YAMAHA YZ125LC 2013 Manual PDF

Manufacturer: YAMAHA, Model Year: 2013, Model line: YZ125LC, Model: YAMAHA YZ125LC 2013Pages: 168, PDF Size: 8.19 MB

Page 71 of 168

4-9

CARBURETOR AND REED VALVE

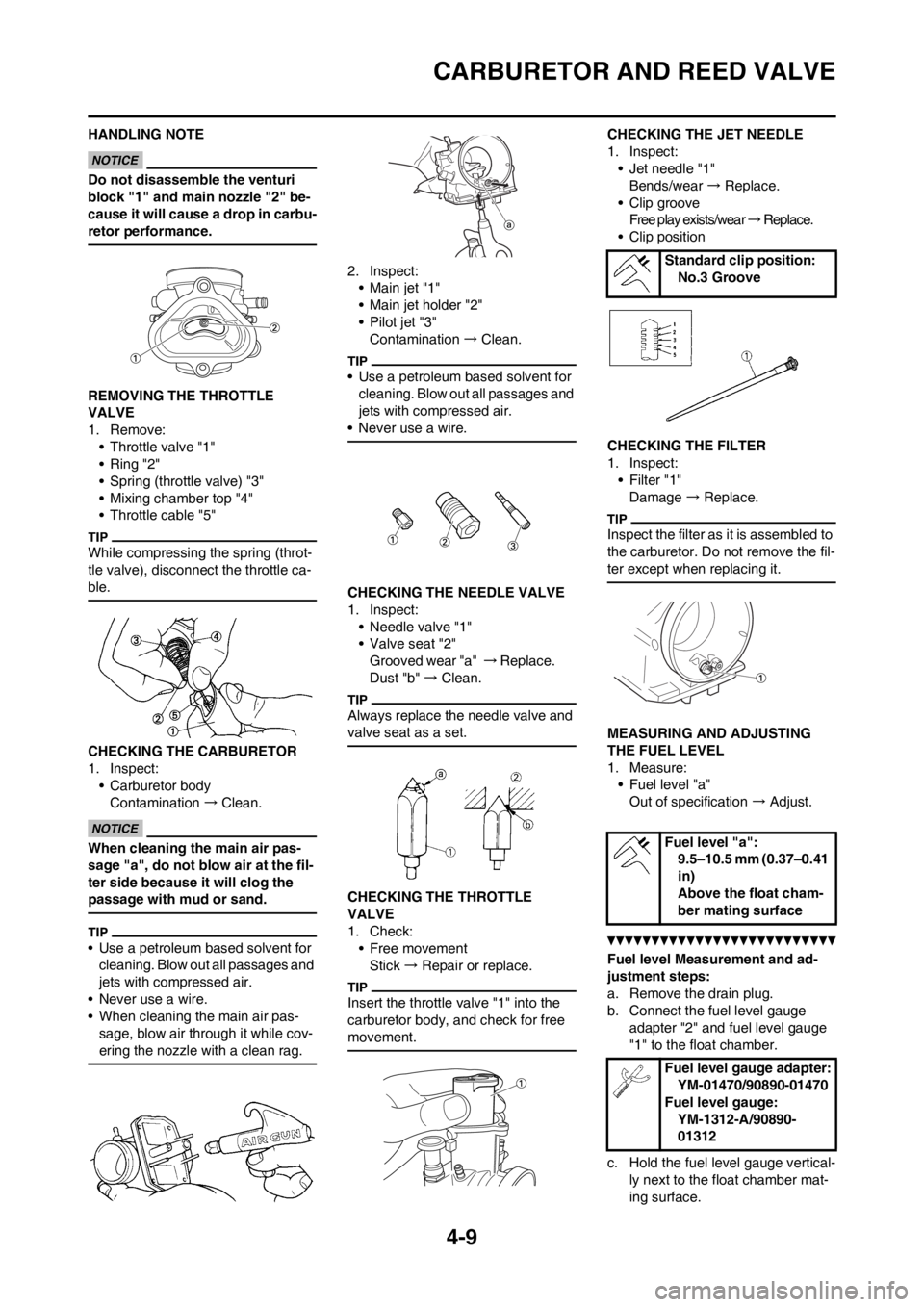

HANDLING NOTE

Do not disassemble the venturi

block "1" and main nozzle "2" be-

cause it will cause a drop in carbu-

retor performance.

REMOVING THE THROTTLE

VALVE

1. Remove:

• Throttle valve "1"

• Ring "2"

• Spring (throttle valve) "3"

• Mixing chamber top "4"

• Throttle cable "5"

While compressing the spring (throt-

tle valve), disconnect the throttle ca-

ble.

CHECKING THE CARBURETOR

1. Inspect:

• Carburetor body

Contamination → Clean.

When cleaning the main air pas-

sage "a", do not blow air at the fil-

ter side because it will clog the

passage with mud or sand.

• Use a petroleum based solvent for

cleaning. Blow out all passages and

jets with compressed air.

• Never use a wire.

• When cleaning the main air pas-

sage, blow air through it while cov-

ering the nozzle with a clean rag.

2. Inspect:

•Main jet "1"

• Main jet holder "2"

• Pilot jet "3"

Contamination → Clean.

• Use a petroleum based solvent for

cleaning. Blow out all passages and

jets with compressed air.

• Never use a wire.

CHECKING THE NEEDLE VALVE

1. Inspect:

• Needle valve "1"

• Valve seat "2"

Grooved wear "a" → Replace.

Dust "b" → Clean.

Always replace the needle valve and

valve seat as a set.

CHECKING THE THROTTLE

VALVE

1. Check:

• Free movement

Stick → Repair or replace.

Insert the throttle valve "1" into the

carburetor body, and check for free

movement.

CHECKING THE JET NEEDLE

1. Inspect:

• Jet needle "1"

Bends/wear → Replace.

• Clip groove

Free play exists/wear → R e p l a c e .

• Clip position

CHECKING THE FILTER

1. Inspect:

•Filter "1"

Damage → Replace.

Inspect the filter as it is assembled to

the carburetor. Do not remove the fil-

ter except when replacing it.

MEASURING AND ADJUSTING

THE FUEL LEVEL

1. Measure:

• Fuel level "a"

Out of specification → Adjust.

Fuel level Measurement and ad-

justment steps:

a. Remove the drain plug.

b. Connect the fuel level gauge

adapter "2" and fuel level gauge

"1" to the float chamber.

c. Hold the fuel level gauge vertical-

ly next to the float chamber mat-

ing surface.

