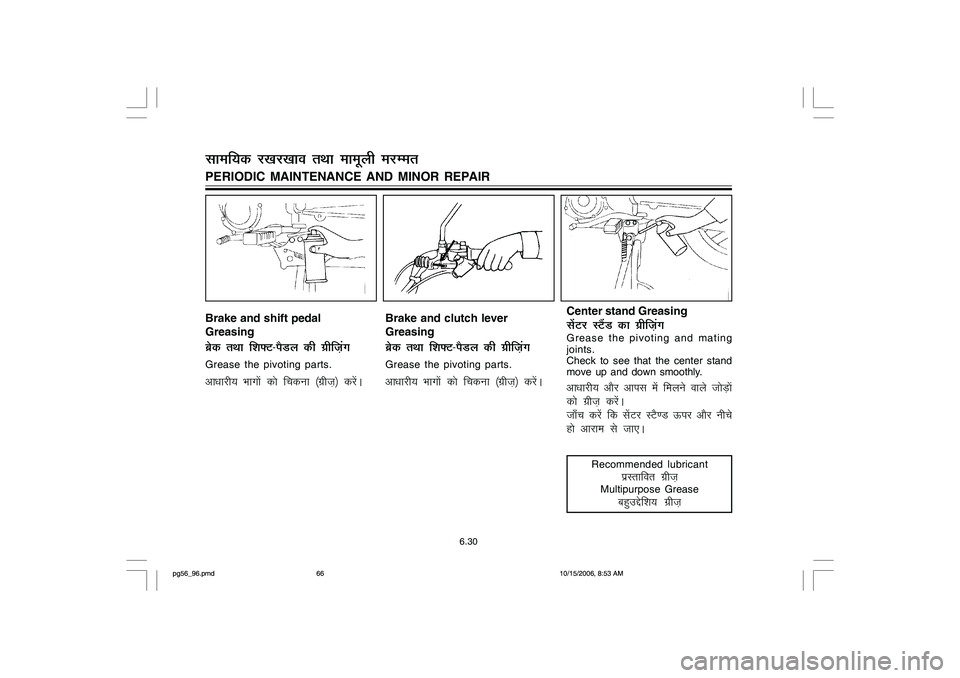

Brake and shift pedal

Greasingczsd rFkk f'k¶V&iSMy dh xzhft+axGrease the pivoting parts.vk/kkjh; Hkkxksa dks fpduk ¼xzht+½ djsaA

Brake and clutch lever

Greasingczsd rFkk f'k¶V&iSMy dh xzhft+axGrease the pivoting parts.vk/kkjh; Hkkxksa dks fpduk ¼xzht+½ djsaA

Center stand GreasinglsaVj LVSaM dk xzhft+axGrease the pivoting and mating

joints.

Check to see that the center stand

move up and down smoothly.vk/kkjh; vkSj vkil esa feyus okys tksM+ksa

dks xzht+ djsaA

tk¡p djsa fd lsaVj LVS.M Åij vkSj uhps

gks vkjke ls tk,A

6.30

PERIODIC MAINTENANCE AND MINOR REPAIRlkef;d j[kj[kko rFkk ekewyh ejEer

Recommended lubricant

izLrkfor xzht+

Multipurpose Grease

cgqmísf'k; xzht+

pg56_96.pmd10/15/2006, 8:53 AM 66

Page 69 of 158

![YAMAHA YD110 2007 Repair Manual Front fork inspectionÝaV QksdZ dk fujh{k.k WARNINGSecurely support the Motorcycle

so there is no danger of it falling

over. psrkouhlqjf{kr rjhds ls eksVjlkbfdy dks lgkjk

nsa] ftlls blds fxjus dk YAMAHA YD110 2007 Repair Manual Front fork inspectionÝaV QksdZ dk fujh{k.k WARNINGSecurely support the Motorcycle

so there is no danger of it falling

over. psrkouhlqjf{kr rjhds ls eksVjlkbfdy dks lgkjk

nsa] ftlls blds fxjus dk](/img/51/53673/w960_53673-68.png)

Front fork inspectionÝaV QksdZ dk fujh{k.k WARNINGSecurely support the Motorcycle

so there is no danger of it falling

over. psrkouhlqjf{kr rjhds ls eksVjlkbfdy dks lgkjk

nsa] ftlls blds fxjus dk [krjk u jgssA1. Visual check

Check for scratches or

damage on the inner tube and

traces if oil leakage from the

front fork.

n f"Vxr ¼us=kh;½ tk¡p %

vkxs yxs QksdZ esa ls vR;f/kd rsy

fjlko vkSj vanj dh V~;wc ij [kjksapks

rFkk blds {kfrxzLr gksus dh tk¡p

djsaA

2. Operation check

Place the Motorcycle on a level

place.

izfØ;k dh tk¡p %

eksVjlkbfdy dks ,d ysoy fd;s gq,

¼likV½ LFkku ij [kM+k djsaA

a. Hold the Motorcycle in an

upright position and apply the

front brake.

eksVjlkbfdy dks lh/kk Åij mBkdj

j[ksa vkSj vxyh czsd dk mi;ksx djsaA

b. Push down hard on the

handlebars several times and

check if the fork bounds

smoothly.

