YAMAHA YZ250F 2008 Owners Manual

Manufacturer: YAMAHA, Model Year: 2008, Model line: YZ250F, Model: YAMAHA YZ250F 2008Pages: 192, PDF Size: 7.03 MB

Page 161 of 192

5-29

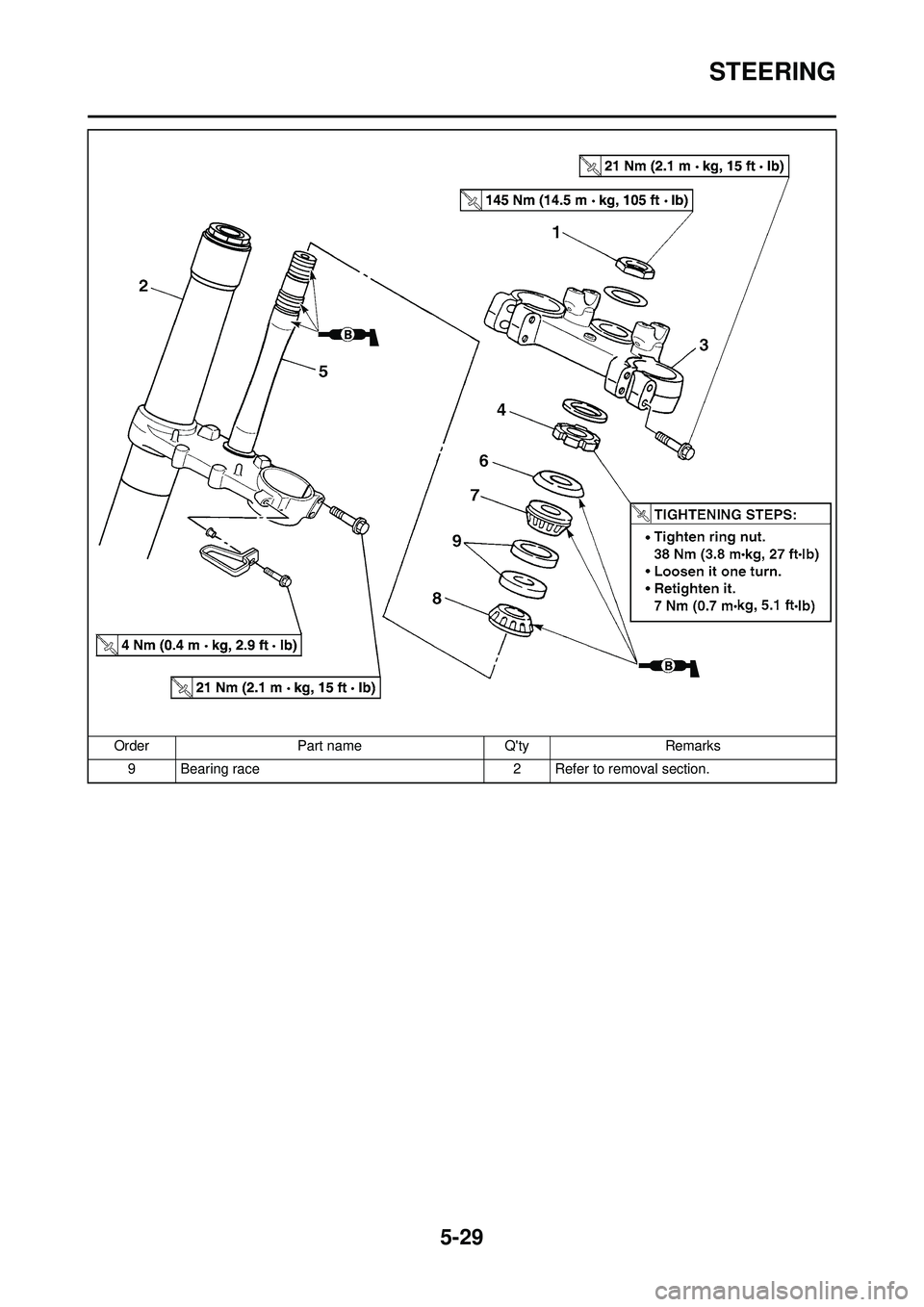

STEERING

9 Bearing race2 Refer to removal section.

Order

Part name Q'tyRemarks

Page 162 of 192

5-30

STEERING

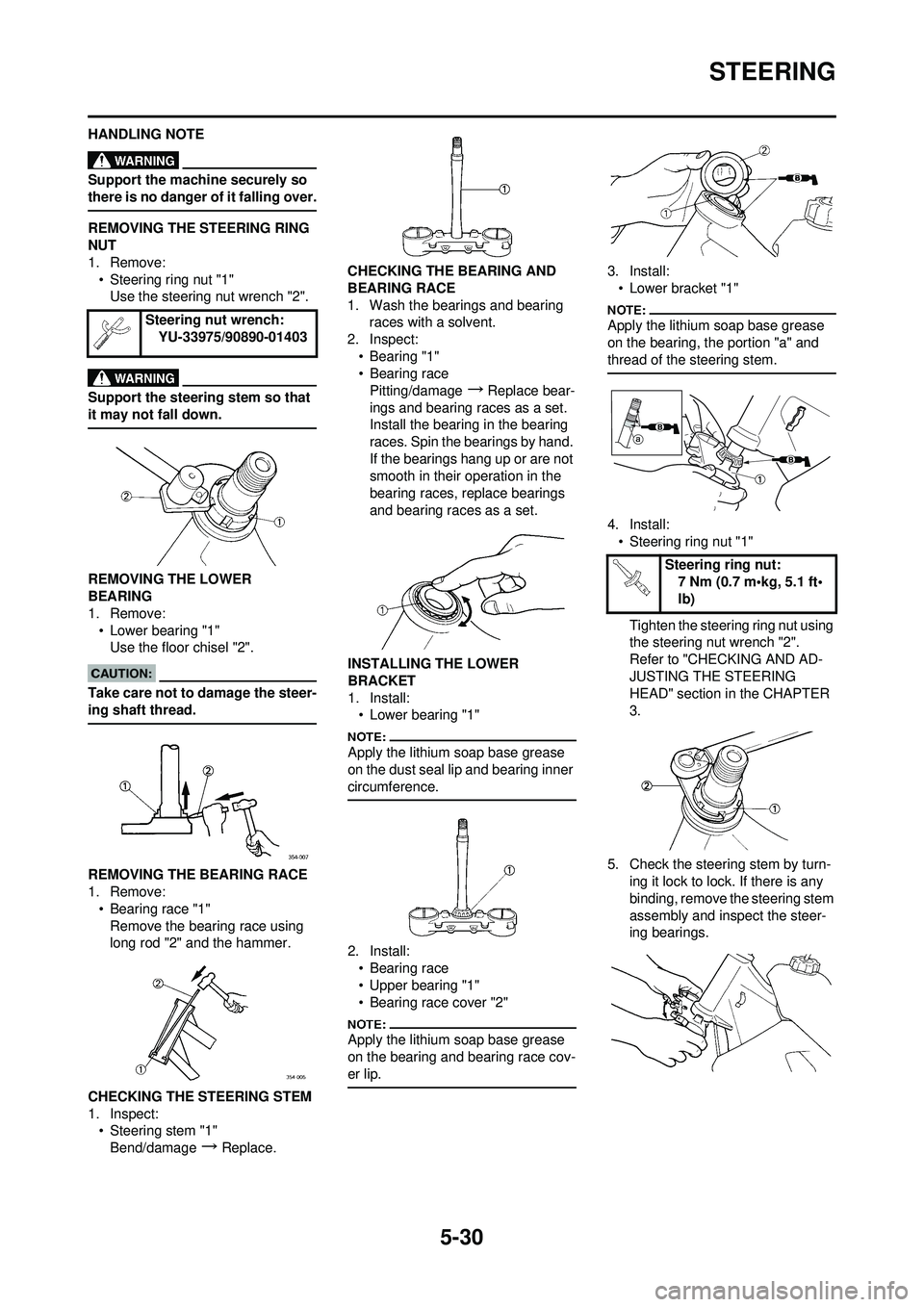

HANDLING NOTE

Support the machine securely so

there is no danger of it falling over.

REMOVING THE STEERING RING

NUT

1. Remove:• Steering ring nut "1"Use the steering nut wrench "2".

Support the steering stem so that

it may not fall down.

REMOVING THE LOWER

BEARING

1. Remove:

• Lower bearing "1"Use the floor chisel "2".

Take care not to damage the steer-

ing shaft thread.

REMOVING THE BEARING RACE

1. Remove:

• Bearing race "1"Remove the bearing race using

long rod "2" and the hammer.

CHECKING THE STEERING STEM

1. Inspect: • Steering stem "1"

Bend/damage

→Replace. CHECKING THE BEARING AND

BEARING RACE

1. Wash the bearings and bearing

races with a solvent.

2. Inspect: • Bearing "1"

• Bearing racePitting/damage

→Replace bear-

ings and bearing races as a set.

Install the bearing in the bearing

races. Spin the bearings by hand.

If the bearings hang up or are not

smooth in their operation in the

bearing races, replace bearings

and bearing races as a set.

INSTALLING THE LOWER

BRACKET

1. Install: • Lower bearing "1"

Apply the lithium soap base grease

on the dust seal lip and bearing inner

circumference.

2. Install:

• Bearing race

• Upper bearing "1"

• Bearing race cover "2"

Apply the lithium soap base grease

on the bearing and bearing race cov-

er lip.

3. Install:• Lower bracket "1"

Apply the lithium soap base grease

on the bearing, the portion "a" and

thread of the steering stem.

4. Install:• Steering ring nut "1"

Tighten the steering ring nut using

the steering nut wrench "2".

Refer to "CHECKING AND AD-

JUSTING THE STEERING

HEAD" section in the CHAPTER

3.

5. Check the steering stem by turn- ing it lock to lock. If there is any

binding, remove the steering stem

assembly and inspect the steer-

ing bearings.

Steering nut wrench:

YU-33975/90890-01403

Steering ring nut:7 Nm (0.7 m•kg, 5.1 ft•

lb)