Standard clip position:

No.3 Groove

Fuel level "a":

9.5–10.5 mm (0.37–0.41

in)

Above the float cham-

ber mating surface

Fuel level gauge adapter:

YM-01470/90890-01470

Fuel level gauge:

YM-1312-A/90890-

01312

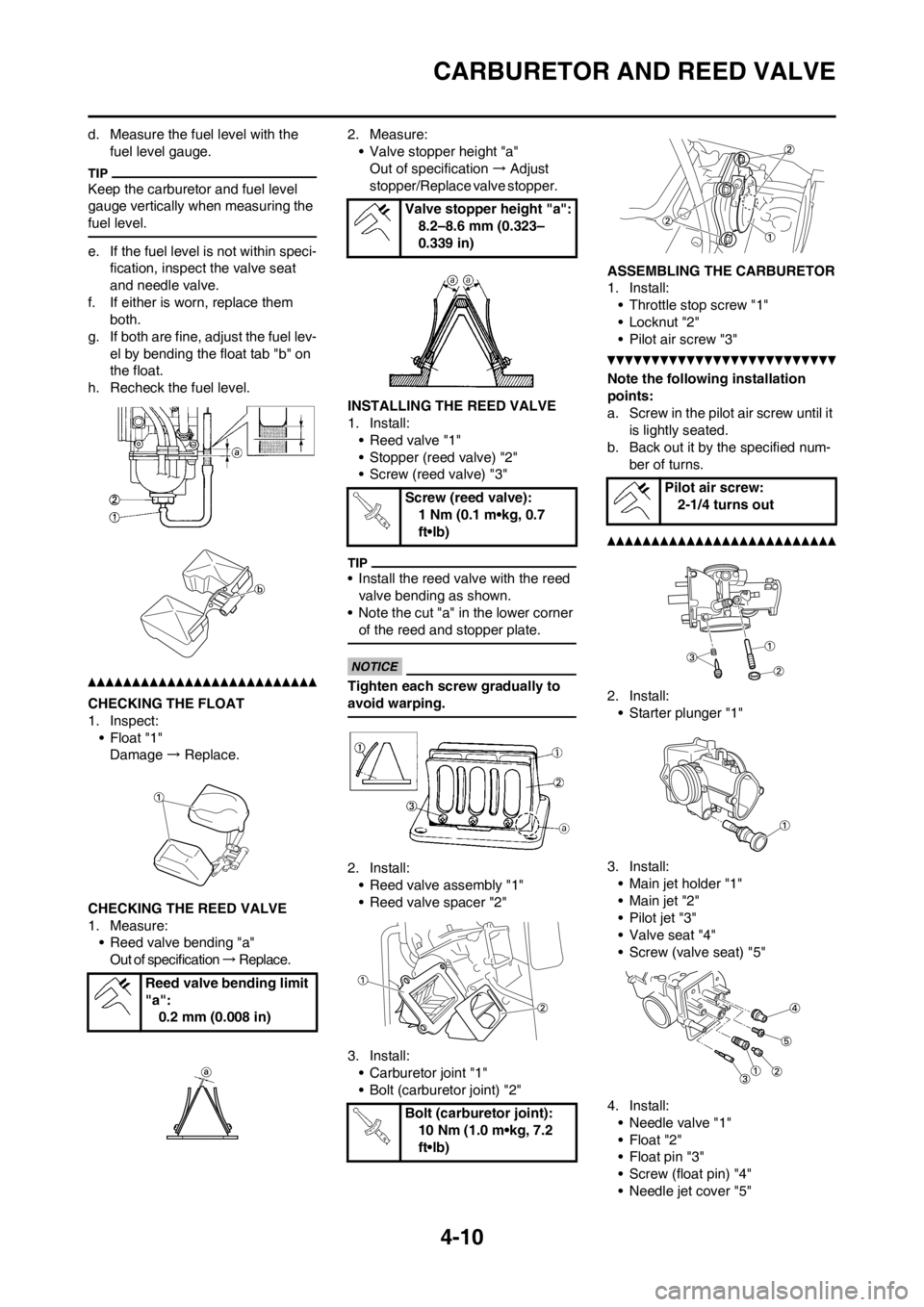

Page 72 of 168

4-10

CARBURETOR AND REED VALVE

d. Measure the fuel level with the

fuel level gauge.

Keep the carburetor and fuel level

gauge vertically when measuring the

fuel level.

e. If the fuel level is not within speci-

fication, inspect the valve seat

and needle valve.

f. If either is worn, replace them

both.

g. If both are fine, adjust the fuel lev-

el by bending the float tab "b" on

the float.

h. Recheck the fuel level.

CHECKING THE FLOAT

1. Inspect:

• Float "1"

Damage → Replace.

CHECKING THE REED VALVE

1. Measure:

• Reed valve bending "a"

Out of specification → R e p l a c e . 2. Measure:

• Valve stopper height "a"

Out of specification → Adjust

stopper/Replace valve stopper.

INSTALLING THE REED VALVE

1. Install:

• Reed valve "1"

• Stopper (reed valve) "2"

• Screw (reed valve) "3"

• Install the reed valve with the reed

valve bending as shown.

• Note the cut "a" in the lower corner

of the reed and stopper plate.

Tighten each screw gradually to

avoid warping.

2. Install:

• Reed valve assembly "1"

• Reed valve spacer "2"

3. Install:

• Carburetor joint "1"

• Bolt (carburetor joint) "2"ASSEMBLING THE CARBURETOR

1. Install:

• Throttle stop screw "1"

• Locknut "2"

• Pilot air screw "3"

Note the following installation

points:

a. Screw in the pilot air screw until it

is lightly seated.

b. Back out it by the specified num-

ber of turns.

2. Install:

• Starter plunger "1"

3. Install:

• Main jet holder "1"

•Main jet "2"

• Pilot jet "3"

• Valve seat "4"

• Screw (valve seat) "5"

4. Install:

• Needle valve "1"

• Float "2"

• Float pin "3"

• Screw (float pin) "4"

• Needle jet cover "5" Reed valve bending limit

"a":

0.2 mm (0.008 in)

Valve stopper height "a":

8.2–8.6 mm (0.323–

0.339 in)

Screw (reed valve):

1 Nm (0.1 m•kg, 0.7

ft•lb)

Bolt (carburetor joint):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Pilot air screw:

