fuse ACURA NSX 1991 Service User Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 274 of 1640

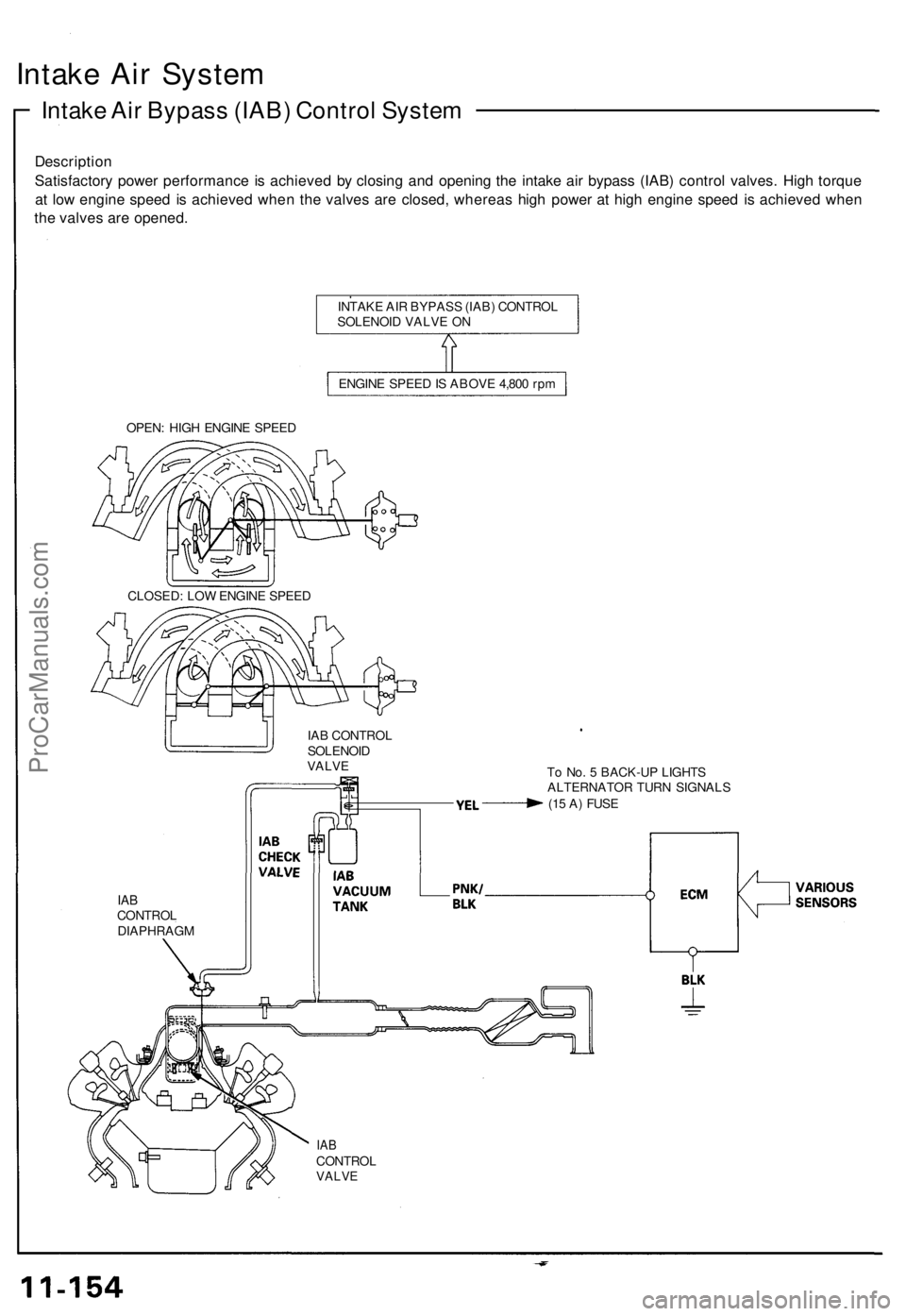

Intake Air System

Intake Air Bypass (IAB) Control System

Description

Satisfactory power performance is achieved by closing and opening the intake air bypass (IAB) control valves. High torque

at low engine speed is achieved when the valves are closed, whereas high power at high engine speed is achieved when

the valves are opened.