Page 163 of 192

5-31

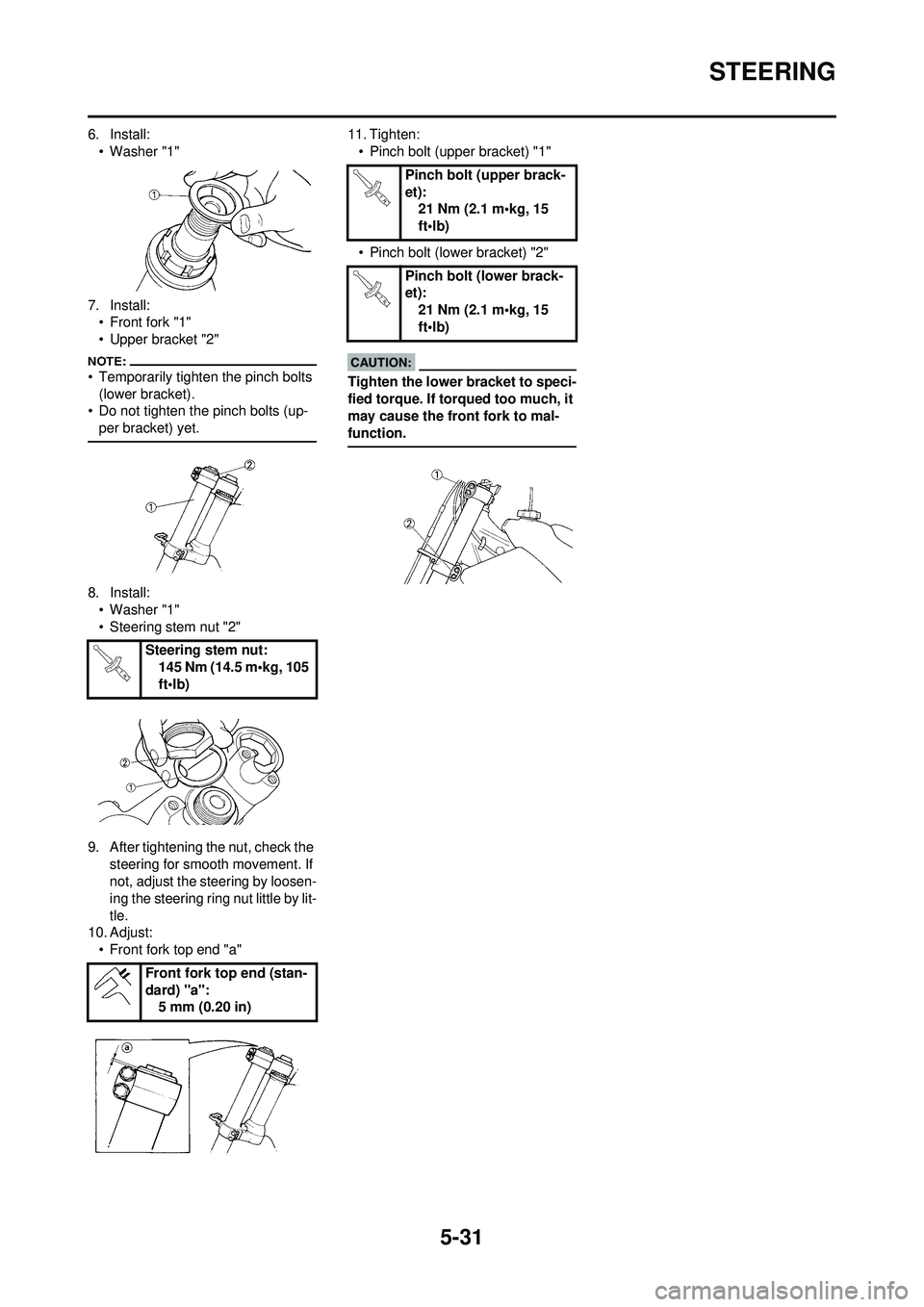

STEERING

6. Install:• Washer "1"

7. Install: • Front fork "1"

• Upper bracket "2"

• Temporarily tighten the pinch bolts

(lower bracket).

• Do not tighten the pinch bolts (up-

per bracket) yet.

8. Install:• Washer "1"

• Steering stem nut "2"

9. After tightening the nut, check the steering for smooth movement. If

not, adjust the steering by loosen-

ing the steering ring nut little by lit-

tle.

10. Adjust:

• Front fork top end "a" 11. Tighten:

• Pinch bolt (upper bracket) "1"

• Pinch bolt (lower bracket) "2"

Tighten the lower bracket to speci-

fied torque. If torqued too much, it

may cause the front fork to mal-

function.

Steering stem nut: 145 Nm (14.5 m•kg, 105

ft•lb)

Front fork top end (stan-

dard) "a": 5 mm (0.20 in)

Pinch bolt (upper brack-

et):21 Nm (2.1 m•kg, 15

ft•lb)

Pinch bolt (lower brack-

et): 21 Nm (2.1 m•kg, 15

ft•lb)

Page 164 of 192

5-32

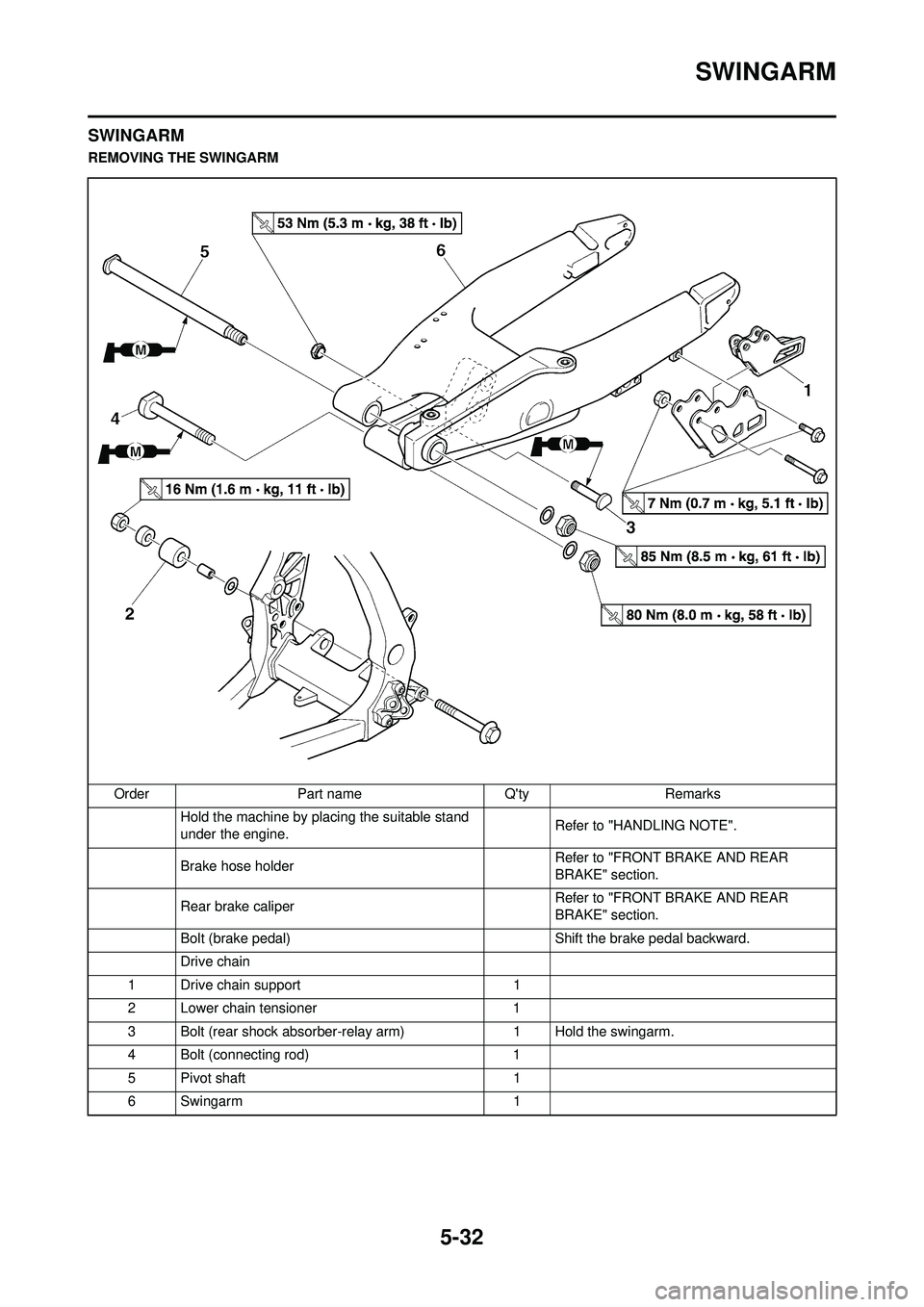

SWINGARM

SWINGARM

REMOVING THE SWINGARMOrder Part name Q'ty Remarks Hold the machine by placing the suitable stand

under the engine. Refer to "HANDLING NOTE".