2-1/4 turns out

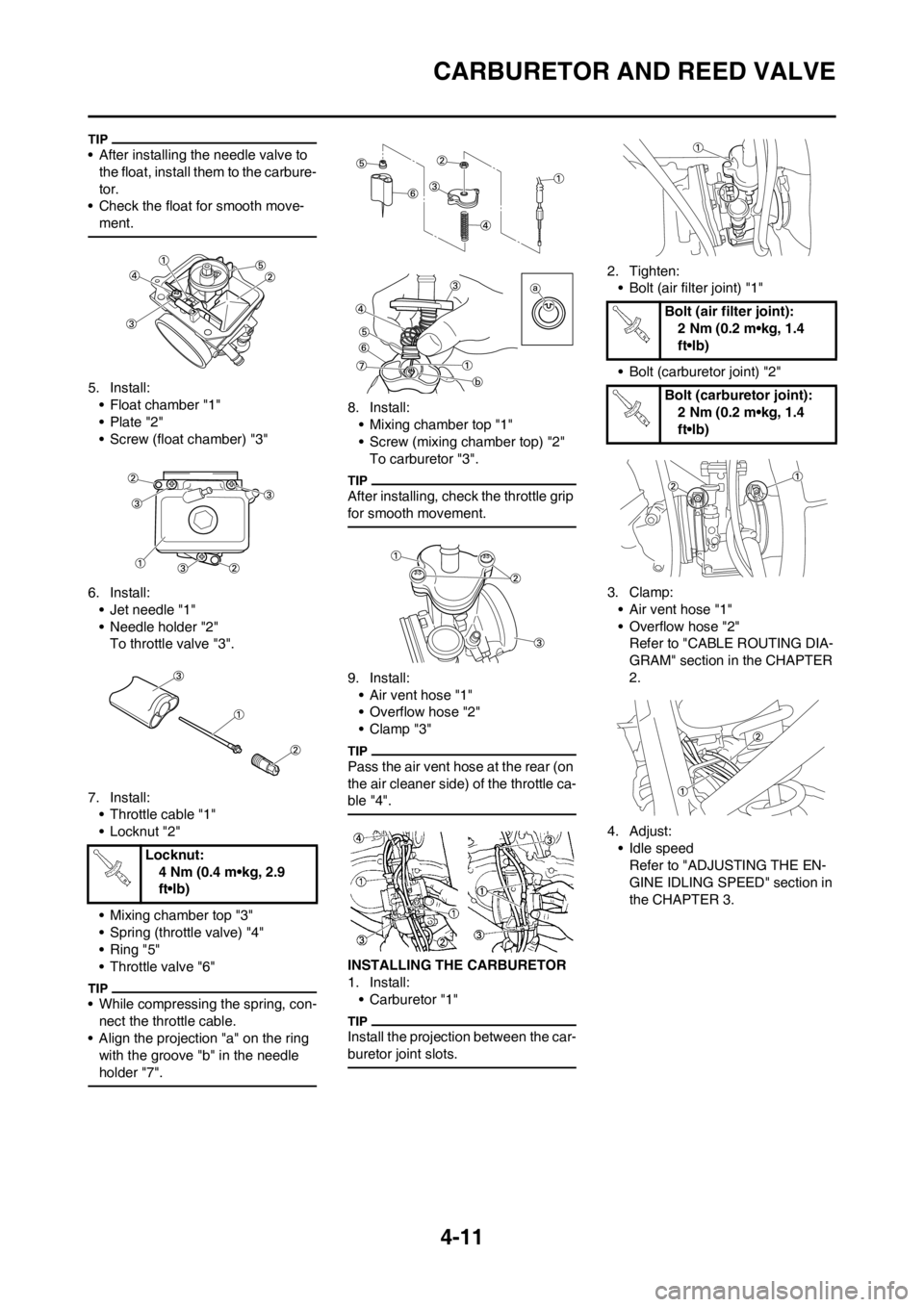

Page 73 of 168

4-11

CARBURETOR AND REED VALVE

• After installing the needle valve to

the float, install them to the carbure-

tor.

• Check the float for smooth move-

ment.

5. Install:

• Float chamber "1"

• Plate "2"

• Screw (float chamber) "3"

6. Install:

• Jet needle "1"

• Needle holder "2"

To throttle valve "3".

7. Install:

• Throttle cable "1"

• Locknut "2"

• Mixing chamber top "3"

• Spring (throttle valve) "4"

• Ring "5"

• Throttle valve "6"

• While compressing the spring, con-

nect the throttle cable.

• Align the projection "a" on the ring

with the groove "b" in the needle

holder "7".

8. Install:

• Mixing chamber top "1"

• Screw (mixing chamber top) "2"

To carburetor "3".

After installing, check the throttle grip

for smooth movement.

9. Install:

• Air vent hose "1"

• Overflow hose "2"

•Clamp "3"

Pass the air vent hose at the rear (on

the air cleaner side) of the throttle ca-

ble "4".

INSTALLING THE CARBURETOR

1. Install:

• Carburetor "1"

Install the projection between the car-

buretor joint slots.

2. Tighten:

• Bolt (air filter joint) "1"

• Bolt (carburetor joint) "2"

3. Clamp:

• Air vent hose "1"

• Overflow hose "2"

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2.

4. Adjust:

• Idle speed

Refer to "ADJUSTING THE EN-

GINE IDLING SPEED" section in

the CHAPTER 3. Locknut:

4 Nm (0.4 m•kg, 2.9

ft•lb)

Bolt (air filter joint):

2 Nm (0.2 m•kg, 1.4

ft•lb)

Bolt (carburetor joint):

2 Nm (0.2 m•kg, 1.4

ft•lb)

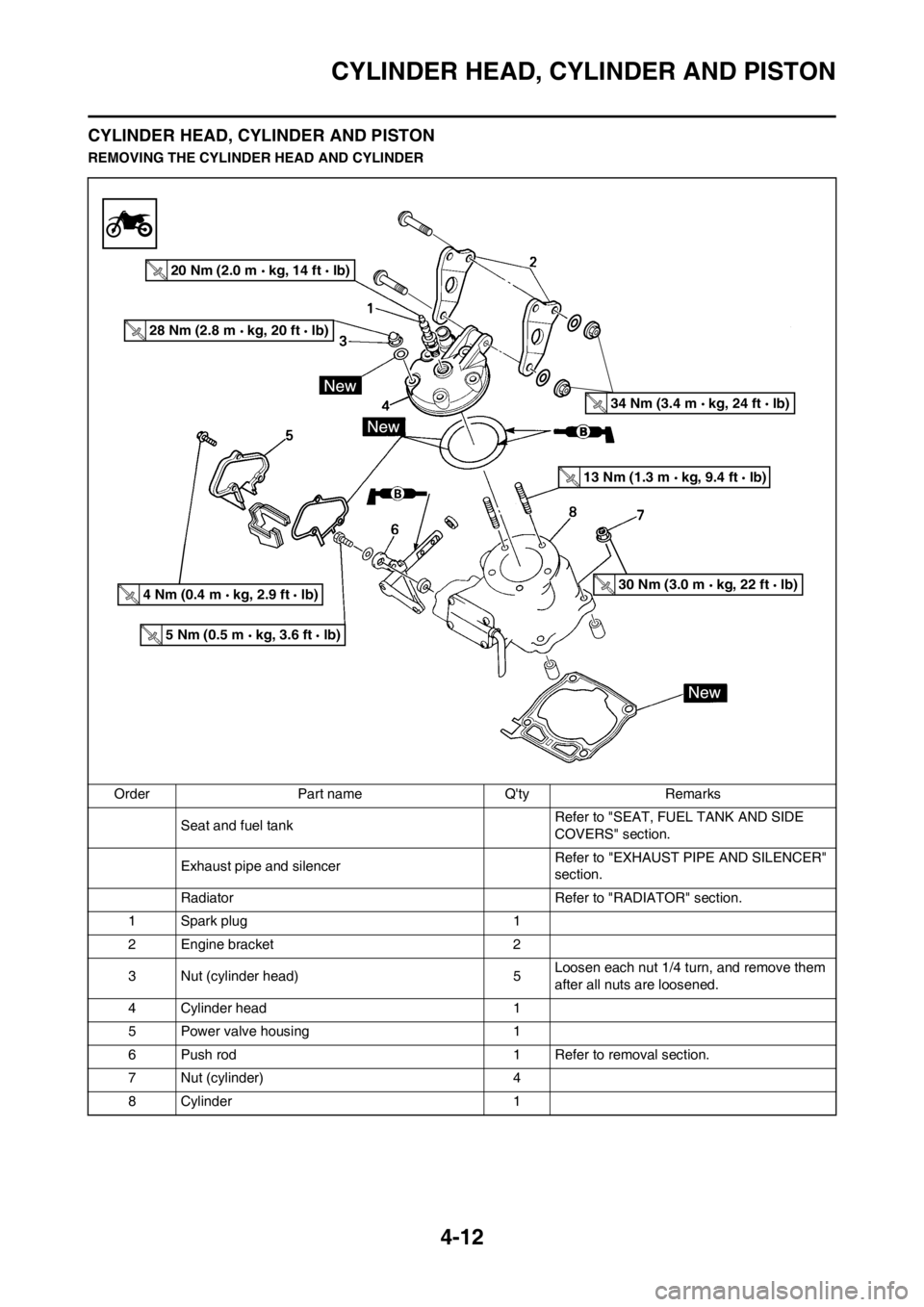

Page 74 of 168

4-12

CYLINDER HEAD, CYLINDER AND PISTON

CYLINDER HEAD, CYLINDER AND PISTON

REMOVING THE CYLINDER HEAD AND CYLINDER

Order Part name Q'ty Remarks

Seat and fuel tank Refer to "SEAT, FUEL TANK AND SIDE

COVERS" section.

