ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 331 of 1640

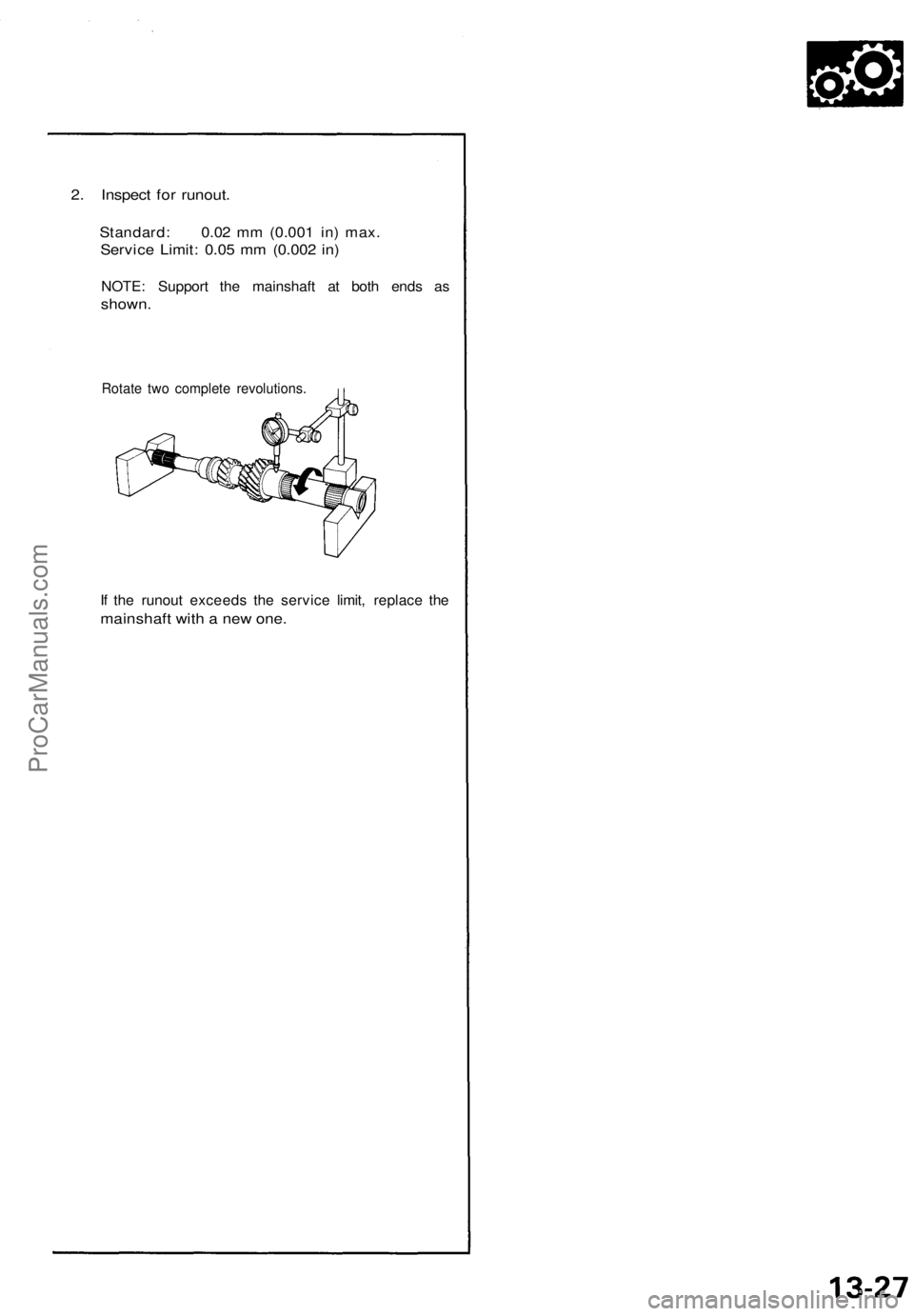

2. Inspect for runout.

Standard: 0.02 mm (0.001 in) max.

Service Limit: 0.05 mm (0.002 in)

NOTE: Support the mainshaft at both ends as

shown.

Rotate two complete revolutions.

