YAMAHA YZ250F 2008 Owners Manual

Manufacturer: YAMAHA, Model Year: 2008, Model line: YZ250F, Model: YAMAHA YZ250F 2008Pages: 192, PDF Size: 7.03 MB

Page 131 of 192

4-62

TRANSMISSION, SHIFT CAM AND SHIFT FORK

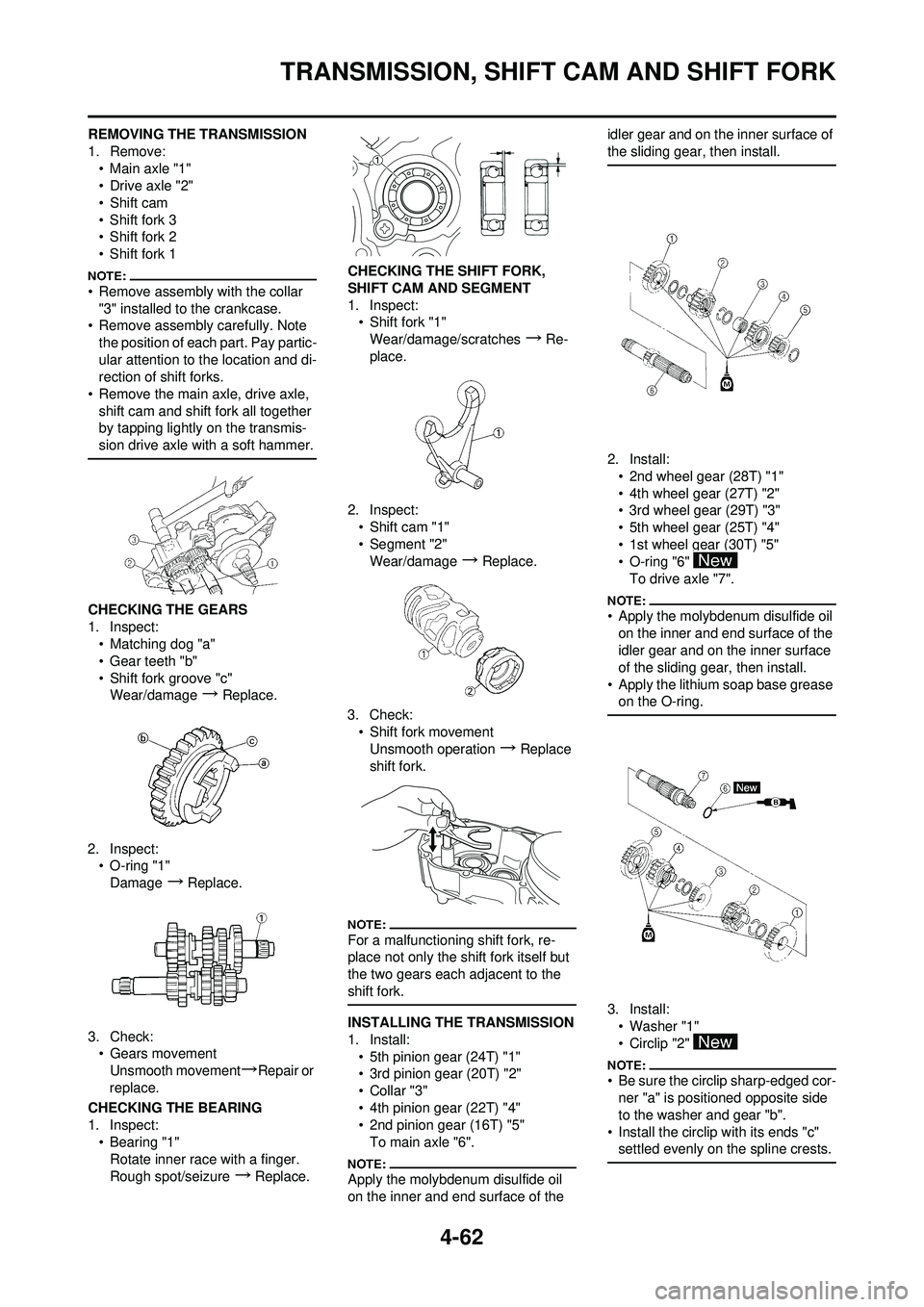

REMOVING THE TRANSMISSION

1. Remove:• Main axle "1"

•Drive axle "2"

•Shift cam

• Shift fork 3

• Shift fork 2

• Shift fork 1

• Remove assembly with the collar "3" installed to the crankcase.

• Remove assembly carefully. Note

the position of each part. Pay partic-

ular attention to the location and di-

rection of shift forks.

• Remove the main axle, drive axle, shift cam and shift fork all together

by tapping lightly on the transmis-

sion drive axle with a soft hammer.

CHECKING THE GEARS

1. Inspect:• Matching dog "a"

• Gear teeth "b"

• Shift fork groove "c"Wear/damage

→Replace.

2. Inspect: • O-ring "1"

Damage

→Replace.

3. Check: • Gears movement

Unsmooth movement

→Repair or

replace.

CHECKING THE BEARING

1. Inspect: • Bearing "1"

Rotate inner race with a finger.

Rough spot/seizure

→Replace. CHECKING THE SHIFT FORK,

SHIFT CAM AND SEGMENT

1. Inspect:

• Shift fork "1"

Wear/damage/scratches

→Re-

place.

2. Inspect: • Shift cam "1"

• Segment "2"Wear/damage

→Replace.

3. Check: • Shift fork movement

Unsmooth operation

→Replace

shift fork.

For a malfunctioning shift fork, re-

place not only the shift fork itself but

the two gears each adjacent to the

shift fork.

INSTALLING THE TRANSMISSION

1. Install: • 5th pinion gear (24T) "1"

• 3rd pinion gear (20T) "2"

•Collar "3"

• 4th pinion gear (22T) "4"

• 2nd pinion gear (16T) "5"To main axle "6".

Apply the molybdenum disulfide oil

on the inner and end surface of the idler gear and on the inner surface of

the sliding gear, then install.

2. Install:

• 2nd wheel gear (28T) "1"

• 4th wheel gear (27T) "2"

• 3rd wheel gear (29T) "3"

• 5th wheel gear (25T) "4"

• 1st wheel gear (30T) "5"

• O-ring "6" To drive axle "7".

• Apply the molybdenum disulfide oil on the inner and end surface of the

idler gear and on the inner surface

of the sliding gear, then install.