Brake hose holder Refer to "FRONT BRAKE AND REAR

BRAKE" section.

Rear brake caliper Refer to "FRONT BRAKE AND REAR

BRAKE" section.

Bolt (brake pedal) Shift the brake pedal backward.

Drive chain

1 Drive chain support 1

2 Lower chain tensioner 1

3 Bolt (rear shock absorber-relay arm) 1 Hold the swingarm.

4 Bolt (connecting rod) 1

5Pivot shaft 1

6 Swingarm 1

Page 165 of 192

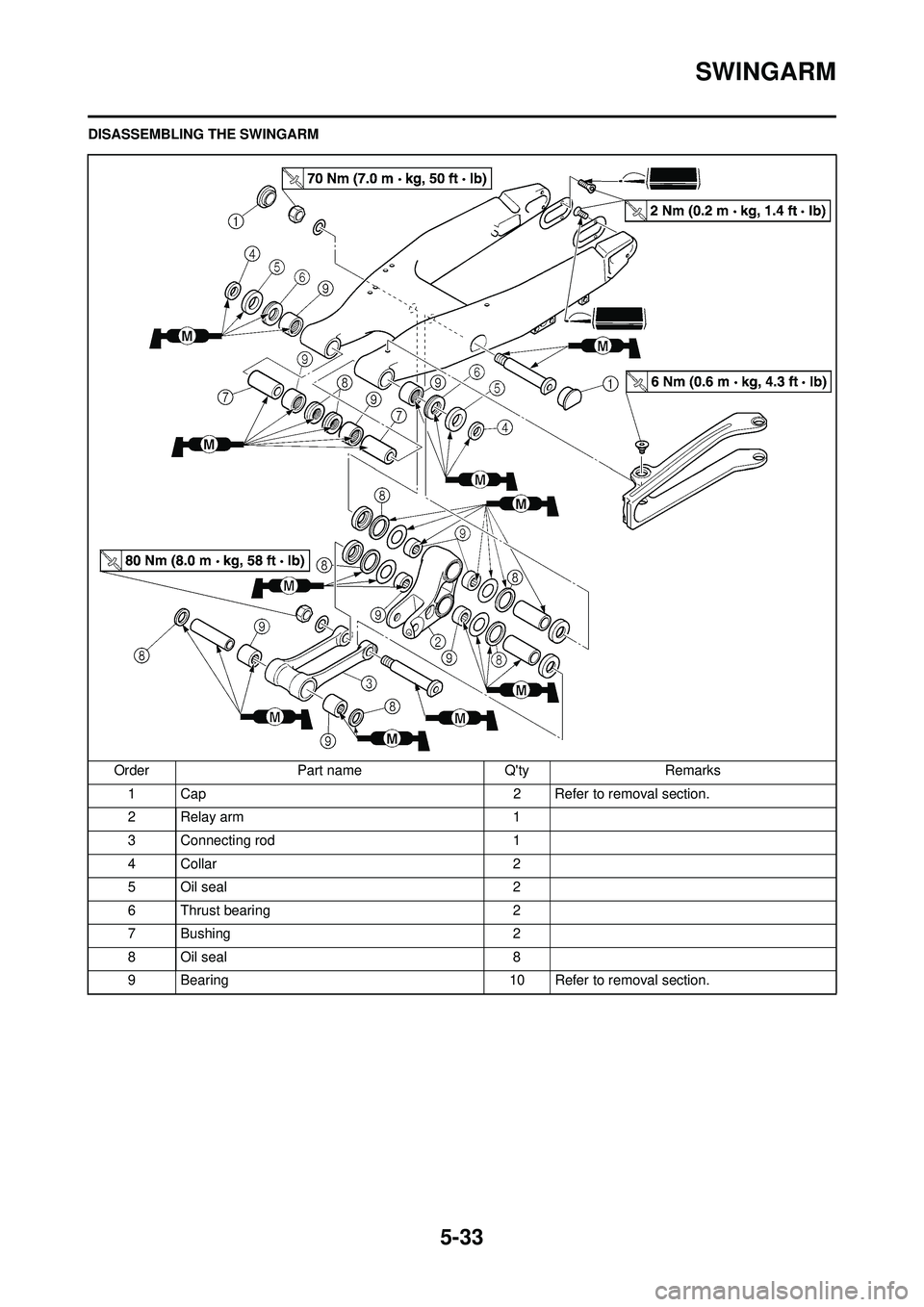

5-33

SWINGARM

DISASSEMBLING THE SWINGARMOrder Part name Q'ty Remarks1 Cap 2 Refer to removal section.