If the runout exceeds the service limit, replace the

mainshaft with a new one.ProCarManuals.com

Page 332 of 1640

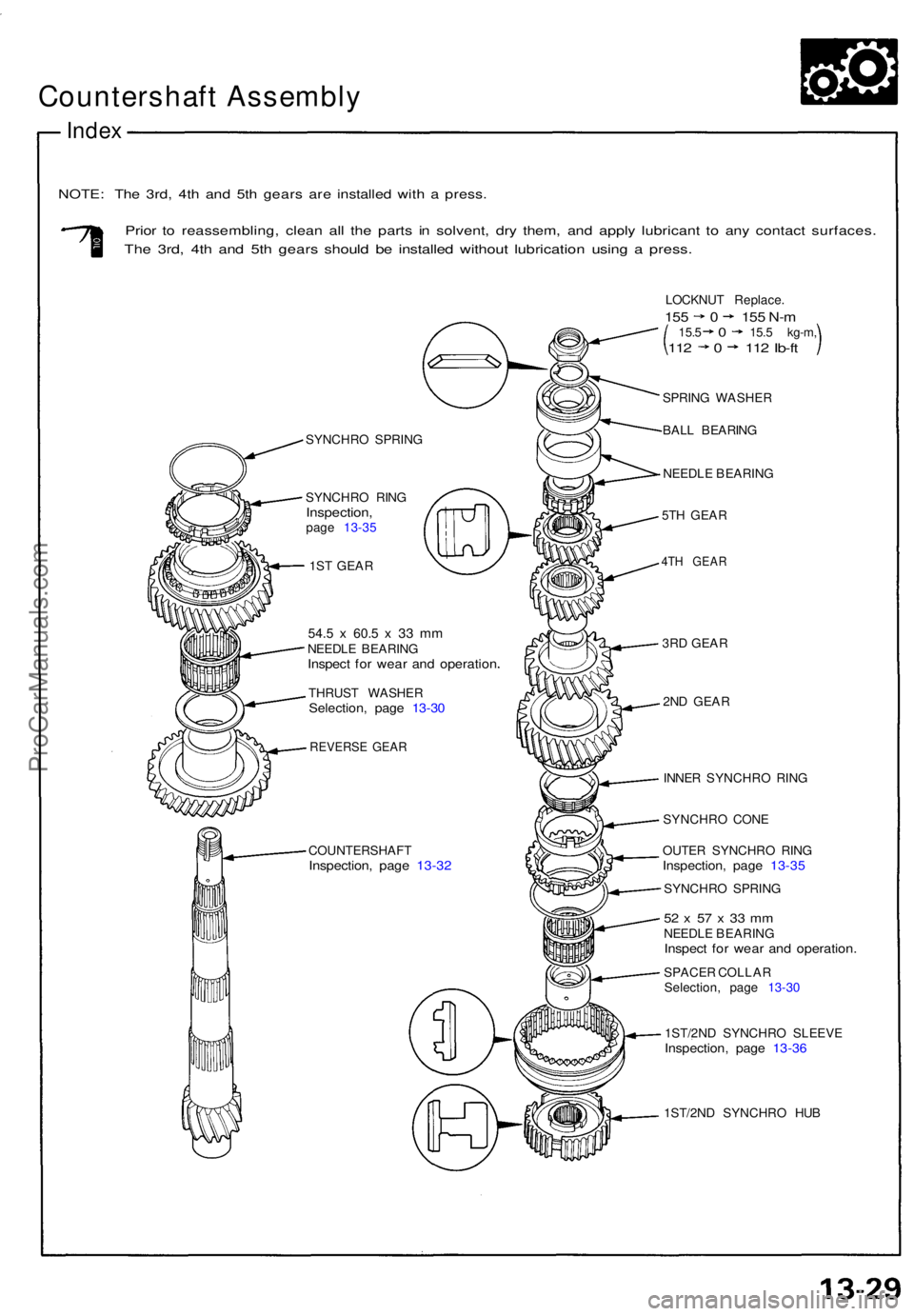

Countershaft Assembl y

Index

NOTE : Th e 3rd , 4t h an d 5t h gear s ar e installe d wit h a press .

Prior t o reassembling , clea n al l th e part s i n solvent , dr y them , an d appl y lubrican t t o an y contac t surfaces .

The 3rd , 4t h an d 5t h gear s shoul d b e installe d withou t lubricatio n usin g a press .

SYNCHR O SPRIN G

SYNCHR O RIN G

Inspection ,page 13-3 5

1S T GEA R

54.5 x 60. 5 x 3 3 m mNEEDL E BEARIN GInspect fo r wea r an d operatio n

THRUST WASHE RSelection, pag e 13-3 0

REVERS E GEA R

COUNTERSHAF TInspection, pag e 13-3 2

SPRIN G WASHE R

BAL L BEARIN G

NEEDL E BEARIN G

5T H GEA R

4TH GEA R

3RD GEA R

2N D GEA R

INNE R SYNCHR O RIN G

SYNCHR O CON E

OUTE R SYNCHR O RIN G

Inspection , pag e 13-3 5

SYNCHR O SPRIN G

52 x 5 7 x 33 m mNEEDL E BEARIN GInspect fo r wea r an d operation .

SPACER COLLA R

Selection , pag e 13-3 0

1ST/2N D SYNCHR O SLEEV E

Inspection , pag e 13-3 6

1ST/2N D SYNCHR O HU B

LOCKNU

T Replace .