gSafMyckj dk dbZ ckj tksj ls uhps

dh vksj nck,a vkSj bl ckr dh tk¡p

djsa fd D;k QksdZ vkjke ls ^mNky*

ys ysrk gSA

6.31

WARNING

If the center stand does not move

smoothly, consult a YMIS dealer. psrkouh;fn eksVjlkbfdy dk lsaVj LVS.M vkjke

ls ¼fcuk fdlh :dkoV ds½ dke ugha

djrk gks rks okbZñ,eñvkbZñ,lñ Mhyj ls

laidZ djsaA

PERIODIC MAINTENANCE AND MINOR REPAIR

lkef;d j[kj[kko rFkk ekewyh ejEer

pg56_96.pmd10/15/2006, 8:53 AM 67

Page 70 of 158

fy, batu ds uhps ,d LVS.M yxk ysaaA

vxys QksdsZa ds fupys fljs dks idM+ dj

j[ksa vkSj mUgsa vkxs rFkk ihNs dh vksj

pykus dk iz;Ru djsaA ;fn fdlh rjg

dk Lora=k ¼Ýh½ Iys eglwl fd;k tk jgk

gks rks okbZñ,eñvkbZñ,lñ Mhyj ls LVs;¯jx

dh tk¡p djus vkSj ^,MtLV* djus dks

dgsaA ;fn vkxs dk ifg;k gVk fn;k tk,

rks tk¡p djuk vklku gks tkrk gSA WARNINGSecurely support the Motorcycle

so there is no danger of it falling

over. psrkouheksVjlkbfdy dks lqjf{kr rjhds ls lgkjk

nsdj j[ksa rkfd blds iyV dj fxjus

dk [krjk u jgsA

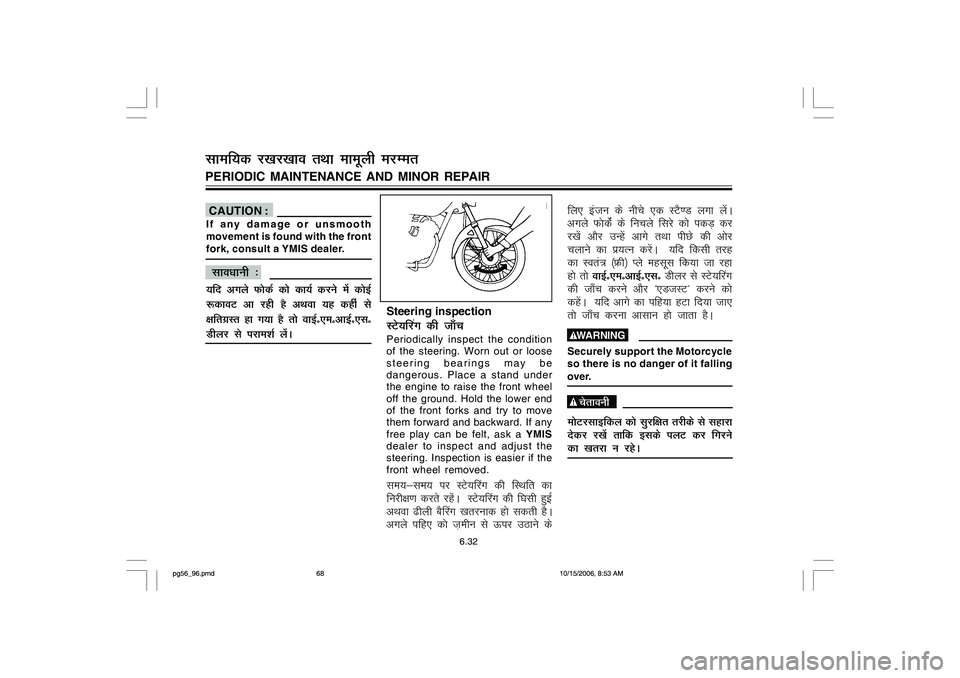

Steering inspectionLVs;¯jx dh tk¡pPeriodically inspect the condition

of the steering. Worn out or loose

steering bearings may be

dangerous. Place a stand under

the engine to raise the front wheel

off the ground. Hold the lower end

of the front forks and try to move

them forward and backward. If any

free play can be felt, ask a YMIS

dealer to inspect and adjust the

steering. Inspection is easier if the

front wheel removed.le;≤ ij LVs;¯jx dh fLFkfr dk

fujh{k.k djrs jgasA LVs;¯jx dh f?klh gqbZ

vFkok

6.32

CAUTION :If any damage or unsmooth

movement is found with the front

fork, consult a YMIS dealer. lko/kkuh %;fn vxys QksdZ dks dk;Z djus esa dksbZ

:dkoV vk jgh gS vFkok ;g dgha ls

{kfrxzLr gk x;k gS rks okbZñ,eñvkbZñ,lñ

Mhyj ls ijke'kZ ysaAPERIODIC MAINTENANCE AND MINOR REPAIRlkef;d j[kj[kko rFkk ekewyh ejEer

pg56_96.pmd10/15/2006, 8:53 AM 68