INTAKE AIR BYPASS (IAB) CONTROL

SOLENOID VALVE ON

ENGINE SPEED IS ABOVE 4,800 rpm

OPEN: HIGH ENGINE SPEED

IAB CONTROL

SOLENOID

VALVE

To No. 5 BACK-UP LIGHTS

ALTERNATOR TURN SIGNALS

(15 A) FUSE

IAB

CONTROL

DIAPHRAGM

IAB

CONTROL

VALVE

CLOSED: LOW ENGINE SPEEDProCarManuals.com

Page 280 of 1640

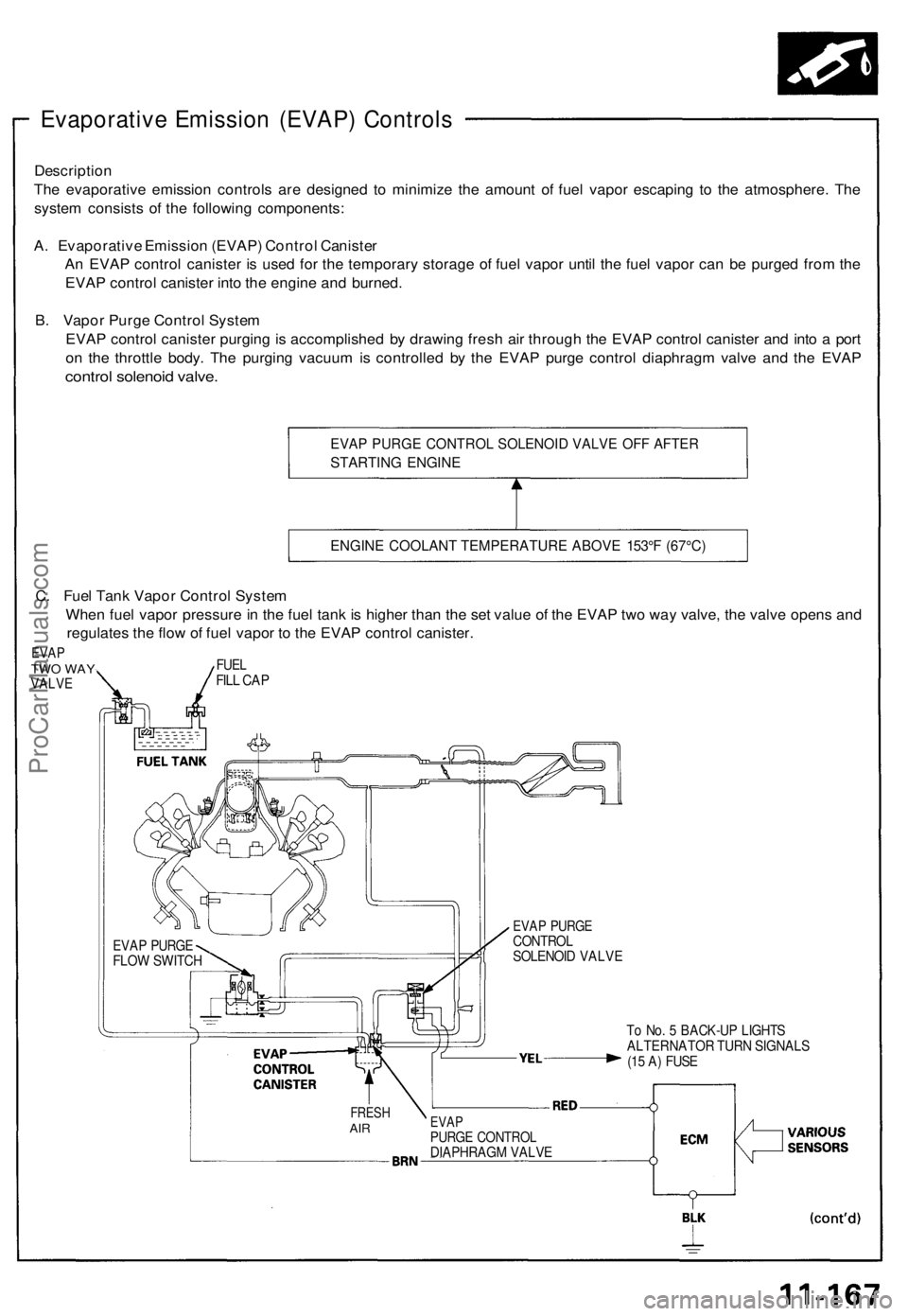

Evaporative Emission (EVAP) Controls

Description

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the following components:

A. Evaporative Emission (EVAP) Control Canister

An EVAP control canister is used for the temporary storage of fuel vapor until the fuel vapor can be purged from the

EVAP control canister into the engine and burned.

B. Vapor Purge Control System

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a port

on the throttle body. The purging vacuum is controlled by the EVAP purge control diaphragm valve and the EVAP

control solenoid valve.

EVAP PURGE CONTROL SOLENOID VALVE OFF AFTER

STARTING ENGINE

ENGINE COOLANT TEMPERATURE ABOVE 153°F (67°C)

To No. 5 BACK-UP LIGHTS

ALTERNATOR TURN SIGNALS

(15 A) FUSE

FRESH

AIR

EVAP

PURGE CONTROL

DIAPHRAGM VALVE

EVAP PURGE

CONTROL

SOLENOID VALVE

EVAP PURGE

FLOW SWITCH

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens and

regulates the flow of fuel vapor to the EVAP control canister.