155 0 15 5 N- m15. 5 0 15. 5 kg-m ,112 0 11 2 Ib-f t

ProCarManuals.com

Page 333 of 1640

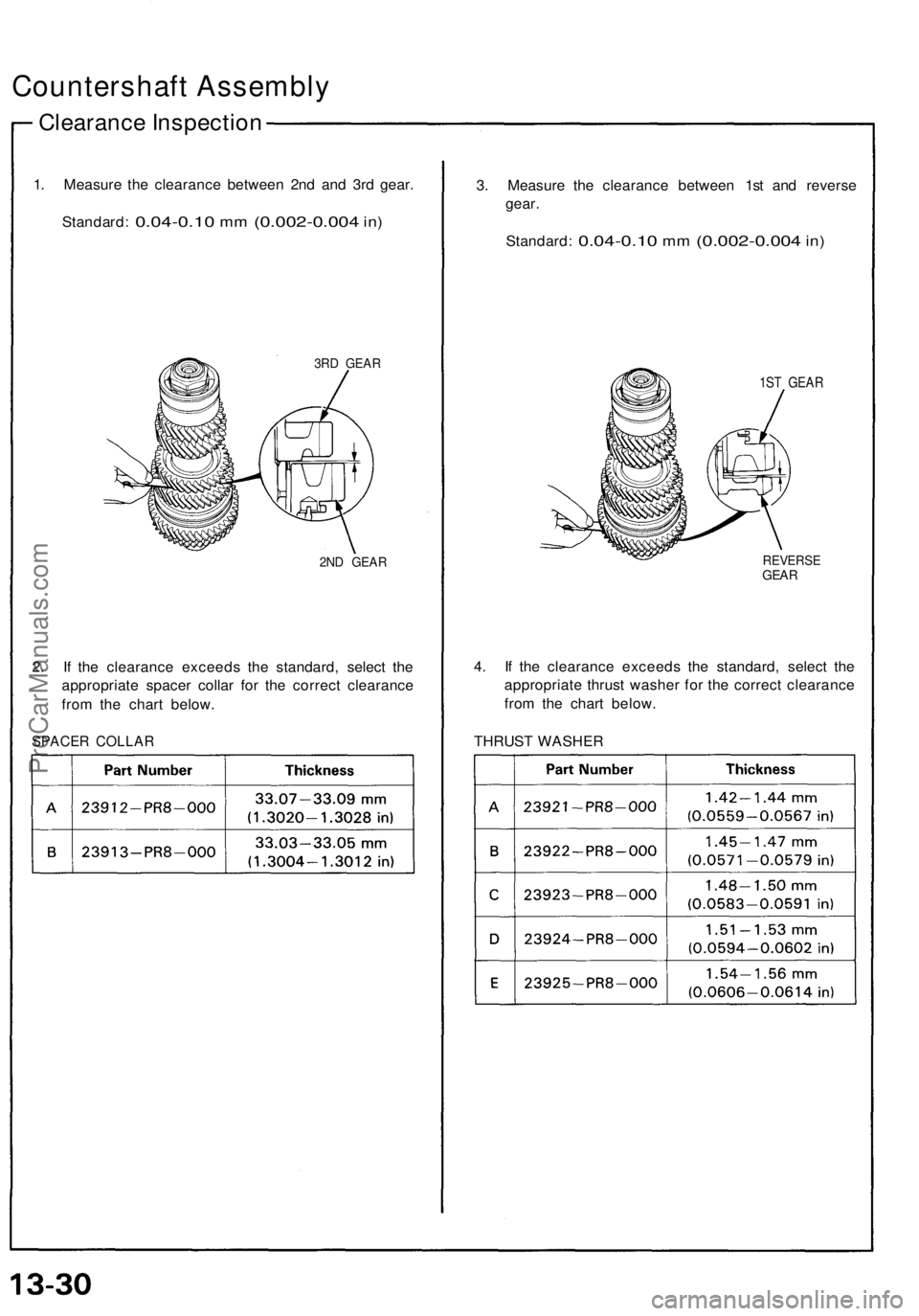

Countershaft Assembly

Clearance Inspectio n

1. Measur e th e clearanc e betwee n 2n d an d 3r d gear .

Standard :

0.04-0.10 mm (0.002-0.00 4 in)

3R D GEA R

2ND GEA R

2. I f th e clearanc e exceed s th e standard , selec t th e

appropriat e space r colla r fo r th e correc t clearanc e

fro m th e char t below .

SPACE R COLLA R

3. Measur e th e clearanc e betwee n 1s t an d revers e

gear .

Standard :

0.04-0.10 mm (0.002-0.00 4 in)

1S T GEA R

REVERS EGEAR

4. I f th e clearanc e exceed s th e standard , selec t th e

appropriat e thrus t washe r fo r th e correc t clearanc e

fro m th e char t below .

THRUS T WASHE R

ProCarManuals.com

Page 334 of 1640

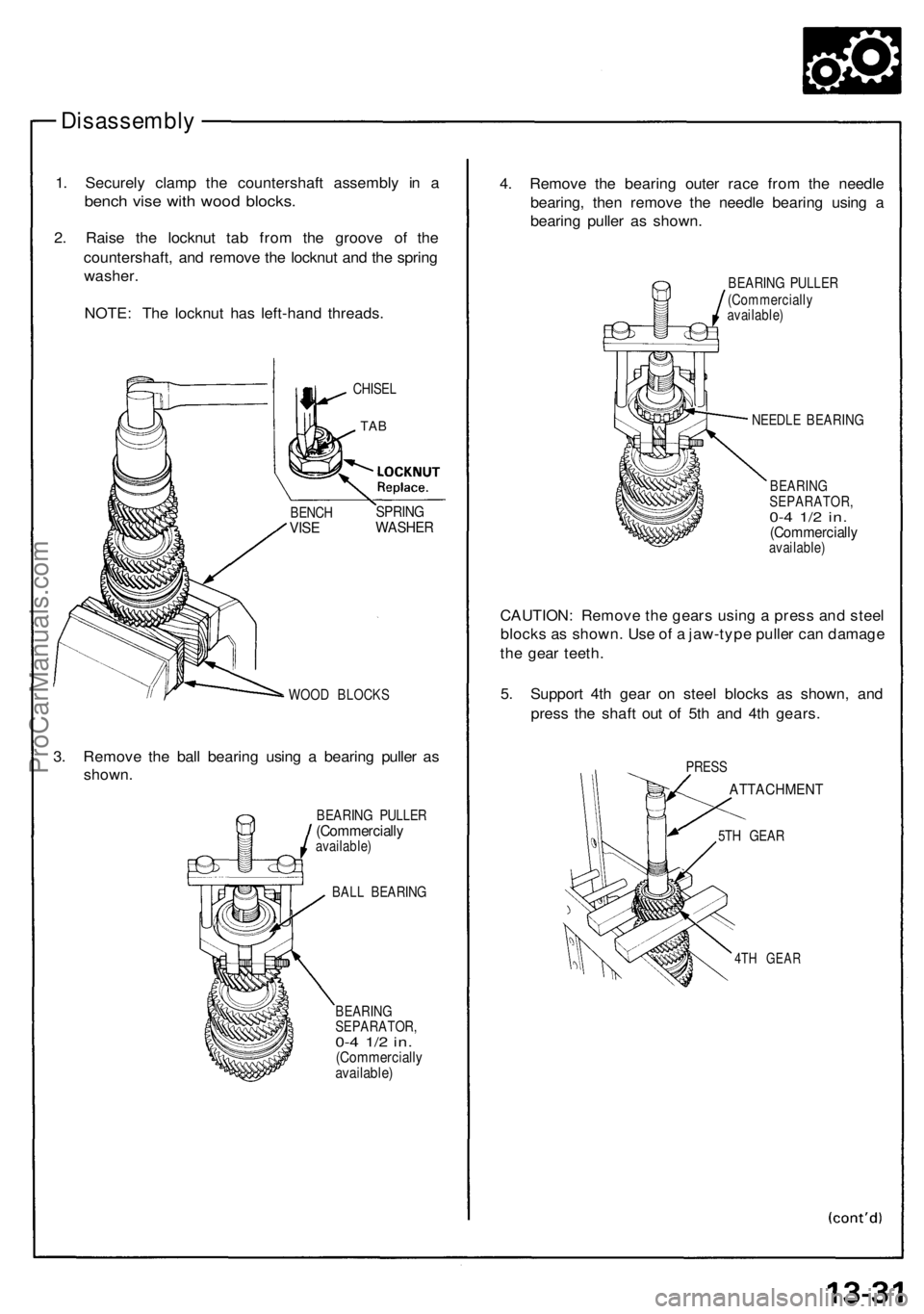

Disassembly

1. Securely clamp the countershaft assembly in a

bench vise with wood blocks.

2. Raise the locknut tab from the groove of the

countershaft, and remove the locknut and the spring

washer.