Exhaust pipe and silencerRefer to "EXHAUST PIPE AND SILENCER"

section.

Radiator Refer to "RADIATOR" section.

1 Spark plug 1

2 Engine bracket 2

3 Nut (cylinder head) 5Loosen each nut 1/4 turn, and remove them

after all nuts are loosened.

4 Cylinder head 1

5 Power valve housing 1

6 Push rod 1 Refer to removal section.

7 Nut (cylinder) 4

8 Cylinder 1

5 Nm (0.5 m kg, 3.6 ft lb)

4 Nm (0.4 m kg, 2.9 ft lb)

13 Nm (1.3 m kg, 9.4 ft lb)

28 Nm (2.8 m kg, 20 ft lb)

20 Nm (2.0 m kg, 14 ft lb)

30 Nm (3.0 m kg, 22 ft lb)

34 Nm (3.4 m kg, 24 ft lb)

Page 75 of 168

4-13

CYLINDER HEAD, CYLINDER AND PISTON

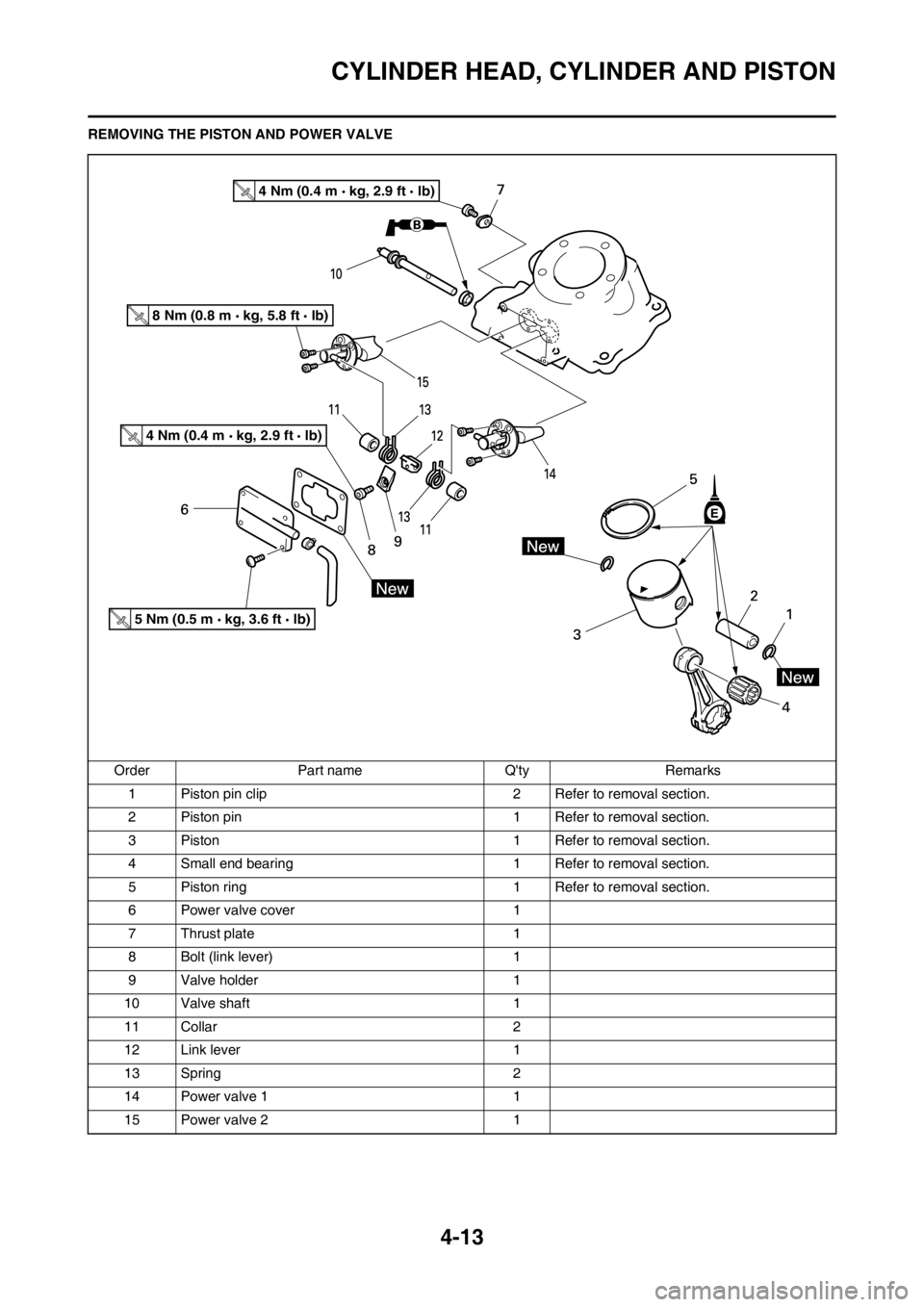

REMOVING THE PISTON AND POWER VALVE

Order Part name Q'ty Remarks

1 Piston pin clip 2 Refer to removal section.

2 Piston pin 1 Refer to removal section.

3 Piston 1 Refer to removal section.

4 Small end bearing 1 Refer to removal section.

5 Piston ring 1 Refer to removal section.

6 Power valve cover 1

7 Thrust plate 1

8 Bolt (link lever) 1

9 Valve holder 1

10 Valve shaft 1

11 Collar 2

12 Link lever 1

13 Spring 2

14 Power valve 1 1

15 Power valve 2 1

4 Nm (0.4 m kg, 2.9 ft lb)

4 Nm (0.4 m kg, 2.9 ft lb)

8 Nm (0.8 m kg, 5.8 ft lb)

5 Nm (0.5 m kg, 3.6 ft lb)

Page 76 of 168

4-14

CYLINDER HEAD, CYLINDER AND PISTON

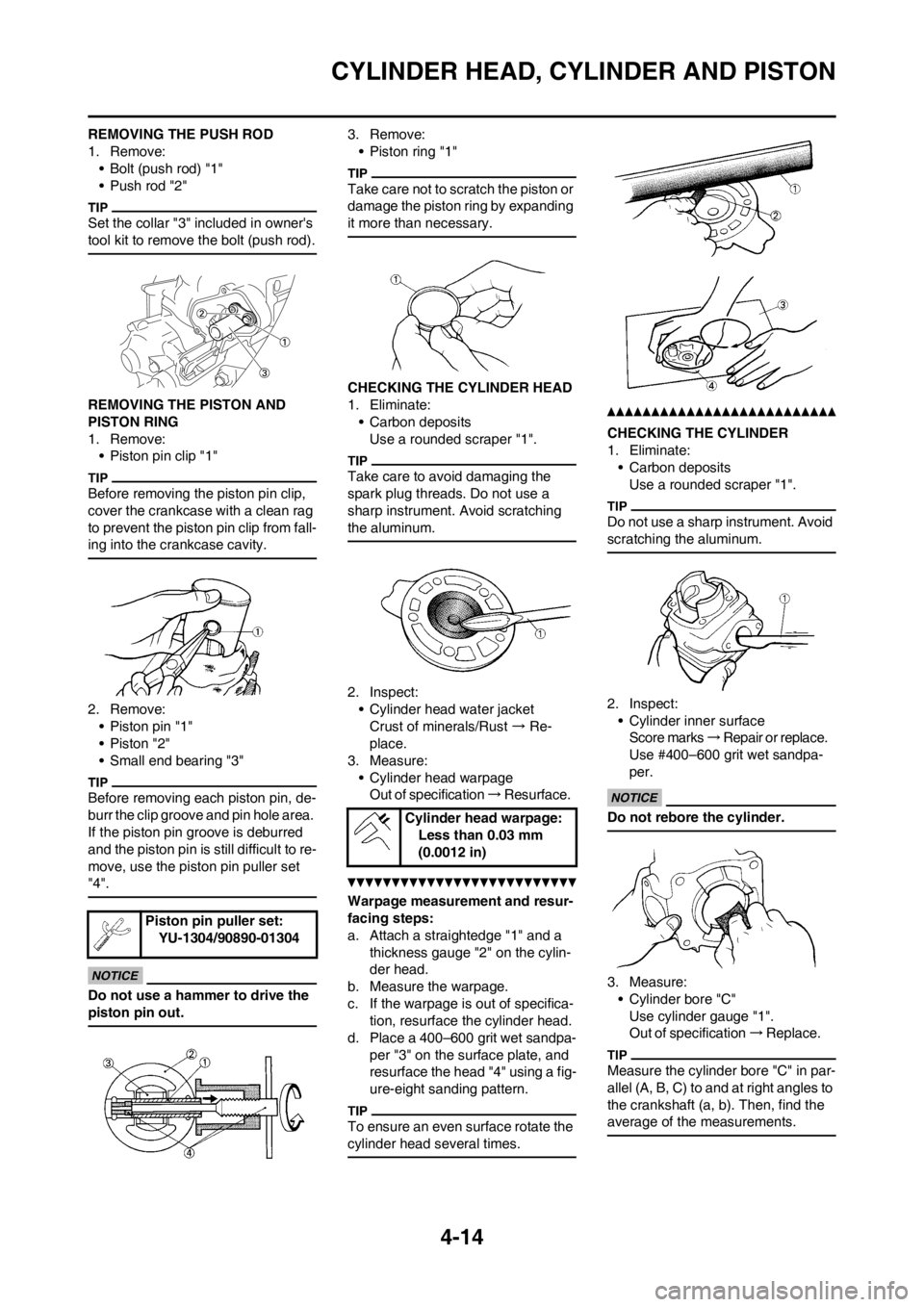

REMOVING THE PUSH ROD

1. Remove:

• Bolt (push rod) "1"

• Push rod "2"

Set the collar "3" included in owner's

tool kit to remove the bolt (push rod).

REMOVING THE PISTON AND

PISTON RING

1. Remove:

• Piston pin clip "1"

Before removing the piston pin clip,

cover the crankcase with a clean rag

to prevent the piston pin clip from fall-

ing into the crankcase cavity.

2. Remove:

• Piston pin "1"

• Piston "2"

• Small end bearing "3"