• Apply the lithium soap base grease on the O-ring.

3. Install:

• Washer "1"

• Circlip "2"

• Be sure the circlip sharp-edged cor-ner "a" is positioned opposite side

to the washer and gear "b".

• Install the circlip with its ends "c" settled evenly on the spline crests.

Page 132 of 192

4-63

TRANSMISSION, SHIFT CAM AND SHIFT FORK

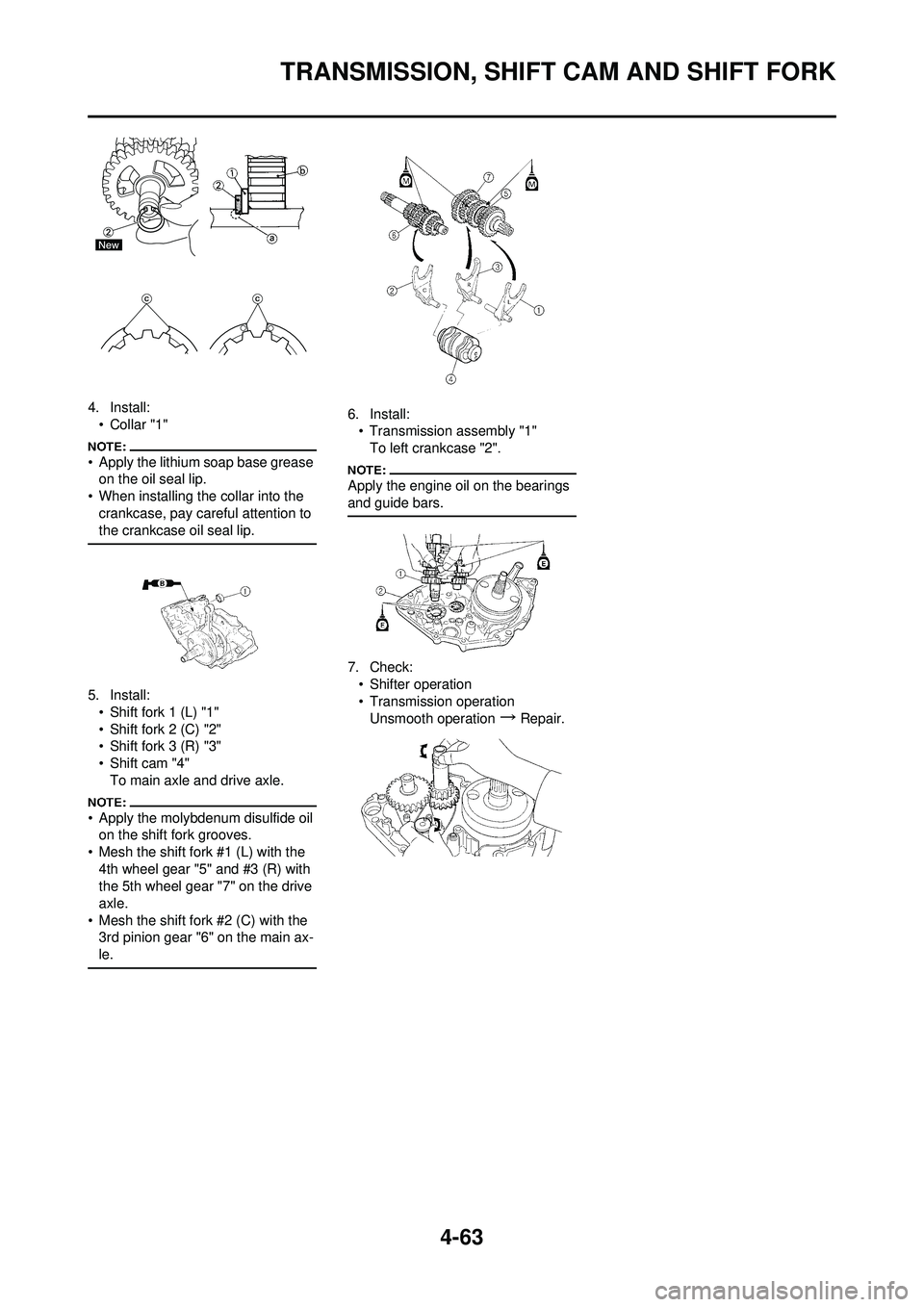

4. Install:•Collar "1"

• Apply the lithium soap base grease on the oil seal lip.

• When installing the collar into the crankcase, pay careful attention to

the crankcase oil seal lip.

5. Install:• Shift fork 1 (L) "1"

• Shift fork 2 (C) "2"

• Shift fork 3 (R) "3"

•Shift cam "4"To main axle and drive axle.

• Apply the molybdenum disulfide oil on the shift fork grooves.

• Mesh the shift fork #1 (L) with the 4th wheel gear "5" and #3 (R) with

the 5th wheel gear "7" on the drive

axle.

• Mesh the shift fork #2 (C) with the 3rd pinion gear "6" on the main ax-

le.

6. Install:• Transmission assembly "1"

To left crankcase "2".

Apply the engine oil on the bearings

and guide bars.

7. Check:• Shifter operation

• Transmission operationUnsmooth operation

→Repair.