2 Relay arm 1

3 Connecting rod 1

4Collar 2

5 Oil seal 2

6 Thrust bearing 2

7 Bushing 2

8 Oil seal 8

9 Bearing 10 Refer to removal section.

Page 166 of 192

5-34

SWINGARM

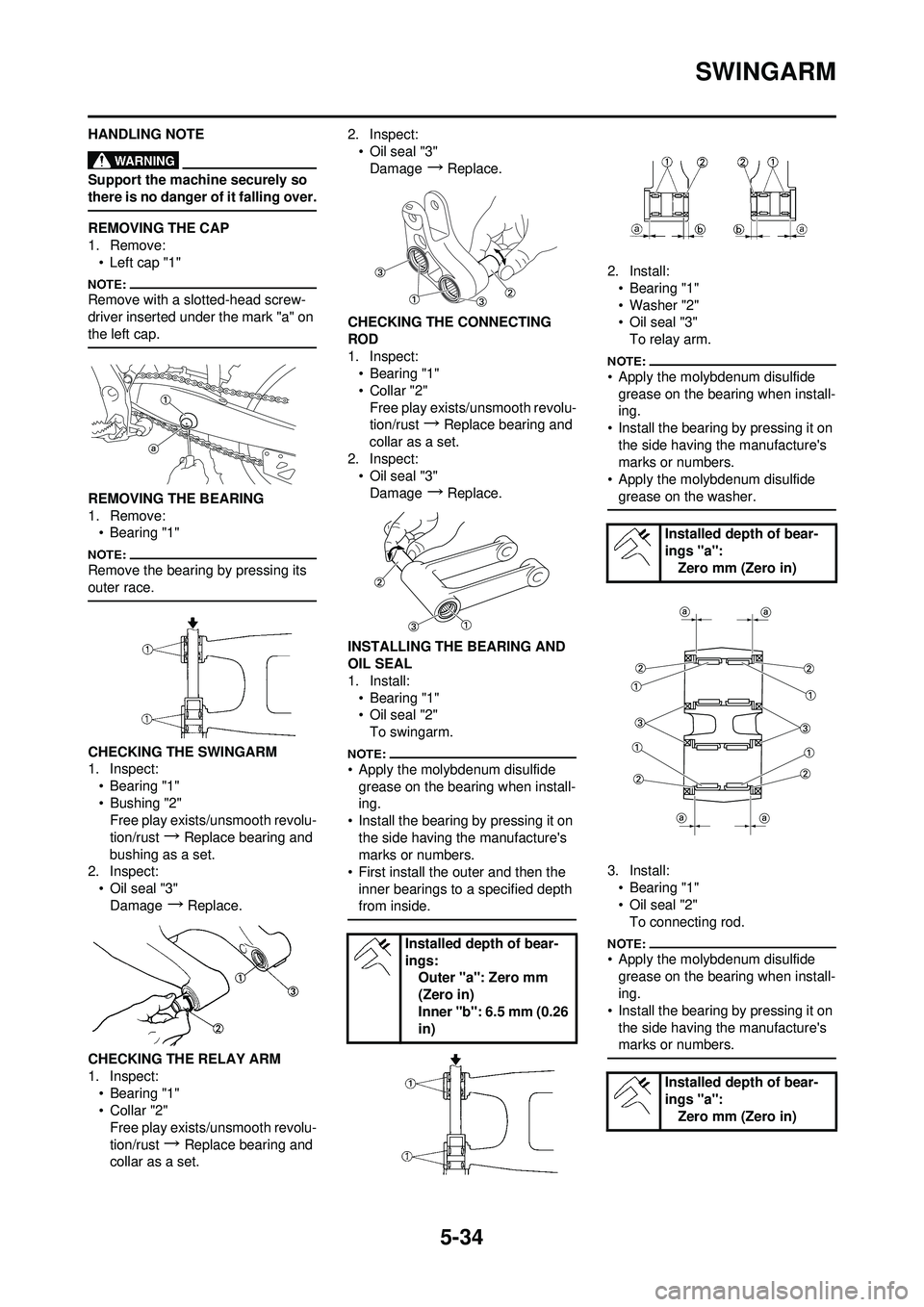

HANDLING NOTE

Support the machine securely so

there is no danger of it falling over.

REMOVING THE CAP

1. Remove:• Left cap "1"

Remove with a slotted-head screw-

driver inserted under the mark "a" on

the left cap.

REMOVING THE BEARING

1. Remove:• Bearing "1"

Remove the bearing by pressing its

outer race.

CHECKING THE SWINGARM

1. Inspect:

• Bearing "1"

• Bushing "2"Free play exists/unsmooth revolu-

tion/rust

→Replace bearing and

bushing as a set.

2. Inspect:

•Oil seal "3"Damage

→Replace.

CHECKING THE RELAY ARM

1. Inspect: • Bearing "1"

•Collar "2"Free play exists/unsmooth revolu-

tion/rust

→ Replace bearing and

collar as a set. 2. Inspect:

• Oil seal "3"Damage

→Replace.

CHECKING THE CONNECTING

ROD

1. Inspect: • Bearing "1"

•Collar "2"

Free play exists/unsmooth revolu-

tion/rust

→Replace bearing and

collar as a set.

2. Inspect: • Oil seal "3"

Damage

→Replace.

INSTALLING THE BEARING AND

OIL SEAL

1. Install: • Bearing "1"

• Oil seal "2"To swingarm.

• Apply the molybdenum disulfide grease on the bearing when install-

ing.

• Install the bearing by pressing it on the side having the manufacture's

marks or numbers.

• First install the outer and then the inner bearings to a specified depth

from inside.

2. Install:• Bearing "1"

• Washer "2"

•Oil seal "3"To relay arm.

• Apply the molybdenum disulfide grease on the bearing when install-

ing.

• Install the bearing by pressing it on the side having the manufacture's

marks or numbers.

• Apply the molybdenum disulfide grease on the washer.

3. Install:• Bearing "1"

•Oil seal "2"To connecting rod.

• Apply the molybdenum disulfide grease on the bearing when install-

ing.

• Install the bearing by pressing it on the side having the manufacture's

marks or numbers.

Installed depth of bear-

ings: Outer "a": Zero mm

(Zero in)

Inner "b": 6.5 mm (0.26

in)

Installed depth of bear-

ings "a":

Zero mm (Zero in)

Installed depth of bear-

ings "a": Zero mm (Zero in)