EVAP

TWO WAY

VALVE

FUEL

FILL CAPProCarManuals.com

Page 416 of 1640

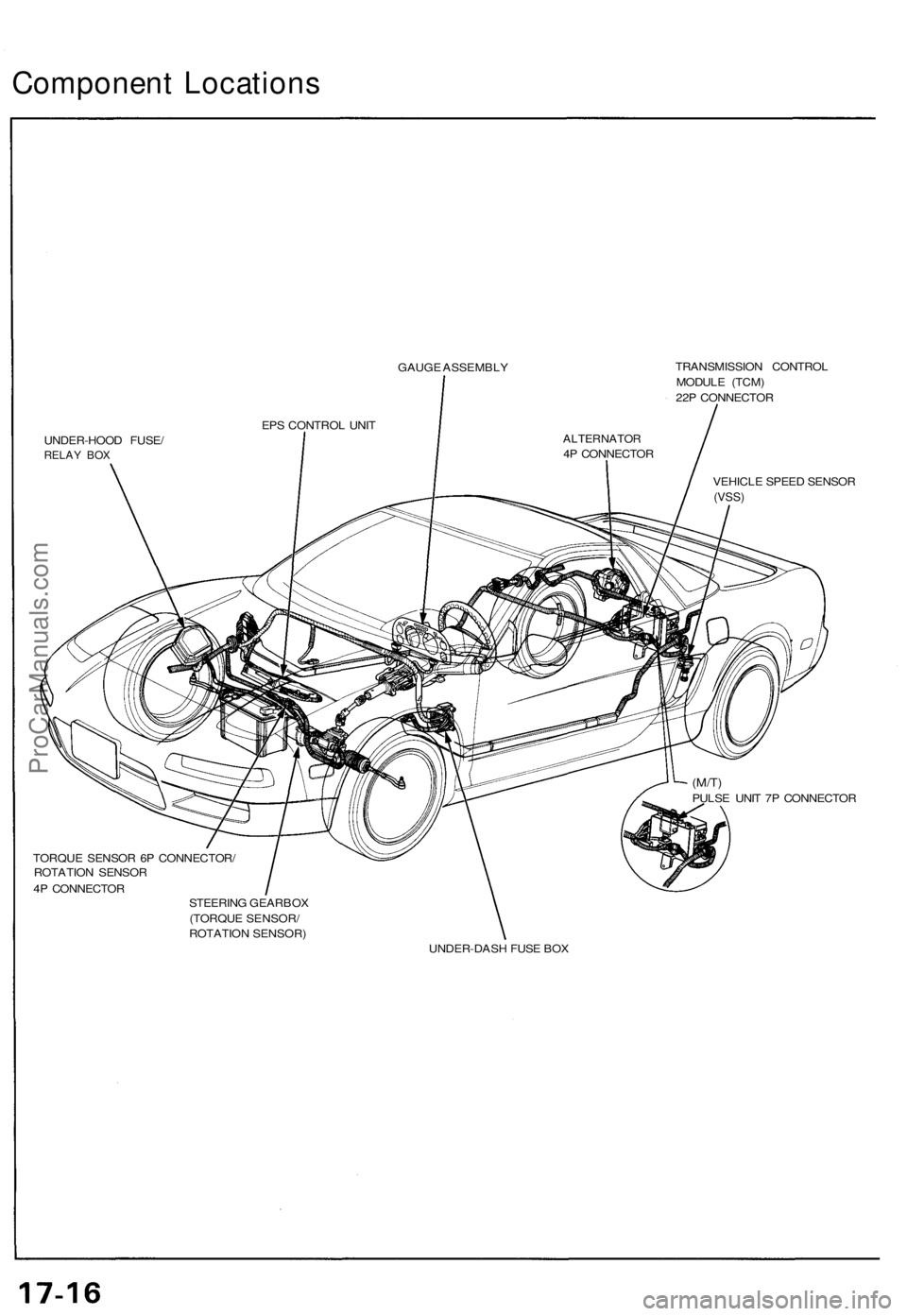

Component Location s

GAUGE ASSEMBL Y

UNDER-HOO D FUSE /

RELAY BO X

TRANSMISSIO N CONTRO L

MODUL E (TCM )

22 P CONNECTO R

VEHICL E SPEE D SENSO R

(VSS)

(M/T)PULS E UNI T 7 P CONNECTO R

TORQU E SENSO R 6 P CONNECTOR /

ROTATIO N SENSO R

4 P CONNECTO R

STEERING GEARBO X

(TORQU E SENSOR /

ROTATIO N SENSOR )