Page 133 of 192

5-1

FRONT WHEEL AND REAR WHEEL

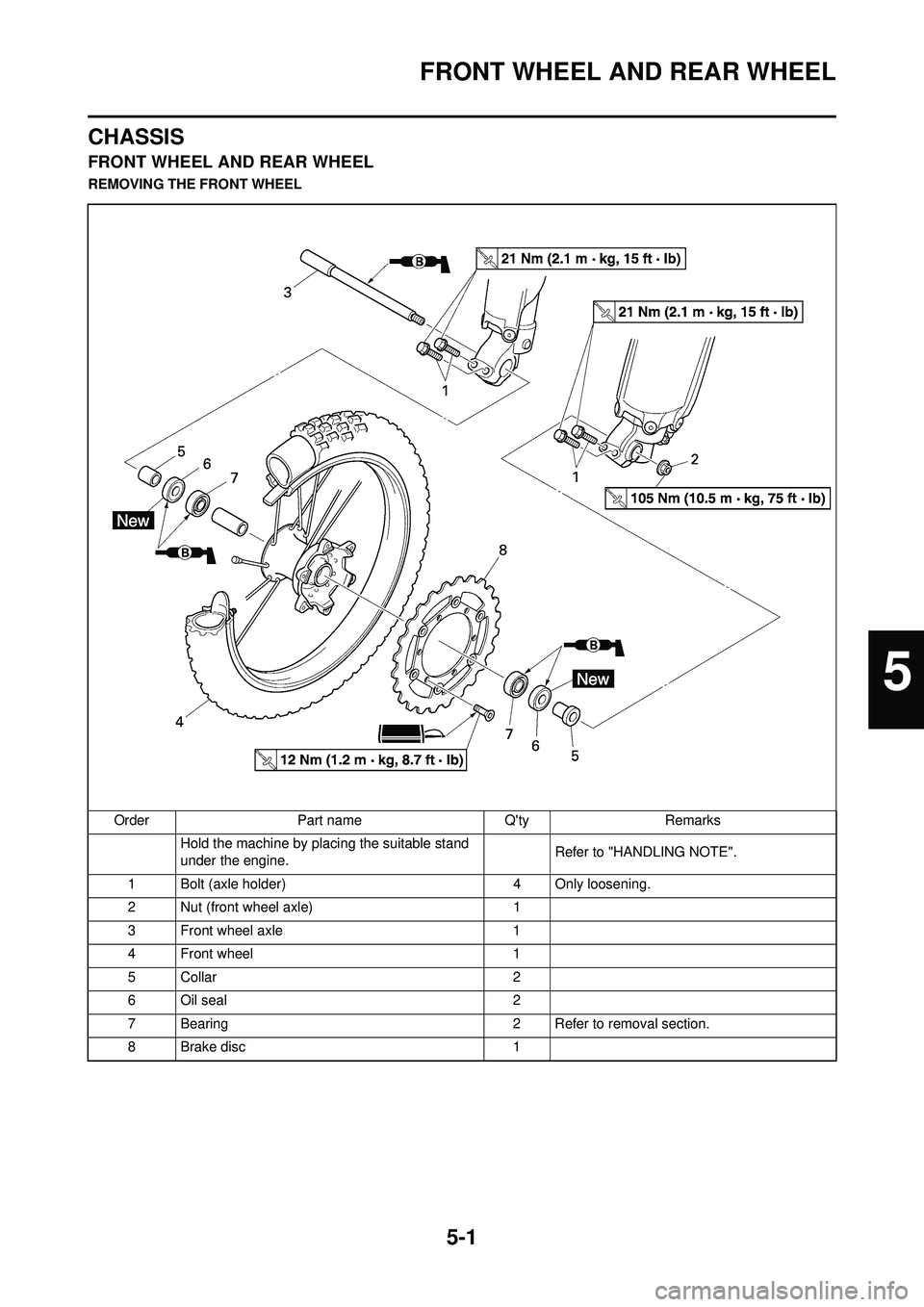

CHASSIS

FRONT WHEEL AND REAR WHEEL

REMOVING THE FRONT WHEELOrder Part name Q'ty Remarks Hold the machine by placing the suitable stand

under the engine. Refer to "HANDLING NOTE".

1 Bolt (axle holder) 4 Only loosening.

2 Nut (front wheel axle) 1

3 Front wheel axle 1

4 Front wheel 1

5Collar 2

6 Oil seal 2

7 Bearing 2 Refer to removal section.

8Brake disc 1

5

Page 134 of 192

5-2

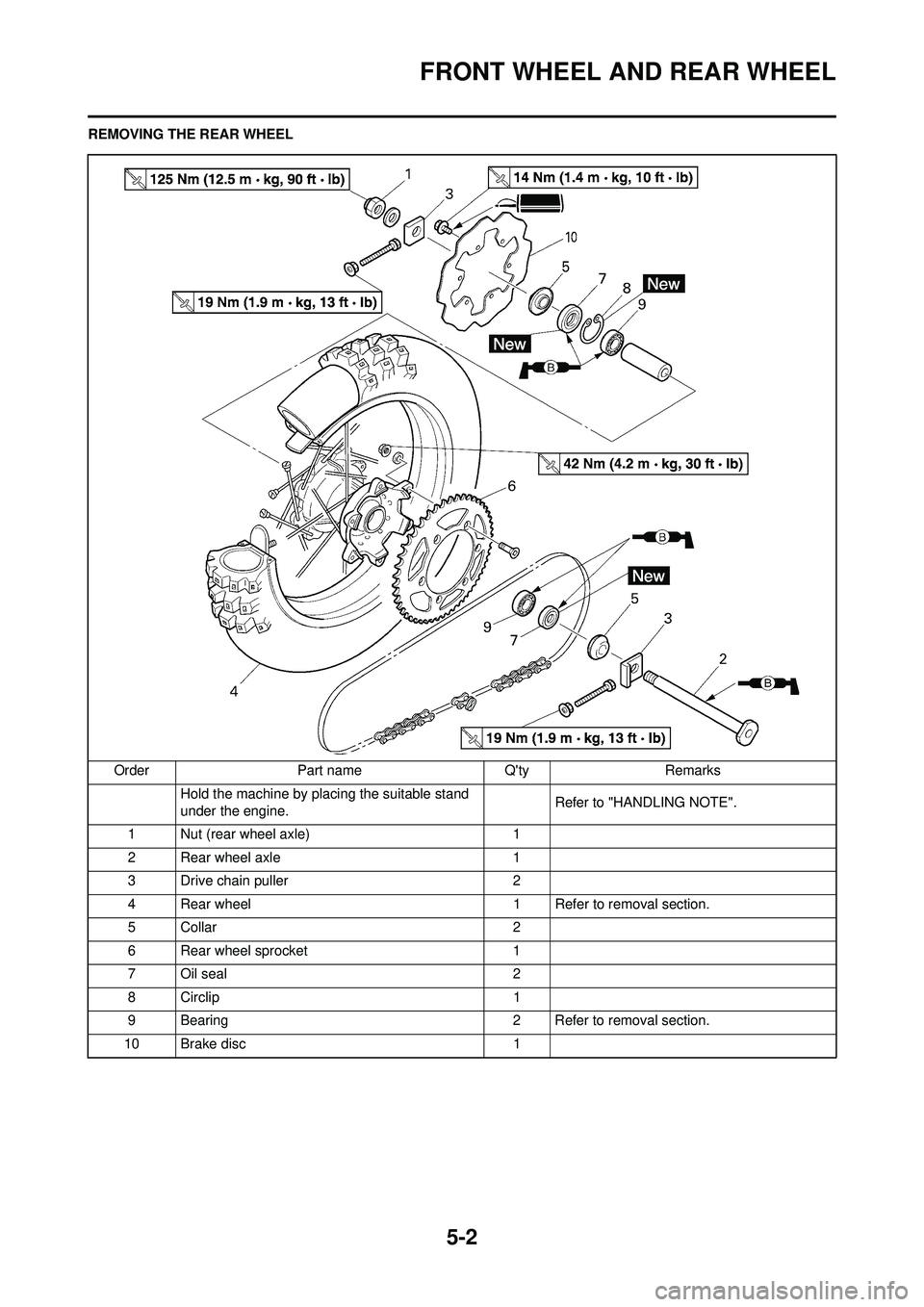

FRONT WHEEL AND REAR WHEEL

REMOVING THE REAR WHEELOrder Part name Q'ty Remarks Hold the machine by placing the suitable stand