Before removing each piston pin, de-

burr the clip groove and pin hole area.

If the piston pin groove is deburred

and the piston pin is still difficult to re-

move, use the piston pin puller set

"4".

Do not use a hammer to drive the

piston pin out.

3. Remove:

• Piston ring "1"

Take care not to scratch the piston or

damage the piston ring by expanding

it more than necessary.

CHECKING THE CYLINDER HEAD

1. Eliminate:

• Carbon deposits

Use a rounded scraper "1".

Take care to avoid damaging the

spark plug threads. Do not use a

sharp instrument. Avoid scratching

the aluminum.

2. Inspect:

• Cylinder head water jacket

Crust of minerals/Rust → Re-

place.

3. Measure:

• Cylinder head warpage

Out of specification → Resurface.

Warpage measurement and resur-

facing steps:

a. Attach a straightedge "1" and a

thickness gauge "2" on the cylin-

der head.

b. Measure the warpage.

c. If the warpage is out of specifica-

tion, resurface the cylinder head.

d. Place a 400–600 grit wet sandpa-

per "3" on the surface plate, and

resurface the head "4" using a fig-

ure-eight sanding pattern.

To ensure an even surface rotate the

cylinder head several times.

CHECKING THE CYLINDER

1. Eliminate:

• Carbon deposits

Use a rounded scraper "1".

Do not use a sharp instrument. Avoid

scratching the aluminum.

2. Inspect:

• Cylinder inner surface

Score marks → Repair or replace.

Use #400–600 grit wet sandpa-

per.

Do not rebore the cylinder.

3. Measure:

• Cylinder bore "C"

Use cylinder gauge "1".

Out of specification → R e p l a c e .

Measure the cylinder bore "C" in par-

allel (A, B, C) to and at right angles to

the crankshaft (a, b). Then, find the

average of the measurements.

Piston pin puller set:

YU-1304/90890-01304

Cylinder head warpage:

Less than 0.03 mm

(0.0012 in)