Page 167 of 192

5-35

SWINGARM

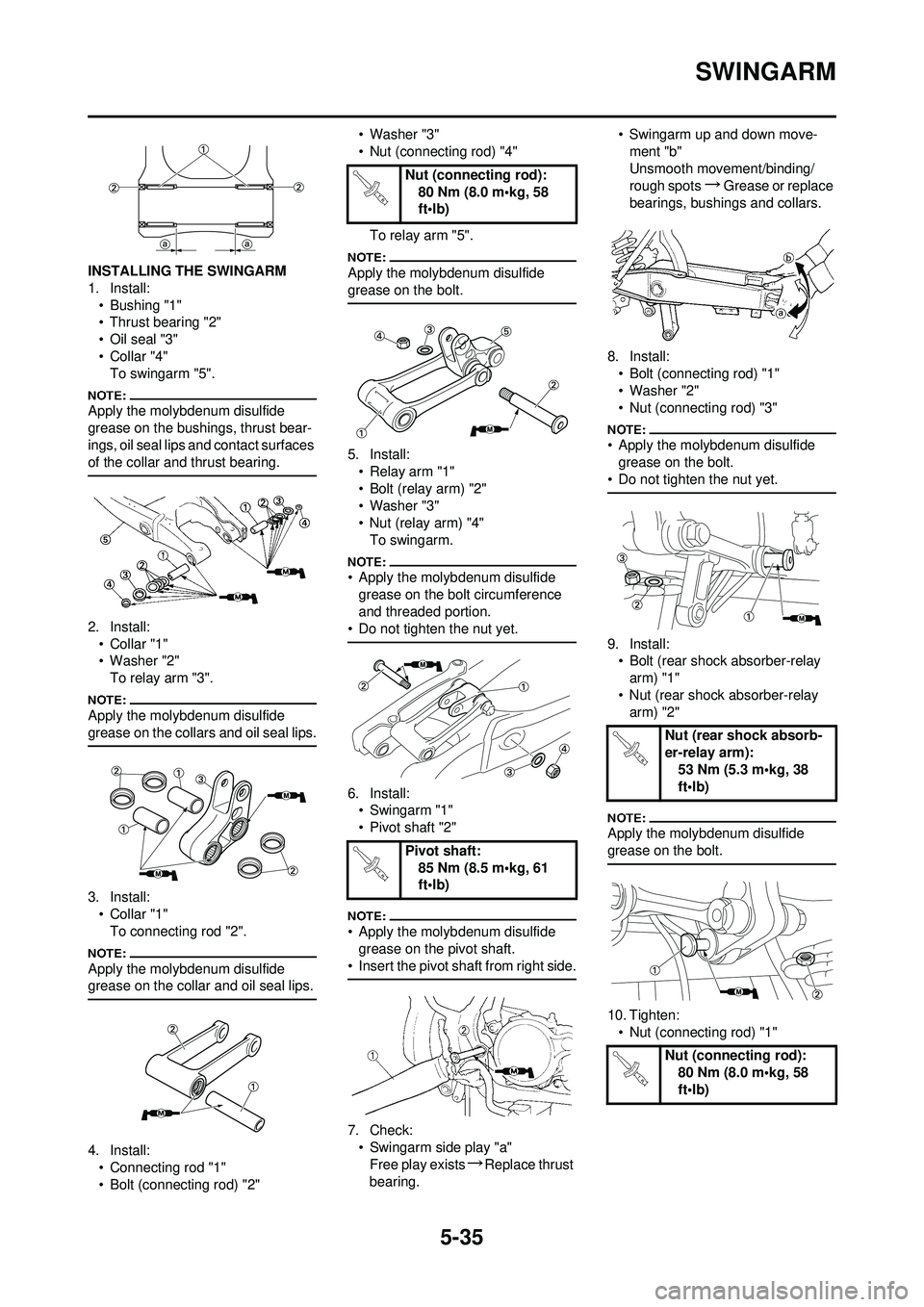

INSTALLING THE SWINGARM

1. Install:• Bushing "1"

• Thrust bearing "2"

•Oil seal "3"

•Collar "4"To swingarm "5".

Apply the molybdenum disulfide

grease on the bushings, thrust bear-

ings, oil seal lips and contact surfaces

of the collar and thrust bearing.

2. Install:

•Collar "1"

• Washer "2"To relay arm "3".

Apply the molybdenum disulfide

grease on the collars and oil seal lips.

3. Install:•Collar "1"To connecting rod "2".

Apply the molybdenum disulfide

grease on the collar and oil seal lips.

4. Install:• Connecting rod "1"

• Bolt (connecting rod) "2" •Washer "3"

• Nut (connecting rod) "4"

To relay arm "5".

Apply the molybdenum disulfide

grease on the bolt.

5. Install:• Relay arm "1"

• Bolt (relay arm) "2"

•Washer "3"

• Nut (relay arm) "4"To swingarm.

• Apply the molybdenum disulfide grease on the bolt circumference

and threaded portion.

• Do not tighten the nut yet.

6. Install: • Swingarm "1"

• Pivot shaft "2"

• Apply the molybdenum disulfide

grease on the pivot shaft.

• Insert the pivot shaft from right side.

7. Check: • Swingarm side play "a"Free play exists

→Replace thrust

bearing. • Swingarm up and down move-

ment "b"

Unsmooth movement/binding/

rough spots

→Grease or replace

bearings, bushings and collars.

8. Install: • Bolt (connecting rod) "1"

• Washer "2"

• Nut (connecting rod) "3"

• Apply the molybdenum disulfide grease on the bolt.

• Do not tighten the nut yet.

9. Install: • Bolt (rear shock absorber-relay

arm) "1"

• Nut (rear shock absorber-relay arm) "2"

Apply the molybdenum disulfide

grease on the bolt.

10. Tighten:• Nut (connecting rod) "1"

Nut (connecting rod):

80 Nm (8.0 m•kg, 58

ft•lb)

Pivot shaft: 85 Nm (8.5 m•kg, 61

ft•lb)

Nut (rear shock absorb-

er-relay arm):53 Nm (5.3 m•kg, 38

ft•lb)

Nut (connecting rod): 80 Nm (8.0 m•kg, 58

ft•lb)