under the engine. Refer to "HANDLING NOTE".

1 Nut (rear wheel axle) 1

2 Rear wheel axle 1

3 Drive chain puller 2

4 Rear wheel 1 Refer to removal section.

5Collar 2

6 Rear wheel sprocket 1

7 Oil seal 2

8 Circlip 1

9 Bearing 2 Refer to removal section.

10 Brake disc 1

Page 135 of 192

5-3

FRONT WHEEL AND REAR WHEEL

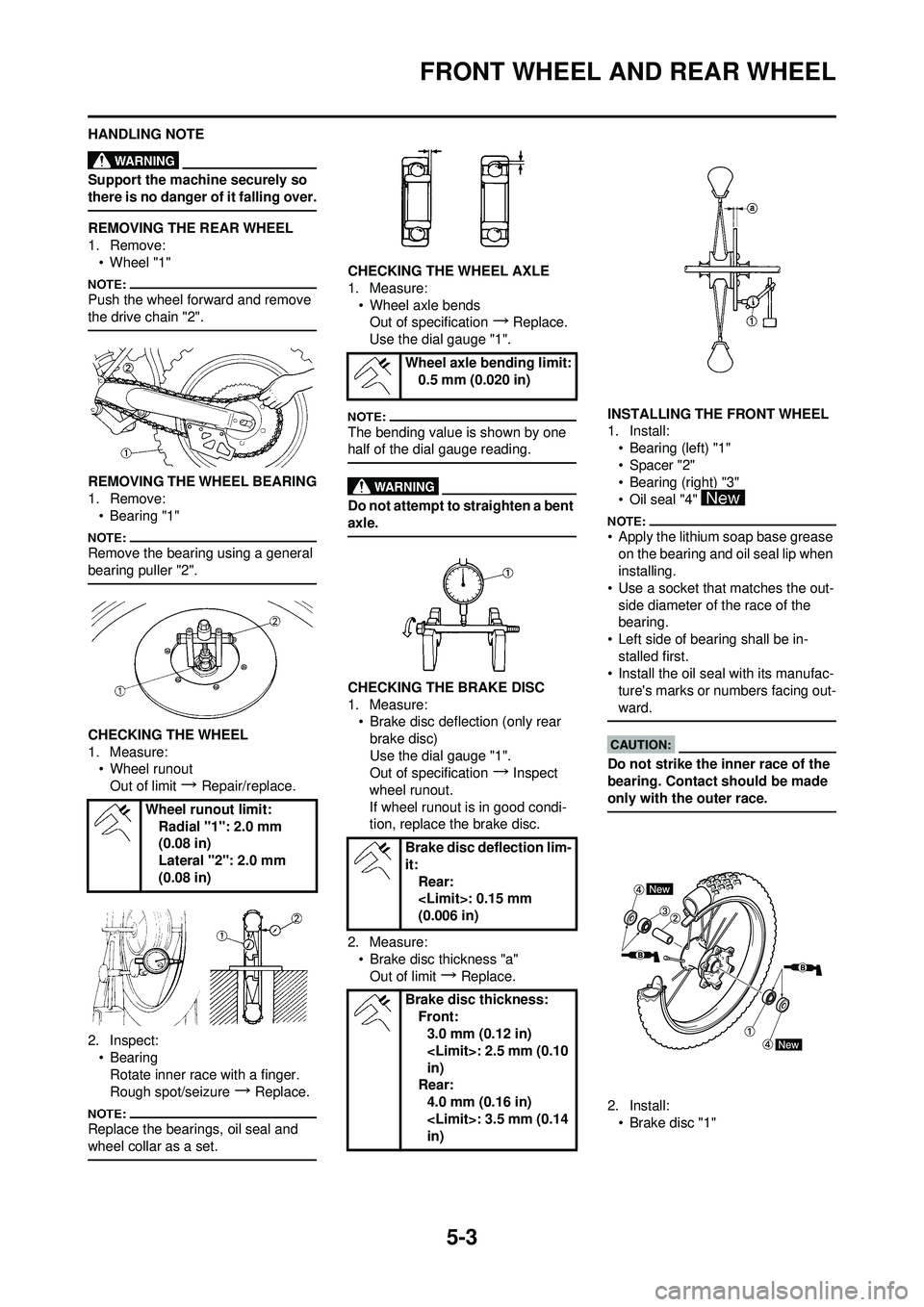

HANDLING NOTE

Support the machine securely so

there is no danger of it falling over.

REMOVING THE REAR WHEEL

1. Remove:• Wheel "1"

Push the wheel forward and remove

the drive chain "2".

REMOVING THE WHEEL BEARING

1. Remove:• Bearing "1"

Remove the bearing using a general

bearing puller "2".

CHECKING THE WHEEL

1. Measure:• Wheel runout

Out of limit

→ Repair/replace.

2. Inspect: • BearingRotate inner race with a finger.

Rough spot/seizure

→ Replace.

Replace the bearings, oil seal and

wheel collar as a set.

CHECKING THE WHEEL AXLE

1. Measure:• Wheel axle bendsOut of specification

→ Replace.

Use the dial gauge "1".

The bending value is shown by one

half of the dial gauge reading.

Do not attempt to straighten a bent

axle.

CHECKING THE BRAKE DISC

1. Measure: • Brake disc deflection (only rear

brake disc)

Use the dial gauge "1".

Out of specification

→ Inspect

wheel runout.

If wheel runout is in good condi-

tion, replace the brake disc.