Page 77 of 168

4-15

CYLINDER HEAD, CYLINDER AND PISTON

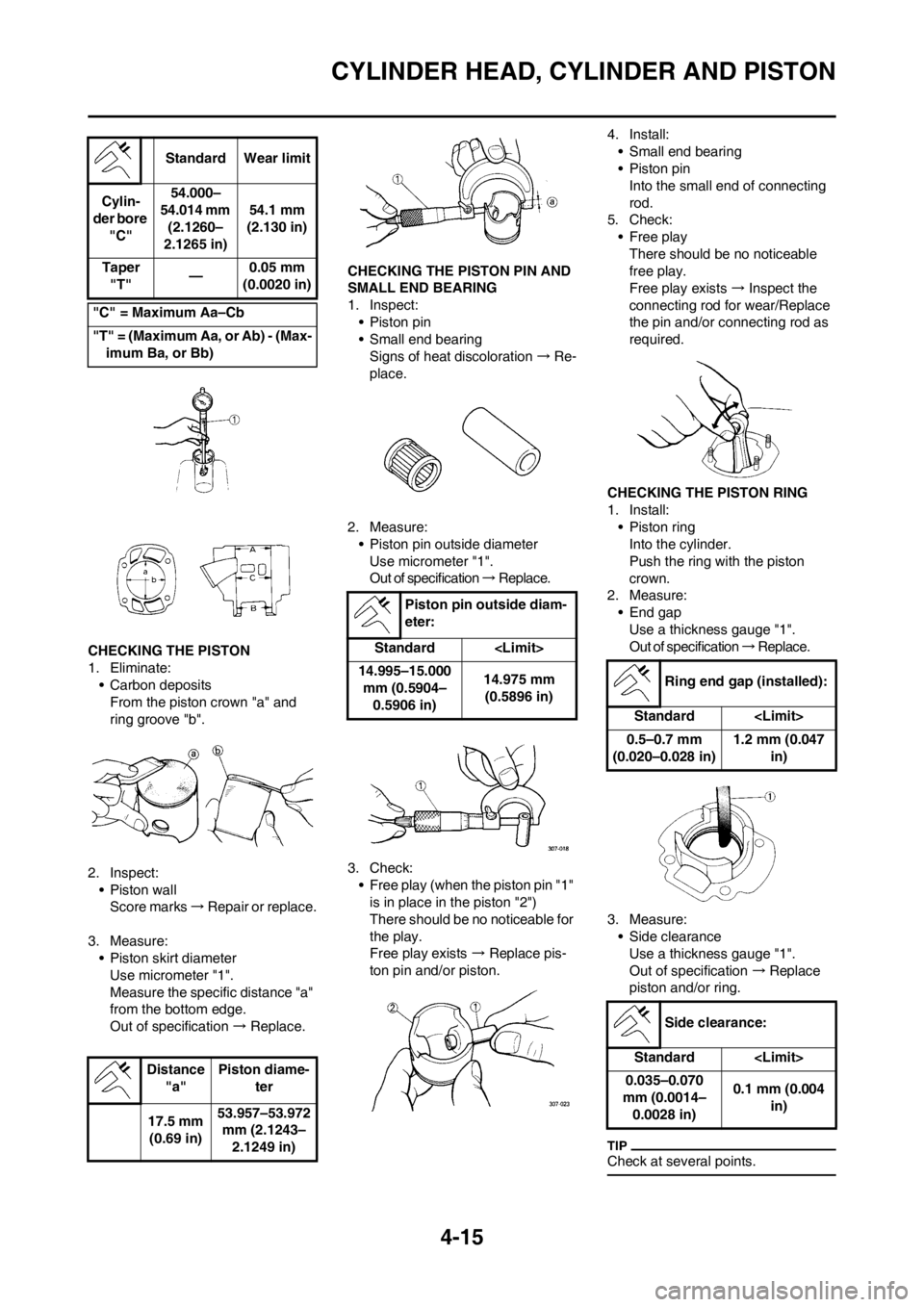

CHECKING THE PISTON

1. Eliminate:

• Carbon deposits

From the piston crown "a" and

ring groove "b".

2. Inspect:

• Piston wall

Score marks → Repair or replace.

3. Measure:

• Piston skirt diameter

Use micrometer "1".

Measure the specific distance "a"

from the bottom edge.

Out of specification → Replace.

CHECKING THE PISTON PIN AND

SMALL END BEARING

1. Inspect:

• Piston pin

• Small end bearing

Signs of heat discoloration → Re-

place.

2. Measure:

• Piston pin outside diameter

Use micrometer "1".

Out of specification → R e p l a c e .

3. Check:

• Free play (when the piston pin "1"

is in place in the piston "2")

There should be no noticeable for

the play.

Free play exists → Replace pis-

ton pin and/or piston. 4. Install:

• Small end bearing

• Piston pin

Into the small end of connecting

rod.

5. Check:

• Free play

There should be no noticeable

free play.

Free play exists → Inspect the

connecting rod for wear/Replace

the pin and/or connecting rod as

required.

CHECKING THE PISTON RING

1. Install:

• Piston ring

Into the cylinder.

Push the ring with the piston

crown.

2. Measure:

• End gap

Use a thickness gauge "1".

Out of specification → R e p l a c e .

3. Measure:

• Side clearance

Use a thickness gauge "1".

Out of specification →Replace

piston and/or ring.

Check at several points.

Standard Wear limit

Cylin-

der bore

"C"54.000–

54.014 mm

(2.1260–

2.1265 in)54.1 mm

(2.130 in)

Taper

"T"—0.05 mm

(0.0020 in)

"C" = Maximum Aa–Cb

"T" = (Maximum Aa, or Ab) - (Max-

imum Ba, or Bb)

Distance

"a"Piston diame-

ter

17.5 mm

(0.69 in)53.957–53.972

mm (2.1243–

2.1249 in)

Piston pin outside diam-

eter:

Standard

14.995–15.000

mm (0.5904–

0.5906 in)14.975 mm

(0.5896 in)

Ring end gap (installed):

Standard

0.5–0.7 mm

(0.020–0.028 in)1.2 mm (0.047

in)

Side clearance:

Standard

0.035–0.070

mm (0.0014–

0.0028 in)0.1 mm (0.004

in)

Page 78 of 168

4-16

CYLINDER HEAD, CYLINDER AND PISTON

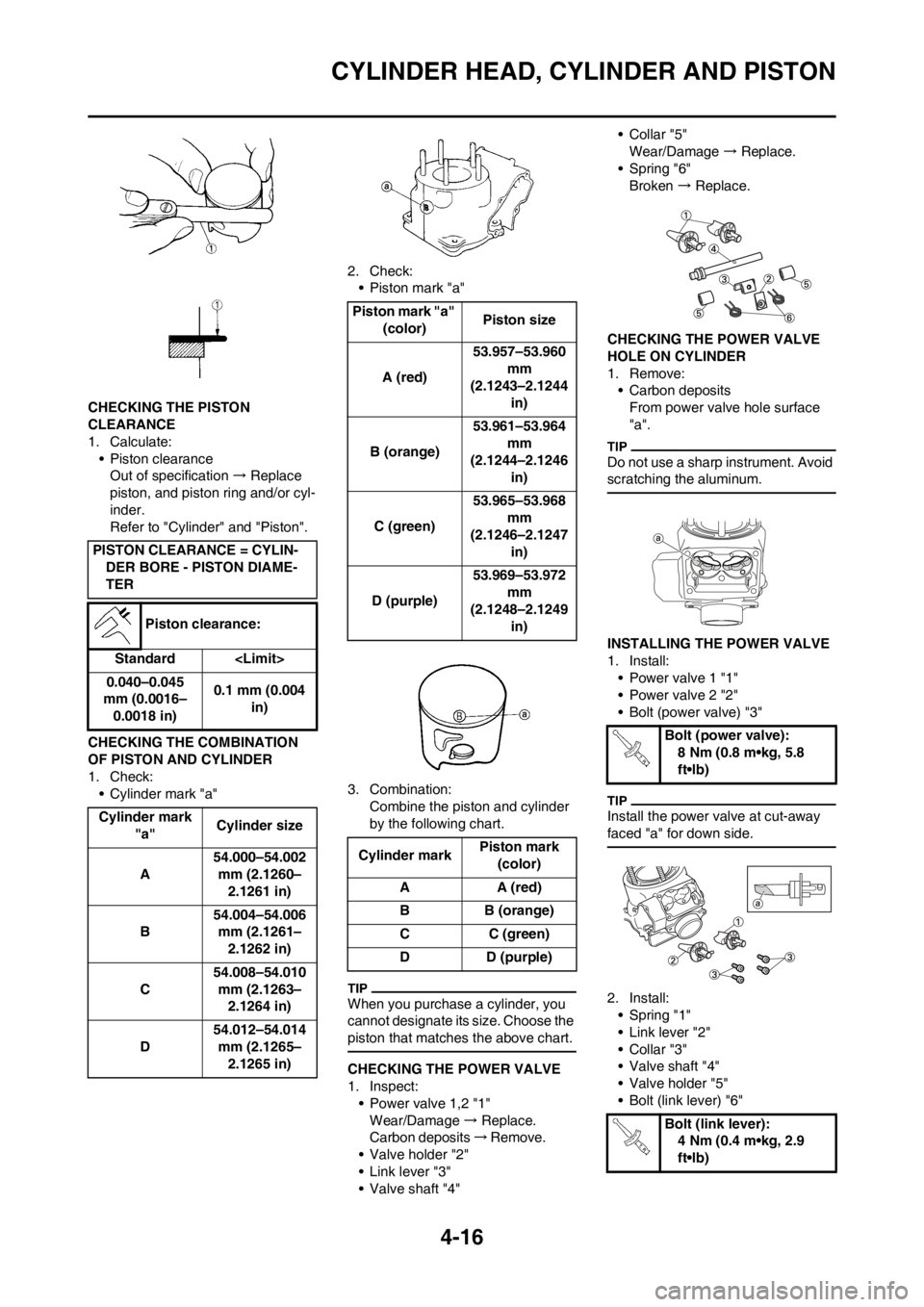

CHECKING THE PISTON

CLEARANCE

1. Calculate:

• Piston clearance

Out of specification → Replace

piston, and piston ring and/or cyl-

inder.