UNDER-DASH FUS E BO X

EP

S CONTRO L UNI T

ALTERNATO R4P CONNECTO R

ProCarManuals.com

Page 417 of 1640

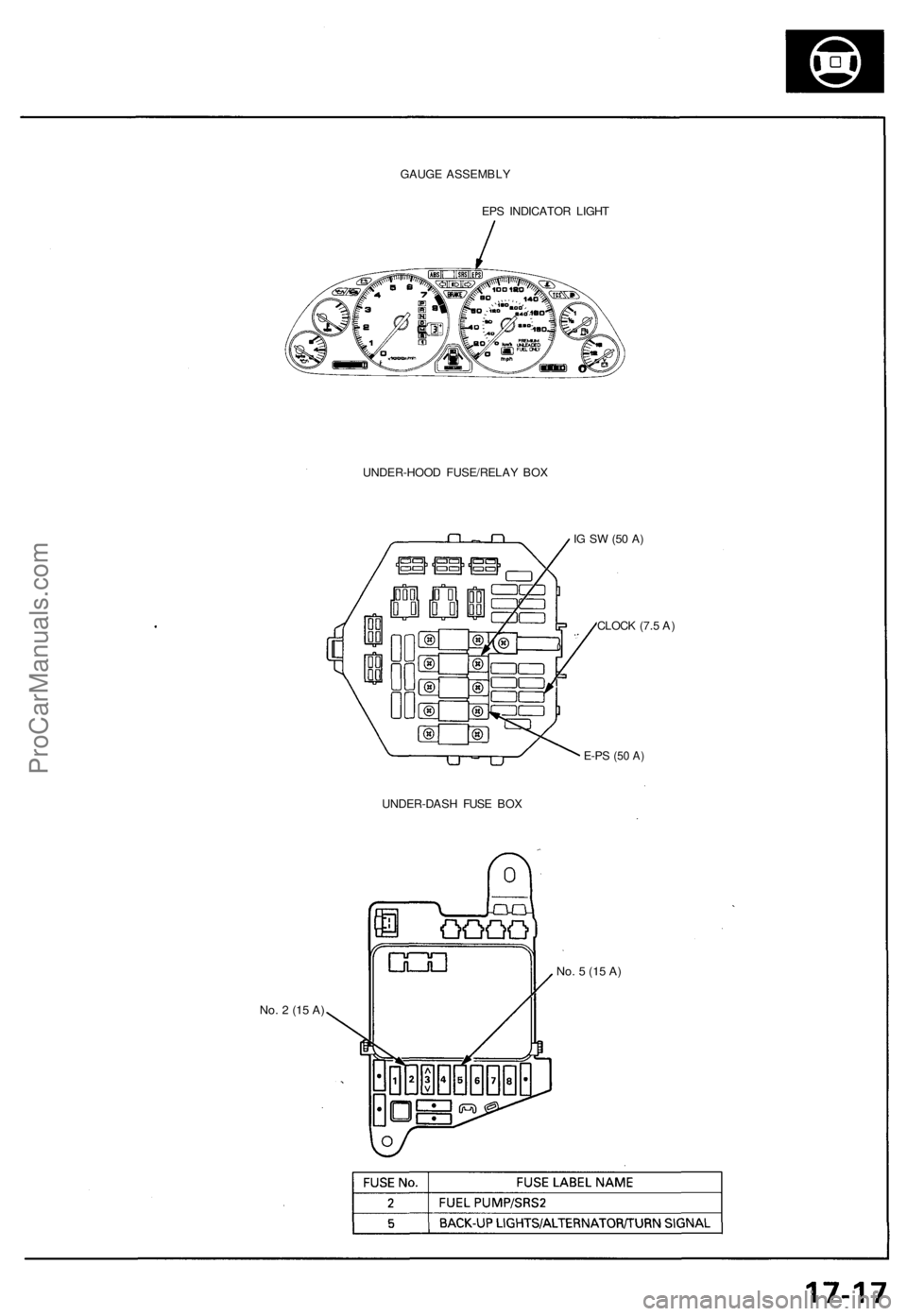

GAUGE ASSEMBLY

EPS INDICATOR LIGHT

UNDER-HOOD FUSE/RELAY BOX

No. 2 (15 A)

IG SW (50 A)

CLOCK (7.5 A)

E-PS

(50 A)

UNDER-DASH FUSE BOX

No. 5 (15 A)ProCarManuals.com

Page 420 of 1640

Troubleshooting Precautions

EPS Indicator Light

Under normal conditions, the EPS indicator light in the gauge assembly comes on when the ignition switch is turned to

the ON (II) position, then goes off after the engine is started. This indicates that the bulb and its circuits are operating cor-

rectly. If there is any trouble in the system, the EPS indicator light turns on during driving, and the power steering assist is

turned off. When the EPS indicator light comes on, the control unit memorizes the DTC. In this case, the control unit does

not activate the EPS system after the engine starts again but it keeps the EPS indicator light on.

Diagnostic Trouble Code (DTC)

• The lowest DTC is indicated first.

• The DTCs continue blinking until the ignition switch is turned off.

• The DTCs are erased from the control unit when the EPS control unit VBU power supply or connector is disconnected.

• The EPS system can be reset and the control unit's memory can be erased by disconnecting the CLOCK (7.5 A) fuse for

more than ten seconds.

Self-diagnosis:

The CPU (central processing unit) controls the following when it detects a problem during self-diagnosis:

1. Turns the EPS indicator light ON to alert the driver.

2. Power assist stops, and normal manual steering operation resumes (except DTC 21 and DTC 33).

3. The EPS control unit memorizes the diagnostic trouble code (DTC).

4. After the DTC is stored in the control unit, the CPU stops self-diagnosis.

Troubleshooting:

• Before starting the troubleshooting, clear the DTC by disconnecting the CLOCK (7.5 A) fuse for ten seconds or more,

and test-drive the car. Check that the symptom of the trouble appears again, and then troubleshoot. If the problem is an

intermittent problem, the system does not become active after the engine starts even though the problem is solved.

• When both EPS indicator light and A/T "D" indicator light come on, perform the A/T troubleshooting first.

• When the customer's reported problem cannot be verified in the car, ask the customer about the conditions when the

EPS indicator light came ON, then test-drive the car under those conditions, if possible. If the EPS indicator light does

not come ON during the test, check for loose connections or poor contacts at the connectors by wiggling the harness,

etc.

• The connector terminal numbers are viewed from the wire side for the female terminals and from the terminal side for

the male terminals.

• After the repair, test-drive the car and check that the EPS indicator light does not come ON again during the test. (Refer