2. Measure: • Brake disc thickness "a"

Out of limit

→ Replace. INSTALLING THE FRONT WHEEL

1. Install:

• Bearing (left) "1"

•Spacer "2"

• Bearing (right) "3"

•Oil seal "4"

• Apply the lithium soap base grease on the bearing and oil seal lip when

installing.

• Use a socket that matches the out- side diameter of the race of the

bearing.

• Left side of bearing shall be in- stalled first.

• Install the oil seal with its manufac-

ture's marks or numbers facing out-

ward.

Do not strike the inner race of the

bearing. Contact should be made

only with the outer race.

2. Install:• Brake disc "1"

Wheel runout limit:

Radial "1": 2.0 mm

(0.08 in)

Lateral "2": 2.0 mm

(0.08 in)

Wheel axle bending limit:0.5 mm (0.020 in)

Brake disc deflection lim-

it: Rear:

(0.006 in)

Brake disc thickness: Front:3.0 mm (0.12 in)

in)

Rear:

4.0 mm (0.16 in)

in)

Page 136 of 192

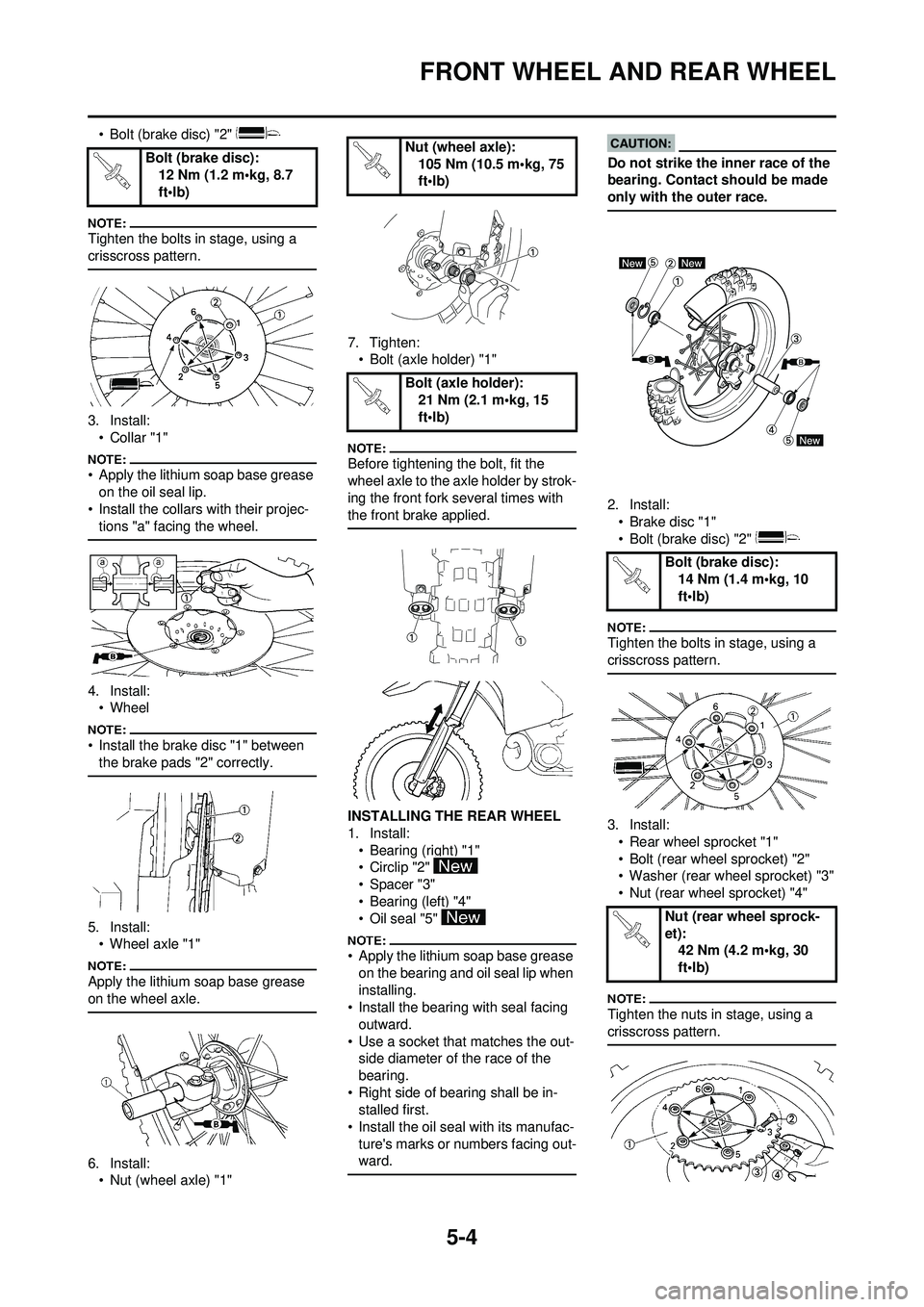

5-4

FRONT WHEEL AND REAR WHEEL

• Bolt (brake disc) "2"

Tighten the bolts in stage, using a

crisscross pattern.

3. Install:•Collar "1"

• Apply the lithium soap base grease on the oil seal lip.

• Install the collars with their projec- tions "a" facing the wheel.

4. Install:• Wheel

• Install the brake disc "1" between

the brake pads "2" correctly.

5. Install:• Wheel axle "1"

Apply the lithium soap base grease

on the wheel axle.

6. Install:• Nut (wheel axle) "1" 7. Tighten:

• Bolt (axle holder) "1"

Before tightening the bolt, fit the

wheel axle to the axle holder by strok-

ing the front fork several times with

the front brake applied.

INSTALLING THE REAR WHEEL

1. Install:

• Bearing (right) "1"

•Circlip "2"

•Spacer "3"

• Bearing (left) "4"

• Oil seal "5"

• Apply the lithium soap base grease on the bearing and oil seal lip when

installing.

• Install the bearing with seal facing

outward.

• Use a socket that matches the out- side diameter of the race of the

bearing.

• Right side of bearing shall be in- stalled first.

• Install the oil seal with its manufac- ture's marks or numbers facing out-

ward.

Do not strike the inner race of the

bearing. Contact should be made

only with the outer race.

2. Install:• Brake disc "1"

• Bolt (brake disc) "2"

Tighten the bolts in stage, using a

crisscross pattern.