NOTE: The locknut has left-hand threads.

WOOD BLOCKS

3. Remove the ball bearing using a bearing puller as

shown.

BEARING PULLER

(Commercially

available)

BALL BEARING

BEARING

SEPARATOR,

0-4 1/2 in.

(Commercially

available)

4. Remove the bearing outer race from the needle

bearing, then remove the needle bearing using a

bearing puller as shown.

BEARING PULLER

(Commercially

available)

NEEDLE BEARING

BEARING

SEPARATOR,

0-4 1/2 in.

(Commercially

available)

CAUTION: Remove the gears using a press and steel

blocks as shown. Use of a jaw-type puller can damage

the gear teeth.

5. Support 4th gear on steel blocks as shown, and

press the shaft out of 5th and 4th gears.

5TH GEAR

4TH GEAR

PRESS

ATTACHMENT

BENCH

VISE

SPRING

WASHER

TAB

CHISELProCarManuals.com

Page 335 of 1640

Countershaft Assembl y

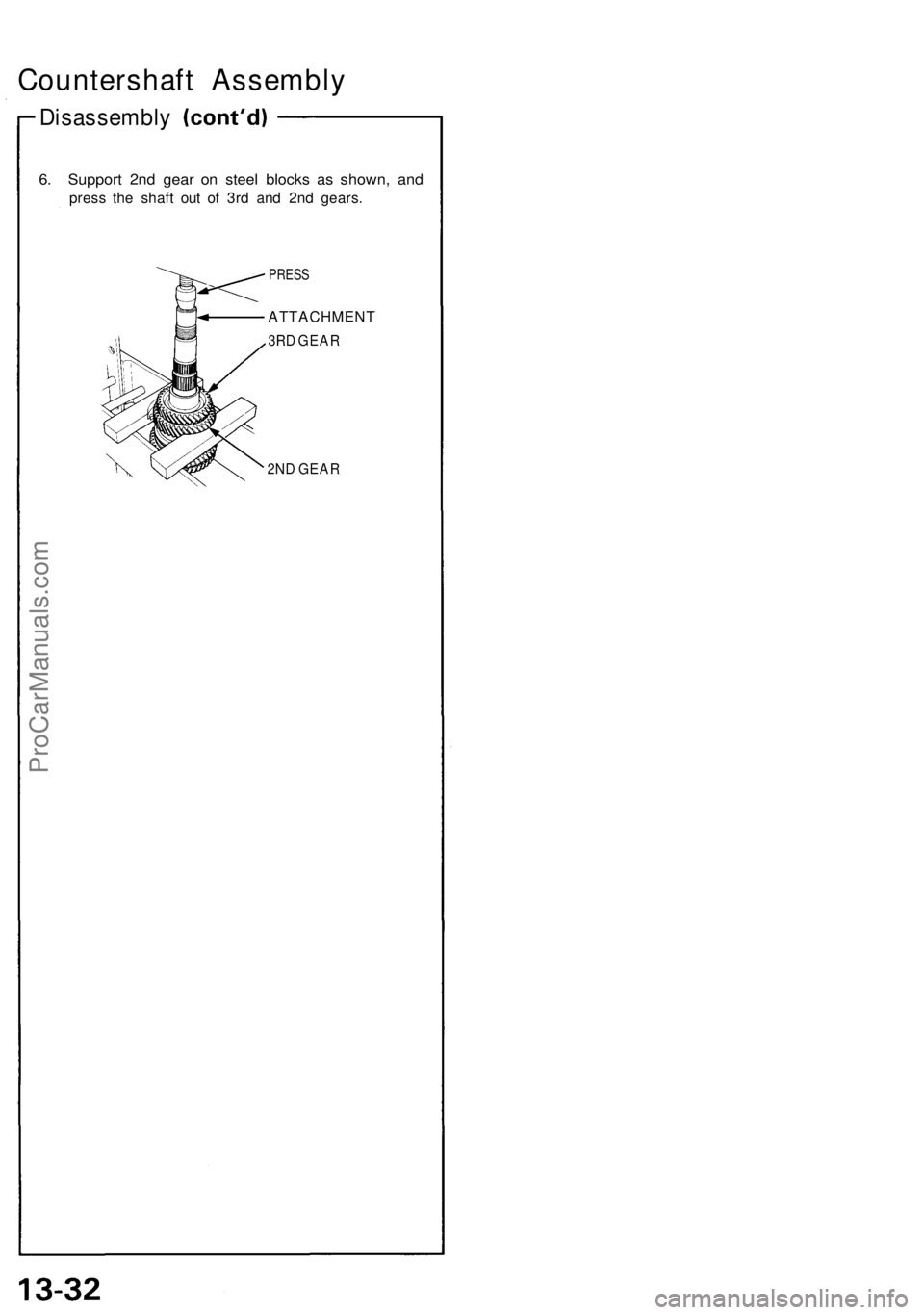

Disassembl y

6. Suppor t 2n d gea r o n stee l block s a s shown , an d

pres s th e shaf t ou t o f 3r d an d 2n d gears .