Page 168 of 192

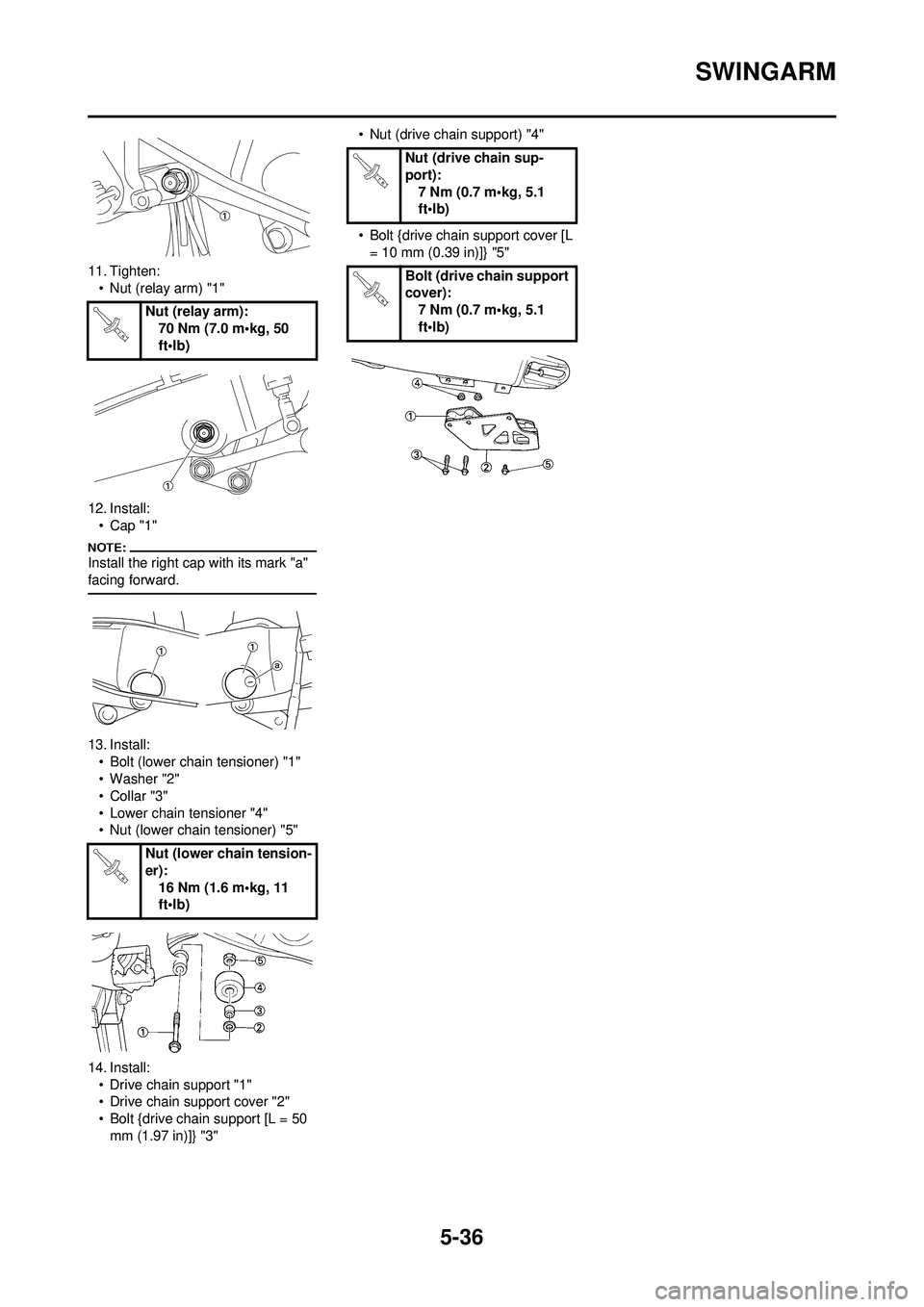

5-36

SWINGARM

11. Tighten:• Nut (relay arm) "1"

12. Install: • Cap "1"

Install the right cap with its mark "a"

facing forward.

13. Install:• Bolt (lower chain tensioner) "1"

• Washer "2"

•Collar "3"

• Lower chain tensioner "4"

• Nut (lower chain tensioner) "5"

14. Install: • Drive chain support "1"

• Drive chain support cover "2"

• Bolt {drive chain support [L = 50 mm (1.97 in)]} "3" • Nut (drive chain support) "4"

• Bolt {drive chain support cover [L

= 10 mm (0.39 in)]} "5"

Nut (relay arm): 70 Nm (7.0 m•kg, 50

ft•lb)

Nut (lower chain tension-

er): 16 Nm (1.6 m•kg, 11

ft•lb)

Nut (drive chain sup-

port):7 Nm (0.7 m•kg, 5.1

ft•lb)

Bolt (drive chain support

cover): 7 Nm (0.7 m•kg, 5.1

ft•lb)