3. Install:• Rear wheel sprocket "1"

• Bolt (rear wheel sprocket) "2"

• Washer (rear wheel sprocket) "3"

• Nut (rear wheel sprocket) "4"

Tighten the nuts in stage, using a

crisscross pattern.

Bolt (brake disc): 12 Nm (1.2 m•kg, 8.7

ft•lb)Nut (wheel axle):105 Nm (10.5 m•kg, 75

ft•lb)

Bolt (axle holder): 21 Nm (2.1 m•kg, 15

ft•lb)

Bolt (brake disc):14 Nm (1.4 m•kg, 10

ft•lb)

Nut (rear wheel sprock-

et): 42 Nm (4.2 m•kg, 30

ft•lb)

Page 137 of 192

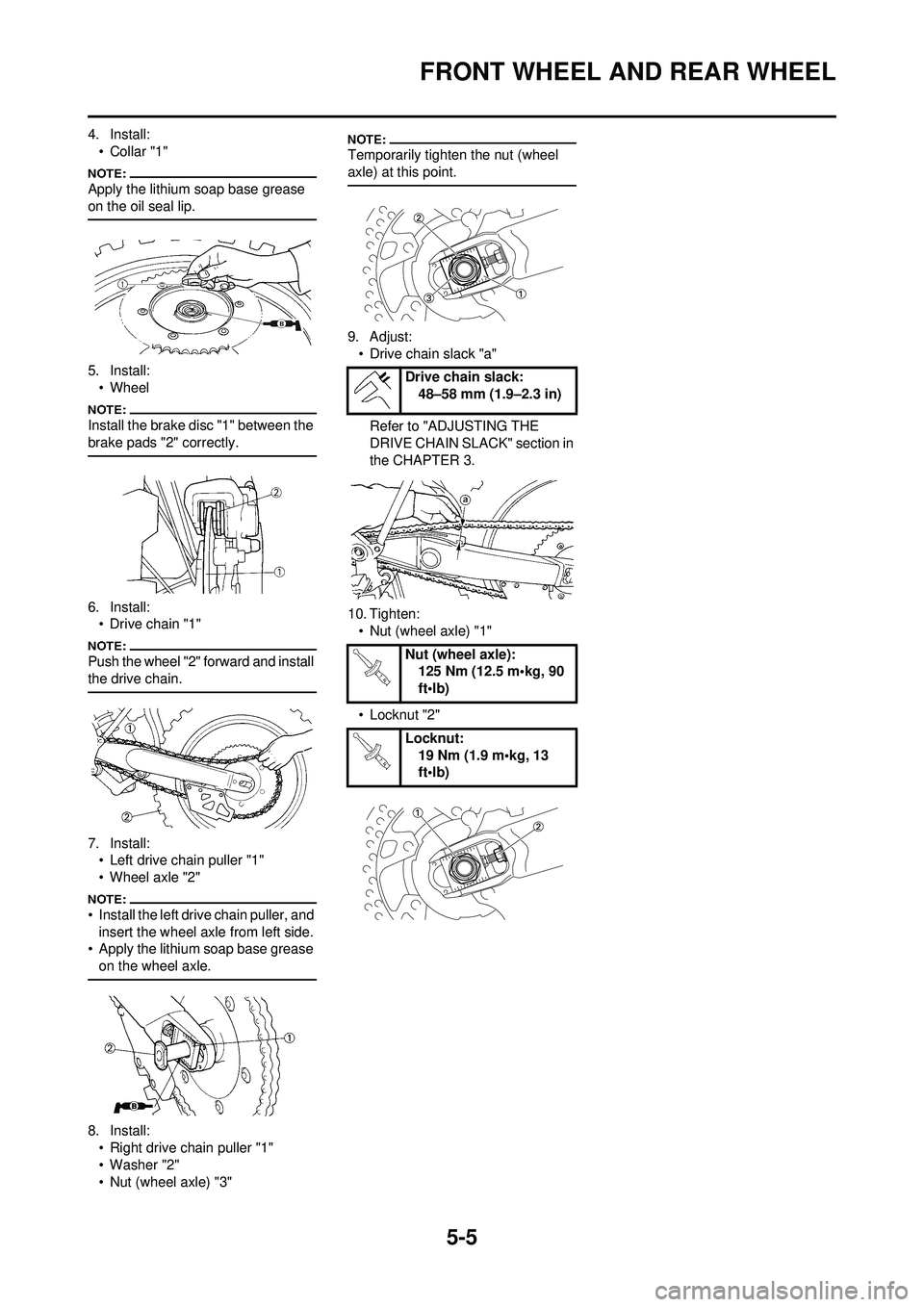

5-5

FRONT WHEEL AND REAR WHEEL

4. Install:•Collar "1"

Apply the lithium soap base grease

on the oil seal lip.

5. Install:• Wheel

Install the brake disc "1" between the

brake pads "2" correctly.

6. Install:• Drive chain "1"

Push the wheel "2" forward and install

the drive chain.

7. Install:• Left drive chain puller "1"

• Wheel axle "2"

• Install the left drive chain puller, and

insert the wheel axle from left side.

• Apply the lithium soap base grease

on the wheel axle.

8. Install:• Right drive chain puller "1"

• Washer "2"

• Nut (wheel axle) "3"

Temporarily tighten the nut (wheel

axle) at this point.

9. Adjust:

• Drive chain slack "a"

Refer to "ADJUSTING THE

DRIVE CHAIN SLACK" section in

the CHAPTER 3.

10. Tighten: • Nut (wheel axle) "1"

• Locknut "2"

Drive chain slack: 48–58 mm (1.9–2.3 in)

Nut (wheel axle): 125 Nm (12.5 m•kg, 90

ft•lb)

Locknut: 19 Nm (1.9 m•kg, 13

ft•lb)