PRESS

ATTACHMEN T

3RD GEA R

2N D GEA R

ProCarManuals.com

Page 336 of 1640

Countershaft Assembl y

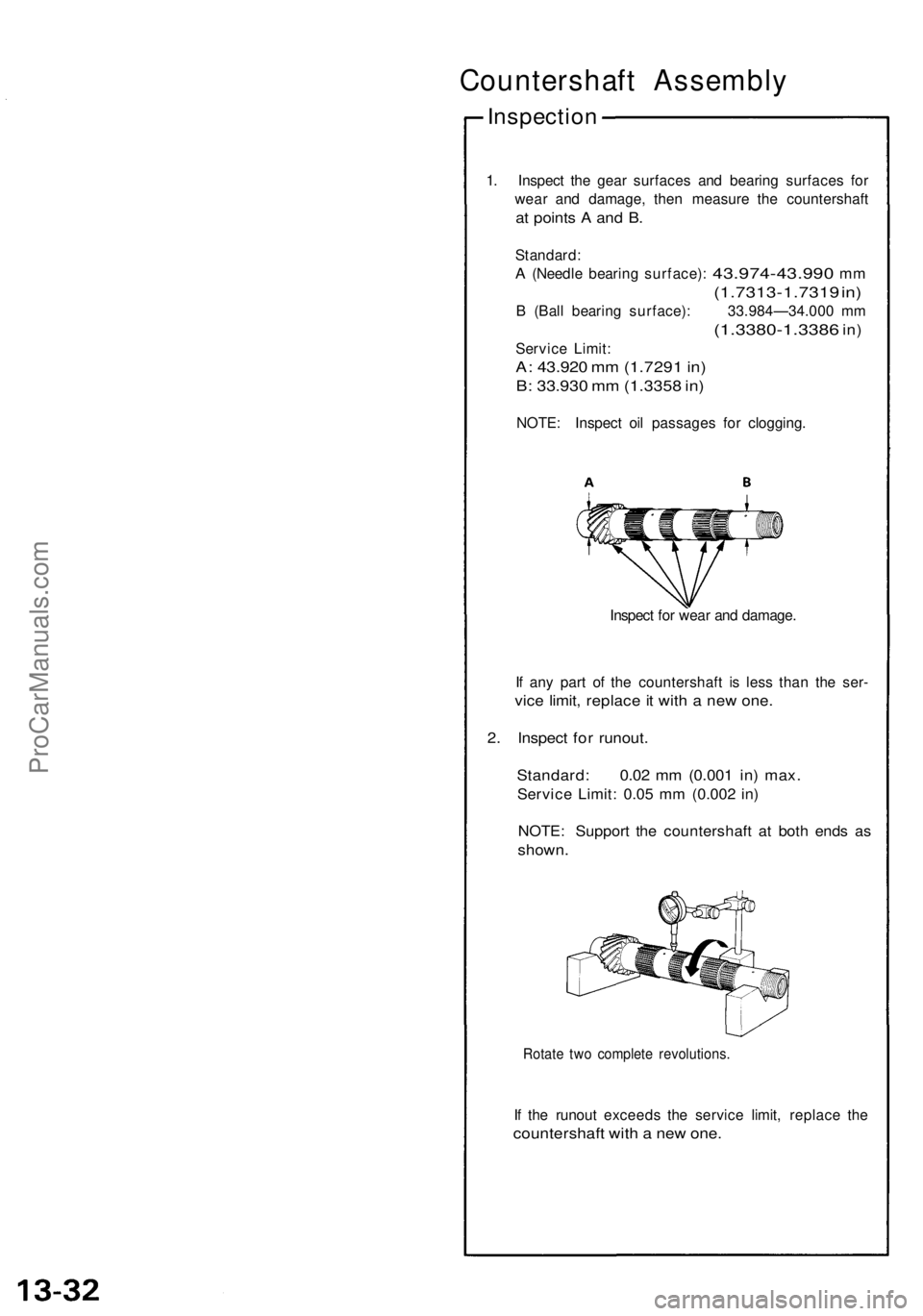

Inspection

1. Inspec t th e gea r surface s an d bearin g surface s fo r

wea r an d damage , the n measur e th e countershaf t

at point s A an d B .

Standard :

A (Needle bearin g surface) : 43.974-43.99 0 mm

(1.7313-1.731 9 in )

B (Bal l bearin g surface) : 33.984—34.00 0 m m

(1.3380-1.338 6 in)

Servic e Limit :

A: 43.92 0 m m (1.729 1 in )

B: 33.93 0 m m (1.335 8 in )

NOTE : Inspec t oi l passage s fo r clogging .

Inspec t fo r wea r an d damage .

I f an y par t o f th e countershaf t i s les s tha n th e ser -

vice limit , replac e it wit h a ne w one .

2. Inspec t fo r runout .

Standard : 0.0 2 m m (0.00 1 in ) max .

Servic e Limit : 0.0 5 m m (0.00 2 in )

NOTE : Suppor t th e countershaf t a t bot h end s a s

shown .

Rotate tw o complet e revolutions .

If th e runou t exceed s th e servic e limit , replac e th e

countershaf t wit h a ne w one .