to the Symptom-to-System Chart for diagnostic period.)ProCarManuals.com

Page 422 of 1640

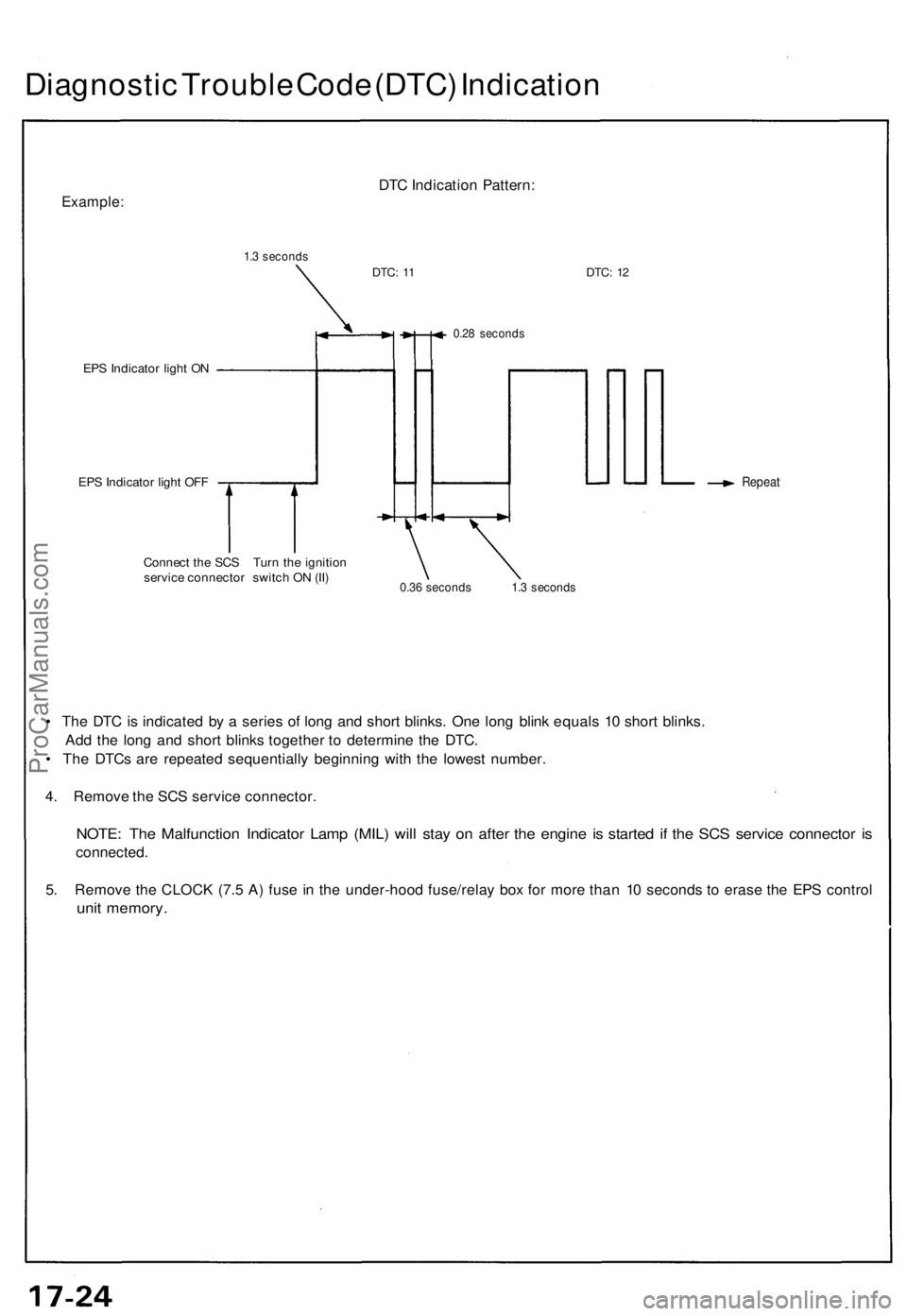

Diagnostic Trouble Code (DTC) Indication

Example:

1.3 seconds

DTC Indication Pattern:

DTC:

11

DTC:

12

EPS Indicator light ON

EPS Indicator light OFF

0.28 seconds

Repeat

Connect the SCS Turn the ignition

service connector switch ON (II)

0.36 seconds 1.3 seconds

• The DTC is indicated by a series of long and short blinks. One long blink equals 10 short blinks.

Add the long and short blinks together to determine the DTC.

• The DTCs are repeated sequentially beginning with the lowest number.

4. Remove the SCS service connector.

NOTE: The Malfunction Indicator Lamp (MIL) will stay on after the engine is started if the SCS service connector is

connected.

5. Remove the CLOCK (7.5 A) fuse in the under-hood fuse/relay box for more than 10 seconds to erase the EPS control

unit memory.ProCarManuals.com

Page 492 of 1640

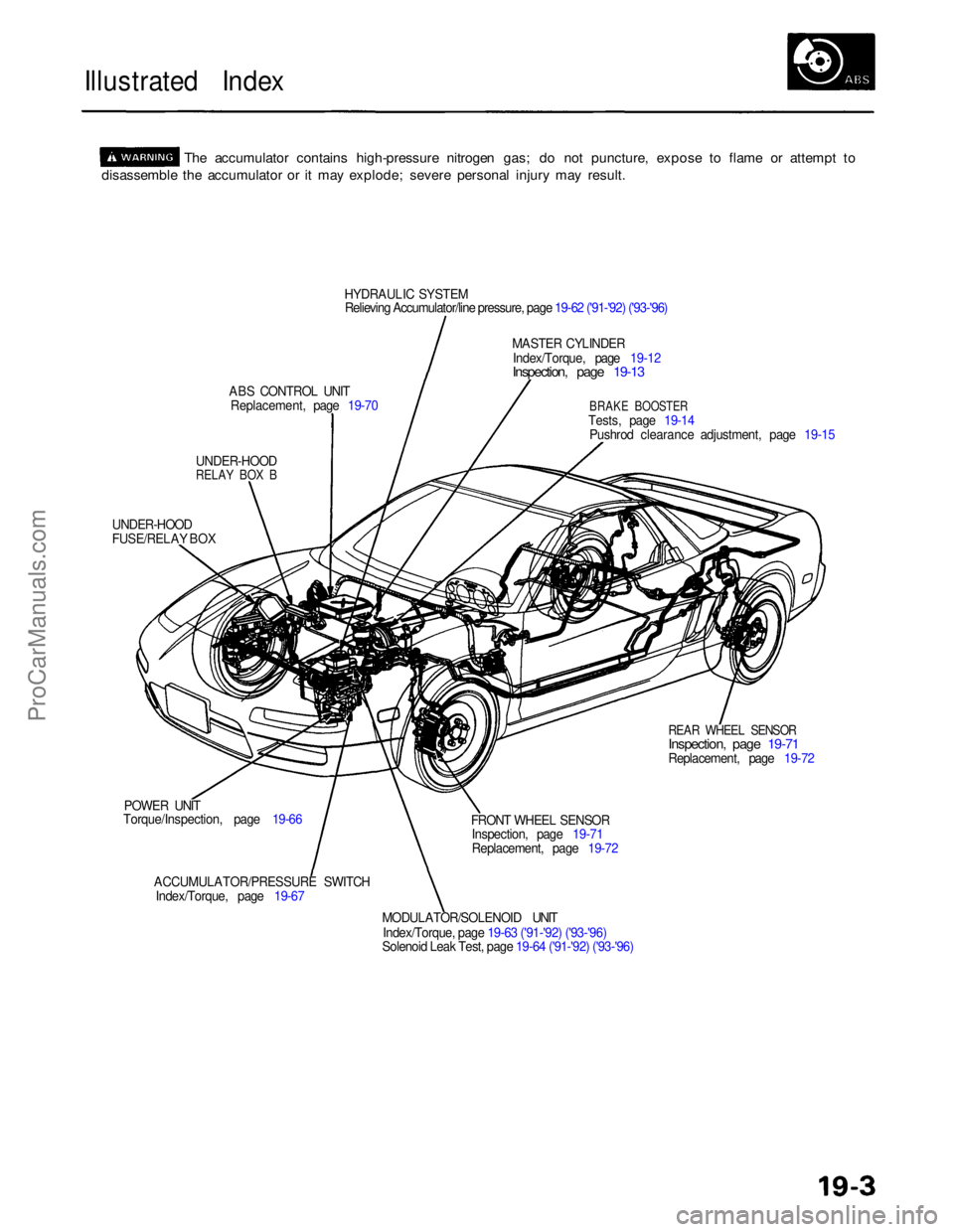

Illustrated Index

The accumulator contains high-pressure nitrogen gas; do not puncture, expose to flame or attempt to

disassemble the accumulator or it may explode; severe personal injury may result.