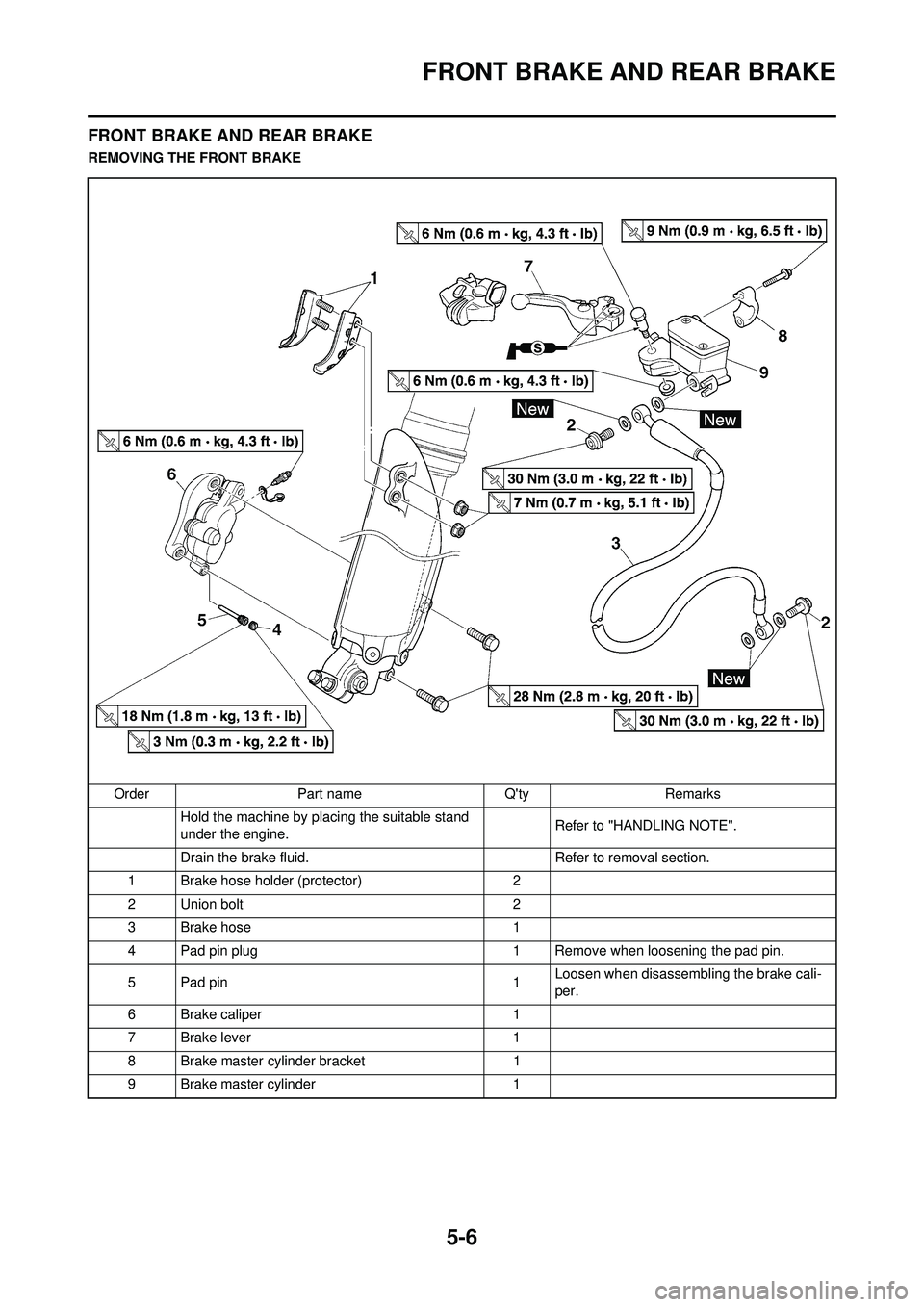

Page 138 of 192

5-6

FRONT BRAKE AND REAR BRAKE

FRONT BRAKE AND REAR BRAKE

REMOVING THE FRONT BRAKEOrder Part name Q'ty Remarks Hold the machine by placing the suitable stand

under the engine. Refer to "HANDLING NOTE".

Drain the brake fluid. Refer to removal section.

1 Brake hose holder (protector) 2

2 Union bolt 2

3Brake hose 1

4 Pad pin plug 1 Remove when loosening the pad pin.

5 Pad pin 1Loosen when disassembling the brake cali-

per.