ProCarManuals.com

Page 337 of 1640

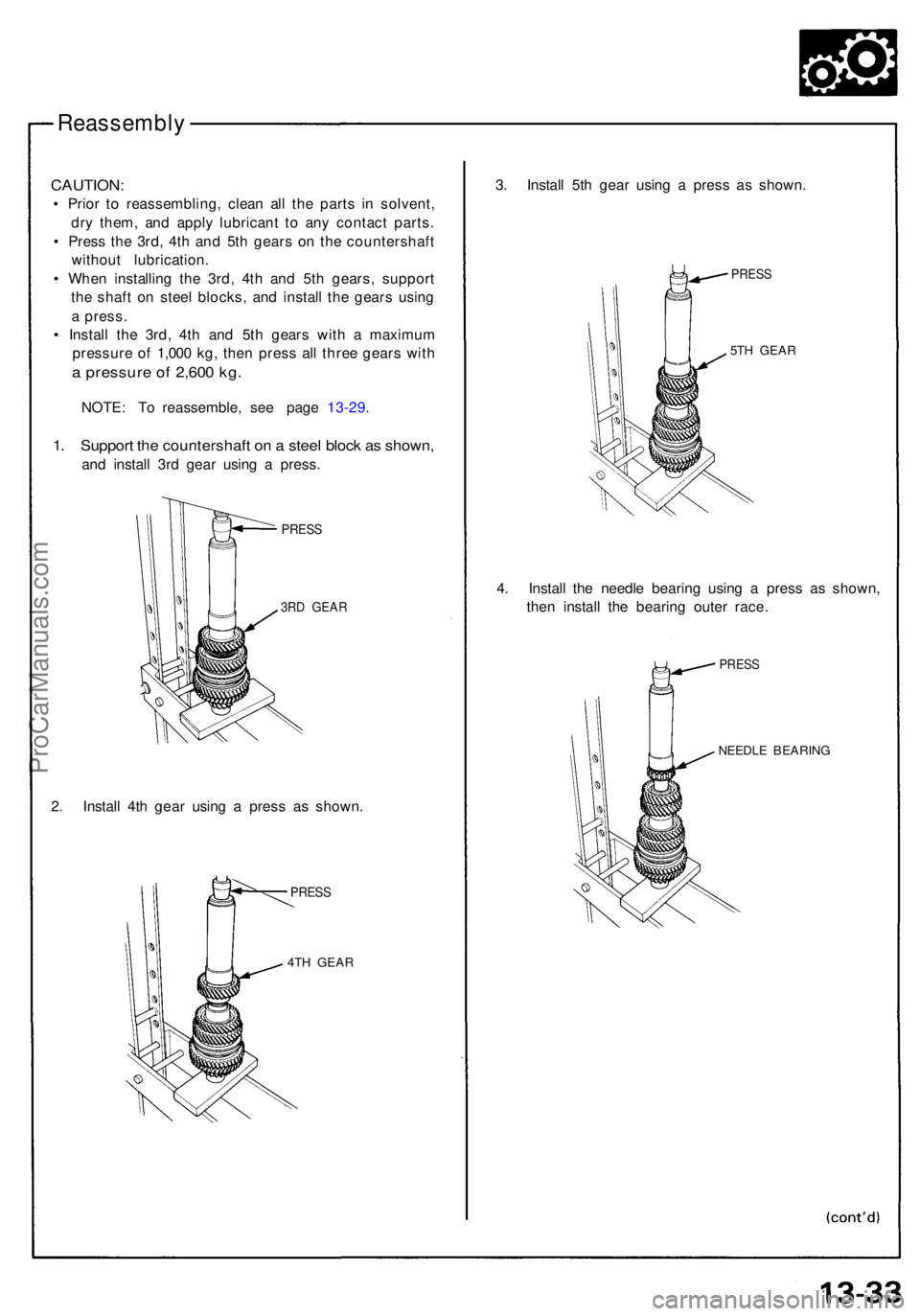

Reassembly

CAUTION:

• Prio r t o reassembling , clea n al l th e part s i n solvent ,

dr y them , an d appl y lubrican t t o an y contac t parts .

• Pres s th e 3rd , 4t h an d 5t h gears on th e countershaf t

withou t lubrication .

• Whe n installin g th e 3rd , 4t h an d 5t h gears , suppor t

th e shaf t o n stee l blocks , an d instal l th e gear s usin g

a press .

• Instal l th e 3rd , 4t h an d 5t h gear s wit h a maximu m

pressur e o f 1,00 0 kg , the n pres s al l thre e gears with

a pressur e o f 2,60 0 kg .

NOTE : T o reassemble , se e pag e 13-29 .

1. Suppor t th e countershaf t o n a stee l bloc k a s shown ,

and instal l 3r d gea r usin g a press .

PRESS

3RD GEA R

2. Instal l 4t h gea r usin g a pres s a s shown .

PRESS

4TH GEA R

3. Instal l 5t h gea r usin g a pres s a s shown .

PRESS

5TH GEA R

4. Instal l th e needl e bearin g usin g a pres s a s shown ,

the n instal l th e bearin g oute r race .

PRES S

NEEDL E BEARIN G

ProCarManuals.com

Page 338 of 1640

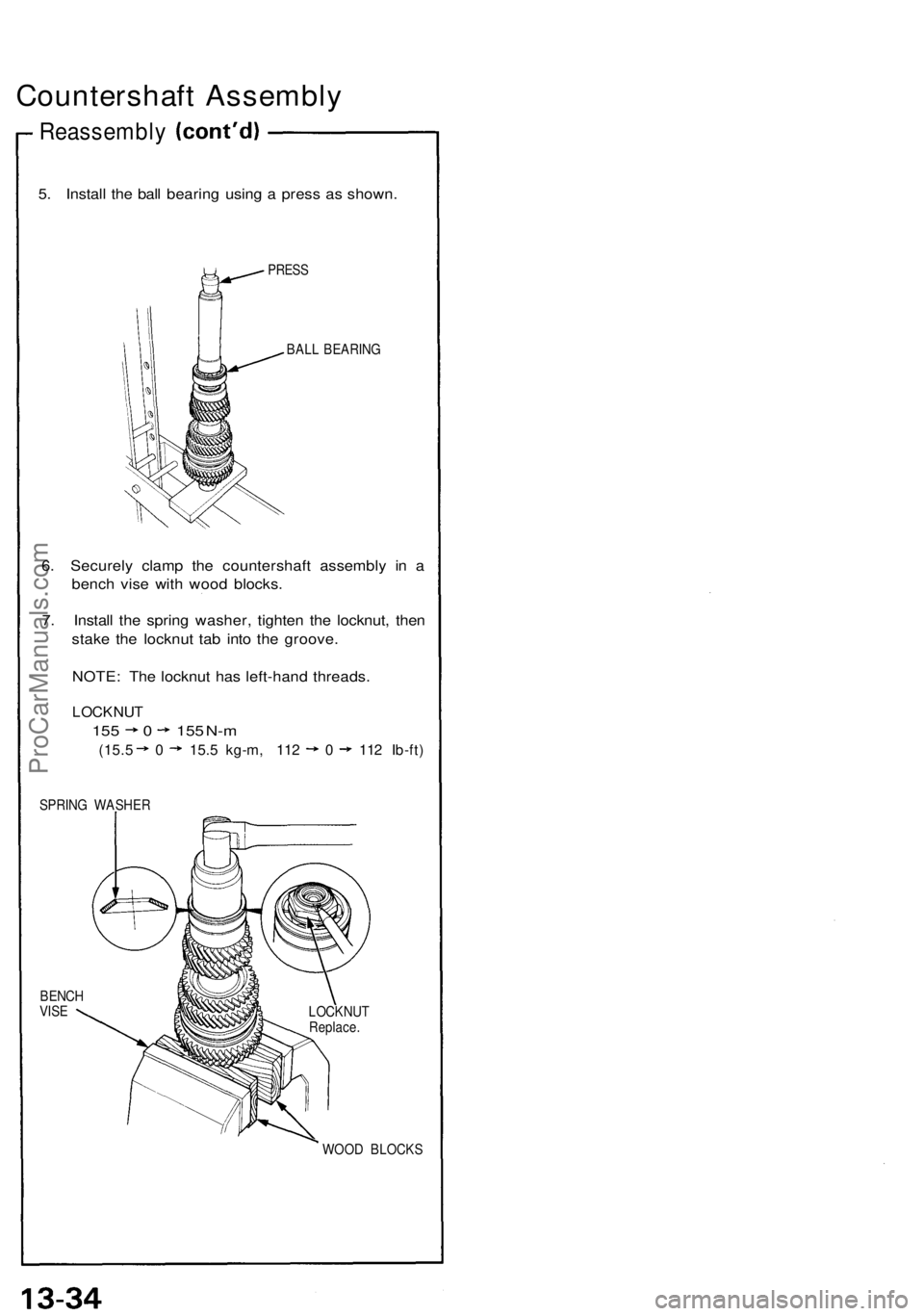

Countershaft Assembly

Reassembly

5. Install the ball bearing using a press as shown.

PRESS

BALL BEARING

6. Securely clamp the countershaft assembly in a

bench vise with wood blocks.