Refer to "Cylinder" and "Piston".

CHECKING THE COMBINATION

OF PISTON AND CYLINDER

1. Check:

• Cylinder mark "a"2. Check:

• Piston mark "a"

3. Combination:

Combine the piston and cylinder

by the following chart.

When you purchase a cylinder, you

cannot designate its size. Choose the

piston that matches the above chart.

CHECKING THE POWER VALVE

1. Inspect:

• Power valve 1,2 "1"

Wear/Damage → Replace.

Carbon deposits → R e m o v e .

• Valve holder "2"

• Link lever "3"

• Valve shaft "4"•Collar "5"

Wear/Damage → Replace.

• Spring "6"

Broken → Replace.

CHECKING THE POWER VALVE

HOLE ON CYLINDER

1. Remove:

• Carbon deposits

From power valve hole surface

"a".

Do not use a sharp instrument. Avoid

scratching the aluminum.

INSTALLING THE POWER VALVE

1. Install:

• Power valve 1 "1"

• Power valve 2 "2"

• Bolt (power valve) "3"

Install the power valve at cut-away

faced "a" for down side.

2. Install:

• Spring "1"

• Link lever "2"

•Collar "3"

• Valve shaft "4"

• Valve holder "5"

• Bolt (link lever) "6" PISTON CLEARANCE = CYLIN-

DER BORE - PISTON DIAME-

TER

Piston clearance:

Standard

0.040–0.045

mm (0.0016–

0.0018 in)0.1 mm (0.004

in)

Cylinder mark

"a"Cylinder size

A54.000–54.002

mm (2.1260–

2.1261 in)

B54.004–54.006

mm (2.1261–

2.1262 in)

C54.008–54.010

mm (2.1263–

2.1264 in)

D54.012–54.014

mm (2.1265–

2.1265 in)

Piston mark "a"

(color)Piston size

A (red)53.957–53.960

mm

(2.1243–2.1244

in)

B (orange)53.961–53.964

mm

(2.1244–2.1246

in)

C (green)53.965–53.968

mm

(2.1246–2.1247

in)

D (purple)53.969–53.972

mm

(2.1248–2.1249

in)

Cylinder markPiston mark

(color)

AA (red)

BB (orange)

CC (green)

D D (purple)

Bolt (power valve):

8 Nm (0.8 m•kg, 5.8

ft•lb)

Bolt (link lever):

4 Nm (0.4 m•kg, 2.9

ft•lb)

Page 79 of 168

4-17

CYLINDER HEAD, CYLINDER AND PISTON

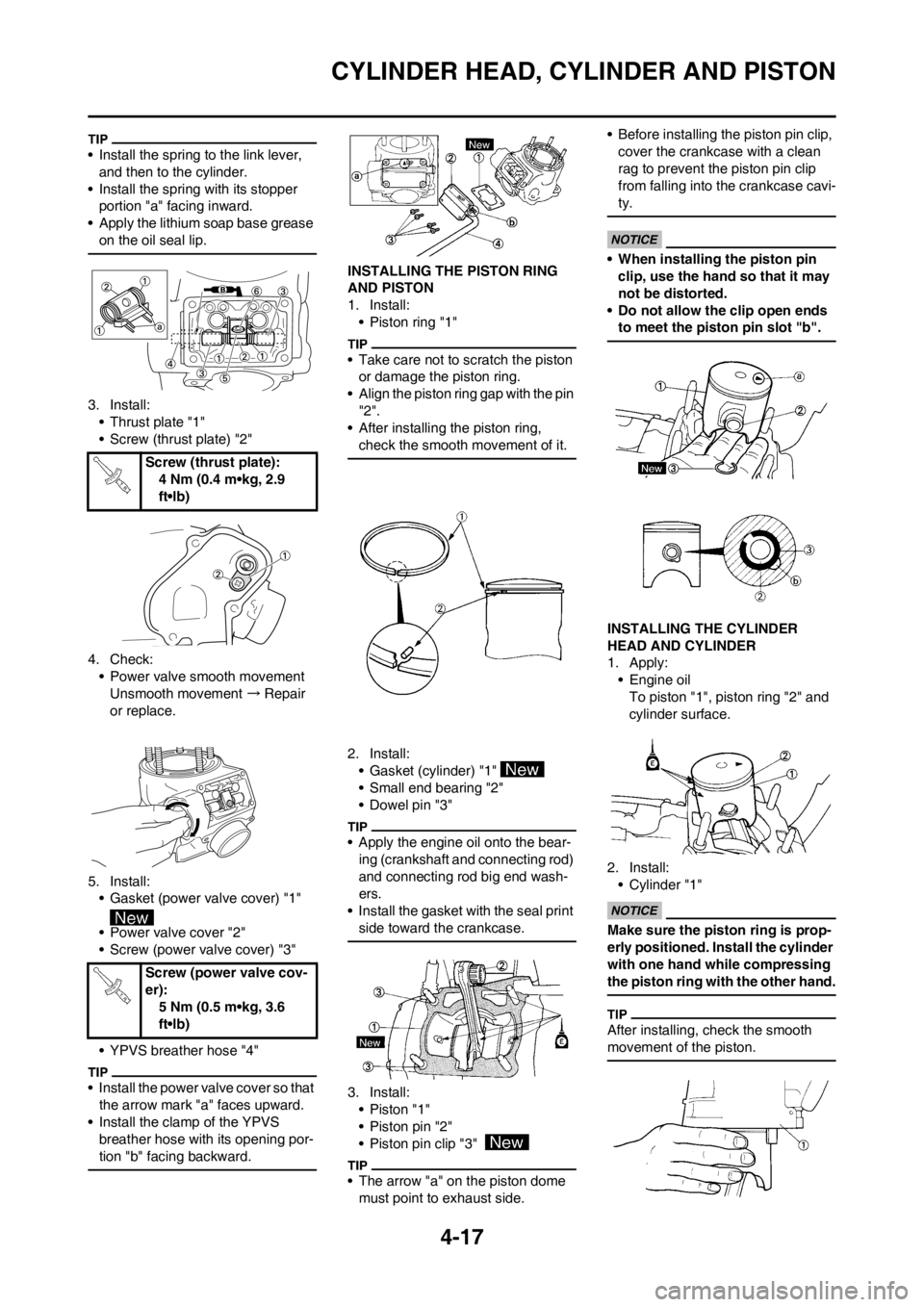

• Install the spring to the link lever,

and then to the cylinder.

• Install the spring with its stopper

portion "a" facing inward.

• Apply the lithium soap base grease

on the oil seal lip.

3. Install:

• Thrust plate "1"

• Screw (thrust plate) "2"

4. Check:

• Power valve smooth movement

Unsmooth movement → Repair

or replace.