6 Brake caliper 1

7Brake lever 1

8 Brake master cylinder bracket 1

9 Brake master cylinder 1

Page 139 of 192

5-7

FRONT BRAKE AND REAR BRAKE

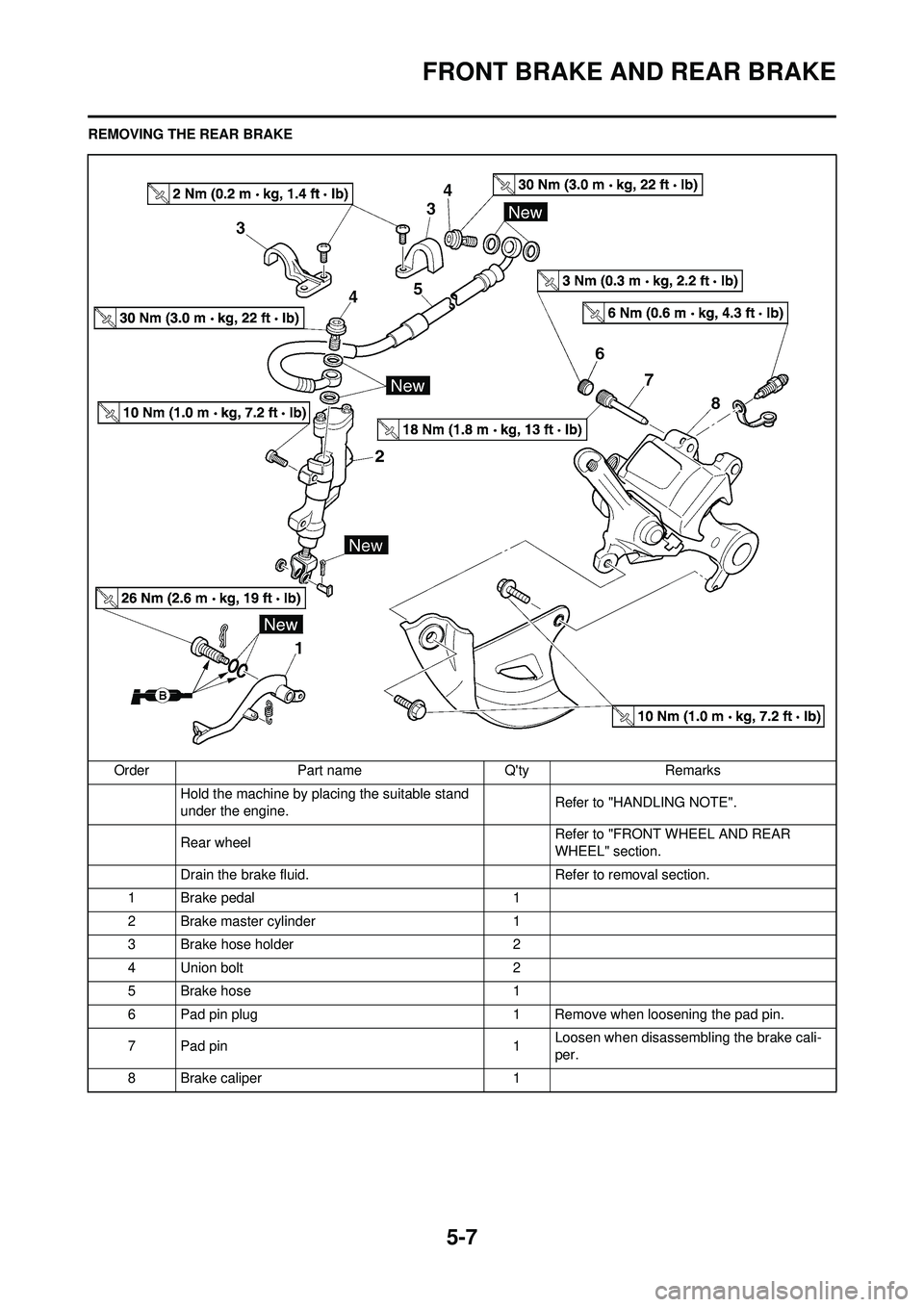

REMOVING THE REAR BRAKEOrder Part name Q'ty Remarks Hold the machine by placing the suitable stand

under the engine. Refer to "HANDLING NOTE".

Rear wheel Refer to "FRONT WHEEL AND REAR

WHEEL" section.

Drain the brake fluid. Refer to removal section.

1 Brake pedal 1

2 Brake master cylinder 1

3 Brake hose holder 2

4 Union bolt 2

5Brake hose 1

6 Pad pin plug 1 Remove when loosening the pad pin.

7 Pad pin 1Loosen when disassembling the brake cali-

per.

8 Brake caliper 1

Page 140 of 192

5-8

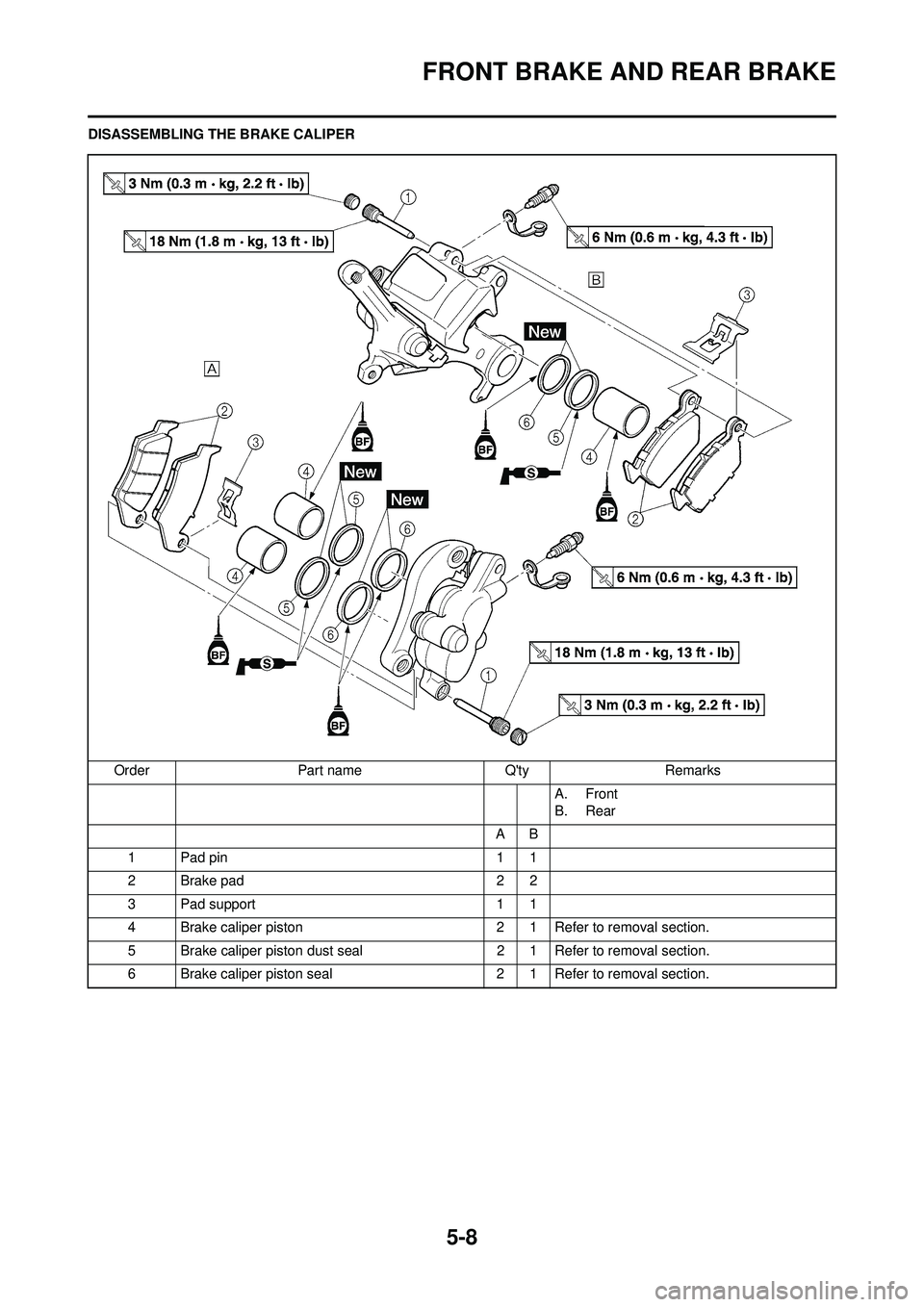

FRONT BRAKE AND REAR BRAKE

DISASSEMBLING THE BRAKE CALIPEROrder Part name Q'ty Remarks A. Front

B. Rear

AB

1 Pad pin 1 1

2Brake pad 22

3 Pad support 1 1

4 Brake caliper piston 2 1 Refer to removal section.

5 Brake caliper piston dust seal 2 1 Refer to removal section.

6 Brake caliper piston seal 2 1 Refer to removal section.