HYDRAULIC SYSTEM

Relieving Accumulator/line pressure, page 19-62 ('91-'92) ('93-'96)

MASTER CYLINDER

Index/Torque, page 19-12

Inspection, page 19-13

ABS CONTROL UNIT Replacement, page 19-70

BRAKE BOOSTER

Tests, page 19-14 Pushrod clearance adjustment, page 19-15

UNDER-HOOD

RELAY BOX B

UNDER-HOOD

FUSE/RELAY BOX

REAR WHEEL SENSOR

Inspection, page 19-71

Replacement, page 19-72

POWER UNIT

Torque/Inspection, page 19-66

ACCUMULATOR/PRESSURE SWITCHIndex/Torque, page 19-67 FRONT WHEEL SENSOR

Inspection, page 19-71

Replacement, page 19-72

MODULATOR/SOLENOID UNIT

Index/Torque, page 19-63 ('91-'92) ('93-'96)

Solenoid Leak Test, page 19-64 ('91-'92) ('93-'96)

ProCarManuals.com

Page 530 of 1640

Troubleshooting

Anti-lock Brak e Syste m (ABS ) Indicato r Ligh t

Temporar y Drivin g Conditions :

1. Th e AB S indicato r ligh t wil l com e o n an d th e AB S

contro l uni t memorize s th e diagnosti c troubl e cod e

(DTC ) unde r certai n conditions .

NOTE : Th e DT C explaine d o n page s 19-46 .

• Th e tire(s ) adhesio n is los t du e to excessiv e cor -

nerin g speed .

DTC: 5, 5-4 , 5-8 .

• Th e vehicl e lose s tractio n whe n startin g fro m a

stuc k conditio n o n a muddy , snowy , o r sand y

road.

DTC: 4-1 , 4-2 , 4-4 , 4-8 .

• Whe n th e parkin g brak e is applie d fo r mor e tha n

3 0 second s whil e th e vehicl e i s bein g driven .

DTC: 2.

• Th e vehicl e is drive n o n extremel y roug h road .

Th e AB S is OK , i f th e AB S indicato r ligh t goe s

of f afte r th e engin e i s restarted .

2 . I f yo u receiv e a customer' s repor t tha t th e AB S in -

dicato r ligh t sometime s come s on , chec k fo r a DTC .

I f a DT C is stored , refe r t o th e appropriat e trouble -

shootin g (se e pag e 19-46 ). I f n o DT C is stored ,

chec k th e syste m usin g th e AL B checke r t o confir m

whethe r ther e is an y troubl e in th e system . Se e pag e

19-41 .

3. Th e AB S indicato r ligh t wil l com e o n an d th e AB S

contro l uni t wil l stor e a DT C whe n ther e i s insuffi -

cien t batter y voltag e t o th e AB S contro l unit . A n

exampl e woul d b e whe n th e batter y is s o wea k tha t

th e ca r mus t b e jump-started . Afte r th e batter y i s

sufficientl y recharged , th e AB S indicato r ligh t wil l

wor k normall y afte r th e engin e i s stoppe d an d

restarted .

However , afte r rechargin g th e battery , th e DT C

mus t b e cleare d fro m th e AB S contro l unit' s

memor y b y disconnectin g th e AB S 2, 3 (20A ) fus e

fo r a t leas t thre e seconds . AB

S Indicato r Ligh t Circuit :

CAUTION : Us e onl y th e digita l multimete r t o

chec k th e system .

1. Th e indicato r ligh t doe s no t g o o n whe n th e ignitio n

switc h i s turne d on .

Chec k th e followin g items . I f the y ar e OK , chec k

th e AB S contro l uni t connectors .

I f no t loos e o r disconnected , instal l a ne w AB S con -

tro l uni t an d recheck :

• Blow n AB S indicato r ligh t bulb .

• Ope n circui t i n YE L wir e betwee n No . 5 (1 5 A )

fus e an d gaug e assembly .

• Ope n circui t i n BLU/WH T wir e betwee n gaug e

assembl y an d AB S contro l unit .

• Loos e componen t groundin g of the AB S contro l

uni t t o th e body .

2 . Th e AB S indicato r ligh t remain s O N afte r th e engin e

i s started , howeve r th e AB S indicato r ligh t doe s no t

blin k an y cod e o r sub-code . Chec k th e followin g

items :

• Loos e o r poo r connectio n of the wir e harnes s a t

th e AB S contro l unit .

• Fault y AB S 2, 3 (20A ) fuse .

• Ope n circui t i n WHT/BL K wir e betwee n AB S 2, 3

(20A ) fus e an d AB S contro l unit .

• Ope n circui t i n YEL/BL K wir e betwee n fus e No .

4 (1 5 A ) an d AB S contro l unit .

• Shor t circui t i n BLU/WH T wir e betwee n gaug e

assembl y an d AB S contro l unit .

• Ope n circui t i n WHT/BL U wir e betwee n alter -

nato r an d AB S contro l unit .

• Loos e componen t groundin g o f th e AB S contro l

uni t t o th e body .

I f th e proble m is no t found , substitut e a known-goo d

AB S contro l uni t an d rechec k whethe r th e AB S in -

dicato r ligh t remain s ON .