7. Install the spring washer, tighten the locknut, then

stake the locknut tab into the groove.

NOTE: The locknut has left-hand threads.

LOCKNUT

155 0 155 N-m

(15.5 0 15.5 kg-m, 112 0 112 Ib-ft)

SPRING WASHER

BENCH

VISE

WOOD BLOCKS

LOCKNUT

Replace.ProCarManuals.com

Page 339 of 1640

Synchro Ring , Gea r

Inspectio n

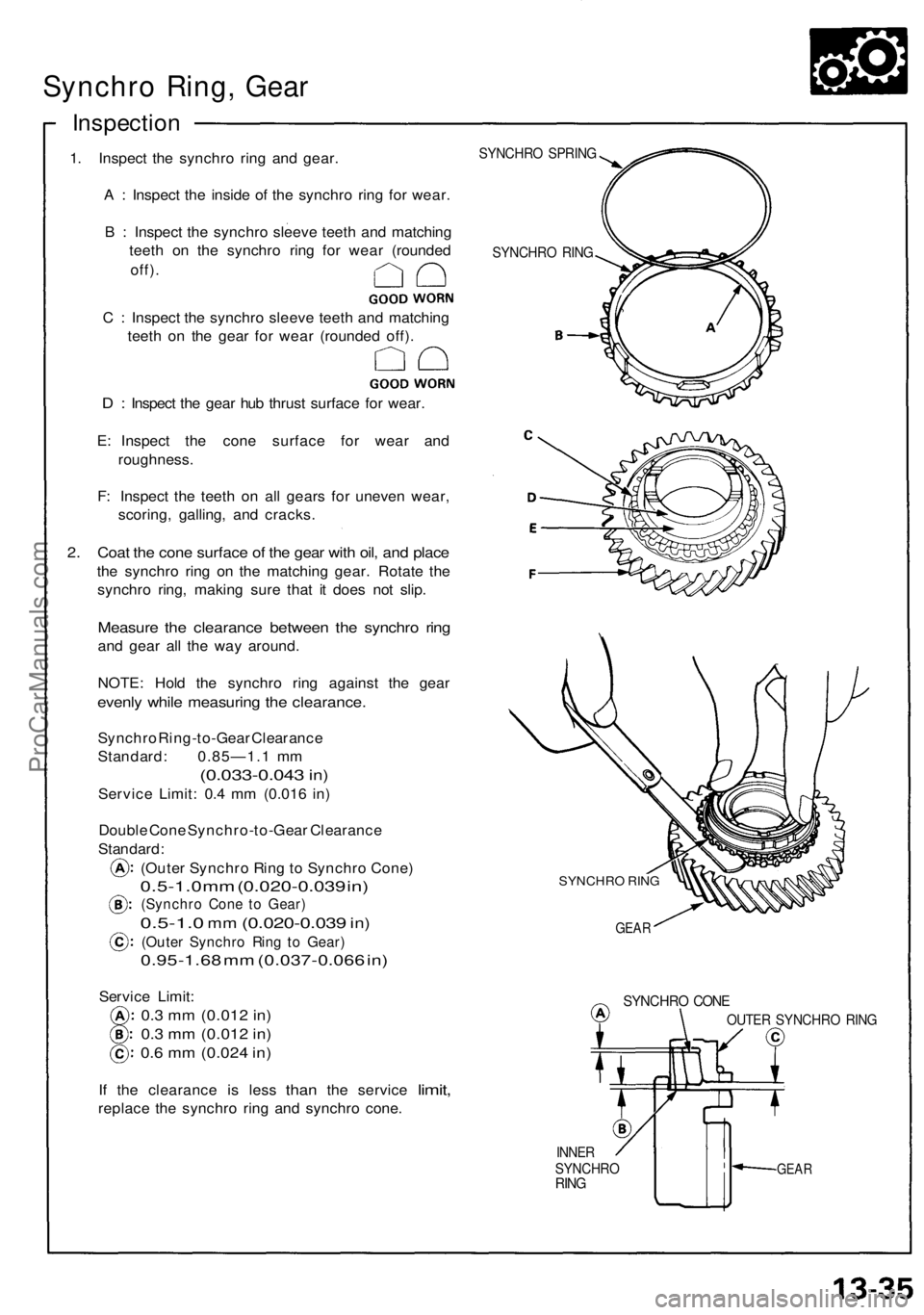

1. Inspec t th e synchr o rin g an d gear .

A : Inspec t th e insid e of the synchr o rin g fo r wear .

B : Inspec t th e synchr o sleev e teet h an d matchin g

teet h o n th e synchr o rin g fo r wea r (rounde d

off).

C : Inspec t th e synchr o sleev e teet h an d matchin g

teet h o n th e gea r fo r wea r (rounde d off) .

D : Inspec t th e gea r hu b thrus t surfac e fo r wear .

E : Inspec t th e con e surfac e fo r wea r an d

roughness .

F : Inspec t th e teet h o n al l gear s fo r uneve n wear ,

scoring , galling , an d cracks .

2. Coa t th e con e surfac e o f th e gea r wit h oil , an d plac e

the synchr o rin g o n th e matchin g gear . Rotat e th e

synchr o ring , makin g sur e tha t i t doe s no t slip .

Measur e th e clearanc e betwee n th e synchr o rin g

and gea r al l th e wa y around .