5. Install:

• Gasket (power valve cover) "1"

• Power valve cover "2"

• Screw (power valve cover) "3"

• YPVS breather hose "4"

• Install the power valve cover so that

the arrow mark "a" faces upward.

• Install the clamp of the YPVS

breather hose with its opening por-

tion "b" facing backward.

INSTALLING THE PISTON RING

AND PISTON

1. Install:

• Piston ring "1"

• Take care not to scratch the piston

or damage the piston ring.

• Align the piston ring gap with the pin

"2".

• After installing the piston ring,

check the smooth movement of it.

2. Install:

• Gasket (cylinder) "1"

• Small end bearing "2"

• Dowel pin "3"

• Apply the engine oil onto the bear-

ing (crankshaft and connecting rod)

and connecting rod big end wash-

ers.

• Install the gasket with the seal print

side toward the crankcase.

3. Install:

•Piston "1"

• Piston pin "2"

• Piston pin clip "3"

• The arrow "a" on the piston dome

must point to exhaust side.• Before installing the piston pin clip,

cover the crankcase with a clean

rag to prevent the piston pin clip

from falling into the crankcase cavi-

ty.

• When installing the piston pin

clip, use the hand so that it may

not be distorted.

• Do not allow the clip open ends

to meet the piston pin slot "b".

INSTALLING THE CYLINDER

HEAD AND CYLINDER

1. Apply:

• Engine oil

To piston "1", piston ring "2" and

cylinder surface.

2. Install:

• Cylinder "1"

Make sure the piston ring is prop-

erly positioned. Install the cylinder

with one hand while compressing

the piston ring with the other hand.

After installing, check the smooth

movement of the piston.

Screw (thrust plate):

4 Nm (0.4 m•kg, 2.9

ft•lb)

Screw (power valve cov-

er):

5 Nm (0.5 m•kg, 3.6

ft•lb)

Page 80 of 168

4-18

CYLINDER HEAD, CYLINDER AND PISTON

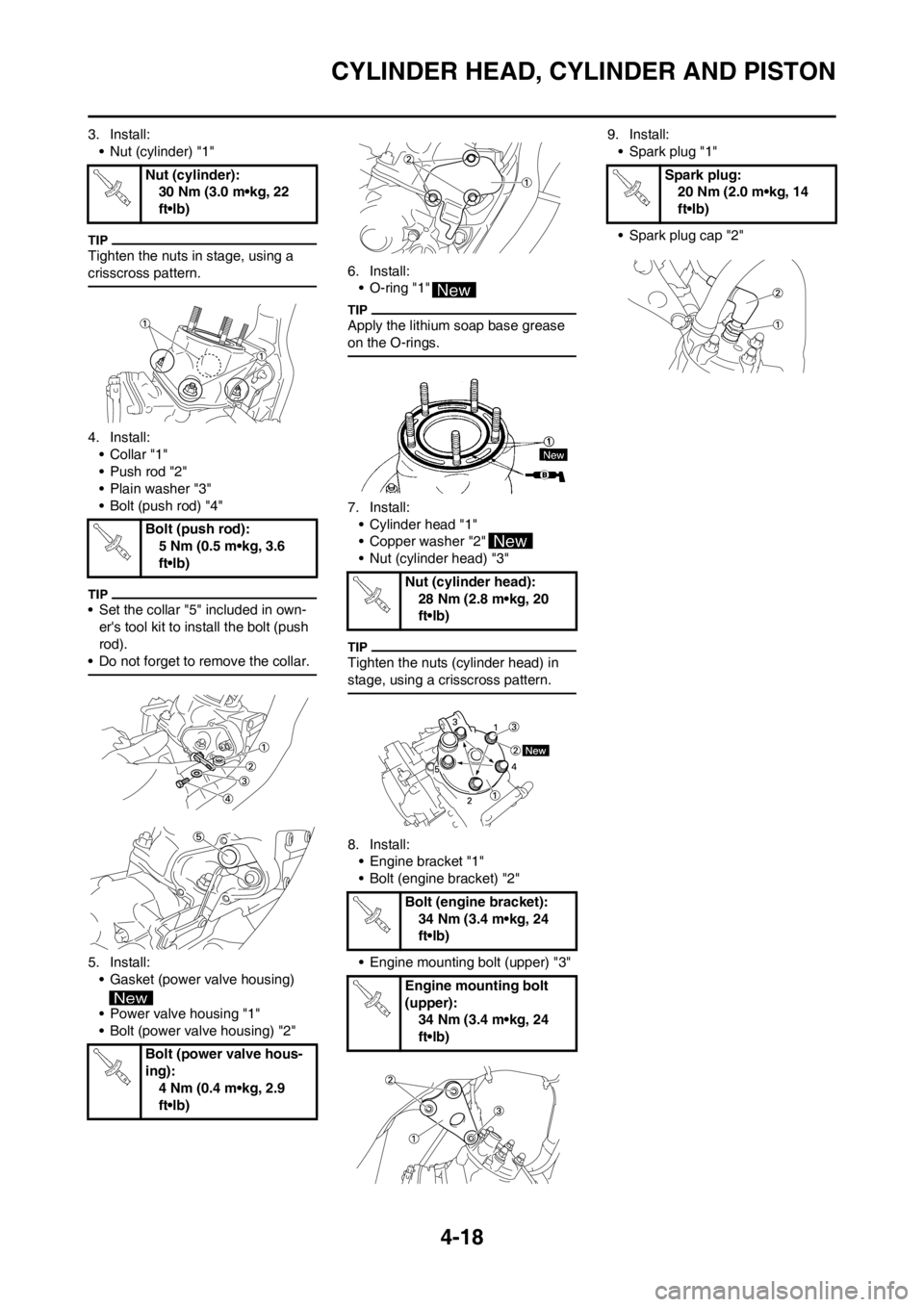

3. Install:

• Nut (cylinder) "1"

Tighten the nuts in stage, using a

crisscross pattern.

4. Install:

•Collar "1"

• Push rod "2"

• Plain washer "3"

• Bolt (push rod) "4"

• Set the collar "5" included in own-

er's tool kit to install the bolt (push

rod).

• Do not forget to remove the collar.

5. Install:

• Gasket (power valve housing)

• Power valve housing "1"

• Bolt (power valve housing) "2" 6. Install:

• O-ring "1"

Apply the lithium soap base grease

on the O-rings.

7. Install:

• Cylinder head "1"

• Copper washer "2"

• Nut (cylinder head) "3"

Tighten the nuts (cylinder head) in

stage, using a crisscross pattern.

8. Install:

• Engine bracket "1"

• Bolt (engine bracket) "2"

• Engine mounting bolt (upper) "3"9. Install:

• Spark plug "1"

• Spark plug cap "2" Nut (cylinder):

30 Nm (3.0 m•kg, 22

ft•lb)

Bolt (push rod):

5 Nm (0.5 m•kg, 3.6

ft•lb)

Bolt (power valve hous-

ing):

4 Nm (0.4 m•kg, 2.9

ft•lb)

Nut (cylinder head):

28 Nm (2.8 m•kg, 20

ft•lb)

Bolt (engine bracket):

34 Nm (3.4 m•kg, 24

ft•lb)

Engine mounting bolt

(upper):

34 Nm (3.4 m•kg, 24

ft•lb)

Spark plug:

20 Nm (2.0 m•kg, 14

ft•lb)