Page 169 of 192

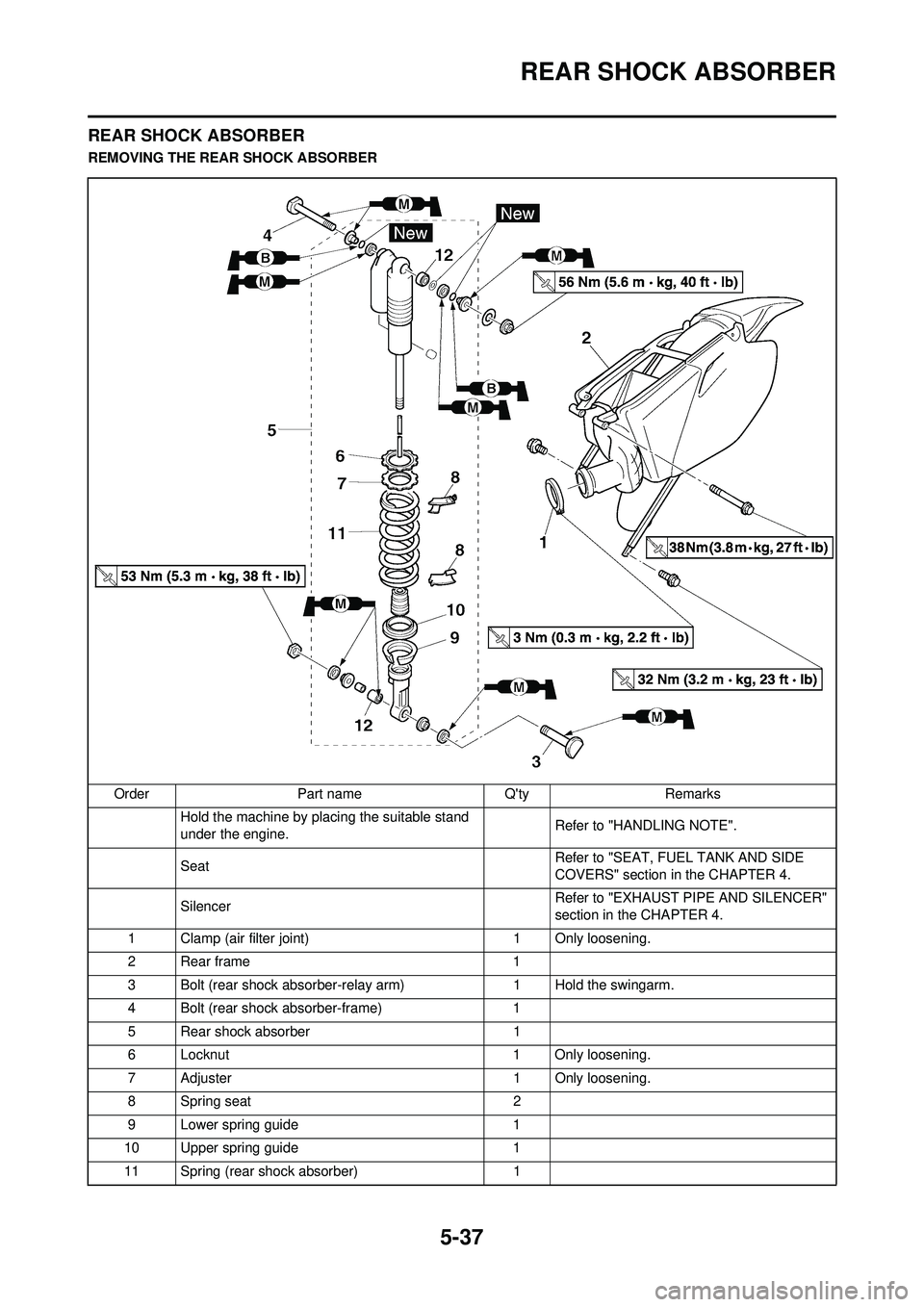

5-37

REAR SHOCK ABSORBER

REAR SHOCK ABSORBER

REMOVING THE REAR SHOCK ABSORBEROrder Part name Q'ty Remarks Hold the machine by placing the suitable stand

under the engine. Refer to "HANDLING NOTE".

Seat Refer to "SEAT, FUEL TANK AND SIDE

COVERS" section in the CHAPTER 4.

Silencer Refer to "EXHAUST PIPE AND SILENCER"

section in the CHAPTER 4.

1 Clamp (air filter joint) 1 Only loosening.

2 Rear frame 1

3 Bolt (rear shock absorber-relay arm) 1 Hold the swingarm.

4 Bolt (rear shock absorber-frame) 1

5 Rear shock absorber 1

6 Locknut 1 Only loosening.

7 Adjuster 1 Only loosening.

8 Spring seat 2

9 Lower spring guide 1

10 Upper spring guide 1

11 Spring (rear shock absorber) 1

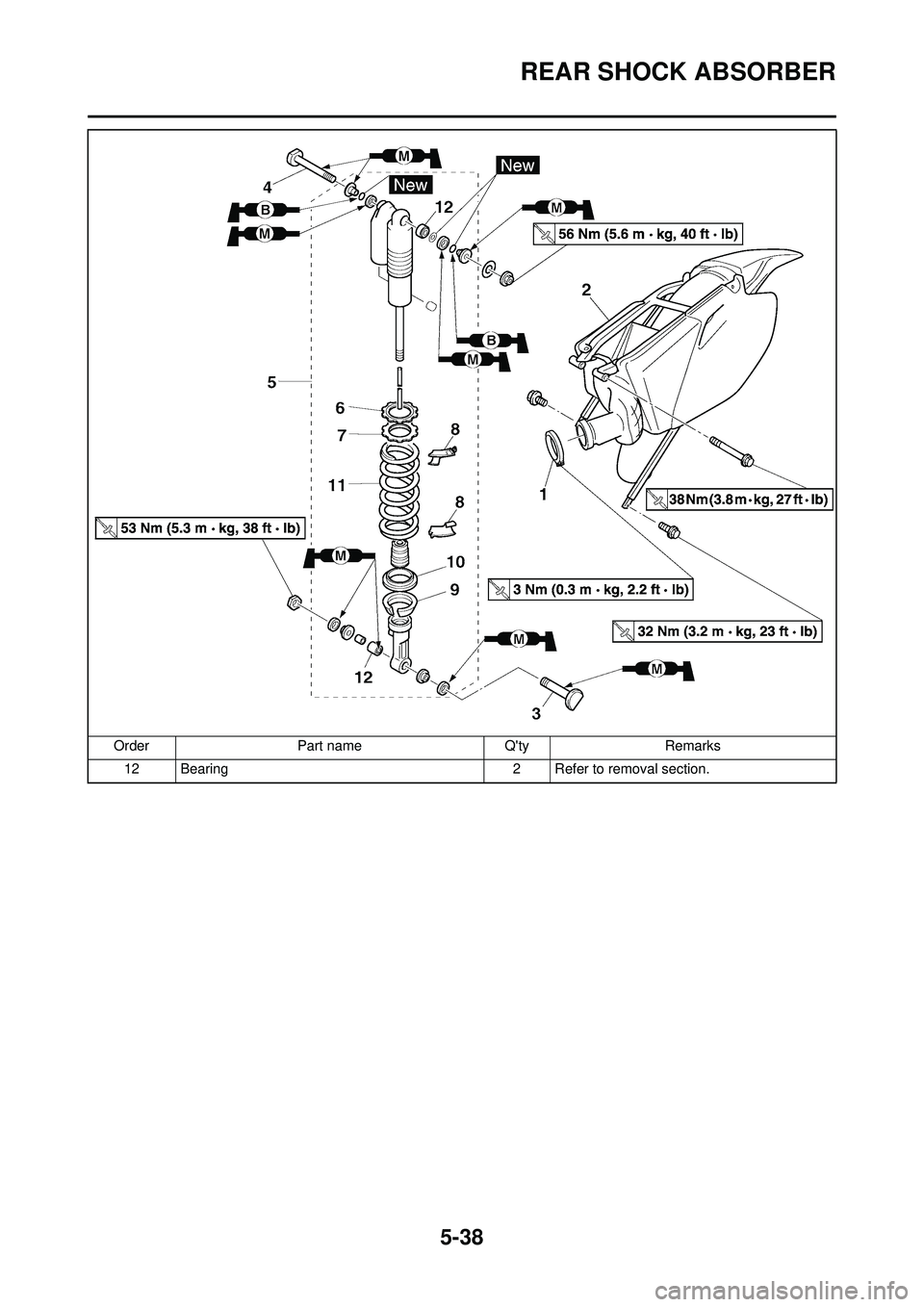

Page 170 of 192

5-38

REAR SHOCK ABSORBER

12 Bearing2 Refer to removal section.

Order

Part name Q'tyRemarks