ProCarManuals.com

Page 531 of 1640

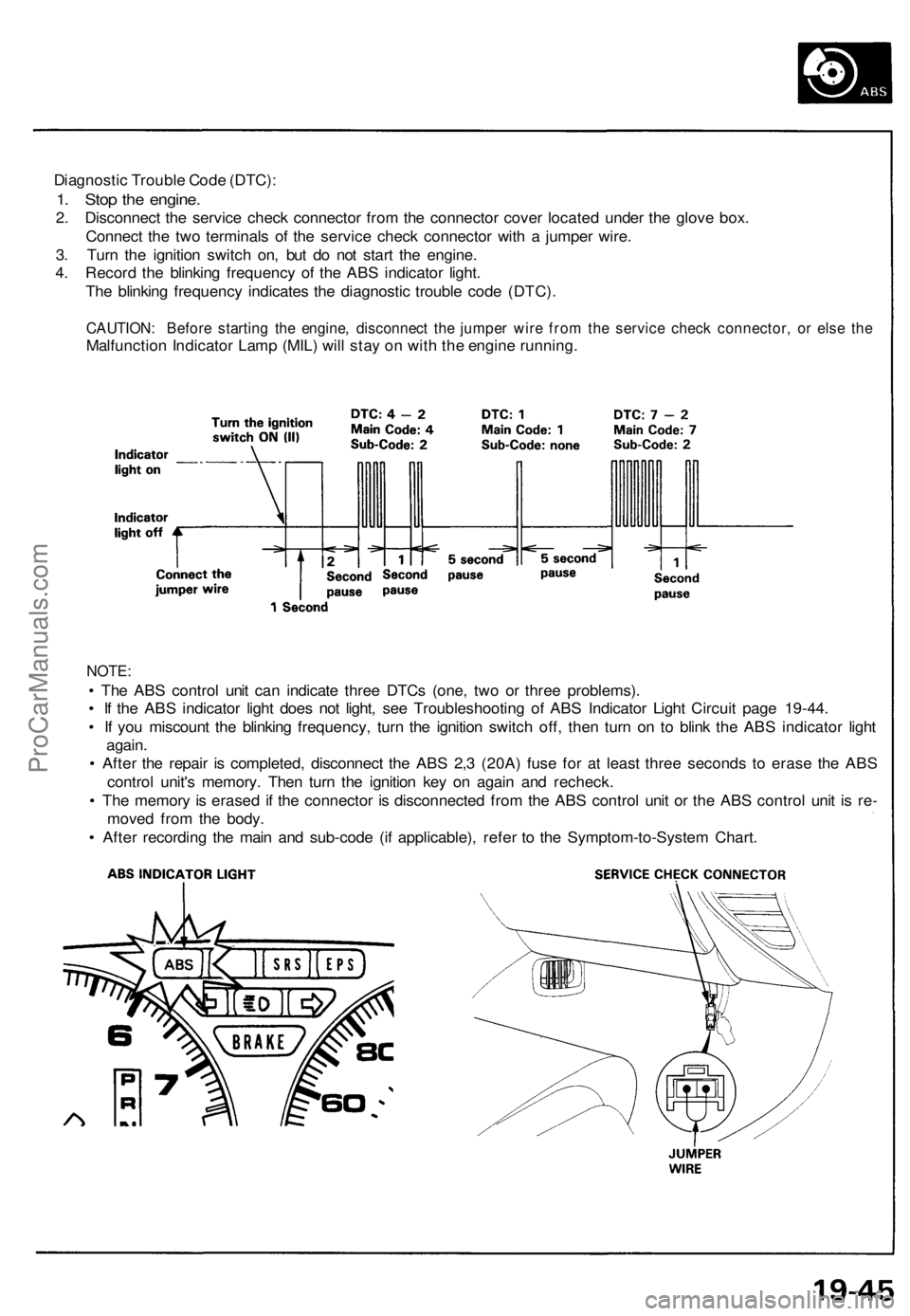

Diagnostic Trouble Code (DTC):

1. Stop the engine.

2. Disconnect the service check connector from the connector cover located under the glove box.

Connect the two terminals of the service check connector with a jumper wire.

3. Turn the ignition switch on, but do not start the engine.

4. Record the blinking frequency of the ABS indicator light.

The blinking frequency indicates the diagnostic trouble code (DTC).

CAUTION: Before starting the engine, disconnect the jumper wire from the service check connector, or else the

Malfunction Indicator Lamp (MIL) will stay on with the engine running.

NOTE:

• The ABS control unit can indicate three DTCs (one, two or three problems).

• If the ABS indicator light does not light, see Troubleshooting of ABS Indicator Light Circuit page 19-44.

• If you miscount the blinking frequency, turn the ignition switch off, then turn on to blink the ABS indicator light

again.

• After the repair is completed, disconnect the ABS 2,3 (20A) fuse for at least three seconds to erase the ABS

control unit's memory. Then turn the ignition key on again and recheck.

• The memory is erased if the connector is disconnected from the ABS control unit or the ABS control unit is re-

moved from the body.