NOTE : Hol d th e synchr o rin g agains t th e gea r

evenly whil e measurin g th e clearance .

Synchro Ring-to-Gea r Clearanc e

Standard : 0.85—1. 1 m m

(0.033-0.04 3 in)

Servic e Limit : 0. 4 m m (0.01 6 in )

Doubl e Con e Synchro-to-Gea r Clearanc e

Standard :

(Oute r Synchr o Rin g to Synchr o Cone )

0.5-1.0 m m (0.020-0.03 9 in )

(Synchr o Con e t o Gear )

0.5-1.0 mm (0.020-0.03 9 in)

(Oute r Synchr o Rin g t o Gear )

0.95-1.6 8 m m (0.037-0.06 6 in )

Servic e Limit :

0.3 m m (0.01 2 in )

0.3 m m (0.01 2 in )

0.6 m m (0.02 4 in )

If th e clearanc e is les s than the servic e limit,

replac e th e synchr o rin g an d synchr o cone .

SYNCHR O SPRIN G

SYNCHR O RIN G

SYNCHR O RIN G

GEA R

SYNCHR O CON E

INNERSYNCHR ORING

OUTE R SYNCHR O RIN G

GEA R

ProCarManuals.com

Page 340 of 1640

Synchro Sleeve , Synchr o Hu b

Inspectio n

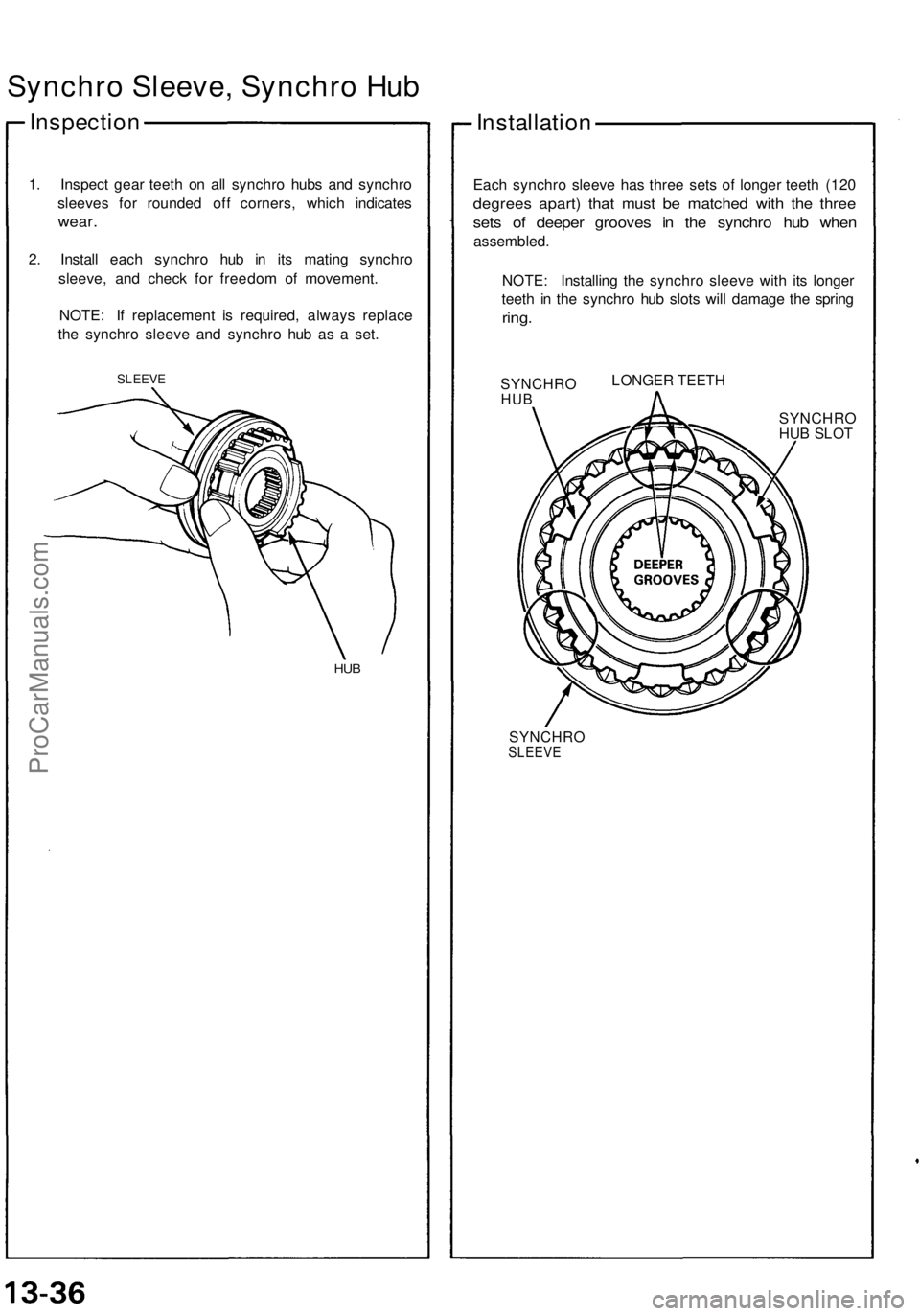

1. Inspec t gea r teet h o n al l synchr o hub s an d synchr o

sleeve s fo r rounde d of f corners , whic h indicate s

wear.

2. Instal l eac h synchr o hu b i n it s matin g synchr o

sleeve , an d chec k fo r freedo m o f movement .

NOTE : I f replacemen t i s required , alway s replac e

th e synchr o sleev e an d synchr o hu b a s a set .

SLEEV E

HUB

Installatio n

Each synchr o sleev e ha s thre e set s o f longe r teet h (12 0

degree s apart ) tha t mus t b e matche d wit h th e thre e

sets o f deepe r groove s i n th e synchr o hu b whe n

assembled .

NOTE : Installin g th e synchr o sleev e wit h it s longe r

teet h i n th e synchr o hu b slot s wil l damag e th e sprin g

ring.

SYNCHR OHUB

LONGER TEETH

SYNCHR OHUB SLOT

SYNCHROSLEEVE

ProCarManuals.com