• After recording the main and sub-code (if applicable), refer to the Symptom-to-System Chart.ProCarManuals.com

Page 537 of 1640

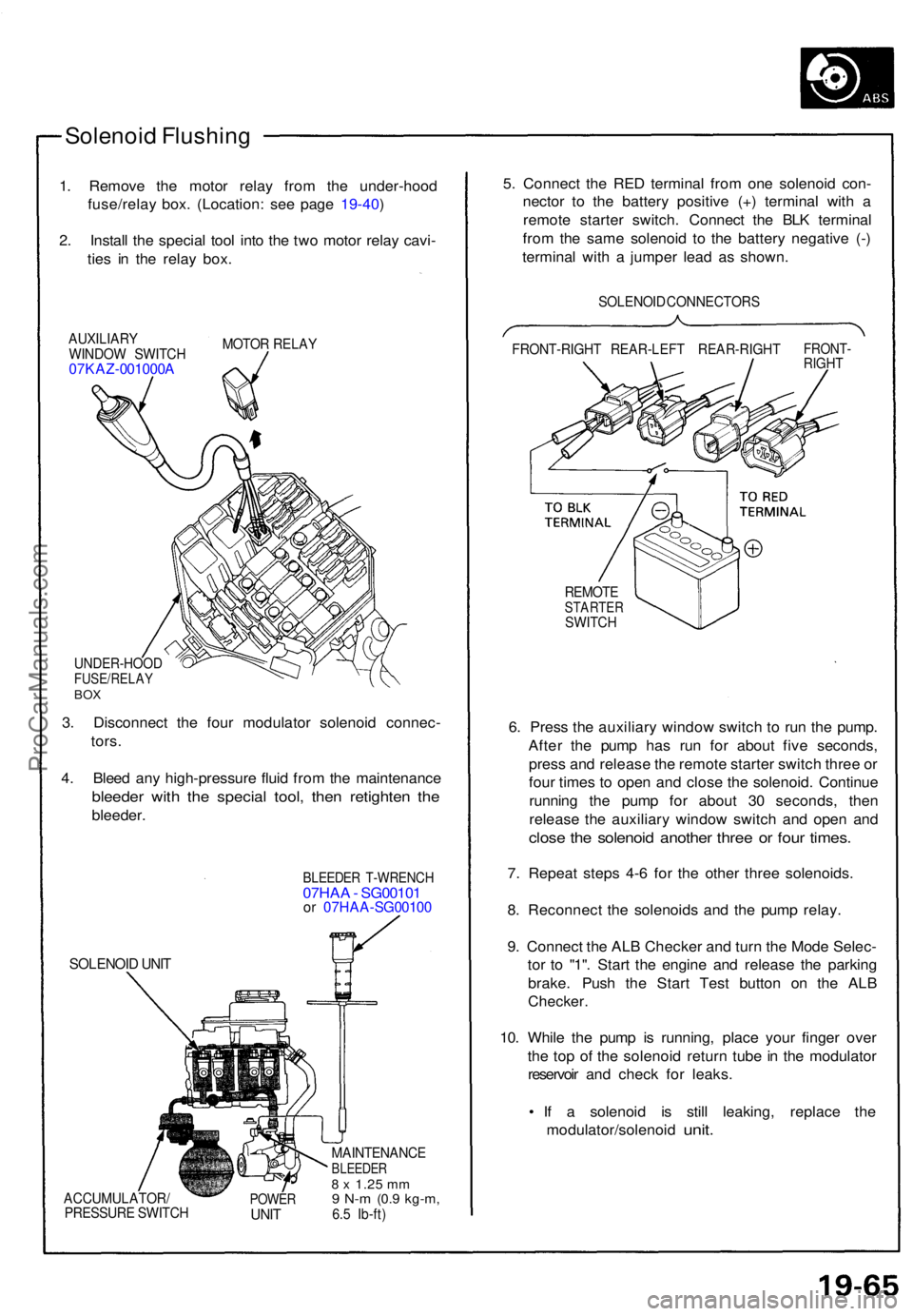

Solenoid Flushin g

1. Remov e th e moto r rela y fro m th e under-hoo d

fuse/rela y box . (Location : se e pag e 19-40 )

2 . Instal l th e specia l too l int o th e tw o moto r rela y cavi -

tie s i n th e rela y box .

AUXILIAR Y

WINDO W SWITC H

07KAZ-001000 A

MOTOR RELA Y

UNDER-HOO DFUSE/RELAYBOX

3. Disconnec t th e fou r modulato r solenoi d connec -

tors .

4 . Blee d an y high-pressur e flui d fro m th e maintenanc e

bleeder wit h th e specia l tool , the n retighte n th e

bleeder .

SOLENOI D UNI T

BLEEDE R T-WRENC H07HAA - SG0010 1or 07HA A-SG0010 0

ACCUMULATOR /

PRESSUR E SWITC HPOWERUNIT

MAINTENANC EBLEEDER8 x 1.2 5 mm9 N- m (0. 9 kg-m ,6.5 Ib-ft )

5. Connec t th e RE D termina l fro m on e solenoi d con -

necto r t o th e batter y positiv e (+ ) termina l wit h a

remot e starte r switch . Connec t th e BL K termina l

fro m th e sam e solenoi d t o th e batter y negativ e (- )

termina l wit h a jumpe r lea d a s shown .

SOLENOI D CONNECTOR S

FRONT-RIGH T REAR-LEF T REAR-RIGH T

FRONT-RIGHT

REMOT ESTARTE RSWITCH

6. Pres s th e auxiliar y windo w switc h t o ru n th e pump .

Afte r th e pum p ha s ru n fo r abou t fiv e seconds ,

pres s an d releas e th e remot e starte r switc h thre e o r

fou r time s t o ope n an d clos e th e solenoid . Continu e

runnin g th e pum p fo r abou t 3 0 seconds , the n

releas e th e auxiliar y windo w switc h an d ope n an d

clos e th e solenoi d anothe r thre e o r fou r times .

7. Repea t step s 4- 6 fo r th e othe r thre e solenoids .

8 . Reconnec t th e solenoid s an d th e pum p relay .

9 . Connec t th e AL B Checke r an d tur n th e Mod e Selec -

to r t o "1" . Star t th e engin e an d releas e th e parkin g

brake . Pus h th e Star t Tes t butto n o n th e AL B

Checker .

10. Whil e th e pum p i s running , plac e you r finge r ove r

th e to p o f th e solenoi d retur n tub e in th e modulato r

reservoi r an d chec k fo r leaks .

• I f a solenoi d i s stil l leaking , replac e th e

modulator/solenoi d

unit.

ProCarManuals.com